Abstract

Based on the B-site modification strategy, excellent energy storage properties were achieved in this work by substituting Nb with Ta of the same valence in niobate-based glass ceramics. Ta substitution was found to lead to the transformation of crystal structures, and the space point group evolved from the non-centrosymmetric P4bm to the centrosymmetric P4/mbm, resulting in a transition from relaxor ferroelectric to paraelectric glass ceramics. Furthermore, the addition of Ta led to a significant decrease in grain size and interfacial activation energy, as well as an increase in the optical band gap, resulting in a dramatic increase in BDS from 800 kV/cm to 1300 kV/cm. The KBSN-4.0mol%Ta2O5 glass ceramic exhibited optimal energy storage properties, including a discharge energy density of ~5.62 J/cm3 and a superfast discharge rate of ~9.7 ns, resulting in an ultrahigh discharge power density of about ~1296.9 MW/cm3 at 1300 kV/cm. Furthermore, this KBSN-Ta glass ceramic also displayed good thermal stability over a temperature range of 20–120 °C, with the Wd decreasing by 9.0% at 600 kV/cm. B-site modification engineering in glass ceramics has proved to be an important way to effectively optimize energy storage performance.

1. Introduction

Inorganic dielectric capacitors are widely used in high-voltage pulse power supply systems due to their high power density, rapid charge and discharge, low cost, and excellent thermal stability [1,2,3]. As one of the main inorganic dielectric capacitors, glass ceramic consists of a nanoscale ceramic phase and an amorphous glass phase, which feature good bulk density, a reasonable dielectric constant, and high electric breakdown strength (BDS) [4,5]. Therefore, glass ceramic dielectric capacitors are a promising candidate in high-voltage, high-power density pulsed devices and have attracted much attention in recent years [6].

Tungsten bronze oxides are the largest class of ferroelectrics with excellent optical and electrical properties; as such, they are the focus of research in the field of ceramic and glass ceramic dielectric energy storage materials. In general, the formula of tungsten bronze oxides can be expressed as ((A1)2(A2)4C4)((B1)2(B2)8)O30 [7,8,9,10]. Within this formula, the A1 and A2 sites are usually occupied by cations with large radii, including K+, Na+, Ba2+, Sr2+, etc., whereas the B1 and B2 sites are generally occupied by excess metals with smaller ionic radii, such as Nb5+, Ta5+, and W6+, and the C site is usually empty [11]. In general, the impact of the ferroelectric behavior of tungsten bronze structures originates from structural distortions due to A-site cation occupancy; moreover, B-site substitution can directly change the displacement of polar cations, leading to crystal transitions and resulting in transitions in ferroelectric behavior, including the transition from normal ferroelectricity to relaxed ferroelectricity and para-electrics [12,13]. Therefore, special crystal structure transitions can be modulated by the A- or B-site substitution strategy in tungsten bronze structures to optimize the ferroelectric behavior and thus improve the energy storage performance, as has been demonstrated in many recent ceramics with tungsten bronze structures. For instance, by introducing Ag+, Ca2+, and Gd3+ ions into the A-site of SrNaNb5O15 ceramics, the recoverable energy density can reach 2.37–3.23 J/cm3 at 290–320 kV/cm [14,15,16]. Furthermore, it was found that substituting Nb for Ta in the B-site could optimize the BDS and relaxor nature in Sr2KNb5O15 ceramics, thus obtaining a recoverable energy density and efficiency of about 3.84 J/cm3 and 93.2% at 410 kV/cm, respectively [17]. Furthermore, B-site Ta5+ substitution in Sr2NaNb5O15 and Sr0.25Ba0.75Nb2O6 ceramics can lead to the transformation of the crystal structure and space point group transitions from P4bm and Im2a to P4/mbm, causing the transition from normal ferroelectricity to relaxed ferroelectricity and then to paraelectricity, resulting in a substantial reduction in Pr and providing an important direction for improving energy storage efficiency [7,12]. Although the A/B-site substitution strategy plays an important role in optimizing the ferroelectric behavior and energy storage performance of tungsten bronze ceramics, the BDS of ceramics is generally below 400 kV/cm, which greatly limits the increases in energy storage density and power density compared to those of some high-performance ceramics [18,19,20,21].

In our previous work, we added Ag2O to the composition of K2O-BaO-SrO-Nb2O5-B2O3 glass to provide Ag+ for A-site substitution during precipitation [22]. It was found that Ag+ substitution in the A-site could exacerbate the structural distortion of the NbO6 octahedra, resulting in optimized dielectric, ferroelectric, and energy storage properties. For example, when the doping of Ag+ was 1.0 mol%, the glass ceramic increased the Pmax while maintaining a smaller residual polarization (Pr), resulting in an increase in Wrec from 4.7 J/cm3 to 5.8 J/cm3 under 800 kV/cm while maintaining efficiency above 90%. In addition, the actual charge–discharge performance was also significantly improved, i.e., discharge energy density (Wd) increased from 2.82 J/cm3 to 3.62 J/cm3 while also exhibiting an ultrahigh power density (Pd) of 1054.8 MW/cm3 under 800 kV/cm.

Based on our previous work, different contents of Ta2O5 were introduced into the composition of K2O-BaO-SrO-Nb2O5-B2O3 glass with the aim of providing Ta5+ for B-site substitution during crystallization. Subsequently, the effects of B-site substitution on the phase structure, microstructure, and dielectric, ferroelectric, and energy storage properties of the glass ceramics combined with impedance analysis were studied systematically.

2. Materials and Methods

2.1. Fabrication of Glass Ceramics

Glass with a composition of 10K2O-7BaO-16SrO-34Nb2O5-33B2O3-xTa2O5 (simplified as KBSN-xTa2O5, x = 0.0, 1.0, 2.0, 4.0, and 8.0 mol%) was prepared by the method of melt quenching. Raw materials, i.e., K2CO3 (≥99%), BaCO3 (≥99%), SrCO3 (≥99%), Nb2O5 (≥99.9%), H3BO3 (≥99.5%), and Ta2O5 (≥99.5%), were used for the glass preparation. All of the raw materials were weighed proportionally, mixed with anhydrous ethanol as a dispersant in a ball mill for 12 h, and then dried at 100 °C for 3 h. The dried mixtures were placed in a corundum crucible (≥99.7%) and melted at 1450 °C for 2 h. The melt was poured into a preheated copper plate to press into shape and then annealed at 550 °C for 6 h to obtain the mother glass. The mother glass was cut into pieces of 1 × 1 × 0.2 cm and crystallized at 740 °C for 2 h to obtain glass ceramics, which was then thinned and polished to about 0.07 mm. Finally, a silver electrode of about 2 mm diameter was coated on both sides of the glass ceramics and then sintered at 550 °C for 40 min to obtain the glass ceramic capacitors for dielectric, ferroelectric, and charge-discharge performance tests.

2.2. Characterization

The phase structures were determined via X-ray diffraction (XRD, Bruker D8 Advance, Karlsruhe, Germany) at room temperature with Cu-Ka radiation. The local structure was studied using a LabRAM HR Evolution Raman spectrometer (HORIBA, Palaiseau, France, 532 nm excitation) at room temperature. The microstructures were obtained using a scanning electron microscope (FE-SEM, Quanta 450 FEG, FEI, Miamisburg, OH, USA), and the samples were treated with 20% HF about 60 s before testing. High-angle annular dark field (HAADF) images and elemental distribution spectra were acquired using a field-emission transmission electron microscope (TEM, Talos F200X, FEI, Pasadena, CA, USA) at 200 kV. The UV-vis absorption spectra were tested with a UV-visible spectrophotometer (Jingdao UV-200, Ōsaka shi, Japan). The impedance spectra were measured via LCR meter (2838A, Tonghui, Changzhou, China) at temperatures from 460 °C to 540 °C and a frequency test range from 0.5 kHz to 1000 kHz. The dielectric temperature spectra were obtained at 0.5, 1.0, 10, 100, and 1000 kHz using an LCR tester (Th 2832, Tonghui, Changzhou, China) with a measurement temperature range of −150 °C to 200 °C. The P-I-E loops were measured using a ferroelectric tester (TF ANALYZER 2000, aixACCT, Aachen, Germany). The charge–discharge properties were studied using an RLC testing circuit (Gogo Instruments, CFD-003, Shanghai, China) with a load resistance of approximately 200 Ω.

