The Effects of Indium Additions on Tribological Behavior of Spark Plasma Sintering-Produced Graphene-Doped Alumina Matrix Composites for Self-Lubricating Applications

Abstract

1. Introduction

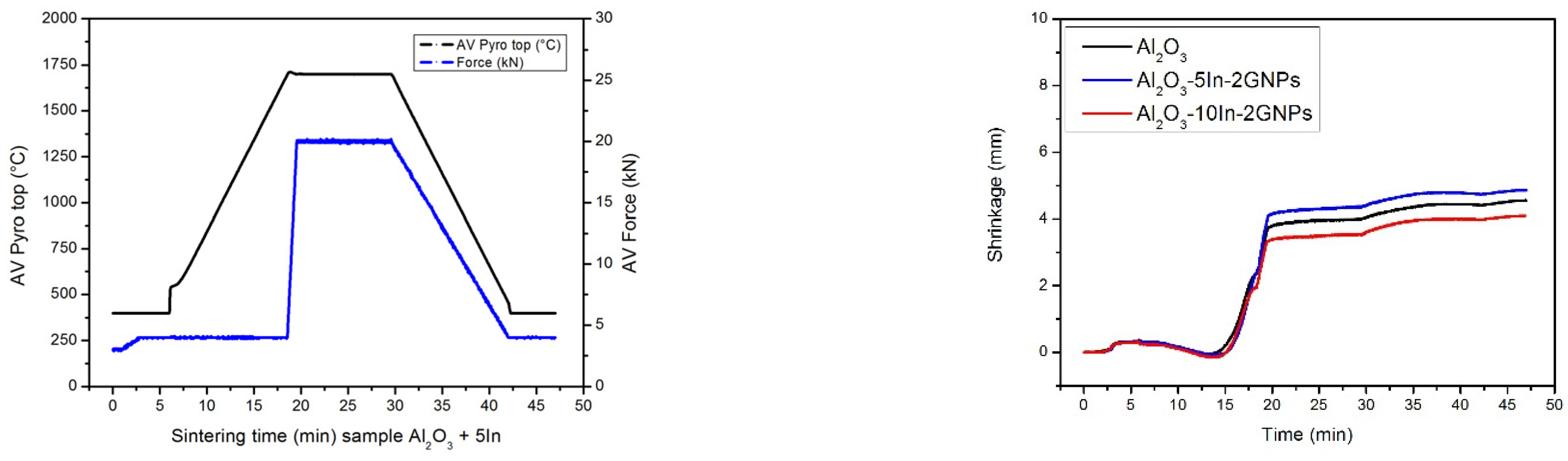

