Effect of Biomimetic Structures on the Tensile Fracture Behavior of TLP Joints for GH4169

Abstract

1. Introduction

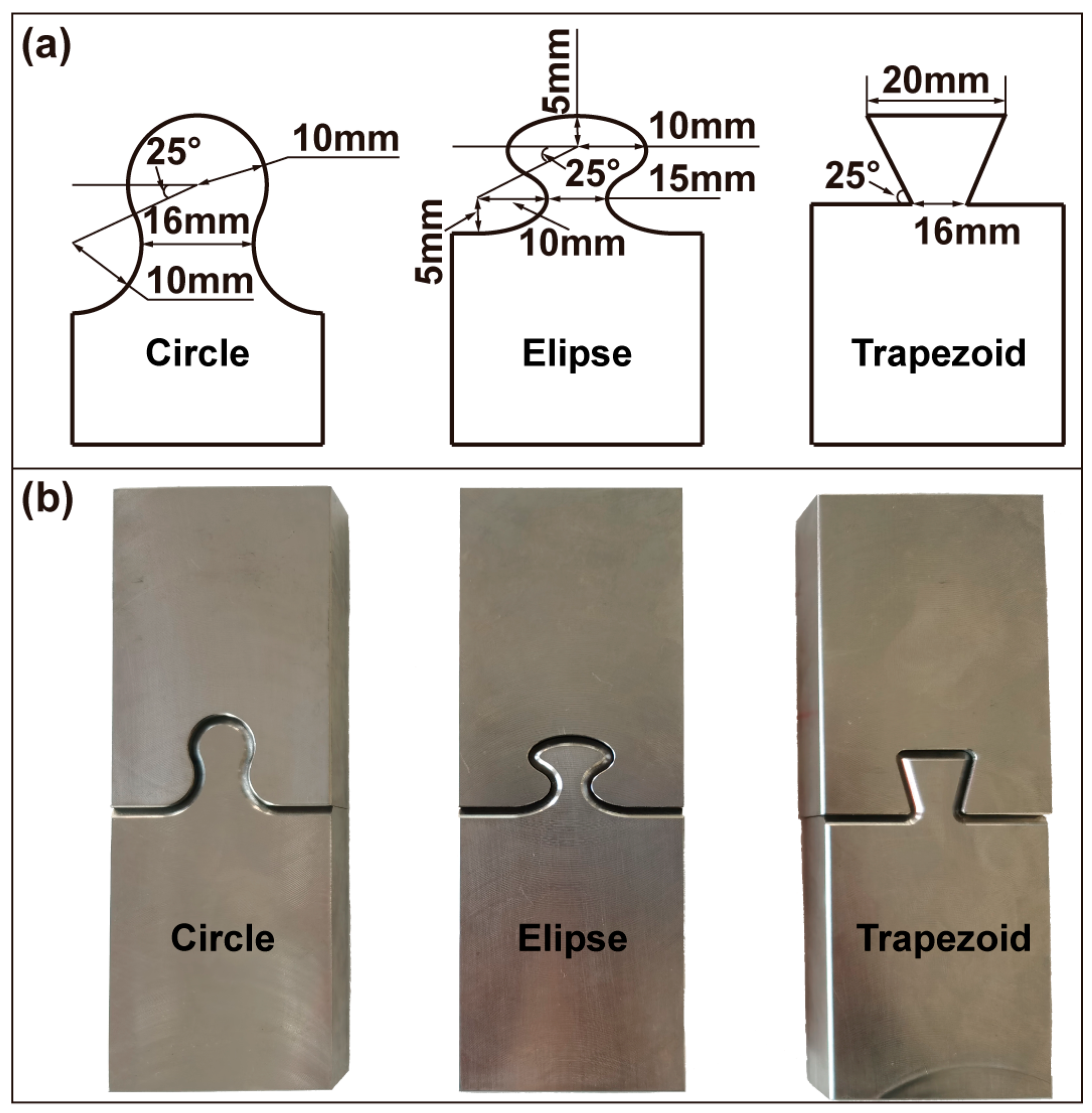

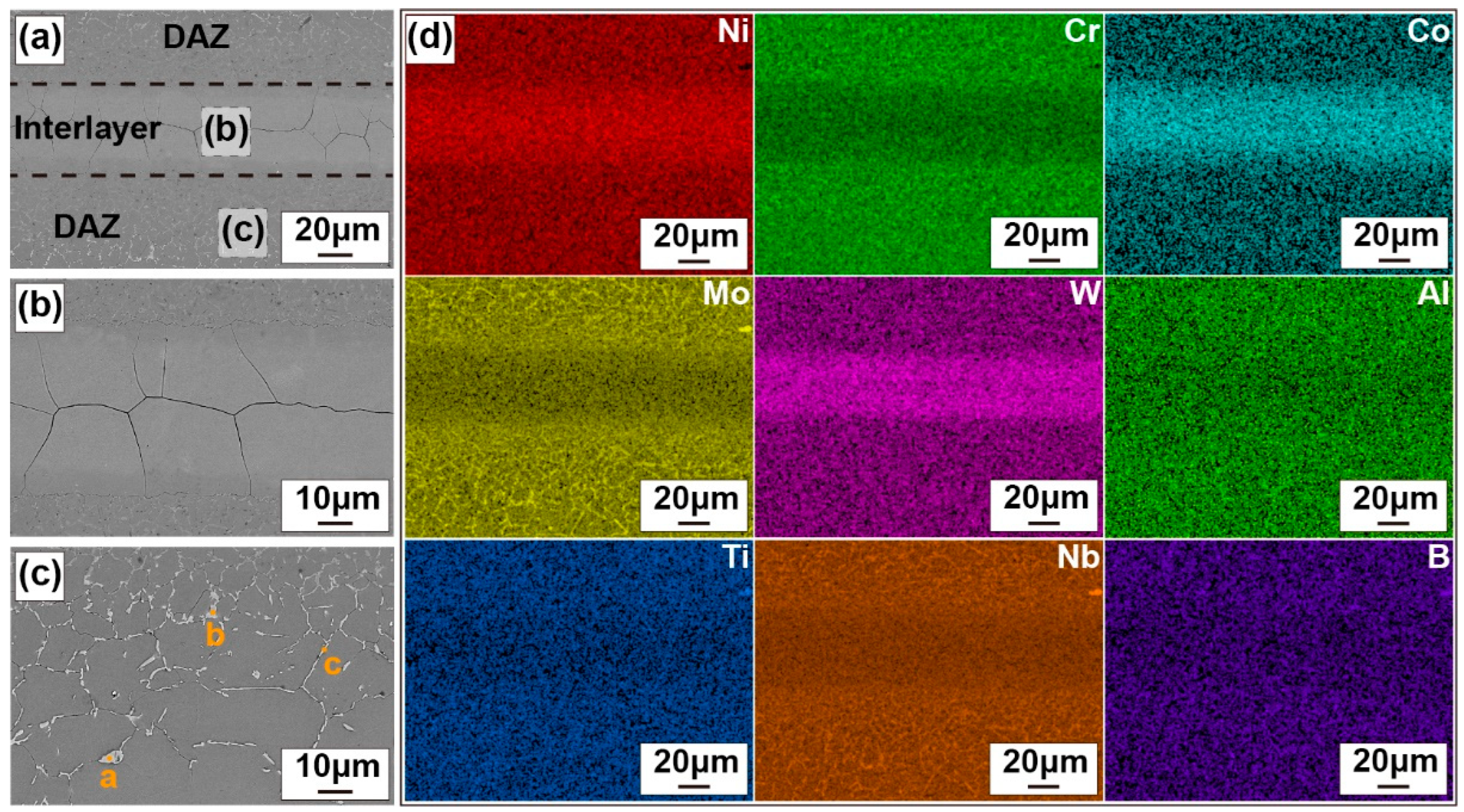

2. Materials and Methods

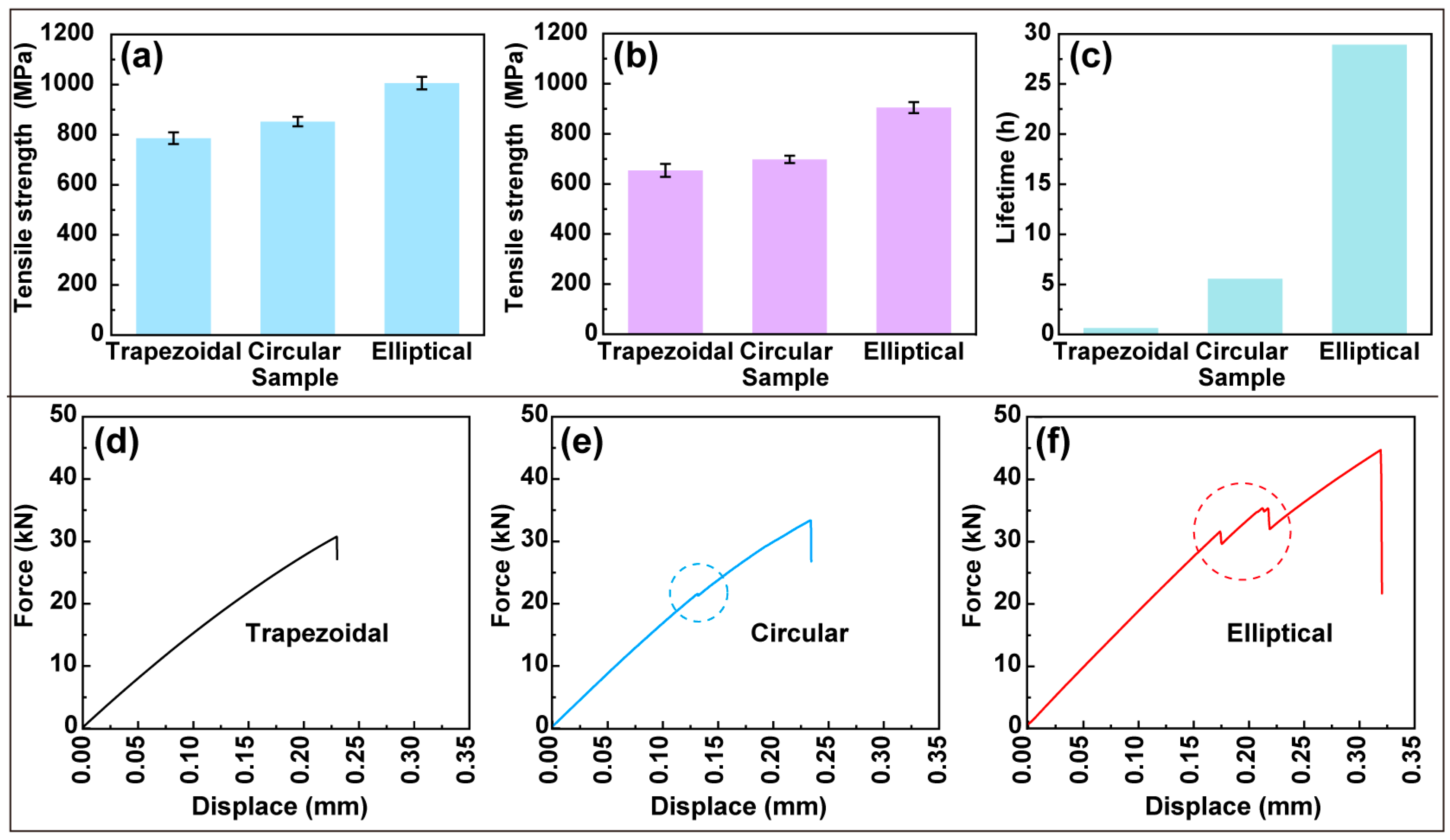

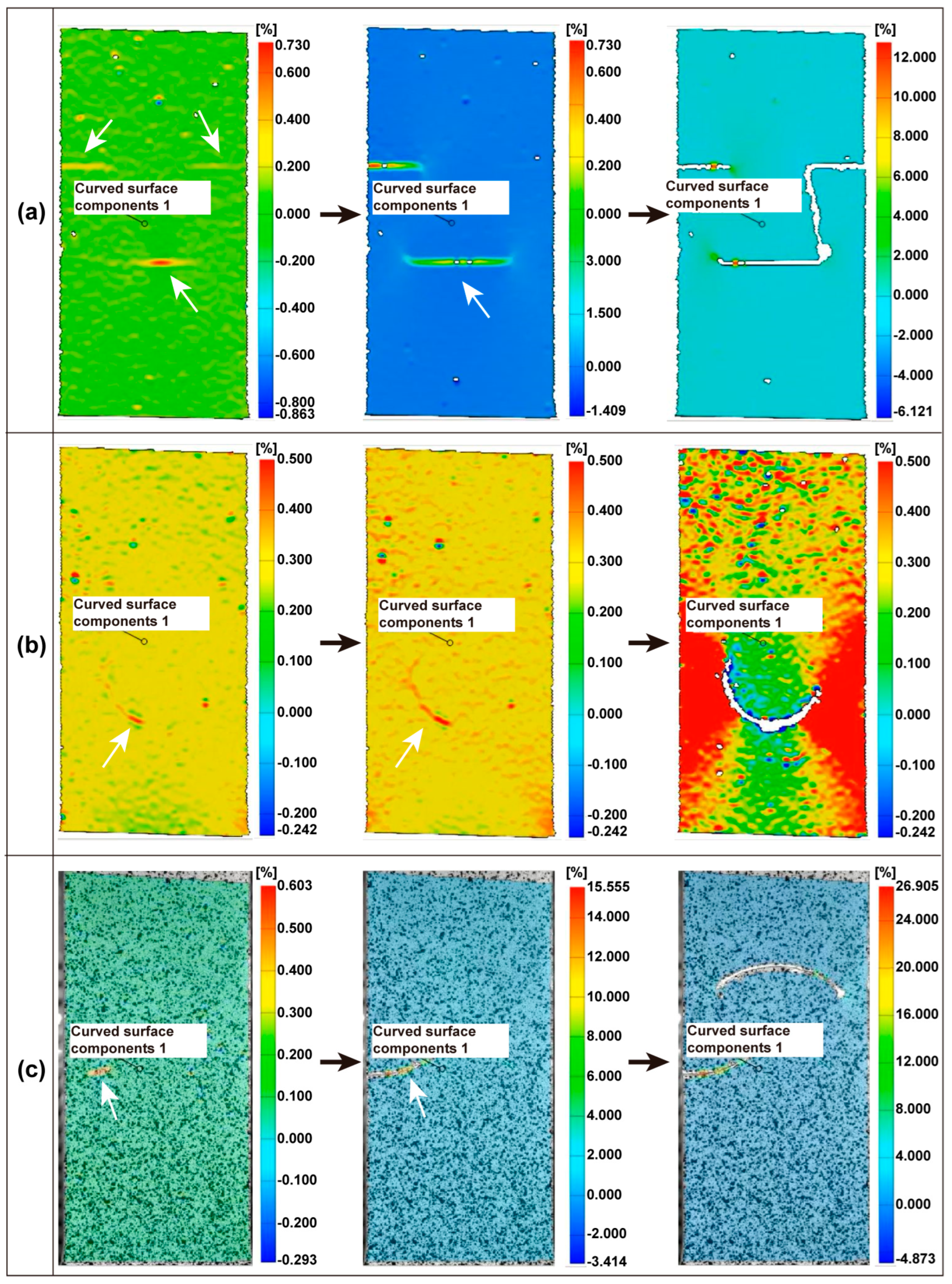

