Mechanistic Decoupling of Giant Electrostrain and Piezoelectric Coefficients at the Morphotropic Phase Boundary in PMN-30PT Single Crystals

Abstract

1. Introduction

2. Materials and Methods

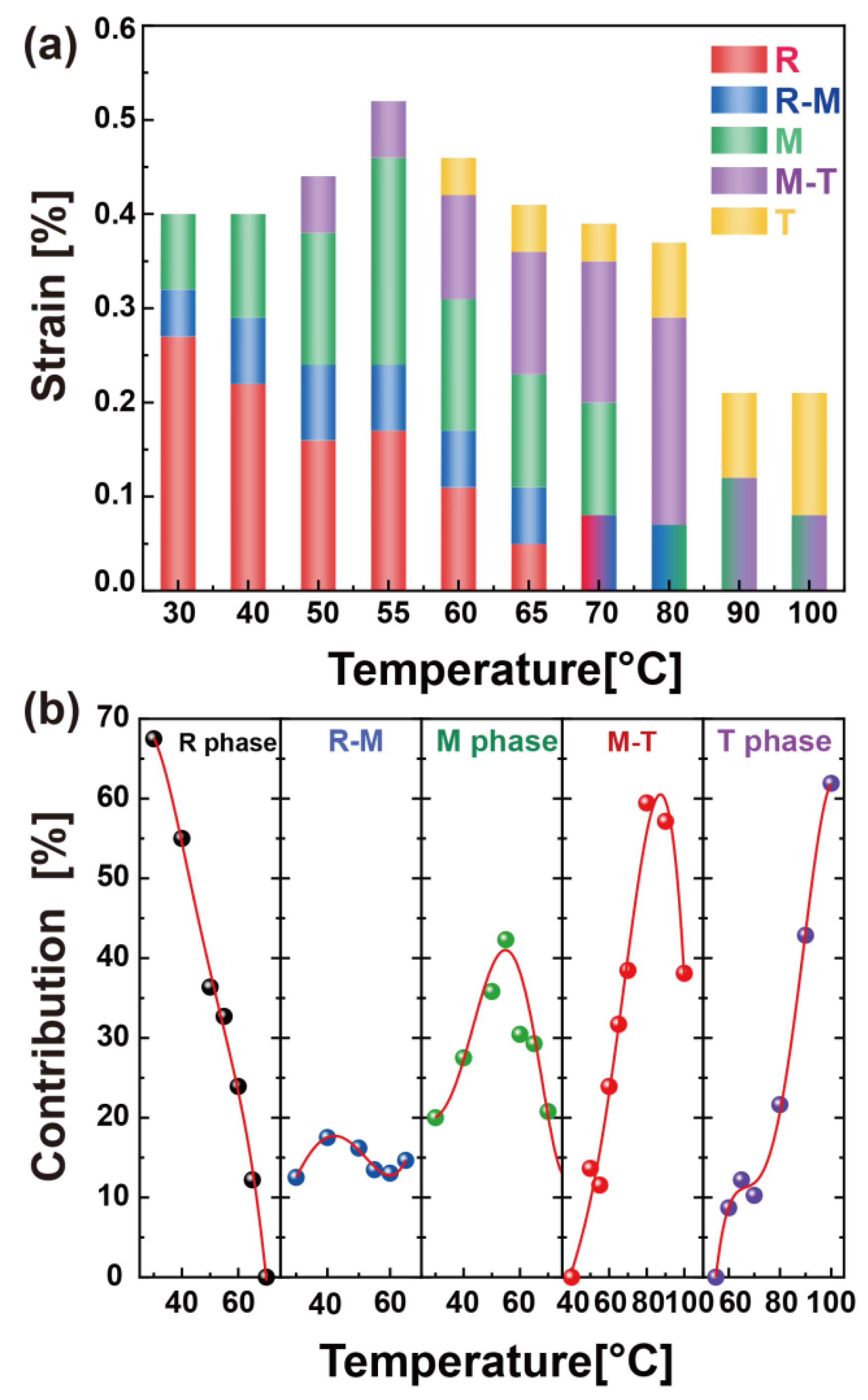

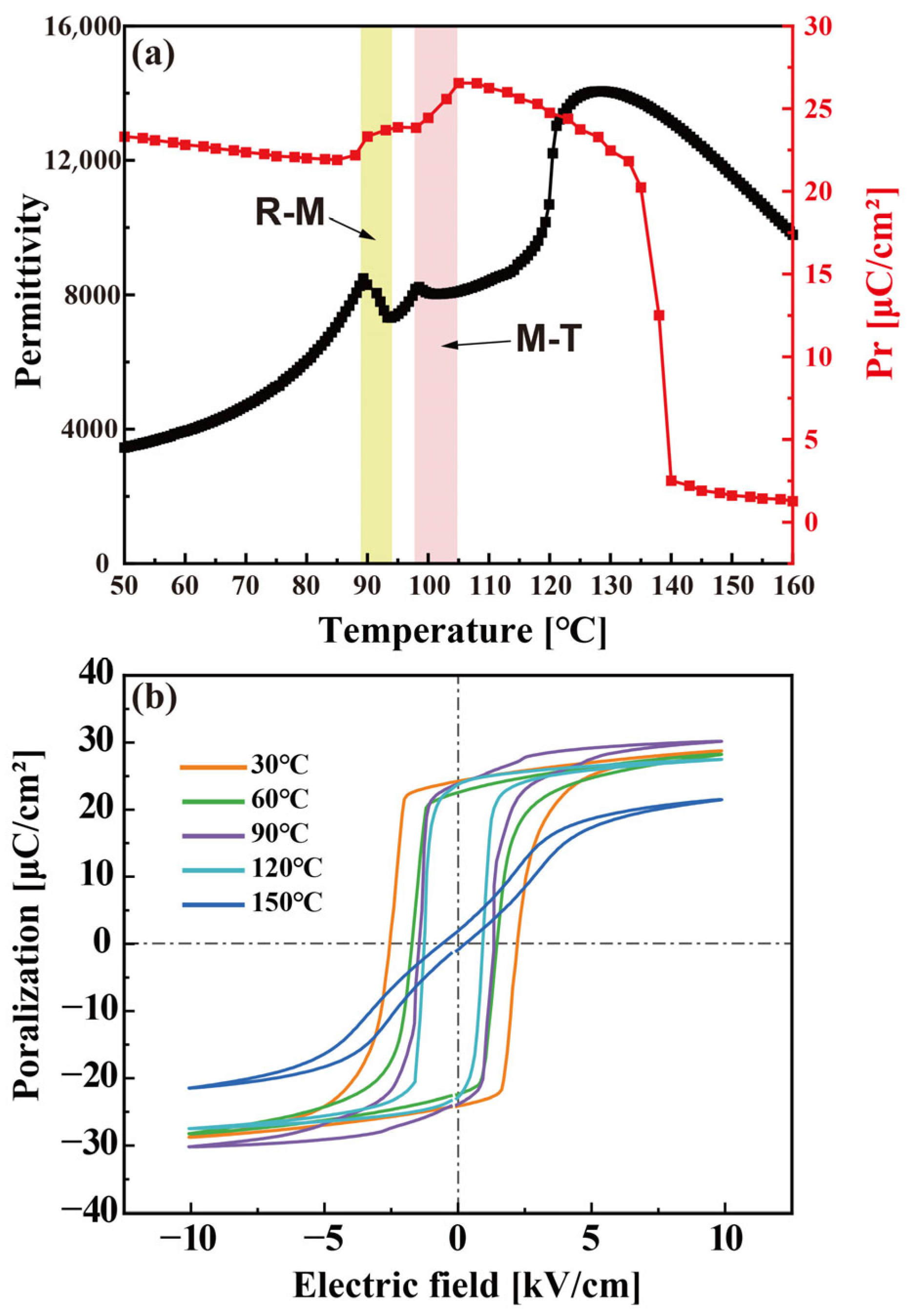

