Microstructural Control by Cooling Rate in β-type and Sintered Ti-3.6Fe-5Zr-0.2B (Mass%) Alloy Fabricated by Spark Plasma Sintering and Heat Treatment

Abstract

1. Introduction

2. Materials and Methods

3. Results

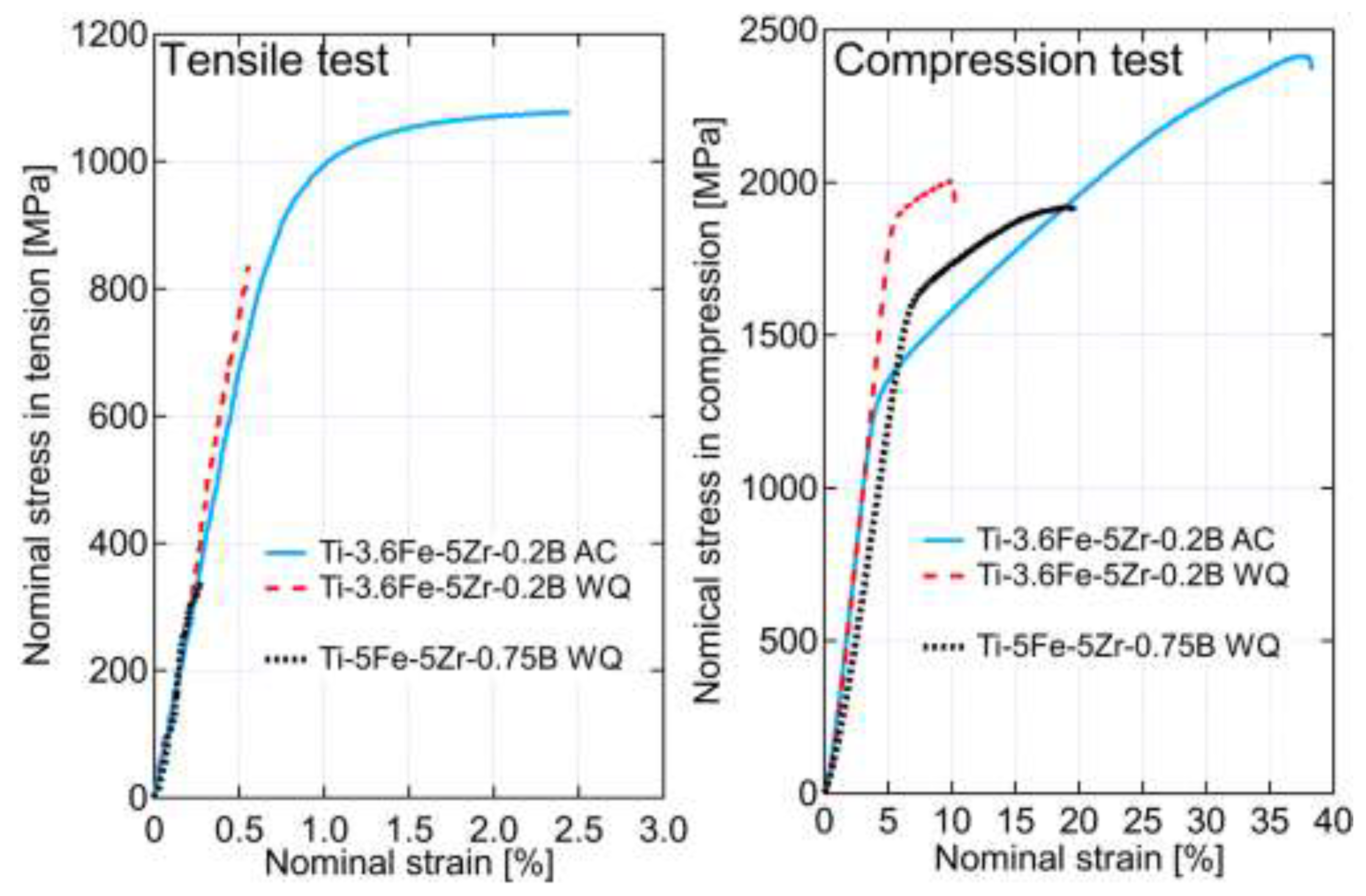

3.1. Relative Density and Nominal Stress–strain Curves

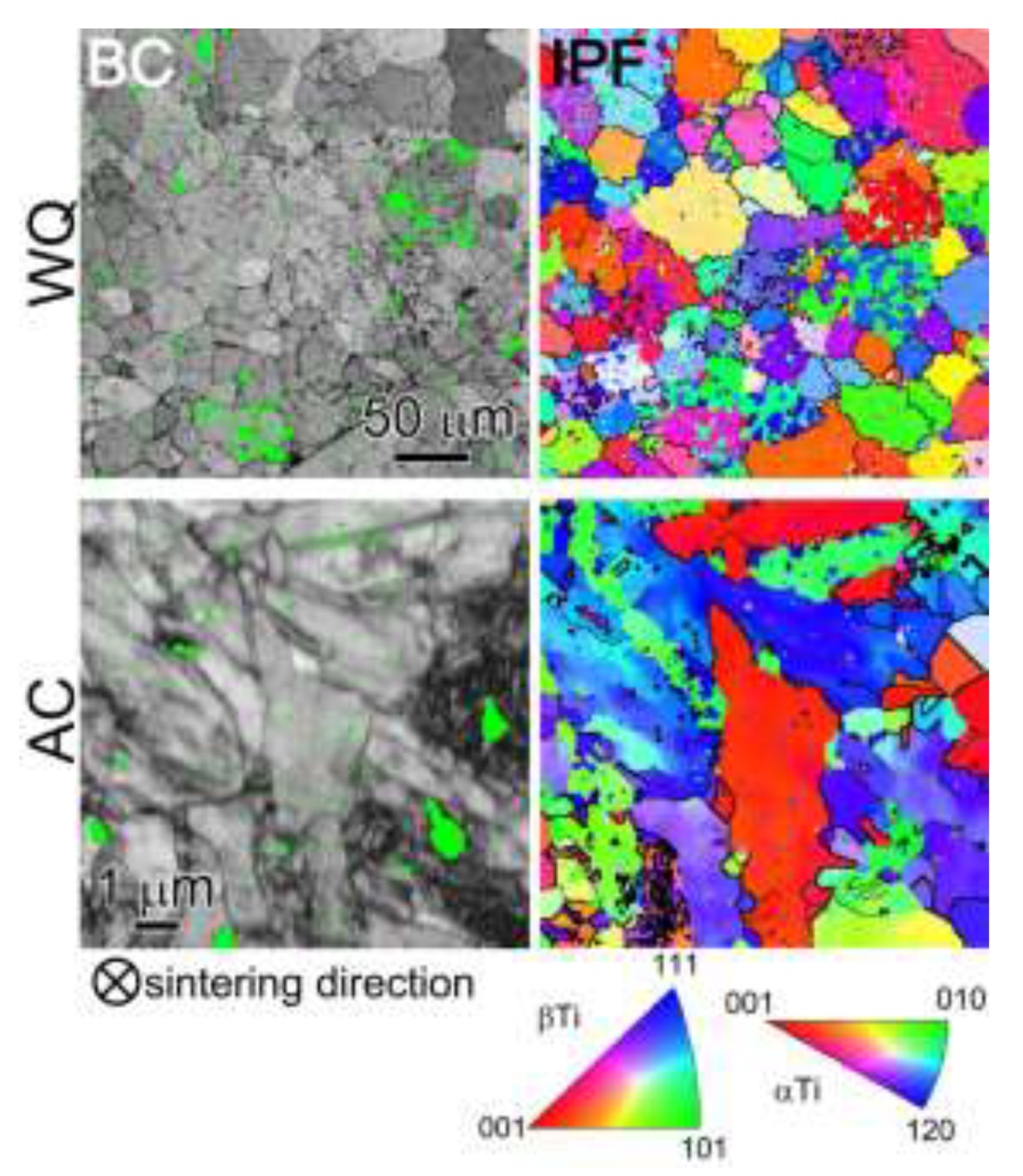

