Supervised Machine Learning Models for Predicting SS304H Welding Properties Using TIG, Autogenous TIG, and A-TIG

Abstract

1. Introduction

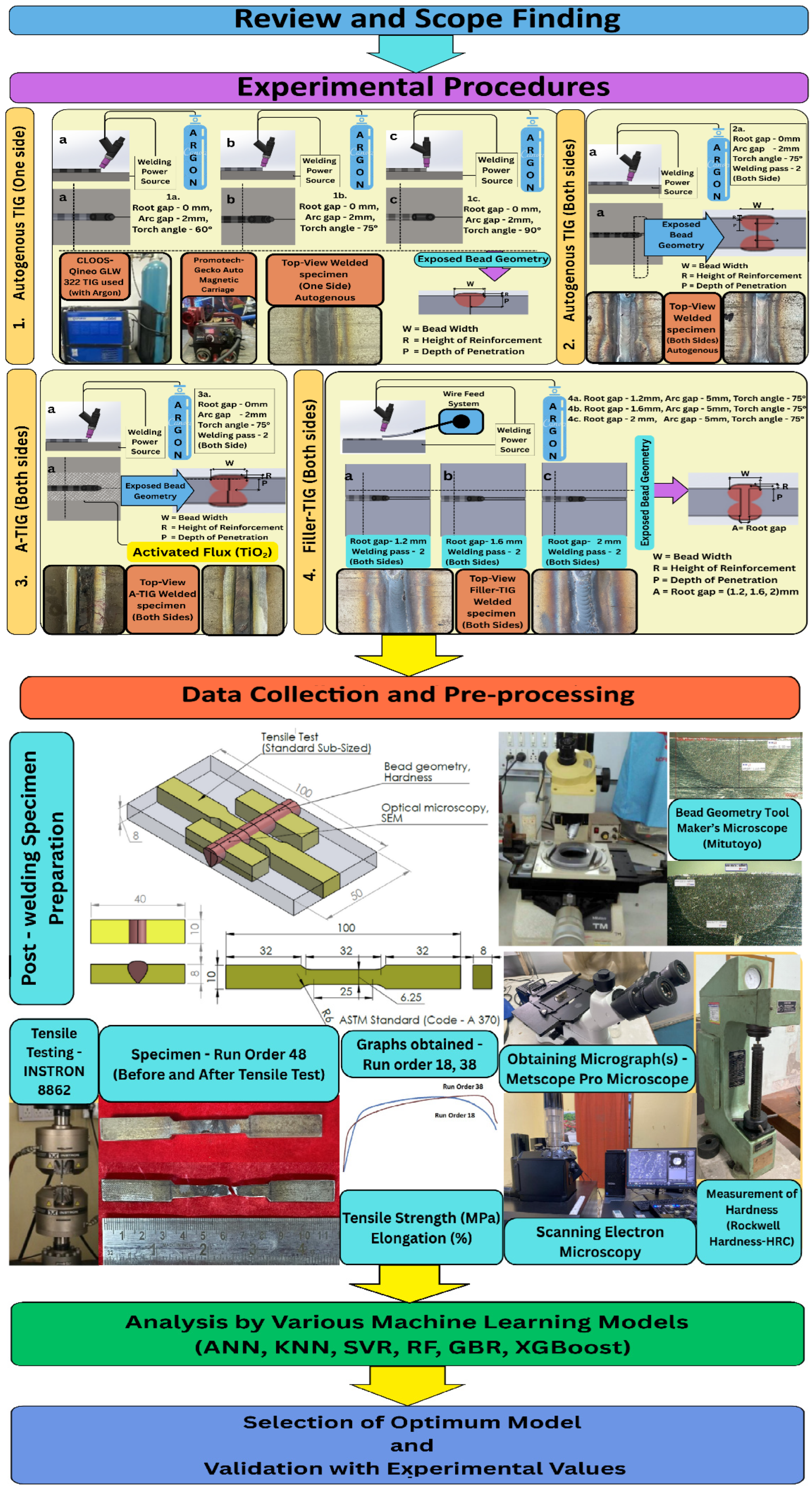

2. Materials and Methods

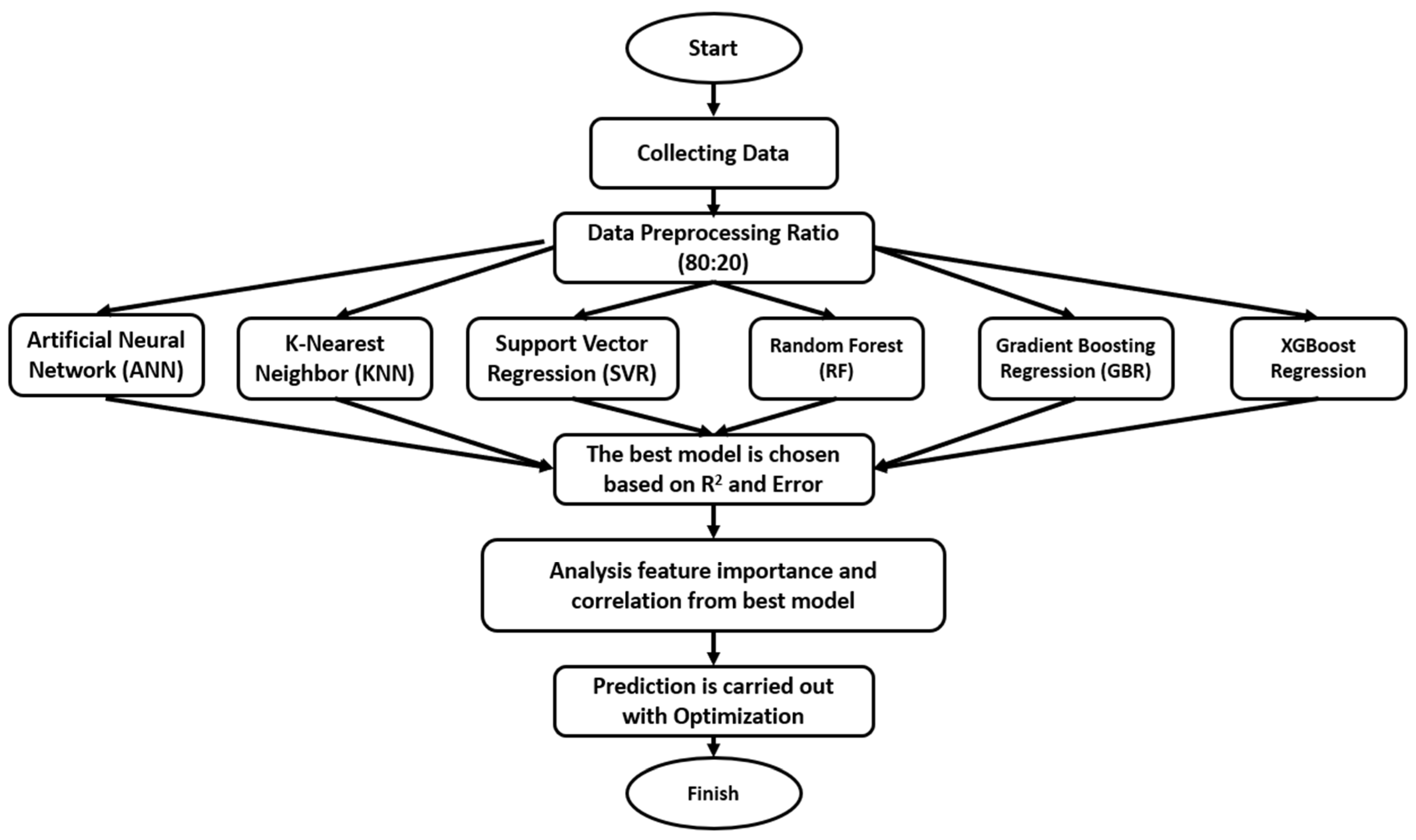

2.1. Modeling of Machine Learning Techniques

2.1.1. Artificial Neural Network (ANN)

2.1.2. K-Nearest Neighbor (KNN)

2.1.3. Support Vector Regression (SVR)

2.1.4. Random Forest (RF)

2.1.5. Gradient Boosting Regression (GBR)

- The model prediction after M iterations (trees) is:

2.1.6. XGBoost (Extreme Gradient Boosting)

- is the loss function (e.g., squared error);

- is the regularization term for each tree , where T is the number of leaves, is the leaf weight, and, are regularization parameters.

