Low Coefficient of Thermal Expansion (CTE) Ceramic–Thermoplastic Composite for Fused Deposition Modelling of RF and Microwave Devices

Abstract

1. Introduction

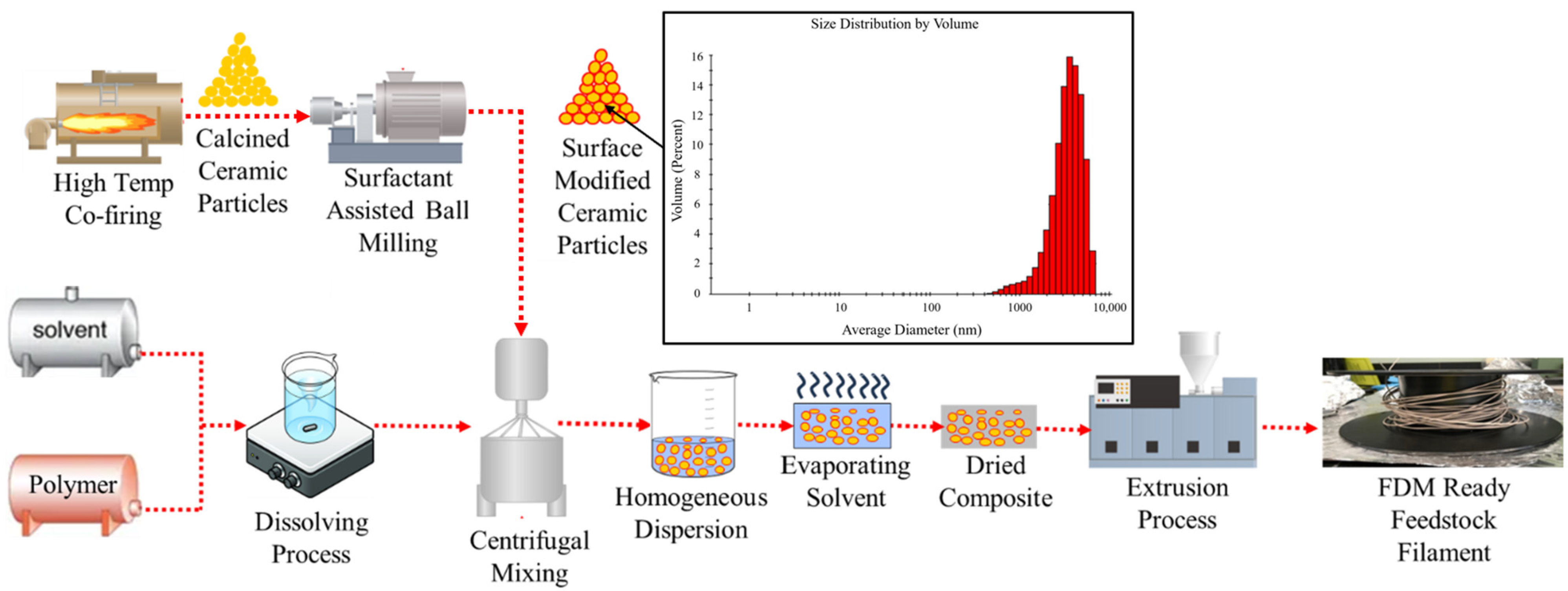

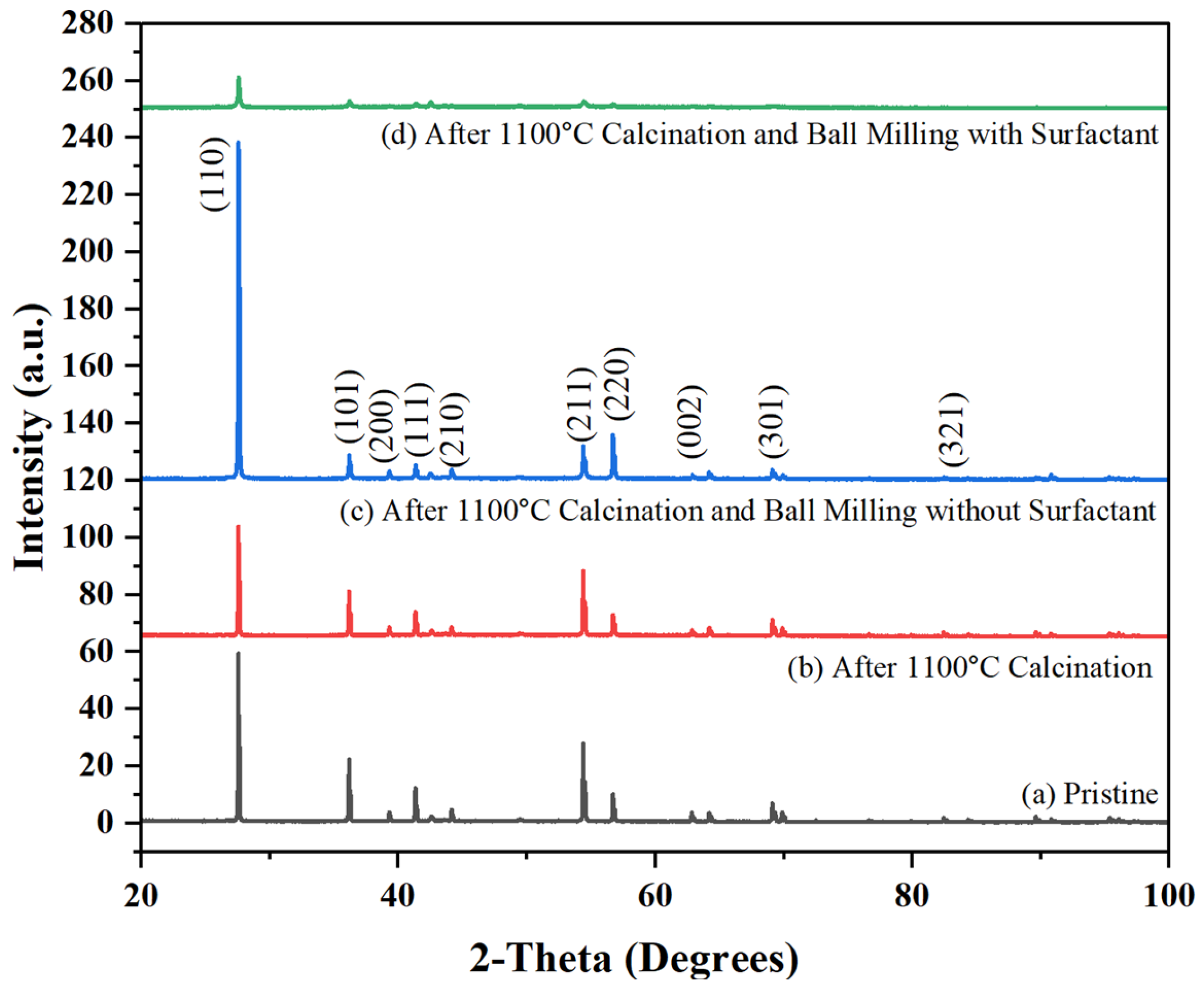

2. Materials and Methods

