Impact of ZrO2 and Si3N4 Ceramics Dispersion on the Ti6Al4V Matrix: Mechanical and Microstructural Characteristics Using SPS

Abstract

1. Introduction

2. Materials and Methods

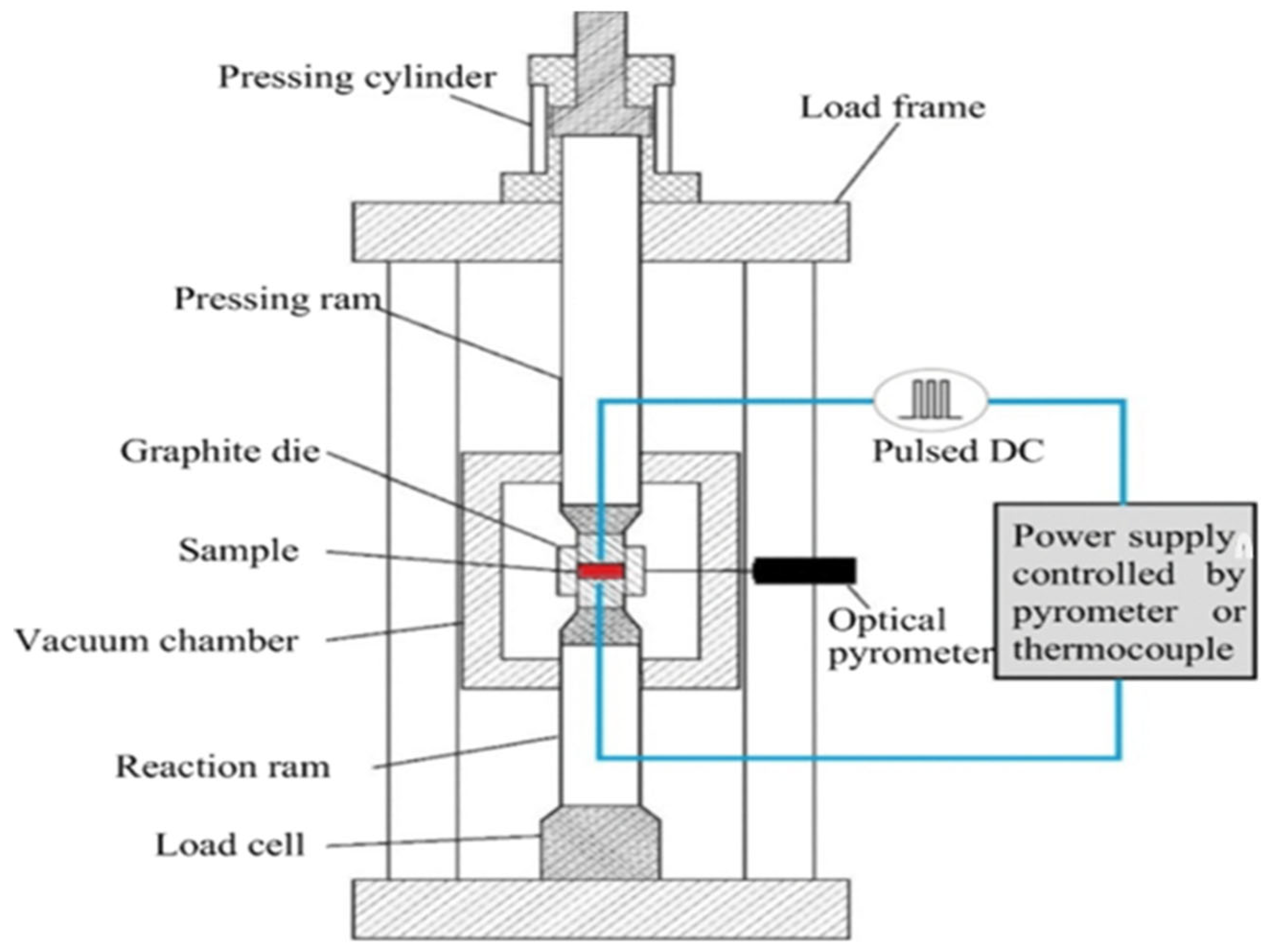

2.1. Algorithms of Execution of Spark Plasma Sintering

- Prepare Powder: Selection and preparation of titanium and bioceramic composite powders.

- Load Powder in Die: Place powder inside the graphite die for sintering.

- Apply Pulsed DC Current: High-frequency pulsed electrical current is introduced.

- Heat via Joule Heating and Pressure: Current induces heat, and uniaxial pressure assists in densification.

- Grain Boundary Diffusion and Densification: Particles fuse due to diffusion processes.

- Hold at Sintering Temperature: Maintains temperature for optimal consolidation.

- Controlled Cooling: Ensures material stability and microstructure refinement.

- Remove from Die: Extracts the sintered composite from the mold.

- Characterization and Quality Control: Mechanical and microstructural evaluation of the final product.