2.1.7. Cross-Validation

2.1.8. Performance Evaluation Metrics

2.1.9. Optimization of Different ML Model’s Parameters

3. Results and Discussion

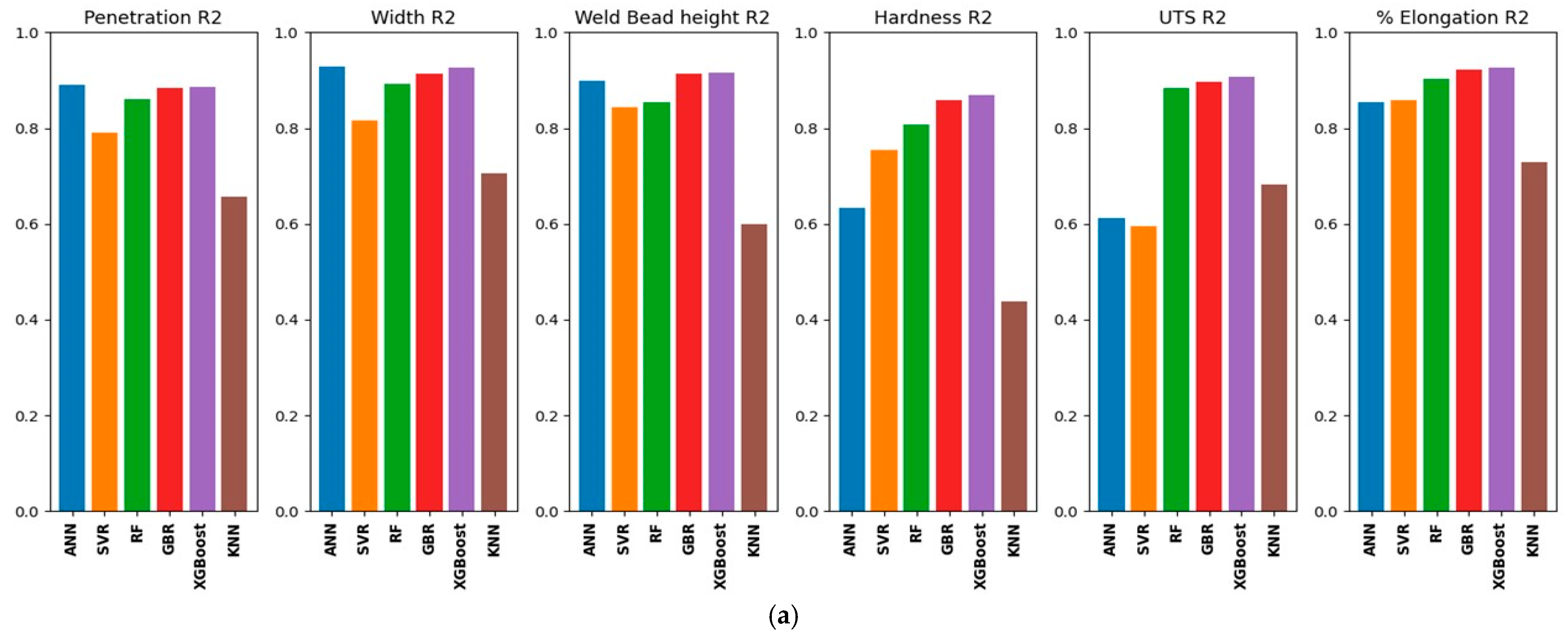

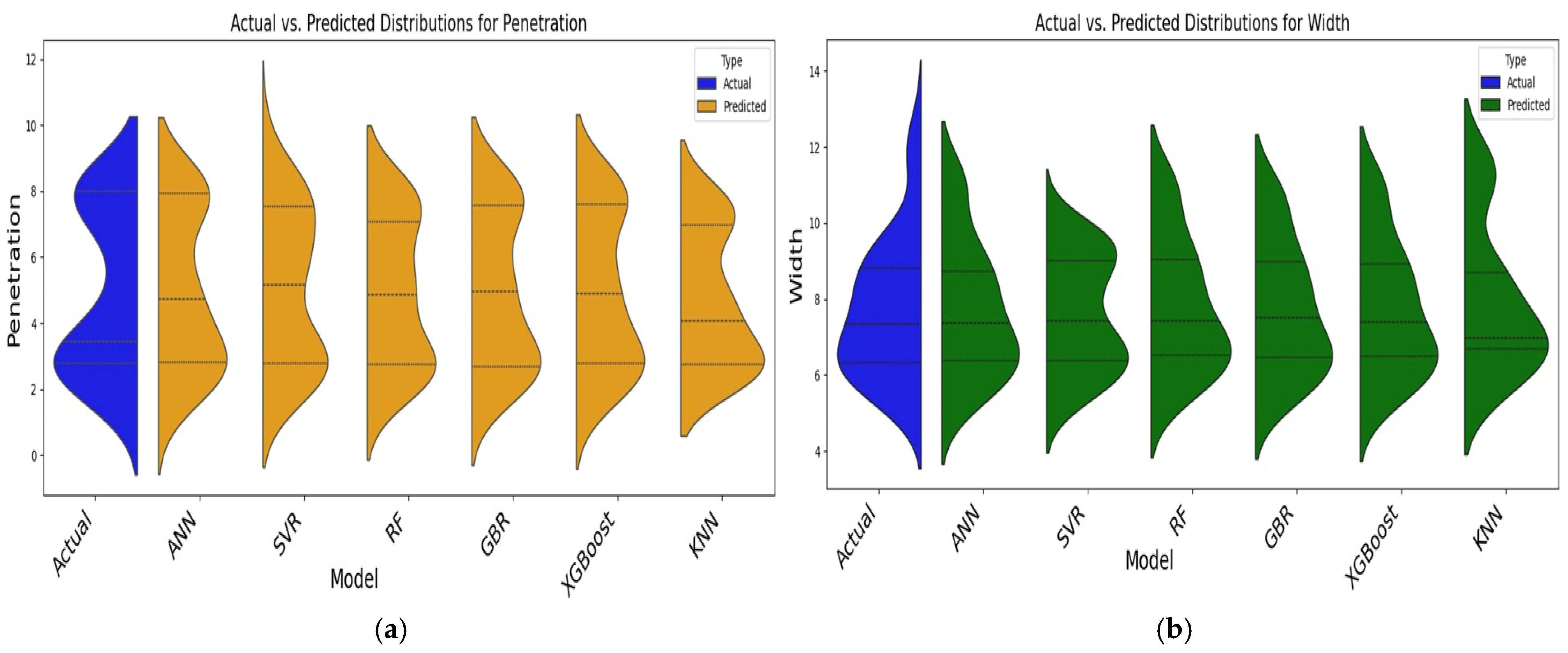

3.1. Model Performance Evaluation

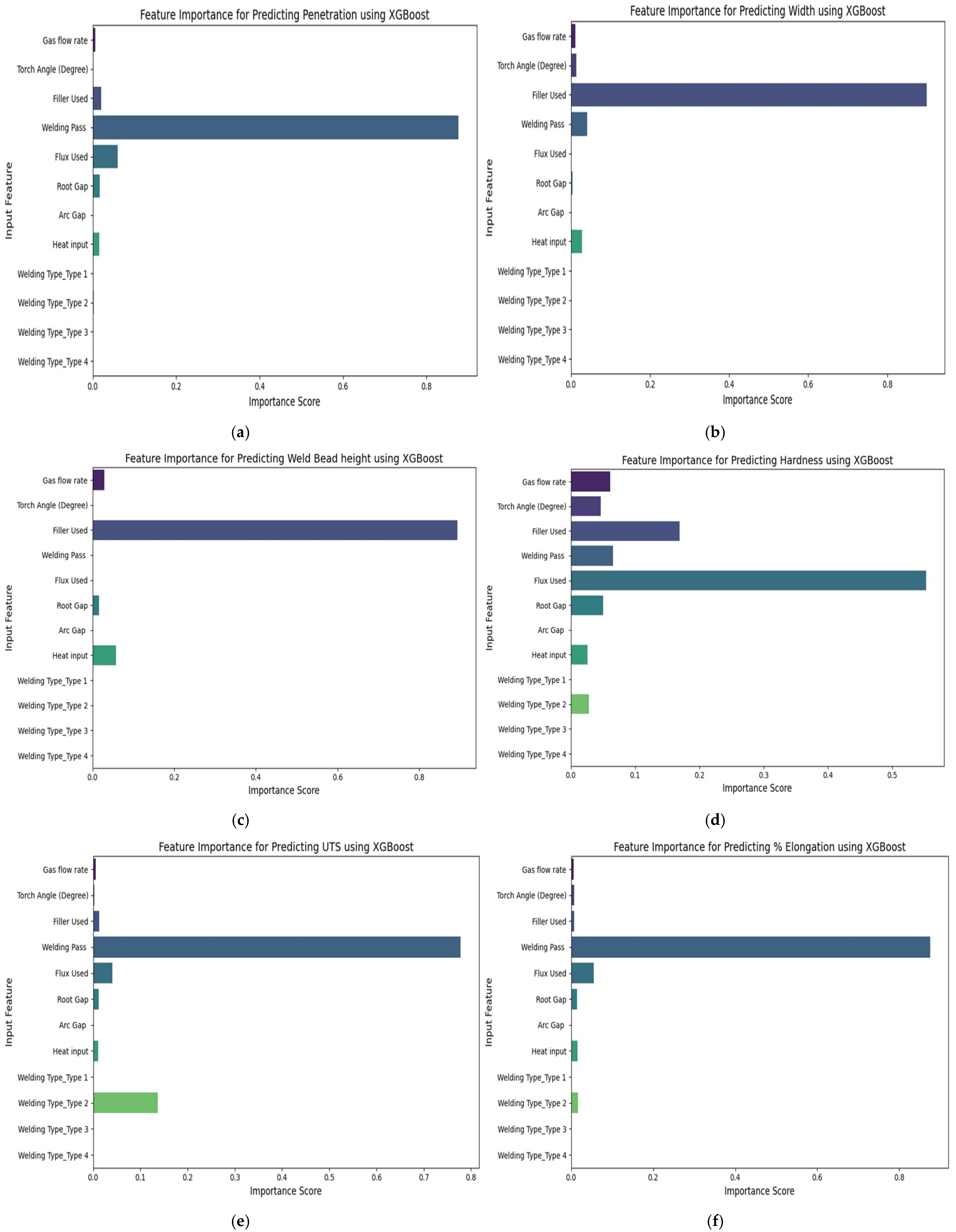

3.2. Feature Importance and Correlation Matrix

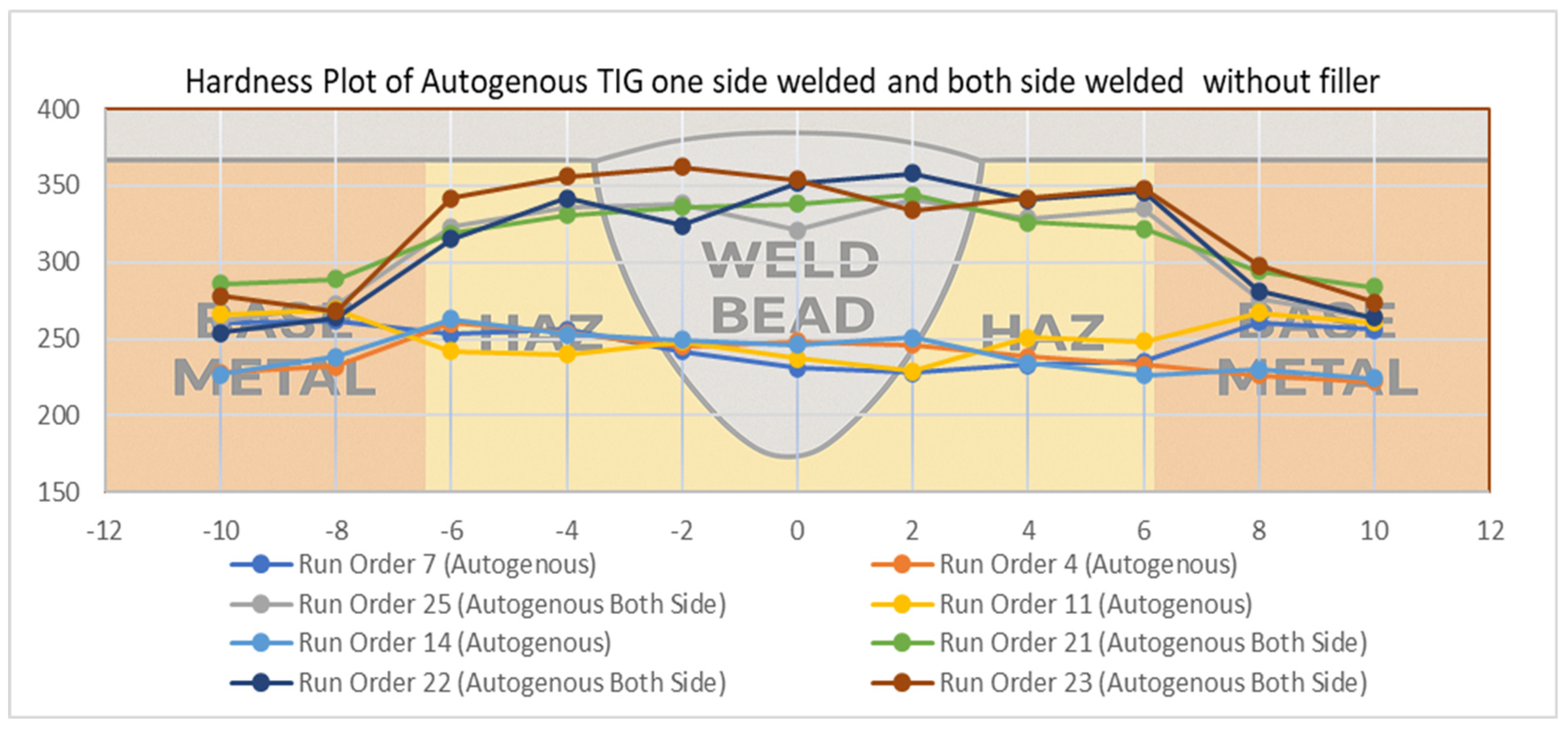

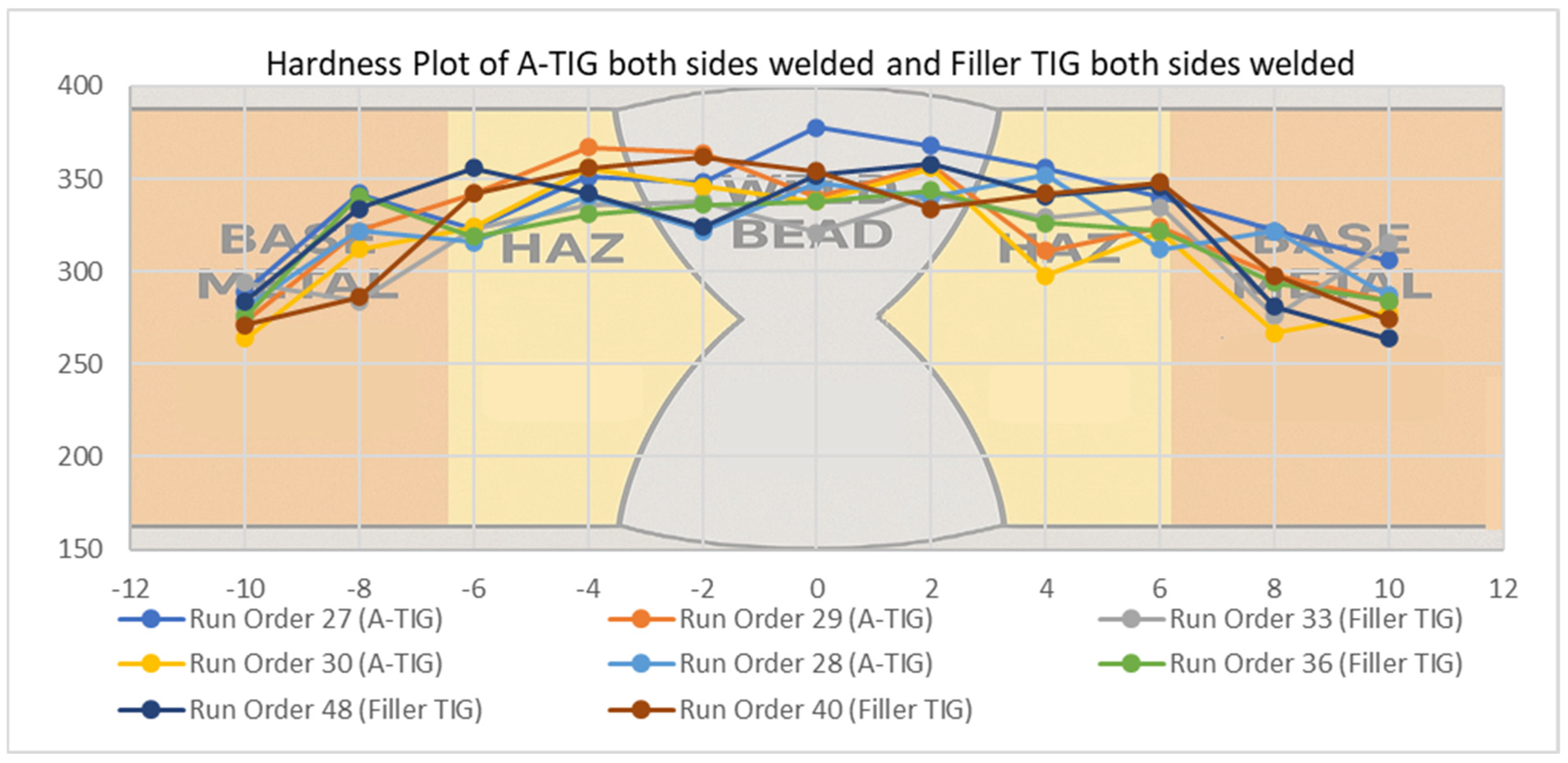

3.3. Microhardness

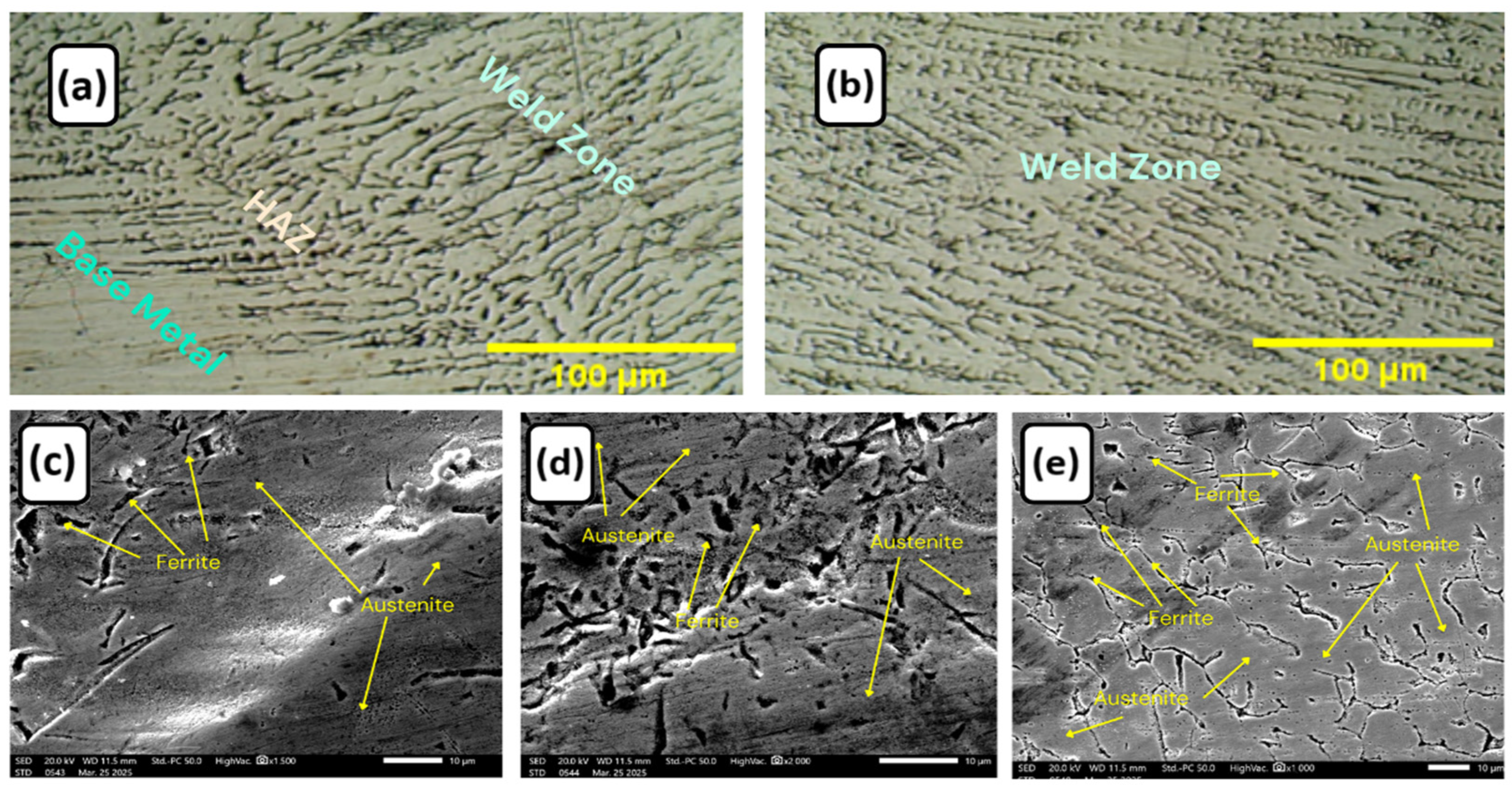

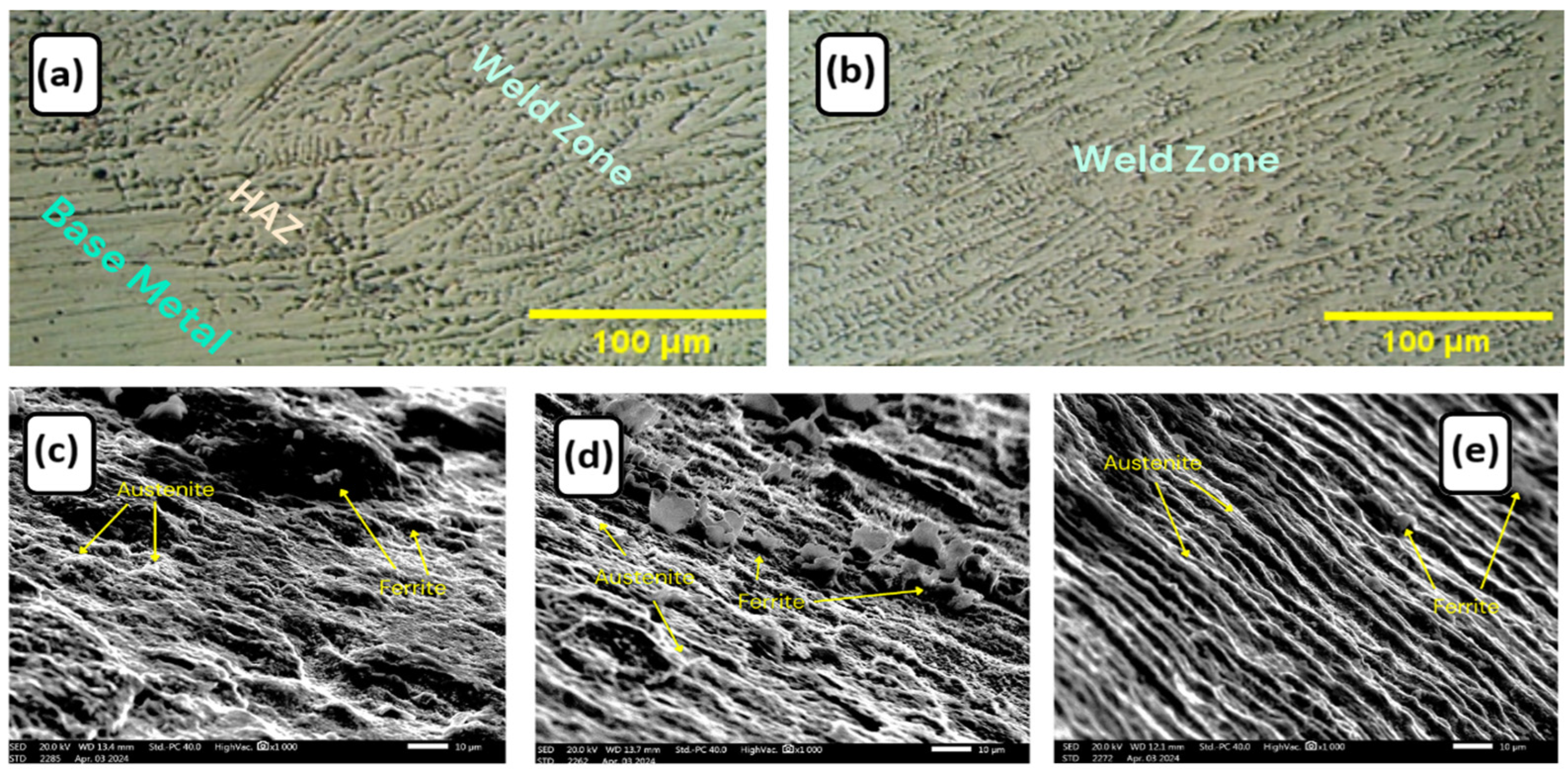

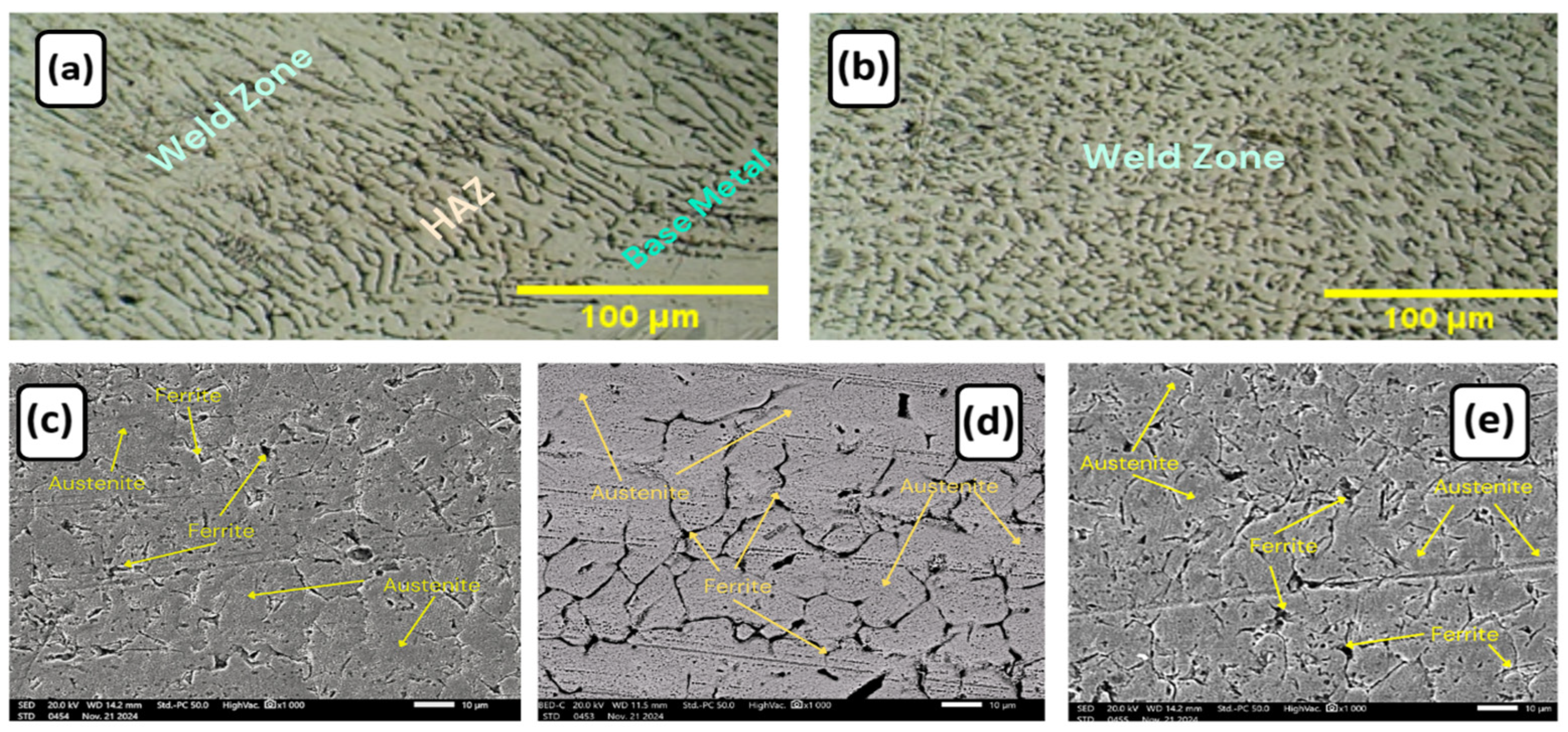

3.4. Microstructure

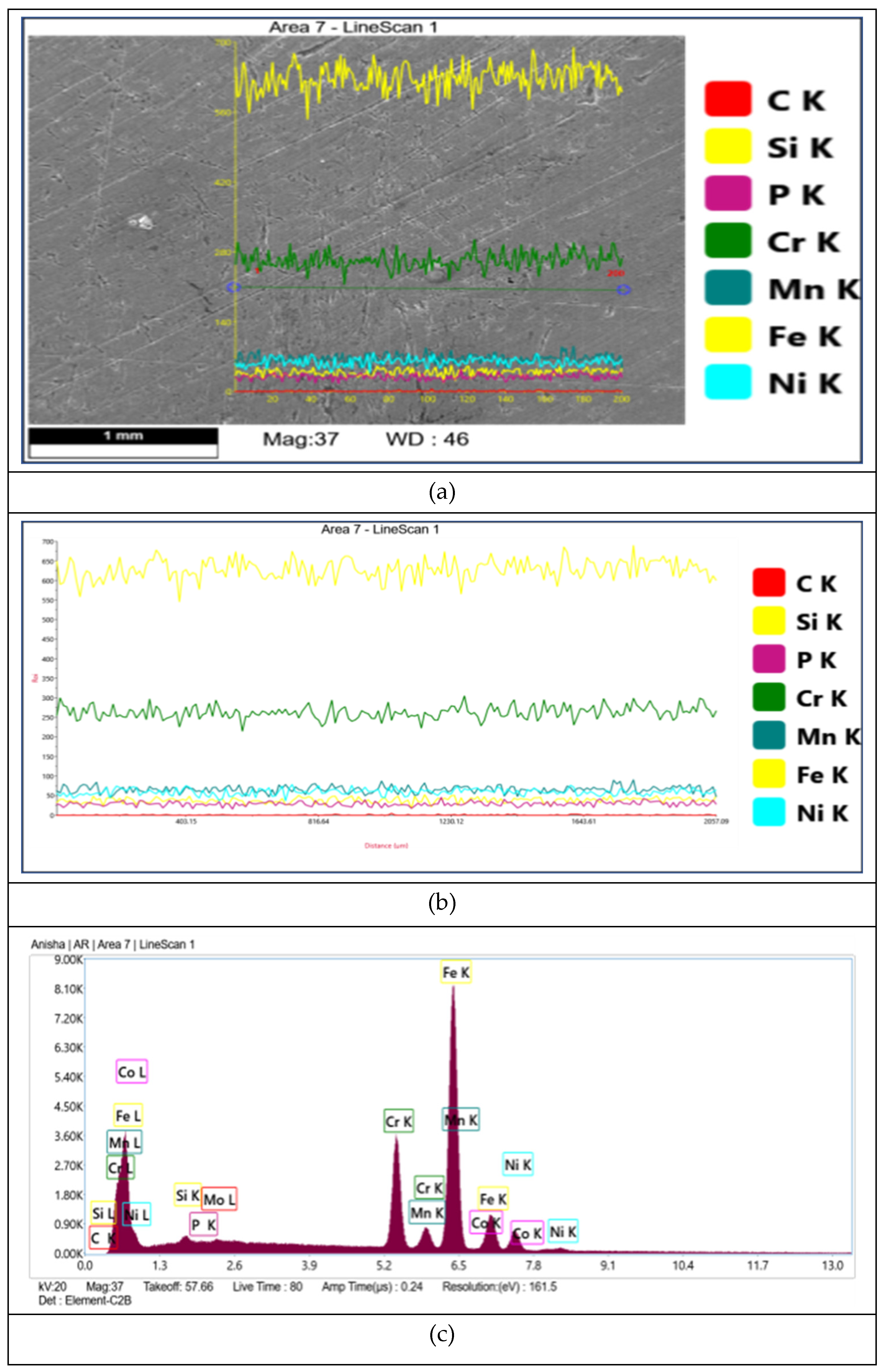

3.5. Line EDX

4. Conclusions

- XGBoost regression has emerged as the most effective model in predicting the welding outputs, exhibiting the highest R2 values and the lowest error rates across all responses, including penetration, width, weld bead height, hardness, ultimate tensile strength and % elongation.

- The feature importance analysis using the XGBoost model highlights the pivotal role of specific input parameters in influencing key weld quality characteristics. Among all variables, the number of welding passes consistently emerges as the most influential factor, particularly in predicting penetration, ultimate tensile strength and percentage elongation, with importance scores nearing or exceeding 0.75. This underscores the critical role of double-sided welding in achieving full penetration and enhanced mechanical performance. The use of filler material significantly influences bead