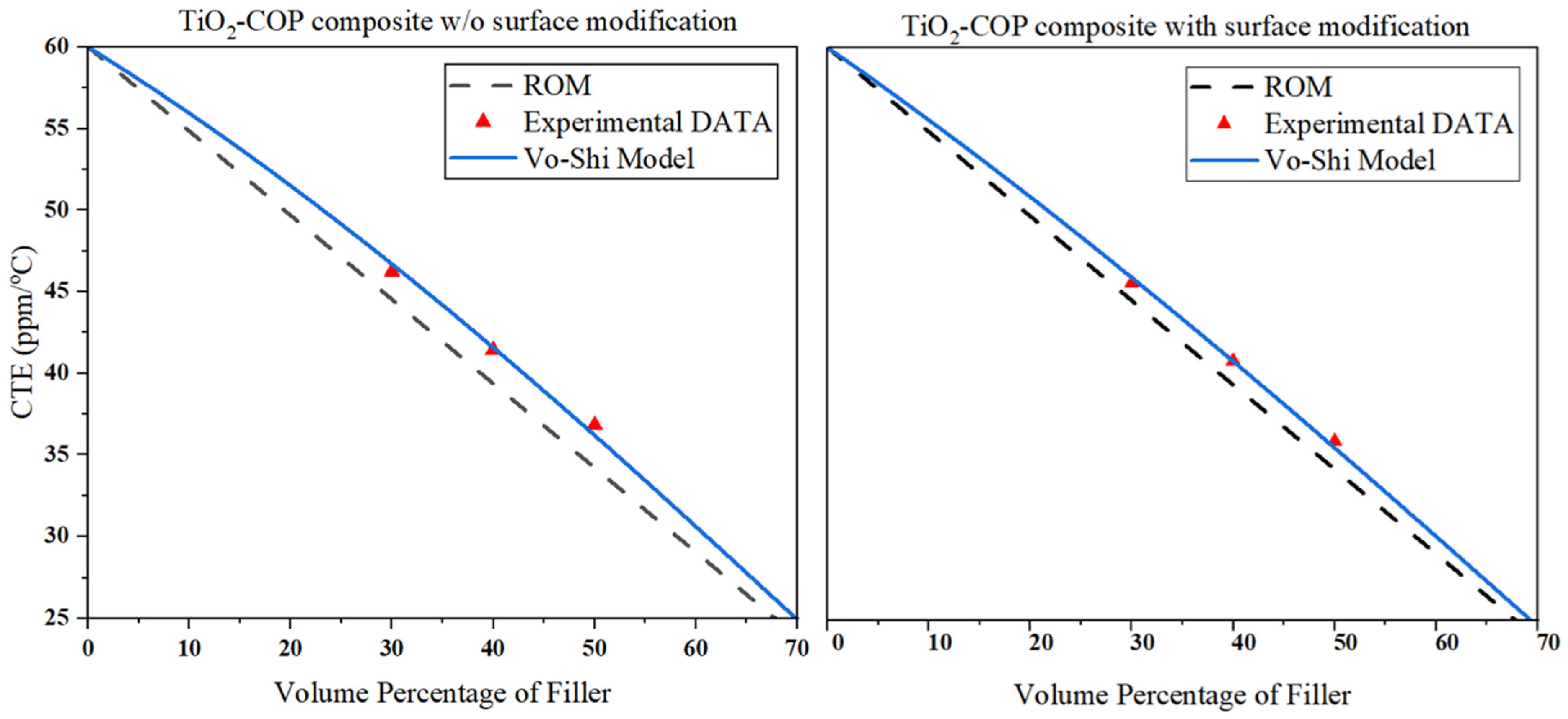

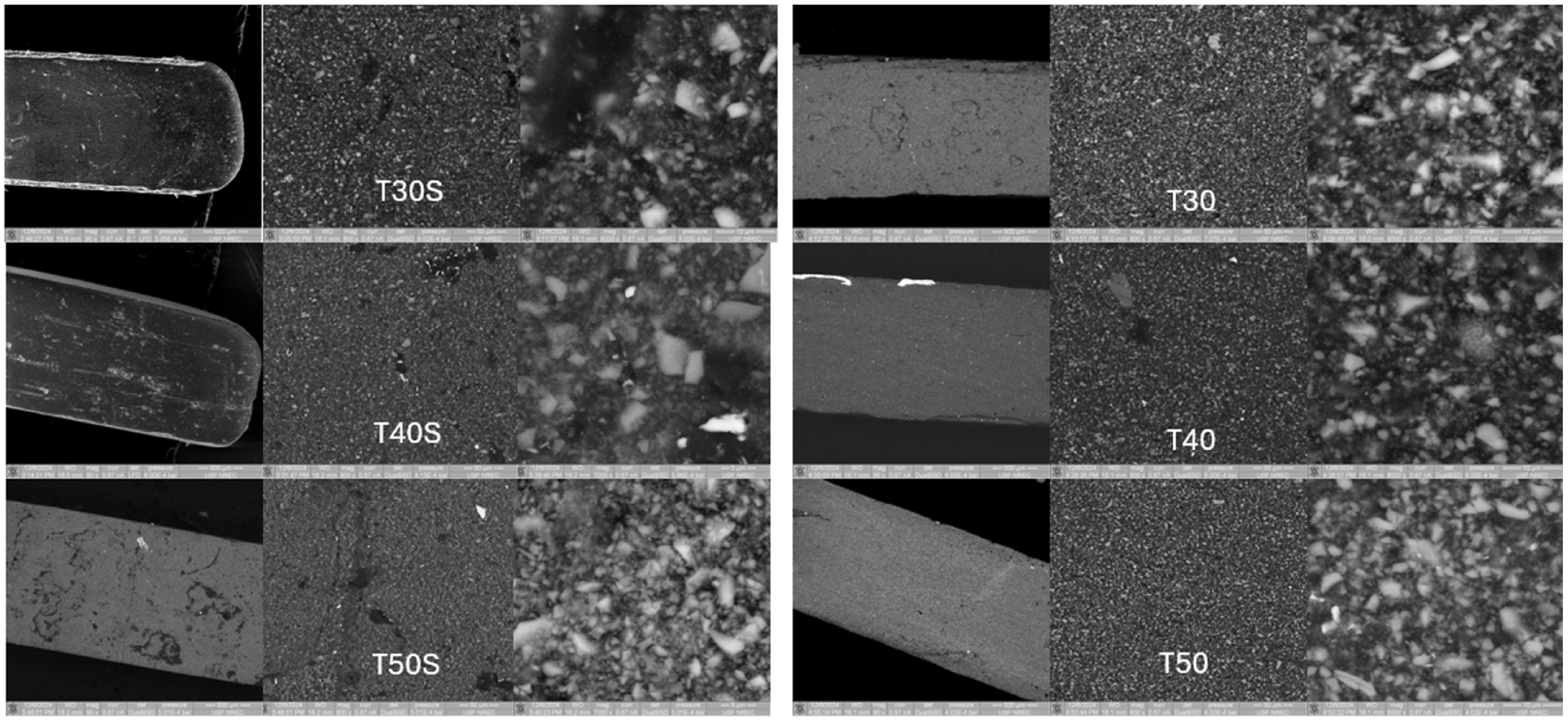

3. Results and Discussion

4. Conclusions

5. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Castro, J.; Rojas, E.; Weller, T.; Wang, J. High-Permittivity and Low-Loss Electromagnetic Composites Based on Co-fired Ba0.55Sr0.45TiO3 or MgCaTiO2 Microfillers for Additive Manufacturing and Their Application to 3-D Printed K-Band Antennas. J. Microelectron. Electron. Packag. 2016, 13, 102–112. [Google Scholar] [CrossRef]