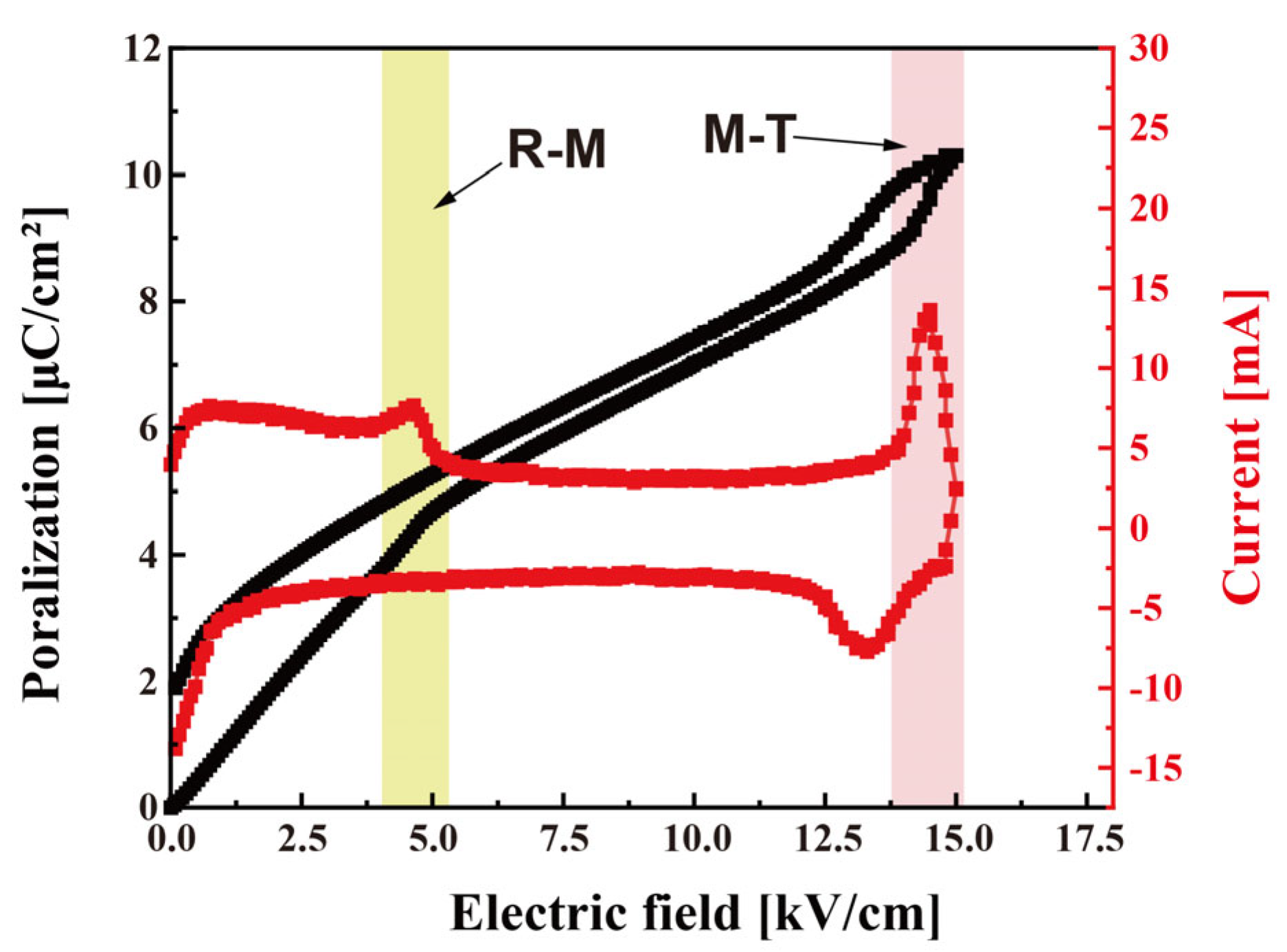

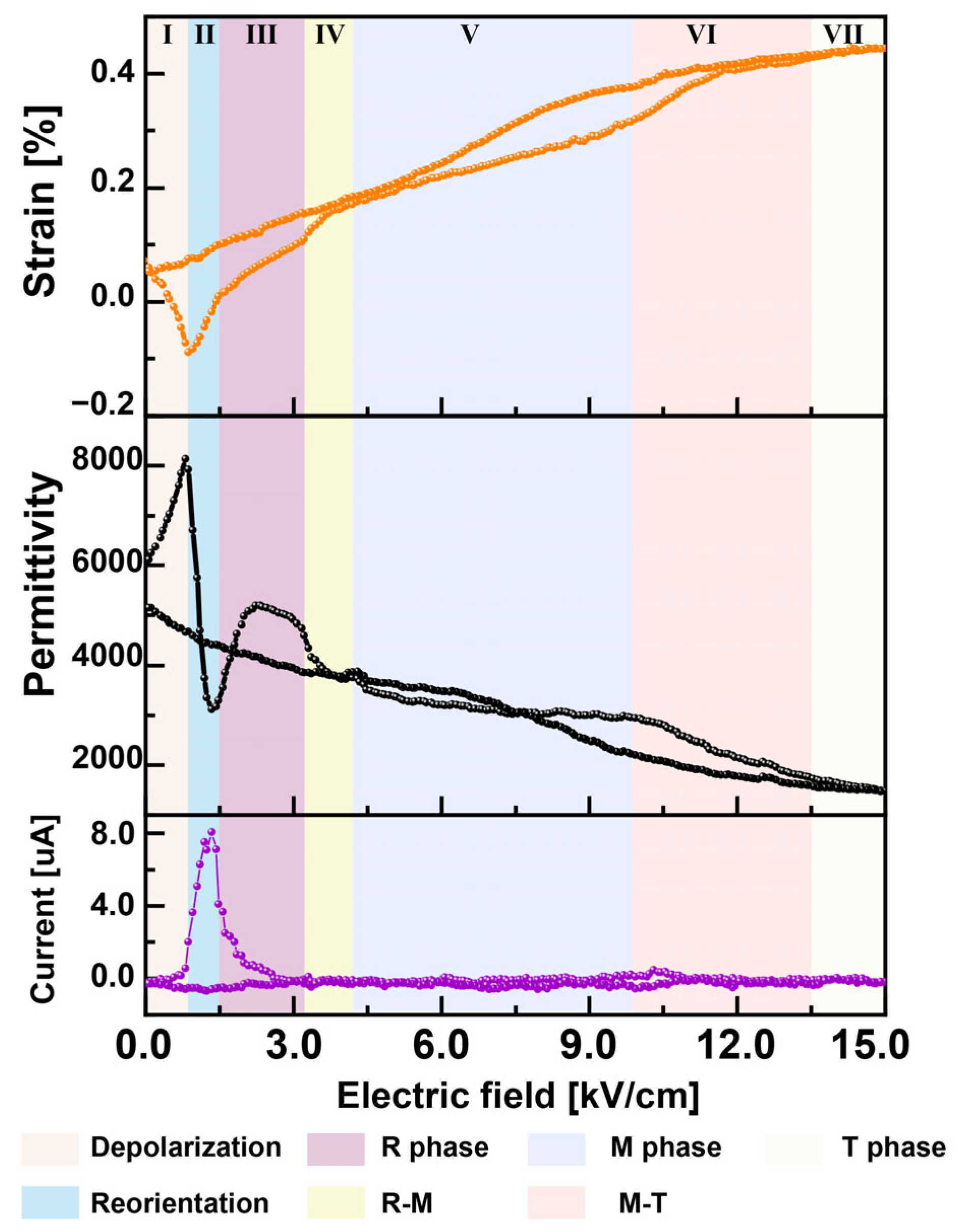

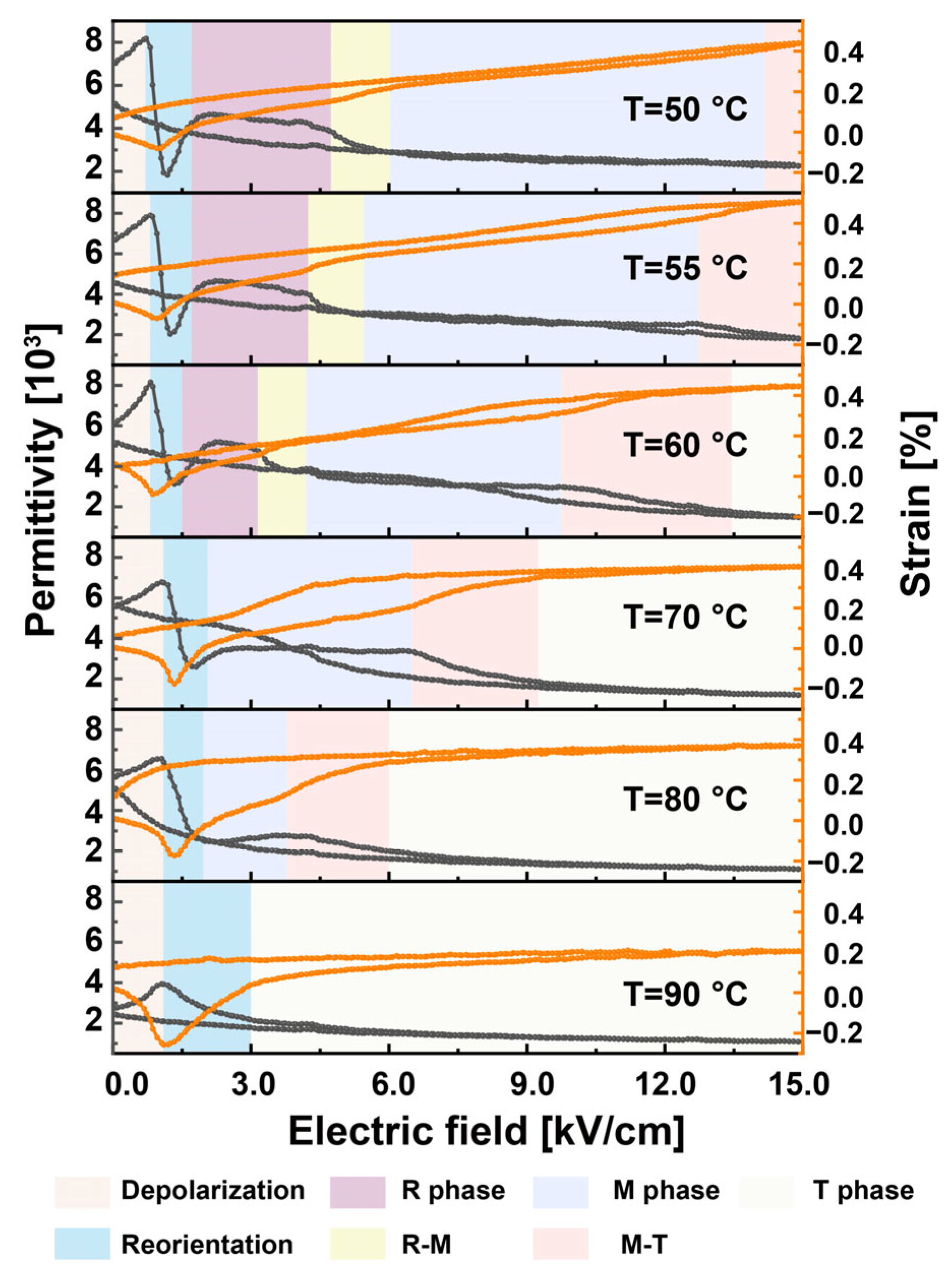

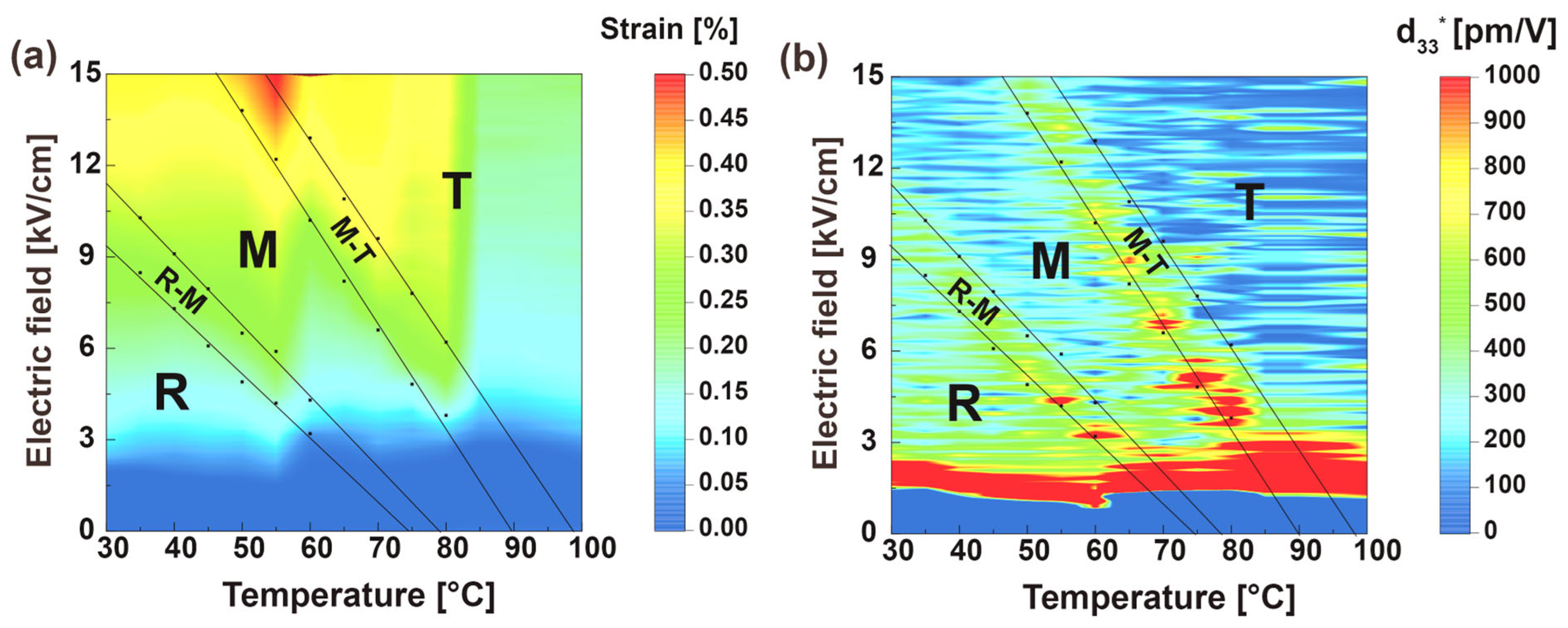

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, T.; Wu, J.; Xiao, D.; Zhu, J. Recent development in lead-free perovskite piezoelectric