Design and Processing of Metamaterials

Abstract

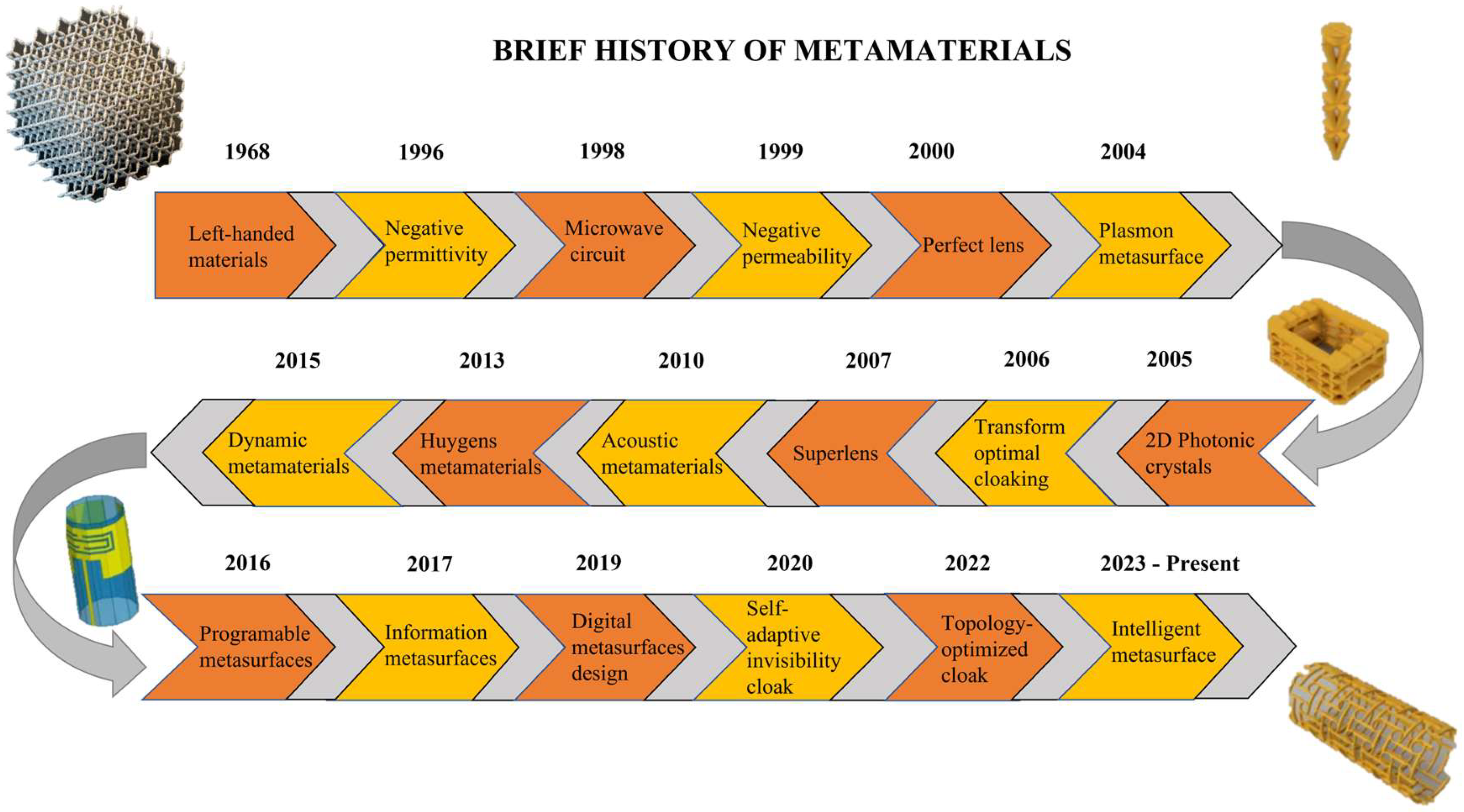

1. Introduction

1.1. Fundamental Principles of Metamaterials

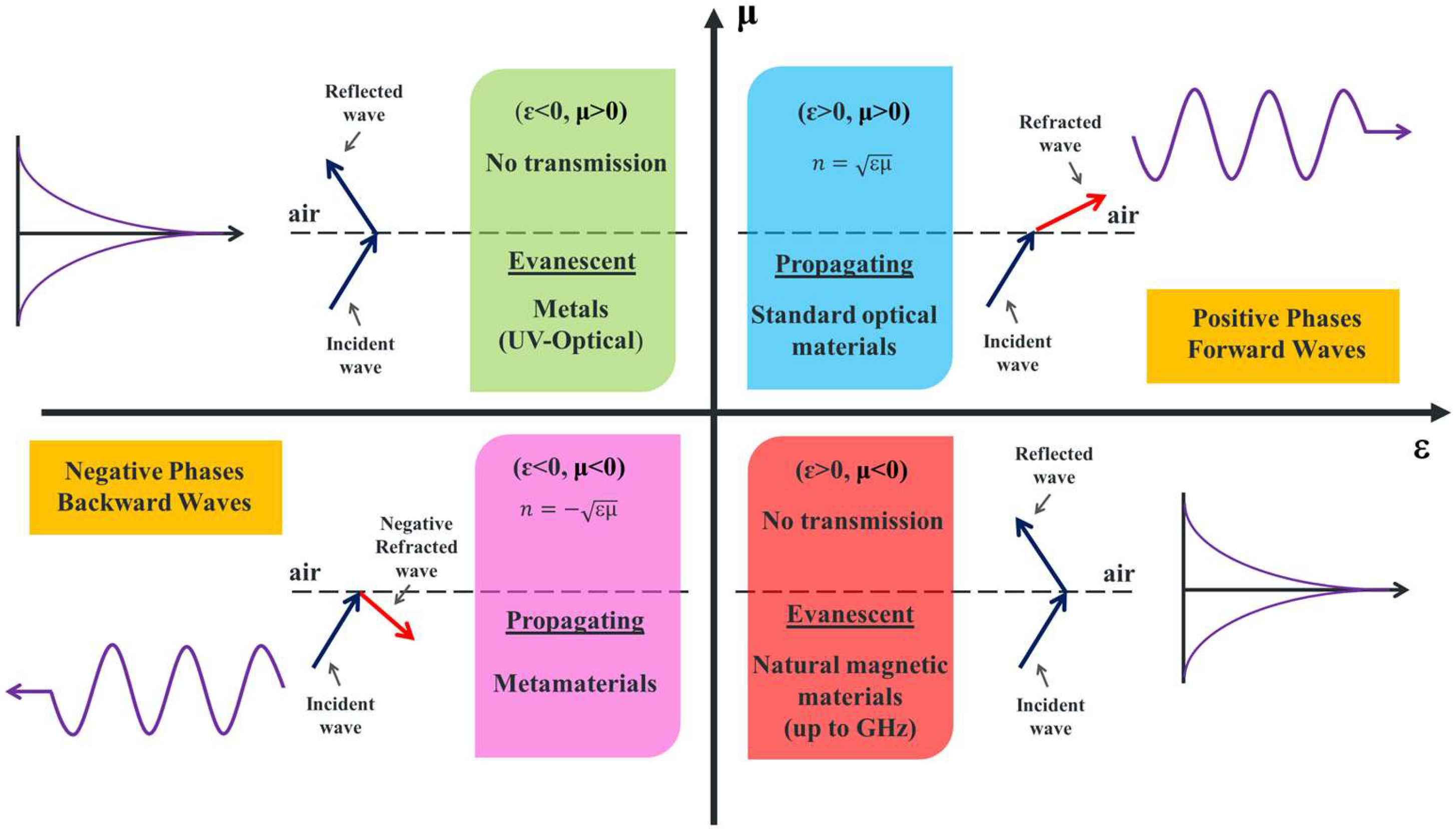

1.2. Electromagnetic Theory

- -

- Double-Positive (DPS): both ε and μ are positive (top-right quadrant), typical of conventional materials like dielectrics.

- -

- Epsilon-Negative (ENG): ε < 0, μ > 0 (top-left quadrant); found in plasmonic materials (e.g., metals at optical frequencies).

- -

- Mu-Negative (MNG): ε > 0, μ < 0 (bottom-right quadrant); exhibited by certain magnetic resonators.

- -

- Double-Negative (DNG): both ε and μ are negative (bottom-left quadrant), enabling negative refraction and superlensing.