width and bead height, due to its influence on spreading molten pool and material deposition. Additionally, activating flux is identified as an impactful factor in determining weld hardness, primarily due to its role in modifying molten pool behavior through the reverse Marangoni effect, thereby improving penetration and weld quality.

- The filler-assisted both side TIG welding also shows satisfactory results in most of the cases, achieving good mechanical properties due to full penetration.

- Heatmap correlation analysis reveals that welding pass, heat input, and flux usage have strong positive correlations with key welding properties of the SS304H-welded joints.

- Prediction and validation analyses confirm that the established machine learning models and in particular, XGBoost, closely match the actual experimental results across all output parameters.

- The close alignment between predicted and experimental data highlights the effectiveness of machine learning in forecasting welding responses and optimizing process parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Habba, M.I.; Alsaleh, N.A.; Badran, T.E.; Seleman, M.M.E.-S.; Ataya, S.; EI-Nikhaily, A.E.; Abdul-Latif, A.; Ahmed, M.M.Z. Comparative study of FSW, MIG, and TIG welding of AA5083-H111 based on the evaluation of welded joints and economic aspect. Materials 2023, 16, 5124. [Google Scholar] [CrossRef] [PubMed]

- Kutelu, B.J.; Seidu, S.O.; Eghabor, G.I.; Ibitoye, A.I. Review of GTAW welding parameters. J. Miner. Mater. Charact. Eng. 2018, 6, 541–554. [Google Scholar] [CrossRef]