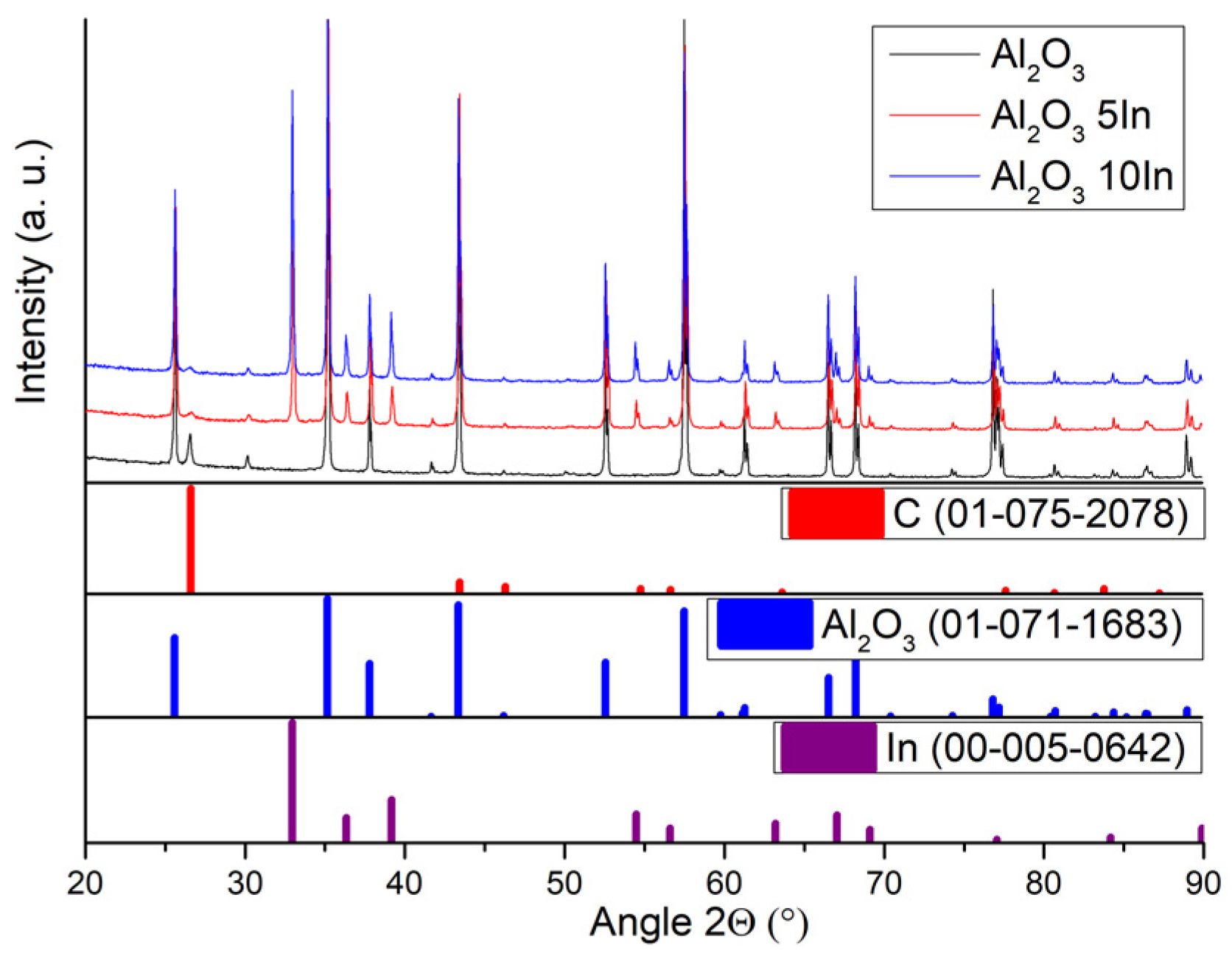

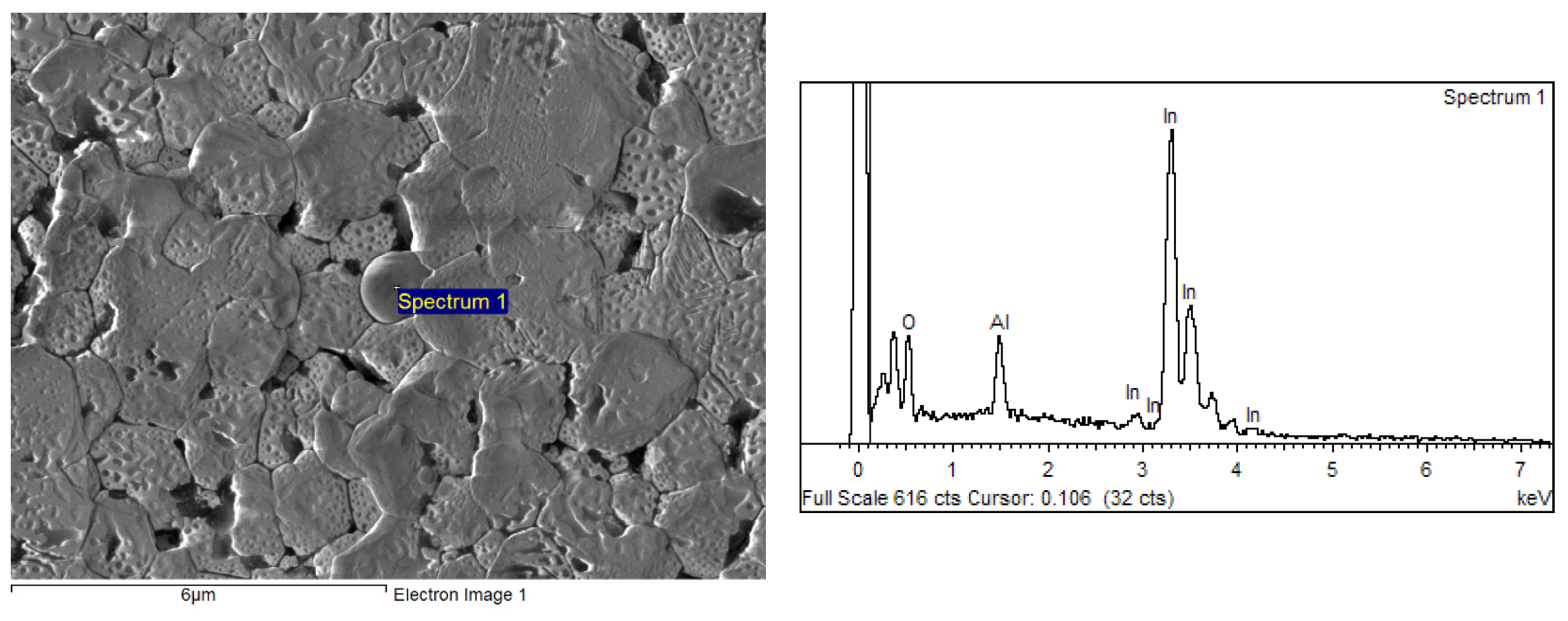

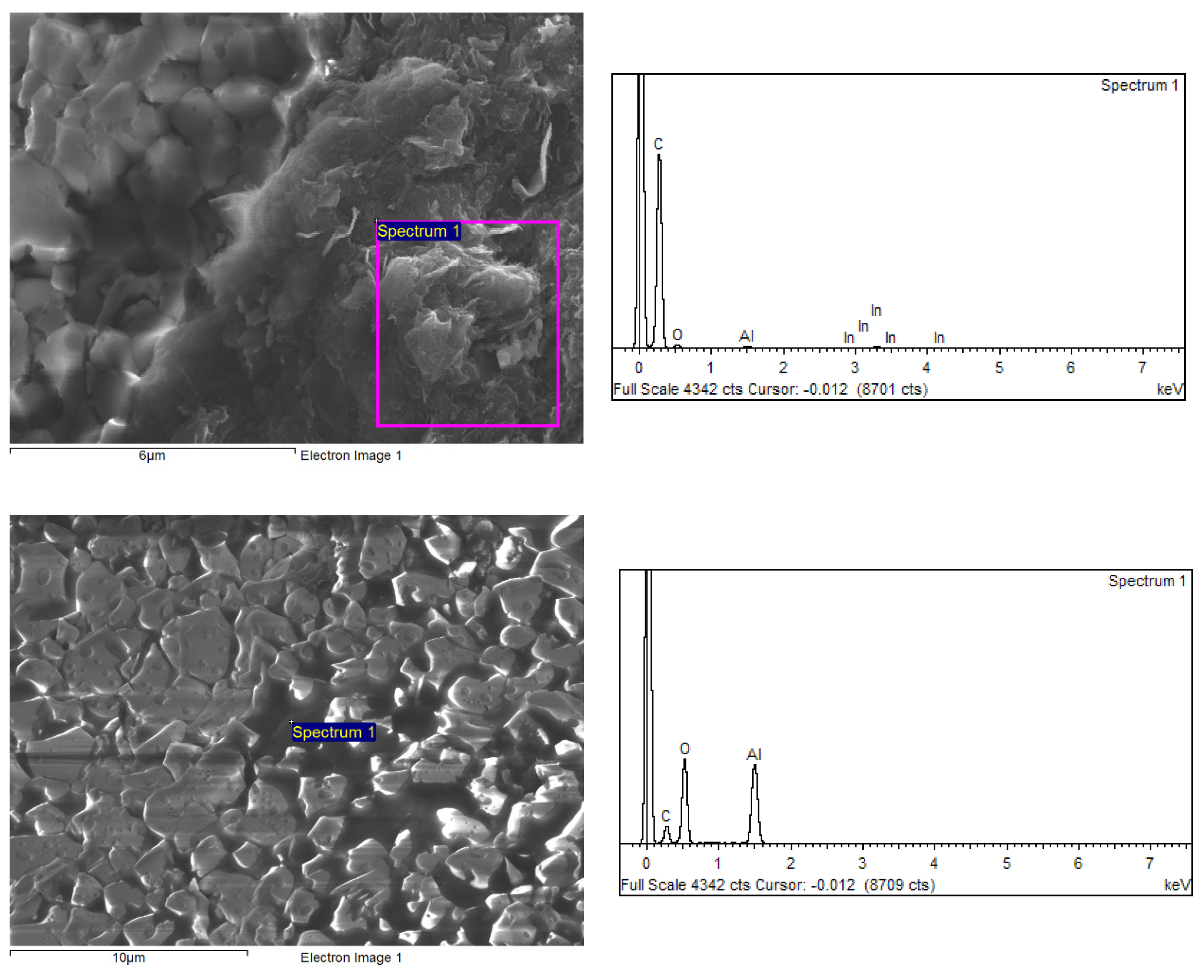

2. Materials and Methods

3. Results and Discussion

4. Conclusions