1.3. Justification of Review Importance

2. Principles of Metamaterial Design

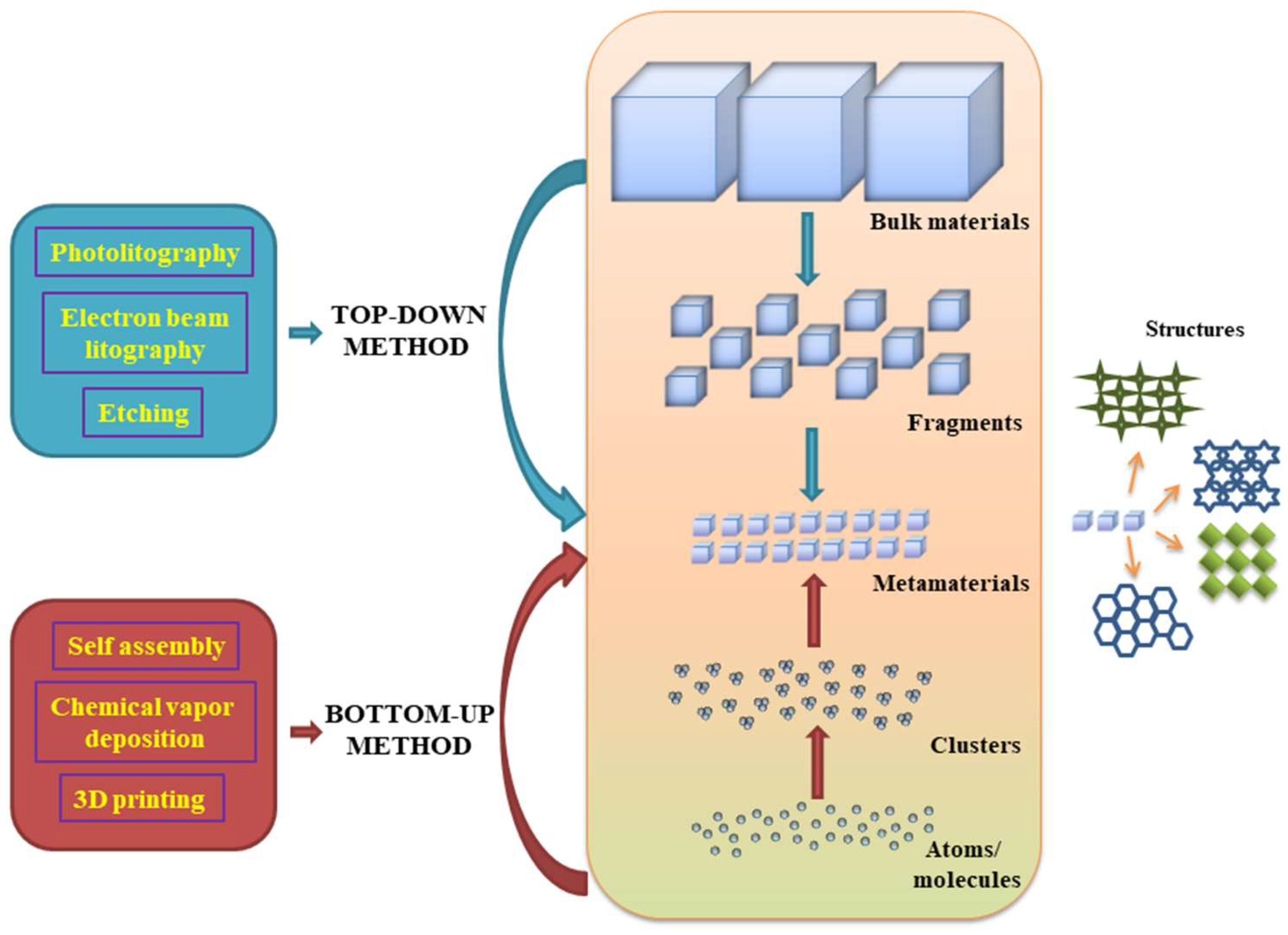

2.1. Metamaterials Design and Fabrication Techniques

2.2. Unit Cell Design

2.3. Topology Optimization

3. Metamaterial Fabrication Techniques

4. Metamaterials in Medicine

5. Conclusions, Challenges, and Future Directions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| EM | electromagnetic |

| LH | left-handed materials |

| BW | backward wave |

| MNG | mu-negative materials |

| ENG | epsilon-negative materials |

| DPS | double-positive materials |

| THz | terahertz |

| NIM | negative-index metamaterial |

| DNG | double-negative |

| SRR | split-ring resonator |

| FDTD | finite-difference time-domain |

| FEM | finite element method |

| MEMSs | microelectrochemical systems |

| LSPRs | localized surface plasmon resonances |

| Poisson’s ratio | A measure of the proportional decrease in diameter to increase in length in a stretched material |

| ADMs | all-dielectric metamaterials |

| CTE | Coefficient of Thermal Expansion |

| PESs | permittivity and permeability of electrical substances |

| HPLs | High-Performance Lenses |

| SLS | selective laser sintering (often used in 3D printing) |

| CVD | chemical vapor deposition |

| 3D printing | Refers to various additive manufacturing processes for creating objects layer by layer |

| LC | liquid crystal |

| TO | topology optimization |

| SIMP | Solid Isotropic Material with Penalization |

| SKB | Soft-Kill Binary |

| FGMs | functionally graded materials |

| BESO | Bi-directional Evolutionary Structural Optimization |

| AC | Alternative Current |

| DC | Direct Current |

| NMR | Nuclear Magnetic Resonance (sometimes used in the context of imaging) |

| CT | Computed Tomography |

| FPs | Frequency Parameters (related to resonant frequencies in metamaterials) |

| CRP | Composite Resonant Properties |

| SCMs | Scalable Composite Materials |

| EBL | electron beam lithography |

| PVD | physical vapor deposition |

| AM | additive manufacturing |

| SLA | stereolithography |

| VSWR | Voltage Standing Wave Ratio |

| MRI | Magnetic Resonance Imaging |

| SNR | signal-to-noise ratio |

| ISM | Industrial, Scientific, and Medical |

| SEM | scanning electron microscopy |

| AFM | atomic force microscopy |

References

- Ali, A.; Mitra, A.; Aïssa, B. Metamaterials and metasurfaces: A review from the perspectives of materials, mechanisms and advanced metadevices. Nanomaterials 2022, 12, 1027. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, Z. Superlenses to overcome the diffraction limit. Nat. Mater. 2008, 7, 435–441. [Google Scholar] [CrossRef]

- Vukusic, P.; Sambles, J.R. Photonic structures in biology. Nature 2003, 424, 852–855. [Google Scholar] [CrossRef]

- Kinoshita, S.; Yoshioka, S.; Miyazaki, J. Physics of structural colors. Rep. Prog. Phys. 2008, 71, 076401. [Google Scholar] [CrossRef]

- Soukoulis, C.M.; Wegener, M. Past achievements and future challenges in the development of three-dimensional photonic metamaterials. Nat. Photonics 2011, 5, 523–530. [Google Scholar] [CrossRef]

- Suresh Kumar, N.; Naidu, K.C.B.; Banerjee, P.; Anil Babu, T.; Venkata Shiva Reddy, B. A review on metamaterials for device applications. Crystals 2021, 11, 518. [Google Scholar] [CrossRef]

- Shamim, S.; Mohsin, A.S.; Rahman, M.M.; Bhuian, M.B.H. Recent advances in the metamaterial and metasurface-based biosensor in the gigahertz, terahertz, and optical frequency domains. Heliyon 2024, 10, e33272. [Google Scholar] [CrossRef]

- Smith, D.R.; Pendry, J.B.; Wiltshire, M.C. Metamaterials and negative refractive index. Science 2004, 305, 788–792. [Google Scholar] [CrossRef]

- Suzuki, T.; Sekiya, M.; Sato, T.; Takebayashi, Y. Negative refractive index metamaterial with high transmission, low reflection, and low loss in the terahertz waveband. Opt. Express 2018, 26, 8314–8324. [Google Scholar] [CrossRef]

- Lorduy G, H.; Castellanos, L. Negative electrical permittivity in metamaterials for a wire of rectangular cross-sectional: An application to antennas design. J. Electromagn. Waves Appl. 2020, 34, 1842–1848. [Google Scholar] [CrossRef]

- Stuart, H.R. The application of negative permittivity materials and metamaterials in electrically small antennas. In Proceedings of the 2007 IEEE Antennas and Propagation Society International Symposium, Honolulu, HI, USA, 9–15 June 2007; pp. 1148–1151. [Google Scholar]

- Chen, J.; Qin, G.; Shi, Y.; Pan, K.; Du, J.; Qiu, J. Negative permittivity and negative magnetic susceptibility of polypyrrole nanorings/carbon nanotubes multi-dimensional metacomposites in the radiowave frequency range. Org. Electron. 2022, 104, 106470. [Google Scholar] [CrossRef]

- Eason, K.; Luk′Yanchuk, B.; Zhou, Y.; Miroshnichenko, A.E.; Kivshar, Y.S. Magnetic microscopy/metrology potential of metamaterials using nanosized spherical particle arrays. In Proceedings of the Smart Nano-Micro Materials and Devices, Melbourne, Australia, 4–7 December 2011; pp. 427–432. [Google Scholar]

- Lu, C.; Hsieh, M.; Huang, Z.; Zhang, C.; Lin, Y.; Shen, Q.; Chen, F.; Zhang, L. Architectural design and additive manufacturing of mechanical metamaterials: A review. Engineering 2022, 17, 44–63. [Google Scholar] [CrossRef]

- Veselago, V.G. The electrodynamics of substances with simultaneously negative values of ε and μ. Phys.-Uspekhi 1968, 10, 509–514. [Google Scholar] [CrossRef]

- Zheludev, N.I.; Kivshar, Y.S. From metamaterials to metadevices. Nat. Mater. 2012, 11, 917–924. [Google Scholar] [CrossRef]

- Pendry, J.B. Negative refraction makes a perfect lens. Phys. Rev. Lett. 2000, 85, 3966. [Google Scholar] [CrossRef]

- Eleftheriades, G.V.; Balmain, K.G. Negative-Refraction Metamaterials: Fundamental Principles and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Papasimakis, N.; Fedotov, V.A.; Zheludev, N.; Prosvirnin, S. Metamaterial analog of electromagnetically induced transparency. Phys. Rev. Lett. 2008, 101, 253903. [Google Scholar] [CrossRef]

- Kurter, C.; Tassin, P.; Zhang, L.; Koschny, T.; Zhuravel, A.P.; Ustinov, A.V.; Anlage, S.M.; Soukoulis, C.M. Classical Analogue of Electromagnetically Induced Transparency with a Metal-Superconductor Hybrid Metamaterial. Phys. Rev. Lett. 2011, 107, 043901. [Google Scholar] [CrossRef]

- Jin, B.; Wu, J.; Zhang, C.; Jia, X.; Jia, T.; Kang, L.; Chen, J.; Wu, P. Enhanced slow light in superconducting electromagnetically induced transparency metamaterials. Supercond. Sci. Technol. 2013, 26, 074004. [Google Scholar] [CrossRef]

- Schurig, D.; Mock, J.J.; Justice, B.; Cummer, S.A.; Pendry, J.B.; Starr, A.F.; Smith, D.R. Metamaterial electromagnetic cloak at microwave frequencies. Science 2006, 314, 977–980. [Google Scholar] [CrossRef]

- Linden, S.; Enkrich, C.; Dolling, G.; Klein, M.W.; Zhou, J.; Koschny, T.; Soukoulis, C.M.; Burger, S.; Schmidt, F.; Wegener, M. Photonic metamaterials: Magnetism at optical frequencies. IEEE J. Sel. Top. Quantum Electron. 2007, 12, 1097–1105. [Google Scholar] [CrossRef]

- Li, C.; Wu, J.; Jiang, S.; Su, R.; Zhang, C.; Jiang, C.; Zhou, G.; Jin, B.; Kang, L.; Xu, W. Electrical dynamic modulation of THz radiation based on superconducting metamaterials. Appl. Phys. Lett. 2017, 111, 092601. [Google Scholar] [CrossRef]

- Shelby, R.A.; Smith, D.R.; Schultz, S. Experimental verification of a negative index of refraction. Science 2001, 292, 77–79. [Google Scholar] [CrossRef]

- Zheludev, N.I. The road ahead for metamaterials. Science 2010, 328, 582–583. [Google Scholar] [CrossRef] [PubMed]

- Tong, L. Micro/nanofibre optical sensors: Challenges and prospects. Sensors 2018, 18, 903. [Google Scholar] [CrossRef]

- Engheta, N.; Alù, A.; Ziolkowski, R.W.; Erentok, A. Fundamentals of waveguide and antenna applications involving DNG and SNG metamaterials. In Metamaterials: Physics and Engineering Explorations; IEEE: New York, NY, USA, 2006; pp. 43–85. [Google Scholar]