- Thakur, P.P.; Chapgaon, A.N. A review on effects of GTAW process parameters on weld. Int. J. Res. Appl. Sci. Eng. Technol. 2016, 4, 136–140. [Google Scholar]

- Pandya, D.; Badgujar, A.; Ghetiya, N. A novel perception toward welding of stainless steel by activated TIG welding: A review. Mater. Manuf. Process. 2021, 36, 877–903. [Google Scholar] [CrossRef]

- Kumar, K.; Sateesh Kumar, C.; Masanta, M.; Pradhan, S. A review on TIG welding technology variants and its effect on weld geometry. Mater. Today Proc. 2022, 50, 999–1004. [Google Scholar] [CrossRef]

- Sun, Z.; Kuo, M.; Pan, D. High deposition rate cladding by non-consumable electrode arc processes. Int. J. Mater. Prod. Technol. 2002, 17, 580–589. [Google Scholar] [CrossRef]

- Masuyama, F. History of power plants and progress in heat resistant steels. ISIJ Int. 2001, 41, 612–625. [Google Scholar] [CrossRef]

- Abe, F. Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants. Sci. Technol. Adv. Mater. 2008, 9, 9–15. [Google Scholar] [CrossRef]

- Abe, F.; Tabuchi, M. Microstructure and creep strength of welds in advanced ferritic power plant steels. Sci. Technol. Weld. Join. 2004, 9, 22–30. [Google Scholar] [CrossRef]

- Sourmail, T.; Bhadeshia, H.K. Microstructural evolution in two variants of NF709 at 1023 and 1073 K. Metall. Mater. Trans. A 2005, 36, 23–34. [Google Scholar] [CrossRef]

- Rongcan, Z.; Liying, T.; Bohan, W.; Shufang, H.; Yan, G. Effect of heat treatment on the microstructure and properties of cold-worked Inconel 740H boiler tubes. In Energy Materials; Springer: Cham, Switzerland, 2014; pp. 279–285. [Google Scholar] [CrossRef]