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kulawik, K.; Buffat, P.A.; Kruk, A.; Wusatowska-Sarnek, A.M.; Czyrska-Filemonowicz, A. Imaging and characterizationnanoparticles of γ′ and γ″ in Inconel 718 by EDX elemental mapping and FIB–SEM tomography. Mater. Charact. 2015, 100, 74–80. [Google Scholar] [CrossRef]

- Yang, J.Y.; Song, W.; Wang, P.; Hao, M.S.; Shi, L.; Lei, L.M.; Zhou, Y.Z.; Sun, X.F.; Liang, J.J.; Li, J.G. A novel high-performance Co-Al-W-based superalloy for additive manufacturing. Scr. Mater. 2025, 266, 116771. [Google Scholar] [CrossRef]

- Ouyang, G.; Palasyuk, O.; Singh, P.; Ray, P.K.; Deodeshmukh, V.; Cui, J.; Johnson, D.D.; Kramer, M.J. Predictive design of novel nickel-based superalloys beyond Haynes 282. Acta Mater. 2024, 275, 120045. [Google Scholar] [CrossRef]

- Yuan, L.; Yang, Y.Z.; Gan, J.; Chou, T.H.; Zhao, Y.M.; Hao, D.; Zhang, J.Y.; Li, J.L.; Xiong, J.T.; Yang, T. Extraordinary strength-ductility synergy in superalloy joints via a high-entropy-alloy modified multi-interlayer composite bonding strategy. Acta Mater. 2025, 295, 121186. [Google Scholar] [CrossRef]

