Role of Internal Cyclic Heat Treatment on Regulating Microstructure and Mechanical Properties of Laser Melting-Deposited Ti2AlNb Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

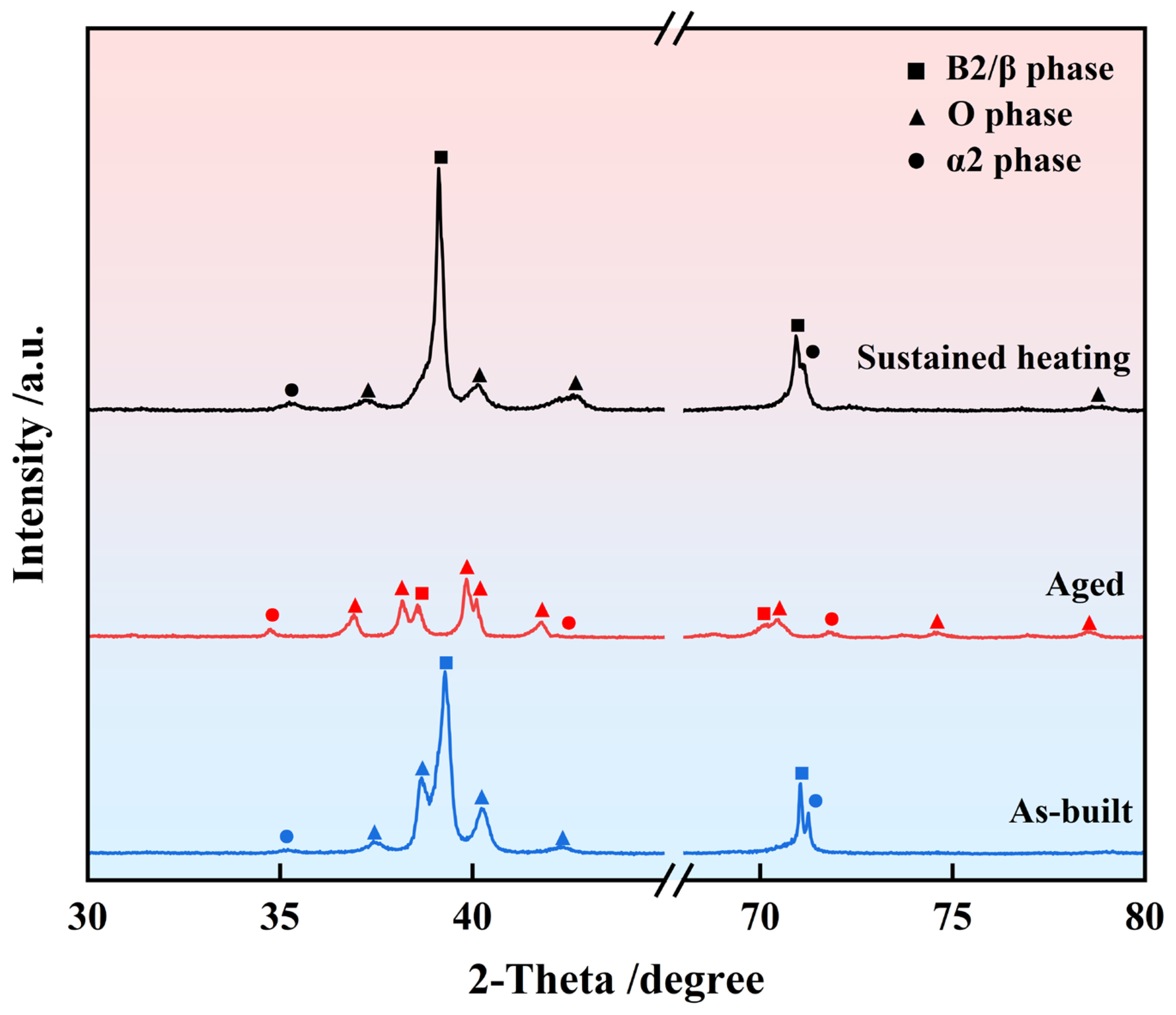

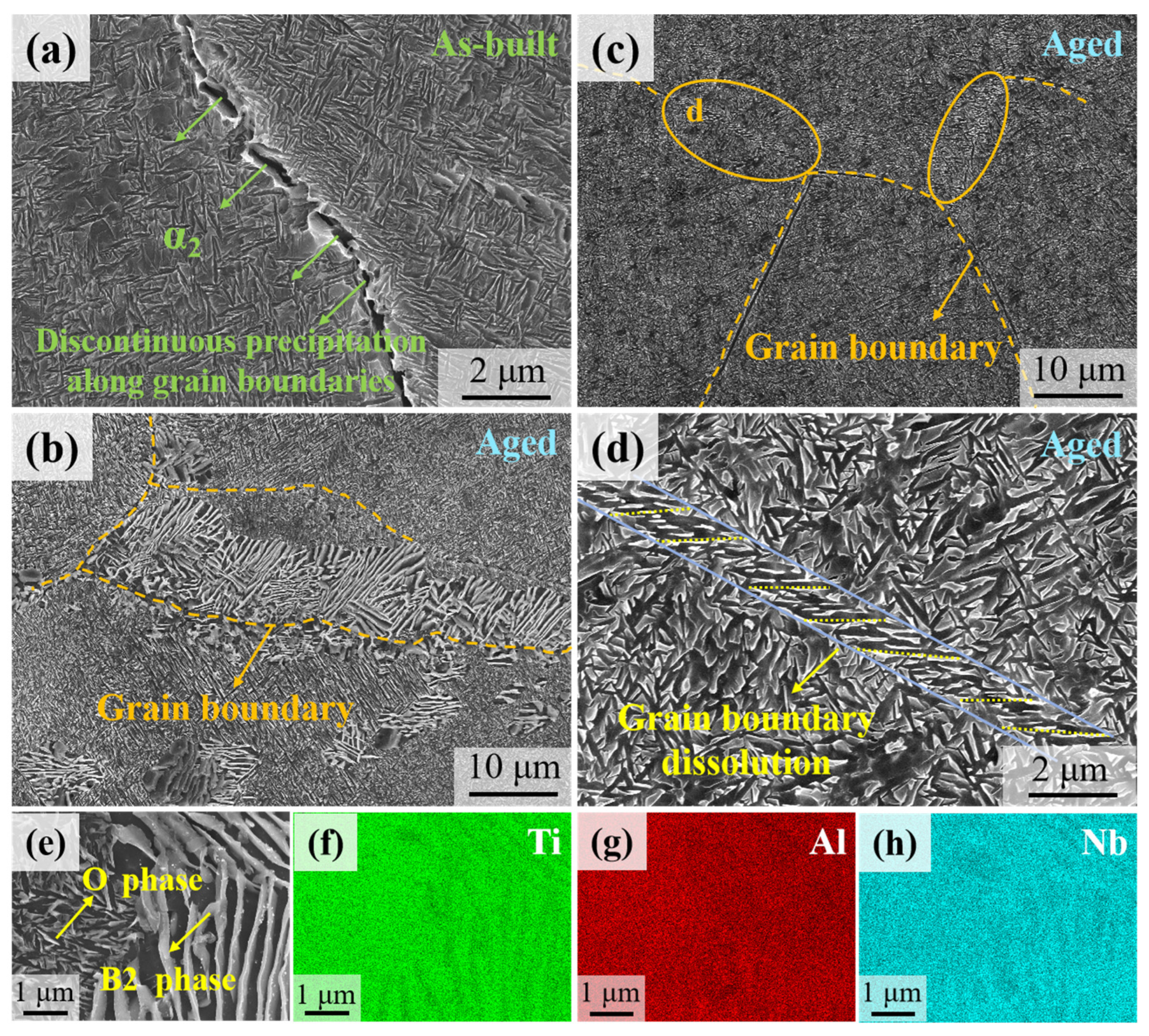

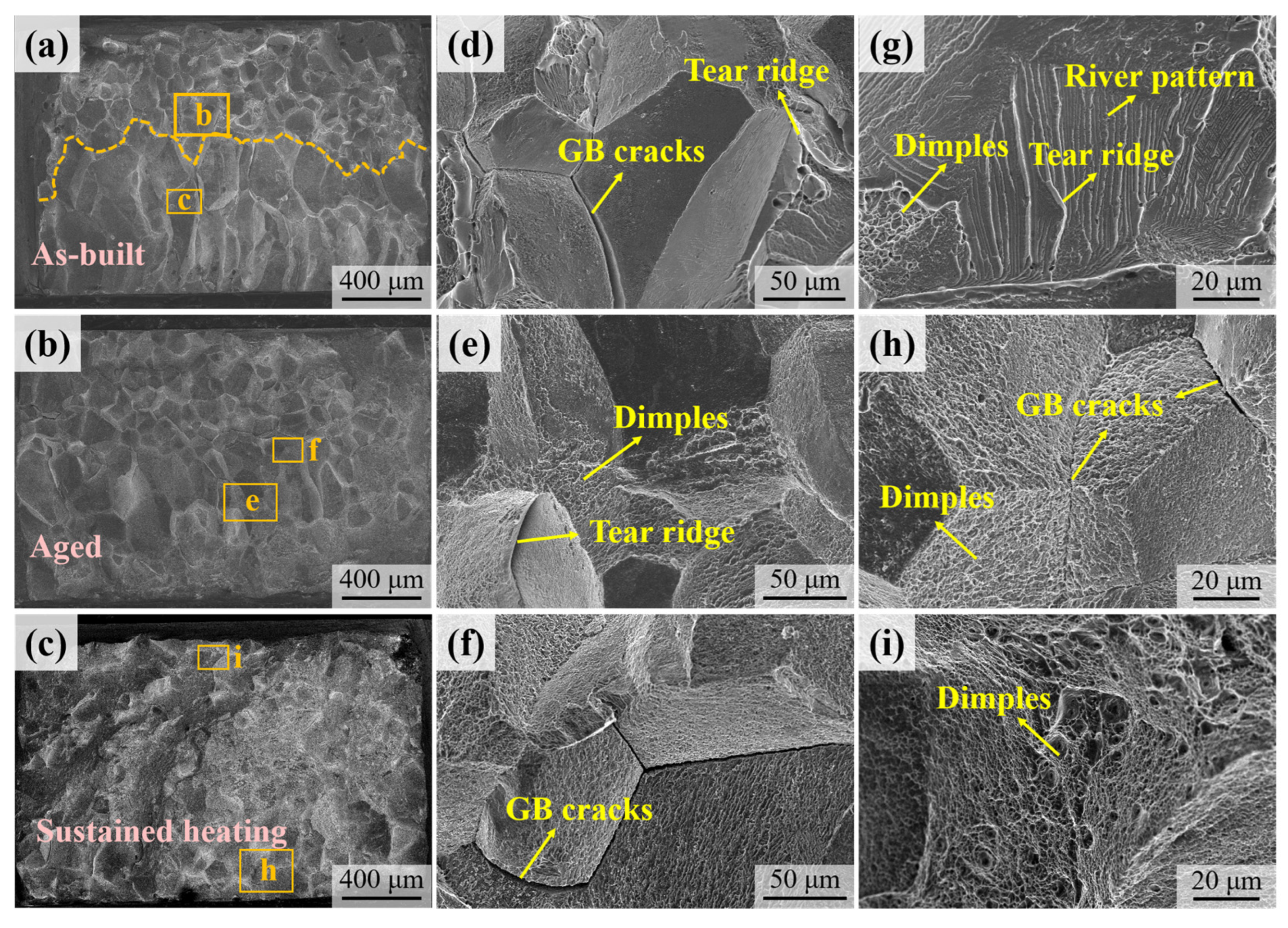

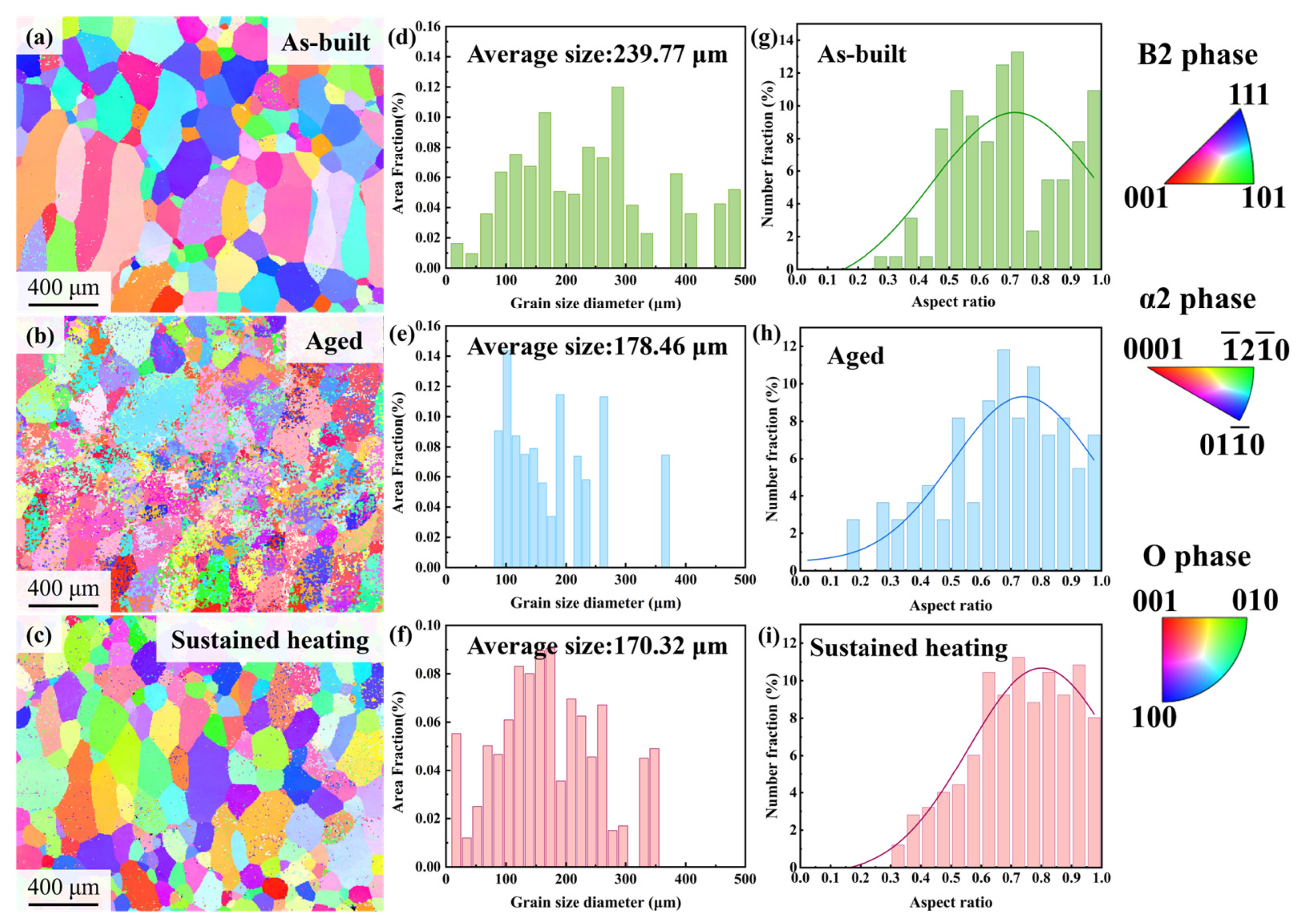

- The as-built alloy exhibits microstructural heterogeneity and unstable mechanical properties due to significant thermal gradients and high cooling rates during deposition, often leading to brittle fracture at elevated temperatures. After prolonged aging treatment at 750 °C for 48 h followed by air cooling, the microstructure exhibits notably refined grains and reduced inhomogeneity.