- Castro, J.; Rojas-Nastrucci, E.A.; Ross, A.; Weller, T.M.; Wang, J. Fabrication, Modeling, and Application of Ceramic-Thermoplastic Composites for Fused Deposition Modeling of Microwave Components. IEEE Trans. Microw. Theory Technol. 2017, 65, 2073–2084. [Google Scholar] [CrossRef]

- Castro, J.D.D. Engineered Nanocomposite Materials for Microwave/Millimeter-Wave Applications of Fused Deposition Modeling. Ph.D. Thesis, University of South Florida, Tampa, FL, USA, 2017. [Google Scholar]

- Church, K.H.; Crane, N.B.; Deffenbaugh, P.I.; Ketterl, T.P.; Neff, C.G.; Nesbitt, P.B.; Nussbaum, J.T.; Perkowski, C.; Tsang, H.; Castro, J.; et al. Multimaterial and Multilayer Direct Digital Manufacturing of 3-D Structural Microwave Electronics. Proc. IEEE 2017, 105, 688–701. [Google Scholar] [CrossRef]

- Czarny, R.; Hoang, T.Q.V.T.Q.; Loiseaux, B.; Bellomonte, G.; Lebourgeois, R.; Leuliet, A.; Qassym, L.; Galindo, C.; Heintz, J.M.; Penin, N.; et al. High Permittivity, Low Loss, and Printable Thermoplastic Composite Material for RF and Microwave Applications. In Proceedings of the 2018 IEEE Conference on Antenna Measurements & Applications (CAMA), Vasteras, Sweden, 3–6 September 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Moritz, T.; Maleksaeedi, S. 4—Additive manufacturing of ceramic components. In Additive Manufacturing; Zhang, J., Jung, Y.-G., Eds.; Butterworth-Heinemann: Amsterdam, The Netherlands, 2018; pp. 105–161. [Google Scholar]

- Song, S.Y.; Park, M.S.; Lee, J.W.; Yun, J.S. A Study on the Rheological and Mechanical Properties of Photo-Curable Ceramic/Polymer Composites with Different Silane Coupling Agents for SLA 3D Printing Technology. Nanomaterials 2018, 8, 93. [Google Scholar] [CrossRef]

- Zenou, M.; Grainger, L. 3—Additive manufacturing of metallic materials. In Additive Manufacturing; Zhang, J., Jung, Y.-G., Eds.; Butterworth-Heinemann: Amsterdam, The Netherlands, 2018; pp. 53–103. [Google Scholar]

- Zhang, Y.; Jarosinski, W.; Jung, Y.-G.; Zhang, J. 2—Additive manufacturing processes and equipment. In Additive Manufacturing; Zhang, J., Jung, Y.-G., Eds.; Butterworth-Heinemann: Amsterdam, The Netherlands, 2018; pp. 39–51. [Google Scholar]

- Zhao, S.; Zhao, Z.; Yang, Z.; Ke, L.; Kitipornchai, S.; Yang, J. Functionally graded graphene reinforced composite structures: A review. Eng. Struct. 2020, 210, 110339. [Google Scholar] [CrossRef]

- Lugo, D.C.; Wang, J.; Weller, T.M. Analytical and Experimental Study of Multilayer Dielectric Rod Waveguides. IEEE Trans. Microw. Theory Technol. 2021, 69, 2088–2097. [Google Scholar] [CrossRef]

- Polenz, S.; Kunz, W.; Braun, B.; Franke, A.; Lopez, E.; Bruckner, F.; Leyens, C. Development of a System for Additive Manufacturing of Ceramic Matrix Composite Structures Using Laser Technology. Materials 2021, 14, 3248. [Google Scholar] [CrossRef]

- Liu, R.; Braun, J.; Mitchell, G.; Wang, J.; Mumcu, G. Packaging of a Beamforming IC by Laser Enhanced Direct Print Additive Manufacturing (LE-DPAM). In Proceedings of the 2022 3rd URSI Atlantic and Asia Pacific Radio Science Meeting (AT-AP-RASC), Gran Canaria, Spain, 30 May–4 June 2022; pp. 1–3. [Google Scholar] [CrossRef]