3.2. Constitutive Phases

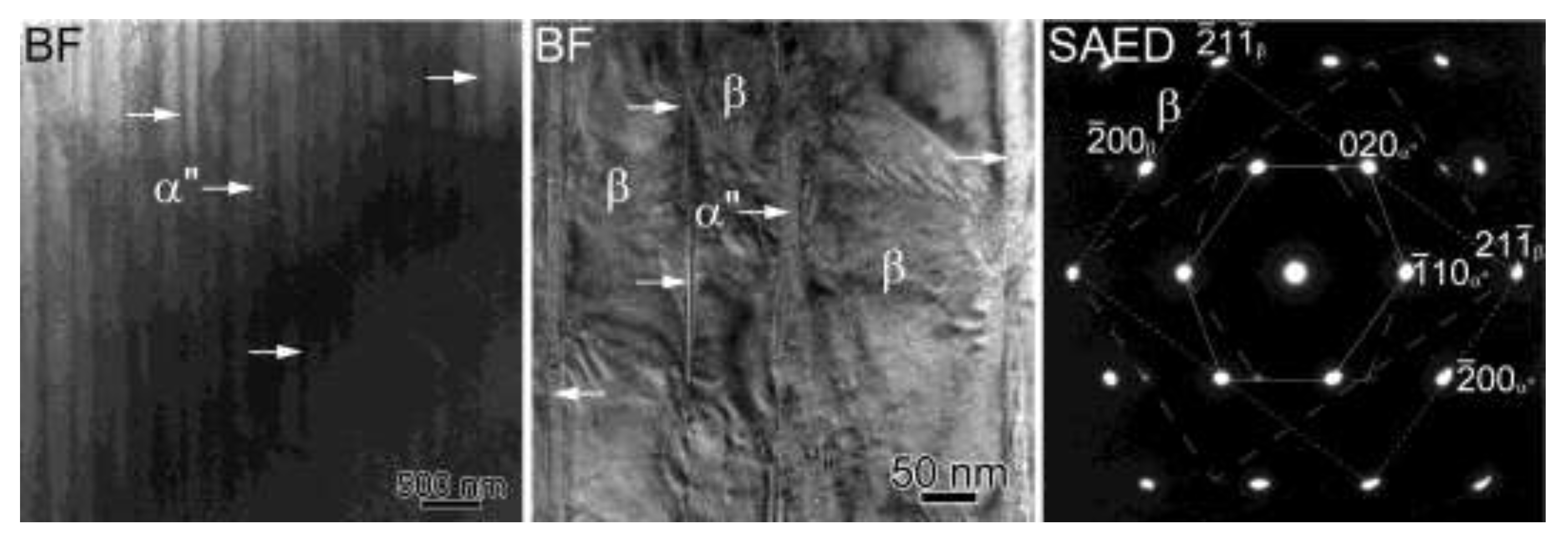

3.3. TEM Nanostructures

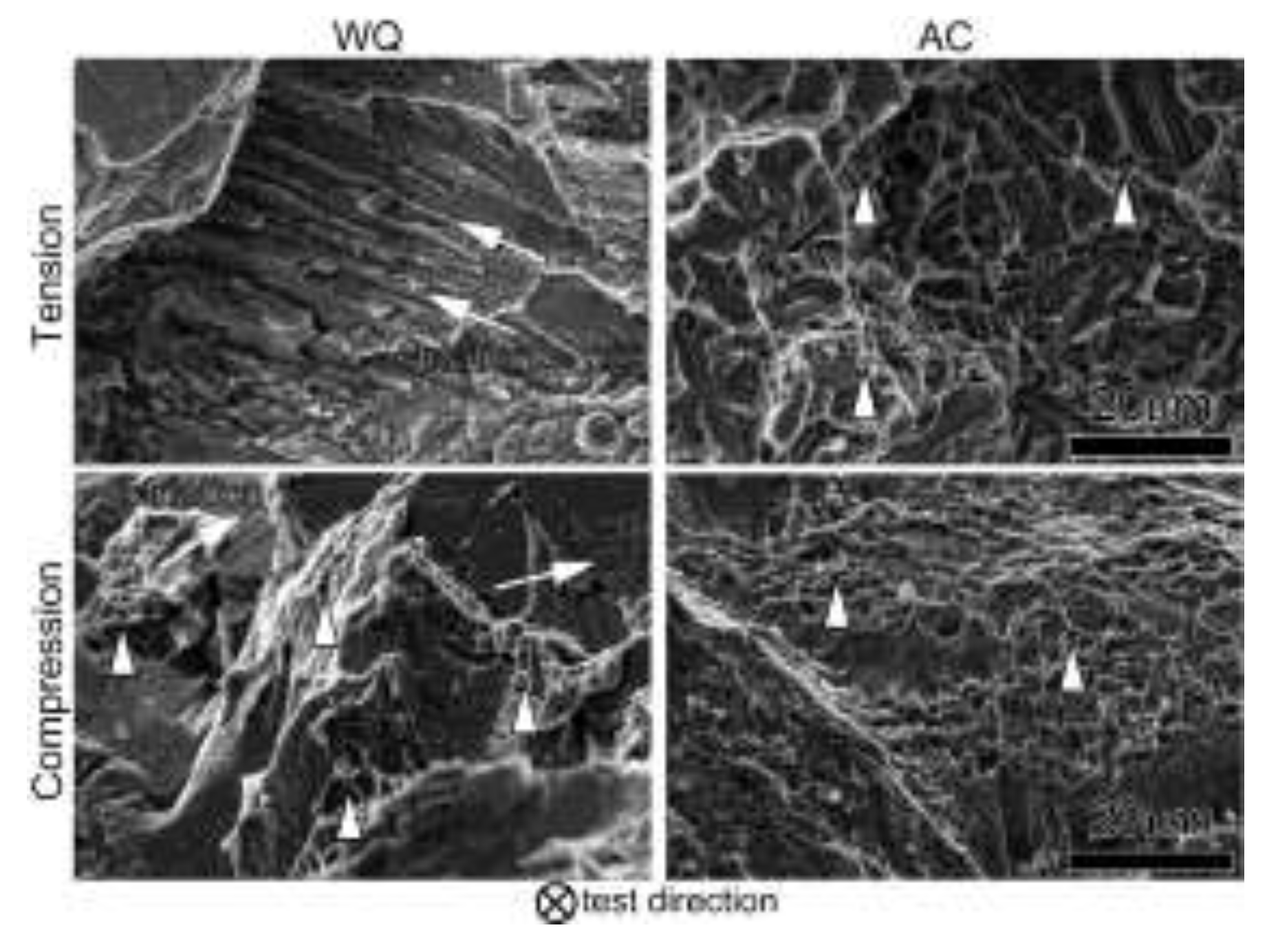

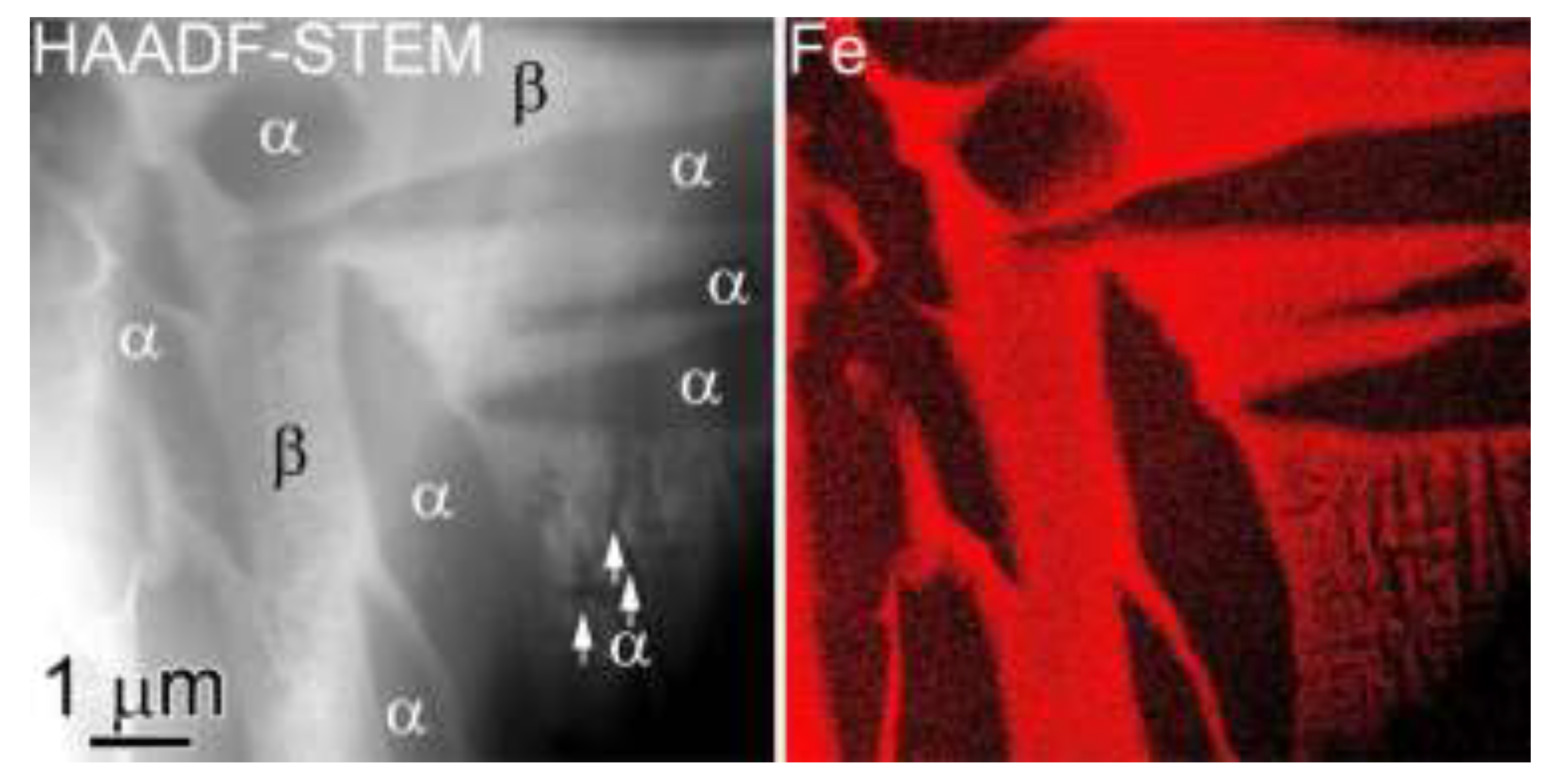

3.4. Fractography and Elemental Distributions to α or β Phases of Air-Cooled Sample

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Saheb, N.; Iqbal, Z.; Khalil, A.; Hakeem, A.S.; Aqeeli, N.A.; Laoui, T.; Al-Qutub, A.; Kirchner, R. Spark plasma sintering of metals and metal matrix nanocomposites: A review. J. Nanomater. 2012, 2012, 983470. [Google Scholar] [CrossRef]