bulk materials. Prog. Mater. Sci. 2018, 98, 552–624. [Google Scholar] [CrossRef]

- Hao, J.; Li, W.; Zhai, J.; Chen, H. Progress in high-strain perovskite piezoelectric ceramics. Mater. Sci. Eng. R Rep. 2019, 135, 1–57. [Google Scholar] [CrossRef]

- Lv, X.; Zhu, J.; Xiao, D.; Zhang, X.-X.; Wu, J. Emerging new phase boundary in potassium sodium-niobate based ceramics. Chem. Soc. Rev. 2020, 49, 671–707. [Google Scholar] [CrossRef] [PubMed]

- Acosta, M.; Novak, N.; Rojas, V.; Patel, S.; Vaish, R.; Koruza, J.; Rossetti, G.A.; Rödel, J. BaTiO3-based piezoelectrics: Fundamentals, current status, and perspectives. Appl. Phys. Rev. 2017, 4, 041305. [Google Scholar] [CrossRef]

- Gao, Z.; Lei, Y.; Li, Z.; Yang, J.; Yu, B.; Yuan, X.; Hou, Z.; Hong, J.; Dong, S. Artificial piezoelectric metamaterials. Prog. Mater. Sci. 2025, 151, 101434. [Google Scholar] [CrossRef]

