Plasma Spraying of W Coatings for Nuclear Fusion Applications: Advancements and Challenges

Abstract

1. Introduction

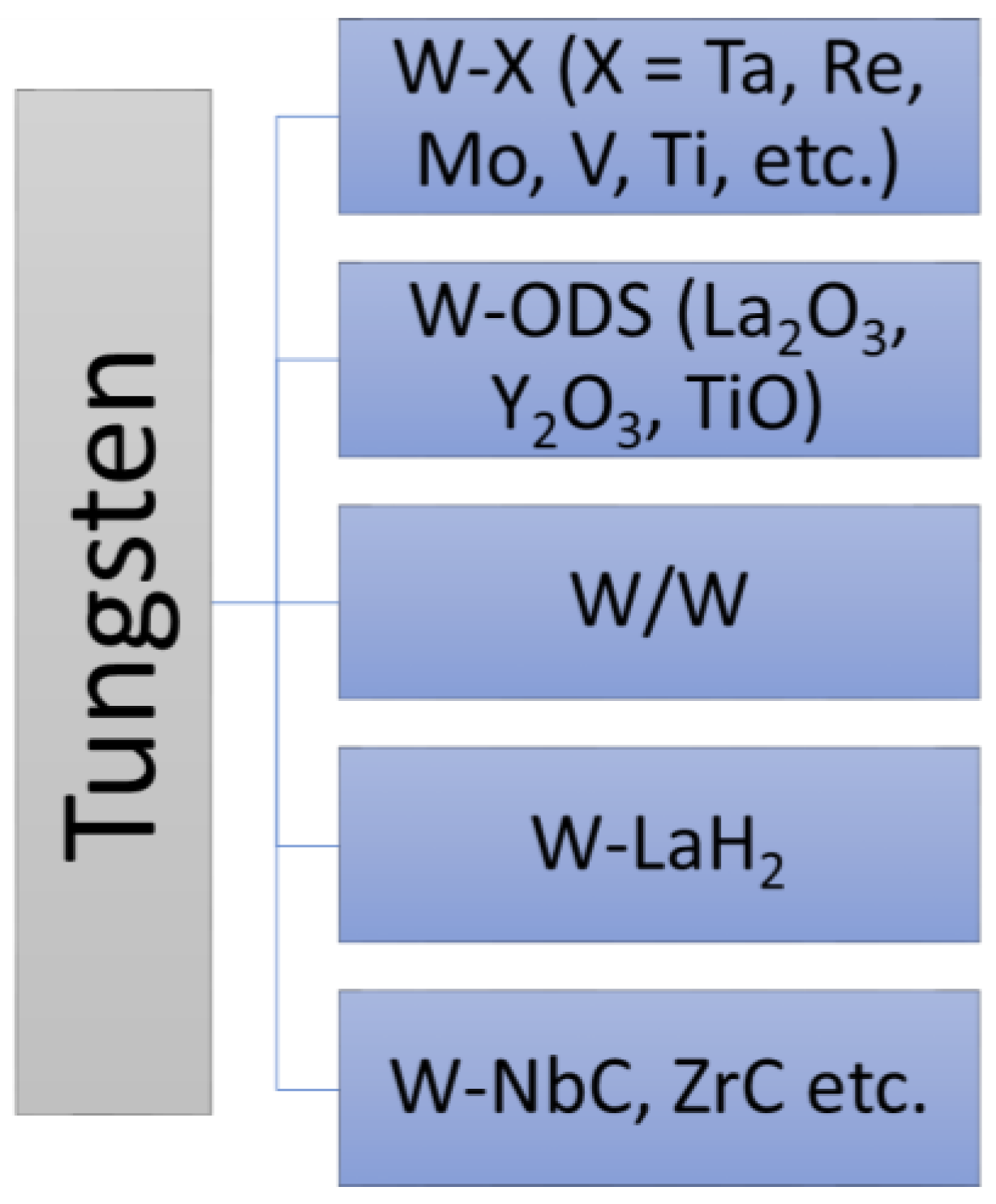

2. W-Based Materials

3. Plasma Spraying Technologies

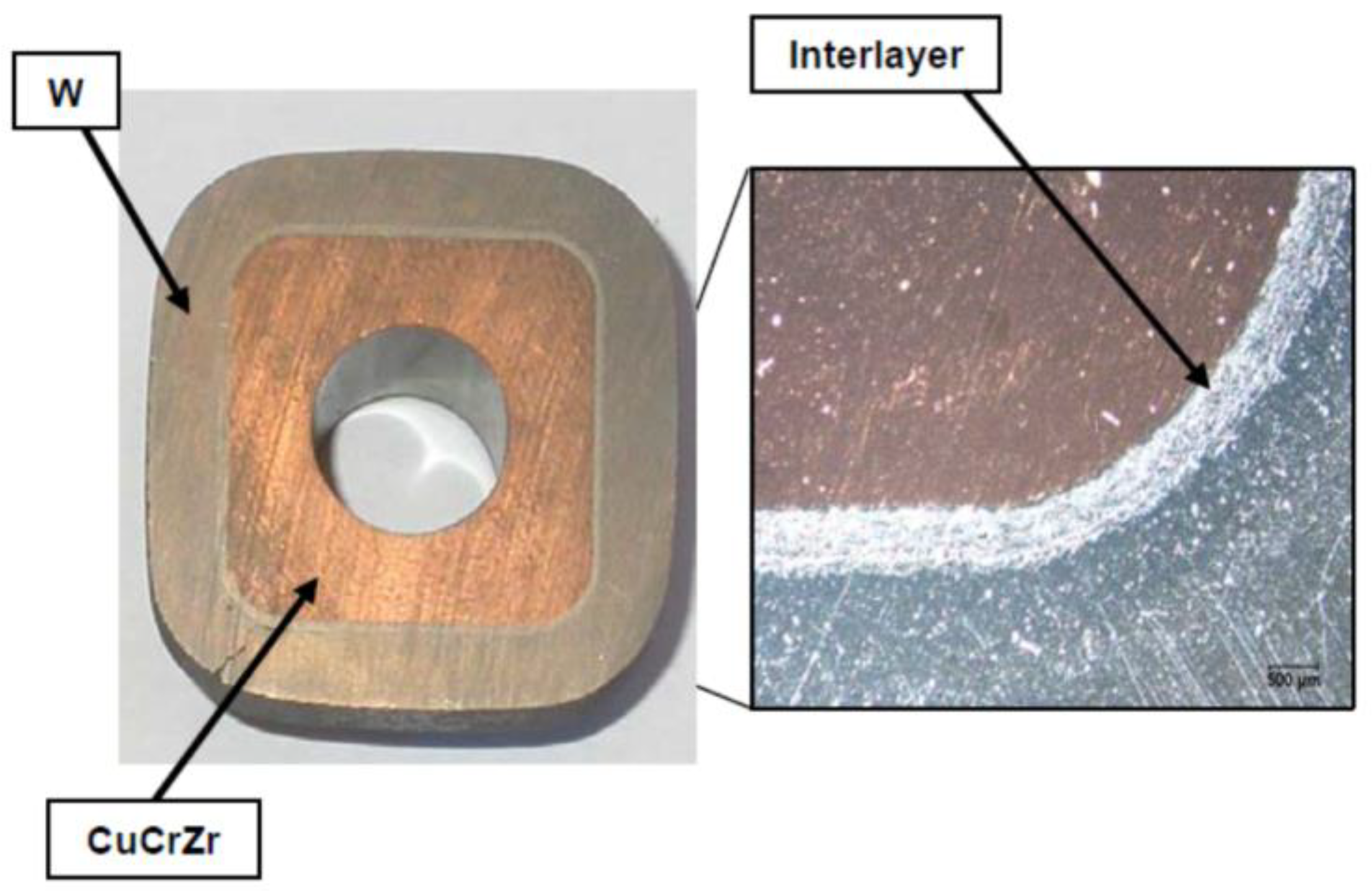

4. The Role of the Interface in Joining W Coating and Metallic Substrates

| Coating/Interlayer/Substrate | Young’s Modulus, GPa | Rs Substrate MPa | Rs Interlayer MPa | Rs Coating MPa | Measurement Method | Ref. |