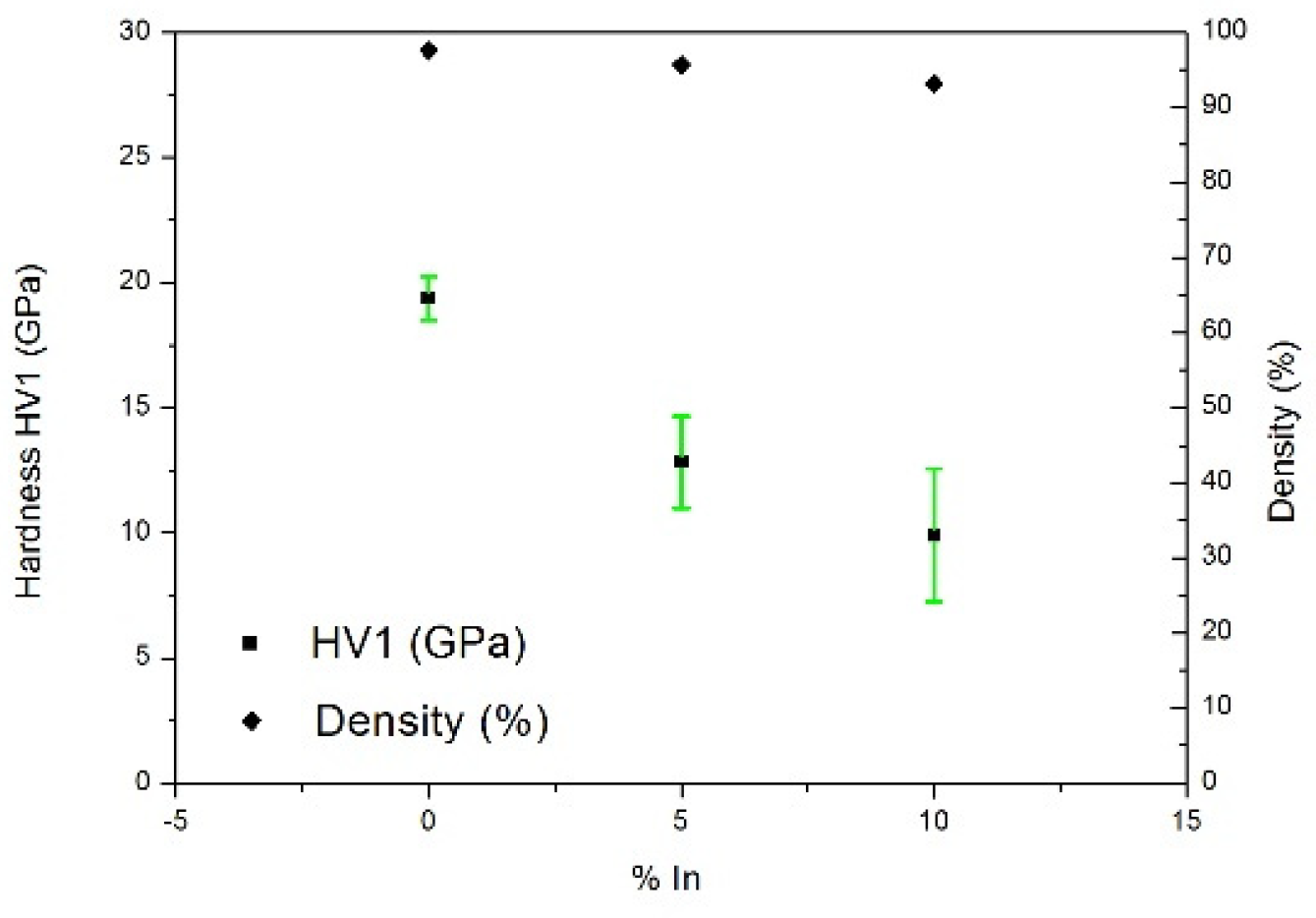

- The wear rate of the ceramic matrix material rises if the amount of indium metal changes from 0 wt.% to 5 wt.% and decreases if the amount of indium metal changes from 5 wt.% to 10 wt.% in Al2O3-In-GNP composite samples. The wear rates can be reduced by ~45% for the Al2O3 ceramic matrix composite with 10 wt.% of indium metal and 2 wt.% of graphene nanoplatelets as solid lubricants compared to the monolithic sample.

