Nanoindentation Stress Relaxation to Quantify Dislocation Velocity–Stress Exponent

Abstract

1. Introduction

2. Materials and Methods

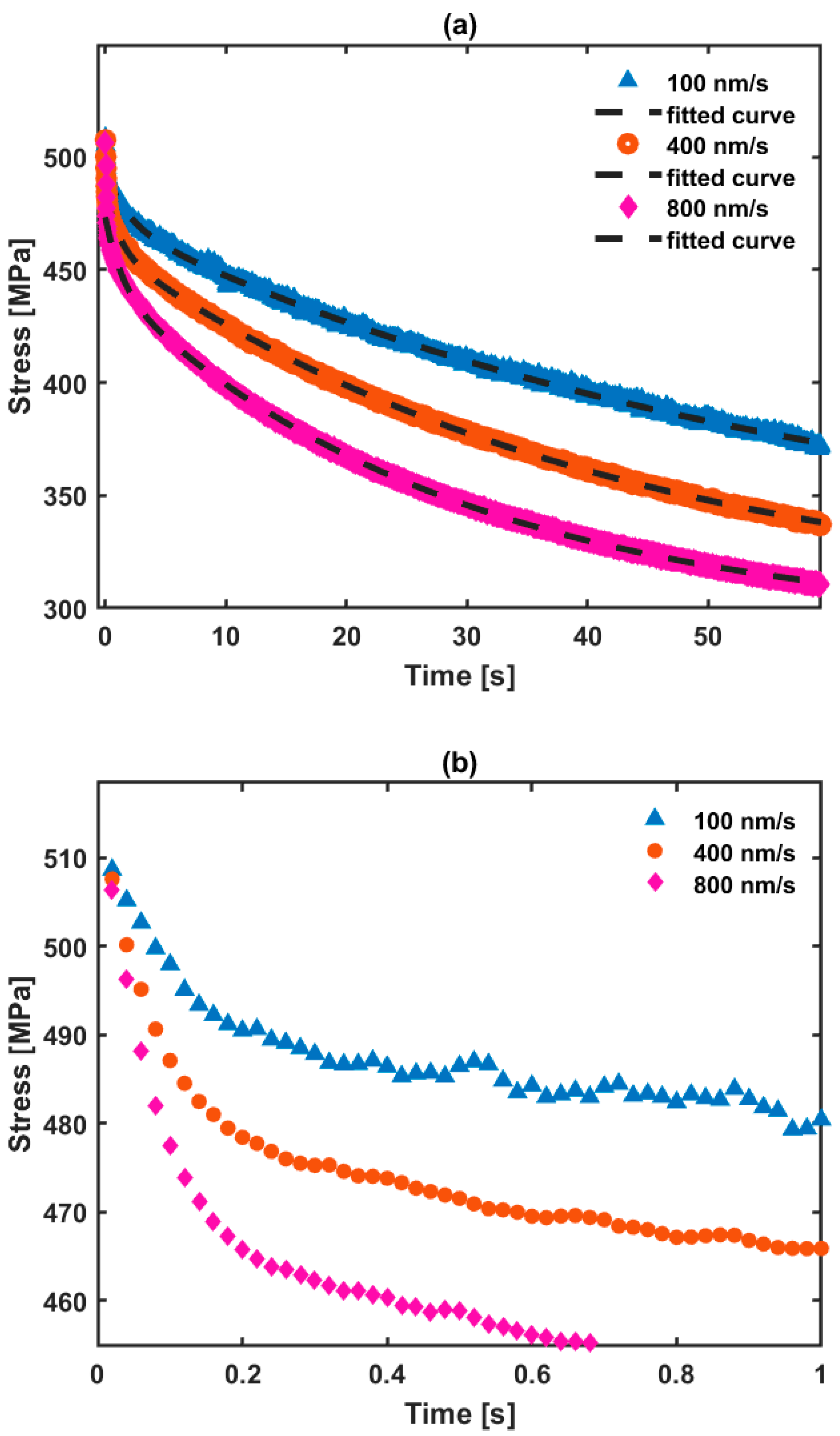

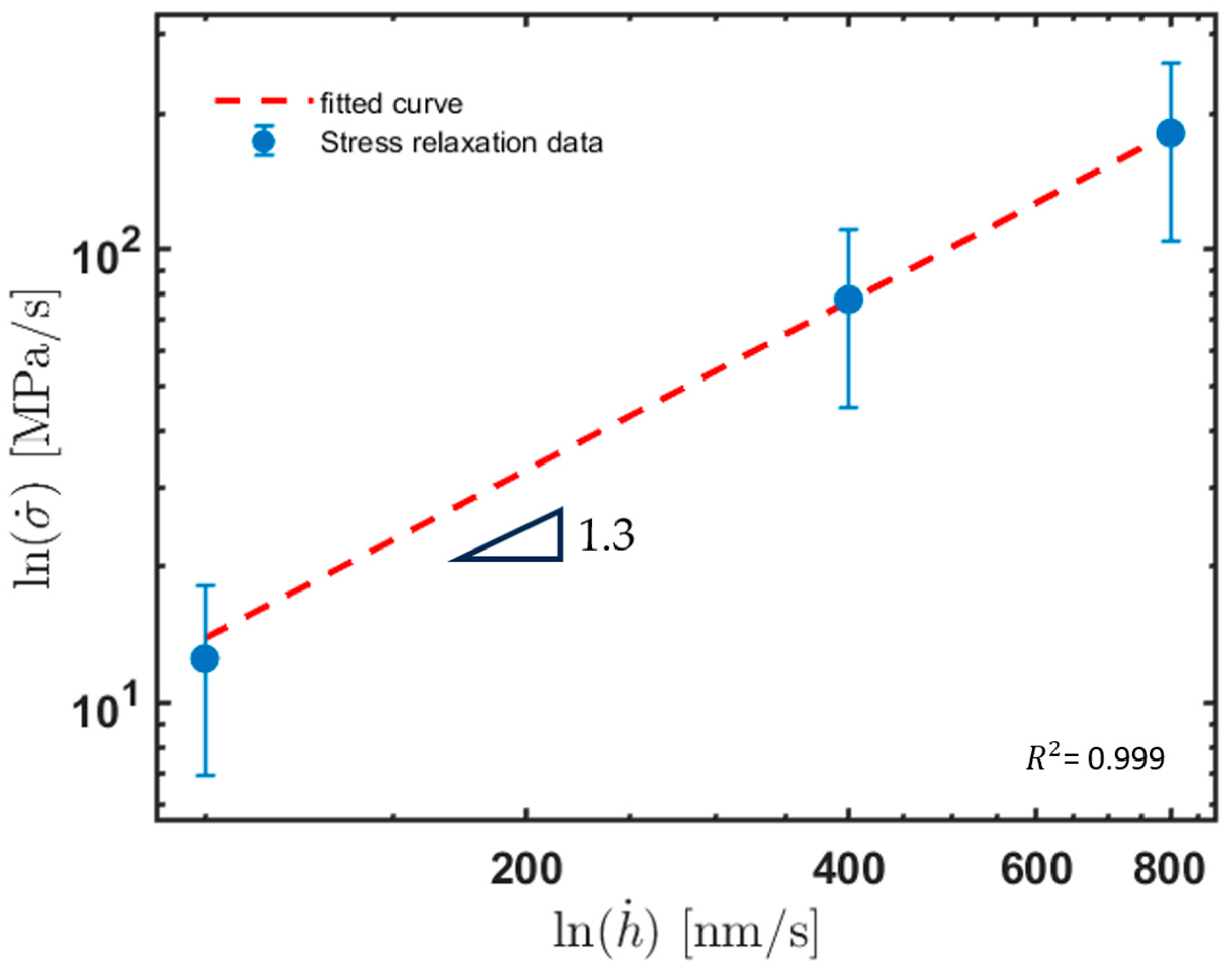

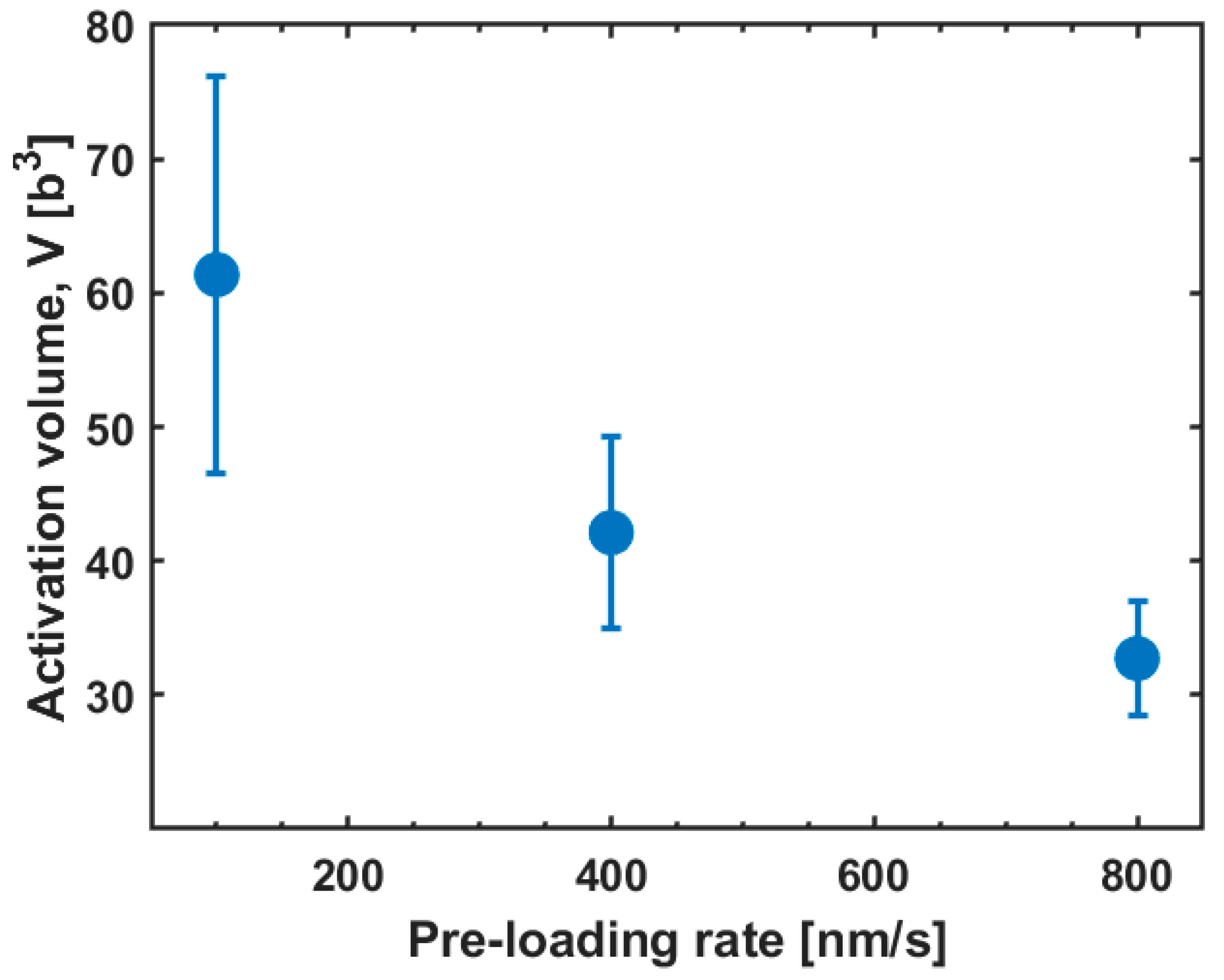

3. Results

4. Discussion

4.1. Data Validation

4.2. Hypothesis Verification

4.3. Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Herbert, E.G.; Pharr, G.M.; Oliver, W.C.; Lucas, B.N.; Hay, J.L. On the Measurement of Stress–Strain Curves by Spherical Indentation. Thin Solid Films 2001, 5, 331–335. [Google Scholar] [CrossRef]