|---|---|---|---|---|---|---|

| APS W (≈1.4 mm)/ FG W/Cu (≈1.2 mm)/ CuCrZr | 110 (Cu bulk) 400 (W bulk) | 60–86 | 103 (Cu) −273 (W) | −149 | XRD | [90] |

| APS W (≈1.4 mm)/ FG W/Cu (≈1.2 mm)/ CuCrZr | 86 (Cu in [96]) 270 (W in [96]) | N.A. | 23 (Cu) −115 (W) | N.A. | Nanoindentation | [91] |

| APS W (≈4 mm)/ Ni-Si-Al (≈800 µm)/ CuCrZr | 110 (Cu bulk) 190 (Ni bulk) 68 (Al bulk) 400 (W bulk) | 106 | 884 (Al) 285 (Ni) | 180 | XRD | [81] |

| APS W (≈3 mm)/ Al-12%Si/W (500 µm)/ AISI 316 | 200 (AISI 316) 68 (Al bulk) 400 (W bulk) | 1060 | 29 (Al) | 358 | XRD | [81] |

| APS W (≈3 mm), Al-12%Si/W (350 µm)/ AISI 420 | 200 (AISI 420) 68 (Al bulk) 400 (W bulk) | 690 | N.A. | −358 | XRD | [81] |

| APS W (≈1 mm)/ FG W/Cu/ Cu | - | 150 (prediction) | 300 | 180 (prediction) | In situ coating properties sensor | [96] |

| VPS W (350–900 µm)/ FG W/steel/ EUROFER97 | - | N.A. | −500 | −360 | Incremental hole drilling | [22] |

5. Coating Surface Erosion Under Steady-State and Transient Heat Loads

| Coating/Interlayer/Substrate | Parameters | Surface Damage | Measured Values | Ref. | |

|---|---|---|---|---|---|

| Electron Beam Irradiation | VPS-W (0.6 mm)/-/RAFM steel | 7.5 MW/m2 180 s | No modification | Tw = 700 °C Tsteel = 500 °C | [107] |

| 12 MW/m2 30 cycles: 60 s ON, 140 s OFF | Fine modification | Tw = 750 °C Tsteel = 350 °C | |||

| 40 MW/m2 30 cycles: 7 s ON, 230 s OFF | Cracks, exfoliation | Tw = 2100 °C Tsteel = 350 °C | |||

| VPS-W (1 mm)/-/RAFM steel brazed to OFHC cooling tube | 0.38–3.4 MW/m2 Ramp-up/plateau, ramp-down/rest 20/40/0 s | No modification | Tw = 350–1000 °C Tsteel = 50–250 °C TOFHC = 50–100 °C | [108] | |

| APS-W (1 mm)/-/RAFM steel brazed to OFHC cooling tube | Tw = 300–600 °C Tsteel = 50–350 °C TOFHC = 50–100 °C | ||||

| APS W (0.5 mm)/-/Cu | 0.4–2.0 GW/m2 0.2 ms, 25 pulses. | Remelting, recrystallization, impurities, precipitates, cracks | T = 3500 °C | [109] | |

| APS W (1.5 mm)/-/Cu | 3–8.5 MW/m2 | No modification | T = 520–880 °C | ||

| APS W (1 mm)/-/OFHC | 0.22–0.9 GW/m2 Pulse 5 ms | Micro-cracks, particle release, surface melting | Materials loss 28 mg | [110] | |

| APS W (0.7 mm)/FG W-Cu (0.3 mm)/OFHC | Materials loss 18 mg | ||||

| APS W (micron and submicron powder size)/-/Cu | 0.4–0.8 GW/m2 0.2 ms, 25 pulses | Remelting | T = 3500 °C Material loss 20–22 mg | [118] | |

| CVD W/-/Mo | Cracks, large internal stress | T = 1250 °C Material loss 1 mg | |||

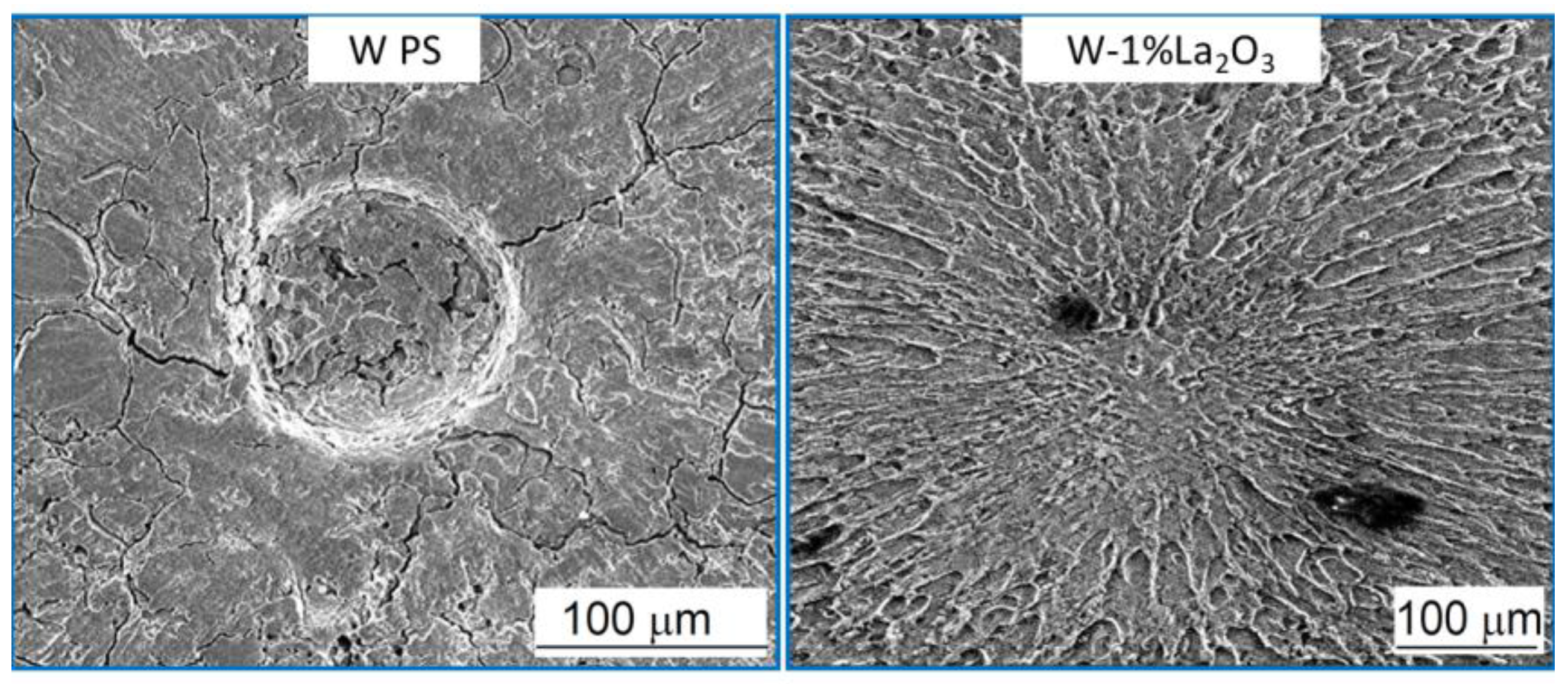

| Laser irradiation | Bulk W | 1.7 × 107 GW/m2 Pulse duration 15 ns Spot Ø 0.2 mm | Crater, ridge, plates with jagged boundaries and cracks, ablation sites from the pores | Material loss 0.37 × 105 µm3 Crater Ø 75 µm | [58,111,112] |

| APS W/FG W-Cu/CuCrZr | Material loss 0.33 × 105 µm3 Crater Ø 80 µm | ||||

| W-1%La2O3 bulk | Material loss 3.06 × 105 µm3 Crater Ø 300 µm | ||||

| Bulk Mo | Material loss 4.00 × 105 µm3 Crater Ø 300 µm | ||||

| Supersonic APS Pure W | 106–107 GW/m2 Traverse velocity 300 mm/min Spot Ø 2 mm | Remelting, cracks | N.A. | [114] | |

| Supersonic APS W doped with 1.5 wt% TiC | Remelting | ||||

| Pulsed plasma discharge | W bulk (ITER grade) | 1.5 MW/m2 0.2–0.6 ms, 10 pulses | Crack | N.A. | [115] |

| W-2%wt Ta alloy | Crack | ||||

| VPS-W/-/RAF/M steel | Remelting and crack formation | ||||

| Cold-worked bulk W/Mo/graphite | 4.3–5 MW/m2 pulse duration of 180–420 s | Recrystallization, bubbles, cracks | Recrystallization depth 1.7–3.0 mm | [116] | |

| APS W (0.3 mm)/Mo/graphite | Better resistance under long pulses |

6. Conclusions and Future Directions

- (i)

- The adhesion of plasma-sprayed W on metallic substrates can be successfully attained through the deposition of suitable interlayers, which could be either ductile alloys or FGMs made of W and substrate metal.