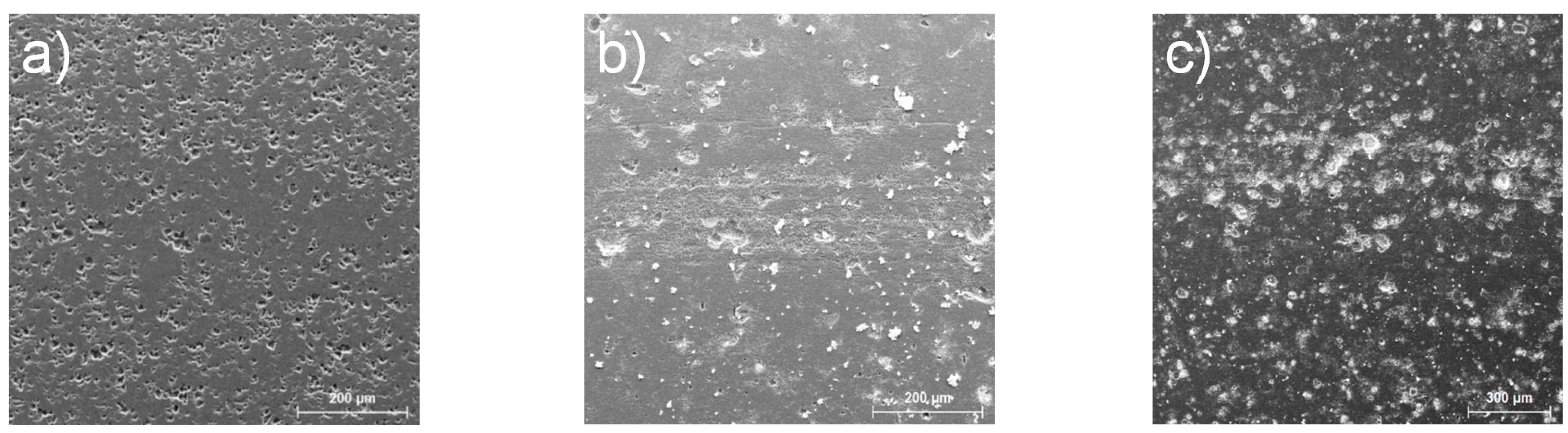

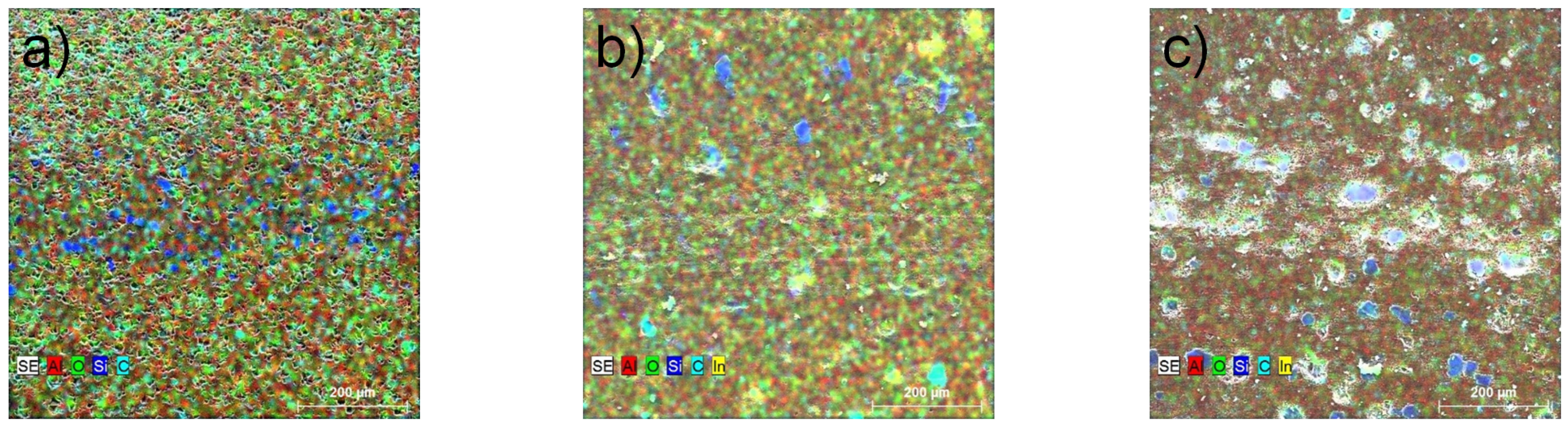

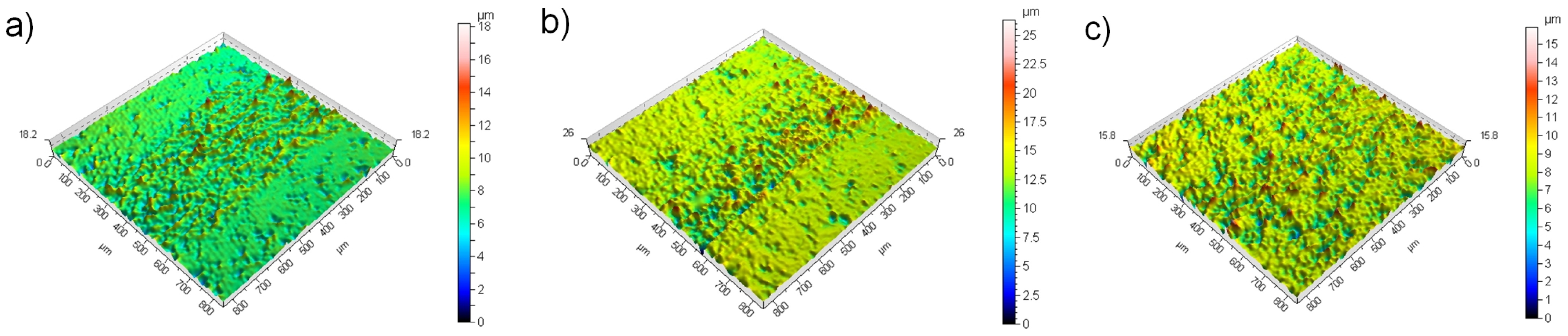

- A sintered alumina composite sample with 5 wt.% indium metal and 2 wt.% graphene nanoplatelets can reduce the average friction coefficient by about 21% compared to the monolithic alumina, while the alumina composite sample with 10 wt.% indium metal and 2 wt.% graphene nanoplatelets as solid lubricants can reduce the average friction coefficient by about 14%. The pores in sintered material can trap wear debris from the friction ball and this mechanism may have an obvious influence on the friction coefficient value under the present conditions.