3. Results and Discussion

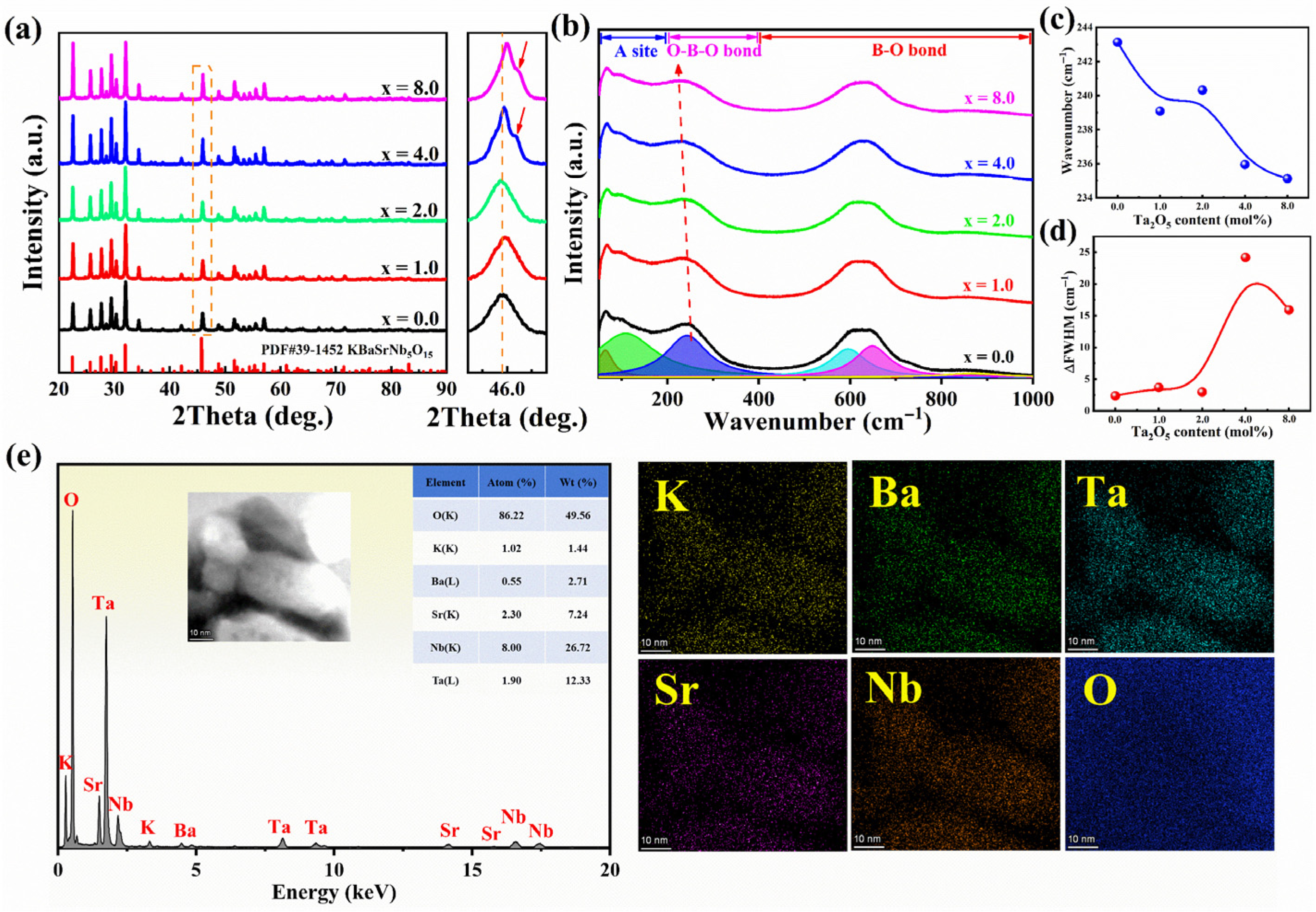

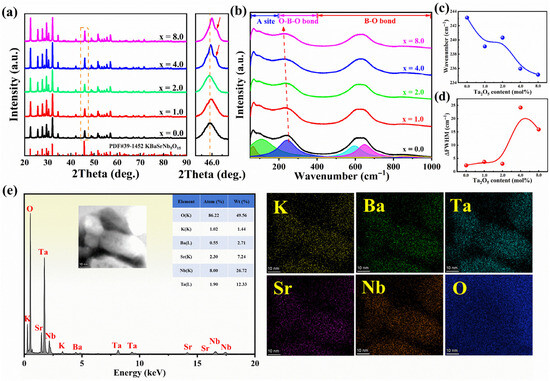

Figure 1a displays the room temperature X-ray diffraction patterns of the KBSN-xTa2O5 (x = 0.0, 1.0, 2.0, 4.0 and 8.0 mol%) glass ceramics. It can be seen that a pure KBaSrNb5O15 phase with a tungsten bronze structure precipitated in all samples, and no second phase was observed. The inset of Figure 1a depicts an enlarged diffraction peak around 46°. Notably, the diffraction peak began to split when the Ta content increased to 4.0 and 8.0 mol%. Considering the changes in polarization behavior of KBSN-xTa2O5 glass ceramics which are discussed in the following sections, the non-centrosymmetric point group of P4bm was used for the x = 0.0, 1.0, and 2.0 components, and the centrosymmetric point group of P4/mbm was used for the x = 4.0 and 8.0 components in the structure refinement program. The structure refinement results are shown in Figure S1, and the lattice parameters of all samples are displayed in Table 1 (Rp is the residual variance factor of the graph and Rwp is the weighted residual variance factor of the graph). As the content of Ta increased, lattice parameter a increased and c decreased, leading to a reduced value of tetragonality c/a [12]. In particular, the trend of the a value for the x = 2.0 component was opposite to that of x = 1.0, with a decreasing and c increasing, but the value of c/a was still lower than the x = 0.0 component. This anomaly may have been caused by the coexistence of the two structures at the beginning of the phase transition, which led the peaks around 46° to shift to a lower angle. As shown in Table 1, when x ≥ 4.0 mol%, both the lattice parameter a and c decreased, although the radii of Nb5+ (0.64 Å, coordination number (CN) = 6) and Ta5+ (0.64 Å, CN = 6) were the same [7]. This lattice contraction may be attributed to the higher electronegativity of Ta and the stronger covalent Ta-O bond (shorten bonding length) due to the enhancement of hybridization between oxygen 2p orbitals and Ta d orbitals; that is, the shortened Ta-O bonds may have enhanced the degree of electronic localization and reduced the driving force of polarity distortion, leading to the lattice contraction. Combined with the clear splitting of the diffraction peak that appeared at x ≥ 4.0, it is reasonable to speculate the symmetry deviation arose from the crystal structure changing from a non-centrosymmetric P4bm to a centrosymmetric P4/mbm space group [16].

Figure 1.

(a) XRD patterns of KBSN-xTa2O5 glass ceramics at room temperature; the inset is the enlarged diffraction peak at around 46°. (b) Raman spectrum of KBSN-xTa2O5 glass ceramics at room temperature; (c) position change of the peak in the 250 cm−1 band; (d) the absolute value of the FWHM difference between the two sub-peaks near the 600 cm−1 band; (e) elemental distribution of the x = 4.0 component.

Table 1.

The Rietveld refinement results for XRD of KBSN-xTa2O5 glass ceramics.

In order to investigate the change in the local structure of the glass ceramics with the addition of Ta2O5, the Raman spectrum was tested, as shown in Figure 1b. Similar to other ceramics with tungsten bronze structures reported in the literature, KBSN-xTa2O5 (x = 0.0, 1.0, 2.0, 4.0 and 8.0 mol%) glass ceramics exhibited the same vibration modes [23]. The Raman peaks in the region below 200 cm−1 (the two deconvoluted peaks marked by dark yellow and green in Figure 1b) were closely related to the vibrations of A-site cations, including K+, Ba2+, and Sr2+ [23]. The Raman peaks in the wavenumber range of 200–1000 cm−1 could be attributed to the internal mode of the BO6 octahedron, including Nb5+ and Ta5+. The peaks around 250 cm−1 (the deconvoluted peak marked in blue in Figure 1b) were attributed to the bending vibration of O-B-O bonds, while the peaks around 630 cm−1 (the two deconvoluted peaks marked in cyan and magenta in Figure 1b) and 840 cm−1 (the deconvoluted peak marked by yellow in Figure 1b) were associated with the stretching vibrations of B-O bonds [14,22,24]. As shown in Figure 1b, the Raman peaks of B-bonds became weaker in intensity and wider in shape with increasing Ta2O5 content, which indicated the weakening of Nb-O and O-Nb-O bonds; additionally, the disorder of B-site increased and the polarity of units decreased, leading to a decrease in the dielectric constant [25,26]. Furthermore, as shown to Figure 1c, the peaks around 200 cm−1 shifted to lower wavenumber values, associated with the displacement of B-site cations, due to the higher atomic mass of Ta compared to Nb [20]. Figure 1d shows the absolute value (ΔFWHM) of the FWHM difference between the two subpeaks in the 600 cm−1 band; it can be clearly observed that the ΔFWHM increased sharply when x ≥ 4.0, which could be attributed to the weakening of one of the peaks and the enhancement of the other. Furthermore, two peaks gradually merged into one peak, indicating a changing structural symmetry. This change may have been related to the change of the space point group from the non-centrosymmetric of P4bm to the centrosymmetric of P4/mbm owing to the transformation of the crystal structure due to Ta substitution.

An element distribution diagram of the KBSN-4.0mol%Ta2O5 sample is displayed in Figure 1e. The results show that all the elements were uniformly distributed in the nanograins, indicating that the precipitated crystals were pure KBaSrNb5O15 ceramic phase with uniform composition, and that Ta5+ had entered the lattice, replacing Nb5+ at the B-site. In addition, the grains were not purely tetragonal, showing that the substitution of Ta led to a crystallographic transformation, consistent with previous XRD analysis.