- Capolino, F. Theory and Phenomena of Metamaterials; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Smith, D.R.; Padilla, W.J.; Vier, D.; Nemat-Nasser, S.C.; Schultz, S. Composite medium with simultaneously negative permeability and permittivity. Phys. Rev. Lett. 2000, 84, 4184. [Google Scholar] [CrossRef]

- Wang, X.; Ehrhardt, K.; Tallet, C.; Warenghem, M.; Baron, A.; Aradian, A.; Kildemo, M.; Ponsinet, V. Hyperbolic-by-design self-assembled metamaterial based on block copolymers lamellar phases. Opt. Laser Technol. 2017, 88, 85–95. [Google Scholar] [CrossRef]

- Ang, L.Y.L.; Koh, Y.K.; Lee, H.P. Plate-type acoustic metamaterials: Experimental evaluation of a modular large-scale design for low-frequency noise control. Acoustics 2019, 1, 354–368. [Google Scholar] [CrossRef]

- Wang, Q.; Du, H.; Li, F.; Ling, D. Nano-Metamaterial: A State-of-the-Art Material for Magnetic Resonance Imaging. Small Sci. 2023, 3, 2300015. [Google Scholar] [CrossRef]

- Pendry, J.B.; Holden, A.J.; Robbins, D.J.; Stewart, W.J. Magnetism from conductors and enhanced nonlinear phenomena. IEEE Trans. Microw. Theory Tech. 1999, 47, 2075–2084. [Google Scholar] [CrossRef]

- Tzarouchis, D.C.; Koutsoupidou, M.; Sotiriou, I.; Dovelos, K.; Rompolas, D.; Kosmas, P. Electromagnetic metamaterials for biomedical applications: Short review and trends. EPJ Appl. Metamater. 2024, 11, 7. [Google Scholar] [CrossRef]

- Liu, J.; Jennings, S.F.; Tong, W.; Hong, H. Next generation sequencing for profiling expression of miRNAs: Technical progress and applications in drug development. J. Biomed. Sci. Eng. 2011, 4, 666. [Google Scholar] [CrossRef] [PubMed]

- Slobozhanyuk, A.P.; Poddubny, A.N.; Raaijmakers, A.J.; Van Den Berg, C.A.; Kozachenko, A.V.; Dubrovina, I.A.; Melchakova, I.V.; Kivshar, Y.S.; Belov, P.A. Enhancement of magnetic resonance imaging with metasurfaces. Adv. Mater. 2016, 28, 1832–1838. [Google Scholar] [CrossRef] [PubMed]

- Velazquez-Ahumada, M.C.; Freire, M.J.; Marques, R. Metamaterial applicator for microwave hyperthermia. In Proceedings of the 2011 XXXth URSI General Assembly and Scientific Symposium, Istanbul, Turkey, 13–20 August 2011; pp. 1–4. [Google Scholar]

- Melik, R.; Unal, E.; Perkgoz, N.K.; Puttlitz, C.; Demir, H.V. Metamaterial-based wireless strain sensors. Appl. Phys. Lett. 2009, 95, 011106. [Google Scholar] [CrossRef]

- Padilla, W.J.; Basov, D.N.; Smith, D.R. Negative refractive index metamaterials. Mater. Today 2006, 9, 28–35. [Google Scholar] [CrossRef]

- Harinarayana, V.; Shin, Y. Two-photon lithography for three-dimensional fabrication in micro/nanoscale regime: A comprehensive review. Opt. Laser Technol. 2021, 142, 107180. [Google Scholar] [CrossRef]

- Leonard, J. Parallel Plate Wave Transmission Structures for Metamaterial Research. J. Appl. Phys. 1968, 39, 1234–1240. [Google Scholar]

- Pendry, J.B.; Smith, D.R. Reversing light with negative refraction. Phys. Today 2004, 57, 37–43. [Google Scholar] [CrossRef]

- Lvov, V.A.; Senatov, F.S.; Veveris, A.A.; Skrybykina, V.A.; Díaz Lantada, A. Auxetic metamaterials for biomedical devices: Current situation, main challenges, and research trends. Materials 2022, 15, 1439. [Google Scholar] [CrossRef]

- Zadpoor, A.A. Design for additive bio-manufacturing: From patient-specific medical devices to rationally designed meta-biomaterials. Int. J. Mol. Sci. 2017, 18, 1607. [Google Scholar] [CrossRef]

- Zhang, K.; Soh, P.J.; Yan, S. Meta-wearable antennas-a review of metamaterial based antennas in wireless body area networks. Materials 2021, 14, 149. [Google Scholar] [CrossRef]

- Salami, P.; Yousefi, L. Wide-band polarisation-independent metasurface-based carpet cloak. IET Microw. Antennas Propag. 2020, 14, 1983–1989. [Google Scholar] [CrossRef]

- Hu, X.; Luo, Y.; Wang, J.; Tang, J.; Gao, Y.; Ren, J.; Yu, H.; Zhang, J.; Ye, D. Multiband omnidirectional invisibility cloak. Adv. Sci. 2024, 11, 2401295. [Google Scholar] [CrossRef] [PubMed]

- Cui, T.J.; Smith, D.R.; Liu, R. Metamaterials: Theory, Design, and Applications; Springer: New York, NY, USA, 2010. [Google Scholar]

- Holliman, J.E.; Schaef, H.T.; McGrail, B.P.; Miller, Q.R. Review of foundational concepts and emerging directions in metamaterial research: Design, phenomena, and applications. Mater. Adv. 2022, 3, 8390–8406. [Google Scholar] [CrossRef]

- Arjunan, A.; Baroutaji, A.; Robinson, J.; Vance, A.; Arafat, A. Acoustic metamaterials for sound absorption and insulation in buildings. Build. Environ. 2024, 251, 111250. [Google Scholar] [CrossRef]

- Tang, W.; Mei, Z.; Cui, T. Theory, experiment and applications of metamaterials. Sci. China Phys. Mech. Astron. 2015, 58, 1–11. [Google Scholar] [CrossRef]

- Cui, T.J.; Li, L.; Liu, S.; Ma, Q.; Zhang, L.; Wan, X.; Jiang, W.X.; Cheng, Q. Information metamaterial systems. iScience 2020, 23, 101403. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, T.; Qin, X.; Luo, W.; Leng, N.; He, Y.; Yuan, Y.; Bai, M.; Sun, J.; Zhou, J. High-permittivity ceramics enabled highly homogeneous zero-index metamaterials for high-directivity antennas and beyond. eLight 2024, 4, 4. [Google Scholar] [CrossRef]

- Giri, R.; Payal, R. Negative-Index Metamaterials. In Electromagnetic Metamaterials: Properties and Applications; Scrivener Publishing LLC: Beverly, MA, USA, 2023; pp. 205–217. [Google Scholar]

- Liu, Y.; Wang, Y.; Wang, Q.; Guo, S. A Dual-polarized Broadband Fabry-Perot Antenna Loaded with an Energy-selective Surface. In Proceedings of the 2024 IEEE 7th International Conference on Electronic Information and Communication Technology (ICEICT), Nanjing, China, 15–17 April 2024; pp. 1496–1498. [Google Scholar]

- Liu, M.; Lan, X.; Zhang, H.; Xie, P.; Wu, N.; Yuan, H.; Sui, K.; Fan, R.; Liu, C. Iron/epoxy random metamaterials with adjustable epsilon-near-zero and epsilon-negative property. J. Mater. Sci. Mater. Electron. 2021, 32, 15995–16007. [Google Scholar] [CrossRef]

- Gholipur, R.; Bahari, A. Random nanocomposites as metamaterials: Preparation and investigations at microwave region. Opt. Mater. 2015, 50, 175–183. [Google Scholar] [CrossRef]

- Kadic, M.; Bückmann, T.; Schittny, R.; Wegener, M. Metamaterials beyond electromagnetism. Rep. Prog. Phys. 2013, 76, 126501. [Google Scholar] [CrossRef]

- An, H.; Liu, G.; Li, Y.; Song, J.; Zhang, C.; Liu, M. Inhomogeneous electromagnetic metamaterial design method for improving efficiency and range of wireless power transfer. IET Microw. Antennas Propag. 2019, 13, 2110–2118. [Google Scholar] [CrossRef]

- Cui, T.J.; Qi, M.Q.; Wan, X.; Zhao, J.; Cheng, Q. Coding metamaterials, digital metamaterials and programmable metamaterials. Light Sci. Appl. 2014, 3, e218. [Google Scholar] [CrossRef]

- Choi, J.R. Analysis of light-wave nonstaticity in the coherent state. Sci. Rep. 2021, 11, 23974. [Google Scholar] [CrossRef]

- McPhedran, R.C.; Shadrivov, I.V.; Kuhlmey, B.T.; Kivshar, Y.S. Metamaterials and metaoptics. NPG Asia Mater. 2011, 3, 100–108. [Google Scholar] [CrossRef]

- Cai, W.; Shalaev, V. Optical Metamaterials; Fundamentals and Applications; Springer: New York, NY, USA, 2011. [Google Scholar]

- Zhang, D.; Ren, J.; Zhou, T.; Li, B. Dark state, zero-index and topology in phononic metamaterials with negative mass and negative coupling. New J. Phys. 2019, 21, 093033. [Google Scholar] [CrossRef]

- Xiao, S.; Drachev, V.P.; Kildishev, A.V.; Ni, X.; Chettiar, U.K.; Yuan, H.-K.; Shalaev, V.M. Loss-free and active optical negative-index metamaterials. Nature 2010, 466, 735–738. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, X. Metamaterials: A new frontier of science and technology. Chem. Soc. Rev. 2011, 40, 2494–2507. [Google Scholar] [CrossRef]

- Shalaev, V.M. Optical negative-index metamaterials. Nat. Photonics 2007, 1, 41–48. [Google Scholar] [CrossRef]

- Zhang, B. Electrodynamics of transformation-based invisibility cloaking. Light Sci. Appl. 2012, 1, e32. [Google Scholar] [CrossRef]

- Zhang, L.; Koschny, T.; Soukoulis, C.M. Creating double negative index materials using the Babinet principle with one metasurface. Phys. Rev. B—Condens. Matter Mater. Phys. 2013, 87, 045101. [Google Scholar] [CrossRef]

- Wu, X.; Su, Y.; Shi, J. Perspective of additive manufacturing for metamaterials development. Smart Mater. Struct. 2019, 28, 093001. [Google Scholar] [CrossRef]

- Wang, L.; Karaaslan, M. Advanced Metamaterials for Engineers; IOP Publishing: Bristol, UK, 2023. [Google Scholar]

- Sidhwa, H.H. Application of transformation optics for the purpose of cloaking. Phys. Astron. Int. J. 2018, 2, 111–114. [Google Scholar]

