Effect of Heat Treatment on Tensile Properties of Deposited Metal from a New Nitrogen-Containing Nickel-Based Flux-Cored Welding Wire

Abstract

1. Introduction

2. Experimental

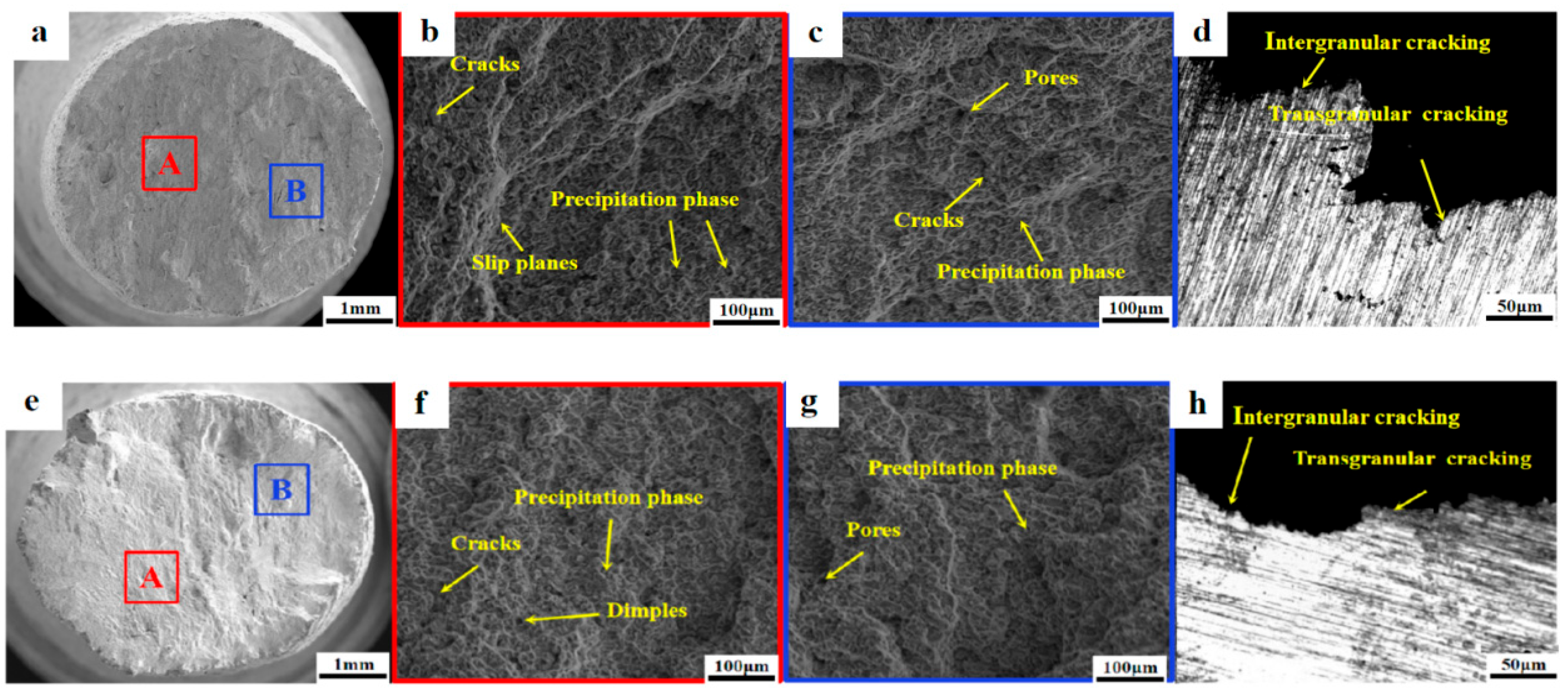

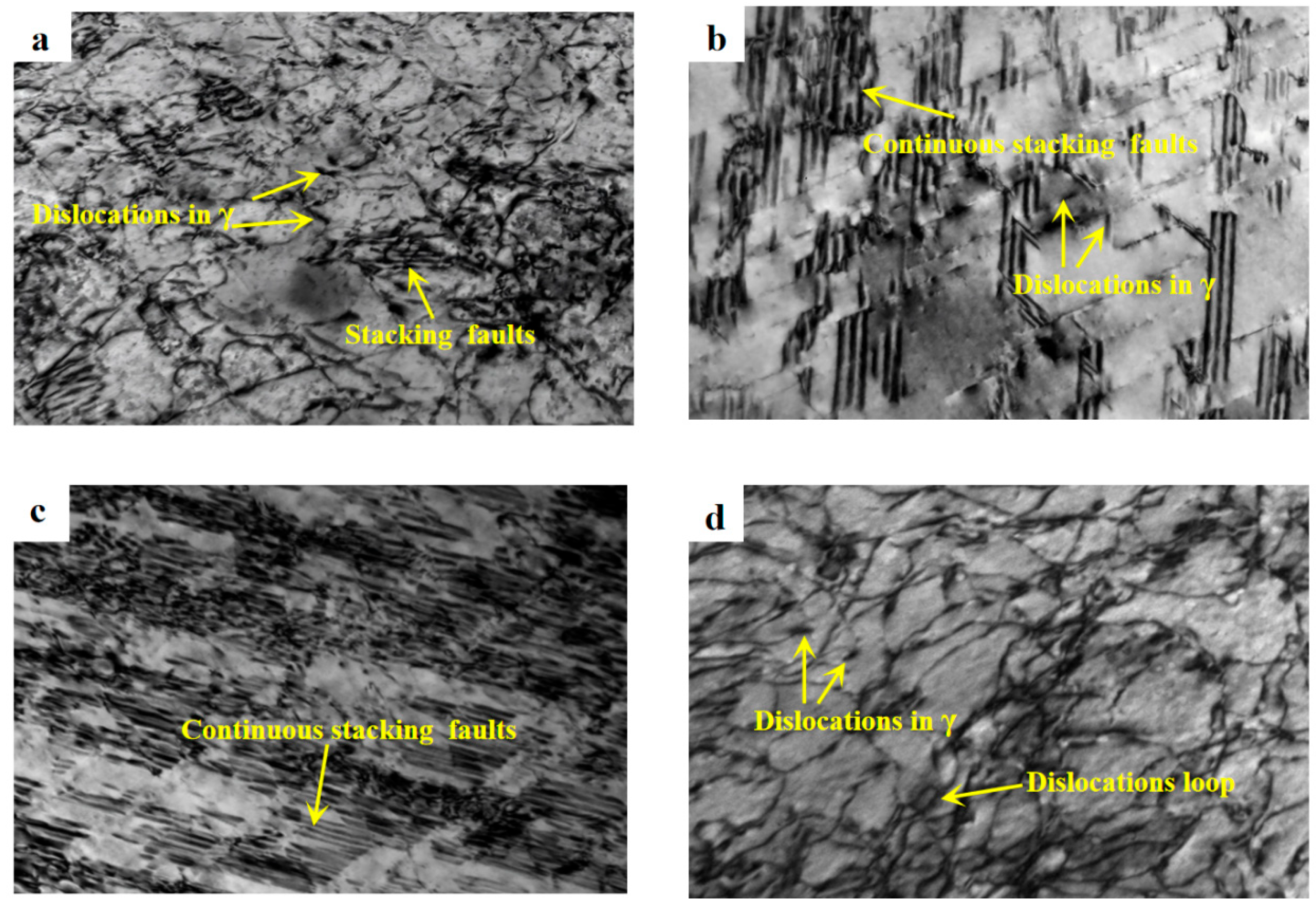

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kimura, H.; Sato, T.; Bergins, C.; Imano, S.; Saito, E. Development of technologies for improving efficiency of large coal-fired thermal power plants. Hitachi Rev. 2011, 60, 365–371. [Google Scholar]

- Bugge, J.; Kjær, S.; Blum, R. High-efficiency coal-fired power plants development and perspectives. Energy 2006, 31, 1437–1445. [Google Scholar] [CrossRef]

- Gao, S.; He, X.; Tang, Z.; Li, Q.; Liu, Z.; Dong, W. Precipitation behavior and mechanical property evolution in a solid solution strengthened Ni-Cr-W superalloy during short-term aging. J. Alloys Compd. 2024, 981, 173678. [Google Scholar] [CrossRef]

- Song, W.; Tang, C.; Wang, D.; Yang, J.; Xu, Z.; Sun, P.; Hu, Q.; Zeng, X. Study on W/Ni interface reaction and strengthening mechanism of tungsten particle reinforced nickel-based alloys by laser-direct energy deposition. Mater. Sci. Eng. A 2022, 857, 43991. [Google Scholar] [CrossRef]