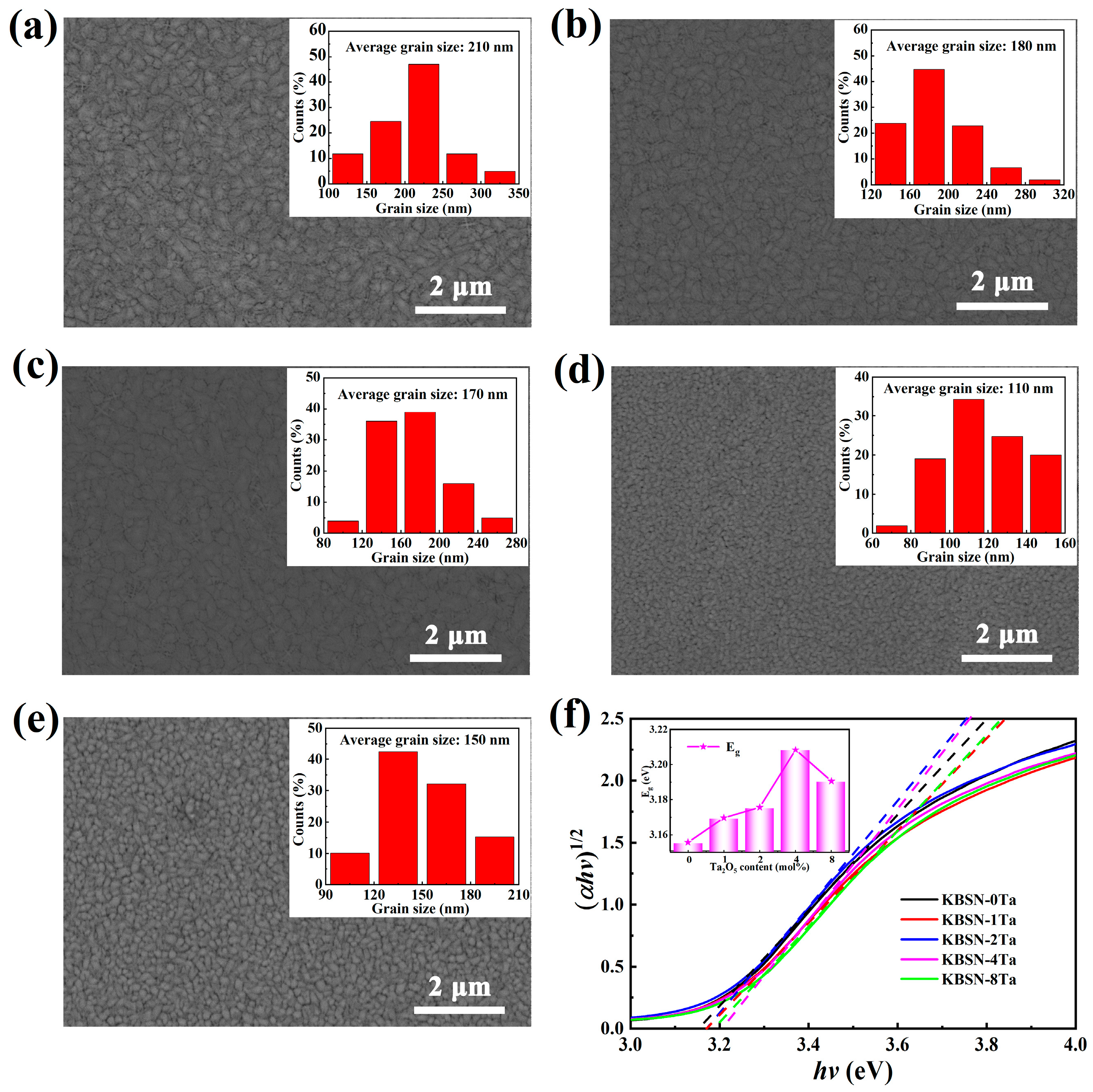

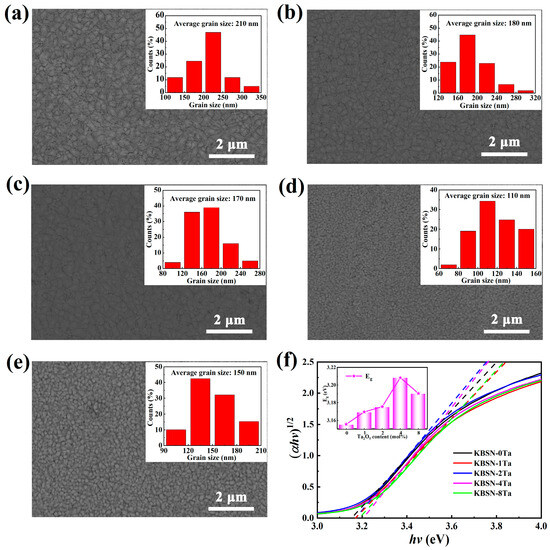

Scanning electron microscope (SEM) images of the KBSN-xTa2O5 (x = 0.0, 1.0, 2.0, 4.0 and 8.0 mol%) glass ceramics are displayed in Figure 2a–e. Obviously, for all samples, the crystal grains were uniformly embedded in the glass matrix, forming a dense microstructure without obvious pores and crystal grain aggregation. The inset of Figure 2a–e shows the grain size distribution; it is clear that the crystal particles were at the nanoscale in all samples. Furthermore, the grain size became more uniform and smaller after the addition of Ta2O5. Notably, when the Ta2O5 addition was 4.0 mol%, the average grain size was significantly reduced to 90 nm, i.e., nearly 60% less than that of the sample without the addition of Ta2O5. A dense internal structure and small grain size are conducive to a high electric breakdown strength (BDS) [22,27,28,29]; thus, the KBSN-4.0mol%Ta2O5 glass ceramics may have had the highest BDS among all samples. The UV-vis absorption spectra of KBSN-xTa2O5 glass ceramics and corresponding optical band gaps (Eg) are shown in Figure 2f. Obviously, with an increase of Ta2O5 content, the trend of Eg increased first and then decreased; this is the same trend as the average grain size variation observed by SEM. When the addition amount of Ta2O5 was 4 mol%, the maximum value of Eg reached 3.205 eV. A wider band gap makes it more difficult for electrons in the valence band to jump into the conduction band, which served to improve the BDS [30].

Figure 2.

(a–e) Scanning electron microscope (SEM) micrographs of KBSN-xTa2O5 glass ceramics; (f) UV-vis absorption spectra of KBSN-xTa2O5 glass ceramics. The inset is band gap Eg.

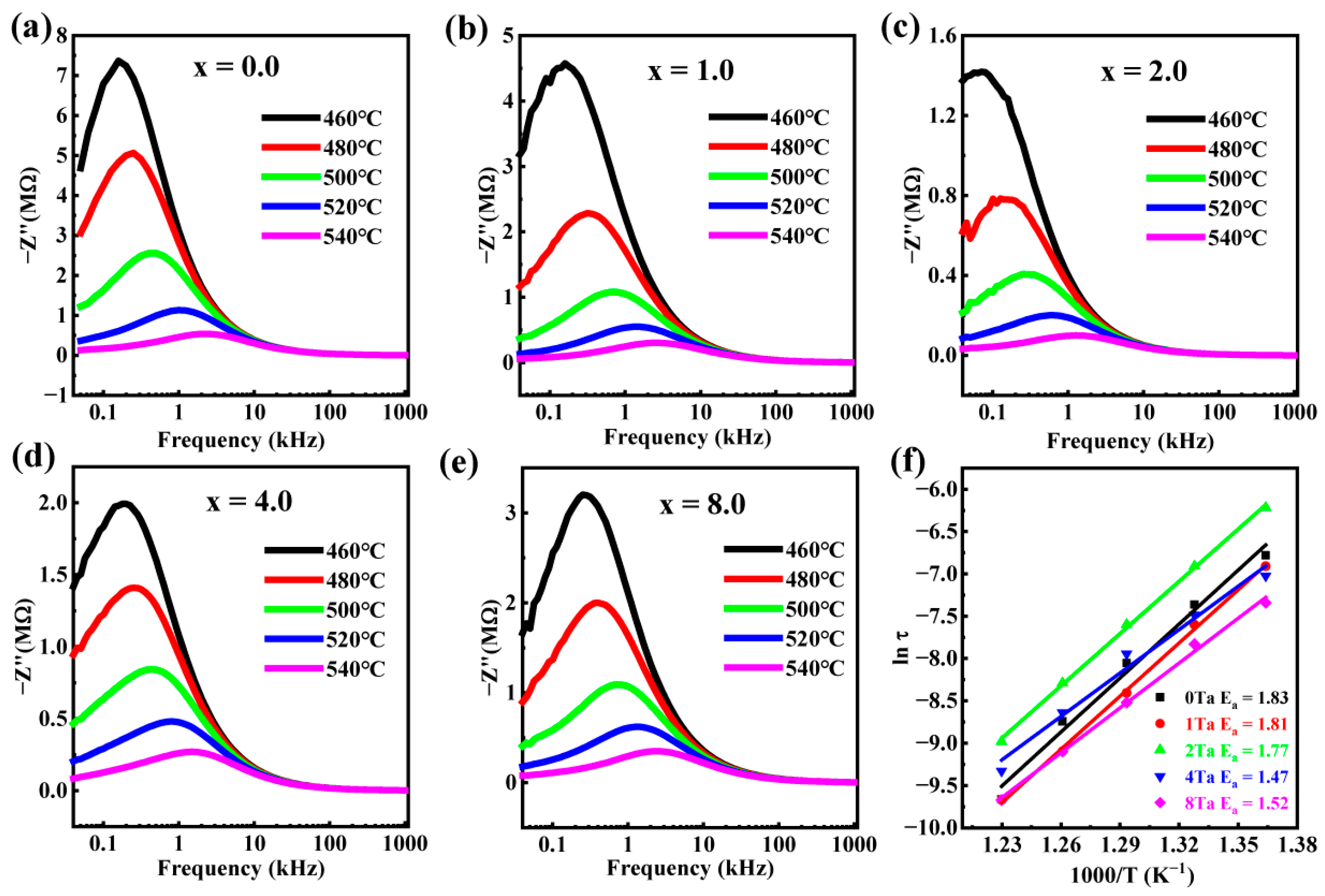

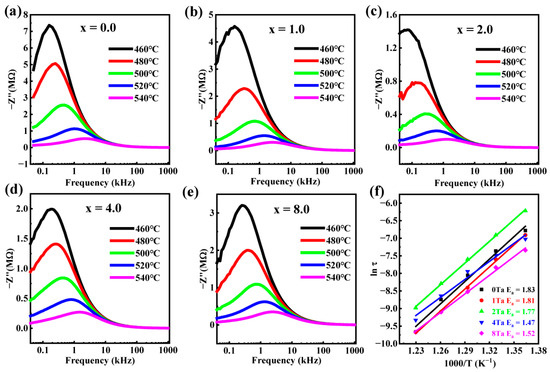

As we all know, glass ceramics are composed of a glass phase and a ceramic phase. When an electric field is applied, the huge relative permittivity gap between the glass and ceramic phases induces an inhomogeneous distribution of the electric field, resulting in charge aggregation, thus triggering dielectric breakdown, which is the interfacial polarization phenomenon of glass ceramics [31,32]. The activation energy (Ea) calculated from the complex impedance spectrum can be used to analyze the charge migration, illustrating the intrinsic relationship between interfacial polarization and BDS [33,34]. Ea can be obtained from the Arrhenius formula:

where T, kB, τ, and τ0 represent absolute temperature, the Boltzmann constant, the relaxation time, and the pre-exponential factor, respectively [35,36,37], and τ is related to the frequency of the impedance and can be calculated using the following equation:

where fmax represents the frequency of the crest value of the imaginary part of impedance (−Z″) [38]. Figure 3a–e shows −Z″ as a function of frequency at various test temperatures for KBSN-x Ta2O5 (x = 0.0, 1.0, 2.0, 4.0 and 8.0 mol%) glass ceramics. For all samples, only one peak could be observed for each test temperature, and the crest value decreased with the increase of the test temperature, indicating a rise in conductivity [24]. In addition, it should be noted that the peak shifted to a high frequency with the increase of the test temperature, resulting in changes in the value of τ. According to Formula (1), the Ea of the relaxation process can be calculated by a linear function of lnτ with 1/T, as displayed in Figure 3f. Commonly, Ea reflects the space charge mobility at the interface [39]; a smaller Ea indicates higher space charge mobility and less likelihood of local agglomeration, which leads to a higher BDS [31,34]. As the Ta2O5 content increases, Ea first decreased and then increased. In particular, Ea reached a minimum value of 1.47 eV when the Ta2O5 content was 4.0 mol%; this was related to the small grain size observed via SEM. Owing to the fact that a smaller grain size leads to a smaller relative permittivity, the difference in relative permittivity between the glass and ceramic phases was smaller, resulting in higher charge mobility, less susceptibility to local agglomeration, more uniform electric field distribution, and less susceptibility to dielectric breakdown. Therefore, it can be considered that the KBSN-4.0mol%Ta2O5 glass ceramics exhibited the highest BDS, which is consistent with the former analysis, as shown in Figure 4a.

Figure 3.

(a–e) Relationship between the imaginary part of impedance (−Z″) and the frequency of KBSN-x Ta2O5 (x = 0.0, 1.0, 2.0, 4.0 and 8.0 mol%) glass ceramics at different temperatures; (f) lnτ as a function of 1000/T for the glass ceramics.

