Computational Modelling and Comparative Analysis of Friction Stir Welding and Stationary Shoulder Friction Stir Welding on AA6061

Abstract

:1. Introduction

2. Novelty and Application

3. Numerical Modelling

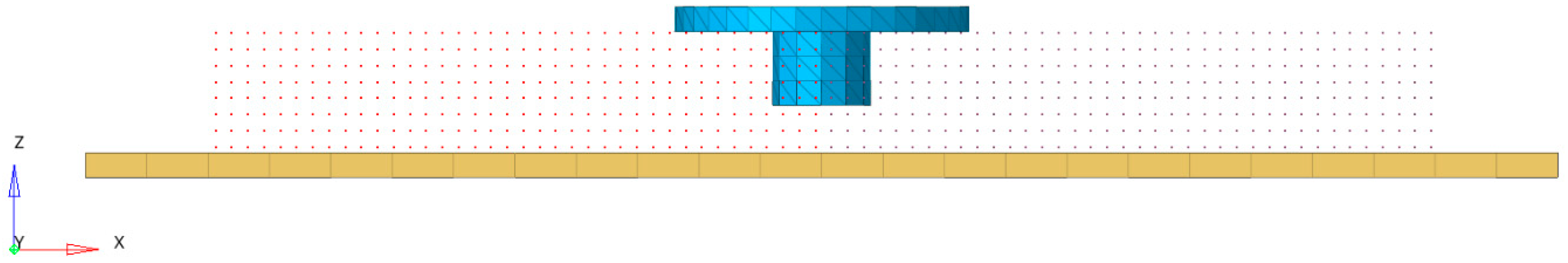

3.1. Geometry

3.2. Material Model

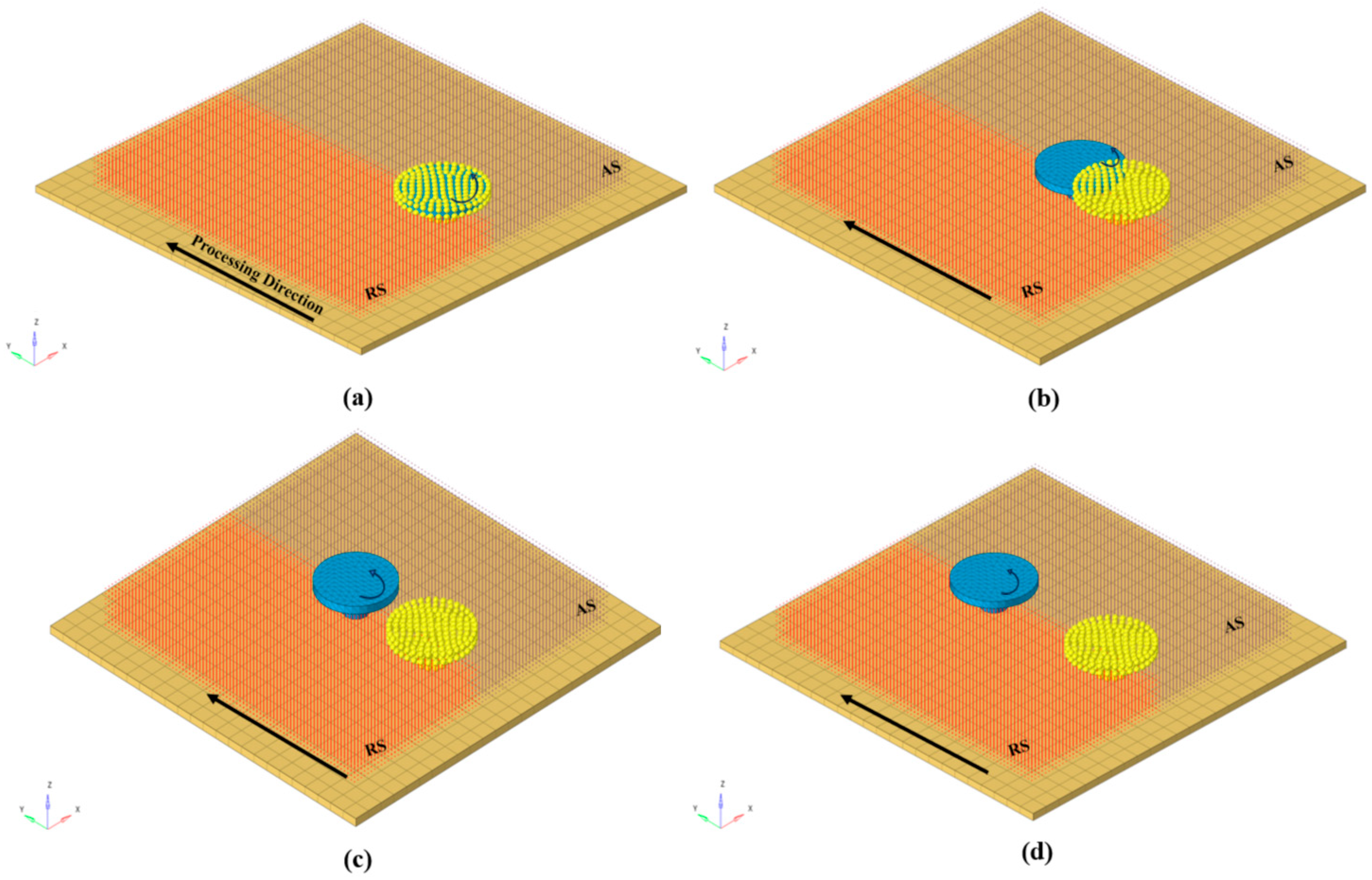

3.3. Meshing and Contact