- (ii)

- Since ductile alloys often are made of elements which activate under neutron irradiation, the deposition of FGMs seems to be the most promising approach.

- (iii)

- Among plasma spraying methods, APS combined with post-processing by means of techniques such as vacuum annealing, friction stir processing, or electron beam remelting represents a valid alternative to VPS with lower costs and similar performances in terms of coating density, hardness, and thermal properties.

- (iv)

- Since erosion is the main cause of component damage and plasma contamination, the present results indicate that bulk W and PS-W are the best choice as PFMs because they exhibit lower erosion if compared to W-1%La2O3 and Mo. The PS W coatings exhibit excellent thermo-mechanical resistance under constant and cyclic heat loads and are even superior to that of bulk W under long pulses. The coating density, however, remains a crucial factor in determining the coating quality for this application.

- (i)

- Testing alternative interlayers using the APS technique, particularly the V interlayer, which has shown promising results. The same studies have revealed that the most effective results were achieved with samples featuring direct W-EUROFER joints. A more in-depth examination of this unexpected finding would be of significant interest.

- (ii)

- Recently, scaled-up mock-ups were successfully produced by VPS. The results are promising and show the potential of technology transferring to the industrial scale. The tests of scaled up fabrication via APS could be very interesting, taking into account the cost efficiency of this technology.

- (iii)

- Experiments were conducted on the WEST tokamak, with limited details available regarding the plasma-sprayed coated PFC, suggesting the need for more comprehensive research in this area.

- (iv)

- Simulations of VDE events with PS W would be highly beneficial for understanding the behavior of PS W-based coatings.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| APS | Atmosphere plasma spraying |

| CTE | Coefficient of thermal expansion |

| CVD | Chemical vapor deposition |

| DBTT | Ductile-to-brittle transition temperature |

| EBRT | Electron beam remelting treatments |

| ELM | Edge-localized modes |

| FEA | Finite element analysis |

| FEM | Finite element modeling |

| FG | Functionally graded |

| FGM | Functionally graded material |

| HIP | Hot isostatic pressing |

| ICP | In situ coating properties |

| MW | Micrometric tungsten |

| OFHC | Oxygen-free high-purity Copper |

| PFC | Plasma-facing components |

| PFM | Plasma-facing material |

| PS | Plasma spraying |

| PVD | Physical vapor deposition |

| RE | Rare earth |

| SAPS | Super atmospheric plasma spraying |

| SMW | Sub-micrometric tungsten |

| VDEs | Vertical displacement events |

| VPS | Vacuum plasma spraying |

| XRD | X-ray diffraction |

References

- Romanelli, F. Fusion energy. EPJ Web Conf. 2020, 246, 00013. [Google Scholar] [CrossRef]

- Romanelli, F.; Gelfusa, M. On the optimal mix of renewable energy sources, electrical energy storage and thermoelectric generation for the de-carbonization of the Italian electrical system. Eur. Phys. J. Plus 2020, 135, 72. [Google Scholar] [CrossRef]

- Kembleton, R. Nuclear fusion: What of the future? In Managing Global Warming; Academic Press: Cambridge, MA, USA, 2019; pp. 199–220. [Google Scholar]

- Federici, G.; Bachmann, C.; Barucca, L.; Baylard, C.; Biel, W.; Boccaccini, L.V.; Bustreo, C.; Ciattaglia, S.; Cismondi, F.; Corato, V.; et al. Overview of the DEMO staged design approach in Europe. Nucl. Fusion 2019, 59, 066013. [Google Scholar] [CrossRef]

- Peluso, E.; Pakhomova, E.; Gelfusa, M. New Challenges in Nuclear Fusion Reactors: From Data Analysis to Materials and Manufacturing. Appl. Sci. 2023, 13, 6240. [Google Scholar] [CrossRef]

- Linke, J.; Du, J.; Loewenhoff, T.; Pintsuk, G.; Spilker, B.; Steudel, I.; Wirtz, M. Challenges for Plasma-facing Components in Nuclear Fusion. Matter Radiat. Extrem. 2019, 4, 56201. [Google Scholar] [CrossRef]

- Hirai, T.; Panayotis, S.; Barabash, V.; Amzallag, C.; Escourbiac, F.; Durocher, A.; Merola, M.; Linke, J.; Loewenhoff, T.; Pintsuk, G. Use of Tungsten Material for the ITER Divertor. Nucl. Mater. Energy 2016, 9, 616–622. [Google Scholar] [CrossRef]

- You, J.H.; Visca, E.; Bachmann, C.; Barrett, T.; Crescenzi, F.; Fursdon, M.; Greuner, H.; Guilhem, D.; Languille, P.; Li, M. European DEMO Divertor Target: Operational Requirements and Material-design Interface. Nucl. Mater. Energy 2016, 9, 171–176. [Google Scholar] [CrossRef]

- De Temmerman, G.; Bystrov, K.; Zielinski, J.J.; Balden, M.; Matern, G.; Arnas, C.; Marot, L. Nanostructuring of Molybdenum and Tungsten Surfaces by Low-energy Helium Ions. J. Vac. Sci. Technol. A Vac. Surf. Film. 2012, 30, 41306. [Google Scholar] [CrossRef]

- Tripathi, J.K.; Novakowski, T.J.; Hassanein, A. Tailoring Molybdenum Nanostructure Evolution by Low-energy He+ Ion Irradiation. Appl. Surf. Sci. 2015, 353, 1070–1081. [Google Scholar] [CrossRef]

- Sinclair, G.; Tripathi, J.K.; Diwakar, P.K.; Hassanein, A. Structural Response of Transient Heat Loading on a Molybdenum Surface Exposed to Low-energy Helium Ion Irradiation. Nucl. Fusion 2016, 56, 036005. [Google Scholar] [CrossRef]

- Brooks, J.N.; El-Guebaly, L.; Hassanein, A.; Sizyuk, T. Plasma-facing Material Alternatives to Tungsten. Nucl. Fusion 2015, 55, 043002. [Google Scholar] [CrossRef]

- Sinclair, G.; Tripathi, J.K.; Diwakar, P.K.; Hassanein, A. Melt Layer Erosion During ELM-like Heat Loading on Molybdenum as an Alternative Plasma-facing Material. Sci. Rep. 2017, 7, 12273. [Google Scholar] [CrossRef] [PubMed]

- Sizyuk, T.; Hassanein, A. Dynamic Analysis and Evolution of Mixed Materials Bombarded with Multiple Ions Beams. J. Nucl. Mater. 2010, 404, 60–67. [Google Scholar] [CrossRef]

- Lu, S.; Jin, S.; Li, X.-C.; Zhang, Y.; Lu, G.-H. Hydrogen Behaviors in Molybdenum and Tungsten and a Generic Vacancy Trapping Mechanism for H Bubble Formation. J. Nucl. Mater. 2013, 434, 395–401. [Google Scholar] [CrossRef]