- The mechanism for improving the tribological properties of alumina composite materials is that the indium metal and graphene nanoplatelets incorporated into the matrix can act as a lubricant store for creating a friction film and also on a smaller scale can capture wear debris, which could play an important role in promoting the engineering applications of Al2O3-In-GNP self-lubricating composite materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Surappa, M.K. Aluminium matrix composites: Challenges and opportunities. Sadhana 2003, 28, 319–334. [Google Scholar] [CrossRef]

- Zhang, C.; Nieto, A.; Agarwal, A. Ultrathin graphene tribofilm formation during wear of Al2O3–graphene composites. Nanomater. Energy 2016, 5, 1–9. [Google Scholar] [CrossRef]

- Ramirez, C.; Figueiredo, F.M.; Miranzo, P.; Poza, P.; Osendi, M.I. Graphene nanoplatelet/silicon nitride composites with high electrical conductivity. Carbon 2012, 50, 3607–3615. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, L.; Li, J. Preparation and electrical properties of graphene nanosheet/Al2O3 composites. Carbon 2010, 48, 1743–1749. [Google Scholar] [CrossRef]

- Centeno, A.; Rocha, V.G.; Alonso, B. 2013 Graphene for tough and electroconductive alumina ceramics. J. Eur. Ceram. Soc. 2013, 33, 3201–3210. [Google Scholar] [CrossRef]

- Porwal, H.; Tatarko, P.; Saggar, R.; Grasso, S.; Kumar Mani, M.; Dlouhý, I.; Dusza, J.; Reece, M.J. Tribological properties of silica-graphene nano-platelet composites. Ceram. Int. 2014, 40, 12067–12074. [Google Scholar] [CrossRef]

- Rutkowski, P.; Stobierski, L.; Zientara, D.; Jaworska, L.; Klimczyk, P.; Urbanik, M. The influence of the graphene additive on mechanical properties and wear of hot-pressed Si3N4 matrix composites. J. Eur. Ceram. Soc. 2015, 35, 87–94. [Google Scholar] [CrossRef]

- Li, H.; Xie, Y.; Li, K.; Huang, L.; Huang, S.; Zhao, B.; Zheng, X. Microstructure and wear behavior of graphene nanosheets-reinforced zirconia coating. Ceram. Int. 2014, 40, 12821–12829. [Google Scholar] [CrossRef]

- Balko, J.; Hvizdos, P.; Dusza, J.; Balazsi, C.; Gamcova, J. Wear damage of Si3N4-graphene nanocomposites at room and elevated temperatures. J. Eur. Ceram. Soc. 2014, 34, 3309–3317. [Google Scholar] [CrossRef]

- Belmonte, M.; Ramirez, C.; Gonzalez-Julian, J.; Schneider, J.; Miranzo, P.; Osendi, M.I. The beneficial effect of graphene nanofillers on the tribological performance of ceramics. Carbon 2013, 61, 431–435. [Google Scholar] [CrossRef]

- Hvizdos, P.; Dusza, J.; Balazsi, C. Tribological properties of Si3N4-graphene nanocomposites. J. Eur. Ceram. Soc. 2013, 33, 2359–2364. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Few layer graphene to reduce wear and friction on sliding steel surfaces. Carbon 2013, 54, 454–459. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, S.M.; Oh, Y.S.; Yang, Y.H.; Lim, Y.S.; Yoon, D.H.; Lee, C.; Kim, J.Y.; Ruoff, R.S. Unoxidized graphene/alumina nanocomposite: Fracture-and wear-resistance effects of graphene on alumina matrix. Sci. Rep. 2014, 4, 5176. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Lee, H.J.; Lee, C.; Lee, S.K.; Jang, H.; Ahn, J.H.; Kim, J.H.; Lee, H.J. Chemical Vapor Deposition-Grown Graphene: The Thinnest Solid Lubricant. ACS Nano 2011, 5, 5107–5114. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Li, Q.; Kalb, W.; Liu, X.Z.; Berger, H.; Carpick, R.W.; Hone, J. Frictional Characteristics of Atomically Thin Sheets. Science 2010, 328, 76–80. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Mora, F.; Cano-Crespo, R.; Rincón, A.; Moreno, R.; Domínguez-Rodríguez, A. Friction and wear behavior of alumina-based graphene and CNFs composites. J. Eur. Ceram. Soc. 2017, 37, 3805–3812. [Google Scholar] [CrossRef]

- Huang, T.; Xin, Y.; Li, T.; Nutt, S.; Su, C.; Chen, H.; Liu, P.; Lai, Z. Modified graphene/polyimide nanocomposites: Reinforcing and tribological effects. ACS Appl. Mater. Interfaces 2013, 5, 4878–4891. [Google Scholar] [CrossRef]