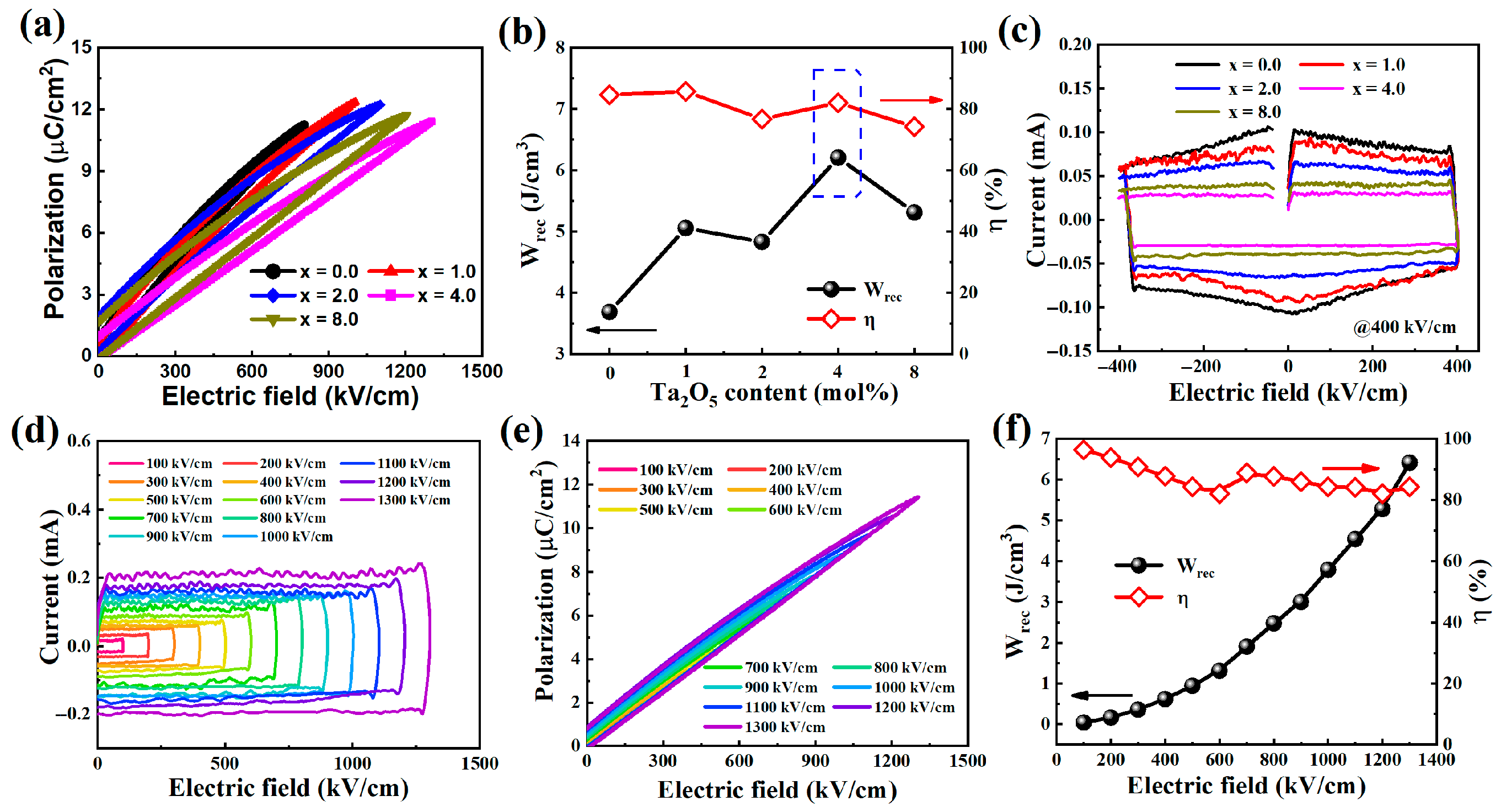

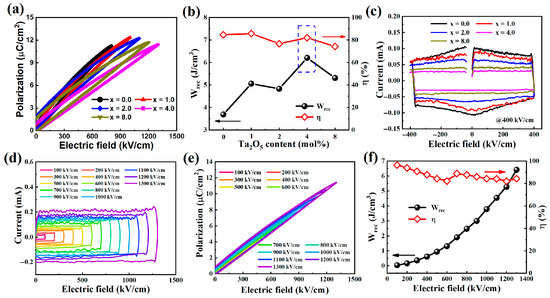

Figure 4.

(a) The room temperature P-E loops of KBSN-xTa2O5 (x = 0.0, 1.0, 2.0, 4.0 and 8.0 mol%) glass ceramic at the critical electric field; (b) the change of energy storage density and efficiency with the increase of Ta2O5 content; (c) I-E loops at 400 kV/cm; (d) I-E loops with x = 4.0 components under various electric fields; (e) P-E loops under various electric fields; (f) variation of Wrec and η with electric field (the black and red arrows present the curves of Wrec and η depends on the electric field strength).

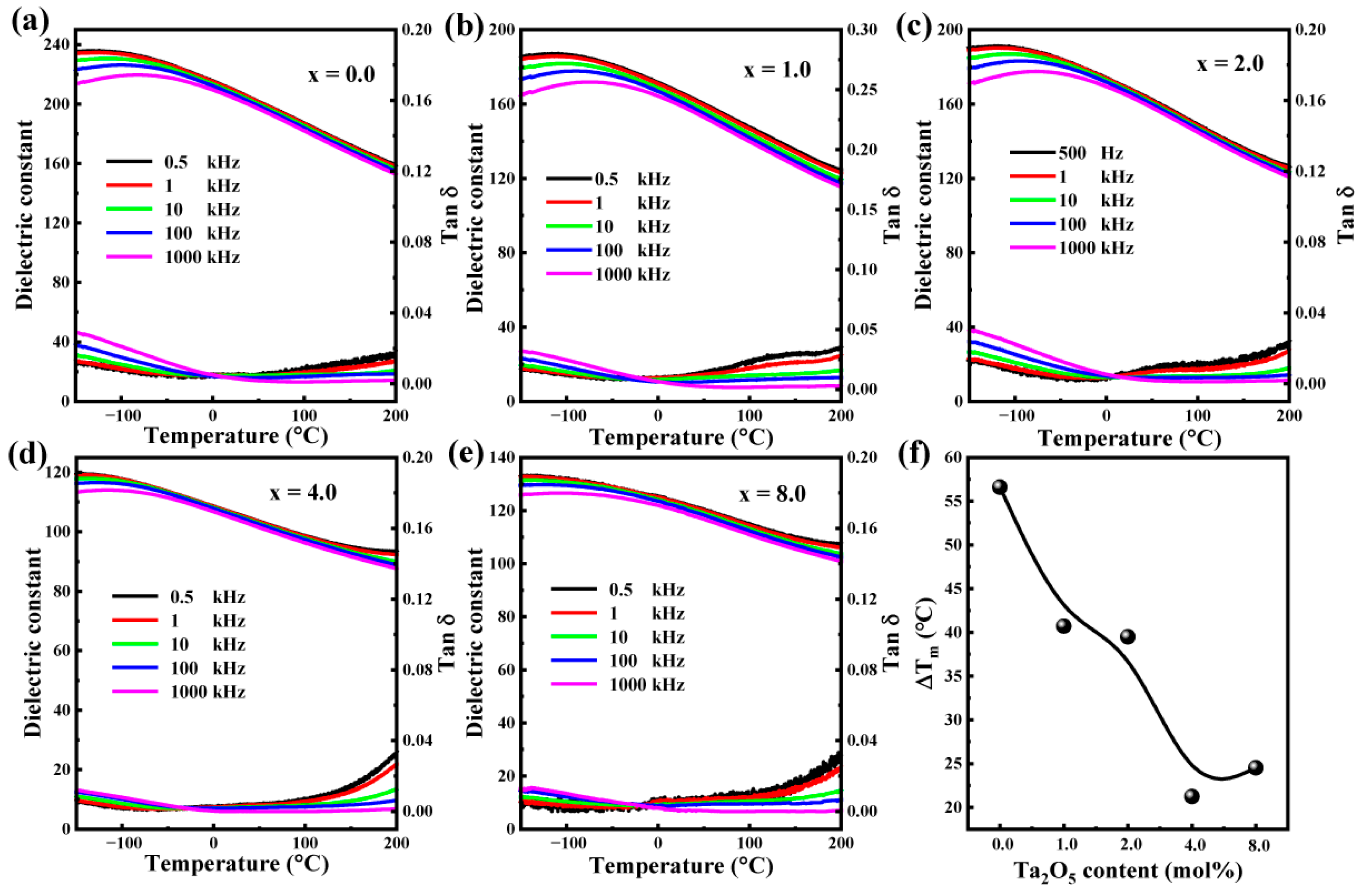

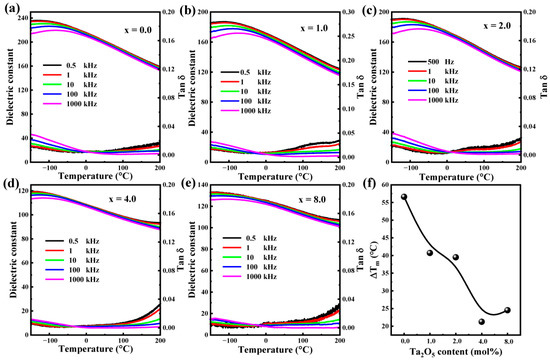

Figure 5a–e shows the temperature dependent spectrum of the dielectric constant and loss for the KBSN-xTa2O5 (x = 0.0, 1.0, 2.0, 4.0 and 8.0 mol%) glass ceramic at various frequencies. For all samples, a unique dielectric peak could be observed with varying degrees of frequency dispersion. ΔTm (the difference of Tm between 1 MHz and 100 Hz) was then introduced to characterize the degree of frequency dispersion; the variations of ΔTm with x are shown in Figure 5f. As shown in Figure 5f, a large ΔTm of KBSN-xTa2O5 (x = 0.0, 1.0 and 2.0 mol%) indicated strong frequency dispersion over a wide temperature range, revealing the typical relaxor ferroelectric features of these samples [40,41]. Interestingly, when the addition of Ta2O5 was greater than 2.0 mol%, ΔTm decreased sharply, indicating that the dielectric frequency dispersion had been substantially weakened, as shown in Figure 5d,e. This allowed us to predict the phase transition from relaxor ferroelectric to paraelectric; a similar phenomenon appeared in the Sr2Na(Nb1−xTax)5O15 ceramics [7]. The above results indicate that the introduction of a certain amount of Ta2O5 induced a transition from relaxor ferroelectric to paraelectric in KBSN glass ceramics, which may be beneficial for the energy storage performance. Notably, the dielectric constants of glass ceramics without the addition of other dopants were inconsistent when comparing our previously reported work and this paper, although their ratios, as well as the preparation methods, were the same. We give an explanation for this discrepancy in the Supporting Information.

Figure 5.

Temperature dependence of dielectric constant and loss for KBSN-xTa2O5 glass ceramics measures at frequencies of 0.5 kHz, 1 kHz, 10 kHz, 100 kHz, and 1000 kHz, (a) x = 0.0, (b) x = 1.0, (c) x = 2.0, (d) x = 4.0, and (e) x = 8.0; (f) the ΔTm of KBSN-xTa2O5 glass ceramics.

The unipolar P-E loops of KBSN-xTa2O5 (x = 0.0, 1.0, 2.0, 4.0 and 8.0 mol%) glass ceramics at a critical electric field and the corresponding variation of recoverable energy density (Wrec) and efficiency (η) are displayed in Figure 4a and Figure 4b, respectively. Eb improved from 800 kV/cm to 1300 kV/cm as the Ta2O5 increased from 0.0 to 4.0 mol%, which greatly contributed to obtaining high energy storage density, as illustrated in the equation of , where Pr is the residual polarization and Pm is the maximal polarization [3]. The significant increase in Eb could be attributed to the decrease of the interfacial activation energy (Ea) and the increase of the bandgap width (seen Figure 2f and Figure 3f). For the x = 4.0 component sample, the maximum value of Wrec reached about 6.20 J/cm3, i.e., about 1.68 times higher than that of the x = 0.0 component sample (3.69 J/cm3), and also kept a high η of about 82%. The room temperature I-E loops of KBSN-xTa2O5 (x = 0.0, 1.0, 2.0, 4.0 and 8.0 mol%) glass ceramics under 400 kV/cm are presented in Figure 4c. For the I-E loops, there was only one broader current peak near 0 kV/cm for components with x = 0.0, 1.0, and 2.0; this was related to the relaxation ferroelectric characteristics of the glass ceramics [42]. With an increase in the Ta2O5 content, this current peak disappeared and the shape of the I-E loop approximated a rectangle without spontaneous polarization, indicating a transition from a relaxation ferroelectric to a paraelectric phase, corresponding to an anomalous weakening of the frequency dispersion in the dielectric temperature spectrum.