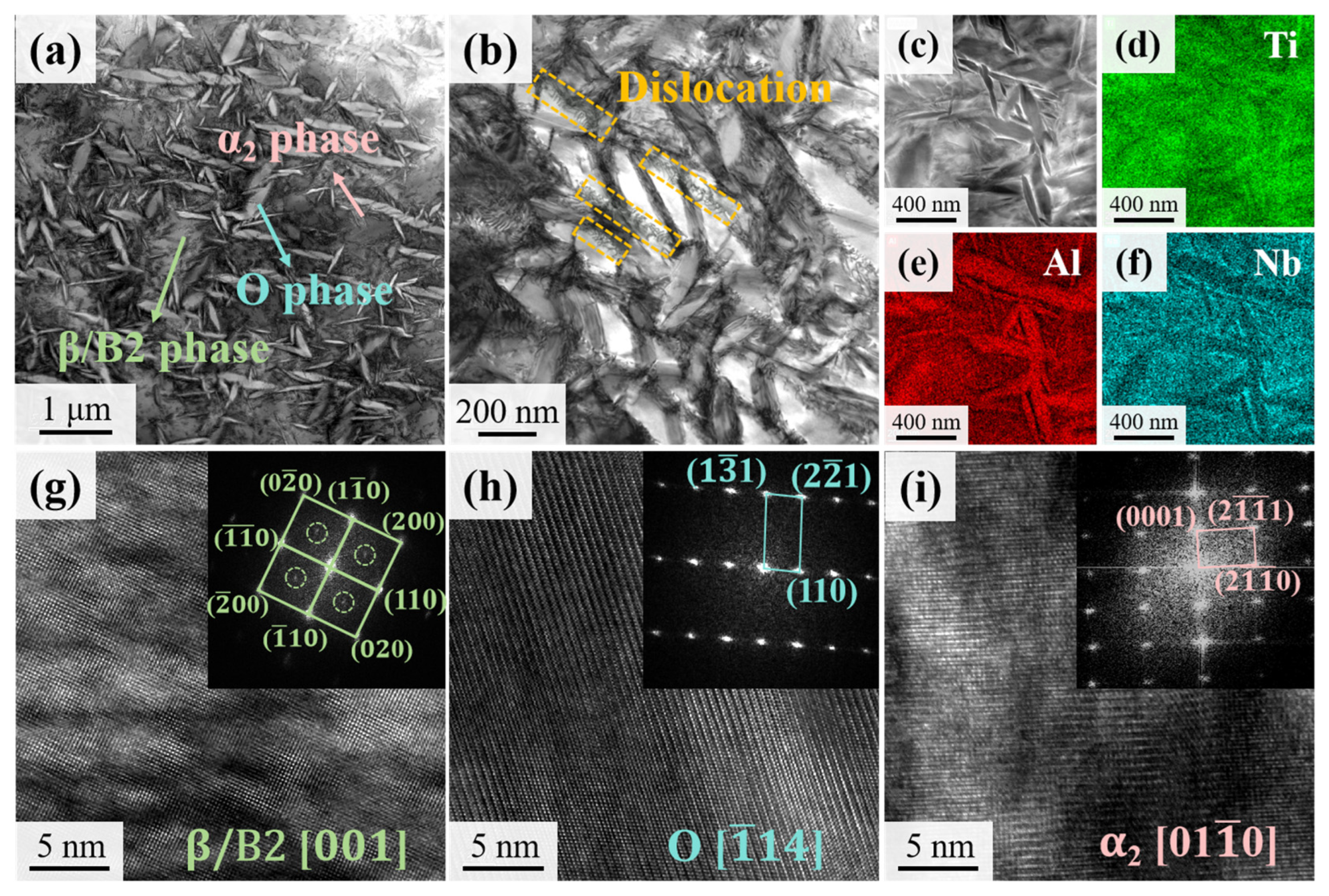

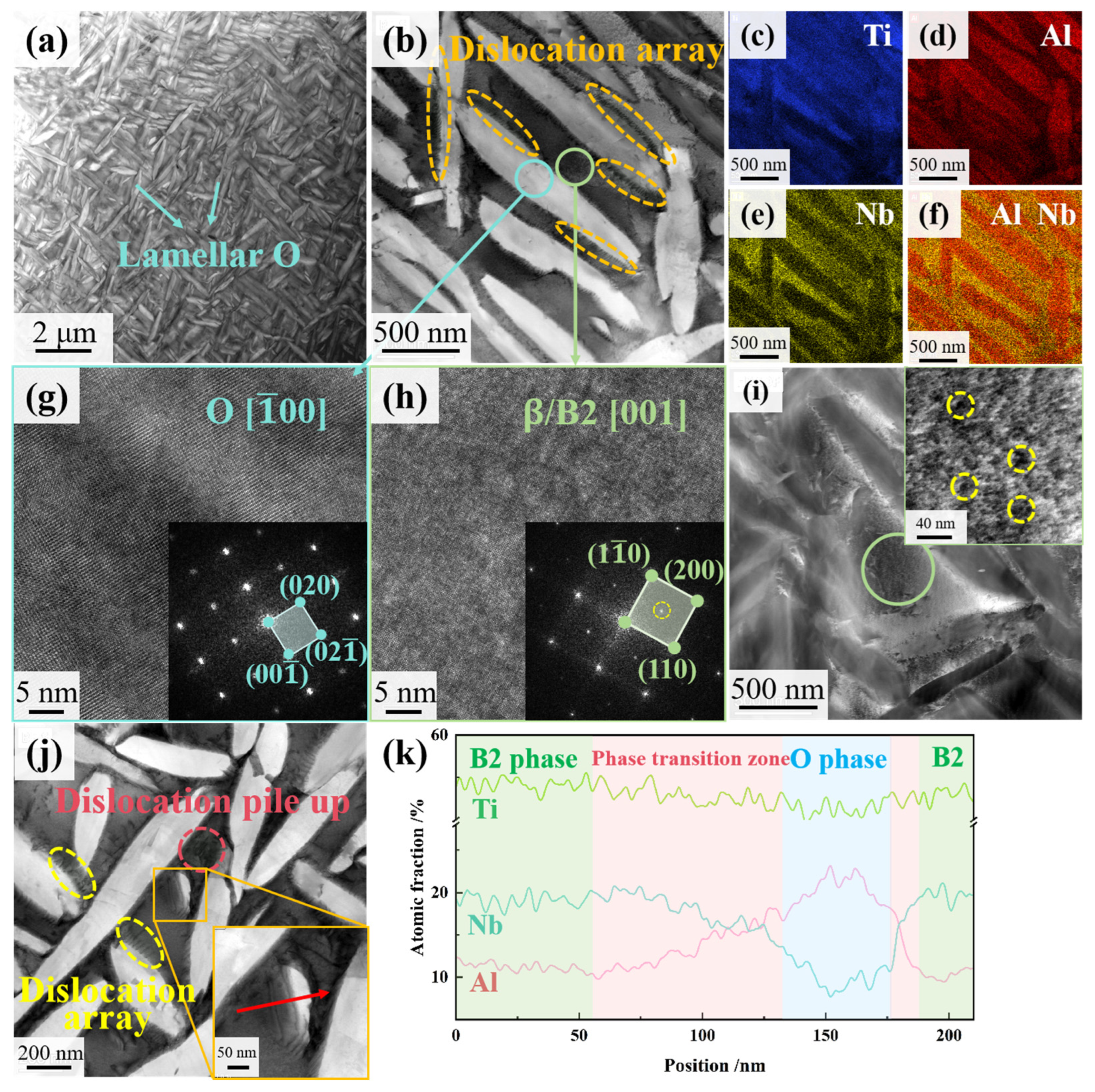

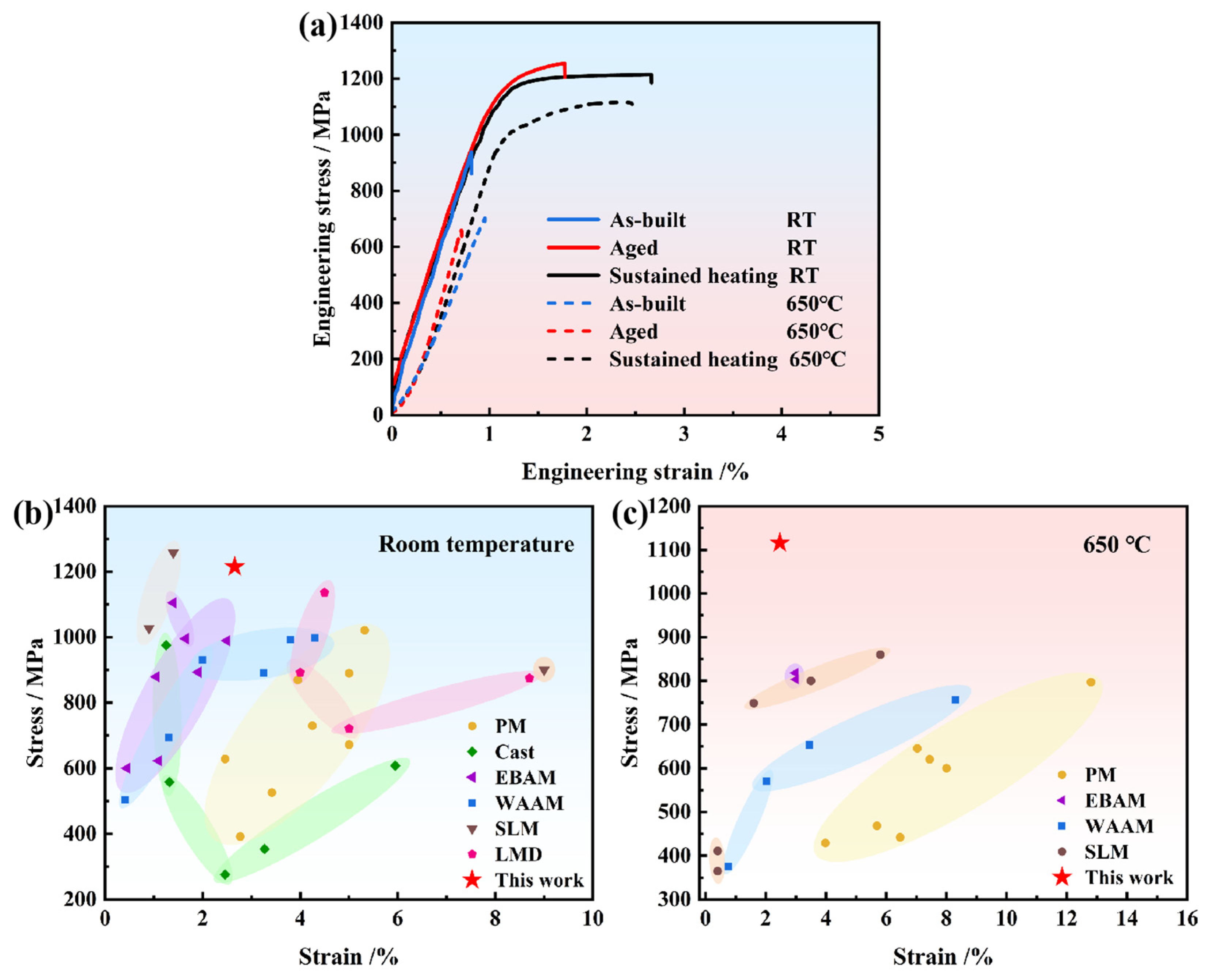

- Prolonged aging treatment promotes sufficient growth and precipitation of the lath-shaped O phase. Simultaneously, it forms a network-like structure of “dual-scale lath-shaped O-phase” that balances resistance to dislocation motion and strengthening effects. This enhances the room-temperature strength of the Ti2AlNb alloy from 938 MPa to 1255 MPa, while maintaining an elongation of 1.77%. However, the abnormally coarsened lath structures at grain boundaries are highly unstable at elevated temperatures, prone to decomposition and fracture, compromising high-temperature strength.