- Ren, G.; Zhang, Z.; Zhu, X.; Ge, B.; Guo, F.; Men, X.; Liu, W. Influence of functional grapheneas filler on the tribological behaviors of Nomex fabric/phenolic composite. Compos. Part A 2013, 49, 157–164. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Tribological performance of self-lubricating aluminum matrix nanocomposites: Role of graphene nanoplatelets. Eng. Sci. Technol. Int. J. 2016, 19, 463–469. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Tabandeh-Khorshid, M.; Omrani, E.; Lovell, M.R.; Menezes, P.L. Tribology of Metal Matrix Composites. In Tribology for Scientists and Engineers; Menezes, P.L., Nosonovsky, M., Ingole, S., Kailas, S., Lovell, M., Eds.; Springer: New York, NY, USA, 2013; pp. 233–268. ISBN 978-1-4614-1945-7. [Google Scholar] [CrossRef]

- Omrani, E.; Rohatgi, P.K.; Menezes, P.L. Tribology and Applications of Self-Lubricating Materials, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781315154077. [Google Scholar] [CrossRef]

- Kasar, A.K.; Menezes, P.L. Friction and wear behavior of alumina composites with in-situ formation of aluminum borate and boron nitride. Materials 2020, 13, 4502. [Google Scholar] [CrossRef]

- Furlan, K.P.; Gonçalves, P.D.C.; Consoni, D.R.; Dias, M.V.G.; De Lima, G.A.; de Mello, J.D.B.; Klein, A.N. Metallurgical Aspects of Self-lubricating Composites Containing Graphite and MoS2. J. Mater. Eng. Perform. 2017, 26, 1135–1145. [Google Scholar] [CrossRef]

- Kelly, P.; Arnell, R. Magnetron sputtering: A review of recent developments and applications. Vacuum 2000, 56, 159–172. [Google Scholar] [CrossRef]

- Quazi, M.M.; Fazal, M.A.; Haseeb, A.S.M.A.; Yusof, F.; Masjuki, H.H.; Arslan, A. A Review to the Laser Cladding of Self-Lubricating Composite Coatings. Lasers Manuf. Mater. Process. 2016, 3, 67–99. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, J.; Guo, B.; Zhou, H.; Pu, Y.; Chen, J. Friction and wear behavior of laser cladding Ni/hBN self-lubricating composite coating. Mater. Sci. Eng. A 2008, 491, 47–54. [Google Scholar] [CrossRef]

- Wang, H.M.; Yu, R.L.; Li, S.Q. Microstructure and tribological properties of laser clad NiO/Al2O3 self-lubrication wear-resistant ceramic matrix composite coatings. Mocaxue Xuebao (Tribol.) (China) 2002, 22, 157–160. [Google Scholar]

- Huang, B.; Zhang, C.; Zhang, G.; Liao, H. Wear and corrosion resistant performance of thermal-sprayed Fe-based amorphous coatings: A review. Surf. Coat. Technol. 2019, 377, 124896. [Google Scholar] [CrossRef]

- Chen, X.; Peng, Z.; Yu, X.; Fu, Z.; Yue, W.; Wang, C. Microstructure and tribological performance of self-lubricating diamond/tetrahedral amorphous carbon composite film. Appl. Surf. Sci. 2011, 257, 3180–3186. [Google Scholar] [CrossRef]

- Kalss, W.; Reiter, A.; Derflinger, V.; Gey, C.; Endrino, J. Modern coatings in high performance cutting applications. Int. J. Refract. Met. Hard Mater. 2006, 24, 399–404. [Google Scholar] [CrossRef]

- Sahin, Y.; Sur, G. The effect of Al2O3, TiN and Ti (C,N) based CVD coatings on tool wear in machining metal matrix composites. Surf. Coat. Technol. 2004, 179, 349–355. [Google Scholar] [CrossRef]

- Niu, M.; Bi, Q.; Yang, J.; Liu, W. Tribological performance of a Ni3Al matrix self-lubricating composite coating tested from 25 to 1000 °C. Surf. Coat. Technol. 2012, 206, 3938–3943. [Google Scholar] [CrossRef]

- Shi, X.; Song, S.; Zhai, W.; Wang, M.; Xu, Z.; Yao, J.; Din, A.Q.U.; Zhang, Q. Tribological behavior of Ni3Al matrix self-lubricating composites containing WS2, Ag and hBN tested from room temperature to 800 °C. Mater. Des. 2014, 55, 75–84. [Google Scholar] [CrossRef]

- Zhu, S.; Bi, Q.; Yang, J.; Liu, W.; Xue, Q. Ni3Al matrix high temperature self-lubricating composites. Tribol. Int. 2011, 44, 445–453. [Google Scholar] [CrossRef]

- John, M.; Menezes, P.L. Self-Lubricating Materials for Extreme Condition Applications. Materials 2021, 14, 5588. [Google Scholar] [CrossRef] [PubMed]

- Puchý, V.; Hvizdoš, P.; Ivor, M.; Medveď, D.; Hnatko, M.; Kovalčíková, A.; Sedlák, R.; Dusza, J. Preparation, friction, wear, and fracture of the Si3N4-Ag-GNPs composites prepared by SPS. J. Eur. Ceram. Soc. 2020, 40, 4853–4859. [Google Scholar] [CrossRef]

