Effects of Ce-Modified TiN Inclusions on the Fatigue Properties of Gear Steel 20CrMnTi

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

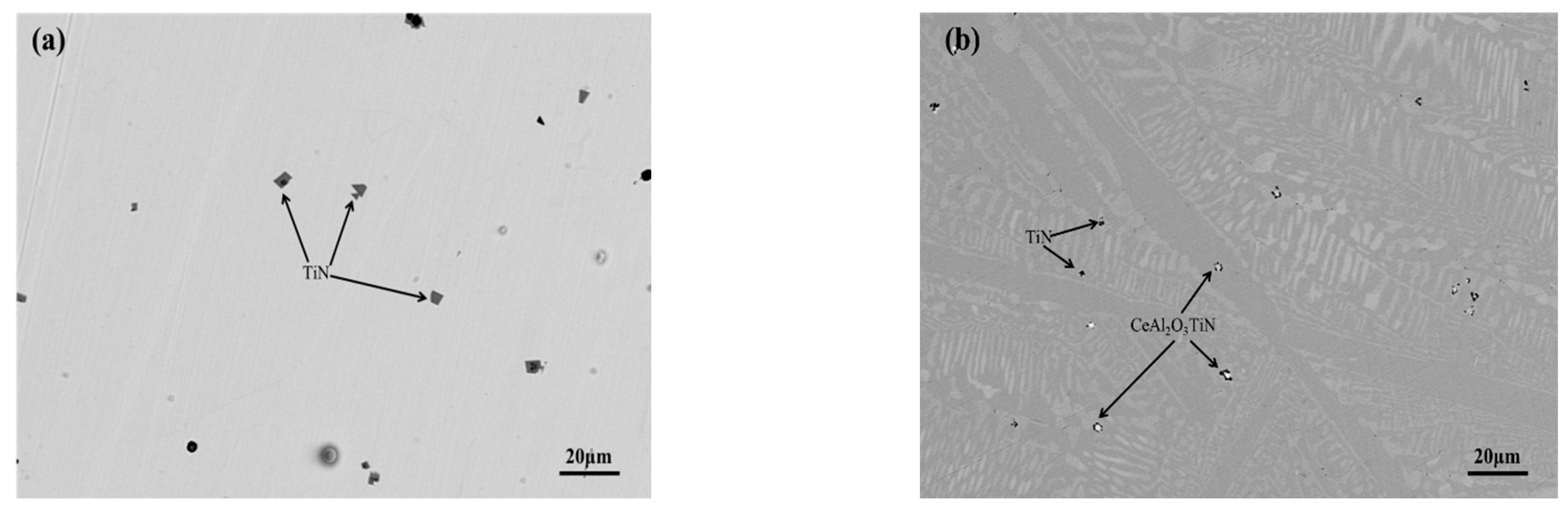

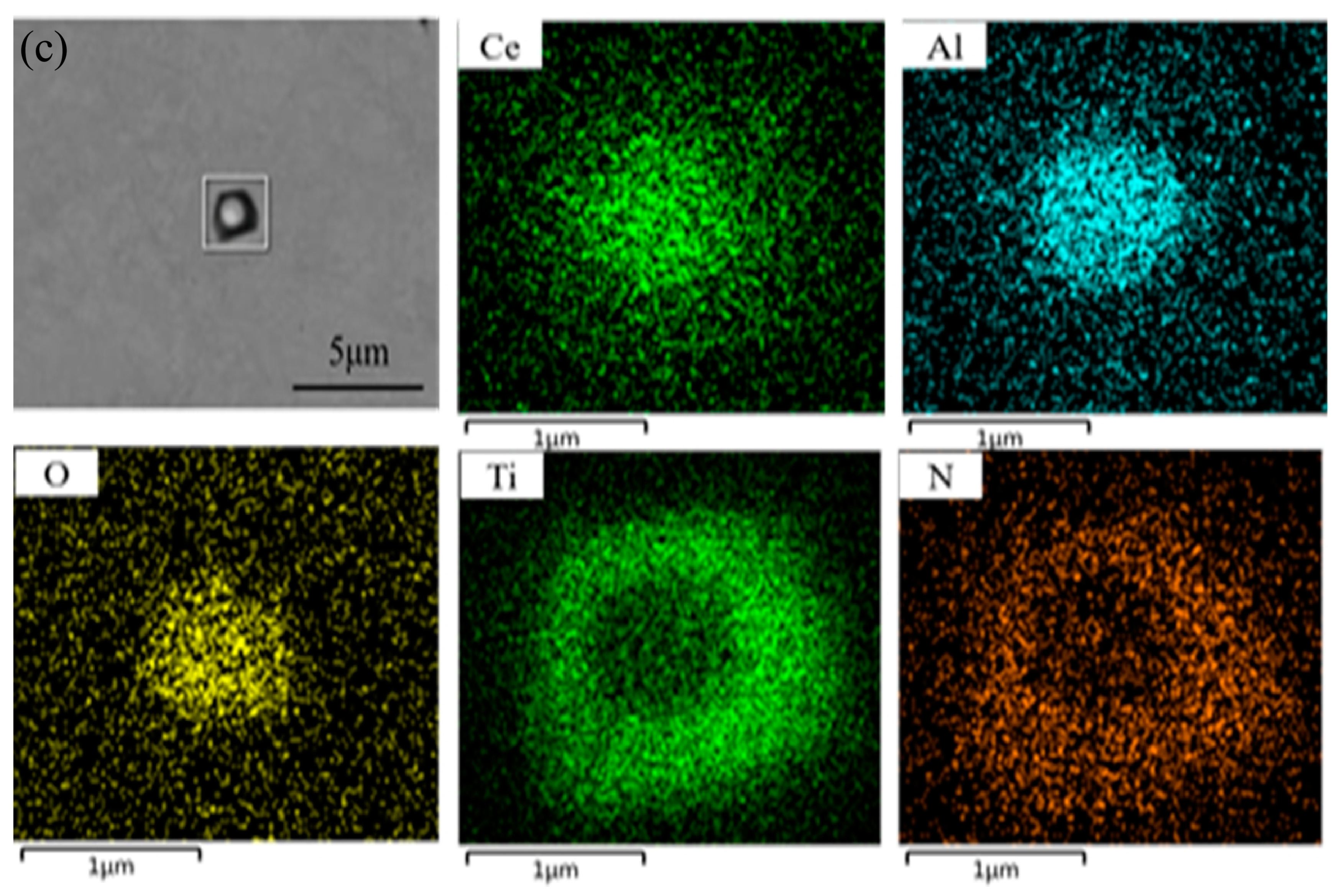