- Zhao, G.P.; Zhao, B.K. Behavior of W and Hf in GH586 alloy. Acta Metall. Sin. 1995, 31, S193–S197. [Google Scholar]

- Bannykyh, I.O.; Bannykh, O.A. Computational Construction of Phase Diagram for Cr–Mn–N Steel with a Variable Manganese Concentration. Inorg. Mater. Appl. Res. 2021, 12, 946–949. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Gao, H. Online measurement of droplet size by actively exciting droplet oscillation in GMAW and GMAW-AM. Manuf. Process. 2023, 85, 1144–1153. [Google Scholar] [CrossRef]

- Aslam, M.; Sahoo, C.K. Development of hard and wear-resistant SiC-AISI304 stainless steel clad layer on low carbon steel by GMAW process. Mater. Today Commun. 2023, 36, 106444. [Google Scholar] [CrossRef]

- Shukla, P.; Chitral, S.; Kumar, T.; Kiran, D.V. The influence of GMAW correction parameters on stabilizing the deposition char-acteristics for wire arc additive manufacturing. J. Manuf. Process. 2023, 90, 54–68. [Google Scholar] [CrossRef]

- Wu, K.; Cao, X.; Yin, T.; Zeng, M.; Liang, Z. Metal transfer process and properties of double-wire double pulsed gas metal arc welding. J. Manuf. Process. 2019, 44, 367–375. [Google Scholar] [CrossRef]

- Becerra, H.G.; Morelos, V.H.L.; Ruiz, A. Microstructural characterization and creep deformation response of an Inconel-600/Inconel-625 welded joint obtained by oscillating GMAW process. Mater. Charact. 2024, 216, 114236. [Google Scholar] [CrossRef]

- Marchese, G.; Parizia, S.; Rashidi, M.; Saboori, A.; Manfredi, D.; Ugues, D.; Lombardi, M.; Hryha, E.; Biamino, S. The role of texturing and microstructure evolution on the tensile behavior of heat-treated Inconel 625 produced via laser powder bed fusion. Mater. Sci. Eng. A 2020, 769, 138500. [Google Scholar] [CrossRef]

- Lee, J.; Terner, M.; Jun, S.; Hong, H.-U.; Copin, E.; Lours, P. Heat treatments design for superior high-temperature tensile properties of Alloy 625 produced by selective laser melting. Mater. Sci. Eng. A 2020, 790, 139720. [Google Scholar] [CrossRef]

- Xing, X.; Di, X.; Wang, B. The effect of post-weld heat treatment temperature on the microstructure of Inconel 625 deposited metal. Alloys Compd. 2014, 593, 110–116. [Google Scholar] [CrossRef]

- Hu, Y.; Lin, X.; Zhang, S.; Jiang, Y.; Lu, X.; Yang, H.; Huang, W. Effect of solution heat treatment on the microstructure and mechanical properties of Inconel 625 superalloy fabricated by laser solid forming. J. Alloys Compd. 2018, 767, 330–344. [Google Scholar] [CrossRef]

- Chu, Z.; Yu, J.; Sun, X.; Guan, H.; Hu, Z. High-temperature creep deformation and fracture behavior of a directionally solidified Ni-base superalloy DZ95. Metall. Mater. Trans. A 2009, 40, 2927–2937. [Google Scholar] [CrossRef]

- Liu, X.; Hu, R.; Zou, H.; Zhou, M.; Gao, Z.; Zhang, K.; Zheng, J. Tailoring the microstructure and deformation mechanisms of an additively manufactured nickel-based superalloy by post-aging heat treatment. Vacuum 2024, 225, 113238–113254. [Google Scholar] [CrossRef]

- Xiong, X.; Dai, P.; Quan, D.; Wang, Z.; Zhang, Q.; Yue, Z. Intermediate temperature brittleness and directional coarsening behavior of nickel-based single-crystal superalloy DD6. Mater. Des. 2015, 86, 482–486. [Google Scholar] [CrossRef]