- Wardzinski, B.; Buttery, M.; Roberts, E. The potential of indium as a soft metal lubricant replacement for lead. In ‘15th European Space Mechanisms & Tribology Symposium—ESMATS 2013′ Noordwijk, The Netherlands, 25–27 September 2013; Ouwehand, L., Ed.; ESA-SP: Noordwijk, The Netherlands, 2013; Volume 718, p. 32. ISBN 978-92-9221-282-7. [Google Scholar]

- Gutierrez-Gonzalez, C.F.; Smirnov, A.; Centeno, A.; Fernández, A.; Alonso, B.; Rocha, V.G.; Torrecillas, R.; Zurutuza, A.; Bartolome, J.F. Wear behavior of graphene/alumina composite. Ceram. Int. 2015, 41, 7434–7438. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, J.; Huang, Z.; Yan, K.; Shen, X.; Xing, J.; Gao, Y.; Jian, Y.; Yang, H.; Li, B. A Review on Binderless Tungsten Carbide: Development and Application. Nano-Micro Lett. 2020, 12, 13. [Google Scholar] [CrossRef] [PubMed]

- Ashby, M.F. The CES EduPack Resource Booklet 2: Material and Process Selection Charts; Granta Design Limited: Cambridge, UK, 2009. [Google Scholar]

- Wang, J.; Cheng, Y.; Zhang, Y.; Yin, Z.; Hu, X.; Yuan, Q. Friction and wear behavior of microwave sintered Al2O3/TiC/GPLs ceramic sliding against bearing steel and their cutting performance in dry turning of hardened steel. Ceram. Int. 2017, 43, 14827–14835. [Google Scholar] [CrossRef]

- Parchovianský, M.; Balko, J.; Švančárek, P.; Sedláček, J.; Dusza, J.; Lofaj, F.; Galusek, D. Mechanical properties and sliding wear behaviour of Al2O3-SiC nanocomposites with 3–20 vol% SiC. J. Eur. Ceram. Soc. 2017, 37, 4297–4306. [Google Scholar] [CrossRef]

- Rodriguez-Suarez, T.; Bartolomé, J.; Smirnov, A.; Lopez-Esteban, S.; Torrecillas, R.; Moya, J. Sliding wear behaviour of alumina/nickel nanocomposites processed by a conventional sintering route. J. Eur. Ceram. Soc. 2011, 31, 1389–1395. [Google Scholar] [CrossRef]

| Material | COF | Wear Rate (mm3/m.N) | Friction Partner | Filler Content | Ref. |

|---|---|---|---|---|---|

| Al2O3/TiC/GPLs | 0.43–0.47 | 1–1.5 × 10−6 | GCr15 steel ball | 30 wt.% TiC, 0.2 wt.% GPLs | [41] |

| Al2O3-SiC | 0.4–0.5 | 2–8 × 10−6 | Al2O3, SiC, ZrO2 balls | 3–20 vol.% SiC | [42] |

| Al2O3/nNi | 0.45 | 2–8 × 10−8 | Al2O3 ball | 2.5 vol.% Ni | [43] |

| Al2O3-CNF/GO | 0.3–0.6 | 1–2 × 10−7 | Al2O3 ball | 2 vol.% CNF, 2 vol.% GO | [16] |

| Al2O3-In-GNPs | 0.33–0.35 | 14–32 × 10−6 | SiC ball | 5–10 wt.% In, 2 wt.% GNPs | Present work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puchý, V.; Podobová, M.; Sedlák, R.; Falat, L.; Džunda, R.; Kromka, F.; Dusza, J. The Effects of Indium Additions on Tribological Behavior of Spark Plasma Sintering-Produced Graphene-Doped Alumina Matrix Composites for Self-Lubricating Applications. Crystals 2024, 14, 104. https://doi.org/10.3390/cryst14010104

Puchý V, Podobová M, Sedlák R, Falat L, Džunda R, Kromka F, Dusza J. The Effects of Indium Additions on Tribological Behavior of Spark Plasma Sintering-Produced Graphene-Doped Alumina Matrix Composites for Self-Lubricating Applications. Crystals. 2024; 14(1):104. https://doi.org/10.3390/cryst14010104

Chicago/Turabian StylePuchý, Viktor, Mária Podobová, Richard Sedlák, Ladislav Falat, Róbert Džunda, František Kromka, and Ján Dusza. 2024. "The Effects of Indium Additions on Tribological Behavior of Spark Plasma Sintering-Produced Graphene-Doped Alumina Matrix Composites for Self-Lubricating Applications" Crystals 14, no. 1: 104. https://doi.org/10.3390/cryst14010104

APA StylePuchý, V., Podobová, M., Sedlák, R., Falat, L., Džunda, R., Kromka, F., & Dusza, J. (2024). The Effects of Indium Additions on Tribological Behavior of Spark Plasma Sintering-Produced Graphene-Doped Alumina Matrix Composites for Self-Lubricating Applications. Crystals, 14(1), 104. https://doi.org/10.3390/cryst14010104