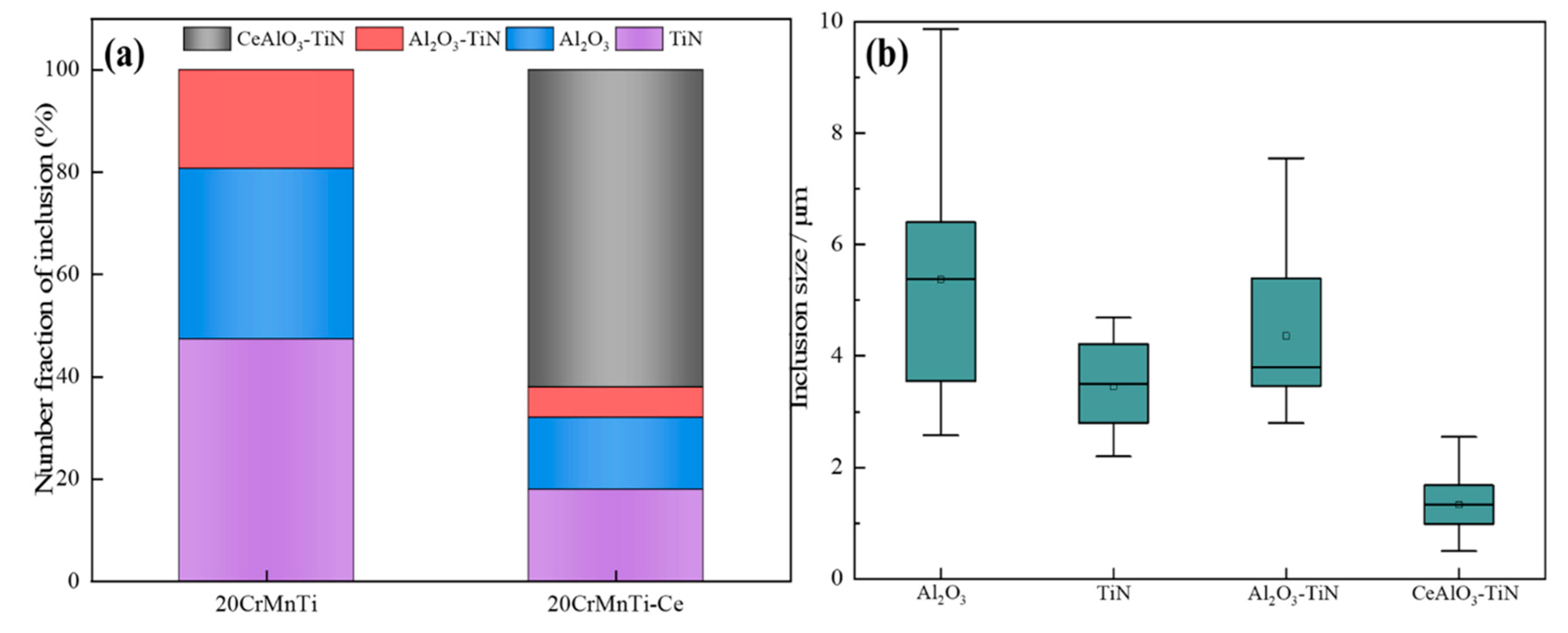

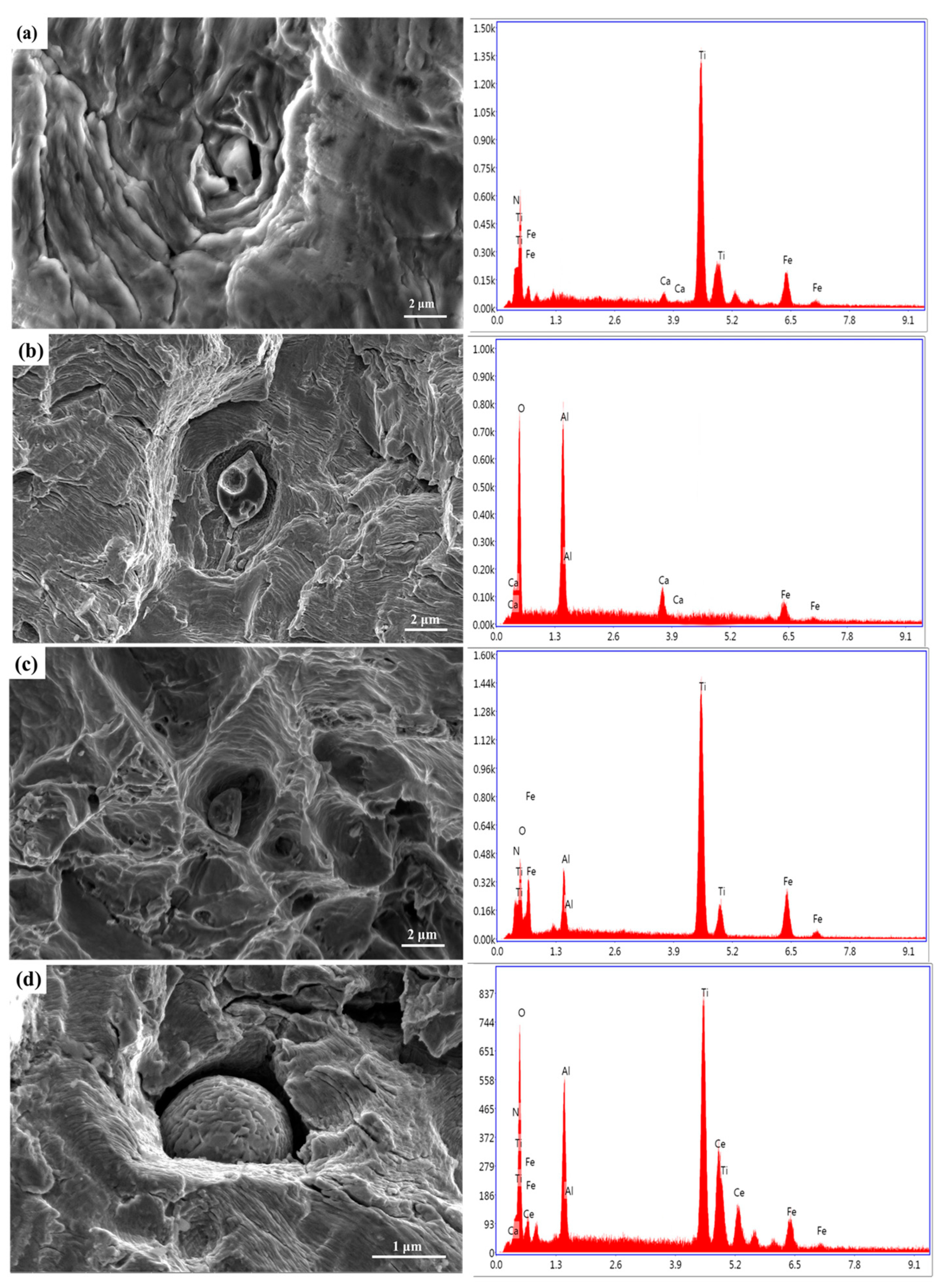

3.1. Compositions of Inclusions in the Steels

