Microstructure and Compressive Properties of (Ti51Zr25Cu6Be18)100−xVx Bulk Metallic Glass Matrix Composites

Abstract

1. Introduction

2. Experimental Procedures

3. Results

3.1. Effect of Element V on Ti-Based BMGMCs

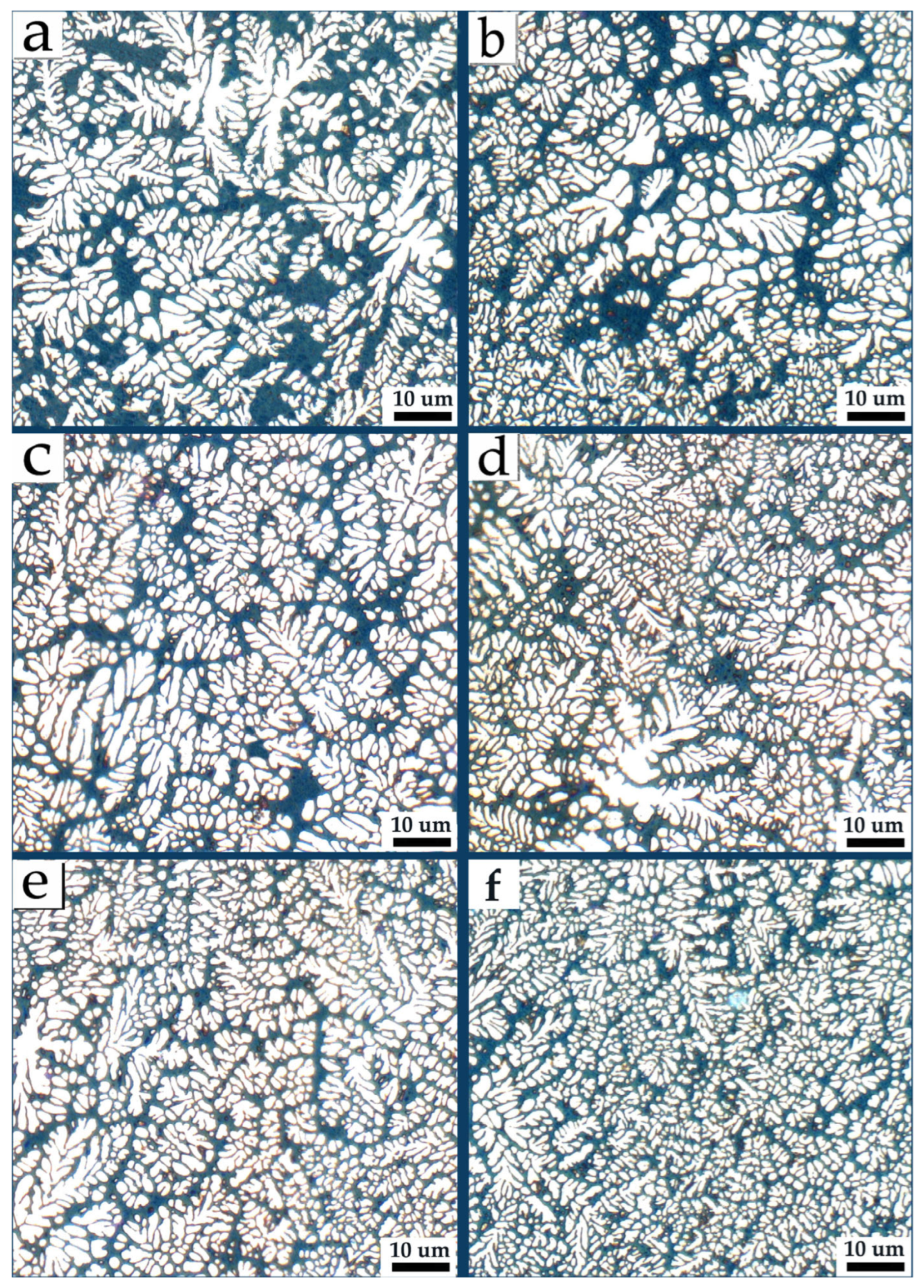

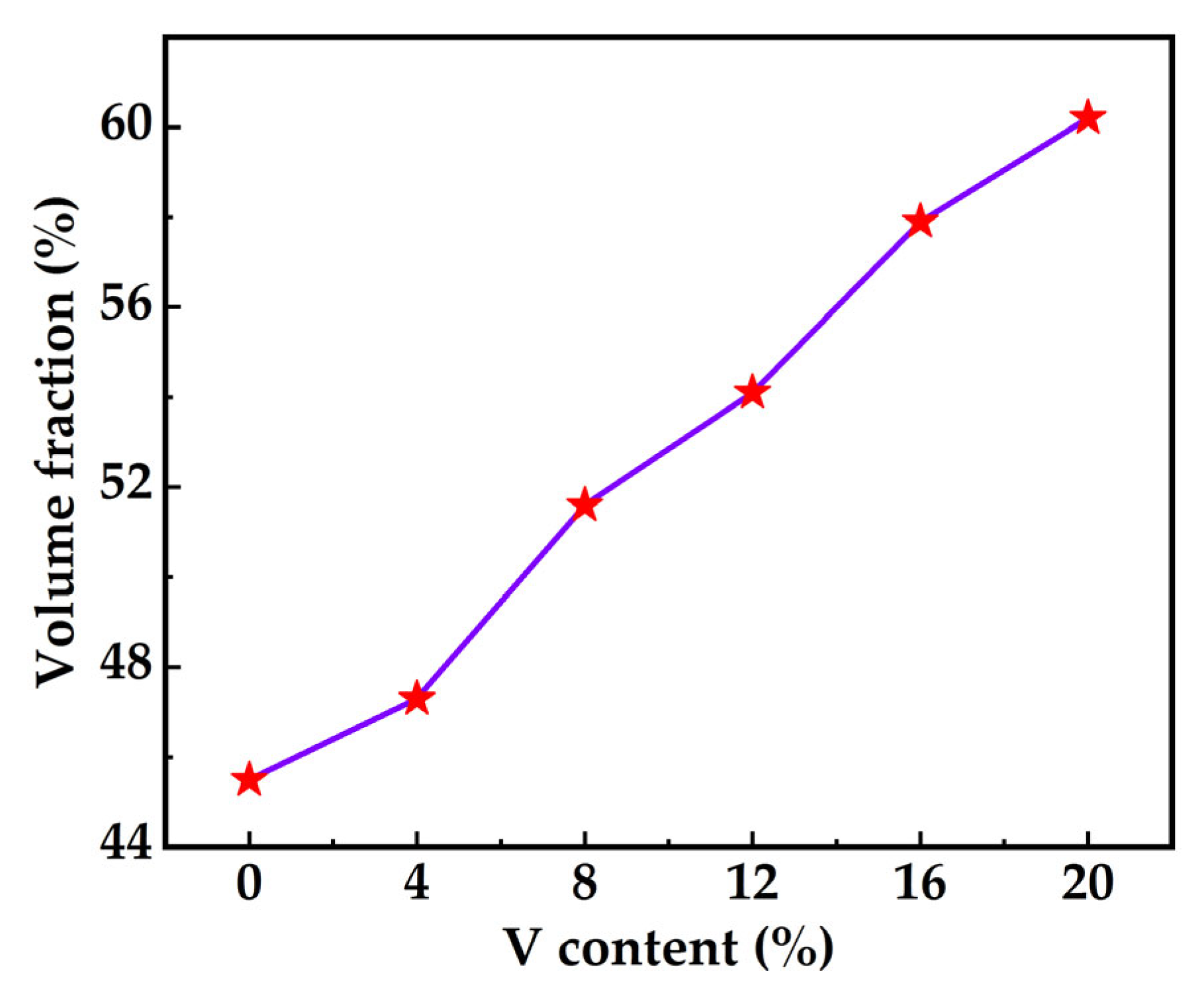

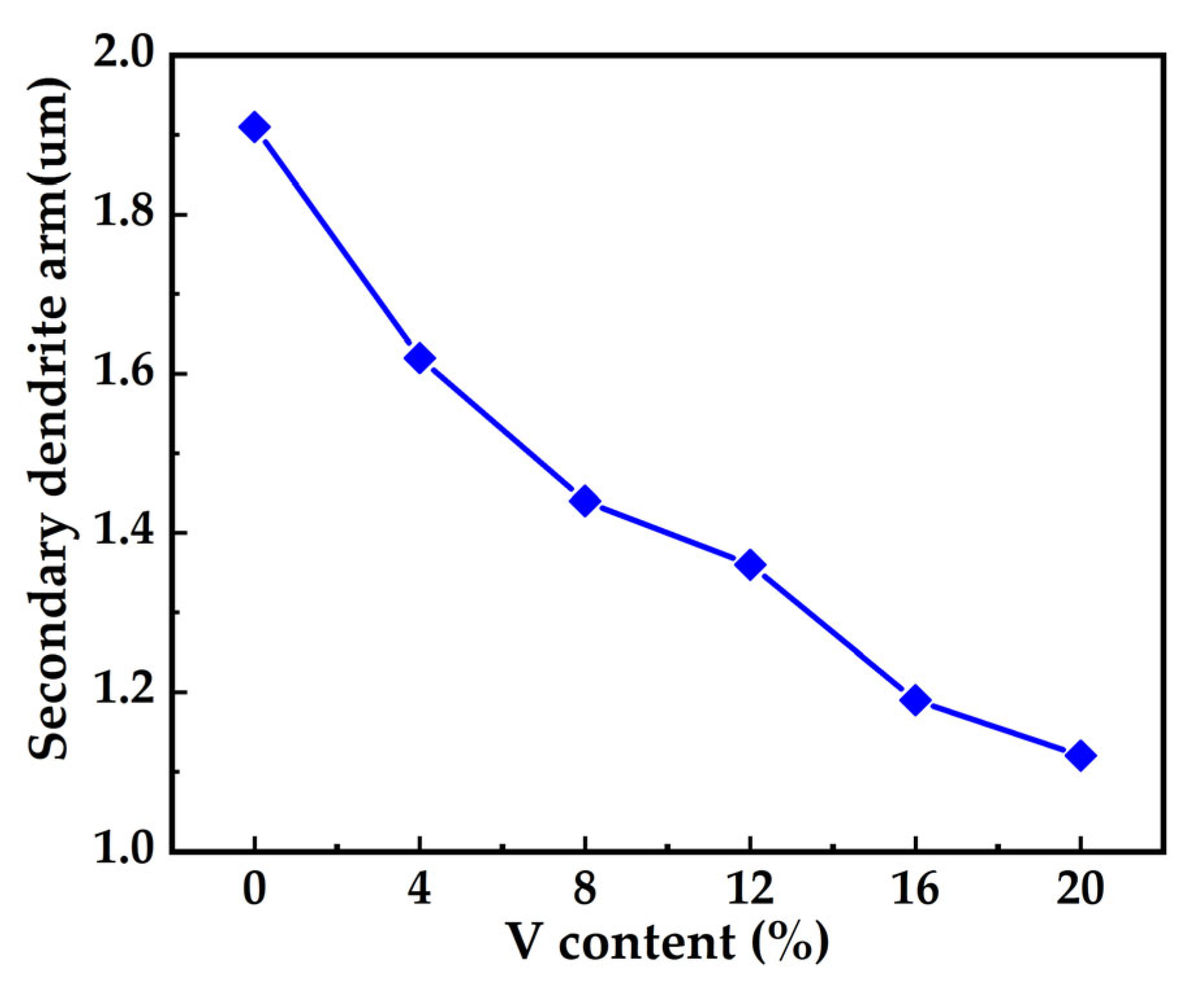