- Siefert, J.A.; Shingledecker, J.P.; DuPont, J.N.; David, S.A. Weldability and weld performance of candidate nickel based superalloys for advanced ultra-supercritical fossil power plants part II: Weldability and cross-weld creep performance. Sci. Technol. Weld. Join. 2016, 21, 397–427. [Google Scholar] [CrossRef]

- Shibli, I.A.; Hamata, N.L. Creep crack growth in P22 and P91 welds—Overview from SOTA and HIDA projects. Int. J. Press. Vessel. Pip. 2001, 78, 785–793. [Google Scholar] [CrossRef]

- David, S.A.; Siefert, J.A.; DuPont, J.N.; Shingledecker, J.P. Weldability and weld performance of candidate nickel base superalloys for advanced ultra-supercritical fossil power plants part I: Fundamentals. Sci. Technol. Weld. Join. 2015, 20, 532–552. [Google Scholar] [CrossRef]

- Saha, S.; Das, S.; Mondal, S. Exploring the weldability of austenitic stainless steels in advanced ultra-supercritical power plant applications: An extensive review. Indian Weld. J. 2023, 56, 54–66. [Google Scholar] [CrossRef]

- Sirohi, S.; Kumar, A.; Pandey, S.M.; Fydrych, D.; Kumar, S.; Pandey, C. Dissimilar autogenous TIG joint of Alloy 617 and AISI 304H steel for AUSC application. Heliyon 2023, 9, e19945. [Google Scholar] [CrossRef]

- Sharma, P.; Dwivedi, D.K. A-TIG welding of dissimilar P92 steel and 304H austenitic stainless steel: Mechanisms, microstructure and mechanical properties. J. Manuf. Process. 2019, 44, 166–178. [Google Scholar] [CrossRef]