2.2. Metallography, Characterization, and Densification Studies

2.3. The Procedure for the Measurement of Relative Density Through Archimedes’ Principle

2.4. Nanoindentation Properties of Ti64-W% ZrO2-X% Si3N4 Composites

3. Results and Discussion

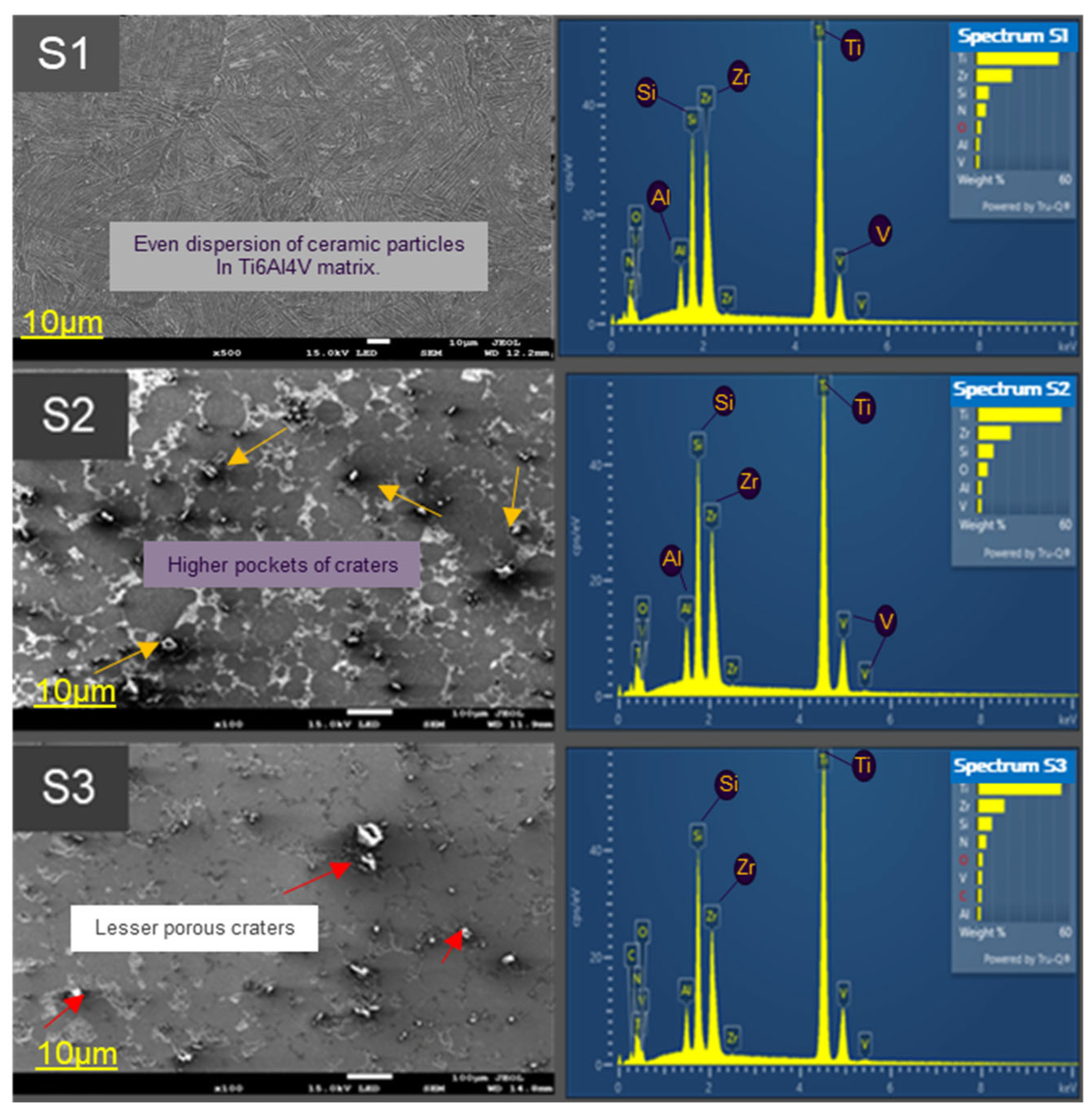

3.1. Properties of the Consolidated Composites’ Microstructure

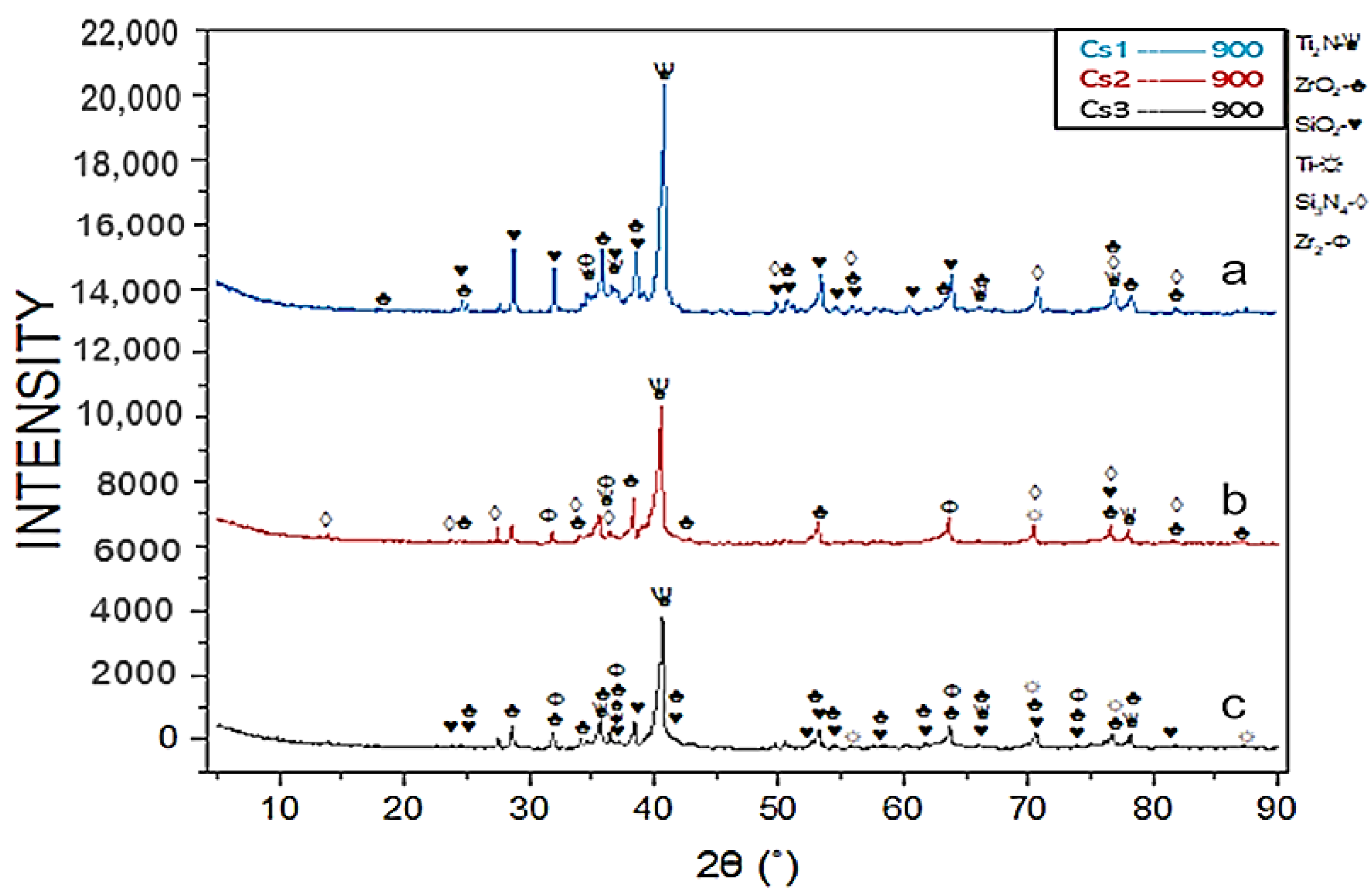

3.2. XRD Analysis

3.3. Relative Density and Porosity Calculations for Ternary Composites Sintered at 900 °C

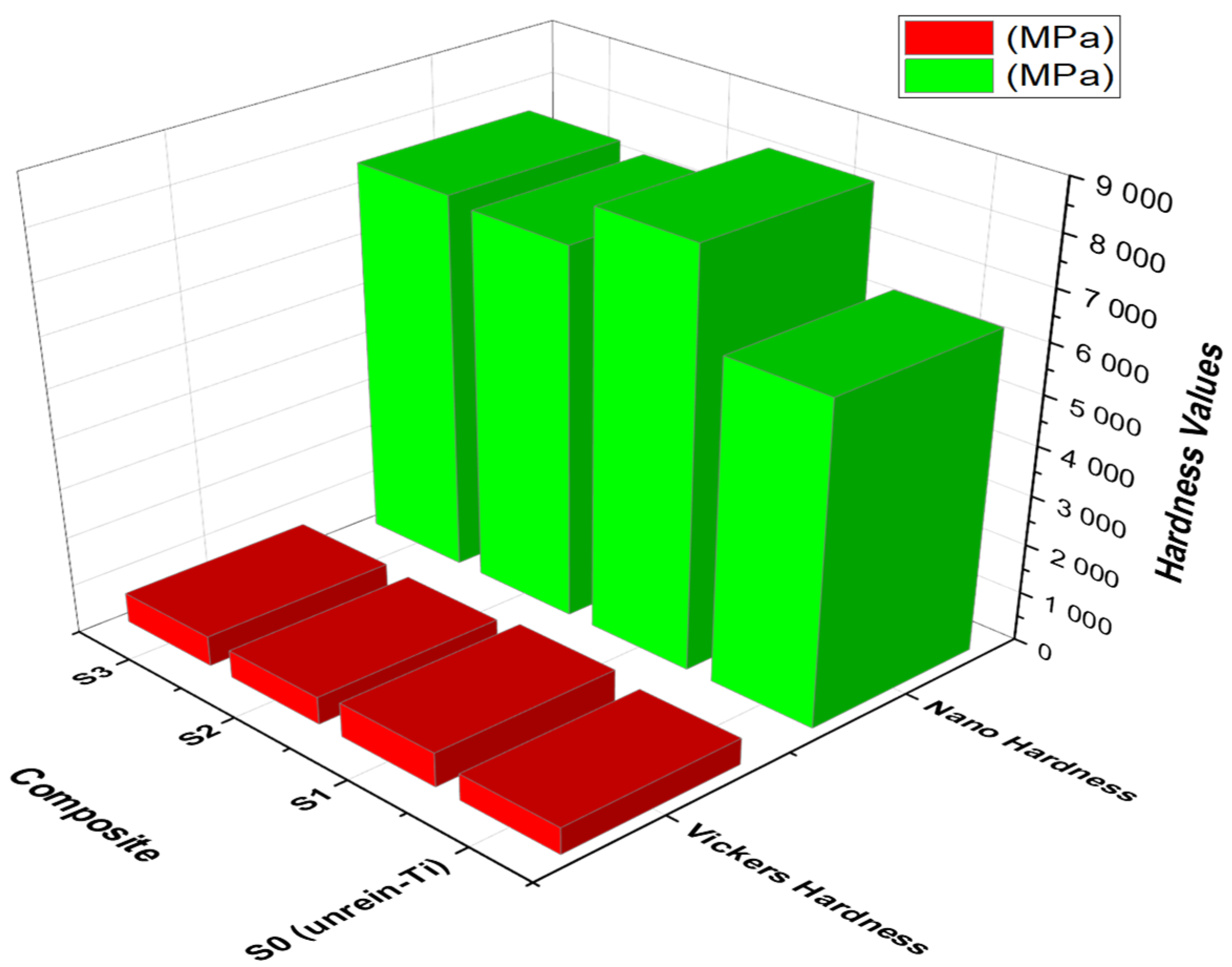

3.4. Sintered Composites’ Nanomechanical Quantities

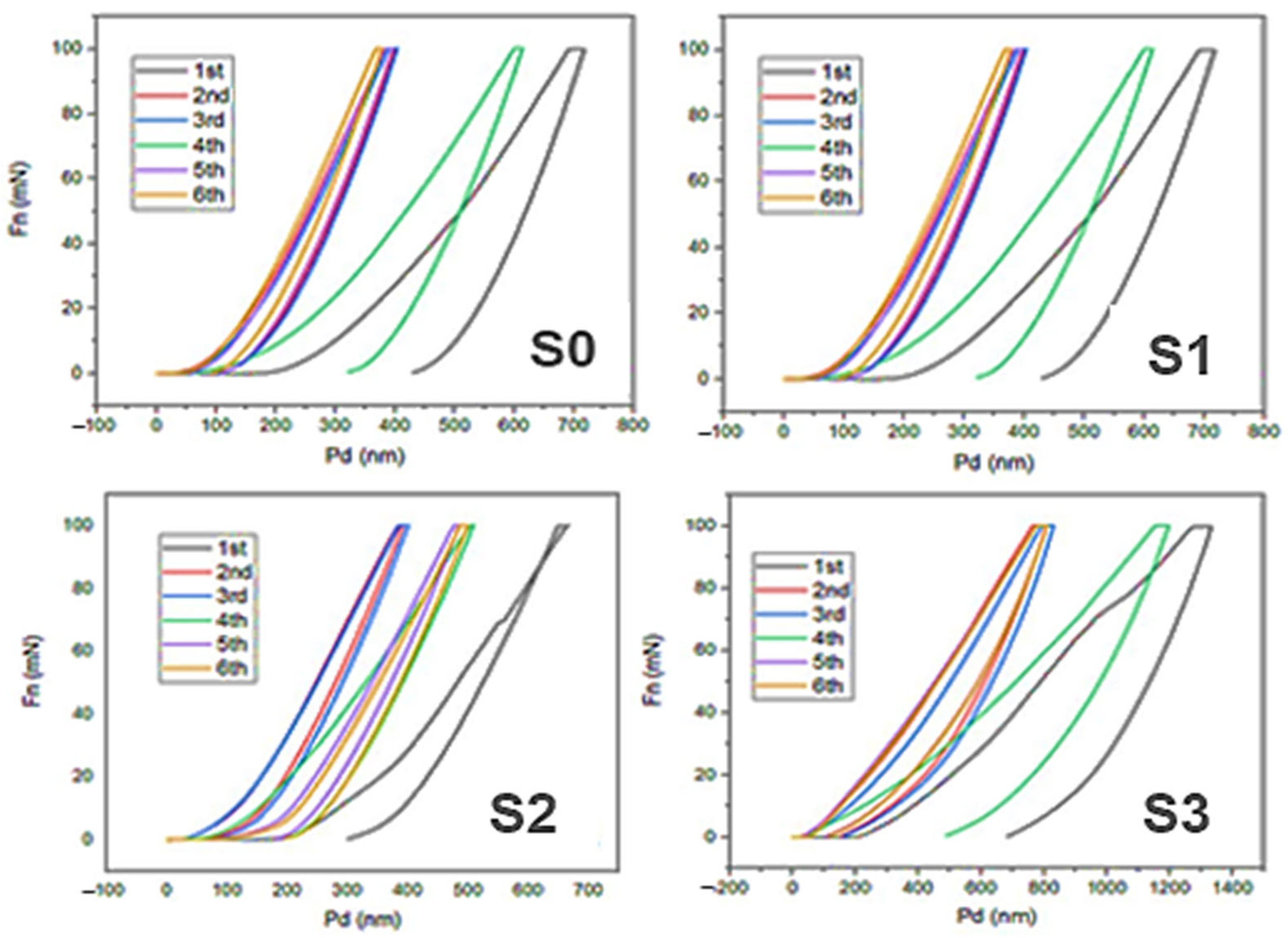

3.5. Nanoindentation Analysis of Mechanical Properties of the Sintered Composites

4. Conclusions

- By dispersing the two ceramic particles into the Ti-alloy matrix, the generated composites’ densification and mechanical properties were improved.