- Hosemann, P. Small-Scale Mechanical Testing on Nuclear Materials: Bridging the Experimental Length-Scale Gap. Scr. Mater. 2018, 143, 161–168. [Google Scholar] [CrossRef]

- Frazer, D.; Hosemann, P. Plasticity of UO2 Studied and Quantified via Elevated Temperature Micro Compression Testing. J. Nucl. Mater. 2019, 525, 140–144. [Google Scholar] [CrossRef]

- Frazer, D.; Abad, M.D.; Krumwiede, D.; Back, C.A.; Khalifa, H.E.; Deck, C.P.; Hosemann, P. Localized Mechanical Property Assessment of SiC/SiC Composite Materials. Compos. Part A Appl. Sci. Manuf. 2015, 70, 93–101. [Google Scholar] [CrossRef]

- Chen, T.; Frazer, D.; Cullison, M.; Teng, F.; Lian, J.; Mo, K.; Cappia, F. The Effects of Radiation-Induced Grain Subdivision and Dislocations on the Fracture Properties of Uranium Dioxide. J. Nucl. Mater. 2023, 577, 154297. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation Size Effects in Crystalline Materials: A Law for Strain Gradient Plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Frazer, D.; Shaffer, B.; Gong, B.; Peralta, P.; Lian, J.; Hosemann, P. Elevated Temperature Nanoindentation Creep Study of Plastically Deformed and Spark Plasma Sintered UO2. J. Nucl. Mater. 2021, 545, 152605. [Google Scholar] [CrossRef]