3.2. Crystallographic Analysis of CeAlO3-TiN Inclusion Formation

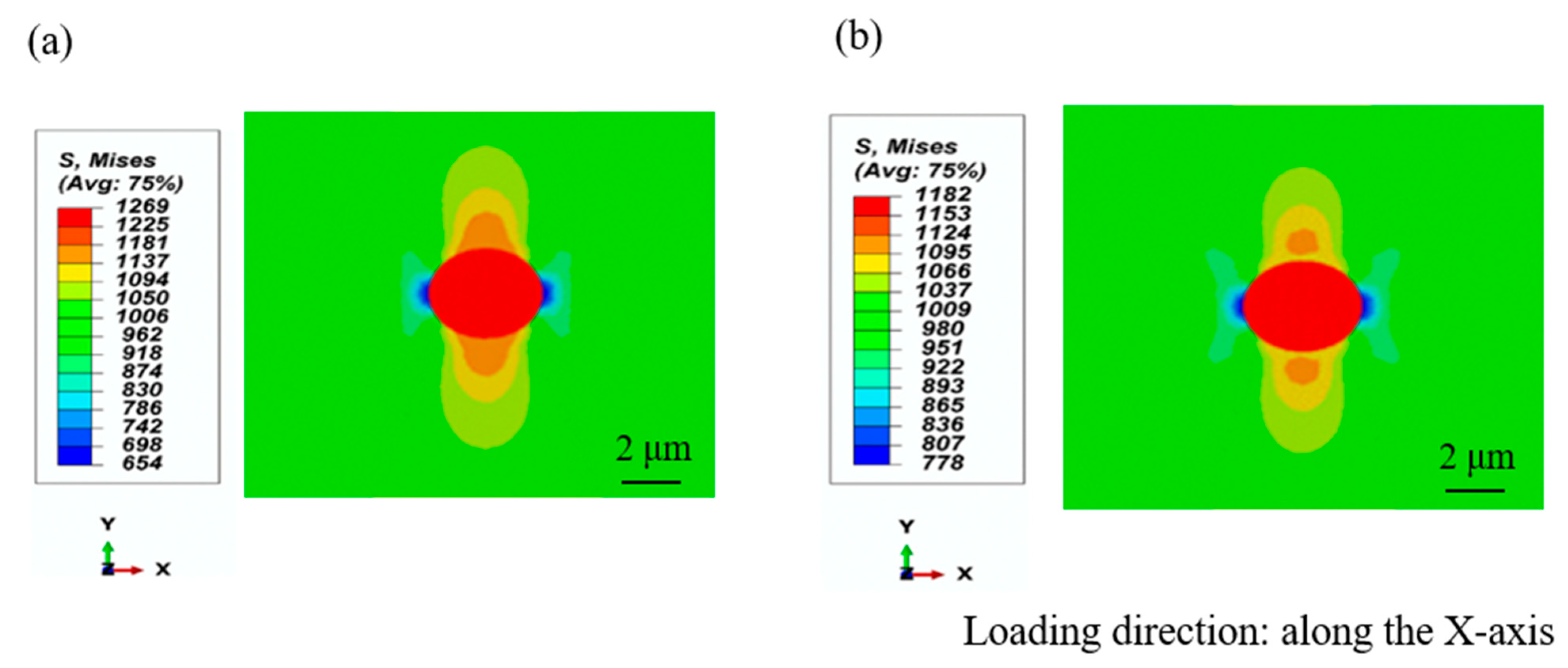