- Liu, R.; Mumcu, G.; Wang, J. Towards Additive Manufacturing Based Packaging of Mm-Wave Antenna Arrays and Beamformer ICs. In Proceedings of the 2024 IEEE Wireless and Microwave Technology Conference (WAMICON), Clearwater, FL, USA, 15–16 April 2024; pp. 1–3. [Google Scholar] [CrossRef]

- Firat, O.F.; Wang, J.; Weller, T. Characterization of Additively Manufactured Suspended Finite Ground CPW Interconnects Enhanced by Femtosecond Laser Micromachining. IEEE Trans. Compon. Packag. Manuf. Technol. 2024, 14, 965–972. [Google Scholar] [CrossRef]

- Chen, H.; Guo, L.; Zhu, W.; Li, C. Recent Advances in Multi-Material 3D Printing of Functional Ceramic Devices. Polymers 2022, 14, 4635. [Google Scholar] [CrossRef]

- Akbari, S.; Kostov, K.; Brinkfeldt, K.; Adolfsson, E.; Lim, J.K.; Andersson, D.; Bakowski, M.; Wang, Q.; Salter, M. Ceramic Additive Manufacturing Potential for Power Electronics Packaging. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 1857–1866. [Google Scholar] [CrossRef]

- Ryu, K.; Kim, J.; Choi, J.; Kim, U. The 3D Printing Behavior of Photocurable Ceramic/Polymer Composite Slurries Prepared with Different Particle Sizes. Nanomaterials 2022, 12, 2631. [Google Scholar] [CrossRef]

- Przybyła, S.; Kwiatkowski, M.; Kwiatkowski, M.; Hebda, M. Optimization of Ceramic Paste Composition for 3D Printing via Robocasting. Materials 2024, 17, 4560. [Google Scholar] [CrossRef] [PubMed]

- Kattel, B.; Ayan, U.; Mohoppu, M.; Villacorta, B.; Hutchcraft, W.E. Enhancing Permittivity of 3D Printing Filaments via Nanocompounding for Electromagnetic Applications. In Proceedings of the SoutheastCon 2024, Atlanta, GA, USA, 15–24 March 2024; pp. 1016–1021. [Google Scholar] [CrossRef]