- The sintered composites, S1, S2, and S3, attained practically full theoretical density in sample S1 (with equal (5 vol. %) and lesser quantities of both ceramics) records 98.94%, followed by S3 (with 10 vol.% ZrO2 and 5 vol. % Si3N4 ceramic contents) at 97.74%, and S2 (with the highest ceramic contents, viz., 15 vol.% ZrO2-5 vol. % Si3N4) recorded the lowest relative density at 97.10%. The densities are directly proportional to their mechanical properties.

- Composite S1 confirms the effect of the duo-ceramic reinforcement in the titanium matrix, with evidence of a higher value than other samples, which also determines the mechanical proficiency at 900 °C.

- The improved strength of the sintered composites was mainly consequent upon the production of secondary phases of Ti2N and SiO2 during the sintering process.

- The result confirmed that the sample with a lower percentage volume fraction of varying duo-ceramic particles, S1, exhibited the highest values of measured elastic modulus, nano hardness, Vickers microhardness, and elastic recovery properties compared to other samples, especially S2, which has the highest volume fraction of varying ceramic reinforcement.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Falodun, O.E.; Oke, S.R.; Obadele, B.A.; Okoro, A.M.; Olubambi, P.A. Influence of SiAlON ceramic reinforcement on Ti6Al4V alloy matrix via spark plasma sintering technique. Met. Mater. Int. 2021, 27, 1769–1778. [Google Scholar] [CrossRef]

- Namini, A.S.; Motallebzadeh, A.; Nayebi, B.; Asl, M.S.; Azadbeh, M. Microstructure–mechanical properties correlation in spark plasma sintered Ti–4.8 wt.% TiB2 composites. Mater. Chem. Phys. 2019, 223, 789–796. [Google Scholar] [CrossRef]

- Larsen, J.M.; Russ, S.M.; Jones, J. An evaluation of fiber-reinforced titanium matrix composites for advanced high-temperature aerospace applications. Metall. Mater. Trans. A 1995, 26, 3211–3223. [Google Scholar] [CrossRef]

- Digole, S.; Karki, S.; Mugale, M.; Choudhari, A.; Gupta, R.K.; Borkar, T. Spark Plasma Sintering of Pure Titanium: Microstructure and Mechanical Characteristics. Materials 2024, 17, 3469. [Google Scholar] [CrossRef] [PubMed]