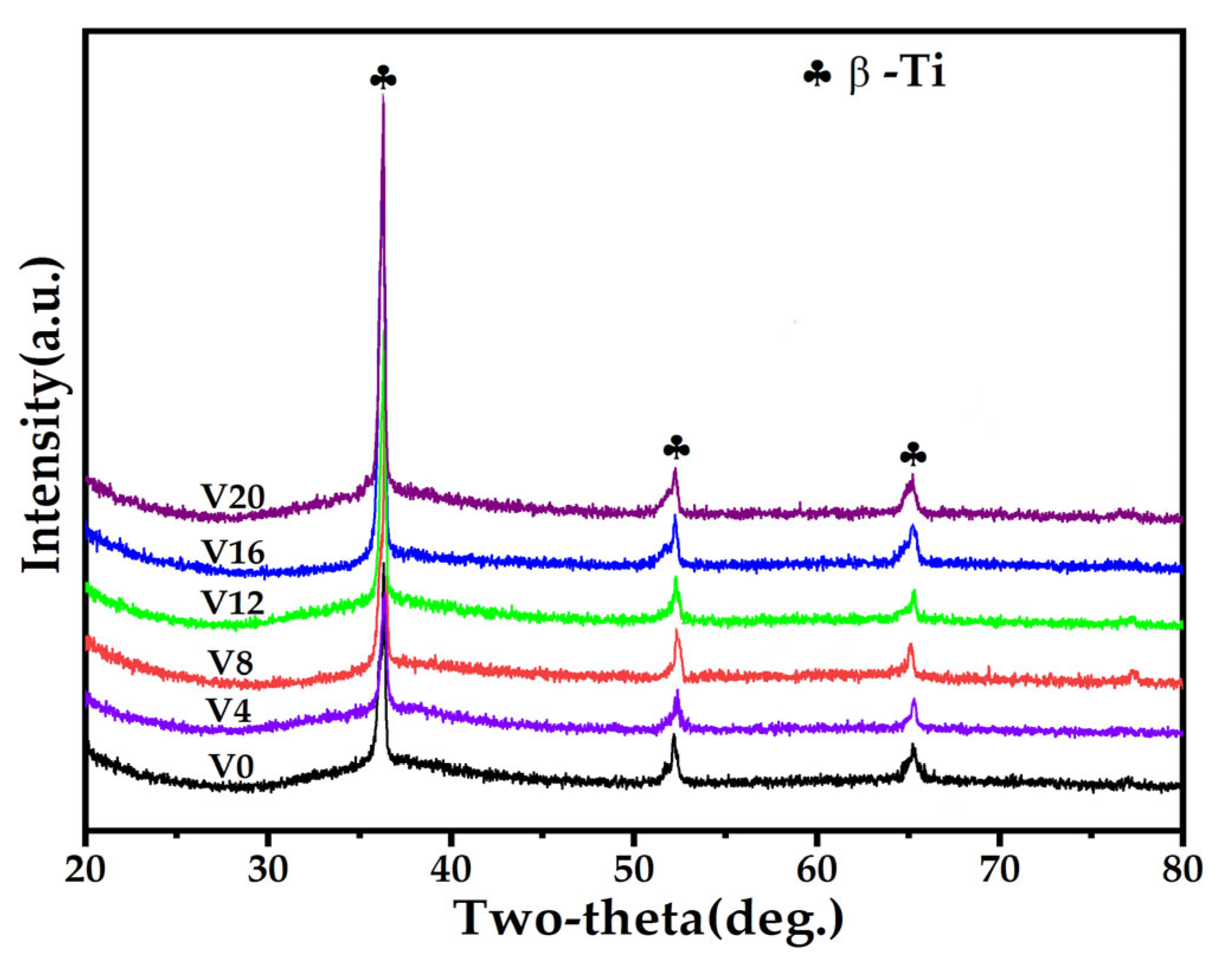

3.1.1. Microstructure

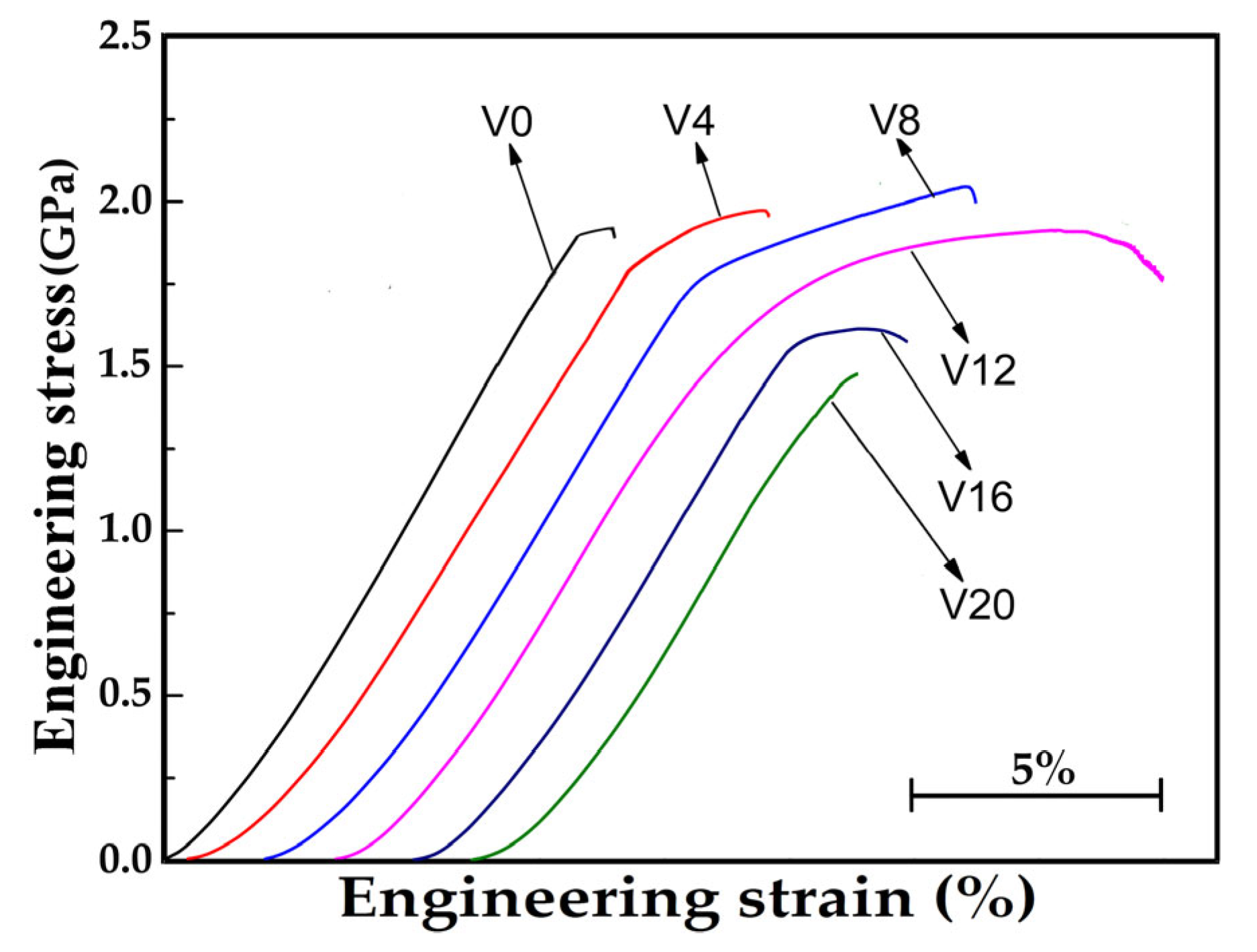

3.1.2. Mechanical Properties

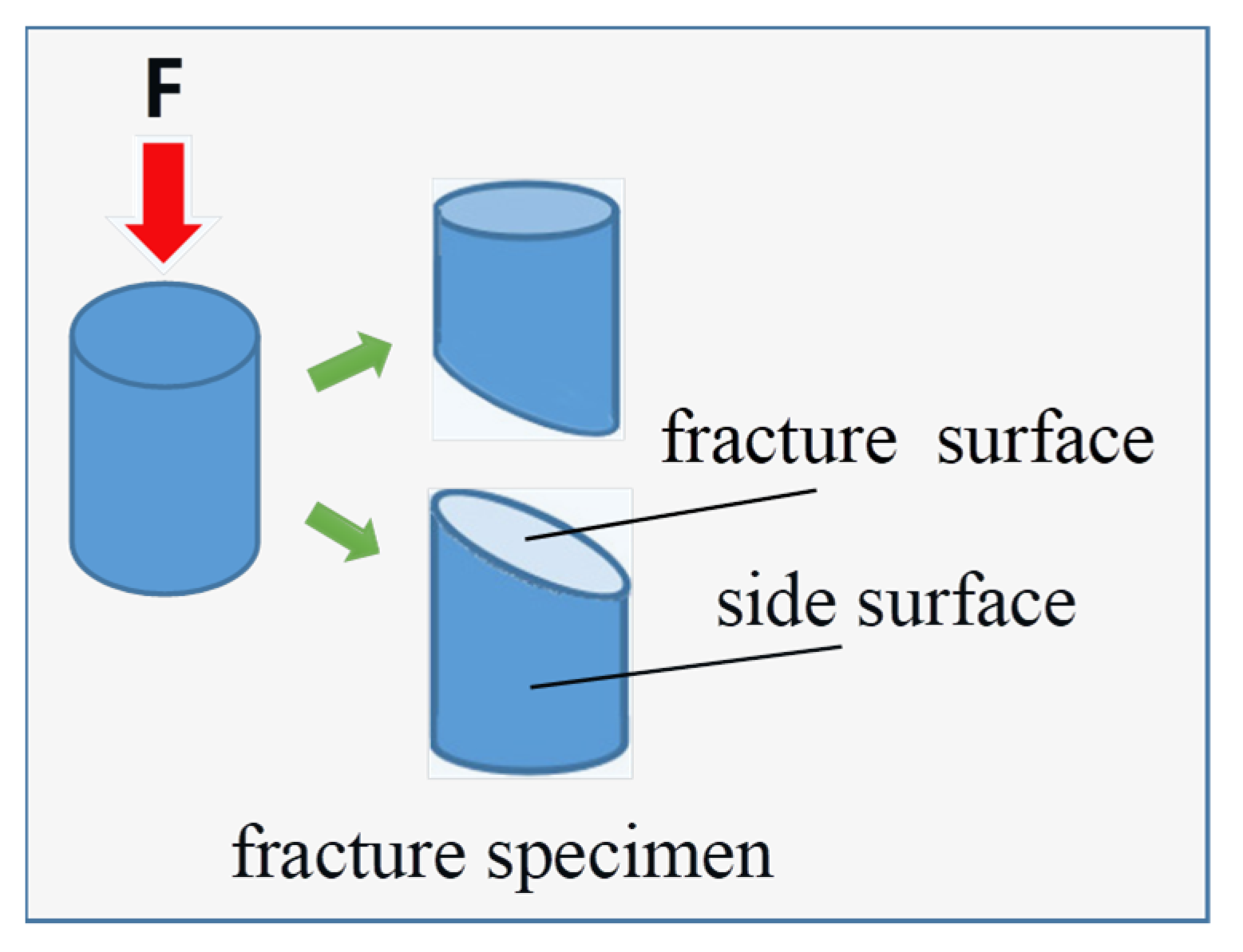

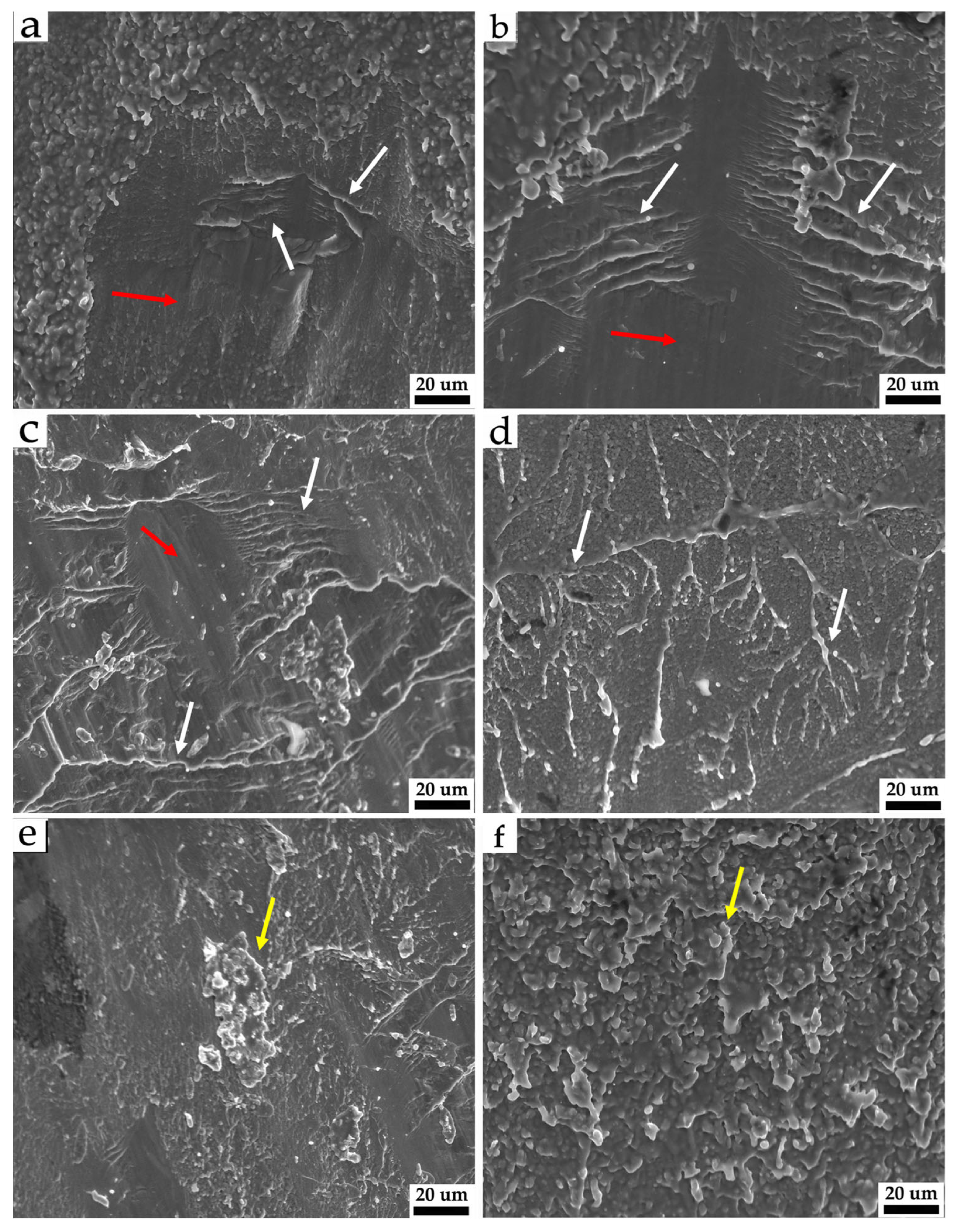

3.1.3. Observation of the Surface of the Fractured Specimen

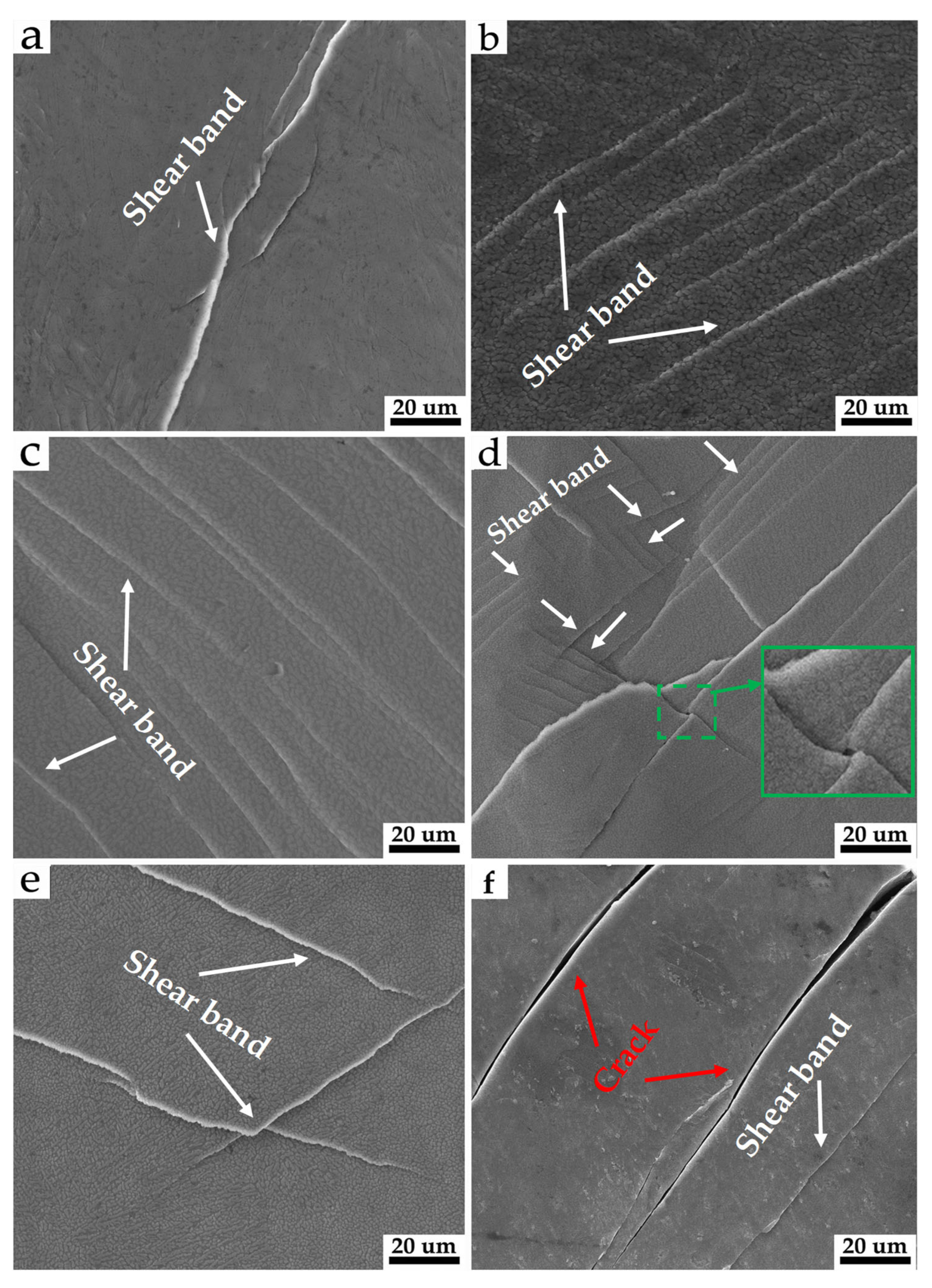

3.1.4. Observation of the Side Surfaces of Fractured Specimens