The performance of the optimized combination of the KBSN-4.0mol%Ta2O5 glass ceramics exhibited great superiority in terms of energy storage. Hence, KBSN-4.0mol%Ta2O5 glass ceramics were chosen for further investigation. Variations in the I-E and P-E loops as the electric field increased are displayed in Figure 4d,e, and the energy storage density combined with the energy storage efficiency calculated from P-E loops under different electric field strengths are exhibited in Figure 4f. As shown in the Figure 4d, with an increase in the electric field, the current increased but the shape of the I-E loops remained rectangular, without any spontaneous polarization behavior, indicating that the sample remained in a paraelectric state, without phase transition. Furthermore, all P-E loops yielded slim features with large Pm and small Pr, as well as excellent resistance to electric fields, as shown in Figure 4e, all of which are advantageous for achieving high energy storage performance. As expected, Wrec improved considerably from 0.0426 to 6.20 J/cm3, and the efficiency remained high, i.e., >80%. When the electric field reached 1300 kV/cm, excellent energy storage performance was achieved with KBSN-4.0 mol%Ta2O5, including a Wrec value of 6.20 J/cm3, as well as efficiency of about 82%.

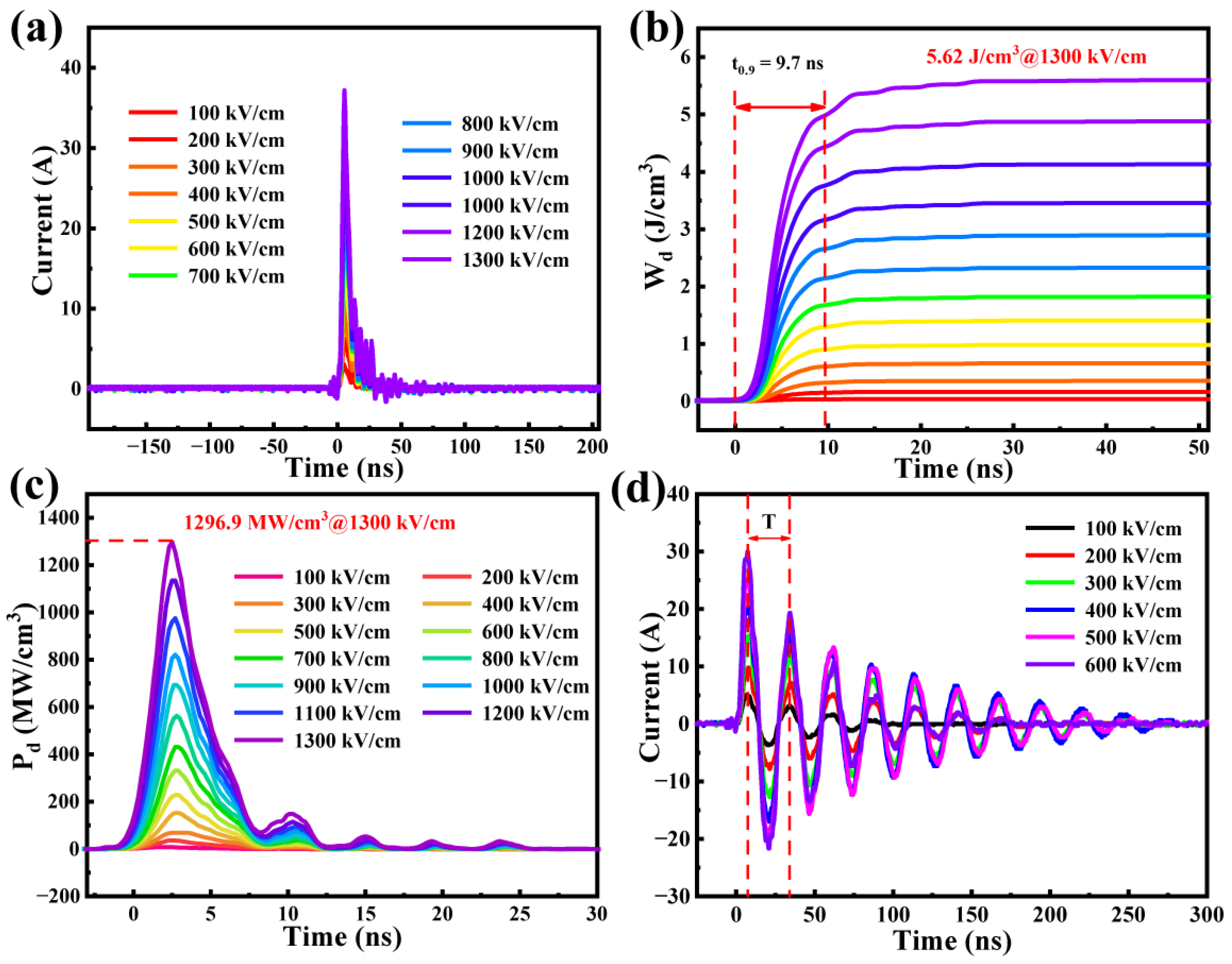

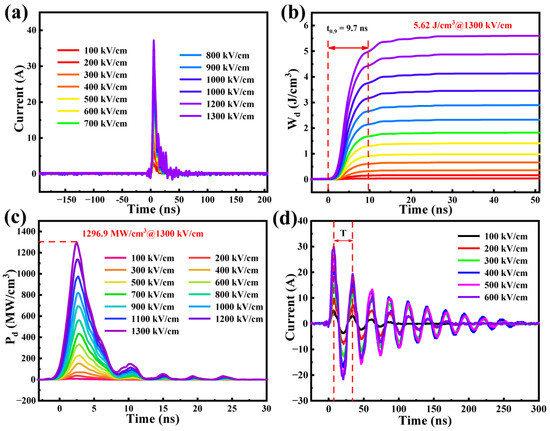

Generally, a P-E circuit is measured in a quasi-static electric field, so it is impossible to calculate the actual discharge rate and discharge power density of the capacitor [19]. In contrast, the pulse charge–discharge test takes place in an RLC oscillation circuit, applying an electric field to charge the capacitor, and discharging it via a load resistor for a short time after removing the electric field. The pulse charge–discharge performance of the capacitor can be obtained by collecting the current change in this process. Therefore, it is necessary to carry out pulse charge–discharge tests on glass ceramics dielectric capacitors to simulate the operating conditions in practical applications. The discharge energy density (Wd) can be calculated by:

where R is the load resistance (200 Ω), V is the volume of glass ceramic dielectric capacitor, and i(t) is the current in the circuit [43,44]. Figure 6a,b comprises the room temperature overdamped discharge current and energy density (Wd) over time curves for the KBSN-4.0mol%Ta2O5 glass ceramic under different electric fields. In particular, a sharp current peak emerged, as shown in Figure 6a, indicating the unique pulsed charge–discharge characteristics of the glass ceramic. With an increase in the electric field, the value of the maximum current and Wd increased sharply, and a value of Wd of about 5.62 J/cm3 was reached at 1300 kV/cm. Typically, t0.9 is defined as the time required for the release of 90% of the stored energy [45]. It can be seen that a t0.9 of about 9.7 ns was maintained when the electric field increased to 1300 kV/cm, revealing a superfast discharge rate of the capacitor. The Wd values of other KBSN-xTa2O5 glass ceramics with x = 0.0, 1.0, 2.0, and 8.0 mol% can be found in Figure S2 in the Supporting Information for reference. The discharge power density is particularly important in pulsed power supplies. The overdamped instantaneous discharge power density (Pd) is obtained using the following equation:

where the meanings of V, R, and i(t) are all described in Equation (3) [46]. The instantaneous discharge power densities over time of the KBSN-4.0mol%Ta2O5 glass ceramic are shown in Figure 6c. As expected, Pd was positively correlated with the electric field. The highest Pd was 1296.9 MW/cm3 under a 1300 kV/cm electric field. Commonly, the underdamped discharge behavior is used to determine whether the discharge behavior of the capacitor is linear or not [47]. The underdamped discharge period (T) can be expressed as:

where L is the inductance and C is the capacitance of the sample. In the RLC oscillation circuit, L can be considered as a constant [48]. Therefore, the discharge period (T) is proportional to the root of the square of C. Figure 6d displays the underdamped discharge current curves over time for the KBSN-4.0mol%Ta2O5 glass ceramic. Significantly, the discharge period (T) remained constant with an increasing electric field, indicating that the capacitance of the glass ceramics also remained constant, according to Formula (5). Thus, it can be concluded that the KBSN-4.0mol%Ta2O5 glass ceramic was linear dielectric.

Figure 6.

(a) Overdamped discharge current curves, (b) discharge energy density, and (c) instantaneous discharge power density curves of the KBSN-4.0mol%Ta2O5 glass ceramics under various electric fields; (d) underdamped discharge current curves versus time under different electric fields.