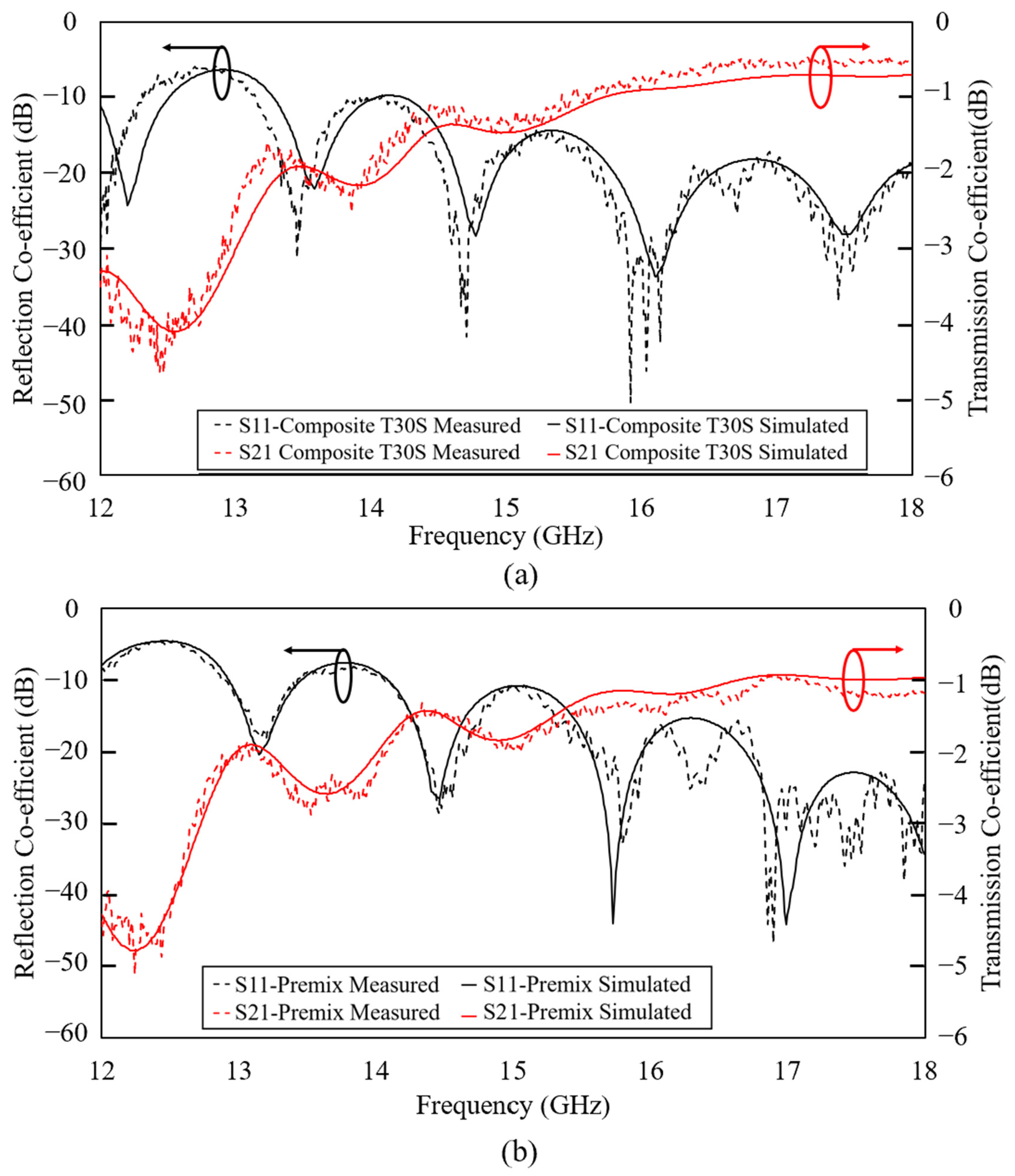

- Kosamiya, V.; Wang, J. Composite Feedstock Filaments for Fused Deposition Modeling (FDM) of Microwave Interconnects. IEEE Trans. Compon. Packag. Manuf. Technol. 2023, 13, 249–256. [Google Scholar] [CrossRef]

- Vo, H.T.; Shi, F.G. Towards model-based engineering of optoelectronic packaging materials: Dielectric constant modeling. Microelectron. J. 2002, 33, 409–415. [Google Scholar] [CrossRef]

- Vo, H.T.; Todd, M.; Shi, F.G.; Shapiro, A.A.; Edwards, M. Towards model-based engineering of underfill materials: CTE modeling. Microelectron. J. 2001, 32, 331–338. [Google Scholar] [CrossRef]

- Ahmed, H.M.; Abdel-Gawad, N.M.; Afifi, W.A.; Mansour, D.-E.A.; Lehtonen, M.; Darwish, M.M. A novel polyester varnish nanocomposites for electrical machines with improved thermal and dielectric properties using functionalized TiO2 nanoparticles. Materials 2023, 16, 6478. [Google Scholar] [CrossRef]

- Ashokbabu, A.; Thomas, P. Dielectric and Thermal Properties of PTFE/CaCu3Ti4O12(CCTO) Nanocomposites. In Proceedings of the 2019 International Conference on High Voltage Engineering and Technology (ICHVET), Hyderabad, India, 7–8 February 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Filaments. Available online: https://zetamix.fr/categorie-produit/filaments/ (accessed on 31 October 2025).

- Carias, V.; Thompson, J.; Myers, P.D.; Kumar, P.; Racz, L.M.; Toomey, R.; Wang, J. Development of Mold Compounds with Ultralow Coefficient of Thermal Expansion and High Glass Transition Temperature for Fan-Out Wafer-Level Packaging. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 921–929. [Google Scholar] [CrossRef]

- Karunaratne, M.S.A.; Kyaw, S.; Jones, A.; Morrell, R.; Thomson, R.C. Modelling the coefficient of thermal expansion in Ni-based superalloys and bond coatings. J. Mater. Sci. 2016, 51, 4213–4226. [Google Scholar] [CrossRef]

- Cazan, C.; Enesca, A.; Andronic, L. Synergic Effect of TiO2 Filler on the Mechanical Properties of Polymer Nanocomposites. Polymers 2021, 13, 2017. [Google Scholar] [CrossRef]

- Jeon, H.; Yoon, C.; Song, Y.-G.; Han, J.; Kwon, S.; Kim, S.; Chang, I.; Lee, K. Reducing the Coefficient of Thermal Expansion of Polyimide Films in Microelectronics Processing Using ZnS Particles at Low Concentrations. ACS Appl. Nano Mater. 2018, 1, 1076–1082. [Google Scholar] [CrossRef]

- Ou, J.; Chen, Y.; Zhao, J.; Luo, S.; Wong, K.W.; Ng, K.M. Nano-Sized Calcium Copper Titanate for the Fabrication of High Dielectric Constant Functional Ceramic-Polymer Composites. Polymers 2022, 14, 4328. [Google Scholar] [CrossRef] [PubMed]

- Sahu, M.; Satapathy, A. Processing and characterization of TiO2 filled polymer composites. Mater. Today Proc. 2021, 44, 4945–4951. [Google Scholar] [CrossRef]