- Zhu, T.; Zhou, Y.; Lou, Y.; Ye, H.; Qiu, M.; Ruan, Z.; Fan, S. Plasmonic computing of spatial differentiation. Nat. Commun. 2017, 8, 15391. [Google Scholar] [CrossRef]

- Kanamori, Y.; Hokari, R.; Hane, K. MEMS for plasmon control of optical metamaterials. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 137–146. [Google Scholar] [CrossRef]

- Takaloo, S.; Xu, A.H.; Zaidan, L.; Irannejad, M.; Yavuz, M. Towards Point-of-Care Single Biomolecule Detection Using Next Generation Portable Nanoplasmonic Biosensors: A Review. Biosensors 2024, 14, 593. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, M.; Wu, H.; Song, Y.; Wang, Q. Plasmonic biosensor based on Ag-TiO 2-ZnO gratings for cancer detection in the optical communication band. IEEE Sens. J. 2023, 23, 20959–20967. [Google Scholar] [CrossRef]

- Eissa, M.E. Nanosensors for early detection and diagnosis of cancer: A review of recent advances. J. Cancer Res. Rev. 2024, 1, 1–13. [Google Scholar] [CrossRef]

- Fatema, M. Advances in Nanomaterial-Based Sensors for Early Disease Detection. Int. J. Adv. Res. Sci. Commun. Technol. 2024, 10, 653–658. [Google Scholar] [CrossRef]

- Cummer, S.A.; Christensen, J.; Alù, A. Controlling sound with acoustic metamaterials. Nat. Rev. Mater. 2016, 1, 16001. [Google Scholar] [CrossRef]

- Bertoldi, K.; Vitelli, V.; Christensen, J.; Van Hecke, M. Flexible mechanical metamaterials. Nat. Rev. Mater. 2017, 2, 17066. [Google Scholar] [CrossRef]

- Lakes, R. Foam structures with a negative Poisson′s ratio. Science 1987, 235, 1038–1040. [Google Scholar] [CrossRef] [PubMed]

- Dede, E.M.; Zhou, F.; Schmalenberg, P.; Nomura, T. Thermal metamaterials for heat flow control in electronics. J. Electron. Packag. 2018, 140, 010904. [Google Scholar] [CrossRef]

- Zadpoor, A.A.; Mirzaali, M.J.; Valdevit, L.; Hopkins, J.B. Design, material, function, and fabrication of metamaterials. APL Mater. 2023, 11, 020401. [Google Scholar] [CrossRef]

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A. Ultralight, ultrastiff mechanical metamaterials. Science 2014, 344, 1373–1377. [Google Scholar] [CrossRef]

- Chanda, D.; Shigeta, K.; Gupta, S.; Cain, T.; Carlson, A.; Mihi, A.; Baca, A.J.; Bogart, G.R.; Braun, P.; Rogers, J.A. Large-area flexible 3D optical negative index metamaterial formed by nanotransfer printing. Nat. Nanotechnol. 2011, 6, 402–407. [Google Scholar] [CrossRef]

- Nandja, S. Light control with negative index metamaterial and phase change material at optical wavelength. Optik 2022, 267, 169742. [Google Scholar] [CrossRef]

- Yu, M.; Wang, Y.; Zhong, W.; Guo, R.; Zhou, X. Optical properties of strongly anisotropic metamaterials. Appl. Phys. A 2012, 108, 65–73. [Google Scholar] [CrossRef]

- Jia, X.; Yan, M.; Hong, M. Sound energy enhancement via impedance-matched anisotropic metamaterial. Mater. Des. 2021, 197, 109254. [Google Scholar] [CrossRef]

- Chang, Y.; Wei, J.; Lee, C. Metamaterials–from fundamentals and MEMS tuning mechanisms to applications. Nanophotonics 2020, 9, 3049–3070. [Google Scholar] [CrossRef]

- Grimberg, R. Electromagnetic metamaterials. Mater. Sci. Eng. B 2013, 178, 1285–1295. [Google Scholar] [CrossRef]

- RoyChoudhury, S.; Rawat, V.; Jalal, A.H.; Kale, S.; Bhansali, S. Recent advances in metamaterial split-ring-resonator circuits as biosensors and therapeutic agents. Biosens. Bioelectron. 2016, 86, 595–608. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Erturk, A.; Ruzzene, M. Topological edge states in quasiperiodic locally resonant metastructures. Phys. Rev. Appl. 2020, 13, 014023. [Google Scholar] [CrossRef]

- Contreras, N.; Zhang, X.; Hao, H.; Hernández, F. Application of elastic metamaterials/meta-structures in civil engineering: A review. Compos. Struct. 2024, 327, 117663. [Google Scholar] [CrossRef]

- Besteiro, L.V.; Yu, P.; Wang, Z.; Holleitner, A.W.; Hartland, G.V.; Wiederrecht, G.P.; Govorov, A.O. The fast and the furious: Ultrafast hot electrons in plasmonic metastructures. Size and structure matter. Nano Today 2019, 27, 120–145. [Google Scholar] [CrossRef]

- Khanikaev, A.B.; Wu, C.; Shvets, G. Fano-resonant metamaterials and their applications. Nanophotonics 2013, 2, 247–264. [Google Scholar] [CrossRef]

- Feng, Y.; Liang, M.; Zhao, X.; You, R. Fabrication and modulation of flexible electromagnetic metamaterials. Microsyst. Nanoeng. 2025, 11, 14. [Google Scholar] [CrossRef]

- Li, X.; Pu, M.; Ma, X.; Guo, Y.; Gao, P.; Luo, X. Dispersion engineering in metamaterials and metasurfaces. J. Phys. D Appl. Phys. 2018, 51, 054002. [Google Scholar] [CrossRef]

- Teixeira, F.; Sarris, C.; Zhang, Y.; Na, D.-Y.; Berenger, J.-P.; Su, Y.; Okoniewski, M.; Chew, W.; Backman, V.; Simpson, J.J. Finite-difference time-domain methods. Nat. Rev. Methods Primers 2023, 3, 75. [Google Scholar] [CrossRef]

- Yang, P.; Liou, K. Finite-difference time domain method for light scattering by small ice crystals in three-dimensional space. J. Opt. Soc. Am. A 1996, 13, 2072–2085. [Google Scholar] [CrossRef]

- Taravati, S. Generalized FDTD Numerical Modeling of Space-Time-Varying Media. In Proceedings of the 2024 54th European Microwave Conference (EuMC), Paris, France, 24–26 September 2024; pp. 920–923. [Google Scholar]

- Huang, Y.; Li, J.; Yang, W. Modeling backward wave propagation in metamaterials by the finite element time-domain method. SIAM J. Sci. Comput. 2013, 35, B248–B274. [Google Scholar] [CrossRef]

- David Müzel, S.; Bonhin, E.P.; Guimarães, N.M.; Guidi, E.S. Application of the finite element method in the analysis of composite materials: A review. Polymers 2020, 12, 818. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.X.; Zhou, E.L.; Wei, B.L.; Wu, Y.; Wang, G. An efficient and accurate numerical method for the heat conduction problems of thermal metamaterials based on edge-based smoothed finite element method. Eng. Anal. Bound. Elem. 2022, 134, 282–297. [Google Scholar] [CrossRef]

- Weismann, M.; Gallagher, D.F.; Panoiu, N.C. Accurate near-field calculation in the rigorous coupled-wave analysis method. J. Opt. 2015, 17, 125612. [Google Scholar] [CrossRef]

- Tihon, D.; Sozio, V.; Ozdemir, N.A.; Albani, M.; Craeye, C. Numerically stable eigenmode extraction in 3-D periodic metamaterials. IEEE Trans. Antennas Propag. 2016, 64, 3068–3079. [Google Scholar] [CrossRef]

- Barbarić, D.; Bosiljevac, M.; Šipuš, Z. Analysis of curved metasurfaces based on method of moments. In Proceedings of the 2020 14th European Conference on Antennas and Propagation (EuCAP), Copenhagen, Denmark, 15–20 March 2020; pp. 1–5. [Google Scholar]

- Bashir, I.; Carley, M. Development of 3D boundary element method for the simulation of acoustic metamaterials/metasurfaces in mean flow for aerospace applications. Int. J. Aeroacoustics 2020, 19, 324–346. [Google Scholar] [CrossRef]

- Hamza, M.N.; Koziel, S.; Pietrenko-Dabrowska, A. Design and experimental validation of a metamaterial-based sensor for microwave imaging in breast, lung, and brain cancer detection. Sci. Rep. 2024, 14, 16177. [Google Scholar] [CrossRef] [PubMed]

- Chronopoulos, D.; Meng, H.; Elmadih, W.; Fabro, A.; Maskery, I. Rainbow metamaterials for broadband multi-frequency vibration attenuation: Numerical analysis and experimental validation. J. Sound Vib. 2020, 465, 115005. [Google Scholar]

- Hermann, S.; Billon, K.; Parlak, A.-M.; Orlowsky, J.; Collet, M.; Madeo, A. Design and experimental validation of a finite-size labyrinthine metamaterial for vibro-acoustics: Enabling upscaling towards large-scale structures. Philos. Trans. A 2024, 382, 20230367. [Google Scholar] [CrossRef]

- Fischer, S.C.; Hillen, L.; Eberl, C. Mechanical metamaterials on the way from laboratory scale to industrial applications: Challenges for characterization and scalability. Materials 2020, 13, 3605. [Google Scholar] [CrossRef]

- Zhu, S.; Cao, Y.; Fu, Y.; Gao, L.; Li, X.; Chen, H.; Xu, Y. 3D broadband waveguide cloak and light squeezing in terahertz regime. Opt. Lett. 2020, 45, 652–655. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, X.; Chen, T.T.; Watanabe, I. Deep learning in mechanical metamaterials: From prediction and generation to inverse design. Adv. Mater. 2023, 35, 2302530. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Sun, R.; Lee, D.; Portela, C.M.; Chen, W. Generative Inverse Design of Metamaterials with Functional Responses by Interpretable Learning. Adv. Intell. Syst. 2024, 2400611. [Google Scholar] [CrossRef]

- Ha, C.S.; Yao, D.; Xu, Z.; Liu, C.; Liu, H.; Elkins, D.; Kile, M.; Deshpande, V.; Kong, Z.; Bauchy, M. Rapid inverse design of metamaterials based on prescribed mechanical behavior through machine learning. Nat. Commun. 2023, 14, 5765. [Google Scholar] [CrossRef] [PubMed]

- Nezaratizadeh, A.; Hashemi, S.M.; Bod, M. Deep Learning for Electromagnetic Metamaterial Inverse Design. In Proceedings of the 2024 11th International Symposium on Telecommunications (IST), Tehran, Iran, 9–10 October 2024; pp. 279–282. [Google Scholar]