4. Discussions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Poulsen, H.F.; Wert, J.A.; Neuefeind, J.; Honkimäki, V.; Daymond, M. Measuring strain distributions in amorphous materials. Nat. Mater. 2005, 4, 33–36. [Google Scholar] [CrossRef]

- Cao, Q.P.; Liu, J.W.; Yang, K.J.; Xu, F.; Yao, Z.Q.; Minkow, A.; Fecht, H.J.; Ivanisenko, J.; Chen, L.Y.; Wang, X.D.; et al. Effect of pre-existing shear bands on the tensile mechanical properties of a bulk metallic glass. Acta Mater. 2010, 58, 1276. [Google Scholar] [CrossRef]

- Subramanian, J.; Seetharaman, S.; Gupta, M. Processing and properties of aluminum and magnesium based composites containing amorphous reinforcement: A review. Metals 2015, 5, 743. [Google Scholar] [CrossRef]

- Oh, Y.S.; Kim, C.P.; Lee, S.; Kim, N.J. Microstructure and tensile properties of high-strength high-ductility Ti-based amorphous matrix composites containing ductile dendrites. Acta Mater. 2011, 59, 7277–7286. [Google Scholar] [CrossRef]

- Tang, J.; Ahmadi, A.; Alizadeh, A.A.; Abedinzadeh, R.; Abed, A.M.; Smaisim, G.F.; Toghraie, D. Investigation of the mechanical properties of different amorphous composites using the molecular dynamics simulation. J. Mater. Res. Technol. 2023, 24, 1390–1400. [Google Scholar] [CrossRef]

- Lu, S.; Wang, M.; Zhao, Z. Recent advances and future developments in Fe-based amorphous soft magnetic composites. J. Non-Cryst. Solids 2023, 616, 122440. [Google Scholar] [CrossRef]