- Jaffe, B.S.; Roth, R.S.; Marzullo, S. Piezoelectric Properties of Lead Zirconate-Lead Titanate Solid-Solution Ceramics. J. Appl. Phys. 1954, 25, 809–810. [Google Scholar] [CrossRef]

- Liu, H.; Chen, J.; Fan, L.; Ren, Y.; Pan, Z.; Lalitha, K.V.; Rödel, J.; Xing, X. Critical Role of Monoclinic Polarization Rotation in High-Performance Perovskite Piezoelectric Materials. Phys. Rev. Lett. 2017, 119, 017601. [Google Scholar] [CrossRef]

- Fan, L.; Chen, J.; Ren, Y.; Pan, Z.; Zhang, L.; Xing, X. Unique Piezoelectric Properties of the Monoclinic Phase in Pb (Zr,Ti)O3 Ceramics: Large Lattice Strain and Negligible Domain Switching. Phys. Rev. Lett. 2016, 116, 027601. [Google Scholar] [CrossRef]

- Liu, W.; Ren, X. Large Piezoelectric Effect in Pb-Free Ceramics. Phys. Rev. Lett. 2009, 103, 257602. [Google Scholar] [CrossRef]

- Ma, C.; Guo, H.; Beckman, S.; Tan, X. Creation and Destruction of Morphotropic Phase Boundaries through Electrical Poling: A Case Study of Lead-Free (Bi1/2Na1/2)TiO3-BaTiO3 Piezoelectrics. Phys. Rev. Lett. 2012, 109, 107602. [Google Scholar] [CrossRef]

- Liu, X.; Tan, X. Giant Strains in Non-Textured (Bi1/2Na1/2)TiO3-Based Lead-Free Ceramics. Adv. Mater. 2016, 28, 574–578. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.H.; Thong, H.C.; Jiang, B.; Zhang, N.; Zhao, C.; Wu, Z.; Zhou, T.; Wu, C.; Yao, F.; Bi, K.; et al. Field-Induced Polarization Rotation in Order–Disorder (K,Na)NbO3-Based Ferroelectrics. Adv. Mater. 2024, 37, 2413587. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, S.; Li, X.; Li, L.; Liu, Z.; Zhang, J.; Wang, Y. High piezoelectricity and low strain hysteresis in PMN–PT-based piezoelectric ceramics. J. Adv. Ceram. 2023, 12, 792–802. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q.; Luo, H.; Zhu, J. Direct observations of electric-field-induced domain switching and phase transition in 0.95Na0.5Bi0.5TiO3-0.05BaTiO3 single crystals using in situ transmission electron microscopy. Appl. Phys. Lett. 2022, 120, 072901. [Google Scholar] [CrossRef]

- Li, T.; Liu, C.; Shi, P.; Liu, X.; Kang, R.; Long, C.; Wu, M.; Cheng, S.; Mi, S.; Xia, Y.; et al. High-Performance Strain of Lead-Free Relaxor-Ferroelectric Piezoceramics by the Morphotropic Phase Boundary Modification. Adv. Funct. Mater. 2022, 32, 2202307. [Google Scholar] [CrossRef]

- Yin, X.; Chen, C.; Fan, Z.; Qin, M.; Zeng, M.; Lu, X.; Zhou, G.; Gao, X.; Chen, D.; Liu, J.-M. Coexistence of multiple morphotropic phase boundaries in strained La-doped BiFeO3 thin films. Mater. Today Phys. 2021, 17, 100345. [Google Scholar] [CrossRef]

- Narayan, B.; Malhotra, J.S.; Pandey, R.; Yaddanapudi, K.; Nukala, P.; Dkhil, B.; Senyshyn, A.; Ranjan, R. Electrostrain in excess of 1% in polycrystalline piezoelectrics. Nat. Mater. 2018, 17, 427–431. [Google Scholar] [CrossRef]

- Nie, X.; Jing, R.; Yang, Y.; Yan, Y.; Laletin, V.; Shur, V.; Wang, G.; Jin, L. Optimized electrostrain with minimal hysteresis at the MPB in BNT-based ceramics. J. Eur. Ceram. Soc. 2025, 45, 117073. [Google Scholar] [CrossRef]

- Muleta, G.J.; Adhikary, G.D.; Ranjan, R. Structural aspects of the ferroelectric, weak-field piezoelectric, and electrostrain responses in Sr, Nb modified Na0.5Bi0.5TiO3-K0.5Bi0.5TiO3. Acta Mater. 2025, 288, 120825. [Google Scholar] [CrossRef]

- Lin, J.; Lv, F.; Hong, Z.; Liu, B.; Wu, Y.; Huang, Y. Ultrahigh Piezoelectric Response Obtained by Artificially Generating a Large Internal Bias Field in BiFeO3–BaTiO3 Lead-Free Ceramics. Adv. Funct. Mater. 2024, 34, 2313879. [Google Scholar] [CrossRef]