- Hunt, M.P.; Logan, K.V. Pressureless Sintering of Titanium Diboride Powders. Dev. Strateg. Mater. Ceram. Eng. Sci. Proc. 2008, 29, 211–221. [Google Scholar]

- Asl, M.S.; Delbari, S.A.; Shayesteh, F.; Ahmadi, Z.; Motallebzadeh, A. Reactive spark plasma sintering of TiB2–SiC–TiN novel composite. Int. J. Refract. Met. Hard Mater. 2019, 81, 119–126. [Google Scholar]

- Lisiecki, A.; Piwnik, J. Tribological characteristic of titanium alloy surface layers produced by diode laser gas nitriding. Arch. Metall. Mater. 2016, 61, 543–552. [Google Scholar] [CrossRef]

- Ogunmefun, O.A.; Bayode, B.L.; Jamiru, T.; Olubambi, P.A. A critical review of dispersion strengthened titanium alloy fabricated through spark plasma sintering techniques. J. Alloys Compd. 2023, 960, 170407. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, H.; Wang, Q.; Wei, B.; Xin, S.; Gao, Y. Microstructural evolution and mechanical properties of graphene-reinforced Ti6Al4V composites synthesized via spark plasma sintering. Metals 2020, 10, 737. [Google Scholar] [CrossRef]