- Tlili, A.; Pailhes, S.; Debord, R.; Ruta, B.; Gravier, S.; Blandin, J.J.; Blanchard, N.; Gomes, S.; Assy, A.; Tanguy, A.; et al. Thermal transport properties in amorphous/nanocrystalline metallic composites: A microscopic insight. Acta Mater. 2017, 136, 425. [Google Scholar] [CrossRef]

- Gong, P.; Wang, X.; Shao, Y.; Chen, N.; Liu, X.; Yao, K.F. A Ti–Zr–Be–Fe–Cu bulk metallic glass with superior glass-forming ability and high specific strength. Intermetallics 2013, 43, 177. [Google Scholar] [CrossRef]

- Guo, W.; Saida, J.; Zhao, M.; Lu, S.; Wu, S. In-situ Ta-rich particle reinforced Zr-based bulk metallic glass matrix composites with tensile plasticity. J. Alloys Compd. 2019, 775, 1002. [Google Scholar] [CrossRef]

- Zhang, T.; Ye, H.Y.; Shi, J.Y.; Yang, H.J.; Qiao, J.W. Dendrite size dependence of tensile plasticity of in situ Ti-based metallic glass matrix composites. J. Alloys Compd. 2014, 583, 593–597. [Google Scholar] [CrossRef]

- Yang, C.; Qi, L.; Chao, X.; Wang, J.; Ge, J. Highly thermal conductive Csf/Mg composites by in-situ constructing the unidirectional configuration of short carbon fibers. Chem. Eng. J. 2023, 470, 144327. [Google Scholar] [CrossRef]

- Wu, G.; Liu, C.; Yan, Y.Q.; Liu, S.; Ma, X.; Yue, S.; Shan, Z.W. Elemental partitioning-mediated crystalline-to-amorphous phase transformation under quasi-static deformation. Nat. Commun. 2024, 15, 1223. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Hua, D.; Zhou, Q.; Pei, X.; Wang, H.; Ren, Y.; Liu, W. Concurrently achieving strength-ductility combination and robust anti-wear performance in an in-situ high-entropy bulk metallic glass composite. Compos. Part B Eng. 2024, 272, 111222. [Google Scholar] [CrossRef]

- Hasiak, M.; Sobieszczańska, B.; Łaszcz, A.; Biały, M.; Chęcmanowski, J.; Zatoński, T. Fabrication and comprehensive evaluation of Zr-based bulk metallic glass matrix composites for biomedical applications. Sci. China Mater. 2024, 67, 4087–4100. [Google Scholar] [CrossRef]

- Zhao, L.; Hu, L.; Lin, B.; Wang, Y.; Tang, J.; Qi, L.; Liu, X. Significant improvement of corrosion resistance in laser cladded Zr-based metallic glass matrix composite coatings by laser remelting. Corros. Sci. 2024, 238, 112360. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, W. Formation and mechanical properties of a Zr73Al8Cu6Ni13 bulk metallic glass composite containing in-situ beta-Zr dendrites. J. Alloys Compd. 2019, 801, 175–180. [Google Scholar] [CrossRef]

- Shen, Y.; Xu, J. Improving plasticity and toughness of Cu-Zr-Y-Al bulk metallic glasses via compositional tuning towards the CuZr. J. Mater. Res. 2010, 25, 375–382. [Google Scholar] [CrossRef]

- Wang, H.S.; Wu, J.Y.; Liu, Y.T. Effect of the volume fraction of the ex-situ reinforced Ta additions on the microstructure and properties of laser-welded Zr-based bulk metallic glass composites. Intermetallics 2016, 68, 87–94. [Google Scholar] [CrossRef]

- Liu, D.M.; Lin, S.F.; Zhu, Z.W.; Zhang, B.; Li, Z.K.; Zhang, L.; Fu, H.M.; Wang, A.M.; Li, H.; Zhang, H.W.; et al. The design and mechanical behaviors of in-situ formed ductile dendrite Ti-based bulk metallic glass composites with tailored composition and mechanisms. Mat. Sci. Eng. A 2018, 732, 148–156. [Google Scholar] [CrossRef]

- Ma, X.Z.; Ma, D.Q.; Xu, H.; Zhang, H.Y.; Ma, M.Z.; Zhang, X.Y.; Liu, R.P. Enhancing the compressive and tensile properties of Ti-based glassy matrix composites with Nb addition. J. Non-Cryst. Solids 2017, 463, 56–63. [Google Scholar] [CrossRef]

- Li, B.; Sun, W.C.; Qi, H.N.; Lv, J.W.; Wang, F.L.; Ma, M.Z.; Zhang, X.Y. Effects of Ag substitution for Fe on glass-forming ability, crystallization kinetics, and mechanical properties of Ni-free Zr–Cu–Al–Fe bulk metallic glasses. J. Alloys Compd. 2020, 827, 154385. [Google Scholar] [CrossRef]

- Abrosimova, G.E.; Aronin, A.S.; Kholstinina, N.N. On the determination of the volume fraction of the crystalline phase in amorphous-crystalline alloys. Phys. Solid State 2010, 52, 445–451. [Google Scholar] [CrossRef]

- Dua, V.; Singh, K. Crystallization kinetics study of magnesium vanadate glasses using non-isothermal method. J. Non-Cryst. Solids 2022, 595, 121820. [Google Scholar] [CrossRef]

- Zhang, L.; Su, S.; Fu, W. Strain-induced structural evolution of interphase interfaces in CuZr-based metallic-glass composite reinforced by B2 crystalline phase. Compos. Part B Eng. 2023, 258, 110698. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Wang, W.H.; Greerm, A.L. Intrinsic plasticity or brittleness of metallic glasses. Phil. Mag. Lett. 2005, 85, 77–87. [Google Scholar] [CrossRef]