- Yanagisawa, O.; Kuramoto, H.; Matsugi, K.; Komatsu, M. Observation of particle behavior in copper powder compact during pulsed electric discharge. Mater. Sci. Eng. A 2003, 350, 184–189. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Paramore, J.D.; Sun, P.; Chandran, K.S.R.; Zhang, Y.; Xia, Y.; Cao, F.; Koopman, M.; Free, M. Powder metallurgy of titanium–Past, present, and future. Int. Mater. Rev. 2018, 63, 407–459. [Google Scholar] [CrossRef]

- Babu, N.K.; Kallip, K.; Leparoux, M.; AlOgab, K.A.; Talari, M.K.; Alqahtani, N.M. High strength Ti-6Al-4V alloy fabricated by high-energy cube milling using calcium as process control agent (PCA) and spark plasma sintering. Int. Adv. Manuf. Technol. 2017, 93, 445–453. [Google Scholar] [CrossRef]

- Liu, L.H.; Yang, C.; Kang, L.M.; Long, L.; Xiao, Z.Y.; Li, P.J.; Zhang, L.C. Equiaxed Ti-based composites with high strength and large plasticity prepared by sintering and crystallizing amorphous powder. Mater. Sci. Eng. A 2016, 650, 171–182. [Google Scholar] [CrossRef]

- Sim, K.H.; Wang, G.; Kim, T.J.; Ju, K.S. Fabrication of a high strength and ductility Ti-22Al-25Nb alloy from high energy ball-milled powder by spark plasma sintering. J. Alloys Compds. 2018, 741, 1112–1120. [Google Scholar] [CrossRef]

- Bahador, A.; Kariya, S.; Umeda, J.; Kondoh, K. Tailoring microstructure and properties of a superelastic Ti-Ta alloy incorporating spark plasma sintering with thermomechanical processing. J. Mater. Eng. Perform. 2019, 28, 3012–3020. [Google Scholar] [CrossRef]

- Kang, L.M.; Yang, C. A review on high-strength titanium alloys: Microstructure, strengthening, and properties. Adv. Eng. Mater. 2019, 21, 1801359. [Google Scholar] [CrossRef]

- Ashby, M.F.; Jones, D.R.H. Engineering Materials; Pergamon: Oxford, UK, 1980. [Google Scholar]

- Homma, T.; Takano, H. Enhancement in age hardenability of sintered Ti-5Fe alloy by Zr addition processed by pulsed electric current sintering. Philos. Mag. 2018, 98, 2296–2310. [Google Scholar] [CrossRef]

- Homma, T.; Arafah, A.; Haley, D.; Nakai, M.; Niinomi, M.; Moody, M.P. Effect of alloying elements on microstructural evolution in oxygen content controlled Ti-9Nb-13Ta-4.6Zr (wt%) alloys for biomedical applications during aging. Mater. Sci. Eng. A 2018, 709, 312–321. [Google Scholar] [CrossRef]

- Homma, T. Influence of the boron addition on fine microstructures in sintered Ti-Fe-Zr alloy. Titan. Jpn. 2020, 68, 70–75. [Google Scholar]

- Villiars, P.; Calvert, L.D. Pearson’s Handbook of Crystallographic Data for Intermetallic Phase, 2nd ed.; ASM International: Materials Park, OH, USA, 1991. [Google Scholar]

- Martin, J.W.; Doherty, R.D.; Cantor, B.L. Stability of Microstructure in Metallic Systems, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Fujii, H.; Takahashi, K.; Mori, K.; Kawakami, A.; Kunieda, K.; Otsuka, H. Titanium and its alloys using non-rare common elements as alloying ones. Mater. Jpn. 2009, 48, 547–554. [Google Scholar] [CrossRef]

- German, R.M. Coarsening in sintering: Grain shape distribution, grain size distribution, and grain growth kinetics in solid-pre systems. Crit. Rev. Solid State Mater. Sci. 2010, 35, 263–305. [Google Scholar] [CrossRef]

- Olevsky, E.A.; Froyen, L. Impact of thermal diffusion in densification during SPS. J. Am. Ceram. Soc. 2009, 92, S122–S132. [Google Scholar] [CrossRef]