- Thakare, J.G.; Pandey, C.; Gupta, A.; Taraphdar, P.K.; Mahapatra, M.M. Influence of microstructural heterogeneity on the mechanical performance of autogenous GTAW dissimilar joints of F/M P91 and SS304L steel. Fusion Eng. Des. 2021, 168, 112616. [Google Scholar] [CrossRef]

- Ogundimu, E.O.; Akinlabi, E.T.; Erinosho, M.F. Effect of welding current on mechanical properties and microstructure of TIG welding of Type-304 austenite stainless steel. J. Phys. Conf. Ser. 2019, 1378, 032022. [Google Scholar] [CrossRef]

- Zubairuddin, M.; Vasudevan, M.; Das, P.K.; Alam, M.M.; Kumar, K.S.; Prabhakar, S. FEM-based thermal and mechanical analysis of a comparative study of TIG and A-TIG welding on P91 steel. Sci. Rep. 2025, 15, 10271. [Google Scholar] [CrossRef]

- Lee, H.-K.; Yun, K.-H. A study on the applicability of A-TIG welding of semi-automatic cold wire feeding process for cryogenic stainless steel pipes. J. Weld. Join. 2024, 42, 231–238. [Google Scholar] [CrossRef]

- Liu, X.; Su, Y.; Zhang, G.; Wang, R.; Cai, X. Effect of longitudinal magnetic field on the microstructure and properties of A-TIG welding with different TiO2 coating amounts. Crystals 2023, 13, 66. [Google Scholar] [CrossRef]

- Touileb, K.; Djoudjou, R.; Hedhibi, A.C.; Ouis, A.; Benselama, A.; Ibrahim, A.; Abdo, H.S.; Samad, U.A. Comparative microstructural, mechanical, and corrosion study between dissimilar ATIG and conventional TIG weldments of 316L stainless steel and mild steel. Metals 2022, 12, 635. [Google Scholar] [CrossRef]

- Niagaj, J. Influence of activated fluxes on the bead shape of A-TIG welds on carbon and low-alloy steels in comparison with stainless steel AISI 304L. Metals 2021, 11, 530. [Google Scholar] [CrossRef]

- Saha, S.; Paul, B.C.; Das, S. Productivity improvement in butt joining of thick stainless steel plates through the usage of activated TIG welding. SN Appl. Sci. 2021, 3, 416. [Google Scholar] [CrossRef]

- Vidyarthy, R.S.; Dwivedi, D.K.; Muthukumaran, V. Optimization of A-TIG process parameters using response surface methodology. Mater. Manuf. Process. 2018, 33, 709–717. [Google Scholar] [CrossRef]

- Sharma, P.; Dwivedi, D.K. Comparative study of activated flux-GTAW and multipass-GTAW dissimilar P92 steel-304H ASS joints. Mater. Manuf. Process. 2019, 34, 1195–1204. [Google Scholar] [CrossRef]

- Devendranath Ramkumar, K.; Chandrasekhar, A.; Singh, A.K.; Ahuja, S.; Agarwal, A.; Arivazhagan, N.; Rabel, A.M. Comparative studies on the weldability, microstructure, and tensile properties of autogenous TIG-welded AISI 430 ferritic stainless steel with and without flux. J. Manuf. Process. 2015, 20, 54–69. [Google Scholar] [CrossRef]

- Ahmadi, E.; Ebrahimi, A.R. Welding of 316L austenitic stainless steel with activated tungsten inert gas process. J. Mater. Eng. Perform. 2014, 24, 1066–1073. [Google Scholar] [CrossRef]

- Mahajan, A.; Singh, H.; Kumar, S.; Kumar, S. Mechanical properties assessment of TIG welded SS 304 joints. Mater. Today Proc. 2022, 56, 3073–3077. [Google Scholar] [CrossRef]

- Rogalski, G.; Świerczyńska, A.; Landowski, M.; Fydrych, D. Mechanical and microstructural characterization of TIG welded dissimilar joints between 304L austenitic stainless steel and Incoloy 800HT nickel alloy. Metals 2020, 10, 559. [Google Scholar] [CrossRef]

- Rhode, M.; Erxleben, K.; Richter, T.; Schroepfer, D.; Mente, T.; Michael, T. Local mechanical properties of dissimilar metal TIG welded joints of CoCrFeMnNi high entropy alloy and AISI 304 austenitic steel. J. Mater. Sci. 2024, 59, 2623–2633. [Google Scholar] [CrossRef]

- Widyianto, A.; Baskoro, A.S.; Kiswanto, G. Effect of pulse currents on weld geometry and angular distortion in pulsed GTAW of 304 stainless steel butt joint. Int. J. Automot. Mech. Eng. 2020, 17, 7687–7694. [Google Scholar] [CrossRef]

- Ostromęcka, M.; Kolasa, A. The effect of the current pulsation frequency on heat supply results during pulsed current TIG welding in 301L stainless steel. Weld. Technol. Rev. 2019, 91, 20–26. [Google Scholar] [CrossRef][Green Version]

- Cui, S.; Pang, S.; Pang, D.; Zhang, Z. Influence of welding speeds on the morphology, mechanical properties, and microstructure of 2205 DSS welded joint by K-TIG welding. Materials 2021, 14, 3426. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.R.; Khanna, P. Review on A-TIG (activated flux tungsten inert gas) welding. Mater. Today Proc. 2021, 44, 808–820. [Google Scholar] [CrossRef]

- Khara, B.; Mandal, N.D.; Sarkar, A.; Sarkar, M.; Chakrabarti, B.; Das, S. Weld cladding with austenitic stainless steel for imparting corrosion resistance. Indian. Weld. J. 2016, 49, 74–81. [Google Scholar] [CrossRef]

- Saha, M.K.; Hazra, R.; Mondal, A.; Das, S. Effect of heat input on geometry of austenitic stainless steel weld bead on low carbon steel. J. Inst. Eng. (India) Ser. C 2019, 100, 607–615. [Google Scholar] [CrossRef]

- Mondal, A.; Saha, M.K.; Hazra, R.; Das, S. Influence of heat input on weld bead geometry using duplex stainless steel wire electrode on low alloy steel specimens. Cogent Eng. 2016, 3, 1143598. [Google Scholar] [CrossRef]

- Murugan, N.; Parmar, R.S.; Sud, S.K. Effect of submerged arc process variables on dilution and bead geometry in single wire surfacing. J. Mater. Process. Technol. 1993, 37, 767–780. [Google Scholar] [CrossRef]

- Bassey, M.O.; Ohwoekevwo, J.U.; Ikpe, A.E. Thermal analysis of AISI 1020 low carbon steel plate agglutinated by gas tungsten arc welding technique: A computational study of weld dilution using finite element method. J. Eng. Appl. Sci. 2024, 71, 33–54. [Google Scholar] [CrossRef]

- Saha, S.; Das, S.; Mondal, S. Experimental investigation on autogenous TIG and A-TIG welding for enhanced penetration in austenitic SS304H plates. Indian. Weld. J. 2025, 58, 75–82. [Google Scholar] [CrossRef]

- Singh, A.; Singh, V.; Singh, A.P.; Ashutosh, S.; Patel, D. Welding investigations on mechanical property and microstructure of TIG and A-TIG Weld of Hastelloy C-276. Eng. Res. Express 2023, 5, 025004. [Google Scholar] [CrossRef]

- Trinh, S.H.; Ly, H.-B. Enhancing compressive strength prediction of roller compacted concrete using machine learning techniques. Measurement 2023, 213, 113196. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Freund, Y.; Schapire, R.E. Experiments with a new boosting algorithm. In Machine Learning, Proceedings of the Thirteenth International Conference, Bari, Italy, 3–6 July 1996; Morgan Kaufmann Publishers: San Francisco, CA, USA, 1996. [Google Scholar]

- Agarwal, R.; Singh, J.; Gupta, V. An intelligent approach to predict thermal injuries during orthopaedic bone drilling using machine learning. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 320. [Google Scholar] [CrossRef]

- Vieira, J.T.; Pereira, R.B.D.; Lauro, C.H.; Brandão, L.C.; Ferreira, J.R. Multi-objective evolutionary optimization of extreme gradient boosting regression models of the internal turning of PEEK tubes. Expert. Syst. Appl. 2024, 238, 122372. [Google Scholar] [CrossRef]

| Authors, Year, [Reference] | TIG Technique and Joint Base Material (BM) | Used Parameters | Outcomes |

|---|---|---|---|

| Sirohi et al., 2023 [16] | Autogenous TIG; IN617 alloy BM with AISI 304H steel BM (5 mm thick) | Current: 200 A; Voltage: 12 V; Travel speed: 80 mm/min; Arc length: 3 mm; Electrode angle: 60°; Shielding gas: Argon (99.99%); |

|

| Thakare et al., 2021 [18] | Autogenous TIG; Ferritic/Martensitic P91 BM with 304L ASS steel BM (5.6 mm thick) | Current: 240 A; Voltage: 18 V; Arc length: 3 mm; Travel speed: 75 mm/min; Shielding gas: Argon (99.99%); |

|

| Ogundimu et al., 2019 [19] | Autogenous TIG welding; SS 304 BM (6 mm thick) | Current: 150–170 A; Shielding gas: Argon; Root height: 1 mm |