3.4. Simulation Controls and Boundary Conditions

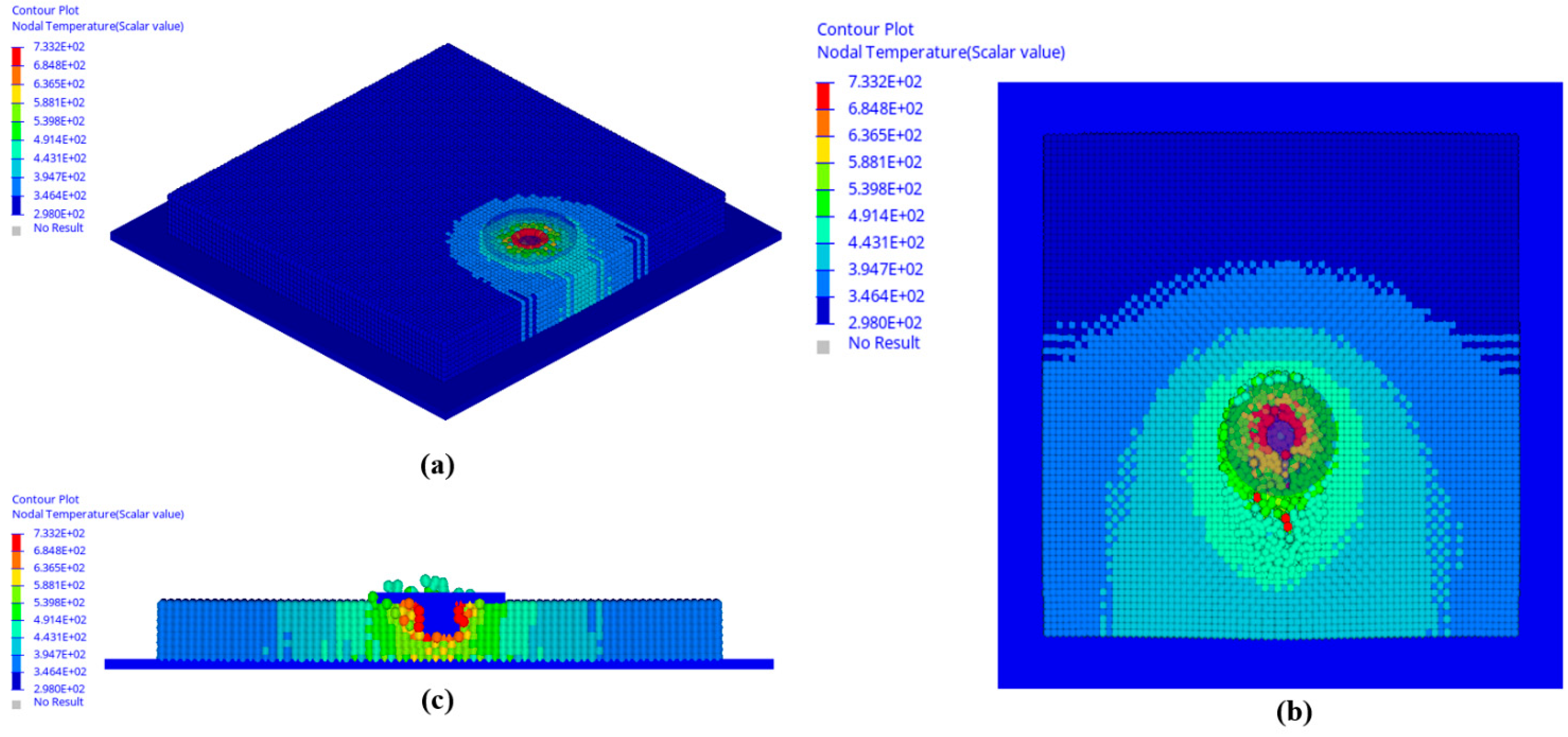

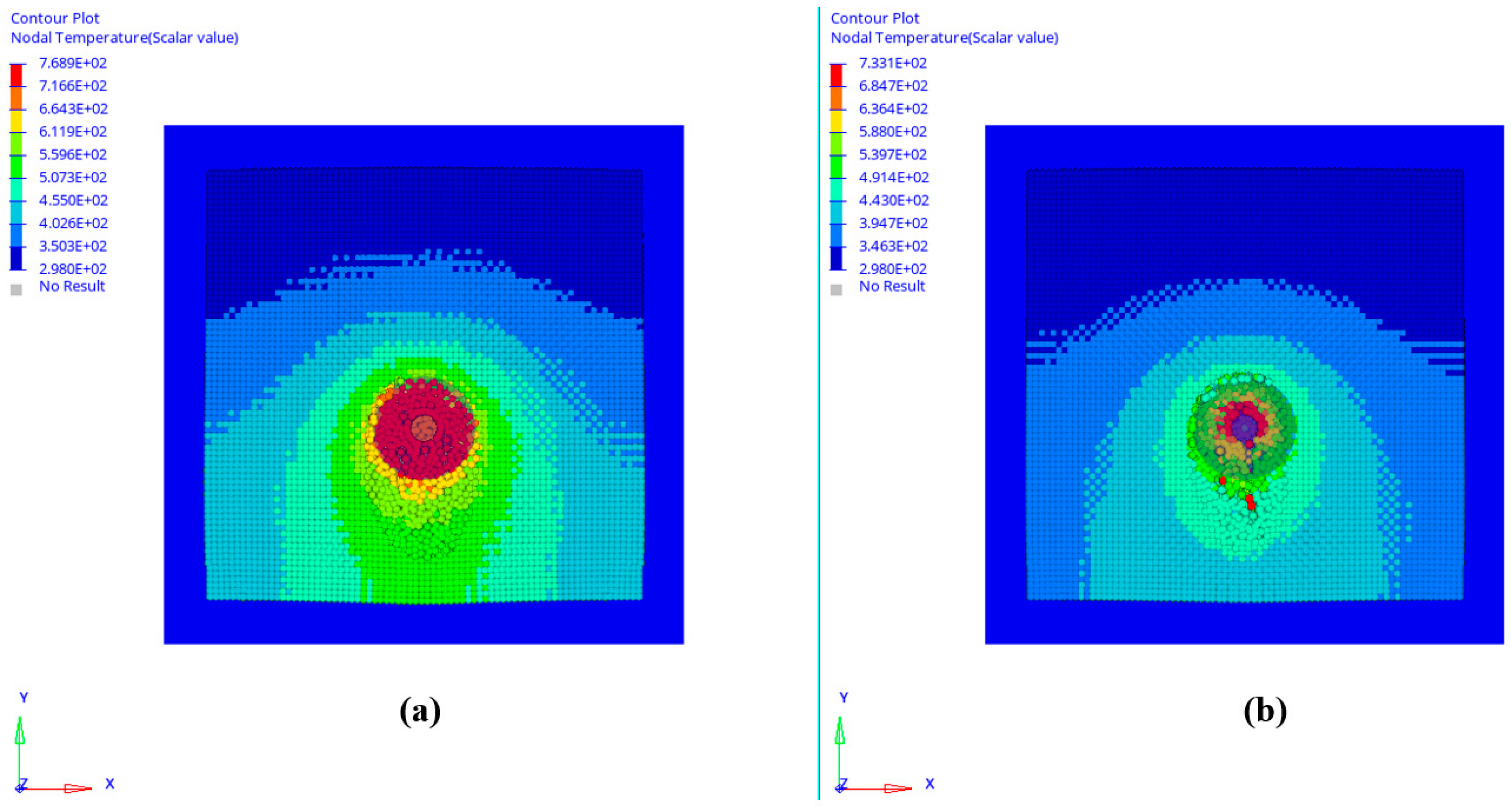

4. Results and Discussion

5. Conclusions and Future Recommendations

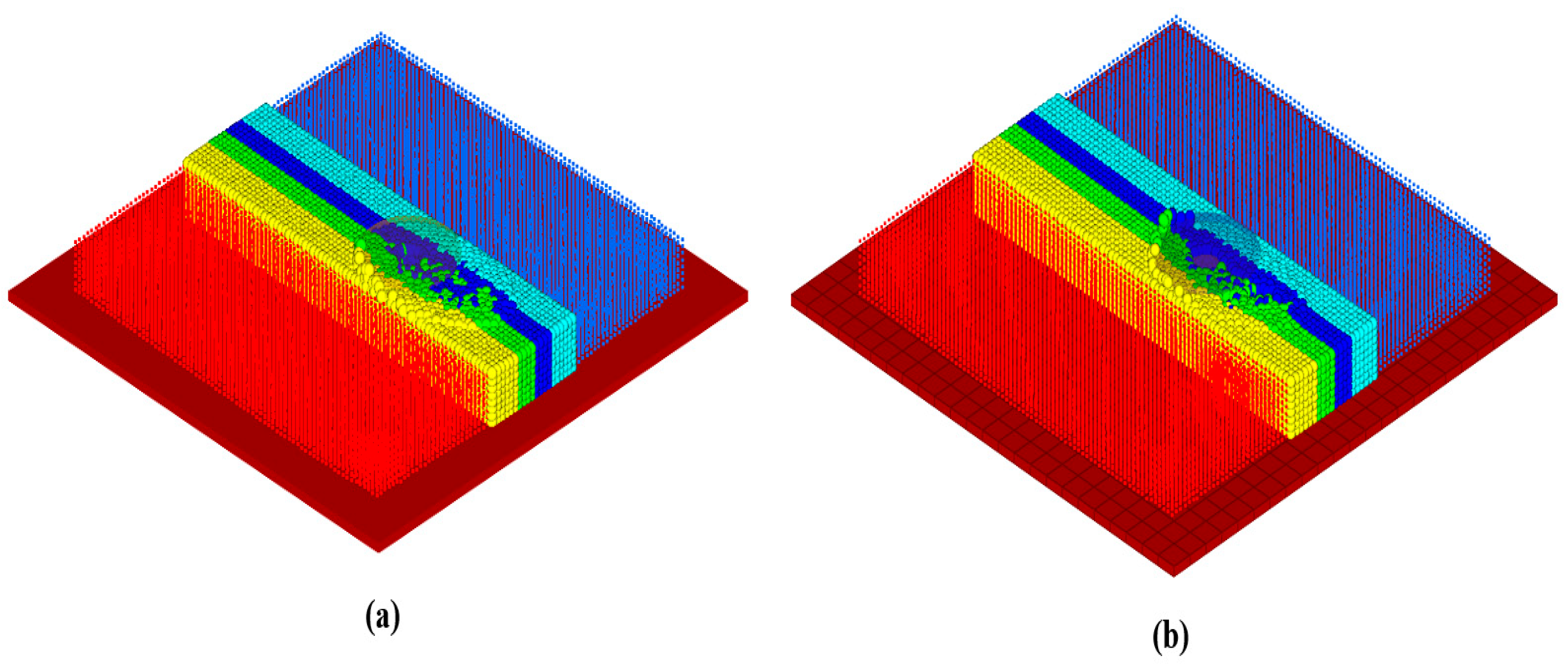

- The current study explored the critical aspects of FSW and SSFSW, revealing complex interactions that involve temperature distribution, plastic strain, material flow, processed zone width, and the unique “ironing effect” exclusive to SSFSW.

- Temperature measurements from the model are in close agreement with experimental values, validating the model. The error percentages are minimal and acceptable, 1.2% and 2.31% in the AS and RS, respectively.