3.3. Finite Element Simulations

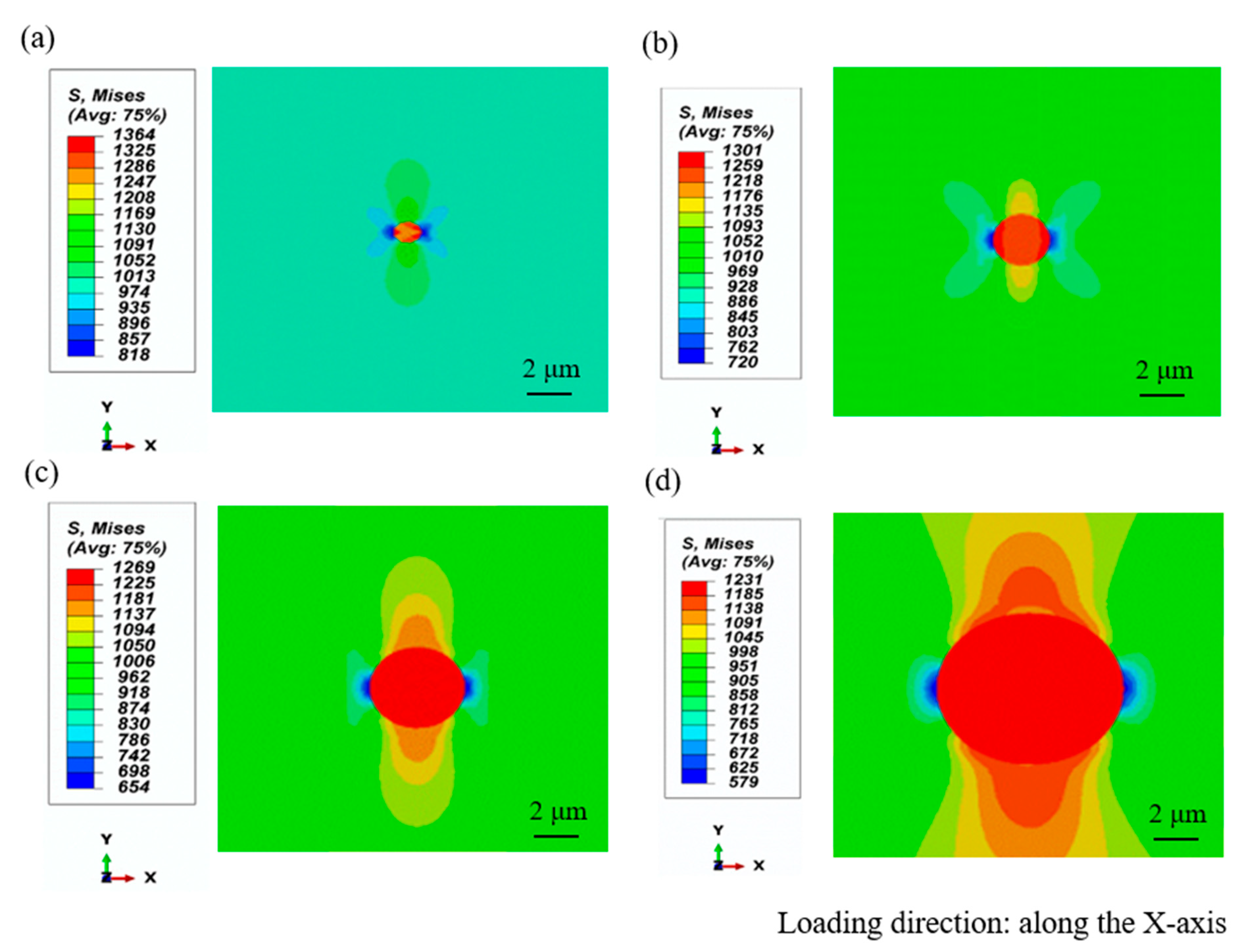

3.3.1. Type Effects of the Inclusions