- Ezugwu, E.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Attabi, S.; Mokhtari, M.; Taibi, Y.; Abdel-Rahman, I.; Hafez, B.; Elmsellem, H. Electrochemical and tribological behavior of surface-treated titanium alloy Ti–6Al–4V. J. Bio-Tribo-Corros. 2019, 5, 2. [Google Scholar] [CrossRef]

- Wang, G.; Liu, X.; Gao, J.; Ding, C. In vitro bioactivity and phase stability of plasma-sprayed nanostructured 3Y-TZP coatings. Acta Biomater. 2009, 5, 2270–2278. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Meng, F.; Ding, C.; Chu, P.K.; Liu, X. Microstructure, bioactivity and osteoblast behavior of monoclinic zirconia coating with nanostructured surface. Acta Biomater. 2010, 6, 990–1000. [Google Scholar] [CrossRef]

- Wright, P.; Evans, A.G. Mechanisms governing the performance of thermal barrier coatings. Curr. Opin. Solid. State Mater. Sci. 1999, 4, 255–265. [Google Scholar] [CrossRef]

- Pareja, R.R.; Ibáñez, R.L.; Martín, F.; Ramos-Barrado, J.; Leinen, D. Corrosion behaviour of zirconia barrier coatings on galvanized steel. Surf. Coat. Technol. 2006, 200, 6606–6610. [Google Scholar] [CrossRef]

- Paek, J.Y.; Chang, I.; Park, J.H.; Ji, S.; Cha, S.W. A study on properties of yttrium-stabilized zirconia thin films fabricated by different deposition techniques. Renew. Energy 2014, 65, 202–206. [Google Scholar] [CrossRef]

- Zhao, W.; Cui, J.; Rao, P. Effect of molten zone ablated by femtosecond lasers on fracture toughness of Si3N4 measured by SEVNB method. J. Eur. Ceram. Soc. 2018, 38, 2243–2246. [Google Scholar] [CrossRef]

- Sayyadi-Shahraki, A.; Rafiaei, S.M.; Ghadami, S.; Nekouee, K.A. Densification and mechanical properties of spark plasma sintered Si3N4/ZrO2 nano-composites. J. Alloys Compd. 2019, 776, 798–806. [Google Scholar] [CrossRef]

- Haubner, R.; Herrmann, M.; Lux, B.; Petzow, G.; Weissenbacher, R.; Wilhelm, M. High Performance Non-Oxide Ceramics II; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Lange, F.; Falk, L.; Davis, B. Structural ceramics based on Si3N4–ZrO2 (+Y2O3) compositions. J. Mater. Res. 1987, 2, 66–76. [Google Scholar] [CrossRef]

- Falak, M.Z.; Ahmed, B.A.; Saeed, H.A.; Butt, S.U.; Hakeem, A.S.; Akbar, U.A. Spark plasma sintering of SiAlON ceramics synthesized via various cations charge stabilizers and their effect on thermal and mechanical characteristics. Crystals 2021, 11, 1378. [Google Scholar] [CrossRef]

- Drouet, C.; Leriche, A.; Hampshire, S.; Kashani, M.; Stamboulis, A.; Iafisco, M.; Tampieri, A. Types of ceramics: Material class. In Advances in Ceramic Biomaterials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 21–82. [Google Scholar]

- Hoffmann, M. Si3N4 Ceramics, Structure and Properties of. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2011; pp. 8469–8471. [Google Scholar]

- Falodun, O.E.; Obadele, B.A.; Oke, S.R.; Maja, M.E.; Olubambi, P.A. Effect of sintering parameters on densification and microstructural evolution of nano-sized titanium nitride reinforced titanium alloys. J. Alloys Compd. 2018, 736, 202–210. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Shen, X.-B.; Wang, F.-C.; Sai, W.; Li, S.-k.; Cai, H.-N. Microstructure characteristics and mechanical properties of TiB/Ti-1.5 Fe-2.25 Mo composites synthesized in situ using SPS process. Trans. Nonferrous Met. Soc. China 2013, 23, 2598–2604. [Google Scholar] [CrossRef]

- Maseko, S.; Popoola, A.; Fayomi, O. Characterization of ceramic reinforced titanium matrix composites fabricated by spark plasma sintering for anti-ballistic applications. Def. Technol. 2018, 14, 408–411. [Google Scholar] [CrossRef]

- Shivakumar, N.; Vasu, V.; Narasaiah, N. Synthesis and characterization of nano-sized Al2O3 particle reinforced ZA-27 metal matrix composites. Procedia Mater. Sci. 2015, 10, 159–167. [Google Scholar] [CrossRef]

- Munir, K.S.; Kingshott, P.; Wen, C. Carbon nanotube reinforced titanium metal matrix composites prepared by powder metallurgy—A review. Crit. Rev. Solid. State Mater. Sci. 2015, 40, 38–55. [Google Scholar] [CrossRef]

- Liu, J.; Wu, M.; Yang, Y.; Yang, G.; Yan, H.; Jiang, K. Preparation and mechanical performance of graphene platelet reinforced titanium nanocomposites for high temperature applications. J. Alloys Compd. 2018, 765, 1111–1118. [Google Scholar] [CrossRef]