- Xiao, X.; Chen, J.; Wang, K.; Yu, Y.; Wei, K. Multimaterial additively manufactured metamaterials functionalized with customizable thermal expansion in multiple directions. ACS Appl. Mater. Interfaces 2023, 15, 47434–47446. [Google Scholar] [CrossRef] [PubMed]

- Askari, M.; Hutchins, D.A.; Thomas, P.J.; Astolfi, L.; Watson, R.L.; Abdi, M.; Ricci, M.; Laureti, S.; Nie, L.; Freear, S. Additive manufacturing of metamaterials: A review. Addit. Manuf. 2020, 36, 101562. [Google Scholar] [CrossRef]

- El Helou, C.; Buskohl, P.R.; Tabor, C.E.; Harne, R.L. Digital logic gates in soft, conductive mechanical metamaterials. Nat. Commun. 2021, 12, 1633. [Google Scholar] [CrossRef]

- Jiao, P.; Mueller, J.; Raney, J.R.; Zheng, X.; Alavi, A.H. Mechanical metamaterials and beyond. Nat. Commun. 2023, 14, 6004. [Google Scholar] [CrossRef]

- Bowen, P.T.; Driscoll, T.; Kundtz, N.B.; Smith, D.R. Using a discrete dipole approximation to predict complete scattering of complicated metamaterials. New J. Phys. 2012, 14, 033038. [Google Scholar] [CrossRef]

- Jiao, P.; Alavi, A.H. Artificial intelligence-enabled smart mechanical metamaterials: Advent and future trends. Int. Mater. Rev. 2021, 66, 365–393. [Google Scholar] [CrossRef]

- Fu, K.; Zhao, Z.; Jin, L. Programmable granular metamaterials for reusable energy absorption. Adv. Funct. Mater. 2019, 29, 1901258. [Google Scholar] [CrossRef]

- Dora, E.A. Advances in Metamaterials; N Y Research Press: Forest Hills, NY, USA, 2017; Chapter 1. [Google Scholar]

- Li, B.; Zhao, Z.; Song, L.; Hu, R.; Fan, L.; Xie, J.; Du, X.; Wang, M. Numerical simulation and electromagnetic parameter retrieve: Performance evaluation of metamaterials under TE and TM polarization conditions. Model. Simul. Mater. Sci. Eng. 2025, 33, 015015. [Google Scholar] [CrossRef]

- Tong, X.C. Functional Metamaterials and Metadevices; Springer: Cham, Switzerland, 2018; Chapter 2. [Google Scholar]

- Jeppesen, C.; Mortensen, N.A.; Kristensen, A. Capacitance tuning of nanoscale split-ring resonators. Appl. Phys. Lett. 2009, 95, 193108. [Google Scholar] [CrossRef]

- Sydoruk, O.; Tatartschuk, E.; Shamonina, E.; Solymar, L. Analytical formulation for the resonant frequency of split rings. J. Appl. Phys. 2009, 105, 014903. [Google Scholar] [CrossRef]

- Menzel, C.; Helgert, C.; Rockstuhl, C.; Kley, E.B.; Tünnermann, A.; Pertsch, T.; Lederer, F. Asymmetric Transmission of Linearly Polarized Light at Optical Metamaterials. Phys. Rev. Lett. 2010, 104, 253902. [Google Scholar] [CrossRef]

- Huang, C.; Feng, Y.; Zhao, J.; Wang, Z.; Jiang, T. Asymmetric electromagnetic wave transmission of linear polarization via polarization conversion through chiral metamaterial structures. Phys. Rev. B 2012, 85, 195131. [Google Scholar] [CrossRef]

- Picozzi, A.; Millot, G.; Wabnitz, S. Nonlinear virtues of multimode fibre. Nat. Photonics 2015, 9, 289–291. [Google Scholar] [CrossRef]

- Maraghechi, S.; Hoefnagels, J.P.M.; Peerlings, R.H.J.; Rokoš, O.; Geers, M.G.D. Experimental full-field analysis of size effects in miniaturized cellular elastomeric metamaterials. Mater. Des. 2020, 193, 108684. [Google Scholar] [CrossRef]

- Rao, K.N.; Laxmareddy, D.; Monika, S.; Sailaja, M. Design of Unit Cells-Based Metamaterial Antenna. J. Phys. Conf. Ser. 2024, 2837, 012013. [Google Scholar]

- Abdulkarim, Y.I.; Deng, L.; Luo, H.; Huang, S.; Karaaslan, M.; Altintas, O.; Bakir, M.; Muhammadsharif, F.F.; Awl, H.N.; Sabah, C.; et al. Design and study of a metamaterial based sensor for the application of liquid chemicals detection. J. Mater. Res. Technol. 2020, 9, 10291–10304. [Google Scholar] [CrossRef]

- Khansanami, M.; Younesian, D. A Novel Unit Cell for Low-Frequency Vibration Suppression Through Meta-Plates: Modeling, Optimization and Testing. Int. J. Appl. Mech. 2022, 15, 2250079. [Google Scholar] [CrossRef]

- Gozhenko, V.V.; Amert, A.K.; Whites, K.W. Homogenization of periodic metamaterials by field averaging over unit cell boundaries: Use and limitations. New J. Phys. 2013, 15, 043030. [Google Scholar] [CrossRef][Green Version]

- Pitilakis, A.; Tsilipakos, O.; Liu, F.; Kossifos, K.M.; Tasolamprou, A.C.; Kwon, D.H.; Mirmoosa, M.S.; Manessis, D.; Kantartzis, N.V.; Liaskos, C.; et al. A Multi-Functional Reconfigurable Metasurface: Electromagnetic Design Accounting for Fabrication Aspects. IEEE Trans. Antennas Propag. 2021, 69, 1440–1454. [Google Scholar] [CrossRef]

- Silveirinha, M.t.a.G. Metamaterial homogenization approach with application to the characterization of microstructured composites with negative parameters. Phys. Rev. B 2007, 75, 115104. [Google Scholar] [CrossRef]

- Wang, C.; Vangelatos, Z.; Grigoropoulos, C.P.; Ma, Z. Micro-engineered architected metamaterials for cell and tissue engineering. Mater. Today Adv. 2022, 13, 100206. [Google Scholar] [CrossRef]

- Rajasri, S.; Rani, R.B. Design and Performance Analysis of Metamaterial-Inspired Decagon-Shaped Antenna for Vehicular Communications. Prog. Electromagn. Res. Lett. 2022, 105, 139–147. [Google Scholar] [CrossRef]

- Gozhenko, V.V. Size Effects in Periodic Metamaterials. arXiv 2023, arXiv:2301.03518. [Google Scholar]

- Rajasri, S.; Rani, B.R. Analysis of Unit Cell with and Without Splits for Understanding Metamaterial Property; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Turkmen, O.; Ekmekci, E.; Turhan-Sayan, G. Nested U-ring resonators: A novel multi-band metamaterial design in microwave region. IET Microw. Antennas Propag. 2012, 6, 1102–1108. [Google Scholar] [CrossRef]

- Savo, S.; Shrekenhamer, D.; Padilla, W.J. Liquid crystal metamaterial absorber spatial light modulator for THz applications. Adv. Opt. Mater. 2014, 2, 275–279. [Google Scholar] [CrossRef]

- Pitchappa, P.; Ho, C.P.; Dhakar, L.; Lee, C. Microelectromechanically reconfigurable interpixelated metamaterial for independent tuning of multiple resonances at terahertz spectral region. Optica 2015, 2, 571. [Google Scholar] [CrossRef]

- Pitchappa, P.; Ho, C.P.; Cong, L.; Singh, R.; Singh, N.; Lee, C. Reconfigurable Digital Metamaterial for Dynamic Switching of Terahertz Anisotropy. Adv. Opt. Mater. 2016, 4, 391–398. [Google Scholar] [CrossRef]

- Vafapour, Z.; Troy, W.; Rashidi, A. Colon Cancer Detection by Designing and Analytical Evaluation of a Water-Based THz Metamaterial Perfect Absorber. IEEE Sens. J. 2021, 21, 19307–19313. [Google Scholar] [CrossRef]

- Jia, D.; He, Y.; Ding, N.; Zhou, J.; Du, B.; Zhang, W. Beam-Steering Flat Lens Antenna Based on Multilayer Gradient Index Metamaterials. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 1510–1514. [Google Scholar] [CrossRef]

- Xu, J.; Yang, R.; Fan, Y.; Fu, Q.; Zhang, F. A Review of Tunable Electromagnetic Metamaterials With Anisotropic Liquid Crystals. Front. Phys. 2021, 9, 633104. [Google Scholar] [CrossRef]

- Ben-Yelun, I.; Saucedo-Mora, L.; Sanz, M.Á.; Benítez, J.M.; Montans, F.J. Topology optimization approach for functionally graded metamaterial components based on homogenization of mechanical variables. Comput. Struct. 2023, 289, 107151. [Google Scholar] [CrossRef]

- Wu, J.; Sigmund, O.; Groen, J.P. Topology optimization of multi-scale structures: A review. Struct. Multidiscip. Optim. 2021, 63, 1455–1480. [Google Scholar] [CrossRef]

- Sigmund, O.; Torquato, S. Design of smart composite materials using topology optimization. Smart Mater. Struct. 1999, 8, 365–379. [Google Scholar] [CrossRef]

- Zheng, R.; Yi, B.; Tao, Y.; Peng, X. Topology optimization of extreme mechanical metamaterials considering the anisotropy of additive manufactured parts. Smart Mater. Struct. 2024, 33, 115024. [Google Scholar] [CrossRef]

- Sigmund, O. Systematic Design of Metamaterials by Topology Optimization. In IUTAM Symposium on Modelling Nanomaterials and Nanosystems; IUTAM Bookseries; Springer: Dordrecht, The Netherlands, 2009; Volume 13. [Google Scholar]

- Sha, W.; Xiao, M.; Wang, Y.; Huang, M.; Li, Q.; Gao, L. Topology optimization methods for thermal metamaterials: A review. Int. J. Heat Mass Transf. 2024, 227, 125588. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Y.; Gao, Z.; Liu, P. Topology Optimization of Metamaterial Microstructures for Negative Poisson’s Ratio under Large Deformation Using a Gradient-Free Method. Comput. Model. Eng. Sci. 2024, 139, 2001–2026. [Google Scholar] [CrossRef]

- Murai, N.; Noguchi, Y.; Matsushima, K.; Yamada, T. Multiscale topology optimization of electromagnetic metamaterials using a high-contrast homogenization method. Comput. Methods Appl. Mech. Eng. 2023, 403, 115728. [Google Scholar] [CrossRef]