- Chen, T.; Tan, L.; Lu, Z.; Xu, H. The Effect of Grain Orientation on Nanoindentation Behavior of Model Austenitic Alloy Fe-20Cr-25Ni. Acta Mater. 2017, 138, 83–91. [Google Scholar] [CrossRef]

- Chen, T.; He, L.; Cullison, M.H.; Hay, C.; Burns, J.; Wu, Y.; Tan, L. The Correlation between Microstructure and Nanoindentation Property of Neutron-Irradiated Austenitic Alloy D9. Acta Mater. 2020, 195, 433–445. [Google Scholar] [CrossRef]

- Goodall, R.; Clyne, T.W. A Critical Appraisal of the Extraction of Creep Parameters from Nanoindentation Data Obtained at Room Temperature. Acta Mater. 2006, 54, 5489–5499. [Google Scholar] [CrossRef]

- Xu, B.X.; Wang, X.M.; Yue, Z.F. Determination of the Internal Stress and Dislocation Velocity Stress Exponent with Indentation Stress Relaxation Test. J. Mater. Res. 2008, 23, 2486–2490. [Google Scholar] [CrossRef]

- Kutty, T.R.G.; Basak, C.B.; Kumar, A.; Kamath, H.S. Creep Behaviour of δ-Phase of U–Zr System by Impression Creep Technique. J. Nucl. Mater. 2011, 408, 90–95. [Google Scholar] [CrossRef]

- Zaiser, M.; Sandfeld, S. Scaling Properties of Dislocation Simulations in the Similitude Regime. Model. Simul. Mater. Sci. Eng. 2014, 22, 065012. [Google Scholar] [CrossRef]

- Hull, D.; Bacon, D.J. Introduction of Dislocation, 5th ed.; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 978-0-7506-4681-9. [Google Scholar]

- Blum, W.; Eisenlohr, P.; Breutinger, F. Understanding Creep—A Review. Metall. Mater. Trans. A 2002, 33, 291–303. [Google Scholar] [CrossRef]

- Blum, W. Mechanisms of Creep Deformation in Steel. In Creep-Resistant Steels; Elsevier: Amsterdam, The Netherlands, 2008; pp. 365–402. ISBN 978-1-84569-178-3. [Google Scholar]

- Varma, A.; Krishnaswamy, H.; Jain, J.; Lee, M.-G.; Barlat, F. Advanced Constitutive Model for Repeated Stress Relaxation Accounting for Transient Mobile Dislocation Density and Internal Stress. Mech. Mater. 2019, 133, 138–153. [Google Scholar] [CrossRef]

- Aifantis, E.C.; Gerberich, W.W. A Theoretical Review of Stress Relaxation Testing. Mater. Sci. Eng. 1975, 21, 107–113. [Google Scholar] [CrossRef]

- Gupta, I.; Li, J.C.M. Stress Relaxation, Internal Stress, and Work Hardening in Some Bcc Metals and Alloys. Metall. Trans. 1970, 1, 2323–2330. [Google Scholar] [CrossRef]

- Dotsenko, V.I. Stress Relaxation in Crystals. Phys. Status Solidi B 1979, 93, 11–43. [Google Scholar] [CrossRef]

- Kruml, T.; Coddet, O.; Martin, J.L. About the Determination of the Thermal and Athermal Stress Components from Stress-Relaxation Experiments. Acta Mater. 2008, 56, 333–340. [Google Scholar] [CrossRef]

- Barlat, F. A Simple Model for Dislocation Behavior, Strain and Strain Rate Hardening Evolution in Deforming Aluminum Alloys. Int. J. Plast. 2002, 18, 919–939. [Google Scholar] [CrossRef]

- Lindsay, A.D.; Gaston, D.R.; Permann, C.J.; Miller, J.M.; Andrš, D.; Slaughter, A.E.; Kong, F.; Hansel, J.; Carlsen, R.W.; Icenhour, C.; et al. 2.0—MOOSE: Enabling Massively Parallel Multiphysics Simulation. SoftwareX 2022, 20, 101202. [Google Scholar] [CrossRef]

- Kalidindi, S.R.; Bronkhorst, C.A.; Anand, L. Crystallographic Texture Evolution in Bulk Deformation Processing of FCC Metals. J. Mech. Phys. Solids 1992, 40, 537–569. [Google Scholar] [CrossRef]

- Karimzadeh, A.; Koloor, S.S.R.; Ayatollahi, M.R.; Bushroa, A.R.; Yahya, M.Y. Assessment of Nano-Indentation Method in Mechanical Characterization of Heterogeneous Nanocomposite Materials Using Experimental and Computational Approaches. Sci. Rep. 2019, 9, 15763. [Google Scholar] [CrossRef] [PubMed]