- Luthra, K.L. Chemical interactions in high-temperature ceramic composites. J. Am. Ceram. Soc. 1988, 71, 1114–1120. [Google Scholar] [CrossRef]

- Tohgo, K.; Fujii, T.; Harada, M.; Isono, H.; Shimamura, Y. Fabrication of PSZ–Ti composites by spark plasma sintering and their mechanical properties. Mater. Sci. Eng. A 2015, 621, 166–172. [Google Scholar] [CrossRef]

- Obadele, B.A.; Ige, O.O.; Olubambi, P.A. Fabrication and characterization of titanium-nickel-zirconia matrix composites prepared by spark plasma sintering. J. Alloys Compd. 2017, 710, 825–830. [Google Scholar] [CrossRef]

- Falodun, O.E.; Obadele, B.A.; Oke, S.R.; Olubambi, P.A.; Westraadt, J. Characterization of spark plasma sintered TiN nanoparticle strengthened titanium alloy using EBSD and TKD. Mater. Res. Bull. 2019, 117, 90–95. [Google Scholar] [CrossRef]

- Falodun, O.E.; Oke, S.R.; Akinwamide, S.O.; Ajibola, O.O.; Adebayo, A.O.; Borisade, S.G.; Adediran, A.A.; Olubambi, P.A. The effect of TiN-TiB2 on the microstructure, wear, and nanoindentation behavior of Ti6Al4V-Ni-Cr matrix composites. J. Mater. Eng. Perform. 2023, 32, 5566–5575. [Google Scholar] [CrossRef]

- Abe, J.; Popoola, A.; Popoola, O. Consolidation of Ti6Al4V alloy and refractory nitride nanoparticles by spark plasma sintering method: Microstructure, mechanical, corrosion and oxidation characteristics. Mater. Sci. Eng. A 2020, 774, 138920. [Google Scholar] [CrossRef]

- Kgoete, F.; Popoola, A.; Fayomi, O.; Adebiyi, I. Influence of Si3N4 on Ti6Al4V via spark plasma sintering: Microstructure, corrosion and thermal stability. J. Alloys Compd. 2018, 763, 322–328. [Google Scholar] [CrossRef]

- Obadele, B.A.; Andrews, A.; Mathew, M.T.; Olubambi, P.A.; Pityana, S. Improving the tribocorrosion resistance of Ti6Al4V surface by laser surface cladding with TiNiZrO2 composite coating. Appl. Surf. Sci. 2015, 345, 99–108. [Google Scholar] [CrossRef]

- Rakotoniaina, J.; Breitenstein, O.; Werner, M.; Al-Rifai, M.H.; Buonassisi, T.; Pickett, M.; Ghosh, M.; Müller, A.; Le Quang, N. Distribution and formation of silicon carbide and silicon nitride precipitates in block-cast multicrystalline silicon. In Proceedings of the 20th European Photovoltaic Solar Energy Conference and Exhibition, Barcelona, Spain, 6–10 June 2005. [Google Scholar]

- Ujah, C.; Popoola, A.; Popoola, O.; Aigbodion, V. Optimisation of spark plasma sintering parameters of Al-CNTs-Nb nano-composite using Taguchi Design of Experiment. Int. J. Adv. Manuf. Technol. 2019, 100, 1563–1573. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Jamwal, A.; Prakash, P.; Kumar, D.; Singh, N.; Sadasivuni, K.K.; Harshit, K.; Gupta, S.; Gupta, P. Microstructure, wear and corrosion characteristics of Cu matrix reinforced SiC–graphite hybrid composites. J. Compos. Mater. 2019, 53, 2545–2553. [Google Scholar] [CrossRef]

- Olorundaisi, E.; Babalola, B.J.; Anamu, U.S.; Teffo, M.L.; Kibambe, N.M.; Ogunmefun, A.O.; Odetola, P.; Olubambi, P.A. Phase formation and mechanical analysis of sintered Ni25Al25Co15Fe15Mn8Ti7Cr5 high entropy alloy. Manuf. Lett. 2024, 41, 153–159. [Google Scholar]

- Pennycook, S.; Rafferty, B.; Nellist, P. Z-contrast imaging in an aberration-corrected scanning transmission electron microscope. Microsc. Microanal. 2000, 6, 343–352. [Google Scholar] [CrossRef]

- Sritharan, T.; Boey, F.; Srinivas, A. Synthesis of complex ceramics by mechanochemical activation. J. Mater. Process. Technol. 2007, 192, 255–258. [Google Scholar] [CrossRef]

- Ogunmefun, A.O.; Ayodele, O.; Bayode, L.; Anamu, U.; Olorundaisi, E.; Mkhatshwa, S.; Babalola, J.; Ngeleshi, M.; Odetola, P.; Olubambi, P.A. Influence of sintering temperature on Ti6Al4V-Si3N4-ZrO2 ternary composites prepared by spark plasma sintering. Manuf. Rev. 2024, 11, 5. [Google Scholar] [CrossRef]