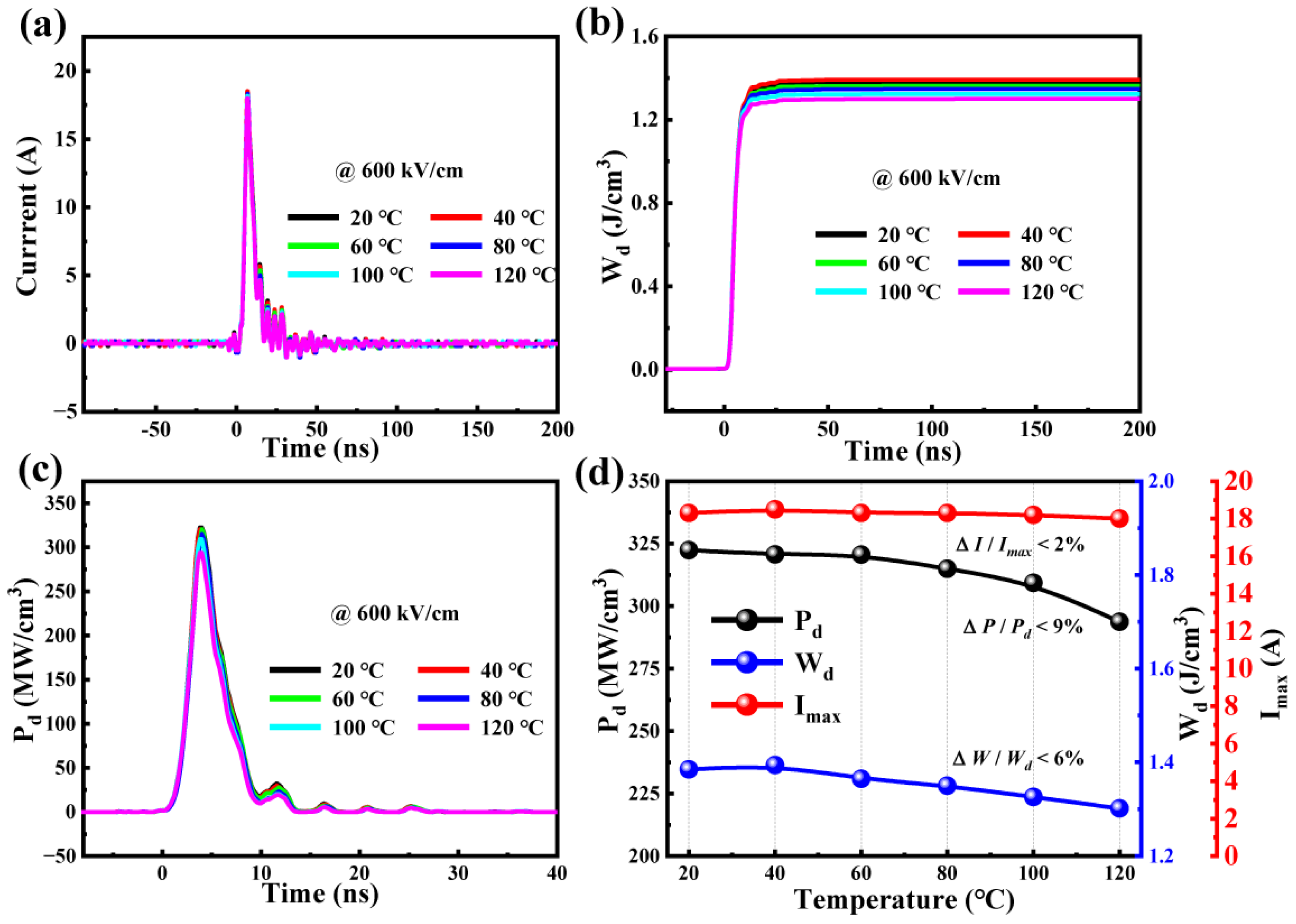

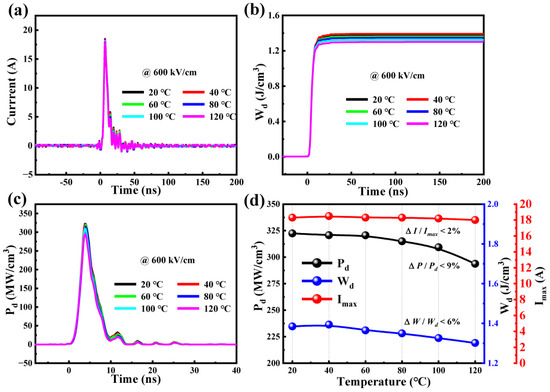

Furthermore, it was necessary to explore the thermal stability of the charge–discharge performance for dielectric capacitors. Figure 7a–c shows the overdamped discharge current, energy density, and instantaneous power density curves versus time at different measured temperatures of KBSN-4.0mol%Ta2O5 glass ceramics under 600 kV/cm. Obviously, all curves show a minor variation with increasing temperature from 20 °C to 120 °C. Figure 7d reveals the maximum values of the discharge current (Imax), energy density (Wd), and power density (Pd) as a function of the measured temperature. As the measured temperature increased from 20 °C to 120 °C, Imax, Wd, and Pd decreased from 18.3 A, 1.385 J/cm3, 322.4 MW/cm3 to 18 A, 1.302 J/cm3, and 293.7 MW/cm3, respectively, representing decreases of about 2%, 9%, and 6%, indicating that the KBSN-4.0mol%Ta2O5 glass ceramics possessed favorable thermal stability.

Figure 7.

(a) Overdamped discharge current, (b) energy density, and (c) instantaneous power density curves of the KBSN-4.0mol%Ta2O5 glass ceramics at different temperatures under 600 kV/cm; (d) corresponding values of Pd, Wd, and Imax versus temperature.

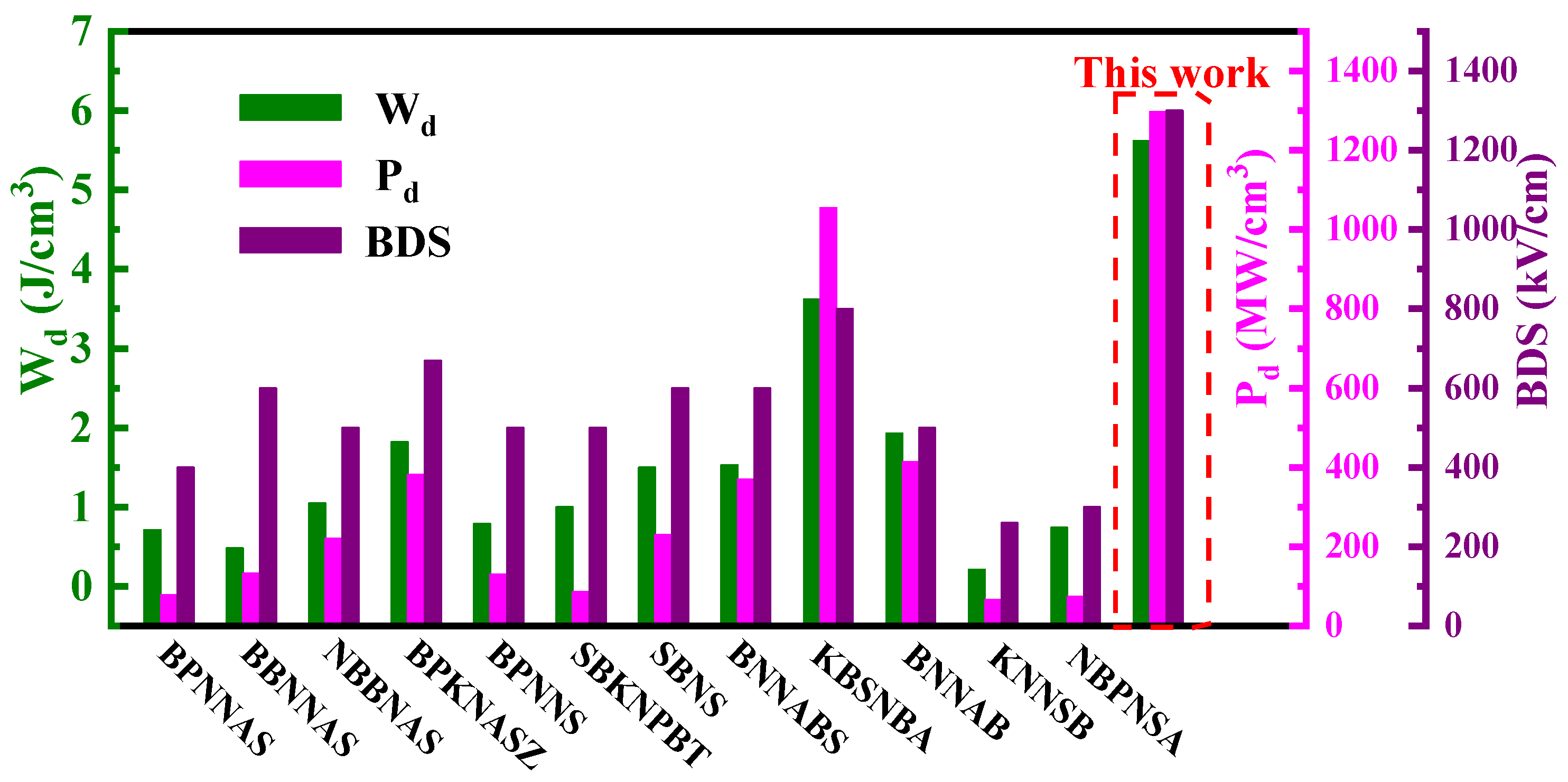

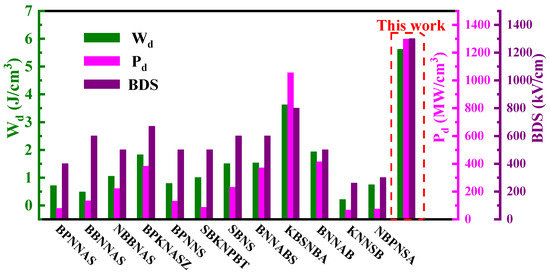

A comparison of the Wd, Pd, and BDS values observed in this work and those from other recently reported research for glass ceramic dielectrics is displayed in Figure 8 [23,31,32,36,46,47,49,50,51,52,53,54]. Significantly, most of the glass ceramic dielectrics had a BDS below 600 kV/cm, resulting in their Wd and Pd being generally lower than 2.0 J/cm3 and 500 MW/cm3. In contrast, the KBSN-Ta glass ceramic in this work simultaneously achieved a Wd of 5.62 J/cm3 and a Pd of 1296.9 MW/cm3 by virtue of its ultra-high BDS of 1300 kV/cm, which is superior to those reported in previous works, revealing it to be a promising candidate glass ceramic dielectric material for high-voltage and high-power capacitors. A comparison of the Wrec in this work and those in ceramic and polymer based dielectrics reported elsewhere is shown in Figure S3 [55,56,57,58,59,60,61,62,63,64,65,66,67,68,69], illustrating that the glass ceramic fabricated by B-site modification engineering is a promising candidate for dielectric energy storage applications.

Figure 8.

Comparison of discharge energy density (Wd), power density (Pd), and BDS with those in other glass ceramics systems.

4. Conclusions

In this work, KBSN-xTa2O5 lead-free glass ceramics were designed and fabricated based on B-site engineering to optimize the energy storage properties. The results show that the KBSN-samples simultaneously achieved record-high Wd (5.62 J/cm3) and Pd (1296.9 MW/cm3) at 1300 kV/cm, as well as a super-fast discharge time, i.e., about 9.7 ns. The XRD, element distribution, and Raman analyses revealed that Ta entered the KBaSrNb5O15 crystal lattice and replaced Nb in B-sites, leading to a change in the cell constant, a decrease in tetragonality, an increase in cation displacement in the BO6 octahedra, and a distortion of structural symmetry, resulting in a dramatic change in ferroelectricity. The P-E loops shows that the addition of Ta2O5 improved the BDS from 800 kV/cm to 1300 kV/cm, and the KBSN-4.0mol%Ta2O5 sample exhibited an excellent Wrec of about 6.20 J/cm3 and a favorable energy storage efficiency of about 82%. The SEM, UV-Vis absorbance spectrum, and impedance analyses revealed that the excellent BDS of the KBSN-4.0mol%Ta2O5 sample was a result of the reduced grain size, modified band gap, and the decreased interfacial activation energy (Ea). Moreover, the KBSN-4.0mol%Ta2O5 sample also presented superior thermal stability in the temperature range of 20 °C to 120 °C. The above results indicate that the KBSN-4.0mol%Ta2O5 glass ceramics showed superior, comprehensive performance and have promise for application in high voltage pulse power systems.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/cryst15050444/s1, Figure S1: XRD Rietveld refinement of KBSN-xTa2O5 (x = 0.0, 1.0, 2.0, 4.0, and 8.0 mol%) glass ceramics.; Figure S2: The discharge energy density (Wd) of KBSN-xTa2O5 glass ceramics at different electric field, (a) x = 0.0, (b) x = 1.0, (c) x = 2.0, and (d) x = 8.0. Figure S3: The comparison of Wrec under different charging electric field strength between this work, ceramics and polymer based dielectrics[55,56,57,58,59,60,61,62,63,64,65,66,67,68,69].

Author Contributions

Conceptualization, F.S. and G.C.; methodology, F.S.; formal analysis, F.S. and Y.Q.; investigation, K.G. and Y.Q.; resources, F.S. and G.C.; data curation, F.S. and G.C.; writing—original draft preparation, K.G. and Y.Q.; writing—review and editing, F.S.; supervision, F.S. and G.C.; project administration, F.S. and G.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by National Natural Science Foundation of China (52362001), Guangxi Nature Science Foundation (2024GXNSFAA010500) and National Natural Science Foundation of China (52162001).