- Kurimoto, M.; Ozaki, H.; Sawada, T.; Kato, T.; Funabashi, T.; Suzuoki, Y. Filling ratio control of TiO2 and SiO2 in epoxy composites for permittivity-graded insulator with low coefficient of thermal expansion. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1112–1120. [Google Scholar] [CrossRef]

- Shah, M.; Ullah, A.; Azher, K.; Ur Rehman, A.; Akturk, N.; Juan, W.; Tüfekci, C.S.; Salamci, M.U. The Influence of Nanoparticle Dispersions on Mechanical and Thermal Properties of Polymer Nanocomposites Using SLA 3D Printing. Crystals 2023, 13, 285. [Google Scholar] [CrossRef]

- Chao, S.; Liaw, Y.; Chou, J.-H. The Effects of Filler Shape, Type, and Size on the Properties of Encapsulation Molding Components. Electronics 2021, 10, 98. [Google Scholar] [CrossRef]

- Keshyagol, K.; Hiremath, S.; Vishwanatha, H.M.; Rao, P.K.; Hiremath, P.; Naik, N. Analysis of Polymer-Ceramic Composites Performance on Electrical and Mechanical Properties through Finite Element and Empirical Models. Materials 2024, 17, 3837. [Google Scholar] [CrossRef]

- Rodzi, M.L.M.; Ismail, M.F.; Minhat, M. Applicability of Rule of Mixtures to Estimate Effective Properties of Nanocomposite Materials. In Proceedings of International Conference of Aerospace and Mechanical Engineering 2019; Rajendran, P., Mazlan, N.M., Rahman, A.A.A., Suhadis, N.M., Razak, N.A., Abidin, M.S.Z., Eds.; Springer Singapore: Singapore, 2020; pp. 191–205. [Google Scholar]

- Kosamiya, V.; Wang, J. High-k and Low-Loss Dielectric Composite Feedstock Filaments, Tailored for Additive Manufacturing of Microwave Devices. In Proceedings of the 2020 IEEE/MTT-S International Microwave Symposium (IMS), Los Angeles, CA, USA, 4–6 August 2020; pp. 928–931. [Google Scholar] [CrossRef]

- Savijarvi, A.M.; Paajanen, M.; Saarimaki, E.; Minkkinen, H. Novel heat durable electromechanical films: Cellular film making from cyclic olefin polymers. In Proceedings of the 2005 12th International Symposium on Electrets, Salvador, Brazil, 11–14 September 2005; pp. 75–78. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Wadsworth, M.; Ahmed, M.F.; Liu, Z.; Zeng, C. Design, Fabrication, Structure Optimization and Pressure Sensing Demonstration of COC Piezoelectret Sensor and Sensor Array. Micromachines 2022, 13, 1177. [Google Scholar] [CrossRef]

- Beccaria, M.; Massaccesi, A.; Lumia, M.; Addamo, G.; Freni, A.; Pirinoli, P. Ka-Band Reflectarray with Cylindrical Dielectric Unit Cells: Optimized Additive Manufacturing and High-Permittivity Material Characterization. Sensors 2025, 25, 5480. [Google Scholar] [CrossRef]

- González-Benito, J.; Castillo, E.; Caldito, J.F. Coefficient of thermal expansion of TiO2 filled EVA based nanocomposites. A new insight about the influence of filler particle size in composites. Eur. Polym. J. 2013, 49, 1747–1752. [Google Scholar] [CrossRef]

- Chen, J.; Li, B.; Zhang, S.; Li, H. Effect of the Presence of a Silane Coupling Agent on Reaction Kinetics of Cationic Thermopolymerization of Epoxy Resin Adhesive. Coatings 2023, 13, 1782. [Google Scholar] [CrossRef]

- Heo, G.-Y.; Park, S.-J. Effect of coupling agents on thermal, flow, and adhesion properties of epoxy/silica compounds for capillary underfill applications. Powder Technol. 2012, 230, 145–150. [Google Scholar] [CrossRef]

- Sasikala, T.S.; Raman, S.; Mohanan, P.; Pavithran, C.; Sebastian, M.T. Effect of silane coupling agent on the dielectric and thermal properties of DGEBA-forsterite composites. J. Polym. Res. 2011, 18, 811–819. [Google Scholar] [CrossRef]

- Peng, L.; Zhang, R.; Fan, Y.; Yang, Y.; Fu, K.; Li, G.; Sun, R.; Zhu, P. A mechanical model for predicting the thermal expansion behavior of spherical particle reinforced epoxy composites. Polym. Compos. 2024, 45, 5256–5266. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, Q.; Fang, R.; Huang, Z.; Shi, X. Development of a Predictive Model for the Thermal Expansion Coefficient of Elastic Disordered Microporous Metal Rubber Based on Virtual Manufacturing Technology. Chin. J. Mech. Eng. 2025, 38, 61. [Google Scholar] [CrossRef]