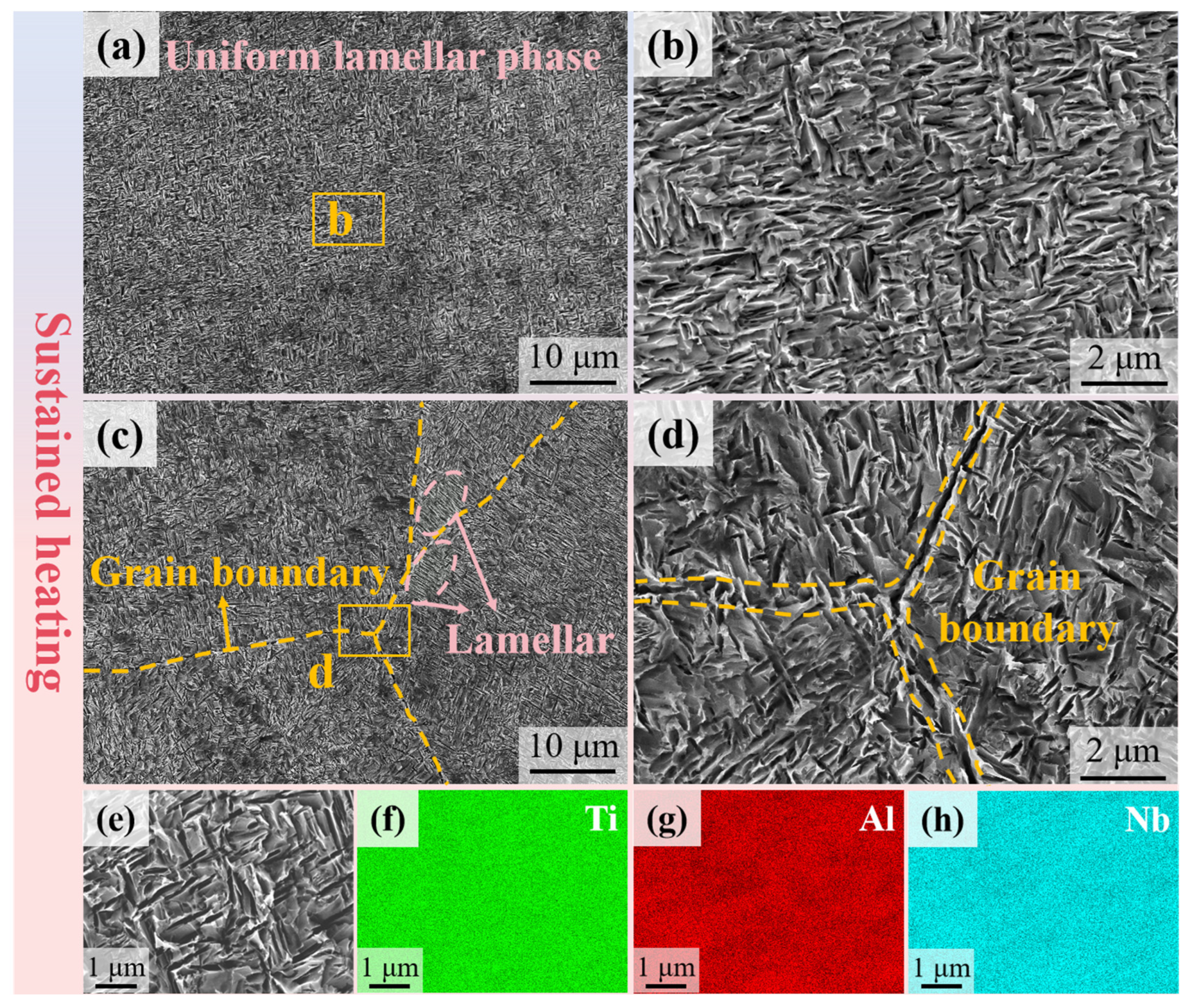

- By providing controlled and sustained thermal input during deposition, this internal cyclic heating technique offers excellent thermal management, significantly reducing cooling rates, promoting grain morphology transition from columnar to equiaxed, and refining grain structure. It also minimizes elemental segregation, facilitates homogeneous distribution of equiaxed grains, and enables the uniform precipitation of a high density of fine, dispersed O-phase precipitates in the matrix.

- Such microstructure of the internally cyclically heated sample contributes to the strengthening mechanism of grain refinement and precipitate dispersion, thereby achieving simultaneous optimization of both room-temperature and high-temperature performance. Specifically, it delivers a room-temperature strength of 1215 MPa with an elongation of 2.66%, and a 650 °C high-temperature strength of 1116 MPa with an elongation of 2.47%, providing a novel processing approach to balance performance and efficiency in Ti2AlNb alloys.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.H.; Li, W.P.; Zhang, L.; Zhou, S.Y.; Jia, X.; Wang, D.W.; Yan, M. Selective laser melting of Ti–22Al–25Nb intermetallic: Significant effects of hatch distance on microstructural features and mechanical properties. J. Mater. Process. Technol. 2020, 276, 116398. [Google Scholar] [CrossRef]

- Zhang, S.; Xi, M.; Sun, X.; Liu, Y.; Zheng, C.; Bai, D.; Wang, S. Significant effect of press down volume on microstructural evolution and mechanical properties of Ti2AlNb intermetallic alloy prepared by point-forging and laser-deposition. Mater. Sci. Eng. A 2024, 907, 146672. [Google Scholar] [CrossRef]

- He, Y.-S.; Hu, R.; Luo, W.-Z.; He, T.; Liu, X.-H. Oxidation behavior of a novel multi-element alloyed Ti2AlNb-based alloy in temperature range of 650–850 °C. Rare Met. 2018, 37, 838–845. [Google Scholar] [CrossRef]

- Illarionov, A.G.; Stepanov, S.I.; Naschetnikova, I.A.; Popov, A.A.; Soundappan, P.; Thulasi Raman, K.H.; Suwas, S. A Review—Additive Manufacturing of Intermetallic Alloys Based on Orthorhombic Titanium Aluminide Ti2AlNb. Materials 2023, 16, 991. [Google Scholar] [CrossRef] [PubMed]

- Shao, B.; Tang, W.; Guo, S.; Zong, Y.; Shan, D.; Guo, B. Investigation of the O phase in the Ti–22Al–25Nb alloy during deformation at elevated temperatures: Plastic deformation mechanism and effect on B2 grain boundary embrittlement. Acta Mater. 2023, 242, 118467. [Google Scholar] [CrossRef]

- Chen, Z.; Wan, J.; Li, J.; Li, J.; Wang, J. Uncovering the different roles of lack-of-fusion and keyhole defects on the tensile behavior of additively manufactured Ti-6Al-4V alloy. Addit. Manuf. 2025, 110, 104944. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Wu, Q.; Xu, T. The Creep Properties and Mechanism of Ti-6Al-4V with Ultra-Low β Contents Fabricated by Wire Arc Additive Manufacturing. Addit. Manuf. Front. 2025, 200246. [Google Scholar] [CrossRef]

- Lu, F.; Ma, Q.; Liu, E.; Wei, R.; Bai, J.; Gao, Q.; Qi, J. Advancements in understanding the microstructure and properties of additive manufacturing Ti-6Al-4V alloy: A comprehensive review. J. Alloys Compd. 2025, 1027, 180543. [Google Scholar] [CrossRef]

- Mohanty, I.; Kar, S.K. A comprehensive review of aspects of columnar to equiaxed transition, phase stability, and properties in novel Ti-alloys developed by additive manufacturing. J. Alloys Compd. 2025, 1038, 182642. [Google Scholar] [CrossRef]

- Zhou, W.; Shen, C.; Wang, L.; Li, Y.; Zhang, T.; Xin, J.; Ding, Y.; Zhang, D.; Zhang, Y.; Li, F.; et al. High-temperature tensile and fatigue properties of Ti-48Al-2Cr-2Nb alloy additively manufactured via twin-wire directed energy deposition-arc. Intermetallics 2025, 184, 108833. [Google Scholar] [CrossRef]

- Nie, Z.; Guo, Q.; Chai, J.; Chen, Z.; Li, J.; Dong, H.; Ding, R.; Liu, C.; Ma, Z.; Tian, X.; et al. Initial γ’ phase formation mechanism in a GH4099 precipitation strengthened nickel-based superalloy. Scr. Mater. 2025, 264, 116702. [Google Scholar] [CrossRef]

- Hao, Z.; He, Z.; Nie, Z.; Li, J.; Ma, Z.; Guo, Q. Effects of residual Laves phase on microstructural evolution and mechanical properties of wire arc additive manufactured GH4169 Ni-based superalloy. Mater. Sci. Eng. A 2024, 914, 147175. [Google Scholar] [CrossRef]

- Nie, Z.; Guo, Q.; Zhao, Y.; Ma, Z.; Liu, Y. Temperature dependence tensile behaviors of additively manufactured GH4099 Ni-based superalloy. Mater. Sci. Eng. A 2024, 899, 146464. [Google Scholar] [CrossRef]