- Montanari, R.; Pakhomova, E.; Rossi, R.; Richetta, M.; Varone, A. Surface Morphological Features of Molybdenum Irradiated by a Single Laser Pulse. Coatings 2020, 10, 67. [Google Scholar] [CrossRef]

- Lipa, M.; Durocher, A.; Tivey, R.; Huber, T.; Schedler, B.; Weigert, J. The Use of Copper Alloy CuCrZr as a Structural Material for Actively Cooled Plasma Facing and in Vessel Components. Fusion Eng. Des. 2005, 75–79, 469–473. [Google Scholar] [CrossRef]

- Zhang, X.; Gong, Z.; Huang, J.; Yu, B. Thermal Shock Resistance of Tungsten with Various Deformation Degrees under Transient High Heat Flux. Mater. Res. Express 2020, 7, 066503. [Google Scholar] [CrossRef]

- Lian, Y.; Feng, F.; Wang, J.; Liu, X.; Song, J.; Wang, Y.; Chen, Z.; Chen, J. Effect of High Temperature Annealing on the Microstructure and Thermal Shock Resistance of Tungsten Coatings Grown by Chemical Vapor Deposition. J. Nucl. Mater. 2019, 513, 241–250. [Google Scholar] [CrossRef]

- Wirtz, M.; Linke, J.; Loewenhoff, T.; Pintsuk, G.; Uytdenhouwen, I. Thermal Shock Tests to Qualify Different Tungsten Grades as Plasma Facing Material. Phys. Scr. 2016, 2016, 014015. [Google Scholar] [CrossRef]

- Keller, T.; Litnovsky, A.; Mauer, G.; Linsmeier, C.; Guillon, O. Innovative Tungsten Coatings for an Application in Modern and Future Fusion Devices. Metals 2023, 13, 531. [Google Scholar] [CrossRef]

- Vaßen, R.; Rauwald, K.-H.; Guillon, O.; Aktaa, J.; Weber, T.; Back, H.C.; Qu, D.; Gibmeier, J. Vacuum Plasma Spraying of Functionally Graded Tungsten/EUROFER97 Coatings for Fusion Applications. Fusion Eng. Des. 2018, 133, 148–156. [Google Scholar] [CrossRef]

- Bang, E.; Choi, H.; Kim, H.C.; Kim, K.; Hong, S.-H. Manufacturing and Testing of Flat Type W/Cu/CuCrZr Mock-ups by HIP Process with PVD Coating. Fusion Eng. Des. 2019, 146, 603–608. [Google Scholar] [CrossRef]

- Lian, Y.; Liu, X.; Wang, J.; Feng, F.; Lv, Y.; Song, J.; Chen, J. Influence of Surface Morphology and Microstructure on Performance of CVD Tungsten Coating Under Fusion Transient Thermal Loads. Appl. Surf. Sci. 2016, 390, 167–174. [Google Scholar] [CrossRef]

- Piskarev, P.Y.; Rulev, R.V.; Mazul, I.V.; Krasilnikov, A.V.; Pisarev, A.A.; Kuteev, B.V.; Kolesnik, M.S.; Dushik, V.V.; Bobrov, S.V.; Montak, N.V.; et al. Coatings on a First Wall Plasma-Facing Surface: Analysis and High Heat Flux Testing on the Tsefey-M E-Beam Facility. Phys. Atom. Nucl. 2024, 87, S118–S128. [Google Scholar] [CrossRef]

- Jackson, M.; Bunting, P.; Lee, V.; Vishnyakov, V.; Bradley, J.W.; Ali, Z.; Thornley, S.; Dutson, J.; Cox, D.; Zhuk, Y.; et al. The Erosion of selected tungsten coatings by ion beam and plasma sources compared to calculated predictions. Fusion Eng. Des. 2023, 192, 113781. [Google Scholar] [CrossRef]

- Matějíček, J.; Dejarnac, R.; Ruset, C.; Grigore, E.; Cvrček, L.; Walter, J.; Perry, F. Development of tungsten coatings on Inconel superalloy for COMPASS upgrade plasma-facing components. Nucl. Mater. Energy 2025, 42, 101844. [Google Scholar] [CrossRef]

- Riccardi, B.; Pizzuto, A.; Orsini, A.; Libera, S.; Visca, E.; Bertamini, L.; Casadei, F.; Severini, E.; Montanari, R.; Vesprini, R.; et al. Tungsten thick coatings for plasma facing components. Fusion Technol. 1998, 1, 223. [Google Scholar]

- Montanari, R.; Riccardi, B.; Volterri, R.; Bertamini, L. Characterisation of Plasma Sprayed W Coatings on a CuCrZr Alloy for Nuclear Fusion Reactor Applications. Mater. Lett. 2002, 52, 100–105. [Google Scholar] [CrossRef]

- Riccardi, B.; Montanari, R.; Casadei, M.; Costanza, G.; Filacchioni, G.; Moriani, A. Optimisation and Characterisation of Tungsten Thick Coatings on Copper Based Alloy Substrates. J. Nucl. Mater. 2006, 352, 29–35. [Google Scholar] [CrossRef]

- Xu, D.; Cheng, J.; Chen, P.; Fu, K.; Wei, B.; Chen, R.; Luo, L.; Xu, Q. Recent progress in research on bonding technologies of W/Cu monoblocks as the divertor for nuclear fusion reactors. Nucl. Mater. Energy 2023, 36, 101482. [Google Scholar] [CrossRef]

- Balijepalli, S.K.; Kaciulis, S.; Maddaluno, G.; Montanari, R. Micro-chemical investigation of thick W coating on AISI 420 martensitic steel. Surf. Interface Anal. 2014, 46, 873–876. [Google Scholar] [CrossRef]

- Costanza, G.; Donnini, R.; Kaciulis, S.; Maddaluno, G.; Montanari, R. HT-XRD analysis of W thick coatings for nuclear fusion technology. Key Eng. Mater. 2014, 605, 31–34. [Google Scholar]

- Waseem, O.A.; Ryu, H.J. Nuclear Material Performance; IntechOpen: Rijeka, Croatia, 2016. [Google Scholar] [CrossRef]

- Luo, C.; Xu, L.; Zong, L.; Shen, H.; Wei, S. Research Status of Tungsten-based Plasma-facing Materials: A Review. Fusion Eng. Des. 2023, 190, 113487. [Google Scholar] [CrossRef]

- Uytdenhouwen, I.; Massaut, V.; Linke, J.; Van Oost, G. Plasma Wall Interaction Phenomena on Tungsten Armour Materials for Fusion Applications. In Proceedings of the International Youth Nuclear Congress, Interlaken, Switzerland, 20–26 September 2008. [Google Scholar]

- Gaudio, P.; Montanari, R.; Pakhomova, E.; Richetta, M.; Varone, A. W-1% La2O3 Submitted to a Single Laser Pulse: Effect of Particles on Heat Transfer and Surface Morphology. Metals 2018, 8, 389. [Google Scholar] [CrossRef]

- Sun, M.; Wang, M.; Xi, X.; Nie, Z. Synergistical Improvement in Toughness and Strength of Multi-Doped W-Hf-Y2O3 Alloy via Formation of Complex Oxide Particles. Int. J. Refract. Metals Hard Mater. 2024, 124, 106823. [Google Scholar] [CrossRef]

- Ye, J.; Xu, L.; Zhao, Y.; Li, Z.; Yu, H.; Wei, S.; Shen, H. DBTT and Tensile Properties of As-Sintered Tungsten Alloys Reinforced by Yttrium-Zirconium Oxide. J. Nucl. Mater. 2023, 578, 154318. [Google Scholar] [CrossRef]

- Yuan, Y.; Xu, B.; Fu, B.Q.; Greuner, H.; Boswirth, B.; Xu, H.Y.; Li, C.; Jia, Y.Z.; Qu, S.L.; Luo, G.N.; et al. Suppression of cavitation in melted tungsten by doping with lanthanum oxide. Nucl. Fusion 2014, 54, 083026. [Google Scholar] [CrossRef]