- Ishikawa, A.; Tanaka, T. Three-dimensional plasmonic metamaterials and their fabrication techniques. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 4700312. [Google Scholar] [CrossRef]

- Suárez, L.; del Mar Espinosa, M. Assessment on the use of additive manufacturing technologies for acoustic applications. Int. J. Adv. Manuf. Technol. 2020, 109, 2691–2705. [Google Scholar] [CrossRef]

- Bruns, T.E. A reevaluation of the SIMP method with filtering and an alternative formulation for solid-void topology optimization. Struct. Multidiscip. Optim. 2005, 30, 428–436. [Google Scholar] [CrossRef]

- Sanfui, S.; Sharma, D. Soft- and Hard-Kill Hybrid GPU-based Bi-Directional Evolutionary Structural Optimization. J. Comput. Inf. Sci. Eng. 2024, 24, 041008. [Google Scholar] [CrossRef]

- Ghabraie, K. An improved soft-kill BESO algorithm for optimal distribution of single or multiple material phases. Struct. Multidiscip. Optim. 2015, 52, 773–790. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q.; Hu, J.; Chen, W.; Zhang, Y.; Luo, Y.; Wang, Q. A Survey of Topology Optimization Methods Considering Manufacturable Structural Feature Constraints for Additive Manufacturing Structures. Addit. Manuf. Front. 2024, 3, 200143. [Google Scholar] [CrossRef]

- Kumar, P.K.A.V.; Li, P.; Reinoso, J.; He, Q.C.; Yvonnet, J.; Paggi, M. SIMP Phase-field topology optimization framework to maximize fracture resistance in FGMs. Compos. Struct. 2024, 329, 117750. [Google Scholar] [CrossRef]

- Xue, H.; Yu, H.; Zhang, X.; Quan, Q. A novel method for structural lightweight design with topology optimization. Energies 2021, 14, 4367. [Google Scholar] [CrossRef]

- Luo, Y.; Sigmund, O.; Li, Q.; Liu, S. Topology optimization of structures with infill-supported enclosed voids for additive manufacturing. Addit. Manuf. 2022, 55, 102795. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Ren, H.; Meng, Z.; Chen, X.; Li, Z.; Wang, L.; Chen, W.; Wang, Y.; Du, J. Ultrastiff metamaterials generated through a multilayer strategy and topology optimization. Nat. Commun. 2024, 15, 47089. [Google Scholar] [CrossRef] [PubMed]

- Akhmetshin, L.; Iokhim, K.; Kazantseva, E.; Smolin, I. Influence of Topological Defects on the Mechanical Response of Unit Cells of the Tetrachiral Mechanical Metamaterial. Designs 2023, 7, 129. [Google Scholar] [CrossRef]

- Zeng, Q.; Duan, S.; Zhao, Z.; Wang, P.; Lei, H. Inverse Design of Energy-Absorbing Metamaterials by Topology Optimization. Adv. Sci. 2023, 10, 2204977. [Google Scholar] [CrossRef]

- Stepanova, M.; Dew, S. (Eds.) Nanofabrication: Techniques and Principles; Springer: Vienna, Austria, 2012. [Google Scholar]

- Feng, F.; He, C.; Cui, Z.; Ying, T.; Cai, J.; Tao, M. Topology Optimization of Multi-Material Underwater Broadband Sound Absorption Metamaterial Based on Genetic Algorithm. Available online: https://ouci.dntb.gov.ua/en/works/7PP83wQ7/ (accessed on 5 April 2025).

- Zheng, R.; Yi, B.; Liu, W.; Liu, L.; Peng, X.; Tao, Y. Topology optimization of self-supporting metamaterials for additive manufacturing: A novel framework and validation. Smart Mater. Struct. 2025, 34, 015056. [Google Scholar] [CrossRef]

- Viswanath, A.; Abueidda, D.W.; Modrek, M.; Al-Rub, R.K.A.; Koric, S.; Khan, K.A. Designing a TPMS metamaterial via deep learning and topology optimization. Front. Mech. Eng. 2024, 10, 1417606. [Google Scholar] [CrossRef]

- Qin, H.; Yang, D.; Ren, C. Design method of lightweight metamaterials with arbitrary Poisson′s ratio. Materials 2018, 11, 1574. [Google Scholar] [CrossRef]

- Sha, W.; Xiao, M.; Zhang, J.; Ren, X.; Zhu, Z.; Zhang, Y.; Xu, G.; Li, H.; Liu, X.; Chen, X.; et al. Robustly printable freeform thermal metamaterials. Nat. Commun. 2021, 12, 27543. [Google Scholar] [CrossRef]

- Gustavo Méndez, C.; Podestá, J.M.; Lloberas-Valls, O.; Toro, S.; Huespe, A.E.; Oliver, J. Computational material design for acoustic cloaking. Int. J. Numer. Methods Eng. 2017, 112, 1353–1380. [Google Scholar] [CrossRef]

- Stankiewicz, G.; Dev, C.; Weichelt, M.; Fey, T.; Steinmann, P. Towards advanced piezoelectric metamaterial design via combined topology and shape optimization. Res. Sq. 2023, 67, 26. [Google Scholar] [CrossRef]

- Han, Z.; Xiao, X.; Chen, J.; Wei, K.; Wang, Z.; Yang, X.; Fang, D. Bifunctional Metamaterials Incorporating Unusual Geminations of Poisson’s Ratio and Coefficient of Thermal Expansion. ACS Appl. Mater. Interfaces 2022, 14, 50068–50078. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Lin, Y.T.; Salehi, H.; Che, Z.; Zhu, Y.; Ding, J.; Sheng, B.; Zhu, R.; Jiao, P. Advanced Fabrication of Mechanical Metamaterials Based on Micro/Nanoscale Technology. Adv. Eng. Mater. 2023, 22, 202300750. [Google Scholar]

- Baracu, A.M.; Avram, M.A.; Breazu, C.; Bunea, M.C.; Socol, M.; Stanculescu, A.; Matei, E.; Thrane, P.C.V.; Dirdal, C.A.; Dinescu, A.; et al. Silicon metalens fabrication from electron beam to uvnanoimprint lithography. Nanomaterials 2021, 11, 2329. [Google Scholar] [CrossRef] [PubMed]

- Leontiev, A.P.; Sotnichuk, S.V.; Klimenko, A.A.; Malysheva, I.V.; Kolmychek, I.A.; Mumlyakov, A.M.; Tsiniaikin, I.I.; Murzina, T.V.; Napolskii, K.S. Ion beam etching of anodic aluminium oxide barrier layer for Au nanorod-based hyperbolic metamaterials. J. Mater. Chem. C 2024, 12, 9274–9283. [Google Scholar] [CrossRef]

- Park, S.J.; Cunningham, J. Effect of substrate etching on terahertz metamaterial resonances and its liquid sensing applications. Sensors 2020, 20, 3133. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y. Nanofabrication by electron beam lithography and its applications: A review. Microelectron. Eng. 2015, 135, 57–72. [Google Scholar] [CrossRef]

- Tan, Y.S.; Wang, H.; Wang, H.; Pan, C.; Yang, J.K.W. High-throughput fabrication of large-scale metasurfaces using electron-beam lithography with SU-8 gratings for multilevel security printing. Photonics Res. 2023, 11, B103. [Google Scholar] [CrossRef]

- Huff, M. Recent advances in reactive ion etching and applications of high-aspect-ratio microfabrication. Micromachines 2021, 12, 991. [Google Scholar] [CrossRef]

- Baron, A.; Aradian, A.; Ponsinet, V.; Barois, P. Self-assembled optical metamaterials. Opt. Laser Technol. 2016, 82, 94–100. [Google Scholar] [CrossRef]

- Walia, S.; Shah, C.M.; Gutruf, P.; Nili, H.; Chowdhury, D.R.; Withayachumnankul, W.; Bhaskaran, M.; Sriram, S. Flexible metasurfaces and metamaterials: A review of materials and fabrication processes at micro- and nano-scales. Appl. Phys. Rev. 2015, 2, 011303. [Google Scholar] [CrossRef]

- Dogan, E.; Bhusal, A.; Cecen, B.; Miri, A.K. 3D Printing metamaterials towards tissue engineering. Appl. Mater. Today 2020, 20, 100752. [Google Scholar] [CrossRef]

- Loh, L.Y.W.; Gupta, U.; Wang, Y.; Foo, C.C.; Zhu, J.; Lu, W.F. 3D Printed Metamaterial Capacitive Sensing Array for Universal Jamming Gripper and Human Joint Wearables. Adv. Eng. Mater. 2021, 23, 2001082. [Google Scholar] [CrossRef]

- Zhao, X. Bottom-up fabrication methods of optical metamaterials. J. Mater. Chem. 2012, 22, 9439–9449. [Google Scholar] [CrossRef]

- Peng, J.; Wang, S.; Liang, B.; Wen, Q.; Sun, C.; Li, K.; Zhang, X.; Zhang, Y. Review of micro and nano scale 3D printing of electromagnetic metamaterial absorbers: Mechanism, fabrication, and functionality. Virtual Phys. Prototyp. 2024, 19, e2378937. [Google Scholar] [CrossRef]

- Jin, H.; Espinosa, H.D. Mechanical Metamaterials Fabricated From Self-Assembly: A Perspective. J. Appl. Mech. Trans. ASME 2024, 91, 1–25. [Google Scholar] [CrossRef]

- Wang, K.; Park, S.H.; Zhu, J.; Kim, J.K.; Zhang, L.; Yi, G.R. Self-Assembled Colloidal Nanopatterns toward Unnatural Optical Meta-Materials. Adv. Funct. Mater. 2021, 31, 2008246. [Google Scholar] [CrossRef]

- Mühlig, S.; Cunningham, A.; Dintinger, J.; Scharf, T.; Bürgi, T.; Lederer, F.; Rockstuhl, C. Self-assembled plasmonic metamaterials. Nanophotonics 2013, 2, 211–240. [Google Scholar] [CrossRef]

- Wohlwend, J.; Haberfehlner, G.; Galinski, H. Strong Coupling in Two-Phase Metamaterials Fabricated by Sequential Self-Assembly. Adv. Opt. Mater. 2023, 11, 2300568. [Google Scholar] [CrossRef]

- Turek, V.A.; Francescato, Y.; Cadinu, P.; Crick, C.R.; Elliott, L.; Chen, Y.; Urland, V.; Ivanov, A.P.; Velleman, L.; Hong, M.; et al. Self-Assembled Spherical Supercluster Metamaterials from Nanoscale Building Blocks. ACS Photonics 2016, 3, 35–42. [Google Scholar] [CrossRef]