- Sun, F.; Gu, Y.F.; Yan, J.B.; Zhong, Z.H.; Yuyama, M. Tensile deformation-induced dislocation configurations at intermediate temperatures in a Ni-Fe-based superalloy for advanced ultra-supercritical coal-fired power plant. J. Alloys Compd. 2016, 657, 565–569. [Google Scholar] [CrossRef]

- Zhang, P.; Yuan, Y.; Shen, S.C.; Li, B.; Zhu, R.H.; Yang, G.X.; Song, X.L. Tensile deformation mechanisms at various temperatures in a new directionally solidified Ni-base superalloy. J. Alloys Compd. 2017, 694, 502–509. [Google Scholar] [CrossRef]

- Yang, Y.H.; Yu, J.J.; Sun, X.F.; Jin, T.; Guan, H.R.; Hu, Z.Q. Investigation of impact toughnessof a Ni-based superalloy at elevated temperature. Mater. Des. 2012, 36, 699–704. [Google Scholar] [CrossRef]

- Chu, Z.; Yu, J.; Sun, X.; Guan, H.; Hu, Z. Tensile property and deformation behavior of adirectionally solidified Ni-base superalloy. Mater. Sci. Eng. A 2010, 527, 3010–3014. [Google Scholar] [CrossRef]

- Yu, J.; Lian, Z.; Chu, Z.; Sun, X.; Guan, H.; Hu, Z. Properties and microstructures of M951 alloyafter long-term exposure. Mater. Sci. Eng. A 2010, 527, 1896–1902. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovskia, V.; Turenne, S. Effect of heat treatment and hot isostatic pressing on the microstructure and mechanical properties of Inconel 625 alloy processed by laser powder bed fusion. Mater. Sci. Eng. A 2017, 689, 1–10. [Google Scholar] [CrossRef]

- He, L.Z.; Zheng, Q.; Sun, X.F.; Hou, G.C.; Guan, H.R.; Hu, Z.Q. M23C6 precipitation behavior in a Ni-base superalloy M963. J. Mater. Sci. 2005, 40, 2959–2964. [Google Scholar] [CrossRef]

- Hong, S.G.; Kang, K.B.; Park, C.G. Strain-induced precipitation of NbC in Nb-Ti microalloyed HSLA steels. Scr. Mater. 2002, 46, 163–168. [Google Scholar] [CrossRef]

- Volz, N.; Xue, F.; Zenk, C.H.; Bezold, A.; Gabel, S.; Subramanyam, A.P.A.; Drautz, R.; Hammerschmidt, T.; Makineni, S.K.; Gault, B.; et al. Understanding creep of a single-crystalline Co-Al-W-Ta superalloy by studying the deformation mechanism, segregation tendency and stacking fault energy. Acta Mater. 2021, 214, 117019–117029. [Google Scholar] [CrossRef]

- Esleben, K.; Gorr, B.; Christ, H.J.; Mukherji, D.; Rösler, J. The effect of Ni additions on the oxidation behaviour of Co-Re-Cr high-temperature alloys. Mater. High Temp. 2018, 35, 177–186. [Google Scholar] [CrossRef]

- Sengupta, A.; Putatunda, S.K.; Bartosiewicz, L.; Hangas, J.; Nailos, P.J.; Peputapeck, M.; Alberts, F.E. Tensile behavior of a new single-crystal nickel-based superalloy (CMSX-4) at room and elevated temperatures. J. Mater. Eng. Perform. 1994, 3, 73–81. [Google Scholar] [CrossRef]

- Chellali, R.; Hamou, A.; Zheng, L.; Adjdir, M. Investigation on relationship between intermediate temperature embrittlement and intergranular precipitation in AlCoCrCuFeNi alloy. Int. J. Cast Met. Res. 2014, 27, 199–201. [Google Scholar] [CrossRef]

- Wu, D.; Li, D.; Lu, S. Microstructures and intermediate temperature brittleness of newly developed Ni-Fe based weld metal for ultra-supercritical power plants. Mater. Sci. Eng. A 2017, 684, 146–157. [Google Scholar] [CrossRef]

- Ghaedrahmati, A.; Jafarian, H.R.; Eivani, A.R.; Moghanaki, S.K. Effect of rolling temperature on the occurrence of dynamic strain aging of Inconel 617 superalloy. Mater. Sci. Eng. A 2023, 871, 144879. [Google Scholar] [CrossRef]