- Kaciulis, S.; Mezzi, A.; Montanari, R.; Richetta, M.; Pakhomova, E.; Varone, A. La Distribution on the Crater Surface of W-1%La2O3 Produced by a Single Laser Pulse. Surf. Interface Anal. 2020, 52, 1093–1097. [Google Scholar] [CrossRef]

- Lee, Y.J.; Sung, H.M.; Jin, Y.; Lee, K.; Park, C.R.; Kim, G.H.; Han, H.N. Improvement of Mechanical Property of Air Plasma Sprayed Tungsten Film Using Pulsed Electric Current Treatment. Int. J. Refract. Met. Hard Mater. 2016, 60, 99–103. [Google Scholar] [CrossRef]

- Park, J.Y.; Yang, S.J.; Jin, Y.G.; Park, C.R.; Kim, G.H.; Han, H.N. Effect of Annealing with Pressure on Tungsten Film Properties Fabricated by Atmospheric Plasma Spray. Met. Mater. Int. 2014, 20, 1037–1042. [Google Scholar] [CrossRef]

- Jianjun, H.; Xinjun, L.; Jun, C.; Ying, L.; Bing, Q.; Shishou, J.; Xisheng, W.; Guangnan, L. Vacuum Annealing Enhances the Properties of a Tungsten Coating Deposited on Copper by Atmospheric Plasma Spray. J. Nucl. Mater. 2013, 432, 16–19. [Google Scholar] [CrossRef]

- Hou, Q.Y.; Luo, L.M.; Huang, Z.Y.; Wang, P.; Ding, T.T.; Wu, Y.C. Lanthanum Hydride Doped Tungsten-based Coating Fabricated by Supersonic Atmospheric Plasma Spraying. Surf. Coat. Technol. 2016, 299, 153–161. [Google Scholar] [CrossRef]

- Hou, Q.Y.; Luo, L.M.; Huang, Z.Y.; Wang, P.; Ding, T.T.; Wu, Y.C. Influence of LaH2 on Oxidation Characteristics and Irradiation Melting Characteristics of a Tungsten Coating Fabricated by Atmospheric Plasma Spraying. Surf. Coat. Technol. 2016, 299, 143–152. [Google Scholar] [CrossRef]

- Hou, Q.Y.; Huang, H.Q.; Zhou, D.H.; Wang, P.; Xie, Q.; Huang, Z.Y. Influence of NbC-doping on the Microstructure and Thermo-mechanical Properties of Tungsten Coating Fabricated by Supersonic Atmospheric Plasma Spraying. Surf. Coat. Technol. 2020, 394, 125823. [Google Scholar] [CrossRef]

- Wu, Z.; Li, Q.; Yang, X. Research and Development of Nanocrystalline W/W-based Materials: Novel Preparation Approaches, Formation Mechanisms, and Unprecedented Excellent Properties. Front. Mater. Sci. 2023, 17, 230634. [Google Scholar] [CrossRef]

- Xu, H.; He, L.L.; Pei, Y.F.; Jiang, C.Z.; Li, W.Q.; Xiao, X.H. Recent Progress of Radiation Response in Nanostructured Tungsten for Nuclear Application. Tungsten 2021, 3, 20–37. [Google Scholar] [CrossRef]

- Dias, M.; Guerreiro, F.; Correia, J.B.; Galatanu, A.; Rosiński, M.; Monge, M.A.; Munoz, A.; Alves, E.; Carvalho, P.A. Consolidation of W–Ta Composites: Hot Isostatic Pressing and Spark and Pulse Plasma Sintering. Fusion Eng. Des. 2015, 98–99, 1950–1955. [Google Scholar] [CrossRef]

- Xianliang, J.; Gitzhofer, F.; Boulos, M.I. Thermal Spray Coating of Tungsten for Tokamak Device. Plasma Sci. Technol. 2006, 8, 164. [Google Scholar] [CrossRef]

- Fali, C.; Chen, J.; Li, J.; Zheng, X.; Ding, C. Thermal Performance Study of VPS-W Coatings on CuCrZr Under High Heat Fluxplasma. Sci. Technol. 2007, 9, 261. [Google Scholar]

- Tokunaga, T.; Watanabe, H.; Yoshida, N.; Nagasaka, T.; Kasada, R.; Lee, Y.J.; Kimura, A.; Tokitani, M.; Mitsuhara, M.; Hinoki, T. Development of High-grade VPS-tungsten Coatings on F82H Reduced Activation Steel. J. Nucl. Mater. 2013, 442, S287–S291. [Google Scholar] [CrossRef]

- Fali, C.; Junling, C. Property Comparison of Vacuum and Air Plasma Sprayed Tungsten Coatings. J. Alloys Compd. 2021, 861, 158422. [Google Scholar] [CrossRef]

- Niu, Y.; Lu, D.; Huang, L.; Zhao, J.; Zheng, X.; Chen, G. Comparison of W–Cu Composite Coatings Fabricated by Atmospheric and Vacuum Plasma Spray Processes. Vacuum 2015, 117, 98–103. [Google Scholar] [CrossRef]

- Wu, X.; Kondo, S.; Yu, H.; Nagasaka, T.; Kasada, R. Mechanical Properties of the W Coating and Interface of Vacuum-Plasma-Sprayed W–Ferritic Steel Joints under Shear and Bending Loads. Surf. Coat. Technol. 2023, 462, 129468. [Google Scholar] [CrossRef]

- Heuer, S.; Matějíček, J.; Vilémová, M.; Koller, M.; Illkova, K.; Veverka, J.; Weber, T.; Pintsuk, G.; Coenen, J.W.; Linsmeier, C. Atmospheric Plasma Spraying of Functionally Graded Steel/tungsten Layers for the First Wall of Future Fusion Reactors. Surf. Coat. Technol. 2019, 366, 170–178. [Google Scholar] [CrossRef]

- Montanari, R.; Pakhomova, E.; Pizzoferrato, R.; Richetta, M.; Varone, A. Laser Pulse Effects on Plasma Sprayed and Bulk Tungsten. Metals 2017, 7, 454. [Google Scholar] [CrossRef]

- Matějíček, J.; Vilémová, M.; Nevrlá, B.; Kocmanová, L.; Veverka, J.; Halasová, M.; Hadraba, H. The Influence of Substrate Temperature and Spraying Distance on the Properties of Plasma Sprayed Tungsten and Steel Coatings Deposited in a Shrouding Chamber. Surf. Coat. Technol. 2017, 318, 217–223. [Google Scholar] [CrossRef]

- Heuer, S.; Coenen, J.W.; Pintsuk, G.; Matějíček, J.; Vilémová, M.; Linsmeier, C. Overview of Challenges and Developments in Joining Tungsten and Steel for Future Fusion Reactors. Phys. Scr. 2020, 2020, 014028. [Google Scholar] [CrossRef]

- Matějíček, J.; Iždinský, K.; Vondrouš, P. Methods of Increasing Thermal Conductivity of Plasma Sprayed Tungsten-based Coatings. Adv. Mater. Res. 2008, 59, 82–86. [Google Scholar]

- Qu, D.; Zhou, Z.; Tan, J.; Aktaa, J. Characterization of W/Fe Functionally Graded Materials Manufactured by Resistance Sintering Under Ultra-high Pressure. Fusion Eng. Des. 2015, 91, 21–24. [Google Scholar] [CrossRef]

- Wang, F.; Luo, G.-N.; Huang, J.; Liu, Y. Properties Improvement of Atmospheric Plasma Sprayed Tungsten Coating by Annealing. Surf. Coat. Technol. 2019, 358, 276–281. [Google Scholar] [CrossRef]

- Ajdari, S.; Shahriari Nogorani, F. The Effect of Vacuum Annealing, Cold Isostatic Pressing, and Hydrogen Annealing on the Microstructure of Atmospheric Plasma Sprayed Tungsten Coating. Vacuum 2020, 175, 109287. [Google Scholar] [CrossRef]

- Daram, P.; Morisada, Y.; Ogura, T.; Kusano, M.; Yu, J.; Fukuda, M.; Fujii, H.; Kuroda, S.; Watanabe, M. Development of Tungsten Repair Technology by Atmospheric Plasma Spraying of Tungsten and Friction Stir Processing. J. Therm. Spray Technol. 2024, 33, 1840–1850. [Google Scholar] [CrossRef]