- Dastgerdi, J.N.; Marquis, G.; Anbarlooie, B.; Sankaranarayanan, S.; Gupta, M. Microstructure-sensitive investigation on the plastic deformation and damage initiation of amorphous particles reinforced composites. Compos. Struct. 2016, 142, 130–139. [Google Scholar] [CrossRef]

- Ha, D.J.; Kim, C.P.; Lee, S. Tensile deformation behavior of two Ti-based amorphous matrix composites containing ductile β dendrites. Mat. Sci. Eng. A 2012, 552, 404–409. [Google Scholar] [CrossRef]

- Ma, Y.; Gong, P.; Yang, X.; Hu, H.; Chi, J.; Xu, X.; Wang, X. Microstructure and mechanical properties of Zr-based metallic glass composites with size-variable tungsten reinforcements. J. Alloys Compd. 2025, 1010, 177721. [Google Scholar] [CrossRef]

- Lund, E.T.; Sohn, S.A.; Curtarolo, S.; Hofmann, D.; Schroers, J. Tension-compression asymmetry of shear band stability in bulk metallic glasses. Materialia 2025, 40, 102408. [Google Scholar] [CrossRef]

- Tian, L.; Narayan, R.L.; Zhou, K.; Babicheva, R.; Ramamurty, U.; Shan, Z.W. A real-time TEM study of the deformation mechanisms in β-Ti reinforced bulk metallic glass composites. Mat. Sci. Eng. A 2021, 818, 141427. [Google Scholar] [CrossRef]

- Sun, L.; Sun, S.; Zhou, H.; Zhang, H.; Wang, G.; Zhang, C.; Wang, X. Effect of vanadium reinforcement on the microstructure and mechanical properties of magnesium matrix composites. Crystals 2021, 11, 806. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, J.; Fan, H.; Ning, Z.; Huang, Y. Effect of crystalline phase on deformation behaviors of amorphous matrix in a metallic glass composite. Mat. Sci. Eng. A 2023, 872, 144957. [Google Scholar] [CrossRef]

- Nayebi, B.; Delbari, S.A.; Asl, M.S.; Ghasali, E.; Parvin, N.; Shokouhimehr, M. A nanostructural approach to the interfacial phenomena in spark plasma sintered TiB2 ceramics with vanadium and graphite additives. Compos. Part B Eng. 2021, 222, 109069. [Google Scholar] [CrossRef]

- Tu, C.L.; Sun, X.D.; Li, J.; Zhu, H.G.; Li, X.D. Effect of vanadium content on microstructure and properties of in situ TiC reinforced V x FeCoNiCu multi-principal-element alloy matrix composites. J. Iron Steel Res. Int. 2021, 28, 1471–1480. [Google Scholar] [CrossRef]

- Ye, Z.; Li, C.; Zhang, X.; Liao, Y.; Gu, J. The influence of vanadium element on the microstructure and mechanical properties of (FeCoNi)100-xVx high-entropy alloys. Mater. Charact. 2022, 192, 112232. [Google Scholar] [CrossRef]

- Zhai, W.; Nie, L.H.; Hui, X.D.; Wang, T.; Wei, B. Ultrasonic excitation induced nanocrystallization and toughening of Zr46.75Cu46.75Al6.5 bulk metallic glass. J. Mater. Sci. Technol. 2020, 45, 157–161. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Zhu, Z.W.; Li, S.T.; Wang, Y.Y.; Li, Z.K.; Li, H.; Zhang, H.F. Shear band evolution and mechanical behavior of cold-rolled Zr-based amorphous alloy sheets: An in-situ study. J. Mater. Sci. Technol. 2024, 181, 115–127. [Google Scholar] [CrossRef]

| Specimen Code | Yield Strength σy/MPa | Plasticity εp/% | Maximum Strength σmax/MPa |

|---|---|---|---|

| V0 | 1898 | 0.7 | 1922 |

| V4 | 1803 | 3.1 | 1976 |

| V8 | 1734 | 6.1 | 2051 |

| V12 | 1596 | 7.9 | 1911 |

| V16 | 1557 | 2.4 | 1615 |

| V20 | 1470 | 0.2 | 1479 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Li, J.; Wang, G.; Chen, B.; Wei, C.; Ouyang, Y. Microstructure and Compressive Properties of (Ti51Zr25Cu6Be18)100−xVx Bulk Metallic Glass Matrix Composites. Crystals 2025, 15, 838. https://doi.org/10.3390/cryst15100838

Huang X, Li J, Wang G, Chen B, Wei C, Ouyang Y. Microstructure and Compressive Properties of (Ti51Zr25Cu6Be18)100−xVx Bulk Metallic Glass Matrix Composites. Crystals. 2025; 15(10):838. https://doi.org/10.3390/cryst15100838

Chicago/Turabian StyleHuang, Xinhua, Junnan Li, Guang Wang, Bin Chen, Chenghao Wei, and Yuejun Ouyang. 2025. "Microstructure and Compressive Properties of (Ti51Zr25Cu6Be18)100−xVx Bulk Metallic Glass Matrix Composites" Crystals 15, no. 10: 838. https://doi.org/10.3390/cryst15100838

APA StyleHuang, X., Li, J., Wang, G., Chen, B., Wei, C., & Ouyang, Y. (2025). Microstructure and Compressive Properties of (Ti51Zr25Cu6Be18)100−xVx Bulk Metallic Glass Matrix Composites. Crystals, 15(10), 838. https://doi.org/10.3390/cryst15100838