- Wang, J.L.; Wang, Y.C.; Qin, Z.W.; Li, P.; Ding, Z.J.; Sun, Y.T.; Li, T.Y.; Jiang, X.; Li, C.; Dong, H.G. Co element gradient character toward achieving high strength diffusion bonding of FGH98 superalloy at low temperature. J. Manuf. Process. 2025, 149, 1126–1137. [Google Scholar] [CrossRef]

- Zhang, S.H.; Qu, W.Q.; Teng, J.F.; Lyu, Y.L.; Zhao, H.Y.; Zhuang, H.S. Development of the interlayer alloy using for TLP diffusion bonding of GH3230 superalloy based on the CALPHAD method. Mater. Sci. Eng. A 2024, 918, 147434. [Google Scholar] [CrossRef]

- Zou, T.Y.; Lang, Z.Q.; Chen, H.P.; Ye, Z.; Wu, T.; Wang, W.L.; Yang, J.; Huang, J.H. Rapidly achieving high-performance joining of single crystal superalloy and powder metallurgy superalloy via partial transient liquid phase diffusion bonding. J. Manuf. Process. 2024, 109, 79–88. [Google Scholar] [CrossRef]

- Zou, T.Y.; Ye, Z.; Lang, Z.Q.; Wu, T.; Wang, W.L.; Liu, Q.M.; Yang, J.; Chen, S.H.; Huang, J.H. A strong joint for single crystal superalloys by constructing mortise-tenon boundaries with interlocking effect. J. Mater. Sci. Technol. 2025, 233, 210–222. [Google Scholar] [CrossRef]

- Yuan, L.; Jiang, F.Y.; Hao, D.; Yang, Y.Z.; Chou, T.H.; Zhang, J.X.; Gan, J.; Li, J.L.; Xiong, J.T.; Yang, T. Ultrastrong and ductile superalloy joints bonded with a novel composite interlayer modified by high entropy alloy. J. Mater. Sci. Technol. 2025, 222, 152–163. [Google Scholar] [CrossRef]

- Xie, C.L.; Deng, K.Y.; Teng, J.F.; Fu, J.Y.; Li, R.; Zhang, T. Microstructural evolution and mechanical properties of Ni-based superalloy joints brazed using a ternary Ni-W-B amorphous brazing filler metal. J. Alloys Compd. 2023, 960, 170663. [Google Scholar] [CrossRef]

- Reeks, W.; Davies, H.; Marchisio, S. A review: Interlayer joining of nickel base alloys. J. Adv. Join. Process. 2020, 2, 100030. [Google Scholar] [CrossRef]

- Jiao, Y.J.; Sheng, G.M.; Zhang, Y.T.; Xu, C.; Yuan, X.J. Transient liquid phase bonding of Inconel 625 with Mar-M247 superalloy using Ni–Cr–B interlayer: Microstructure and mechanical properties. Mater. Sci. Eng. A 2022, 831, 142204. [Google Scholar] [CrossRef]

- Siddiqui, M.A.S.; Rabbi, M.S.; Ahmed, R.U.; Fahad, A.; Hossain, M.A.M.; Ahsan, S.; Miah, N.M. Bioinspired composite structures: A comprehensive review of natural materials, fabrication methods, and engineering applications. Compos. Part C Open Access 2025, 17, 100578. [Google Scholar] [CrossRef]

- Pichard, P.L.; Maheo, L.; Dirrenberger, J.; Castro, M.; Lafont, U.; Le Duigou, A. Efficient energy-dissipative bioinspired architectured composite materials with high mechanical properties. Addit. Manuf. 2025, 109, 104875. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Yazdani Sarvestani, H.; Li, L.; Barroeta Robles, J.; Backman, D.; Lessard, L.; Ashrafi, B. Engineering toughening mechanisms in architectured ceramic-based bioinspired materials. Mater. Des. 2021, 198, 109375. [Google Scholar] [CrossRef]

- Altuntas, U.; Coker, D.; Yavas, D. Bioinspired soft-hard interfaces fabricated by multi-material additive manufacturing: A fracture mechanics investigation using essential work of fracture. Mech. Mater. 2024, 195, 105035. [Google Scholar] [CrossRef]

- Cheng, L.; Thomas, A.; Glancey, J.L.; Karlsson, A.M. Mechanical behavior of bio-inspired laminated composites. Compos. Part A 2011, 42, 211–220. [Google Scholar] [CrossRef]