- Liao, W.B.; Liu, Z.Y.; He, M.J.; Feng, C.; Wang, F.; Huang, J. Effect of Electron Beam Remelting Treatments on the Microstructure and Properties of Atmospheric Plasma Sprayed Tungsten Coatings. J. Therm. Spray Technol. 2021, 30, 2128–2137. [Google Scholar] [CrossRef]

- Wang, F.; Huang, J. Performance Characterization and Improvement of Tungsten Coating Atmospheric Plasma Sprayed with Submicron Powder. Surf. Coat. Technol. 2014, 254, 61–64. [Google Scholar] [CrossRef]

- Matějíček, J.; Kavka, T.; Mušálek, R.; Ctibor, P.; Medřický, J.; Vilémová, M.; Nevrlá, B.; Degot, S.; Denoirjean, A. Tungsten-steel Composites and FGMs Prepared by Argon-shrouded Plasma Spraying. Surf. Coat. Technol. 2021, 406, 126746. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, X.; Wang, F.; Qiu, Y.; Yu, C.; Liu, Y.; Wang, S.; Liao, W.; Huang, J. Improved Structure and Enhanced Properties of Detonation Sprayed W Coating via Hot Isostatic Pressing. Surf. Coat. Technol. 2024, 485, 130903. [Google Scholar] [CrossRef]

- Maier, H.; Neu, R.; Greuner, H.; Böswirth, B.; Balden, M.; Lindig, S.; Matthews, G.F.; Rasinski, M.; Wienhold, P.; Wiltner, A. Qualification of Tungsten Coatings on Plasma-facing Components for JET. Phys. Scr. 2009, 2009, 014031. [Google Scholar] [CrossRef]

- Matějíček, J.; Chráska, P.; Linke, J. Thermal Spray Coatings for Fusion Applications—Review. J. Therm. Spray Technol. 2007, 16, 64–83. [Google Scholar] [CrossRef]

- Matějíček, J.; Koza, Y.; Weinzettl, V. Plasma Sprayed Tungsten-based Coatings and Their Performance Under Fusion Relevant Conditions. Fusion Eng. Des. 2005, 75–79, 395–399. [Google Scholar] [CrossRef]

- Heuer, S.; Weber, T.; Pintsuk, G.; Coenen, J.W.; Matejicek, J.; Linsmeier, C. Aiming at Understanding Thermo-mechanical Loads in the First Wall of DEMO: Stress–strain Evolution in a Eurofer-Tungsten Test Component Featuring a Functionally Graded Interlayer. Fusion Eng. Des. 2018, 135, 141–153. [Google Scholar] [CrossRef]

- Weber, T.; Stüber, M.; Ulrich, S.; Vaßen, R.; Basuki, W.W.; Lohmiller, J.; Sittel, W.; Aktaa, J. Functionally Graded Vacuum Plasma Sprayed and Magnetron Sputtered Tungsten/Eurofer97 Interlayers for Joints in Helium-cooled Divertor Components. J. Nucl. Mater. 2013, 436, 29–39. [Google Scholar] [CrossRef]

- Matějíček, J.; Vilémová, M.; Mušálek, R.; Sachr, P.; Horník, J. The Influence of Interface Characteristics on the Adhesion/cohesion of Plasma Sprayed Tungsten Coatings. Coatings 2013, 3, 108–125. [Google Scholar] [CrossRef]

- Mellali, M.; Fauchais, P.; Grimaud, A. Influence of Substrate Roughness and Temperature on the Adhesion/cohesion of Alumina Coatings. Surf. Coat. Technol. 1996, 81, 275–286. [Google Scholar] [CrossRef]

- Li, L.; Wang, X.Y.; Wei, G.; Vaidya, A.; Zhang, H.; Sampath, S. Substrate melting during thermal spray splat quenching. Thin Solid Films 2004, 468, 113–119. [Google Scholar] [CrossRef]

- Pershin, V.; Lufitha, M.; Chandra, S.; Mostaghimi, J. Effect of Substrate Temperature on Adhesion Strength of Plasma-Sprayed Nickel Coatings. J. Therm. Spray Technol. 2003, 12, 370–376. [Google Scholar] [CrossRef]

- Heidarinejad, A.; Ashrafizadeh, F. Influence of Surface Texture and Coating Thickness on Adhesion of Nickel Plated Coatings to Aluminium Substrate. J. Manuf. Processes 2024, 120, 35–448. [Google Scholar] [CrossRef]

- Riccardi, B.; Pizzuto, A.; Bertamini, L.; Diotalevi, M.; Vieider, G. Development of Tungsten Coatings for ITER Divertor Components. In Proceedings of the 16th IEEE/NPSS Symposium on Fusion Engineering, San Diego, CA, USA, 6–10 October 1997. [Google Scholar]

- Ciambella, L.; Maddaluno, G.; Montanari, R.; Pakhomova, E. Residual Stresses in Tungsten Deposited by Plasma; Spraying: Effect of Substrate and Processing Methods. Metall. Ital. 2015, 107, 31–39. [Google Scholar]

- Riccardi, B.; Montanari, R.; Moreschi, L.F.; Sili, A.; Storai, S. Mechanical Characterisation of Fusion Materials by Indentation Test. Fusion Eng. Des. 2001, 58–59, 755–759. [Google Scholar] [CrossRef]

- Montanari, R.; Varone, A. Flat-Top Cylinder Indenter for Mechanical Characterization: A Report of Industrial Applications. Materials 2021, 14, 1742. [Google Scholar] [CrossRef]

- Niu, Y.; Hu, D.; Ji, H.; Huang, L.; Zheng, X. Effect of Bond Coatings on Properties of Vacuum Plasma Sprayed Tungsten Coatings on Copper Alloy Substrate. Fusion Eng. Des. 2011, 86, 307–311. [Google Scholar] [CrossRef]

- Zhang, H.; Leygraf, C.; Wen, L.; Huang, F.; Chang, H.; Jin, Y. The Formation of Hydride and Its Influence on Ti–6Al–4V Alloy Fracture Behavior. Int. J. Hydrogen Energy 2023, 48, 36169–36184. [Google Scholar] [CrossRef]

- Briant, C.L.; Wang, Z.F.; Chollocoop, N. Hydrogen Embrittlement of Commercial Purity Titanium. Corros. Sci. 2002, 44, 1875–1888. [Google Scholar] [CrossRef]

- Wójcik-Gargula, A.; Rubel, M.; Batistoni, P.; Bekris, N.; Colling, B.; Dutkiewicz, E.; Laas, T.; Nobs, C.R.; Paju, J.; Packer, L.W.; et al. Studies on the Behaviour of Titanium Activation Foils During Long-Term Exposure at the JET Tokamak. Fusion Eng. Des. 2022, 177, 113056. [Google Scholar] [CrossRef]

- Cho, G.S.; Choe, K.H. Characterization of Plasma-sprayed Tungsten Coating on Graphite with Intermediate Layers. Surf. Coat. Technol. 2012, 209, 131–136. [Google Scholar] [CrossRef]

- Matějíček, J.; Nevrlá, B.; Vilémová, M.; Boldyryeva, H. Overview of Processing Technologies for Tungsten-steel Composites and FGMs for Fusion Applications. Nukleonika 2015, 60, 267–273. [Google Scholar] [CrossRef]

- Fava, A.; Pakhomova, E.; Varone, A. Study of Residual Stresses Through X-ray Diffraction of a W/Cu Interlayer Deposited by Plasma Spraying. Metall. Ital. 2020, 112, 16–25. [Google Scholar]

- Cabibbo, M.; Fava, A.; Montanari, R.; Pakhomova, E.; Paoletti, C.; Richetta, M.; Varone, A. Residual Stresses in the Graded Interlayer Between W and CuCrZr Alloy. J. Mater. Sci. 2022, 57, 285–298. [Google Scholar] [CrossRef]