- Kubát, J.; Rigdahl, M. The Exponential and Power Laws of Stress Relaxation Kinetics and a General Relation between the Activation Volume and Effective Stress. Phys. Status Solidi A 1976, 35, 173–180. [Google Scholar] [CrossRef]

- Hérault, Q.; Gozhyk, I.; Balestrieri, M.; Montigaud, H.; Grachev, S.; Lazzari, R. Kinetics and Mechanisms of Stress Relaxation in Sputtered Silver Thin Films. Acta Mater. 2021, 221, 117385. [Google Scholar] [CrossRef]

- Caillard, D.; Martin, J.-L. Thermally Activated Mechanisms in Crystal Plasticity; Pergamon: Amsterdam, The Netherlands, 2003; ISBN 978-0-08-042703-4. [Google Scholar]

- Zinkle, S.J. Radiation-Induced Effects on Microstructure. In Comprehensive Nuclear Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 91–129. ISBN 978-0-08-102866-7. [Google Scholar]

- Kassner, M.E.; Pérez-Prado, M.-T. Fundamentals of Creep in Metals and Alloys, 1st ed.; Elsevier: Amsterdam, The Netherlands; Heidelberg, Germany, 2004; ISBN 978-0-08-043637-1. [Google Scholar]

- Ueda, S.; Kameyama, T.; Matsunaga, T.; Kitazono, K.; Sato, E. Re-Examination of Creep Behaviour of High Purity Aluminium at Low Temperature. J. Phys. Conf. Ser. 2010, 240, 012073. [Google Scholar] [CrossRef]

- Gibbs, G.B. Creep and Stress Relaxation Studies with Polycrystalline Magnesium. Philos. Mag. J. Theor. Exp. Appl. Phys. 1966, 13, 317–329. [Google Scholar] [CrossRef]

- Kombaiah, B.; Murty, K.L. Dislocation Cross-Slip Controlled Creep in Zircaloy-4 at High Stresses. Mater. Sci. Eng. A 2015, 623, 114–123. [Google Scholar] [CrossRef]

| Reference Slip Rate | 0.001 s−1 | |

| Hardening Constants | 75 | |

| Initial Slip Resistance | 31 | |

| Saturated Slip Resistance | 63 | |

| Strain Rate Sensitivity | 0.333 | |

| Latent Hardening Constant | 1.4 | |

| Hardening Exponent | 2.25 | |

| Elasticity Tensor | 107 | |

| Elasticity Tensor | 61 | |

| Elasticity Tensor | 28 |

| Pre-Loading Rate (nm/s) | 800 | 400 | 100 |

|---|---|---|---|

| (MPa) | 61 ± 2 | 44 ± 4 | 23 ± 1 |

| (/s) | 3.2 ± 0.4 | 1.9 ± 0.5 | 0.67 ± 0.01 |

| (MPa) | 150 ± 10 | 163 ± 7 | 154 ± 6 |

| (/s) | 0.037 ± 0.01 | 0.027 ± 0.004 | 0.018 ± 0.004 |

| (MPa) | 300 ± 22 | 340 ± 20 | 363 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, T.-Y.; Vandenbroeder, G.; Frazer, D.M.; Yushu, D.; Pitts, S.; Chen, T. Nanoindentation Stress Relaxation to Quantify Dislocation Velocity–Stress Exponent. Crystals 2024, 14, 680. https://doi.org/10.3390/cryst14080680

Chang T-Y, Vandenbroeder G, Frazer DM, Yushu D, Pitts S, Chen T. Nanoindentation Stress Relaxation to Quantify Dislocation Velocity–Stress Exponent. Crystals. 2024; 14(8):680. https://doi.org/10.3390/cryst14080680

Chicago/Turabian StyleChang, Tzu-Yi, Gavin Vandenbroeder, David M. Frazer, Dewen Yushu, Stephanie Pitts, and Tianyi Chen. 2024. "Nanoindentation Stress Relaxation to Quantify Dislocation Velocity–Stress Exponent" Crystals 14, no. 8: 680. https://doi.org/10.3390/cryst14080680

APA StyleChang, T.-Y., Vandenbroeder, G., Frazer, D. M., Yushu, D., Pitts, S., & Chen, T. (2024). Nanoindentation Stress Relaxation to Quantify Dislocation Velocity–Stress Exponent. Crystals, 14(8), 680. https://doi.org/10.3390/cryst14080680