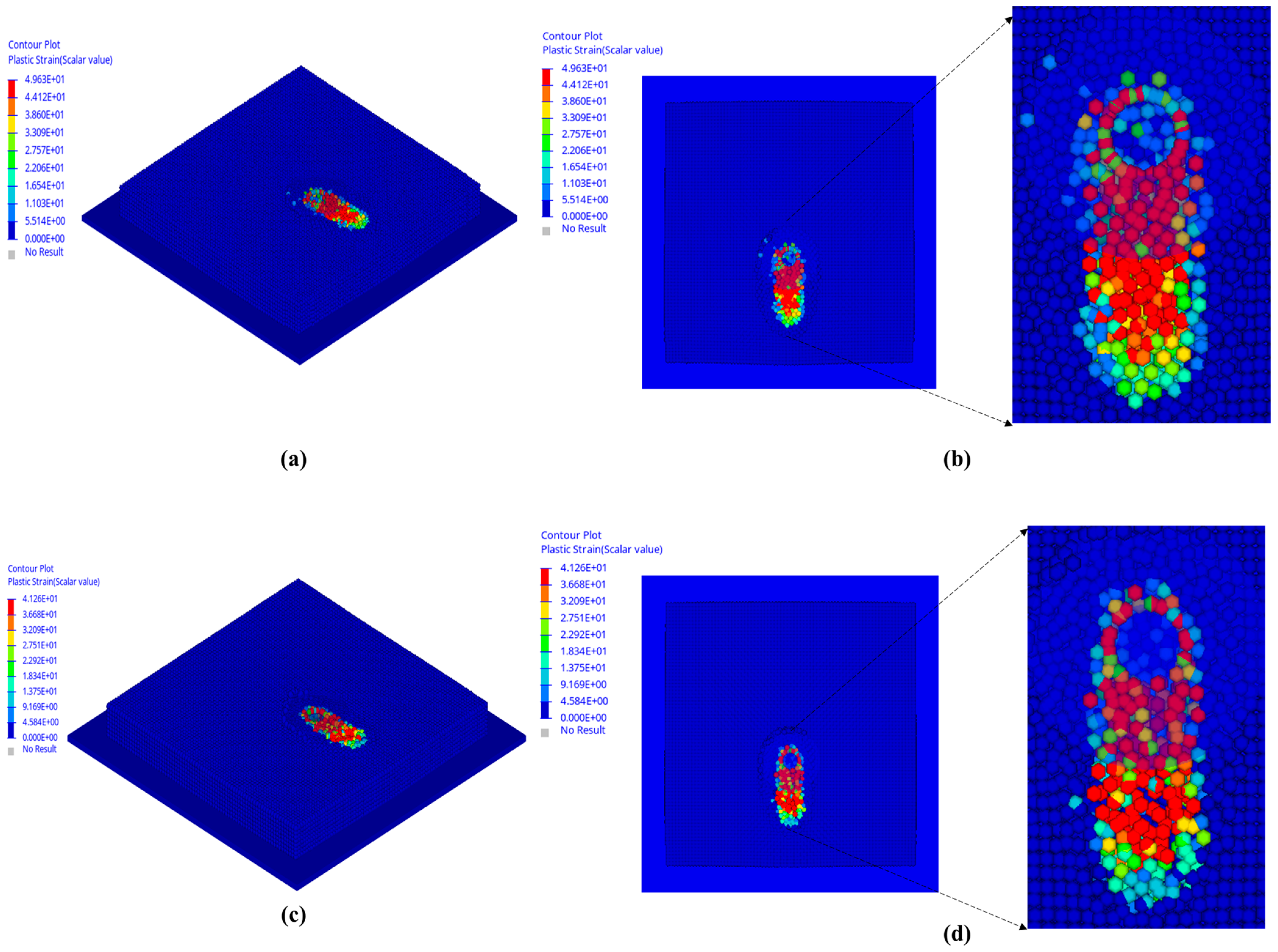

- Differences between conventional FSW and SSFSW were notable in plastic strain distributions. SSFSW exhibited lower strain magnitudes concentrated in the PAZ, while conventional FSW displayed an increased magnitude of plastic strains in PAZ and extended a little wider into the SAZ.