- Silva, C.C.; Silva, R.S.; Miná, É.M.; Motta, M.F.; Miranda, H.C.; Dalpiaz, G.; Marinho, R.R.; Paes, M.T.P.; da Silva, A.K.; Wossack, I.; et al. Heterogeneously structured Ni-based alloy obtained by wire-arc additive manufacturing overcomes the strength-ductility trade-off. J. Mater. Sci. Technol. 2026, 254, 168–179. [Google Scholar] [CrossRef]

- Özsoy, A.; Gaudez, S.; Hearn, W.A.; Baganis, A.; Hegedüs, Z.; Chen, Y.; Rack, A.; Logé, R.E.; Van Petegem, S. Phase-separation-driven cracking in additive manufacturing of Ni-Cu alloy systems. Addit. Manuf. 2025, 110, 104950. [Google Scholar] [CrossRef]

- Jiang, X.; Luo, S.; Chen, M.; Nagaumi, H.; Wu, Y.; Cao, M.; Wang, X.; Hu, Z. In-situ precipitation kinetics and property gradients of a novel Al-Si-Cu-Mg alloy fabricated via CMT wire-arc additive manufacturing. J. Alloys Compd. 2025, 1040, 183430. [Google Scholar] [CrossRef]

- Zhang, W.; Yi, H.; He, H.; Cao, H. Content effects of in-situ synthesis TiC for grain refinement, porosity suppression and performance enhancement in wire arc additive manufactured Al-Cu alloy. J. Mater. Process. Technol. 2025, 340, 118875. [Google Scholar] [CrossRef]

- Zhao, R.; Li, L.; Liu, C.; Wang, Z.; Guo, Q. Effects of intermediate layer on interfacial microstructure and related mechanical properties of Inconel 625 coating on a Cu-Cr-Zr substrate by laser direct energy deposition. Mater. Charact. 2025, 226, 115227. [Google Scholar] [CrossRef]

- Maharjan, N.; Boschen, M.; Meure, S.; Ang, A. Depositing plasma sprayed NiCoCrAlY coating on additively manufactured Inconel 718 surfaces: Is grit blasting always necessary? Mater. Lett. 2025, 387, 138238. [Google Scholar] [CrossRef]

- Zhou, X.; Yu, Y.; Wang, X. Preparation of WC coatings via additive manufacturing technology: Microstructure, friction properties, and finite element simulation. Mater. Lett. 2025, 384, 138072. [Google Scholar] [CrossRef]

- Anand, K.S.; Rajkumar, V.; Nagesha, B.K.; Amit, K.T.; Sanjay, B.; Suresh, T.N. Single crystal metal deposition using laser additive manufacturing technology for repair of aero-engine components. Mater. Today Proc. 2021, 45, 5395–5399. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J.; Li, M.; Xu, W.; Ye, R.; Wang, Z. Improved Inconel 718 superalloy repaired performance on 304 stainless steel shafts via recrystallization and Laves phase suppression in hybrid additive-subtractive manufacturing. J. Mater. Res. Technol. 2025, 37, 3289–3302. [Google Scholar] [CrossRef]

- Javidrad, H.; Koc, B. Additively manufacturing of functionally graded multi-material parts using directed energy deposition. CIRP J. Manuf. Sci. Technol. 2025, 61, 588–600. [Google Scholar] [CrossRef]

- Jeong, T.-W.; Cho, Y.T.; Lee, C.-M.; Kim, D.-H. Effects of ultrasonic treatment on mechanical properties and microstructure of stainless steel 308L and Inconel 718 functionally graded materials fabricated via double-wire arc additive manufacturing. Mater. Sci. Eng. A 2024, 896, 146298. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, Y.; Zhao, D.; Chen, Y.; Guan, S.; Liu, Y.; Liu, L.; Peng, S.; Kong, F.; Poplawsky, J.D.; et al. Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing. Nature 2022, 608, 62–68. [Google Scholar] [CrossRef] [PubMed]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, X.; Fu, Z.; Yang, Q.; Zhang, Y.; Liu, Q.; Li, T.; Tian, Y.; Tan, H.; Li, Z.; et al. Ductile and ultrahigh-strength eutectic high-entropy alloys by large-volume 3D printing. J. Mater. Sci. Technol. 2022, 126, 15–21. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Xie, J.; Chen, L.; Zhang, X. Effect of cooling rate on microstructure and mechanical properties of AlMo0.5NbTa0.5TiZr refractory high-entropy alloy prepared by laser metal deposition. Mater. Sci. Eng. A 2025, 942, 148734. [Google Scholar] [CrossRef]

- Liu, Z.; Qin, Z.-X.; Liu, F.; Lu, X.; Wang, H.-M. The microstructure and mechanical behaviors of the Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy produced by laser melting deposition. Mater. Charact. 2014, 97, 132–139. [Google Scholar] [CrossRef]

- Zhu, Y.; Tian, X.; Li, J.; Wang, H. The anisotropy of laser melting deposition additive manufacturing Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. Mater. Des. 2015, 67, 538–542. [Google Scholar] [CrossRef]

- Yang, L.; Bu, Z.; Li, J. Microstructure and mechanical properties of as-cast Ti2AlNb alloys. Mater. Des. 2025, 254, 114138. [Google Scholar] [CrossRef]

- Ma, H.; Zeng, W.; Kou, Y.; Zhang, P.; Zhang, F.; Liang, X. Formation mechanism of Cube texture components ({001}<100>) associated with dynamic recrystallization during compression in the single BCC phase region of Ti-22Al-25Nb alloy. J. Alloys Compd. 2023, 966, 171563. [Google Scholar] [CrossRef]

- Zhou, M.; Bu, Z.; Zhou, Y.; Wang, J.; Zhu, L.; Huang, X.; Li, J. The effect of primary and secondary O phase on the mechanical properties and deformation behavior of Ti2AlNb alloy. J. Alloys Compd. 2025, 1032, 181160. [Google Scholar] [CrossRef]

- Shao, B.; Wan, S.; Xu, W.; Shan, D.; Guo, B.; Zong, Y. Formation mechanism of an α2 phase-rich layer on the surface of Ti-22Al-25Nb alloy. Mater. Charact. 2018, 145, 205–209. [Google Scholar] [CrossRef]

- Jiang, J.; Li, M.; Wang, Y.; Yang, L.; Gan, Z.; Jia, Q.; Hu, J.; Zhang, Y.; Zhang, X.; Yang, R. Evolution of the O phase in SiCf/Ti2AlNb composites fabricated by hot isostatic pressing. Mater. Charact. 2025, 226, 115218. [Google Scholar] [CrossRef]

- Shi, G.; Du, Z.; Chen, Y.; Zhu, B.; Liu, Y.; Zhang, Y. Effect of heat treatment on the microstructure and mechanical properties of Y2O3/Ti-22Al-25Nb composites. Mater. Sci. Eng. A 2025, 944, 148914. [Google Scholar] [CrossRef]

- Shi, G.; Chen, Y.; Du, Z.; Zhu, B.; Liu, Y.; Zhang, Y. Simultaneously improves the strength and ductility of the Y2O3/Ti-22Al-25Nb composite through multiple forging. J. Alloys Compd. 2025, 1036, 182066. [Google Scholar] [CrossRef]