- Yang, W.; Lu, J.; Zhuang, W.; Qi, J.; Wang, C.; Wang, H.; Su, G.; Xiong, K.; Mao, Y.; Gong, X.; et al. PtS2 metamaterials: Fabrication and physical properties. Appl. Surf. Sci. 2023, 614, 156277. [Google Scholar] [CrossRef]

- Sabzi, M.; Anijdan, S.H.M.; Shamsodin, M.; Farzam, M.; Hojjati-Najafabadi, A.; Feng, P.; Park, N.; Lee, U. A Review on Sustainable Manufacturing of Ceramic-Based Thin Films by Chemical Vapor Deposition (CVD): Reactions Kinetics and the Deposition Mechanisms. Coatings 2023, 13, 188. [Google Scholar] [CrossRef]

- Koppes, A.N.; Kamath, M.; Pfluger, C.A.; Burkey, D.D.; Dokmeci, M.; Wang, L.; Carrier, R.L. Complex, multi-scale small intestinal topography replicated in cellular growth substrates fabricated via chemical vapor deposition of Parylene C. Biofabrication 2016, 8, 035011. [Google Scholar] [CrossRef]

- Hosseinzadeh, H.R.S. Metamaterials in Medicine: A New Era for Future Orthopedics. Orthop. Res. Online J. 2018, 2, 181–183. [Google Scholar] [CrossRef]

- Beliaev, L.Y.; Shkondin, E.; Lavrinenko, A.V.; Takayama, O. Optical, structural and composition properties of silicon nitride films deposited by reactive radio-frequency sputtering, low pressure and plasma-enhanced chemical vapor deposition. Thin Solid Film. 2022, 763, 139568. [Google Scholar] [CrossRef]

- Zhang, K.P.; Liao, Y.F.; Qiu, B.; Zheng, Y.K.; Yu, L.K.; He, G.H.; Chen, Q.N.; Sun, D.H. 3D Printed Embedded Metamaterials. Small 2021, 17, 2103262. [Google Scholar] [CrossRef]

- Yuan, S.; Chua, C.K.; Zhou, K. 3D-Printed Mechanical Metamaterials with High Energy Absorption. Adv. Mater. Technol. 2019, 4, 1800419. [Google Scholar] [CrossRef]

- Xie, Y.; Ye, S.; Reyes, C.; Sithikong, P.; Popa, B.I.; Wiley, B.J.; Cummer, S.A. Microwave metamaterials made by fused deposition 3D printing of a highly conductive copper-based filament. Appl. Phys. Lett. 2017, 110, 181903. [Google Scholar] [CrossRef]

- Kennedy, J.; Flanagan, L.; Dowling, L.; Bennett, G.J.; Rice, H.; Trimble, D. The influence of additive manufacturing processes on the performance of a periodic acoustic metamaterial. Int. J. Polym. Sci. 2019, 2019, 29143. [Google Scholar] [CrossRef]

- Yang, D.; Mei, H.; Yao, L.; Yang, W.; Yao, Y.; Cheng, L.; Zhang, L.; Dassios, K.G. 3D/4D Printed Tunable Electrical Metamaterials with More Sophisticated Structures; Royal Society of Chemistry: London, UK, 2021. [Google Scholar]

- Ma, W.W.S.; Yang, H.; Zhao, Y.; Li, X.; Ding, J.; Qu, S.; Liu, Q.; Hu, Z.; Li, R.; Tao, Q.; et al. Multi-Physical Lattice Metamaterials Enabled by Additive Manufacturing: Design Principles, Interaction Mechanisms, and Multifunctional Applications. Adv. Sci. 2025, 12, 2405835. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Qidong, Y.; Wei, K. Additively manufactured multi-functional metamaterials: Low coefficient of thermal expansion and programmable Poisson’s ratio. Virtual Phys. Prototyp. 2024, 19, e2303714. [Google Scholar] [CrossRef]

- Xu, T.; Wang, C.; Luo, X. Interference photolithography with metamaterials. In Proceedings of the 2008 IEEE PhotonicsGlobal@Singapore, Singapore, 8–11 December 2008. [Google Scholar]

- Lu, J.; Zhang, X.; Su, G.; Yang, W.; Han, K.; Yu, X.; Wan, Y.; Wang, X.; Yang, P. Large-area uniform few-layer PtS2: Synthesis, structure and physical properties. Mater. Today Phys. 2021, 18, 100376. [Google Scholar] [CrossRef]

- Lakamanahalli, A.; Hudedmani, M.; Shweta, G.M.; Hoskeri, P.; Mathad, S. Metamaterials: A Comprehensive Review of Design and Applications. Int. J. Adv. Sci. Eng. 2024, 11, 3816. [Google Scholar] [CrossRef]

- Lipworth, G.; Ensworth, J.; Seetharam, K.; Da, H.; Lee, J.S.; Schmalenberg, P.; Nomura, T.; Reynolds, M.S.; Smith, D.R.; Urzhumov, Y. Magnetic metamaterial superlens for increased range wireless power transfer. Sci. Rep. 2014, 4, 3642. [Google Scholar] [CrossRef] [PubMed]

- Mezache, Z.; Hafdi, Z.; Tao, J. Design of a novel graphene buzzle metamaterial refractometer for sensing of cancerous cells in the terahertz regime. Optik 2023, 287, 171170. [Google Scholar] [CrossRef]

- Santos, W.F.D.; Rodrigues, A.S.L.; Lopes, I.A.R.; Pires, F.M.A.; Proença, S.P.B.; Silveira, Z.C. Analysis of a Novel 3D-Printed Mechanical Metamaterial with Tension-Induced Undulation: Experimental and Numerical Investigations. Available online: https://ouci.dntb.gov.ua/en/works/4zX8aO3r/ (accessed on 5 April 2025).

- Dadouche, N.; Mezache, Z.; Tao, J.; Ali, E.; Alsharef, M.; Alwabli, A.; Jaffar, A.; Alzahrani, A.; Berazguia, A. Design and Fabrication of a Novel Corona-Shaped Metamaterial Biosensor for Cancer Cell Detection. Micromachines 2023, 14, 2114. [Google Scholar] [CrossRef] [PubMed]

- Jagadeesan, V.; Venkatachalam, D.; Vinod, V.M.; Loganathan, A.K.; Muthusamy, S.; Krishnamoorthy, M.; Sadasivuni, K.K.; Geetha, M. Design and development of a new metamaterial sensor-based Minkowski fractal antenna for medical imaging. Appl. Phys. A Mater. Sci. Process. 2023, 129, 391. [Google Scholar] [CrossRef]

- Yue, S.; Xia, W.; Yanan, L.; Mengjun, W. A Midfield Wireless Energy Transmission Antenna Based on Metamaterial for Implanted Capsule Endoscope. In Proceedings of the 2021 13th Global Symposium on Millimeter-Waves & Terahertz (GSMM), Nanjing, China, 23–26 May 2021; pp. 1–3. [Google Scholar]

- Ren, Z.; Chang, Y.; Ma, Y.; Shih, K.; Dong, B.; Lee, C. Leveraging of MEMS Technologies for Optical Metamaterials Applications; Wiley-VCH Verlag: Weinheim, Germany, 2020. [Google Scholar]

- Dhama, R.; Yan, B.; Palego, C.; Wang, Z. Super-resolution imaging by dielectric superlenses: Tio2 metamaterial superlens versus batio3 superlens. Photonics 2021, 8, 222. [Google Scholar] [CrossRef]

- Mollaei, M.S.M.; Simovski, C. Dual-metasurface superlens: A comprehensive study. Phys. Rev. B 2019, 100, 205426. [Google Scholar] [CrossRef]

- Smith, D. Applied physics. How to build a superlens. Science 2005, 308, 502–503. [Google Scholar] [CrossRef][Green Version]

- Raghavan, S.; Rajeshkumar, V. An Overview of Metamaterials in Biomedical Applications. In Proceedings of the Progress in Electromagnetics Research Symposium, Taipei, Taiwan, 25–28 March 2013. [Google Scholar]

- Veerabagu, U.; Palza, H.; Quero, F. Review: Auxetic Polymer-Based Mechanical Metamaterials for Biomedical Applications; American Chemical Society: Washington, DC, USA, 2022. [Google Scholar]

- Sabban, A. Small New Wearable Metamaterials Antennas for IOT, Medical and 5G Applications. In Proceedings of the 2020 14th European Conference on Antennas and Propagation (EuCAP), Copenhagen, Denmark, 15–20 March 2020. [Google Scholar]

- Yu, X.; Zhou, J.; Liang, H.; Jiang, Z.; Wu, L. Mechanical metamaterials associated with stiffness, rigidity and compressibility: A brief review. Prog. Mater. Sci. 2018, 94, 114–173. [Google Scholar] [CrossRef]

- Shirzad, M.; Zolfagharian, A.; Bodaghi, M.; Nam, S.Y. Auxetic metamaterials for bone-implanted medical devices: Recent advances and new perspectives. Eur. J. Mech. A/Solids 2023, 98, 104905. [Google Scholar] [CrossRef]

- Khan, S.A.; Khan, N.Z.; Xie, Y.; Abbas, M.T.; Rauf, M.; Mehmood, I.; Runowski, M.; Agathopoulos, S.; Zhu, J. Optical Sensing by Metamaterials and Metasurfaces: From Physics to Biomolecule Detection; John Wiley and Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Xu, J.; Cai, H.; Wu, Z.; Li, X.; Tian, C.; Ao, Z.; Niu, V.C.; Xiao, X.; Jiang, L.; Khodoun, M.; et al. Acoustic metamaterials-driven transdermal drug delivery for rapid and on-demand management of acute disease. Nat. Commun. 2023, 14, 869. [Google Scholar] [CrossRef]

- Gao, N.; Zhang, Z.; Deng, J.; Guo, X.; Cheng, B.; Hou, H. Acoustic Metamaterials for Noise Reduction: A Review. Adv. Mater. Technol. 2022, 7, 2100698. [Google Scholar] [CrossRef]

- Sabban, A. New Wideband Meta Materials Printed Antennas for Medical Applications. Int. J. Adv. Med. Sci. 2015, 3, 13–24. [Google Scholar] [CrossRef][Green Version]

- Kasban, H.; El-Bendary, M.A.M.; Salama, D.H. A Comparative Study of Medical Imaging Techniques. Int. J. Inf. Sci. Intell. Syst. 2015, 4, 37–58. [Google Scholar]

- Fang, W.; Lv, X.; Ma, Z.; Liu, J.; Pei, W.; Geng, Z. A Flexible Terahertz Metamaterial Biosensor for Cancer Cell Growth and Migration Detection. Micromachines 2022, 13, 631. [Google Scholar] [CrossRef]