- Dong, L.; Fu, Y.; Liu, Y.; Lu, J.; Zhang, W.; Huo, W.; Jin, L.; Zhang, Y. Interface engineering of graphene/copper matrix composites decorated with tungsten carbide for enhanced physico-mechanical properties. Carbon 2021, 173, 41–53. [Google Scholar] [CrossRef]

- Li, H.; Jia, D.; Yang, Z.; Liao, X.; Jin, H.; Cai, D.; Zhou, Y. Effect of heat treatment on microstructure evolution and mechanical properties of selective laser melted Ti–6Al–4V and TiB/Ti–6Al–4V composite: A comparative study. Mater. Sci. Eng. A 2021, 801, 140415. [Google Scholar] [CrossRef]

- Priyadarshi, D.; Sharma, R.K. Porosity in aluminium matrix composites: Cause, effect and defence. Mater. Sci Ind. J. 2016, 14, 119–129. [Google Scholar]

- Cheng, J.; Zhu, S.; Yu, Y.; Yang, J.; Liu, W. Microstructure, mechanical and tribological properties of TiAl-based composites reinforced with high volume fraction of nearly network Ti2AlC particulates. J. Mater. Sci. Technol. 2018, 34, 670–678. [Google Scholar] [CrossRef]

- Ogunmefun, O.A.; Olubambi, P.A.; Bayode, B.L.; Anamu, U.; Olorundaisi, E.; Ayodele, O.; Babalola, B.; Mkhatshwa, S.; Odetola, P.; Ngeleshi, K. Densification, microstructure, and nanomechanical evaluation of pulsed electric sintered zirconia-silicon nitride reinforced Ti-6Al-4 V alloy. Int. J. Adv. Manuf. Technol. 2024, 130, 3649–3660. [Google Scholar] [CrossRef]

- Wang, L.F.; Zhang, Z.H.; Su, T.J.; Wang, F.C. Microstructure and Mechanical Properties of TiB-Ti/Ti6Al4V Composites Fabricated by Spark Plasma Sintering. Proc. Appl. Mech. Mater. 2015, 782, 107–112. [Google Scholar] [CrossRef]

- Jarząbek, D.M. The impact of weak interfacial bonding strength on mechanical properties of metal matrix–ceramic reinforced composites. Compos. Struct. 2018, 201, 352–362. [Google Scholar] [CrossRef]

- Brook, R.J. Concise Encyclopedia of Advanced Ceramic Materials; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Asl, M.S.; Delbari, S.A.; Azadbeh, M.; Namini, A.S.; Mehrabian, M.; Nguyen, V.-H.; Van Le, Q.; Shokouhimehr, M.; Mohammadi, M. Nanoindentational and conventional mechanical properties of spark plasma sintered Ti–Mo alloys. J. Mater. Res. Technol. 2020, 9, 10647–10658. [Google Scholar]

| Composite Samples | Ti6Al4V vol.% | Si3N4 vol.% | ZrO2 vol.% |

|---|---|---|---|

| S1 | 1 | 5 | 5 |

| S2 | 1 | 5 | 15 |

| S3 | 1 | 5 | 10 |

| Elastic Modulus (GPa) | Vickers Hardness (MPa) | Nano Hardness (MPa) | |

|---|---|---|---|

| S1 | 175.65 | 705.23 | 8275.47 |

| S2 | 153.02 | 564.45 | 7403.45 |

| S3 | 156.16 | 615.77 | 7521.39 |

| S0 (Unreinforced Ti6Al4V) | 116.25 | 549.31 | 6447.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogunmefun, A.O.; Sadiku, E.R.; Teffo, L.M.; Kupolati, W.K. Impact of ZrO2 and Si3N4 Ceramics Dispersion on the Ti6Al4V Matrix: Mechanical and Microstructural Characteristics Using SPS. Crystals 2025, 15, 531. https://doi.org/10.3390/cryst15060531

Ogunmefun AO, Sadiku ER, Teffo LM, Kupolati WK. Impact of ZrO2 and Si3N4 Ceramics Dispersion on the Ti6Al4V Matrix: Mechanical and Microstructural Characteristics Using SPS. Crystals. 2025; 15(6):531. https://doi.org/10.3390/cryst15060531

Chicago/Turabian StyleOgunmefun, Anthony O., Emmanuel R. Sadiku, Linda M. Teffo, and Williams K. Kupolati. 2025. "Impact of ZrO2 and Si3N4 Ceramics Dispersion on the Ti6Al4V Matrix: Mechanical and Microstructural Characteristics Using SPS" Crystals 15, no. 6: 531. https://doi.org/10.3390/cryst15060531

APA StyleOgunmefun, A. O., Sadiku, E. R., Teffo, L. M., & Kupolati, W. K. (2025). Impact of ZrO2 and Si3N4 Ceramics Dispersion on the Ti6Al4V Matrix: Mechanical and Microstructural Characteristics Using SPS. Crystals, 15(6), 531. https://doi.org/10.3390/cryst15060531