- Duan, P.; Zhang, P.; Li, J.; Li, B.; Gong, X.F.; Yang, G.X.; Song, X.L. Intermediate temperature brittleness in a directionally solidified nickel-based superalloy M4706. Mater. Sci. Eng. A 2019, 759, 530–536. [Google Scholar] [CrossRef]

- Ekaputra, I.M.W.; Kim, W.G.; Park, J.Y.; Kim, S.J.; Kim, E.S. Influence of dynamic strain aging on tensile deformation behavior of alloy 617. Nucl. Eng. Technol. 2016, 48, 1387–1395. [Google Scholar] [CrossRef]

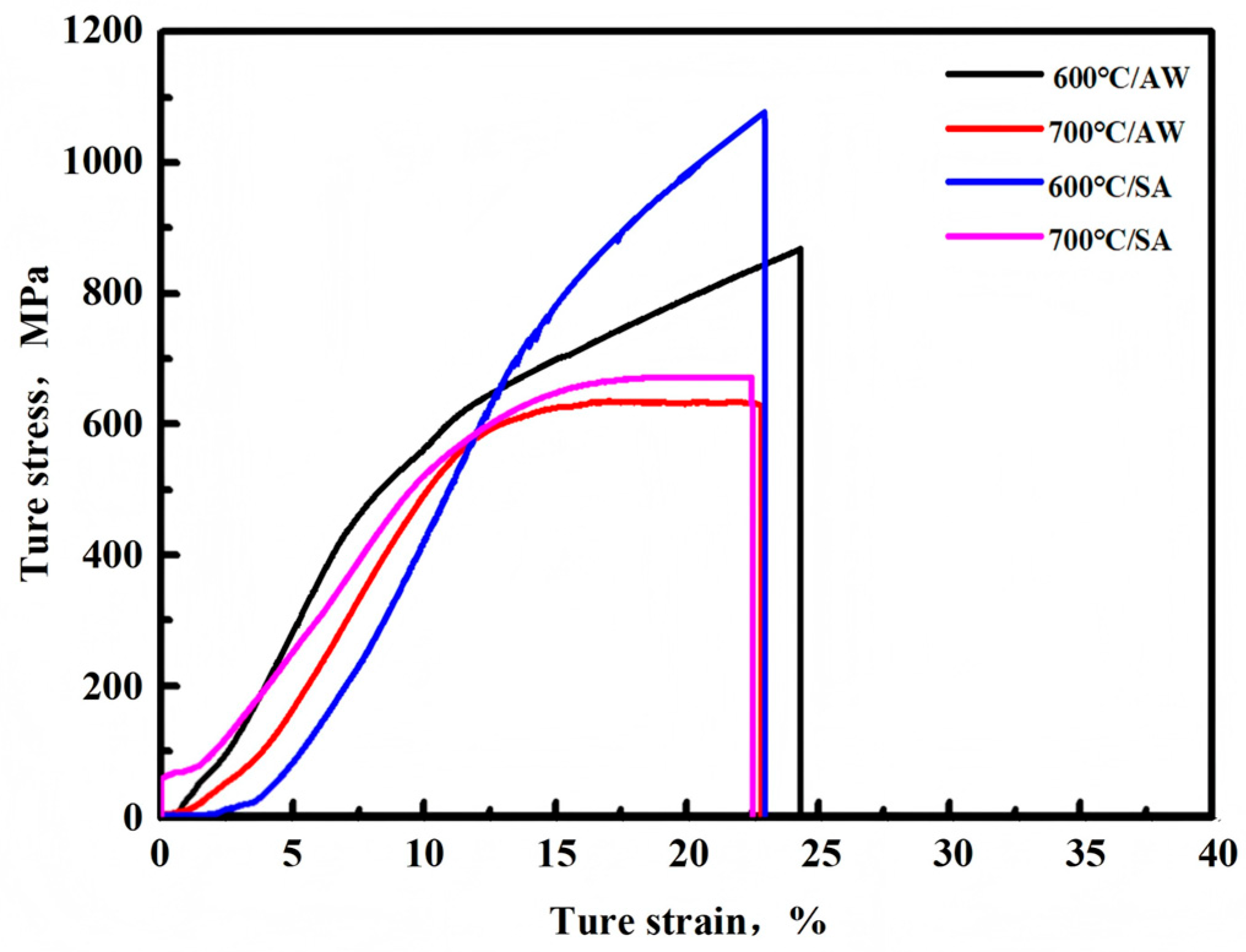

| Sample | AW/600 °C | SA/600 °C | AW/700 °C | SA/700 °C |

|---|---|---|---|---|

| Yield strength (σs/MPa) | 426.5 | 535.4 | 443.2 | 541.7 |

| Elongation (EL) | 24.7% | 23.8% | 23.5% | 22.8% |

| Sample | Position | Ni | Fe | Cr | Nb | W | C | Mo | Ti | N |

|---|---|---|---|---|---|---|---|---|---|---|

| AW/600 °C | 1 | 40.9 | 24.7 | 25.1 | 0.9 | 3.1 | 0.7 | 1.5 | 0.5 | 2.6 |

| 2 | 2.7 | 1.5 | 2.3 | 26.1 | 3.7 | 41.5 | 3.9 | 5.8 | 12.5 | |

| 3 | 23.6 | 12.1 | 19.1 | 14.2 | 6.3 | 2.6 | 14.6 | 6.8 | 0.7 | |

| 4 | 62.2 | 1.6 | 5.1 | 15.3 | 1.2 | 3.6 | 1.7 | 9.0 | 0.3 | |

| AW/700 °C | 1 | 42.1 | 20.2 | 27.1 | 0.8 | 3.9 | 0.5 | 1.9 | 0.4 | 3.1 |

| 2 | 2.8 | 1.5 | 2.5 | 23.1 | 4.4 | 41.6 | 3.7 | 6.2 | 15.2 | |

| 3 | 23.2 | 14.2 | 21.1 | 13.6 | 4.8 | 2.4 | 12.5 | 7.4 | 0.8 | |

| 4 | 61.9 | 2.7 | 4.8 | 15.1 | 0.7 | 2.7 | 1.8 | 10.2 | 0.1 | |

| SA/600 °C | 1 | 45.1 | 22.8 | 22.5 | 1.2 | 3.1 | 0.3 | 1.7 | 0.4 | 2.6 |