- Chen, J.; Chen, J.; Wang, H.; He, L.; Huang, B.; Dadbakhsh, S.; Bartolo, P. Fabrication and development of mechanical metamaterials via additive manufacturing for biomedical applications: A review. Int. J. Extrem. Manuf. 2025, 7, 012001. [Google Scholar] [CrossRef]

- Vogiatzis, P.; Chen, S.; Wang, X.; Li, T.; Wang, L. Topology optimization of multi-material negative Poisson′s ratio metamaterials using a reconciled level set method. CAD Comput. Aided Des. 2017, 83, 15–32. [Google Scholar] [CrossRef]

- Kirillova, A.; Maxson, R.; Stoychev, G.; Gomillion, C.T.; Ionov, L. 4D Biofabrication Using Shape-Morphing Hydrogels. Adv. Mater. 2017, 29, 1703443. [Google Scholar] [CrossRef]

- Jaafar, A.; Hecker, C.; Árki, P.; Joseph, Y. Sol-gel derived hydroxyapatite coatings for titanium implants: A review. Bioengineering 2020, 7, 127. [Google Scholar] [CrossRef]

- Lecina-Tejero, Ó.; Pérez, M.Á.; García-Gareta, E.; Borau, C. The rise of mechanical metamaterials: Auxetic constructs for skin wound healing. J. Tissue Eng. 2023, 14, 20417314231177838. [Google Scholar] [CrossRef]

- Wang, H.; Lyu, Y.; Bosiakov, S.; Zhu, H.; Ren, Y. A review on the mechanical metamaterials and their applications in the field of biomedical engineering. Front. Media 2023, 10, 1273961. [Google Scholar] [CrossRef]

- Liu, R.P.; Zhao, Z.Y.; Ji, C.L.; Zhou, T. Metamaterials beyond negative refractive index: Applications in telecommunication and sensing. Sci. China Technol. Sci. 2016, 59, 1007–1011. [Google Scholar] [CrossRef]

- Mahmud, S.; Nezaratizadeh, A.; Satriya, A.B.; Yoon, Y.K.; Ho, J.S.; Khalifa, A. Harnessing metamaterials for efficient wireless power transfer for implantable medical devices. Bioelectron. Med. 2024, 10, 7. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y. Overview of the Current State of Research on Metamaterials in Biomedicine. BIO Web Conf. 2024, 142, 03020. [Google Scholar] [CrossRef]

- Zeenat, L.; Zolfagharian, A.; Sriya, Y.; Sasikumar, S.; Bodaghi, M.; Pati, F. 4D Printing for Vascular Tissue Engineering: Progress and Challenges. Adv. Mater. Technol. 2023, 8, 2300200. [Google Scholar] [CrossRef]

- Li, N.; Liu, L.; Liu, Y.; Leng, J. Metamaterial-Based Electronic Skin with Conformality and Multisensory Integration. Adv. Funct. Mater. 2024, 34, 2406789. [Google Scholar] [CrossRef]

- Algarin, J.M.; Lopez, M.A.; Freire, M.J.; Marques, R. Signal-to-noise ratio evaluation in resonant ring metamaterial lenses for MRI applications. New J. Phys. 2011, 13, 115006. [Google Scholar] [CrossRef]

- Li, B.; Xie, R.; Sun, Z.; Shao, X.; Lian, Y.; Guo, H.; You, R.; You, Z.; Zhao, X. Nonlinear metamaterials enhanced surface coil array for parallel magnetic resonance imaging. Nat. Commun. 2024, 15, 7949. [Google Scholar] [CrossRef]

- Freire, M.J.; Jelinek, L.; Marques, R.; Lapine, M. On the applications of μr=-1 metamaterial lenses for magnetic resonance imaging. J. Magn. Reson. 2010, 203, 81–90. [Google Scholar] [CrossRef]

- Duan, G.; Zhao, X.; Anderson, S.W.; Zhang, X. Boosting magnetic resonance imaging signal-to-noise ratio using magnetic metamaterials. Commun. Phys. 2019, 2, 35. [Google Scholar] [CrossRef]

- Hurshkainen, A.; Nikulin, A.; Georget, E.; Larrat, B.; Berrahou, D.; Neves, A.L.; Sabouroux, P.; Enoch, S.; Melchakova, I.; Belov, P.; et al. A Novel Metamaterial-Inspired RF-coil for Preclinical Dual-Nuclei MRI. Sci. Rep. 2018, 8, 9190. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, Z.; Wang, C.; Chen, X. Heterogeneous Strain Distribution of Elastomer Substrates to Enhance the Sensitivity of Stretchable Strain Sensors. Acc. Chem. Res. 2019, 52, 82–90. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Liu, Z.; Matsuhisa, N.; Qi, D.; Leow, W.R.; Yang, H.; Yu, J.; Chen, G.; Liu, Y.; Wan, C.; et al. Auxetic Mechanical Metamaterials to Enhance Sensitivity of Stretchable Strain Sensors. Adv. Mater. 2018, 30, 1706589. [Google Scholar] [CrossRef]

- Luo, J.; Lu, W.; Jiao, P.; Jang, D.; Barri, K.; Wang, J.; Meng, W.; Kumar, R.P.; Agarwal, N.; Hamilton, D.K.; et al. Wireless electronic-free mechanical metamaterial implants. Mater. Today 2025, 83, 145–156. [Google Scholar] [CrossRef]

- Xiong, H.; Xie, J.Y.; Liu, Y.J.; Wang, B.X.; Xiao, D.P.; Zhang, H.Q. Microwave Hyperthermia Technology Based on Near-Field Focused Metasurfaces: Design and Implementation. Adv. Funct. Mater. 2024, 35, 2411842. [Google Scholar] [CrossRef]

- Hassanpour, M.; Hassanpour, M.; Rezaie, M.; Khezripour, S.; Faruque, M.R.I.; Khandaker, M.U. The application of graphene/h-BN metamaterial in medical linear accelerators for reducing neutron leakage in the treatment room. Phys. Eng. Sci. Med. 2023, 46, 1023–1032. [Google Scholar] [CrossRef]

- Jaffar, N.A.; Buniyamin, N.; Lias, K. An overview of available metamaterial-based antenna for non-invasive hyperthermia cancer treatment. Indones. J. Electr. Eng. Comput. Sci. 2019, 14, 697–705. [Google Scholar] [CrossRef]

- Leggio, L.; Varona, O.D.; Dadrasnia, E. A Comparison between Different Schemes of Microwave Cancer Hyperthermia Treatment by Means of Left-Handed Metamaterial Lenses. Prog. Electromagn. Res.-Pier 2015, 150, 73–87. [Google Scholar] [CrossRef]

- Osipkov, A.; Makeev, M.; Garsiya, E.; Filyaev, A.; Sinyagaeva, K.; Kirillov, D.; Ryzhenko, D.; Yurkov, G. Radio-shielding metamaterials transparent in the visible spectrum: Approaches to creation. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1060, 012007. [Google Scholar] [CrossRef]

- Anwar, U.; Arslan, T.; Hussain, A.; Lomax, P. Next Generation Cognition-Aware Hearing Aid Devices With Microwave Sensors: Opportunities and Challenges. IEEE Access 2022, 10, 82214–82235. [Google Scholar] [CrossRef]

| Approach | Technique | Advantages | Disadvantages | References |

|---|---|---|---|---|

| Top-down | Photolithography | High-resolution structures, low-cost | Restricted due to limit diffraction, low effective manufacturing | [1,181,210] |

| Electron beam lithography | High resolution pattering for nanoscale structures, rapid prototyping | High operating costs, time intensive for large areas | [181,185] | |

| Etching | High sensitivity, low refractive index | Limited structure, high-cost equipment | [1,182,183] | |

| Bottom-up | Self-assembly | Low-cost, suitable for different types of nanoparticles, homogenous structures | Restricted template types, limited by phase distribution | [193,194,195,196,210] |

| Chemical vapor deposition | Complex and controlled structure, high production efficiency, conformal layer deposition, low-cost fabrication | Low pressure and high temperature limitations, production of chemical compounds waste | [198,211] | |

| 3D printing | Design freedom, suitable for developing advanced metamaterials, low-cost production | Limited extrusion temperature, weak mechanical properties, poor quality surface | [203,204,205] |

| Application | Specific Use | Benefits | Metamaterial Properties | References |

|---|---|---|---|---|

| Optical antennas | Provides effective communication in medical systems | High efficiency | Negative permeability, subunit dielectric constant | [26,223,225,231] |

| Cancer detection | Detects early signs of cancer by localizing malignant cells with biosensors | High precision, cost-effective | High sensitivity, negative values of relative permittivity, electromagnetic properties | [148,201,223] |

| Tissue engineering | Scaffolds for regenerating different tissues such as bone, skin, cartilage, or vascular | Enhanced stem cell proliferation, enhanced biocompatibility, natural-tissue-like behavior | Mechanical stability, high strength and toughness, precise control over structure | [104,189,215,243] |

| Medical imaging | MRI enhancement for accelerated scans and better SNRs | High-resolution images, simple installation | Magnetic, resonant, and dielectric properties | [201,232,248] |

| Strain sensors | Monitories healing of fractured bones, mechanical stimuli detection | Enhanced sensitivity, non-invasive | Auxetic properties, distinctive resonance frequency, reduced Poisson’s ratio | [201,250] |

| Microwave hyperthermia | Superficial cancer treatment in specific locations by focusing resolution | Environmentally friendly, non-invasive, enhanced distribution field | Electromagnetic convergence, thermal and heat properties | [253,255,256] |

| Radiation shields | Protection against extreme electromagnetic radiation of medical equipment | High indicators of transparency, enhanced performance of the system | Absorption properties, tunable and low-profile features | [35,254,257] |

| Hearing aids | Rehabilitates higher cortical functions | High bandwidth, miniaturization, low mutual coupling | Filtration and dielectrics properties, resistance to mechanical properties | [160,240,258] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matei, A.T.; Vișan, A.I.; Popescu-Pelin, G.F. Design and Processing of Metamaterials. Crystals 2025, 15, 374. https://doi.org/10.3390/cryst15040374

Matei AT, Vișan AI, Popescu-Pelin GF. Design and Processing of Metamaterials. Crystals. 2025; 15(4):374. https://doi.org/10.3390/cryst15040374

Chicago/Turabian StyleMatei, Andrei Teodor, Anita Ioana Vișan, and Gianina Florentina Popescu-Pelin. 2025. "Design and Processing of Metamaterials" Crystals 15, no. 4: 374. https://doi.org/10.3390/cryst15040374

APA StyleMatei, A. T., Vișan, A. I., & Popescu-Pelin, G. F. (2025). Design and Processing of Metamaterials. Crystals, 15(4), 374. https://doi.org/10.3390/cryst15040374