Data Availability Statement

The data of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, S.; Shen, B.; Hao, H.; Zhai, J. Glass-ceramic dielectric materials with high energy density and ultra-fast discharge speed for high power energy storage applications. J. Mater. Chem. C 2019, 7, 15118–15135. [Google Scholar] [CrossRef]

- Yang, Z.; Du, H.; Jin, L.; Poelman, D. High-performance lead-free bulk ceramics for electrical energy storage applications: Design strategies and challenges. J. Mater. Chem. A 2021, 9, 18026–18085. [Google Scholar] [CrossRef]

- Yao, Z.; Song, Z.; Hao, H.; Yu, Z.; Cao, M.; Zhang, S.; Lanagan, M.T.; Liu, H. Homogeneous/inhomogeneous-structured dielectrics and their energy-storage performances. Adv. Mater. 2017, 29, 1601727. [Google Scholar] [CrossRef] [PubMed]

- Xiu, S.; Xiao, S.; Xue, S.; Shen, B.; Zhai, J. Crystallization kinetics behaviour and dielectric properties of strontium barium niobate-based glass–ceramics. J. Mater. Sci. Mater. Electron. 2016, 27, 5324–5330. [Google Scholar] [CrossRef]

- Xiu, S.; Xiao, S.; Zhang, W.; Xue, S.; Shen, B.; Zhai, J. Effect of rare-earth additions on the structure and dielectric energy storage properties of BaxSr1-xTiO3-based barium boronaluminosilicate glass-ceramics. J. Alloys Compd. 2016, 670, 217–221. [Google Scholar] [CrossRef]

- Chen, G.H.; Zheng, J.; Yuan, C.L.; Zhou, C.R.; Kang, X.L.; Xu, J.W.; Yang, Y. Enhanced energy storage properties of P2O5 modified niobate-based B2O3 system glass ceramic composites. Mater. Lett. 2016, 176, 46–48. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, T.L.; Zhu, X.L.; Liu, L.; Chen, X.M. Ferroelectric transition and structural modulation in Sr2Na (Nb1−xTax)5O15 tungsten bronze ceramics. J. Appl. Phys. 2021, 129, 244107. [Google Scholar] [CrossRef]

- Kundu, S.; Varma, K.B.R. Evolution of nanocrystalline Ba2NaNb5O15 in 2BaO-0.5Na2O-2.5Nb2O5-4.5B2O3 glass system and its refractive index and band gap tunability. Cryst. Growth Des. 2013, 14, 585–592. [Google Scholar]

- Oliver, J.R.; Neurgaonkar, R.R. Ferroelectric properties of tungsten bronze morphotropic phase bounary systems. J. Am. Ceram. Soc. 1989, 72, 202–211. [Google Scholar] [CrossRef]

- Lin, K.; Zhou, Z.; Liu, L.; Ma, H.; Chen, J.; Deng, J.; Sun, J.; You, L.; Kasai, H.; Kato, K.; et al. Unusual strong incommensurate modulation in a Tungsten-Bronze-Type relaxor PbBiNb5O15. J. Am. Chem. Soc. 2015, 137, 13468–13471. [Google Scholar] [CrossRef]

- Yang, Z.; Gu, R.; Wei, L.; Ren, H. Phase formation, microstructure and dielectric properties of Sr0. 53Ba0. 47Nb2−xTaxO6 ceramics. J. Alloys Compd. 2010, 504, 211–216. [Google Scholar] [CrossRef]

- Yang, Z.J.; Liu, X.Q.; Zhu, X.L.; Chen, X.M. Crossover from normal to relaxor ferroelectric in Sr0. 25Ba0. 75 (Nb1−xTax)2O6 ceramics with tungsten bronze structure. Appl. Phys. Lett. 2020, 117, 122902. [Google Scholar] [CrossRef]

- Feng, W.B.; Zhu, X.L.; Liu, X.Q.; Chen, X.M. Effects of B site ions on the relaxor to normal ferroelectric transition crossover in Ba4Sm2Zr4(NbxTa1−x)6O30 tungsten bronze ceramics. Appl. Phys. Lett. 2018, 112, 262904. [Google Scholar] [CrossRef]

- Xu, S.; Deng, Z.; Shen, S.; Wei, L.; Yang, Z. Structural and electrical effects of Ag substitution in tungsten bronze Sr2AgxNa1− xNb5O15 ceramics. Ceram. Int. 2020, 46, 13997–14004. [Google Scholar] [CrossRef]

- Zhang, X.; Ye, W.; Bu, X.; Zheng, P.; Li, L.; Wen, F.; Bai, W.; Zheng, L.; Zhang, Y. Remarkable capacitive performance in novel tungsten bronze ceramics. Dalton Trans. 2021, 50, 124–130. [Google Scholar] [CrossRef]

- Cao, L.; Yuan, Y.; Meng, X.; Li, E.; Tang, B. Ferroelectric-relaxor crossover and energy storage properties in Sr2NaNb5O15-based tungsten bronze ceramics. ACS Appl. Mater. Interfaces 2022, 14, 9318–9329. [Google Scholar] [CrossRef]

- Wang, H.; Bu, X.; Zhang, X.; Zheng, P.; Li, L.; Wen, F.; Bai, W.; Zhang, J.; Zheng, L.; Zhang, Y. Pb/Bi-free tungsten bronze-based relaxor ferroelectric ceramics with remarkable energy storage performance. ACS Appl. Energy Mater. 2021, 4, 9066–9076. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, P.; Kandula, K.R.; Li, W.; Meng, S.; Qin, Y.; Zhang, H.; Zhang, G. Achieving excellent energy storage density of Pb0. 97La0.02 (ZrxSn0. 05Ti0. 95-x) O3 ceramics by the B-site modification. J. Eur. Ceram. Soc. 2021, 41, 360–367. [Google Scholar] [CrossRef]

- Luo, N.; Han, K.; Cabral, M.J.; Liao, X.; Zhang, S.; Liao, C.; Zhang, G.; Chen, X.; Feng, Q.; Li, J.F. Constructing phase boundary in AgNbO3 antiferroelectrics: Pathway simultaneously achieving high energy density and efficiency. Nat. Commun. 2020, 11, 4824. [Google Scholar] [CrossRef]

- Ge, P.Z.; Tang, X.G.; Meng, K.; Huang, X.X.; Li, S.F.; Liu, Q.X.; Jiang, Y.P. Energy storage density and charge-discharge properties of PbHf1− xSnxO3 antiferroelectric ceramics. Chem. Eng. J. 2022, 429, 132540. [Google Scholar] [CrossRef]

- Wang, M.; Feng, Q.; Luo, C.; Lan, Y.; Yuan, C.; Luo, N.; Zhou, C.; Fujita, T.; Xu, J.; Chen, G.; et al. Ultrahigh energy storage density and efficiency in Bi0.5Na0.5TiO3-based ceramics via the domain and bandgap engineering. ACS Appl. Mater. Interfaces 2021, 13, 51218–51229. [Google Scholar] [CrossRef]

- Qin, Y.; Shang, F.; Chen, G.; Xu, J.; Wang, Y.; Li, Z.; Zhai, J. Achieving ultrahigh discharge energy and power density in niobate-based glass ceramics via A-site substitution modulation during crystallization. J. Mater. Chem. A 2022, 10, 11535–11541. [Google Scholar] [CrossRef]

- Li, R.; Pu, Y.; Zhang, Q.; Wang, W.; Li, J.; Du, X.; Chen, M.; Zhang, X.; Sun, Z. The relationship between enhanced dielectric property and structural distortion in Ca doped Ba2NaNb5O15 tungsten bronze ceramics. J. Eur. Ceram. Soc. 2020, 40, 4509–4516. [Google Scholar] [CrossRef]

- Yang, B.; Hao, S.; Yang, P.; Wei, L.; Yang, Z. Relaxor behavior and energy storage density induced by B-sites substitutions in (Ca0. 28Ba0. 72) 2.1 Na0. 8Nb5O15 tungsten bronze ceramics. Ceram. Int. 2018, 44, 8832–8841. [Google Scholar] [CrossRef]

- Yao, Y.B.; Mak, C.L.; Ploss, B. Phase transitions and electrical characterizations of (K0.5Na0.5)2x(Sr0.6Ba0.4)5−xNb10O30 (KNSBN) ceramics with ‘unfilled’ and ‘filled’ tetragonal tungsten–bronze (TTB) crystal structure. J. Eur. Ceram. Soc. 2012, 32, 4353–4361. [Google Scholar] [CrossRef]

- Li, D.; Zhou, D.; Wang, D.; Zhao, W.; Guo, Y.; Shi, Z. Improved energy storage properties achieved in (K, Na)NbO3-based relaxor ferroelectric ceramics via a combinatorial optimization strategy. Adv. Funct. Mater. 2021, 32, 2111776. [Google Scholar] [CrossRef]

- Xie, A.; Zuo, R.; Qiao, Z.; Fu, Z.; Hu, T.; Fei, L. NaNbO3-(Bi0.5Li0.5)TiO3 lead-free relaxor ferroelectric capacitors with superior energy-storage performances via multiple synergistic design. Adv. Energy Mater. 2021, 11, 2101378. [Google Scholar] [CrossRef]

- Chen, H.; Shi, J.; Chen, X.; Sun, C.; Pang, F.; Dong, X.; Zhang, H.; Zhou, H. Excellent energy storage properties and stability of NaNbO3-Bi (Mg0.5 Ta0.5)O3 ceramics by introducing (Bi0.5Na0.5)0.7Sr0.3TiO3. J. Mater. Chem. A 2021, 9, 4789–4799. [Google Scholar] [CrossRef]

- Wu, L.; Tang, L.; Zhai, Y.; Zhang, Y.; Sun, J.; Hu, D.; Pan, Z.; Su, Z.; Zhang, Y.; Liu, J. Enhanced energy-storage performance in BNT-based lead-free dielectric ceramics via introducing SrTi0. 875Nb0. 1O3. J. Mater. 2022, 8, 537–544. [Google Scholar]

- Kim, C.; Pilania, G.; Ramprasad, R. Machine learning assisted predictions of intrinsic dielectric breakdown strength of ABX3 perovskites. J. Phys. Chem. C 2016, 120, 14575–14580. [Google Scholar] [CrossRef]

- Jiang, T.; Chen, K.; Shen, B.; Zhai, J. Excellent energy storage and charge-discharge performances in sodium-barium-niobium based glass ceramics. Ceram. Int. 2019, 45, 19429–19434. [Google Scholar] [CrossRef]

- Chen, K.; Jiang, T.; Shen, B.; Zhai, J. Effects of crystalline temperature on microstructures and dielectric properties in BaO-Na2O-Bi2O3-Nb2O5-Al2O3-SiO2 glass-ceramics. Mater. Sci. Eng. B 2021, 263, 114885. [Google Scholar] [CrossRef]

- Wang, H.; Liu, J.; Zhai, J.; Pan, Z.; Shen, B. Effects of Sr substitution for Ba on dielectric and energy-storage properties of SrO-BaO-K2O-Nb2O5-SiO2 glass-ceramics. J. Eur. Ceram. Soc. 2017, 37, 3917–3925. [Google Scholar] [CrossRef]