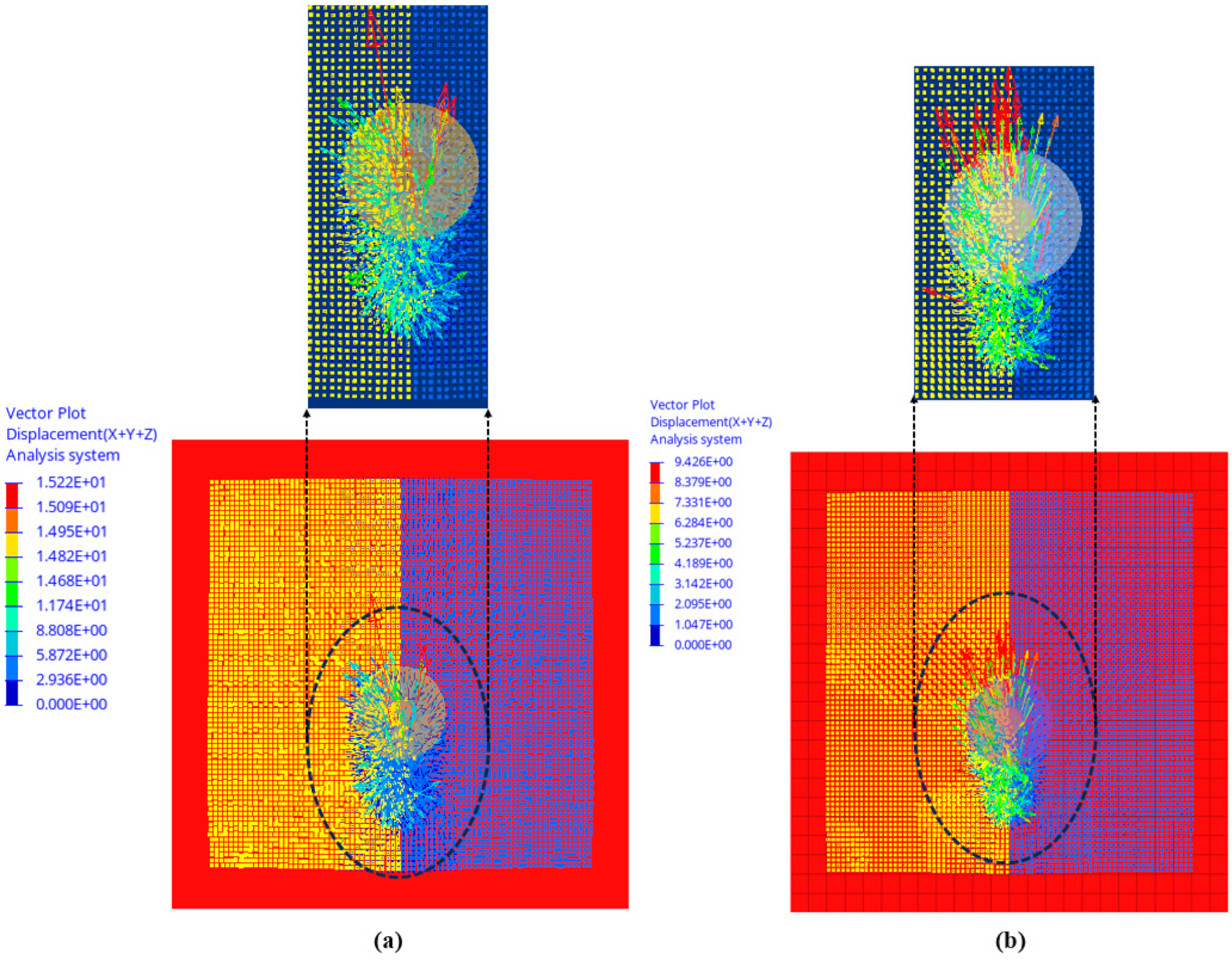

- The distinct “ironing effect” induced by the non-rotating shoulder had a pronounced impact on SSFSW. This effect reduced the processed zone, improved material flow, and enhanced joint attributes, particularly around the pin.