- Bixler, G.D.; Theiss, A.; Bhushan, B.; Lee, S.C. Anti-fouling properties of microstructured surfaces bio-inspired by rice leaves and butterfly wings. J. Colloid Interface Sci. 2014, 419, 114–133. [Google Scholar] [CrossRef] [PubMed]

- Nazari, K.; Tran, P.; Tan, P.; Ghazlan, A.; Ngo, T.D.; Xie, Y.M. Advanced manufacturing methods for ceramic and bioinspired ceramic composites: A review. Open Ceram. 2023, 15, 100399. [Google Scholar] [CrossRef]

- Sharma, A.; Shukla, N.K.; Belarbi, M.O.; Abbas, M.; Garg, A.; Li, L.; Bhutto, J.A. Bhatia, Bio-inspired nacre and helicoidal composites: From structure to mechanical applications. Thin Wall. Struct. 2023, 192, 111146. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, J.; Fang, H.M.; Zhang, Y.F.; Bai, S.L.; He, G.S. Al2O3/graphene reinforced bio-inspired interlocking polyurethane composites with superior mechanical and thermal properties for solid propulsion fuel. Compos. Sci. Technol. 2018, 167, 42–52. [Google Scholar] [CrossRef]

- Lai, S.Y.; Zhao, C.Y.; Gong, L.P.; Liu, S.; Yang, J.J.; Wang, D.P.; Mei, G.L.; Li, W.H.; Gong, X.L. Beetle elytra-inspired shear-stiffening warp-knitted spacer fabric composites with enhanced impact resistance. Compos. Struct. 2025, 370, 119443. [Google Scholar] [CrossRef]

- Yang, C.; Xing, Y.; Feng, X.Q.; Yang, J.L.; Zhao, Z.-L. Interdigital interlocking suture: A strong, tough, and flexible biological design. Thin Wall. Struct. 2025, 215, 113595. [Google Scholar] [CrossRef]

- Zou, T.Y.; Lang, Z.Q.; Lu, R.L.; Liu, J.W.; Xu, X.L. Tensile deformation and fracture behavior at high temperature of the TLP joint for Hastelloy X superalloy with laminated interlayer. Eng. Fail. Anal. 2025, 171, 109363. [Google Scholar] [CrossRef]

| Point | Mo | Si | Cr | Fe | Ti | Al | Nb | B | C | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| Base material | 2.6 | - | 17.6 | 16.4 | 1.2 | 1.0 | 5.2 | - | 0.06 | Bal. |

| Filling material | - | 4.5 | 7.0 | 3.0 | - | - | - | 3.5 | - | Bal. |

| Point | Ni | Cr | Fe | Ti | Nb |

|---|---|---|---|---|---|

| a | 3.07 | 1.02 | 1.53 | 10.27 | 84.10 |

| b | 2.43 | 1.02 | 0.93 | 13.05 | 82.57 |

| c | 3.30 | 1.29 | 1.00 | 16.32 | 78.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lang, Z.; Pan, B.; Wang, X.; Teng, J.; Yang, W.; Zou, T.; Chai, L. Effect of Biomimetic Structures on the Tensile Fracture Behavior of TLP Joints for GH4169. Crystals 2025, 15, 1026. https://doi.org/10.3390/cryst15121026

Lang Z, Pan B, Wang X, Teng J, Yang W, Zou T, Chai L. Effect of Biomimetic Structures on the Tensile Fracture Behavior of TLP Joints for GH4169. Crystals. 2025; 15(12):1026. https://doi.org/10.3390/cryst15121026

Chicago/Turabian StyleLang, Zhenqian, Bo Pan, Xinyan Wang, Junfei Teng, Wenjing Yang, Taiyong Zou, and Lu Chai. 2025. "Effect of Biomimetic Structures on the Tensile Fracture Behavior of TLP Joints for GH4169" Crystals 15, no. 12: 1026. https://doi.org/10.3390/cryst15121026

APA StyleLang, Z., Pan, B., Wang, X., Teng, J., Yang, W., Zou, T., & Chai, L. (2025). Effect of Biomimetic Structures on the Tensile Fracture Behavior of TLP Joints for GH4169. Crystals, 15(12), 1026. https://doi.org/10.3390/cryst15121026