- Ashby, M.F.; Jones, D.R.H. Engineering Materials 2; Pergamon: Oxford, UK, 1986. [Google Scholar]

- Zafari, A.; Xia, K. Stress induced martensitic transformation in metastable b Ti-5Al-5Mo-5V-3Cr alloy: Triggering stress and interaction with deformation bands. Mater. Sci. Eng. A 2018, 724, 75–79. [Google Scholar] [CrossRef]

- Moffat, D.L.; Larbalestier, D.C. The competition between martensite and omega in quenched Ti-Nb alloys. Met. Trans. A 1988, 19A, 1677–1686. [Google Scholar] [CrossRef]

- Trapp, J.; Semenov, A.; Nöthe, M.; Wallmersperger, T.; Kieback, B. Fundamental principle of spark plasma sintering of metals: Part III–Densification by plasticity and creep deformation. Powder Met. 2020, 63, 329–337. [Google Scholar] [CrossRef]

- Zou, L.M.; Yang, C.; Long, Y.; Xiao, Z.Y.; Li, Y.Y. Fabrication of biomedical Ti-35Nb-7Zr-5Ta alloys by mechanical alloying and spark plasma sintering. Powder Met. 2012, 55, 65–70. [Google Scholar] [CrossRef]

- Diouf, S.; Molinari, A. Densification mechanisms in spark plasma sintering: Effect of particle size and pressure. Powder Technol. 2012, 221, 220–227. [Google Scholar] [CrossRef]

- Handtrack, D.; Despang, F.; Sauer, C.; Kieback, B.; Reinfried, N.; Grin, Y. Fabrication of ultra-fine grained and dispersion-strengthened titanium materials by spark plasma sintering. Mater. Sci. Eng. A 2006, 437, 423–429. [Google Scholar] [CrossRef]

- Majima, K.; Isono, T.; Shoji, K. Effect of (a+b)-quenching on the mechanical properties of sintered Ti-Fe binary alloys. Funtai Oyobi Fummatsu Yakin 1987, 34, 349–354. [Google Scholar]

- Ando, I.; Mugita, Y.; Hirayama, K.; Munetoh, S.; Aramaki, M.; Jiang, F.; Tsuji, T.; Takeuchi, A.; Uesugi, M.; Ozaki, Y. Elucidation of pore connection mechanism during ductile fracture of sintered pure iron by applying persistent homology to 4D images of pores: Role of open pore. Mater. Sci. Eng. A 2021, 828, 142112. [Google Scholar] [CrossRef]

- Morinaga, M. Local lattice strain around alloying elements in metals and its influence on alloy properties. Rep. Toyota Phys. Chem. Res. Inst. 2019, 72, 115–127. [Google Scholar]

- Payne, M.C.; Teter, M.P.; Allan, D.C.; Arias, T.A.; Joannopoulos, J.D. Iterative minimization techniques of ab initio total-energy calculations: Molecular dynamics and conjugate gradients. Rev. Mod. Phys. 1992, 64, 1045–1097. [Google Scholar] [CrossRef]

- Cherfliff, H.R.; Ashby, M.F. A process model for age hardening of aluminium alloys—I. the model. Acta Met. Mater. 1990, 38, 1789–1802. [Google Scholar]

- Li, H.; Cai, Q.; Li, S.; Xu, H. Effects of Mo equivalent on the phase constituent, microstructure and compressive mechanical properties of Ti-Nb-Mo-Ta alloys prepared by powder metallurgy. J. Mater. Res. Technol. 2022, 16, 588–598. [Google Scholar] [CrossRef]

- Zhao, G.-H.; Liang, X.Z.; Kim, B.; Rivera-Díaz-del-Castillo, P.E.J. Modelling strengthening mechanisms in beta-type Ti alloys. Mater. Sci. Eng. A 2019, 756, 156–160. [Google Scholar] [CrossRef]