- The SPH technique gave a deeper understanding of the material flow in PAZ and SAZ in both FSW and SSFSW.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rahsepar, M.; Jarahimoghadam, H. The Influence of Multipass Friction Stir Processing on the Corrosion Behavior and Mechanical Properties of Zircon-Reinforced Al Metal Matrix Composites. Mater. Sci. Eng. A 2016, 671, 214–220. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction-Stir Butt Welding. International Patent Application No. PCT/GB92/02203; GB Patent Application No. 9125978.8; U.S. Patent Application No. 5,460,317, 6 December 1991. [Google Scholar]

- Hassan, A.; Pedapati, S.R.; Awang, M.; Soomro, I.A. A Comprehensive Review of Friction Stir Additive Manufacturing (FSAM) of Non-Ferrous Alloys. Materials 2023, 16, 2723. [Google Scholar] [CrossRef] [PubMed]

- Threadgilll, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction Stir Welding of Aluminium Alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Price, D.A.; Williams, S.W.; Wescott, A.; Harrison, C.J.C.; Rezai, A.; Steuwer, A.; Peel, M.; Staron, P.; Koçak, M. Distortion Control in Welding by Mechanical Tensioning. Sci. Technol. Weld. Join. 2007, 12, 620–633. [Google Scholar] [CrossRef]

- Meyghani, B.; Wu, C. Progress in Thermomechanical Analysis of Friction Stir Welding. Chin. J. Mech. Eng. (Eng. Ed.) 2020, 33, 12. [Google Scholar] [CrossRef]

- Martin, J.P. Stationary Shoulder Friction Stir Welding. In Proceedings of the 1st International Joint Symposium on Joining and Welding, Osaka, Japan, 6–8 November 2013; pp. 477–482. [Google Scholar]

- The Welding Institute Dual-Rotation Friction Stir Welding—TWI. Available online: https://www.twi-global.com/media-and-events/insights/dual-rotation-friction-stir-welding (accessed on 15 June 2023).

- Iwashita, T. Method and Apparatus for Joining. Patent No: US6601751B2, 5 August 2003. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Friction Stir Welding and Processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W.; McFadden, S.X.; Mara, N.A.; Mukherjee, A.K. High Strain Rate Superplasticity in a Friction Stir Processed 7075 Al Alloy. Scr. Mater. 1999, 42, 163–168. [Google Scholar] [CrossRef]

- Marode, R.V.; Pedapati, S.R.; Lemma, T.A.; Somi, V.; Janga, R. Thermo-Mechanical Modelling of Friction Stir Processing of AZ91 Alloy: Using Smoothed-Particle Hydrodynamics. Lubricants 2022, 10, 355. [Google Scholar] [CrossRef]

- Sunil, B.R.; Reddy, G.P.K.; Patle, H.; Dumpala, R. Magnesium Based Surface Metal Matrix Composites by Friction Stir Processing. J. Magnes. Alloy. 2016, 4, 52–61. [Google Scholar] [CrossRef]

- Marode, R.V.; Pedapati, S.R.; Lemma, T.A.; Loyte, A.; Devarajan, Y.; Thandavamoorthy, R. Influence of Silicon Carbide on Microhardness and Corrosion Behavior of AZ91/SiC Surface Composites Processed through Friction Stir Processing: Multi-Response Optimization Using Taguchi-Grey Relational Analysis. Silicon 2023, 1–23. [Google Scholar] [CrossRef]

- Sejani, D.; Li, W.; Patel, V. Stationary Shoulder Friction Stir Welding–Low Heat Input Joining Technique: A Review in Comparison with Conventional FSW and Bobbin Tool FSW. Crit. Rev. Solid State Mater. Sci. 2022, 47, 865–914. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Andersson, J.; Li, N. Enhancing Grain Refinement and Corrosion Behavior in AZ31B Magnesium Alloy via Stationary Shoulder Friction Stir Processing. J. Mater. Res. Technol. 2022, 17, 3150–3156. [Google Scholar] [CrossRef]

- Hosseini, A.; Fallahi Arezoudar, A. Determining the Mechanism of Defect Formation and Material Flow Characteristics in Underwater Stationary Shoulder Friction Stir Welding Using Coupled Eulerian-Lagrangian Simulation. Int. J. Adv. Manuf. Technol. 2023, 127, 1755–1778. [Google Scholar] [CrossRef]

- Gingold, R.A.; Monaghan, J.J. Smoothed Particle Hydrodynamics: Theory and Application to Non-Spherical Stars. Mon. Not. R. Astron. Soc. 1977, 181, 375–389. [Google Scholar] [CrossRef]