- Zhang, K.; Lei, Z.; Ni, L.; Zhou, H.; Chen, Y. Improvement in microstructure and high-temperature brittleness of laser-welded Ti-22Al-25Nb joints with the addition of TiB2 powder. J. Mater. Process. Technol. 2021, 288, 116848. [Google Scholar] [CrossRef]

- Li, Y.; Chen, G.; Pang, G.; Fu, X.; Zhou, W. Effect of nano-Al2O3 addition on microstructure and mechanical properties of Ti2AlNb-based composites prepared by powder metallurgy. J. Alloys Compd. 2023, 968, 172268. [Google Scholar] [CrossRef]

- Polozov, I.; Sufiiarov, V.; Starikov, K.; Popovich, A. In situ synthesized Ti2AlNb-based composites produced by selective laser melting by addition of SiC-whiskers. Mater. Lett. 2021, 297, 129956. [Google Scholar] [CrossRef]

- Boehlert, C.J. Part III. The tensile behavior of Ti-Al-Nb O+Bcc orthorhombic alloys. Metall. Mater. Trans. A 2001, 32, 1977–1988. [Google Scholar] [CrossRef]

- Zhang, H.; Zai, L.; Wang, Y.; Xue, X. Insight into microstructural evolution and mechanical property correlations of Ti2AlNb-based alloy fabricated through wire arc additive manufacturing. Mater. Sci. Eng. A 2025, 938, 148477. [Google Scholar] [CrossRef]

- Li, Z.; Chang, B.; Zhang, D.; Zhang, H.; Liang, Z.; Wang, L.; Liu, C.; Du, D. Effect of post-heat treatment on Ti2AlNb-based alloy fabricated by twin-wire alternating dual-electron beam additive manufacturing technology. J. Mater. Sci. Technol. 2023, 157, 130–143. [Google Scholar] [CrossRef]

- Man, J.; Huang, L.; He, J.; Yang, H.; Lin, X. Effect of heat treatment on microstructure and properties of Ti2AlNb alloy formed by selective laser melting. J. Mater. Res. Technol. 2024, 33, 2549–2559. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, B.; Bai, Q.; Xie, G. Correlation of microstructure and mechanical properties of Ti2AlNb manufactured by SLM and heat treatment. Intermetallics 2021, 139, 107367. [Google Scholar] [CrossRef]

- Chen, X.; Weidong, Z.; Wei, W.; Xiaobo, L.; Jianwei, Z. Coarsening behavior of lamellar orthorhombic phase and its effect on tensile properties for the Ti–22Al–25Nb alloy. Mater. Sci. Eng. A 2014, 611, 320–325. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, F.; Jia, S.; Zou, J.; Luo, Y.; Niu, Y.; Yang, X.; Wang, X.; Wang, J. Process-structure relationship and microstructure evolution of Ti–22Al–25Nb alloy under heat treatment. Mater. Chem. Phys. 2025, 343, 131006. [Google Scholar] [CrossRef]

- Shang, Z.; Niu, H.; Wang, A.; Lei, T.; Liu, G.; Zhong, L. Effects of solid solution and aging treatment on the microstructure evolution of Ti2AlNb alloy. J. Mater. Res. Technol. 2024, 30, 1095–1104. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Hua, X.; Shen, C.; Li, F.; Huang, Y.; Ding, Y.; Zhang, P.; Lu, Q.; Zhang, T.; et al. Twin-wire plasma arc additive manufacturing of the Ti–45Al titanium aluminide: Processing, microstructures and mechanical properties. Intermetallics 2021, 136, 107277. [Google Scholar] [CrossRef]

- Mao, Y.; Li, S.; Zhang, J.; Peng, J.; Zou, D.; Zhong, Z. Microstructure and tensile properties of orthorhombic Ti–Al–Nb–Ta alloys. Intermetallics 2000, 8, 659–662. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, Q.; Liu, Y. Formation of diverse B2+O structure and hardness of Mo-modified Ti-22Al-25Nb alloys upon cooling. Vacuum 2019, 165, 199–206. [Google Scholar] [CrossRef]

- Ayadh, W.; Denand, B.; Halkoum, A.; Boulet, P.; Sennour, M.; Delfosse, J.; Sallot, P.; Esin, V.A. Effect of prior α2 phase on precipitation kinetics of O-phase in advanced Ti2AlNb alloy. Acta Mater. 2023, 252, 118930. [Google Scholar] [CrossRef]

- Bu, Z.Q.; Zhang, Y.G.; Yang, L.; Kang, J.M.; Li, J.F. Effect of cooling rate on phase transformation in Ti2AlNb alloy. J. Alloys Compd. 2022, 893, 162364. [Google Scholar] [CrossRef]

- Yang, J.L.; Wang, G.F.; Zhang, W.C.; Chen, W.Z.; Jiao, X.Y.; Zhang, K.F. Microstructure evolution and mechanical properties of P/M Ti-22Al-25Nb alloy during hot extrusion. Mater. Sci. Eng. A 2017, 699, 210–216. [Google Scholar] [CrossRef]

- Wang, G.; Yang, J.; Jiao, X. Microstructure and mechanical properties of Ti–22Al–25Nb alloy fabricated by elemental powder metallurgy. Mater. Sci. Eng. A 2016, 654, 69–76. [Google Scholar] [CrossRef]

- Jia, J.; Zhang, K.; Jiang, S. Microstructure and mechanical properties of Ti–22Al–25Nb alloy fabricated by vacuum hot pressing sintering. Mater. Sci. Eng. A 2014, 616, 93–98. [Google Scholar] [CrossRef]

- Jia, J.; Liu, W.; Xu, Y.; Lu, C.; Liu, H.; Gu, Y.; Luo, J. Microstructure evolution, B2 grain growth kinetics and fracture behaviour of a powder metallurgy Ti-22Al-25Nb alloy fabricated by spark plasma sintering. Mater. Sci. Eng. A 2018, 730, 106–118. [Google Scholar] [CrossRef]

- Xiong, B.; Liu, K.; Wang, Z.; Peng, F. Phase Transformation and Tensile Behavior of Ti-22Al-25Nb Alloys with Bimodal Size Lamellar O-Phase Precipitates. J. Mater. Eng. Perform. 2021, 30, 8598–8605. [Google Scholar] [CrossRef]

- Chen, R.; Wang, Q.; Zhou, Z.; Su, Y.; Guo, J.; Ding, H.; Fu, H. Microstructure, tensile properties and creep behavior of high-Al TiAlNb alloy using electromagnetic cold crucible continuous casting. J. Alloys Compd. 2019, 801, 166–174. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Y.; Zhang, Y.; Liang, H. Thermal stability and mechanical properties of Ti–22Al–25Nb alloy with different initial microstructures. J. Alloys Compd. 2020, 842, 155794. [Google Scholar] [CrossRef]

- Li, Z.; Cui, Y.; Wang, L.; Zhang, H.; Liang, Z.; Liu, C.; Du, D. An investigation into Ti-22Al-25Nb in-situ fabricated by electron beam freeform fabrication with an innovative twin-wire parallel feeding method. Addit. Manuf. 2022, 50, 102552. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, L.; Zhang, Y.; Zhao, L.; Hao, K.; Ren, W.; Han, Y. Additive manufacturing Ti-22Al-25 Nb alloy with excellent high temperature tensile properties by electron beam powder bed fusion. Addit. Manuf. 2024, 86, 104236. [Google Scholar] [CrossRef]