- Ganne, T.; Crépin, J.; Serror, S.; Zaoui, A. Cracking Behaviour of PVD Tungsten Coatings Deposited on Steel Substrates. Acta Mater. 2002, 50, 4149–4163. [Google Scholar] [CrossRef]

- Cabibbo, M.; Fava, A.; Montanari, R.; Pakhomova, E.; Paoletti, C.; Richetta, M.; Varone, A. Grain Orientation and Hardness in the Graded Interlayer of Plasma Sprayed W on CuCrZr. Appl. Sci. 2022, 12, 1822. [Google Scholar] [CrossRef]

- Yu, H.; Das, S.; Yu, H.; Karamched, P.; Tarleton, E.; Hofmann, F. Orientation Dependence of the Nano-indentation Behaviour of Pure Tungsten. Scr. Mater. 2020, 189, 135–139. [Google Scholar] [CrossRef]

- Kucharski, S.; Jarząbek, D. Depth Dependence of Nanoindentation Pile-up Patterns in Copper Single Crystals. Metall. Mater. Trans. A 2014, 45, 4997–5008. [Google Scholar] [CrossRef]

- Matějíček, J.; Mušálek, R.; Veverka, J. Materials and Processing Factors Influencing Stress Evolution and Mechanical Properties of Plasma Sprayed Coatings. Surf. Coat. Technol. 2019, 371, 3–13. [Google Scholar] [CrossRef]

- Chong, F. Optimization of Plasma-sprayed Tungsten Coating on Copper with the Heterogeneous Compliant Layer for Fusion Application. J. Therm. Spray Technol. 2013, 22, 57–60. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, D.; He, C.; Guo, Z.; Wang, Y.; Xuan, C.; Wang, B.; Chen, J. Thermomechanical Analysis for the Theoretical Optimization of W/Cu Monoblocks with Functionally Graded Interlayer. Nucl. Mater. Energy 2025, 43, 101919. [Google Scholar] [CrossRef]

- Matějíček, J.; Boldyryeva, H. Processing and Temperature-dependent Properties of Plasma-sprayed Tungsten–stainless Steel Composites. Phys. Scr. 2009, 2009, 014041. [Google Scholar] [CrossRef]

- Casalegno, V.; Perero, S.; Girman, V.; Sedlák, R.; Scarpellini, A.; Drow-Gerspach, D.; Heuer, S.; Ferraris, M. W/Fe Co-sputtered Layers for Tungsten to Steel Joints. Nucl. Mater. Energy 2023, 35, 101421. [Google Scholar] [CrossRef]

- Heuer, S.; Lienig, T.; Mohr, A.; Weber, T.; Pintsuk, G.; Coenen, J.W.; Gormann, F.; Theisen, W.; Linsmeier, C. Ultra-fast Sintered Functionally Graded Fe/W Composites for the First Wall of Future Fusion Reactors. Compos. Part B Eng. 2019, 164, 205–214. [Google Scholar] [CrossRef]

- Tanigawa, H.; Gaganidze, E.; Hirose, T.; Ando, M.; Zinkle, S.J.; Lindau, R.; Diegele, E. Development of Benchmark Reduced Activation Ferritic/Martensitic Steels for Fusion Energy Applications. Nucl. Fusion 2017, 57, 092004. [Google Scholar] [CrossRef]

- Qu, D.D.; Basuki, W.W.; Aktaa, J. Numerical Assessment of Functionally Graded Tungsten/Eurofer Coating System for First Wall Applications. Fusion Eng. Des. 2015, 98–99, 1389–1393. [Google Scholar] [CrossRef]

- Emmerich, T.; Qu, D.; Vaßen, R.; Aktaa, J. Development of W-coating with Functionally Graded W/EUROFER-layers for Protection of First-wall Materials. Fusion Eng. Des. 2018, 128, 58–67. [Google Scholar] [CrossRef]

- Dose, G.; Roccella, S.; Romanelli, F. Engineering of a FGM Interlayer to Reduce the Thermal Stresses Inside the PFCs. Appl. Sci. 2022, 12, 10215. [Google Scholar] [CrossRef]

- Grammes, T.; Kumar Mishra, A.; Battalov, K.; Purwitasari, A.; Emmerich, T.; Aktaa, J. Mechanical Properties and Quality of Plasma Sprayed, Functionally Graded Tungsten/Steel Coatings After Process Upscaling. Mater. Chem. Phys. 2024, 311, 128530. [Google Scholar] [CrossRef]

- Tokunaga, K.; Hotta, T.; Araki, K.; Miyamoto, Y.; Fujiwara, T.; Hasegawa, M.; Nakamura, K.; Ezato, K.; Suzuki, S.; Enoeda, M. High Heat Loading Properties of Vacuum Plasma Spray Tungsten Coatings on Reduced Activation Ferritic/martensitic Steel. J. Nucl. Mater. 2013, 438, S905–S908. [Google Scholar] [CrossRef]

- Tokunaga, K.; Hotta, T.; Araki, K.; Kurumada, A.; Tokitani, M.; Masuzaki, S.; Ezato, K.; Suzuki, S.; Enoeda, M.; Akiba, M. Heat Loading Behavior and Thermomechanical Analyses on Plasma Spray Tungsten Coated Reduced-activation Ferritic/martensitic Steel. Fusion Eng. Des. 2018, 136, 1624–1628. [Google Scholar] [CrossRef]

- Wang, F.; Luo, G.-N.; Huang, J. Transient and Steady State High Heat Load Testing of Atmospheric Plasma Sprayed Tungsten. Fusion Eng. Des. 2020, 152, 111427. [Google Scholar] [CrossRef]

- Zhou, Z.; Song, S.; Yao, W.; Pintsuk, G.; Linke, J.; Guo, S.; Ge, C. Fabrication of Thick W Coatings by Atmospheric Plasma Spraying and Their Transient High Heat Loading Performance. Fusion Eng. Des. 2010, 85, 1720–1723. [Google Scholar] [CrossRef]

- Richetta, M.; Gaudio, P.; Montanari, R.; Pakhomova, E.; Antonelli, L. Laser Pulse Simulation of High Energy Transient Thermal Loads on Bulk and Plasma Sprayed W for NFR. Mater. Sci. Forum 2016, 879, 1576–1581. [Google Scholar]

- Pakhomova, E.; Gaudio, P.; Montanari, R.; Richetta, M.; Varone, A. Physical Simulation of Plasma-refractory Metals Interaction for Nuclear Applications. Simulazione fisica dell’interazione plasma-metalli refrattari per applicazioni nucleari. Metall. Ital. 2021, 113, 6–12. [Google Scholar]

- Varone, A.; Gaudio, P.; Ferro, P.; Montanari, R.; Pakhomova, E.; Richetta, M.; Rossi, R. Damage Effects of High-Intensity Laser Pulse on W for Fusion Applications: Modelling and Experiments. Mater. Today Commun. 2023, 35, 105961. [Google Scholar] [CrossRef]

- Hou, Q.; Ma, X.; Lu, R.; Wang, W.; Wang, P.; Huang, Z. Microstructure and Laser Irradiation Characteristics of TiC-free and TiC-doped Tungsten-based Coatings Prepared by Supersonic Atmospheric Plasma Spraying. Surf. Coat. Technol. 2019, 358, 796–805. [Google Scholar] [CrossRef]

- Kikuchi, Y.; Sakuma, I.; Iwamoto, D.; Kitagawa, Y.; Fukumoto, N.; Nagata, M.; Ueda, Y. Surface Cracking and Melting of Different Tungsten Grades Under Transient Heat and Particle Loads in a Magnetized Coaxial Plasma Gun. J. Nucl. Mater. 2013, 438, S715–S718. [Google Scholar] [CrossRef]

- Kim, H.S.; Lim, S.T.; Jin, Y.; Lee, J.Y.; Song, J.-M.; Kim, G.H. Recrystallization of Bulk and Plasma-coated Tungsten with Accumulated Thermal Energy Relevant to Type-I ELM in ITER H-mode Operation. J. Nucl. Mater. 2015, 463, 215–218. [Google Scholar] [CrossRef]