- Taibi, N.; Belabed, Z.; Boucham, B.; Benguediab, M.; Tounsi, A.; Khedher, K.M.; Salem, M.A. On the Thermomechanical Behavior of Laminated Composite Plates using different Micromechanical-based Models for Coefficients of Thermal Expansion (CTE). J. Appl. Comput. Mech. 2024, 10, 224–244. [Google Scholar] [CrossRef]

| Composite | Thickness of Interphase Layer (µm) | Radius of Filler Particles (µm) | K1 | K0 | CTE of Filler (ppm/°C) | CTE of Matrix (ppm/°C) |

|---|---|---|---|---|---|---|

| TiO2-COP w/o surface modification | 1 | 10 | 0 | −0.25 | 8.4 | 59.86 |

| TiO2-COP with surface modification | 1 | 10 | −5 | −0.15 | 8.4 | 59.86 |

| Sample Name | Sample Weight g | Avg Volume Value cm3 | Avg Density g/cm3 |

|---|---|---|---|

| Pristine TiO2 | 0.2552 | 0.0634 | 4.0225 |

| Calcined TiO2 | 0.2264 | 0.0542 | 4.1791 |

| Calcined and ball-milled TiO2 w/o surfactant | 0.1566 | 0.0366 | 4.2747 |

| Calcined and ball-milled TiO2 with surfactant | 0.1834 | 0.0435 | 4.2175 |

| Sample Name | Filler | Volume Fraction of Filter % v/v | Avg CTE in ppm/°C from 40 to 120 °C | Surfactant Volume % Based on Filler Volume |

|---|---|---|---|---|

| Pure COP | - | - | 59.86 | 0 |

| T30S | Titania | 30 | 45.61 | 5% |

| T40S | Titania | 40 | 40.83 | 5% |

| T50S | Titania | 50 | 35.93 | 5% |

| T30 | Titania | 30 | 46.24 | 0 |

| T40 | Titania | 40 | 41.43 | 0 |

| T50 | Titania | 50 | 36.83 | 0 |

| Calcination Temperature (°C) | Measured Density (g/cm3) | Surfactant Present During High-Energy Ball-Milling | Avg Particle Size (µm) | a (Å) | b (Å) | c (Å) | V (Å3) | Phase | Crystal Structure |

|---|---|---|---|---|---|---|---|---|---|

| 1100 | 4.2175 | Yes | 6.67 | 4.5933 | 4.5933 | 2.9580 | 62.41 | Rutile | Tetragonal |

| 1100 | 4.2747 | No | 6.77 | 4.5933 | 4.5933 | 2.9580 | 62.41 | ||

| 1100 | 4.1791 | - | 50 | 4.5933 | 4.5933 | 2.9580 | 62.41 | ||

| Pristine | 4.0225 | - | 50 | 4.5933 | 4.5933 | 2.9580 | 62.41 |

| Element | Pristine | Calcined @ 1100 °C |

|---|---|---|

| O | 18.41 | 15.83 |

| Ti | 81.59 | 84.17 |

| Total | 100.00 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosamiya, V.; Li, L.; Gkikas, I.N.; Castro, J.D.; Oppenheimer, J.; Spanopoulos, I.; Wang, J. Low Coefficient of Thermal Expansion (CTE) Ceramic–Thermoplastic Composite for Fused Deposition Modelling of RF and Microwave Devices. Crystals 2025, 15, 963. https://doi.org/10.3390/cryst15110963

Kosamiya V, Li L, Gkikas IN, Castro JD, Oppenheimer J, Spanopoulos I, Wang J. Low Coefficient of Thermal Expansion (CTE) Ceramic–Thermoplastic Composite for Fused Deposition Modelling of RF and Microwave Devices. Crystals. 2025; 15(11):963. https://doi.org/10.3390/cryst15110963

Chicago/Turabian StyleKosamiya, Vishvajitsinh, Liguan Li, Ioannis N. Gkikas, Juan D. Castro, Julia Oppenheimer, Ioannis Spanopoulos, and Jing Wang. 2025. "Low Coefficient of Thermal Expansion (CTE) Ceramic–Thermoplastic Composite for Fused Deposition Modelling of RF and Microwave Devices" Crystals 15, no. 11: 963. https://doi.org/10.3390/cryst15110963

APA StyleKosamiya, V., Li, L., Gkikas, I. N., Castro, J. D., Oppenheimer, J., Spanopoulos, I., & Wang, J. (2025). Low Coefficient of Thermal Expansion (CTE) Ceramic–Thermoplastic Composite for Fused Deposition Modelling of RF and Microwave Devices. Crystals, 15(11), 963. https://doi.org/10.3390/cryst15110963