- Sato, T.; Hukai, S.; Huang, Y.C. The Ms points of binary titanium alloys. J. Aust. Inst. Met. 1960, 5, 149–153. [Google Scholar]

- Bignon, M.; Bertrand, E.; Tancret, F.; Divera-Díaz-del-Castillo, P.E.J. Modelling martensitic transformation in titanium alloys: The influence of temperature and deformation. Materialia 2019, 7, 100382. [Google Scholar] [CrossRef]

- Oshio, E.; Yoshinaga, A.; Adachi, M. Transmission electron microscope observations of w phase in titanium-5% iron alloy. Nippon Kinzoku Gakkaishi 1969, 33, 437–442. [Google Scholar]

- Hanada, S.; Yoshio, Y.; Izumi, O. Plastic deformation mode of retained β phase in β-eutectoid Ti-Fe alloy. J. Mater. Sci. 1986, 21, 866–870. [Google Scholar] [CrossRef]

- Komatsu, S.; Ikeda, M.; Sugimoto, T.; Kamei, K.; Inoue, K. Phase constitution and resistivity of quenched Ti-2 to 15 mass% Fe alloys. Nippon Kinzoku Gakkaishi 1991, 55, 491–496. [Google Scholar]

- Abdel-Hady, M.; Fuwa, H.; Hinoshita, K.; Kimura, H.; Shinzato, Y.; Morinaga, M. Phase stability change with Zr content in b-type Ti-Nb alloys. Scripta Mater. 2007, 57, 1000–1003. [Google Scholar] [CrossRef]

- Mantani, Y.; Takemoto, Y.; Hida, M.; Sakakibara, A.; Tajima, M. Phase transformation of a” martensite structure by aging in Ti-8 mass% Mo alloy. Mater. Trans. 2004, 45, 1629–1634. [Google Scholar] [CrossRef]

| Alloy | Density | Theoretical Density | Relative Density |

|---|---|---|---|

| g/cm3 | g/cm3 | % | |

| Ti-3.6Fe-5Zr-0.2B | 4.65 | 4.65 | 100 |

| Alloy | Cooling | σUTS | σ0.2T | εfT | σUCS | σ0.2C | εfC |

|---|---|---|---|---|---|---|---|

| MPa | MPa | pct | MPa | MPa | pct | ||

| Ti-3.6Fe-5Zr-0.2B | WQ | - | 835 | - | 2006 | 1862 | 5.3 |

| AC | 1078 | 977 | 1.7 | 2419 | 1255 | 32 | |

| Ti-5Fe-5Zr-0.75B | WQ | - | 447 | - | 1963 | 1904 | 4.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Homma, T.; Washizu, T. Microstructural Control by Cooling Rate in β-type and Sintered Ti-3.6Fe-5Zr-0.2B (Mass%) Alloy Fabricated by Spark Plasma Sintering and Heat Treatment. Crystals 2023, 13, 1184. https://doi.org/10.3390/cryst13081184

Homma T, Washizu T. Microstructural Control by Cooling Rate in β-type and Sintered Ti-3.6Fe-5Zr-0.2B (Mass%) Alloy Fabricated by Spark Plasma Sintering and Heat Treatment. Crystals. 2023; 13(8):1184. https://doi.org/10.3390/cryst13081184

Chicago/Turabian StyleHomma, Tomoyuki, and Takashi Washizu. 2023. "Microstructural Control by Cooling Rate in β-type and Sintered Ti-3.6Fe-5Zr-0.2B (Mass%) Alloy Fabricated by Spark Plasma Sintering and Heat Treatment" Crystals 13, no. 8: 1184. https://doi.org/10.3390/cryst13081184

APA StyleHomma, T., & Washizu, T. (2023). Microstructural Control by Cooling Rate in β-type and Sintered Ti-3.6Fe-5Zr-0.2B (Mass%) Alloy Fabricated by Spark Plasma Sintering and Heat Treatment. Crystals, 13(8), 1184. https://doi.org/10.3390/cryst13081184