|

| Zubairuddin et al., 2025 [20] | A-TIG and TIG; P91 steel BM (4 mm thick); Oxide flux | Current: 110 A (TIG), 100 A (A-TIG); Voltage: 12 V (TIG), 11 V (A-TIG); Travel speed: 1.67 mm/s; Arc gap: 3 mm; Gas flow rate: 10 L/min; Torch angle: 30° |

|

| Lee et al., 2024 [21] | A-TIG; SS STS 316L BM (4 mm thick); wire feeding (0.9 mm STS 308L; comercial STS flux | Current (pulse): 60–200 A; Electrode angle: 60°; Arc gap: 0.5–2.0 mm; Travel speed: 20 cm/min; Wire feeding speed: 80 cm/min; Shielding gas: Argon (99.99%) 20 L/min |

|

| Sharma and Dwivedi, 2023 [17] | A-TIG; P92 steel BM with 304H ASS BM (8 mm thick); Flux used: Cr2O3, MoO3, SiO2 and TiO2 | Current: 220 A, Travel speed: 80 mm/min, Arc length: 3 mm, Shielding gas: Argon (99.99%); Gas Flow rate: 10 L/min |

|

| Liu et al., 2023 [22] | A-TIG; Mg-alloy BM (5 mm thick); TiO2 active flux coating rates: 1,2,3,4 and 5 mg/cm2 | Longitudinal Magnetic Field frequency: 30 Hz; Magnetic field current: 1.5 A |

|

| Touileb et al., 2022 [23] | A-TIG; SS 316L BM with Mild Steel (MS) BM (6 mm thick); Flux Used: SiO2, Fe2O3, Cr2O3 | Current: 150 A; Travel speed: 13 cm/min; Arc length: 2.0 mm; Torch angle: 45°; Shielding gas: Pure Argon 10 L/min |

|

| Niagaj et al., 2021 [24] | A-TIG; Various grades of steels (S235JR+N), P265GH, (S355J2+N), WELDOX 1300 BM (7–8 mm thickness); TiO2, SiO2, Cr2O3, NaF, AlF3 Fluxes | Current: 200 A; Voltage: 10.4–12.8 V; Travel speed: 2.5 mm/s; Shielding gas: Argon 9–10 L/min |

|

| Saha et al., (2021) [25] | A-TIG; AISI-316L BM (10 mm thick); Fluxes: Cr2O3, Fe2O3, SiO2; Filler: Similar to BM | Current: 120–150 A; Arc length: 3 mm; Travel speed: 60 mm/min; Shielding gas: Argon (99.99%) 15 L/min |

|

| Vidyarthy et al., 2020 [26] | A-TIG; 9–12% Cr Ferritic SS BM (8 mm thick) | Current: 213.78 A; Travel Speed: 96.22 mm/min; Pure Argon: 10 L/min |

|

| Sharma and Dwivedi, 2019 [27] | A-TIG and multipass TIG; P92 steel BM with 304H ASS BM (8 mm thick); TiO2 flux; ErNiCr-3/Inconel 82 filler | Current: 220 A; Travel speed: 80 mm/min; Arc length: 3 mm; Shielding gas: Argon (99.99%); Gas Flow rate: 10 L/min |

|

| Devendranath et al., 2015 [28] | A-TIG; AISI 430 Ferritic Stainless Steel BM (5 mm thick) | Current: 160–220 A; Voltage: 12.8–13.2 V (without flux), 10.2–12.2 V (with SiO2), 10.2–11.8 V (with Fe2O3); Travel speed: 75 mm/min |

|

| Ahmadi and Ebrahimi, 2014 [29] | A-TIG; SS 316L BM; Fluxes: SiO2, TiO2, Cr2O3, CaO; Coating Densities: 2.6, 1.3, 2.0, 7.8 mg/cm2 | Current: 150 A; Travel speed: 150 mm/min; Arc length: 3 mm; Electrode angle: 60°; Shielding gas: Argon (99.99%) 12 L/min |

|

| Mahajan et al., 2021 [30] | TIG; ASS 304 BM (6 mm thick); Fillers: ER 308L, ER 316L, and ER 310; Single V-groove (60°) | Current: 150 A, 170 A; Root gap: 2.4 mm; Root face: 1.5 mm; Arc length: 3.0 mm; Shielding gas: Argon + Helium |

|

| Rogalski et al., 2020 [31] | TIG; 304L austenitic SS tube with Incoloy 800HT tube; Filler: S Ni 6082 | Current: 60–110 A, 80–110 A; Arc Voltage: 10.5–11.0 V, 9.0–10.0 V; Travel Speed: 1.2–2.5 mm/s |

|

| Rhode et al., 2024 [32] | Pulsed-TIG; CoCrFeMnNi high entropy alloy (HEA) BM with SS AISI 304 BM (1.2 mm thick) | Base current: 35 A; Peak current: 90 A; Voltage: 10 V Pulse frequency: 4 Hz; Travel speed: 300 mm/min; Shielding gas: Argon (99.99%) 15 L/min |

|

| Widyianto et al., 2020 [33] | Pulsed TIG; SS-304 BM (3 mm thick) | Current: 40 A–212 A; Travel Speed: 2.0 mm/sec; 99.99% Argon: 11 L/min 9 (upper), 3 L/min (back) |

|

| Ostromęcka and Kolasa (2019) [34] | Pulsed-TIG; SS 301L BM (3 mm thick) | Current: 140 A; Base Current (Ib): 28 A; Pulse Duty Cycle: 50%; Frequency Range: 0.5–100 Hz; Welding Speed: 2.33 mm/s; Shielding gas: Argon (99.99%) 12 L/min |

|

| Cui et al., 2021 [35] | Keyhole-TIG; 2205 Duplex Stainless Steel (DSS) BM (8 mm thick) | Current: 480 A; Voltage: 16.7 V; Travel speed: 280–360 mm/min Electrode gap: 2.5 mm; Shielding gas: Argon (99.9%) 25 L/min; |

|

| Element | C | Si | Mn | P | S | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| Wt.% | 0.055 | 0.477 | 1.398 | 0.028 | 0.03 | 18.11 | 8.477 | Balance |

| Autogenous TIG Experiment Conducted on One Side | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Input Parameters | Output Parameters | |||||||||||||

| Run Order | Gas Flow Rate | Torch Angle (Degree) | Filler Used | Welding Pass | Flux Used | Root Gap | Arc Gap (mm) | Heat Input (kJ/mm) | Penetration (mm) | Width (mm) | Bead Height (mm) | Tensile Strength (MPa) | % Elongation | Avg. Rockwell Hardness (HRC) |

| 1 | 10 | 60 | 0 | 1 | 0 | 0 | 2 | 0.768 | 2.326 | 5.932 | −0.1 | 284.32 | 3.96 | 27.67 |

| 2 | 14 | 60 | 0 | 1 | 0 | 0 | 2 | 0.768 | 2.156 | 6.045 | 0.00 | 274.86 | 3.61 | 29.67 |

| 3 | 10 | 90 | 0 | 1 | 0 | 0 | 2 | 0.768 | 1.674 | 7.531 | −0.16 | 212.62 | 1.62 | 32.33 |

| 4 | 14 | 90 | 0 | 1 | 0 | 0 | 2 | 0.768 | 1.735 | 6.639 | 0.00 | 218.67 | 1.76 | 29 |

| 5 | 10 | 60 | 0 | 1 | 0 | 0 | 2 | 1.119 | 3.369 | 7.869 | −0.14 | 349.4 | 4.95 | 28 |

| 6 | 14 | 60 | 0 | 1 | 0 | 0 | 2 | 1.119 | 3.058 | 8.422 | 0.12 | 334.96 | 4.58 | 31.33 |

| 7 | 10 | 90 | 0 | 1 | 0 | 0 | 2 | 1.119 | 3.459 | 9.375 | 0.11 | 424.5 | 17.696 | 30.33 |

| 8 | 14 | 90 | 0 | 1 | 0 | 0 | 2 | 1.119 | 2.908 | 6.609 | −0.1 | 346.06 | 5.28 | 27.33 |

| 9 | 10 | 75 | 0 | 1 | 0 | 0 | 2 | 0.943 | 1.826 | 8.264 | 0.1 | 206.29 | 9.232 | 31 |

| 10 | 14 | 75 | 0 | 1 | 0 | 0 | 2 | 0.943 | 2.924 | 6.244 | 0.00 | 370.22 | 13 | 25.33 |

| 11 | 12 | 60 | 0 | 1 | 0 | 0 | 2 | 0.943 | 1.822 | 6.014 | 0.11 | 231.54 | 2.26 | 34.33 |

| 12 | 12 | 90 | 0 | 1 | 0 | 0 | 2 | 0.943 | 2.884 | 6.424 | 0.00 | 351.62 | 4.33 | 29.33 |

| 13 | 12 | 75 | 0 | 1 | 0 | 0 | 2 | 0.768 | 2.787 | 6.548 | 0.00 | 328.31 | 3.71 | 25.33 |

| 14 | 12 | 75 | 0 | 1 | 0 | 0 | 2 | 1.119 | 2.707 | 7.121 | 0.00 | 332.86 | 3.77 | 27.33 |

| 15 | 12 | 75 | 0 | 1 | 0 | 0 | 2 | 0.943 | 2.807 | 6.311 | −0.19 | 352.36 | 4 | 28.33 |

| 16 | 12 | 75 | 0 | 1 | 0 | 0 | 2 | 0.943 | 2.607 | 7.029 | 0.00 | 331.42 | 3.76 | 29.33 |

| 17 | 12 | 75 | 0 | 1 | 0 | 0 | 2 | 0.943 | 2.747 | 7.162 | 0.00 | 339.82 | 4.17 | 31.33 |