- Tartakovsky, A.; Grant, G.; Sun, X.; Khaleel, M. Modeling of Friction Stir Welding (FSW) Process with Smooth Particle Hydrodynamics (SPH); SAE Technical Papers; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Marode, R.V.; Pedapati, S.R.; Lemma, T.A.; Awang, M. A Review on Numerical Modelling Techniques in Friction Stir Processing: Current and Future Perspective. Arch. Civ. Mech. Eng. 2023, 23, 154. [Google Scholar] [CrossRef]

- Hamilton, R.; Mackenzie, D.; Li, H. Multi-Physics Simulation of Friction Stir Welding Process. Eng. Comput. 2010, 27, 967–985. [Google Scholar] [CrossRef]

- Dialami, N.; Cervera, M.; Chiumenti, M.; de Saracibar, C.A. Local–Global Strategy for the Prediction of Residual Stresses in FSW Processes. Int. J. Adv. Manuf. Technol. 2017, 88, 3099–3111. [Google Scholar] [CrossRef]

- Monaghan, J.J.; Kajtar, J.B. SPH Particle Boundary Forces for Arbitrary Boundaries. Comput. Phys. Commun. 2009, 180, 1811–1820. [Google Scholar] [CrossRef]

- Lof, J. Elasto-Viscoplastic FEM Simulations of the Aluminium Flow in the Bearing Area for Extrusion of Thin-Walled Sections. J. Mater. Process. Technol. 2001, 114, 174–183. [Google Scholar] [CrossRef]

- Khan, U.; Pao, W.; Sallih, N. Numerical Gas–Liquid Two-Phase Flow Regime Identification in a Horizontal Pipe Using Dynamic Pressure Data. Appl. Sci. 2023, 13, 1225. [Google Scholar] [CrossRef]

- He, X.; Gu, F.; Ball, A. A Review of Numerical Analysis of Friction Stir Welding. Prog. Mater. Sci. 2014, 65, 1–66. [Google Scholar] [CrossRef]

- Fraser, K.; St-Georges, L.; Kiss, L.I. Meshfree Simulation of the Entire FSW Process on the GPU. In Proceedings of the 11th International Friction Stir Welding Symposium, Cambridge, UK, 17–19 May 2016; p. 15. [Google Scholar]

- Fraser, K.; Kiss, L.I.; St-Georges, L.; Drolet, D. Optimization of Friction Stir Weld Joint Quality Using a Meshfree Fully-Coupled Thermo-Mechanics Approach. Metals 2018, 8, 101. [Google Scholar] [CrossRef]

- Ansari, M.A.; Behnagh, R.A. Numerical Study of Friction Stir Welding Plunging Phase Using Smoothed Particle Hydrodynamics. Model. Simul. Mater. Sci. Eng. 2019, 27, 055006. [Google Scholar] [CrossRef]

- Meyghani, B. A Modified Friction Model and Its Application in Finite-Element Analysis of Friction Stir Welding Process. J. Manuf. Process. 2021, 72, 29–47. [Google Scholar] [CrossRef]

- Wu, T.; Luo, H.; Guo, H.; Fu, J.; Liu, G. Numerical Simulation of Temperature Field and Material Flow in Friction Stir Welding. In Proceedings of the 2019 International Conference on Modeling, Analysis, Simulation Technologies and Applications (MASTA 2019), Beijing, China, 24–25 March 2019; Atlantis Press: Amsterdam, The Netherlands, 2019; pp. 333–338. [Google Scholar]

- Altair Radioss Smooth Particle Hydrodynamics. Available online: https://2021.help.altair.com/2021/hwsolvers/rad/topics/solvers/rad/theory_sph_c.htm (accessed on 22 September 2022).

- Meyghani, B. Thermomechanical Analysis of Friction Stir Welding (FSW) on Curved Plates by Adapting Calculated Temperature Dependent Properties; Universiti Teknologi PETRONAS: Perak, Malaysia, 2018. [Google Scholar]

- Janga, V.S.R.; Awang, M. Influence of Plunge Depth on Temperatures and Material Flow Behavior in Refill Friction Stir Spot Welding of Thin AA7075-T6 Sheets: A Numerical Study. Metals 2022, 12, 927. [Google Scholar] [CrossRef]

- Banerjee, B. MPM Validation: Sphere-Cylinder Impact Tests: Energy Balance; Report No. C-SAFE-CD-IR-04-001; The University of Utah: Salt Lake City, UT, USA, 2004. [Google Scholar]

- Ferreira, G.V.; Neto, F.L.; Miélle, N.; Pestana, M. ANALYSIS OF THE MECHANICAL BEHAVIOR OF A COMPOSITE BLADE USED IN HYDROKINETIC TURBINES. In Proceedings of the 23rd ABCM International Congress of Mechanical Engineering, Rio de Janeiro, Brazil, 6–11 December 2015; ABCM Brazilian Society of Mechanical Sciences and Engineering: Rio de Janeiro, Brazil, 2015. [Google Scholar]

- Agha Amini Fashami, H.; Bani Mostafa Arab, N.; Hoseinpour Gollo, M.; Nami, B. Numerical and Experimental Investigation of Defects Formation during Friction Stir Processing on AZ91. SN Appl. Sci. 2021, 3, 108. [Google Scholar] [CrossRef]