- Xu, K.; Li, J.; Lv, X.; Wu, J.; Zhang, X.-X.; Xiao, D.-Q.; Zhu, J. Superior Piezoelectric Properties in Potassium–Sodium Niobate Lead-Free Ceramics. Adv. Mater. 2016, 28, 8519–8523. [Google Scholar] [CrossRef] [PubMed]

- Jing, R.; Zhang, L.; Hu, Q.; Alikin, D.O.; Shur, V.Y.; Wei, X.; Zhang, L.; Liu, G.; Zhang, H.; Jin, L. Phase evolution and relaxor to ferroelectric phase transition boosting ultrahigh electrostrains in (1−x)(Bi1/2Na1/2)TiO3-x(Bi1/2K1/2)TiO3 solid solutions. J. Mater. 2022, 8, 335–346. [Google Scholar] [CrossRef]

- Li, F.; Jin, L.; Xu, Z.; Zhang, S. Electrostrictive effect in ferroelectrics: An alternative approach to improve piezoelectricity. Appl. Phys. Rev. 2014, 1, 011103. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Jiang, X.; Kim, J.; Luo, J.; Geng, X. Advantages and challenges of relaxor-PbTiO3 ferroelectric crystals for electroacoustic transducers—A review. Prog. Mater. Sci. 2015, 68, 1–66. [Google Scholar] [CrossRef]

- Zheng, L.; Lu, X.; Shang, H.; Xi, Z.; Wang, R.; Wang, J.; Zheng, P.; Cao, W. Hysteretic phase transition sequence in 0.67Pb(Mg1/3Nb2/3)O3−0.33PbTiO3 single crystal driven by electric field and temperature. Phys. Rev. B. 2015, 91, 184105. [Google Scholar] [CrossRef]

- Li, F.; Cabral, M.J.; Xu, B.; Cheng, Z.; Dickey, E.C.; Lebeau, J.M.; Wang, J.; Luo, J.; Taylor, S.; Hackenberger, W.; et al. Giant piezoelectricity of Sm-doped Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystals. Science 2019, 364, 264–268. [Google Scholar] [CrossRef]

- Park, S.-E.; Shrout, T.R. Ultrahigh strain and piezoelectric behavior in relaxor based ferroelectric single crystals. J. Appl. Phys. 1997, 82, 1804–1811. [Google Scholar] [CrossRef]

- Li, J.; Li, J.; Wu, H.; Zhou, O.; Chen, J.; Lookman, T.; Su, Y.; Qiao, L.; Bai, Y. Influence of Phase Transitions on Electrostrictive and Piezoelectric Characteristics in PMN-30PT Single Crystals. ACS Appl. Mater. Interfaces 2021, 13, 38467–38476. [Google Scholar] [CrossRef]

- Noheda, B.; Cox, D.E.; Shirane, G.; Park, S.E.; Cross, L.E.; Zhong, Z. Polarization Rotation via a Monoclinic Phase in the Piezoelectric 92% PbZn1/3Nb2/3O3-8% PbTiO3. Phys. Rev. Lett. 2001, 86, 3891–3894. [Google Scholar] [CrossRef]

- Ye, Z.; Noheda, B.; Dong, M.; Cox, D.; Shirane, G. Monoclinic phase in the relaxor-based piezoelectric/ferroelectric Pb(Mg1/3Nb2/3)O3−PbTiO3 system. Phys. Rev. B. 2001, 64, 184114. [Google Scholar] [CrossRef]

- Guo, R.; Cross, L.E.; Park, S.-E.; Noheda, B.; Noheda, B.; Cox, D.E.; Shirane, G. Origin of the high piezoelectric response in PbZr1-xTixO3. Phys. Rev. Lett. 1999, 84, 5423. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.; Cohen, R.E. Polarization rotation mechanism for ultrahigh electromechanical response in single-crystal piezoelectrics. Nature 2000, 403, 281–283. [Google Scholar] [CrossRef] [PubMed]

- Davis, M.; Damjanovic, D.; Setter, N. Electric-field-, temperature-, and stress-induced phase transitions in relaxor ferroelectric single crystals. Phys. Rev. B. 2006, 73, 014115. [Google Scholar] [CrossRef]

- Liu, Y.; Xia, J.; Finkel, P.; Moss, S.D.; Liao, X.; Cairney, J.M. Real-time observation of stress-induced domain evolution in a [011] PIN-PMN-PT relaxor ferroelectric single crystal. Acta Mater. 2019, 175, 436–444. [Google Scholar] [CrossRef]

- Webber, K.; Zuo, R.; Lynch, C. Ceramic and single-crystal (1–x)PMN–xPT constitutive behavior under combined stress and electric field loading. Acta Mater. 2008, 56, 1219–1227. [Google Scholar] [CrossRef]

- Schader, F.H.; Rossetti, G.A.; Luo, J.; Webber, K.G. Piezoelectric and ferroelectric properties of <001>C Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystals under combined thermal and mechanical loading. Acta Mater. 2017, 126, 174–181. [Google Scholar] [CrossRef]