- Li, Z.; Cui, Y.; Yu, Z.; Liu, C. In-situ fabrication of Ti2AlNb-based alloy through double-wire arc additive manufacturing. J. Alloys Compd. 2021, 876, 160021. [Google Scholar] [CrossRef]

- Fu, R.; Yu, Z.; Wu, Q.; Liu, C. Microstructure evolution and property strengthening of Ti2AlNb alloys prepared by multi-wire arc-directed energy deposition. J. Mater. Process. Technol. 2024, 329, 118460. [Google Scholar] [CrossRef]

- Yu, Z.; Li, Z.; Guo, Y.; Fu, R.; Xu, T.; Liu, C. Homogenizing the composition of in-situ fabricated Ti2AlNb-based alloy via manipulating the droplet transfer mode of twin-wire arc additive manufacturing. J. Alloys Compd. 2022, 923, 165992. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Wang, D.W.; Song, L.J.; Mukhtar, A.; Huang, D.N.; Yang, C.; Yan, M. Effect of heat treatments on the microstructure and mechanical properties of Ti2AlNb intermetallic fabricated by selective laser melting. Mater. Sci. Eng. A 2021, 817, 141352. [Google Scholar] [CrossRef]

- Polozov, I.; Starikov, K.; Popovich, A.; Sufiiarov, V. Mitigating Inhomogeneity and Tailoring the Microstructure of Selective Laser Melted Titanium Orthorhombic Alloy by Heat Treatment, Hot Isostatic Pressing, and Multiple Laser Exposures. Materials 2021, 14, 4946. [Google Scholar] [CrossRef]

- Tang, Y.J.; Zhang, Y.Z.; Liu, Y.T. Numerical and experimental investigation of laser additive manufactured Ti2AlNb-based alloy. J. Alloys Compd. 2017, 727, 196–204. [Google Scholar] [CrossRef]

- Li, L.; Zhang, C.; Liu, C.; Niu, S.; Zhao, R.; Li, C.; Ma, Z.; Guo, Q.; Liu, Y. Improved strength of commercial Ti-based metallic powder modified AlSi10Mg alloy prepared by laser directed energy deposition without sacrificing ductility. Mater. Sci. Eng. A 2025, 945, 148974. [Google Scholar] [CrossRef]

- Xu, G.; Zhao, X.; Xia, W.; Yue, Q.; Zheng, Z.; Gu, Y.; Zhang, Z. A review on microstructure design, processing, and strengthening mechanism of high-strength titanium alloys. Prog. Nat. Sci. Mater. Int. 2025, 35, 258–277. [Google Scholar] [CrossRef]

- Liu, X.W.; Yao, J.Q.; Ma, X.N.; Wang, Y.S.; Gao, N.; Shi, Y.; Fan, Z.T.; Du, H. Columnar-to-equiaxed transition and grain refinement by solute interaction effects. Mater. Charact. 2023, 205, 113288. [Google Scholar] [CrossRef]

- Hou, S.; Feng, J.; Chen, S.; Zhang, F.; Li, D. Effects of Zn Contents on Microstructure and Mechanical Properties of Semisolid Rheo-Diecasting Al-xZn-2Mg-1.5Cu Alloys. Materials 2022, 15, 2873. [Google Scholar] [CrossRef] [PubMed]

- Mclean, D.; Maradudin, A. Grain Boundaries in Metals. Wear 1959, 2, 240. [Google Scholar] [CrossRef]

- Li, C.; Lu, S.; Divinski, S.; Vitos, L. Theoretical and experimental grain boundary energies in body-centered cubic metals. Acta Mater. 2023, 255, 119074. [Google Scholar] [CrossRef]

- Zhou, M.; Li, J.; Zhang, K.; Xiong, J.; Li, J.; Du, Y. Precipitation behavior and strengthening mechanism of the interfacial nano-O phase of Ti2AlNb diffusion welded joints with high-entropy interlayer during aging process. Mater. Charact. 2025, 220, 114704. [Google Scholar] [CrossRef]

- Song, C.; Wu, D.; Di, T.; Xu, G.; Zhang, Z.; Wang, D.; Niu, F.; Ma, G.; Liu, L. Intermetallic phases transition mechanism of the interface of Ti6Al4V-Inconel718 graded material by laser additive manufacturing. Mater. Charact. 2024, 215, 114183. [Google Scholar] [CrossRef]

- Zhang, P.; Zeng, W.; Jia, R.; Kou, Y.; Xu, J.; Liang, X.; Zhao, Y. Tensile behavior and deformation mechanism for Ti–22Al–25Nb alloy with lamellar O microstructures. Mater. Sci. Eng. A 2021, 803, 140492. [Google Scholar] [CrossRef]

- Zheng, Y.; Zeng, W.; Li, D.; Zhao, Q.; Liang, X.; Zhang, J.; Ma, X. Fracture toughness of the bimodal size lamellar O phase microstructures in Ti-22Al-25Nb (at.%) orthorhombic alloy. J. Alloys Compd. 2017, 709, 511–518. [Google Scholar] [CrossRef]

- Cai, H.; Ma, Z.; Zhang, J.; Qi, L.; Hu, J.; Zhou, J. Different Heat-Exposure Temperatures on the Microstructure and Properties of Dissimilar GH4169/IC10 Superalloy Vacuum Electron Beam Welded Joint. Metals 2024, 14, 348. [Google Scholar] [CrossRef]

| Material | Ti | Al | Nb | Fe | C | H | O |

|---|---|---|---|---|---|---|---|

| Ti2AlNb | Bal. | 11.06 | 44.03 | 0.06 | 0.004 | 0.0028 | 0.054 |

| Experimental Parameters | As-Built | Aged | Sustained Heating |

|---|---|---|---|

| Laser power (W) | 1600 | 1600 | 1600 |

| Scanning velocity (mm/s) | 5 | 5 | 5 |

| Layer thickness (mm) | 0.6 | 0.6 | 0.8 |

| Power feeding rate (rpm/min) | 0.6 | 0.6 | 0.6 |

| Inter-layer waiting time (s) | 60 | 60 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Li, L.; Lv, Y.; Pan, Y.; Hao, Z.; Guo, Q. Role of Internal Cyclic Heat Treatment on Regulating Microstructure and Mechanical Properties of Laser Melting-Deposited Ti2AlNb Alloy. Crystals 2025, 15, 910. https://doi.org/10.3390/cryst15110910

Zhang C, Li L, Lv Y, Pan Y, Hao Z, Guo Q. Role of Internal Cyclic Heat Treatment on Regulating Microstructure and Mechanical Properties of Laser Melting-Deposited Ti2AlNb Alloy. Crystals. 2025; 15(11):910. https://doi.org/10.3390/cryst15110910

Chicago/Turabian StyleZhang, Chunyan, Lulu Li, Yupin Lv, Yukun Pan, Zhenghua Hao, and Qianying Guo. 2025. "Role of Internal Cyclic Heat Treatment on Regulating Microstructure and Mechanical Properties of Laser Melting-Deposited Ti2AlNb Alloy" Crystals 15, no. 11: 910. https://doi.org/10.3390/cryst15110910

APA StyleZhang, C., Li, L., Lv, Y., Pan, Y., Hao, Z., & Guo, Q. (2025). Role of Internal Cyclic Heat Treatment on Regulating Microstructure and Mechanical Properties of Laser Melting-Deposited Ti2AlNb Alloy. Crystals, 15(11), 910. https://doi.org/10.3390/cryst15110910