- Mishra, R.S.; De, P.S.; Kumar, N. Friction Stir Welding and Processing: Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 9783319070438. [Google Scholar]

- Awang, M. Simulation of Friction Stir Spot Welding (FSSW) Process: Study of Friction Phenomena. Ph.D. Thesis, West Virginia University, Morgantown, WV, USA, 2007. [Google Scholar]

- Salloomi, K.N.; Hussein, F.I.; Al-Sumaidae, S.N.M. Temperature and Stress Evaluation during Three Different Phases of Friction Stir Welding of AA 7075-T651 Alloy. Model. Simul. Eng. 2020, 2020, 3197813. [Google Scholar] [CrossRef]

- Buffa, G.; Hua, J.; Shivpuri, R.; Fratini, L. A Continuum Based Fem Model for Friction Stir Welding—Model Development. Mater. Sci. Eng. A 2006, 419, 389–396. [Google Scholar] [CrossRef]

- Emamian, S.; Awang, M.; Hussai, P.; Meyghani, B.; Zafar, A. Influences of Tool Pin Profile on the Friction Stir Welding of AA6061. ARPN J. Eng. Appl. Sci. 2016, 11, 12258–12261. [Google Scholar]

- Russell, M.J.; Threadgill, P.L.; Thomas, M.J.; Wynne, B.P. Static Shoulder Friction Stir Welding of Ti-6Al-4V; Process and Evaluation. Presented at the 11th World Conference on Titanium (Ti-2007), (JIMIC-5), Kyoto, Japan, 3–7 June 2007. [Google Scholar]

- Pan, W.; Li, D.; Tartakovsky, A.M.; Ahzi, S.; Khraisheh, M.; Khaleel, M. A New Smoothed Particle Hydrodynamics Non-Newtonian Model for Friction Stir Welding: Process Modeling and Simulation of Microstructure Evolution in a Magnesium Alloy. Int. J. Plast. 2013, 48, 189–204. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Xu, Y. Stationary Shoulder Tool in Friction Stir Processing: A Novel Low Heat Input Tooling System for Magnesium Alloy. Mater. Manuf. Process. 2019, 34, 177–182. [Google Scholar] [CrossRef]

- Tongne, A.; Desrayaud, C.; Jahazi, M.; Feulvarch, E. On Material Flow in Friction Stir Welded Al Alloys. J. Mater. Process. Technol. 2017, 239, 284–296. [Google Scholar] [CrossRef]

- Aval, H.J. Smoothed-Particle Hydrodynamics (SPH) Simulation of AA6061-AA5086 Dissimilar Friction Stir Welding. Metals 2023, 13, 906. [Google Scholar] [CrossRef]

- Bagheri, B.; Abbasi, M.; Abdolahzadeh, A.; Kokabi, A.H. Numerical Analysis of Cooling and Joining Speed Effects on Friction Stir Welding by Smoothed Particle Hydrodynamics (SPH). Arch. Appl. Mech. 2020, 90, 2275–2296. [Google Scholar] [CrossRef]

| Property | AA6061-T6 | H13 |

|---|---|---|

| Density (g/cm3) | 2.7 | 7.7 |

| Young’s Modulus (GPa) | 69 | 209 |

| Poisson’s Ratio | 0.3 | 0.33 |

| Melting Temperature (K) | 925 | 1700 |

| Specific Heat (J/KgK) | 896 | 461 |

| Thermal Conductivity (w/mK) | 166.9 | 24.4 |

| Temperature (°C) | 0–12 | 12–22 | 22–92 | 92–112 | 112–212 | 212–247 | 247–257 |

|---|---|---|---|---|---|---|---|

| Coefficient of friction (µ) | 0.47 | 0.35 | 0.3 | 0.26 | 0.08 | 0.02 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marode, R.V.; Awang, M.; Janga, V.S.R. Computational Modelling and Comparative Analysis of Friction Stir Welding and Stationary Shoulder Friction Stir Welding on AA6061. Crystals 2023, 13, 1317. https://doi.org/10.3390/cryst13091317

Marode RV, Awang M, Janga VSR. Computational Modelling and Comparative Analysis of Friction Stir Welding and Stationary Shoulder Friction Stir Welding on AA6061. Crystals. 2023; 13(9):1317. https://doi.org/10.3390/cryst13091317

Chicago/Turabian StyleMarode, Roshan Vijay, Mokhtar Awang, and Venkata Somi Reddy Janga. 2023. "Computational Modelling and Comparative Analysis of Friction Stir Welding and Stationary Shoulder Friction Stir Welding on AA6061" Crystals 13, no. 9: 1317. https://doi.org/10.3390/cryst13091317

APA StyleMarode, R. V., Awang, M., & Janga, V. S. R. (2023). Computational Modelling and Comparative Analysis of Friction Stir Welding and Stationary Shoulder Friction Stir Welding on AA6061. Crystals, 13(9), 1317. https://doi.org/10.3390/cryst13091317