- Li, J.; Yin, R.; Su, X.; Wu, H.-H.; Li, J.; Qin, S.; Sun, S.; Chen, J.; Su, Y.; Qiao, L.; et al. Complex phase transitions and associated electrocaloric effects in different oriented PMN-30PT single crystals under multi-fields of electric field and temperature. Acta Mater. 2020, 182, 250–256. [Google Scholar] [CrossRef]

- Rajan, K.; Shanthi, M.; Chang, W.; Jin, J.; Lim, L. Dielectric and piezoelectric properties of [001] and [011]-poled relaxor ferroelectric PZN–PT and PMN–PT single crystals. Sens. Actuators A Phys. 2007, 133, 110–116. [Google Scholar] [CrossRef]

- Zhao, X.; Fang, B.; Cao, H.; Guo, Y.; Luo, H. Dielectric and piezoelectric performance of PMN–PT single crystals with compositions around the MPB: Influence of composition, poling field and crystal orientation. Mater. Sci. Eng. B. 2002, 96, 254–262. [Google Scholar] [CrossRef]

- Zhang, Y.; Gong, W.; Li, Z.; Li, J.; Li, C.; Chen, J.; Yang, Y.; Bai, Y.; Rao, W.-F. Two Consecutive Negative Electrocaloric Peaks in <001>-Oriented PMN-30PT Single Crystals. Crystals. 2024, 14, 458. [Google Scholar]

- Wu, H.; Cohen, R.E. Electric-field-induced phase transition and electrocaloric effect in PMN-PT. Phys. Rev. B. 2017, 96, 054116. [Google Scholar] [CrossRef]

- Xu, G.; Luo, H.; Xu, H.; Yin, Z. Third ferroelectric phase in PMNT single crystals near the morphotropic phase boundary composition. Phys. Rev. B. 2001, 64, 020102. [Google Scholar] [CrossRef]

- Fang, F.; Yang, W.; Luo, X. [101]-Oriented Pb(Mg1/3Nb2/3)O3–PbTiO3 Single Crystals Under Electric Loadings: Polarization Rotation Linking MB, O, and R Phases. J. Am. Ceram. Soc. 2010, 93, 3916–3920. [Google Scholar] [CrossRef]

- Liao, L.; Shan, D.; Lei, C.; Pan, K.; Li, J.; Liu, Y. Revealing the mechanisms of electrocaloric effects by simultaneously direct measuring local electrocaloric and electrostrain under ambient conditions. Acta Mater. 2024, 278, 120264. [Google Scholar] [CrossRef]

- Dou, J.; Li, J.; Li, J.; Zhang, H.; Yang, Y.; Bai, Y.; Rao, W.-F. Simultaneous enhancement of the electrocaloric effect and electrostrain via exploiting the reversible polarization rotation. Ceram. Int. 2023, 49, 7094–7098. [Google Scholar] [CrossRef]

- Li, J.; Qin, S.; Bai, Y.; Li, J.; Qiao, L. Flexible control of positive and negative electrocaloric effects under multiple fields for a giant improvement of cooling capacity. Appl. Phys. Lett. 2017, 111, 093901. [Google Scholar] [CrossRef]

| Property | Piezoelectricity | Electrostrain |

|---|---|---|

| Dominant factor |

|

|

| ||

| ||

| Conditions |

|

|

| Requirements |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, R.; Li, S.; Li, J.; Li, J.; Yang, Y.; Rao, W.-F.; Bai, Y. Mechanistic Decoupling of Giant Electrostrain and Piezoelectric Coefficients at the Morphotropic Phase Boundary in PMN-30PT Single Crystals. Crystals 2025, 15, 471. https://doi.org/10.3390/cryst15050471

Yan R, Li S, Li J, Li J, Yang Y, Rao W-F, Bai Y. Mechanistic Decoupling of Giant Electrostrain and Piezoelectric Coefficients at the Morphotropic Phase Boundary in PMN-30PT Single Crystals. Crystals. 2025; 15(5):471. https://doi.org/10.3390/cryst15050471

Chicago/Turabian StyleYan, Ruqing, Shuai Li, Jianting Li, Junjie Li, Yaodong Yang, Wei-Feng Rao, and Yang Bai. 2025. "Mechanistic Decoupling of Giant Electrostrain and Piezoelectric Coefficients at the Morphotropic Phase Boundary in PMN-30PT Single Crystals" Crystals 15, no. 5: 471. https://doi.org/10.3390/cryst15050471

APA StyleYan, R., Li, S., Li, J., Li, J., Yang, Y., Rao, W.-F., & Bai, Y. (2025). Mechanistic Decoupling of Giant Electrostrain and Piezoelectric Coefficients at the Morphotropic Phase Boundary in PMN-30PT Single Crystals. Crystals, 15(5), 471. https://doi.org/10.3390/cryst15050471