- Jiang, T.; Chen, K.; Shen, B.; Zhai, J. Enhanced energy-storage density in sodium-barium-niobate based glass-ceramics realized by doping CaF2 nucleating agent. J. Mater. Sci. Mater. Electron. 2019, 30, 15277–15284. [Google Scholar] [CrossRef]

- Wang, H.; Liu, J.; Zhai, J.; Shen, B.; Xiu, S.; Xiao, S.; Pan, Z. Enhanced energy storage density and discharge efficiency in the strontium sodium niobate-based glass-ceramics. J. Alloys Compd. 2016, 687, 280–285. [Google Scholar] [CrossRef]

- Jiang, D.; Shang, F.; Chen, G. Crystallization behavior, ultrahigh power density and high actual discharge energy density of lead-free borate glass-ceramics containing TiO2. Ceram. Int. 2021, 47, 27142–27150. [Google Scholar] [CrossRef]

- Xue, S.; Liu, S.; Zhang, W.; Shen, B.; Zhai, J. Correlation of energy conversion efficiency and interface polarization in niobate glass-ceramic for energy-storage applications. Appl. Phys. Lett. 2015, 106, 162903. [Google Scholar] [CrossRef]

- Jiang, D.; Zhong, Y.; Shang, F.; Chen, G. Crystallization, microstructure and energy storage behavior of borate glass-ceramics. J. Mater. Sci. Mater. Electron. 2020, 31, 12074–12082. [Google Scholar] [CrossRef]

- Wang, H.; Liu, J.; Zhai, J.; Shen, B.; Cain, M. Ultra high energy-storage density in the barium potassium niobate-based glass-ceramics for energy-storage applications. J. Am. Ceram. Soc. 2016, 99, 2909–2912. [Google Scholar] [CrossRef]

- Pan, Z.; Hu, D.; Zhang, Y.; Liu, J.; Shen, B.; Zhai, J. Achieving high discharge energy density and efficiency with NBT-based ceramics for application in capacitors. J. Mater. Chem. C 2019, 7, 4072–4078. [Google Scholar] [CrossRef]

- Zhou, M.; Liang, R.; Zhou, Z.; Dong, X. Achieving ultrahigh energy storage density and energy efficiency simultaneously in sodium niobate-based lead-free dielectric capacitors via microstructure modulation. Inorg. Chem. Front. 2019, 6, 2148–2157. [Google Scholar] [CrossRef]

- Zhang, L.; Yan, Z.; Chen, T.; Luo, H.; Zhang, H.; Khanom, T.; Zhang, D.; Abrahams, I.; Yan, H. Tunable phase transitions in NaNbO3 ceramics through bismuth/vacancy modification. J. Mater. Chem. C 2021, 9, 4289–4299. [Google Scholar] [CrossRef]

- Luo, N.; Han, K.; Zhuo, F.; Xu, C.; Zhang, G.; Liu, L.; Chen, X.; Hu, C.; Zhou, H.; Wei, Y. Aliovalent A-site engineered AgNbO3 lead-free antiferroelectric ceramics toward superior energy storage density. J. Mater. Chem. A 2019, 7, 14118–14128. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, T.; Ye, J.; Wang, G.; Dong, X.; Withers, R.; Liu, Y. Antiferroelectrics for energy storage applications: A review. Adv. Mater. Technol. 2018, 3, 1800111. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, J.; Li, C.; Bai, W.; Wu, S.; Zheng, P.; Zhang, J.; Zhai, J. High capacitive performance at moderate operating field in (Bi0. 5Na0. 5) TiO3-based dielectric ceramics via synergistic effect of site engineering strategy. Chem. Eng. J. 2021, 426, 130811. [Google Scholar] [CrossRef]

- Wang, S.; Tian, J.; Liu, J.; Yang, K.; Shen, B.; Zhai, J. Ultrahigh energy storage density and instantaneous discharge power density in BaO-PbO-Na2O-Nb2O5-SiO2-Al2O3 glass-ceramics. J. Mater. Chem. C 2018, 6, 12608–12614. [Google Scholar] [CrossRef]

- Chen, K.K.; Bai, H.R.; Yan, F.; He, X.; Liu, C.S.; Xie, S.F.; Shen, B.; Zhai, J.W. Achieving superior energy storage properties and ultrafast discharge speed in environment-friendly niobate-based glass ceramics. ACS Appl. Mater. Interfaces 2021, 13, 4236–4243. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, X.; Cao, F.; Wang, G.; Dong, X.; Hu, Z.; Du, T. Charge-discharge properties of an antiferroelectric ceramics capacitor under different electric fields. J. Am. Ceram. Soc. 2010, 93, 4015–4017. [Google Scholar] [CrossRef]

- Liu, C.S.; Xie, S.F.; Bai, H.R.; Yan, F.; Fu, T.T.; Shen, B.; Zhai, J.W. Excellent energy storage performance of niobate-based glass-ceramics via introduction of nucleating agent. J. Mater. 2022, 8, 763–771. [Google Scholar] [CrossRef]

- Xie, S.; Liu, C.; Bai, H.; Fu, T.; Shen, B.; Zhai, J. Crystallization-temperature controlled alkali-free niobate glass-ceramics with high energy storage density and actual discharge energy density. J. Alloys Compd. 2022, 910, 164923. [Google Scholar] [CrossRef]

- Luo, F.; Xing, J.; Qin, Y.; Zhong, Y.; Shang, F.; Chen, G. Up-conversion luminescence, temperature sensitive and energy storage performance of lead-free transparent Yb3+/Er3+ co-doped Ba2NaNb5O15 glass-ceramics. J. Alloys Compd. 2022, 910, 164859. [Google Scholar] [CrossRef]

- Luo, F.; Qin, Y.; Shang, F.; Chen, G. Crystallization temperature dependence of structure, electrical and energy storage properties in BaO-Na2O-Nb2O5-Al2O3-B2O3 glass ceramics. Ceram. Int. 2022, 48, 30661–30669. [Google Scholar] [CrossRef]

- Peng, X.; Pu, Y.; Du, X.; Ji, J.; Gao, P.; Zhang, L.; Sun, Z. Tailoring of ferroelectrics in (Na2O, K2O)-Nb2O5-SiO2 glass-ceramics via control the crystallization kinetics. Chem. Eng. J. 2021, 422, 130027. [Google Scholar] [CrossRef]

- Wang, S.; Tian, J.; Jiang, T.; Zhai, J.; Shen, B. Effect of phase structures on dielectric properties and energy storage performances in Na2O-BaO-PbO-Nb2O5-SiO2-Al2O3 glass-ceramics. Ceram. Int. 2018, 44, 23109–23115. [Google Scholar] [CrossRef]

- Cheng, S.; Zhou, Y.; Li, Y.; Yuan, C.; Yang, M.; Fu, J.; Li, Q. Polymer dielectrics sandwiched by medium-dielectric-constant nanoscale deposition layers for high-temperature capacitive energy storage. Energy Storage Mater. 2021, 42, 445–453. [Google Scholar] [CrossRef]

- Yin, P.; Xie, P.; Tang, Q.; He, Q.; Wei, S.; Fan, R.; Shi, Z. Enhanced dielectric energy storage properties in linear/nonlinear composites with hybrid-core satellite C/SiO2@TiO2 nanoparticles. Appl. Phys. Lett. 2023, 122, 132905. [Google Scholar] [CrossRef]

- Yang, M.; Wang, Z.; Zhao, Y.; Liu, Z.; Pang, H.; Dang, Z.M. Unifying and suppressing conduction losses of polymer dielectrics for superior high-temperature capacitive energy storage. Adv. Mater. 2024, 36, 2309640. [Google Scholar] [CrossRef]

- Dong, J.; Li, L.; Qiu, P.; Pan, Y.; Niu, Y.; Sun, L.; Wang, H. Scalable polyimide-organosilicate hybrid films for high-temperature capacitive energy storage. Adv. Mater. 2023, 35, 2211487. [Google Scholar] [CrossRef]

- Fang, R.; Xu, R.; Zhang, L.; Sun, X.; Wang, Y.; Zhang, X.; Zhao, L. Polarization structural design in core–shell fillers: An approach to significantly enhance the energy storage properties of BST/PVDF composite films. ACS Appl. Electron. Mater. 2022, 4, 2534–2544. [Google Scholar] [CrossRef]

- Wang, P.; Guo, Y.; Zhou, D.; Li, D.; Pang, L.; Liu, W.; Sun, S. High-temperature flexible nanocomposites with ultra-high energy storage density by nanostructured MgO fillers. Adv. Funct. Mater. 2022, 32, 2204155. [Google Scholar] [CrossRef]

- Xie, A.; Fu, J.; Zuo, R.; Jiang, X.; Li, T.; Fu, Z.; Zhang, S. Supercritical relaxor nanograined ferroelectrics for ultrahigh-energy-storage capacitors. Adv. Mater. 2022, 34, 2204356. [Google Scholar] [CrossRef] [PubMed]

- Yan, F.; Bai, H.; Ge, G.; Lin, J.; Sh, C.; Zhu, K.; Zhang, S. Composition and structure optimized BiFeO3-SrTiO3 lead-free ceramics with ultrahigh energy storage performance. Small 2022, 18, 2106515. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.G.; Li, M.D.; Tang, Z.H.; Tang, X.G. Enhanced energy storage density and efficiency in lead-free Bi(Mg1/2Hf1/2)O3-modified BaTiO3 ceramics. Chem. Eng. J. 2021, 418, 129379. [Google Scholar] [CrossRef]

- Li, C.; Liu, J.; Lin, L.; Bai, W.; Wu, S.; Zheng, P.; Zhai, J. Superior energy storage capability and stability in lead-free relaxors for dielectric capacitors utilizing nanoscale polarization heterogeneous regions. Small 2023, 19, 2206662. [Google Scholar] [CrossRef]

- Shi, J.; Zhao, Y.; Li, J.H.T.; Zhu, F.; Tian, W.; Liu, X. Deferred polarization saturation boosting superior energy-storage efficiency and density simultaneously under moderate electric field in relaxor ferroelectrics. ACS Appl. Energy Mater. 2022, 5, 3436–3446. [Google Scholar] [CrossRef]

- Joseph, J.; Cheng, Z.; Zhang, S. NaNbO3 modified BiScO3-BaTiO3 dielectrics for high-temperature energy storage applications. J. Mater. 2022, 8, 731–738. [Google Scholar] [CrossRef]

- Li, D.; Xu, D.; Zhao, W.; Avdeev, M.; Jing, H.; Guo, Y.; Zhou, D. A high-temperature performing and near-zero energy loss lead-free ceramic capacitor. Energy Environ. Sci. 2023, 16, 4511–4521. [Google Scholar] [CrossRef]

- Ding, Y.; Que, W.; He, J.; Bai, W.; Zheng, P.; Li, P.; Zhai, J. Realizing high-performance capacitive energy storage in lead-free relaxor ferroelectrics via synergistic effect design. J. Eur. Ceram. Soc. 2022, 42, 129–139. [Google Scholar] [CrossRef]

- Ding, Y.; Li, P.; He, J.; Que, W.; Bai, W.; Zheng, P.; Zhai, J. Simultaneously achieving high energy-storage efficiency and density in Bi-modified SrTiO3-based relaxor ferroelectrics by ion selective engineering. Compos. Part B Eng. 2022, 230, 109493. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).