| 2 | 2.6 | 1.4 | 2.1 | 25.8 | 3.9 | 41.2 | 3.1 | 5.2 | 14.7 | |

| 3 | 63.1 | 1.4 | 5.2 | 15.3 | 1.2 | 3.1 | 1.4 | 9.2 | 0.1 | |

| 4 | 2.1 | 1.9 | 2.5 | 24.6 | 3.8 | 41.3 | 3.3 | 6.2 | 14.3 | |

| SA/700 °C | 1 | 39.8 | 23.1 | 28.9 | 1.3 | 2.4 | 0.3 | 1.1 | 0.2 | 2.9 |

| 2 | 2.7 | 1.3 | 2.7 | 25.2 | 3.7 | 41.2 | 3.3 | 5.4 | 14.5 | |

| 3 | 63.2 | 1.3 | 4.8 | 15.4 | 1.3 | 3.2 | 1.4 | 9.3 | 0.1 | |

| 4 | 4.0 | 1.8 | 60.3 | 2.2 | 7.2 | 13.1 | 9.7 | 1.4 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Su, Y.; Wang, Y. Effect of Heat Treatment on Tensile Properties of Deposited Metal from a New Nitrogen-Containing Nickel-Based Flux-Cored Welding Wire. Crystals 2025, 15, 509. https://doi.org/10.3390/cryst15060509

Wang Y, Su Y, Wang Y. Effect of Heat Treatment on Tensile Properties of Deposited Metal from a New Nitrogen-Containing Nickel-Based Flux-Cored Welding Wire. Crystals. 2025; 15(6):509. https://doi.org/10.3390/cryst15060509

Chicago/Turabian StyleWang, Yingdi, Yunhai Su, and Yingdong Wang. 2025. "Effect of Heat Treatment on Tensile Properties of Deposited Metal from a New Nitrogen-Containing Nickel-Based Flux-Cored Welding Wire" Crystals 15, no. 6: 509. https://doi.org/10.3390/cryst15060509

APA StyleWang, Y., Su, Y., & Wang, Y. (2025). Effect of Heat Treatment on Tensile Properties of Deposited Metal from a New Nitrogen-Containing Nickel-Based Flux-Cored Welding Wire. Crystals, 15(6), 509. https://doi.org/10.3390/cryst15060509