| 18 | 12 | 75 | 0 | 1 | 0 | 0 | 2 | 0.943 | 2.968 | 7.008 | 0.08 | 311.691 | 6.781 | 32.33 |

| 19 | 12 | 75 | 0 | 1 | 0 | 0 | 2 | 0.943 | 2.618 | 7.118 | 0.11 | 326.61 | 4 | 27.67 |

| 20 | 12 | 75 | 0 | 1 | 0 | 0 | 2 | 0.943 | 2.712 | 6.582 | 0.00 | 331.42 | 4.05 | 28.67 |

| Autogenous TIG Experiment Conducted on Both Sides with the Best Results of the 1st set. | ||||||||||||||

| Input Parameters | Output Parameters | |||||||||||||

| Run Order | Gas flow rate | Torch Angle (Degree) | Filler Used | Welding Pass | Flux Used | Root Gap | Arc Gap (mm) | Heat input (kJ/mm) | Penetration (mm) | Width (mm) | Bead height (mm) | Tensile Strength (MPa) | % Elongation | Avg. Rockwell Hardness (HRC) |

| 21 | 10 | 75 | 0 | 2 | 0 | 0 | 2 | 1.18 | 6.530 | 5.839 | 0.109 | 481.73 | 23.368 | 28 |

| 22 | 14 | 75 | 0 | 2 | 0 | 0 | 2 | 1.18 | 5.368 | 5.59 | 0.144 | 434.276 | 12.673 | 28.67 |

| 23 | 10 | 75 | 0 | 2 | 0 | 0 | 2 | 1.18 | 6.000 | 6.066 | 0.121 | 476.82 | 17.562 | 30 |

| 24 | 14 | 75 | 0 | 2 | 0 | 0 | 2 | 1.18 | 5.022 | 5.307 | 0.00 | 416.834 | 11.643 | 31.67 |

| 25 | 12 | 75 | 0 | 2 | 0 | 0 | 2 | 0.964 | 5.174 | 6.64 | 0.177 | 422.754 | 12.843 | 31.33 |

| A− TIG Experiment Conducted on Both Sides with the Best Results of the 1st set | ||||||||||||||

| Input Parameters | Output Parameters | |||||||||||||

| Run Order | Gas flow rate | Torch Angle (Degree) | Filler Used | Welding Pass | Flux Used | Root Gap | Arc Gap (mm) | Heat input (kJ/mm) | Penetration (mm) | Width (mm) | Bead height (mm) | Tensile Strength (MPa) | % Elongation | Avg. Rockwell Hardness (HRC) |

| 26 | 10 | 75 | 0 | 2 | 1 | 0 | 2 | 1.264 | 8.000 | 5.214 | −0.14 | 648.64 | 26.884 | 34.33 |

| 27 | 14 | 75 | 0 | 2 | 1 | 0 | 2 | 1.264 | 8.000 | 5.642 | 0.00 | 628.94 | 26.224 | 36.33 |

| 28 | 10 | 75 | 0 | 2 | 1 | 0 | 2 | 1.264 | 8.000 | 5.326 | −0.11 | 656.86 | 28.342 | 35.67 |

| 29 | 14 | 75 | 0 | 2 | 1 | 0 | 2 | 1.264 | 8.000 | 5.881 | 0.00 | 636.41 | 26.482 | 34 |

| 30 | 12 | 75 | 0 | 2 | 1 | 0 | 2 | 1.01 | 6.640 | 6.314 | 0.00 | 602.083 | 30.887 | 32.33 |

| Filler TIG Experiment on Both Sides | ||||||||||||||

| Input Parameters | Output Parameters | |||||||||||||

| Run Order | Gas flow rate | Torch Angle (Degree) | Filler Used | Welding Pass | Flux Used | Root Gap | Arc Gap (mm) | Heat input (kJ/mm) | Penetration (mm) | Width (mm) | Bead height (mm) | Tensile Strength (MPa) | % Elongation | Avg. Rockwell Hardness (HRC) |

| 31 | 10 | 75 | 1 | 2 | 0 | 1.2 | 5 | 1.337 | 2.825 | 8.105 | 1.61 | 361.34 | 11.342 | 30.67 |

| 32 | 14 | 75 | 1 | 2 | 0 | 1.2 | 5 | 1.337 | 4.63 | 8.61 | 1.18 | 468.69 | 16.546 | 30.33 |

| 33 | 10 | 75 | 1 | 2 | 0 | 2 | 5 | 1.337 | 8 | 8.295 | 1.14 | 622.243 | 22.643 | 29 |

| 34 | 14 | 75 | 1 | 2 | 0 | 2 | 5 | 1.337 | 8 | 7.755 | 2.455 | 642.536 | 26.892 | 33.67 |

| 35 | 10 | 75 | 1 | 2 | 0 | 1.2 | 5 | 1.52 | 8 | 8.99 | 1.315 | 656.172 | 31.342 | 34.33 |

| 36 | 14 | 75 | 1 | 2 | 0 | 1.2 | 5 | 1.52 | 8 | 9.65 | 0.665 | 634.562 | 26.472 | 30.67 |

| 37 | 10 | 75 | 1 | 2 | 0 | 2 | 5 | 1.52 | 8 | 9.705 | 0.51 | 664.239 | 31.573 | 27.33 |

| 38 | 14 | 75 | 1 | 2 | 0 | 2 | 5 | 1.52 | 8 | 9.135 | 0.485 | 676.126 | 34.003 | 32.33 |

| 39 | 10 | 75 | 1 | 2 | 0 | 1.6 | 5 | 1.458 | 8 | 8.32 | 1.16 | 616.362 | 24.346 | 32 |

| 40 | 14 | 75 | 1 | 2 | 0 | 1.6 | 5 | 1.458 | 8 | 7.564 | 0.621 | 621.643 | 24.63 | 32 |

| 41 | 12 | 75 | 1 | 2 | 0 | 1.2 | 5 | 1.458 | 3.34 | 9.632 | 0.34 | 416.631 | 16.583 | 30 |

| 42 | 12 | 75 | 1 | 2 | 0 | 2 | 5 | 1.458 | 8 | 9.224 | 0.56 | 616.263 | 23.064 | 26.33 |

| 43 | 12 | 75 | 1 | 2 | 0 | 1.6 | 5 | 1.337 | 8 | 8.19 | 1.045 | 618.472 | 24.664 | 31 |

| 44 | 12 | 75 | 1 | 2 | 0 | 1.6 | 5 | 1.52 | 8 | 8.615 | −0.665 | 671.473 | 29.376 | 31.33 |

| 45 | 12 | 75 | 1 | 2 | 0 | 1.6 | 5 | 1.458 | 2.73 | 11.86 | 0.69 | 334.682 | 6.642 | 31.67 |

| 46 | 12 | 75 | 1 | 2 | 0 | 1.6 | 5 | 1.458 | 2.98 | 11.805 | 0.38 | 346.732 | 8.772 | 29.33 |

| 47 | 12 | 75 | 1 | 2 | 0 | 1.6 | 5 | 1.458 | 3.25 | 12.615 | 0.825 | 364.862 | 12.568 | 32.33 |

| 48 | 12 | 75 | 1 | 2 | 0 | 1.6 | 5 | 1.458 | 8 | 9.63 | 1.59 | 628.02 | 26.568 | 30 |

| 49 | 12 | 75 | 1 | 2 | 0 | 1.6 | 5 | 1.458 | 3.42 | 11.64 | 0.14 | 386.793 | 14.782 | 30 |

| 50 | 12 | 75 | 1 | 2 | 0 | 1.6 | 5 | 1.458 | 8 | 8.89 | 0.442 | 621.462 | 23.843 | 33 |

| Model | Particular Parameters |

|---|---|

| ANN | 1st hidden layer (8), 2nd hidden layer (8), activation = ‘tanh’, solver = ‘lbfgs’, max_iter = 10,000, random_state = 42 |

| KNN | n_neighbors = 5; weights = ‘uniform’ |

| RF | n_estimators = 100; max_features = 2, random_state = 42 |

| SVR | kernel = ‘rbf’, C = 100 |

| GBR | n_iestimators: 100; max depth: 3; learning rate: 0.1, random_state = 42 |

| XGBoost | n_estimators: 100, learning rate: 0.1, max depth: 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saha, S.; Haldar, B.; Joardar, H.; Das, S.; Mondal, S.; Tadepalli, S. Supervised Machine Learning Models for Predicting SS304H Welding Properties Using TIG, Autogenous TIG, and A-TIG. Crystals 2025, 15, 529. https://doi.org/10.3390/cryst15060529

Saha S, Haldar B, Joardar H, Das S, Mondal S, Tadepalli S. Supervised Machine Learning Models for Predicting SS304H Welding Properties Using TIG, Autogenous TIG, and A-TIG. Crystals. 2025; 15(6):529. https://doi.org/10.3390/cryst15060529

Chicago/Turabian StyleSaha, Subhodwip, Barun Haldar, Hillol Joardar, Santanu Das, Subrata Mondal, and Srinivas Tadepalli. 2025. "Supervised Machine Learning Models for Predicting SS304H Welding Properties Using TIG, Autogenous TIG, and A-TIG" Crystals 15, no. 6: 529. https://doi.org/10.3390/cryst15060529

APA StyleSaha, S., Haldar, B., Joardar, H., Das, S., Mondal, S., & Tadepalli, S. (2025). Supervised Machine Learning Models for Predicting SS304H Welding Properties Using TIG, Autogenous TIG, and A-TIG. Crystals, 15(6), 529. https://doi.org/10.3390/cryst15060529