- Lang, P.T.; Loarte, A.; Saibene, G.; Baylor, L.R.; Becoulet, M.; Cavinato, M.; Clement-Lorenzo, S.; Daly, E.; Evans, T.E.; Fenstermacher, M.E.; et al. ELM control strategies and tools: Status and potential for ITER. Nucl. Fusion 2013, 53, 043004. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, G.; Wang, F.; Ru, L.; Wan, S.; Xiao, J.; Luo, G. Transient High Heat Load Tests on Tungsten Coating by High-intensity Current Pulsed Electron Beam. J. Nucl. Mater. 2014, 455, 412–415. [Google Scholar] [CrossRef]

- Richou, M.; Gallay, F.; Böswirth, B.; Chu, I.; Dose, G.; Greuner, H.; Kermouche, G.; Lenci, M.; Loewenhoff, T.; Wirtz, M. Performance Assessment of High Heat Flux W Monoblock Type Target Using Thin Graded and Copper Interlayers for Application to DEMO Divertor. Fusion Eng. Des. 2019, 146, 858–861. [Google Scholar] [CrossRef]

- Hamaji, Y.; Lee, H.T.; Kreter, A.; Möller, S.; Rasinski, M.; Tokitani, M.; Masuzaki, S.; Sagara, A.; Oya, M.; Ibano, K. Damage and Deuterium Retention of Re-solidified Tungsten Following Vertical Displacement Event-like Heat Load. Nucl. Mater. Energy 2017, 12, 1303–1307. [Google Scholar] [CrossRef]

- Dorow-Gerspach, D.; Bram, M.; Ganesh, V.; Matějíček, J.; Pintsuk, G.; Vilemova, M.; Wirtz, M.; Linsmeier, C. Benchmarking by High Heat Flux Testing of W-Steel Joining Technologies. Nucl. Mater. Energy 2023, 37, 101508. [Google Scholar] [CrossRef]

- Diez, M.; Corre, Y.; Delmas, E.; Fedorczak, N.; Firdaouss, M.; Grosjean, A.; Gunn, J.P.; Loarer, T.; Missirlian, M.; Richou, M.; et al. In Situ Observation of Tungsten Plasma-Facing Components After the First Phase of Operation of the WEST Tokamak. Nucl. Fusion 2021, 61, 106011. [Google Scholar] [CrossRef]

- Yuan, Y.; Greuner, H.; Böswirth, B.; Luo, G.N.; Fu, B.Q.; Xu, H.Y.; Liu, W. Melt Layer Erosion of Pure and Lanthanum Doped Tungsten Under VDE-like High Heat Flux Loads. J. Nucl. Mater. 2013, 438, S229–S232. [Google Scholar] [CrossRef]

| Vacuum Annealing [48,63,64,67] | H2 Annealing [63,64] | Cold Isostatic Pressing [64] | Friction Stir Processing [65] | Hot Isostatic Pressing [68,69] | Electron Beam Remelting Treatment [66] | |

|---|---|---|---|---|---|---|

| Oxygen content reduction | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Porosity reduction | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Microhardness increase | ✓ | ✓ | ✓ | ✓ | ||

| Thermal conductivity increase | ✓ | ✓ | ✓ |

| Technology | Parameters | Coating/ Substrate | Coating Thickness | Coating Porosity vol.% | Oxygen Content | Thermal Conductivity W/mK | Ref. |

|---|---|---|---|---|---|---|---|

| Vacuum Plasma Spraying (VPS) | Gas Ar/H2, 35/15 L/min Spraying power, 40 kW Spraying distance, 250 mm Powder carrier Ar, 2.0 L/min | W/Cu | 1 mm | 7.6 | 0.35 wt.% | 58 | [54] |

| 75 W/25 Cu and 75 W/25 Cu | W/Cu composite | 5.8–6.0 | 0.65–0.76 wt.% | 45–120 | [55] | ||

| Atmospheric Plasma Spraying (APS) | Gas Ar/H2, 35/15 L/min Spraying power, 40 kW Spraying distance, 250 mm Powder carrier Ar, 2.0 L/min | W/Cu | 1 mm | 12.9 | 1.2 wt.% | 32 | [54] |

| 75 W/25 Cu and 75 W/25 Cu | W/Cu composite | 9.7–11.5 | 1.31–1.43 wt.% | 19–28 | [55] | ||

| APS + Vacuum Annealing | Gas Ar/H2, 47.5–50/3.5–4.0 L/min Spraying power, 25–30 kW Spraying distance, 70 mm Powder carrier Ar, 5.0 L/min | W | 1 mm | N.A. | 0.49–1.01 wt.% | 33–37 | [63] |

| Vacuum annealing: 2 h, 800 °C + 3 h, 910 °C | 0.36–0.59 wt.% | 61–78 | |||||

| APS + H2 Annealing | Gas Ar/H2, 47.5–50/3.5–4.0 L/min Spraying power, 25–30 kW Spraying distance, 70 mm Powder carrier Ar, 5.0 L/min | W | 1 mm | N.A. | 0.49–1.01 wt.% | 33–37 | [63] |

| H2 annealing: 2 h, 500 °C + 2 h, 600 °C | 0.32–0.63 wt.% | 65–71 | |||||

| APS + Vacuum Annealing + Cold Isostatic Pressing + H2 Annealing | Spraying power, 27.5 kW Gas Ar/H2, 40/7.0 L/min Powder carrier Ar, 9.4 L/min Spray distance, 8 cm | W/Mo | 1 mm | 18.0 | Reduced | N.A. | [64] |

| Vacuum annealing: 2 h, 800 °C + 3 h, 910 °C | |||||||

| Cold isostatic pressing (175 MPa) | 7.0 | ||||||

| Annealing in wet hydrogen: 1.5 h, 1500 °C | |||||||

| APS + Friction Stir Processing | Amperage 350 A Spraying distance 100–140 mm Powder carrier Ar 157.0 L/min | W/W | 1 mm | Less than 1 wt% | N.A. | [65] | |

| Friction stir processing: 12 mm diameter WC-Co plate; rotation speed, 500 rpm; push force, 0.16 MPa; holding time, 30 s | Reduced | N.A. | |||||

| APS + Electron Beam Remelting Treatment | Gas Ar/H2, 56.5/3.6 L/min Spraying power, 22 kW Spraying distance, 80 mm Powder carrier Ar, 17.5 L/min | W/AISI 316 L | 500 μm | 3.9 | 0.6 at.% | N.A. | [66] |

| Electron beam remelting treatment (500 ms and a heat flux of 43.63 MW/m2 and 6000 ms and a heat flux of 13.75 MW/m2) | 0.2–1.6 | 0.04–0.28 at.% | |||||

| APS + Hot Isostatic Pressing | Amperage, 500 A Spraying distance, 320–455 mm Powder carrier Ar, 12–36 L/min | W/AISI 410 | 1.0–9.8 | 9.3–22.2 vol.% | 9.7 | [68] | |

| HIP (parameters N.A.) | No significant improvement for W coating | N.A. | 10.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pakhomova, E.; Palombi, A.; Varone, A. Plasma Spraying of W Coatings for Nuclear Fusion Applications: Advancements and Challenges. Crystals 2025, 15, 408. https://doi.org/10.3390/cryst15050408

Pakhomova E, Palombi A, Varone A. Plasma Spraying of W Coatings for Nuclear Fusion Applications: Advancements and Challenges. Crystals. 2025; 15(5):408. https://doi.org/10.3390/cryst15050408

Chicago/Turabian StylePakhomova, Ekaterina, Alessandra Palombi, and Alessandra Varone. 2025. "Plasma Spraying of W Coatings for Nuclear Fusion Applications: Advancements and Challenges" Crystals 15, no. 5: 408. https://doi.org/10.3390/cryst15050408

APA StylePakhomova, E., Palombi, A., & Varone, A. (2025). Plasma Spraying of W Coatings for Nuclear Fusion Applications: Advancements and Challenges. Crystals, 15(5), 408. https://doi.org/10.3390/cryst15050408