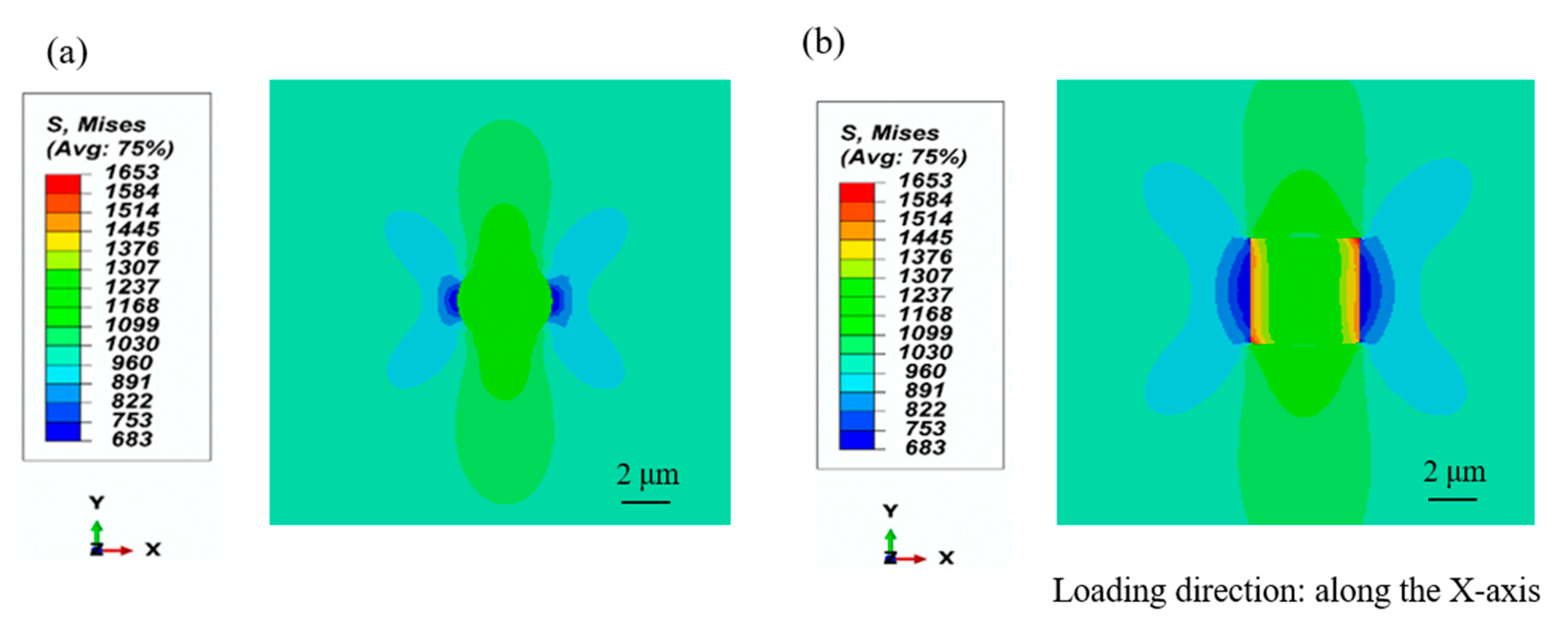

3.3.2. Size Effects of TiN Inclusions

3.3.3. Geometric Effects of TiN Inclusions

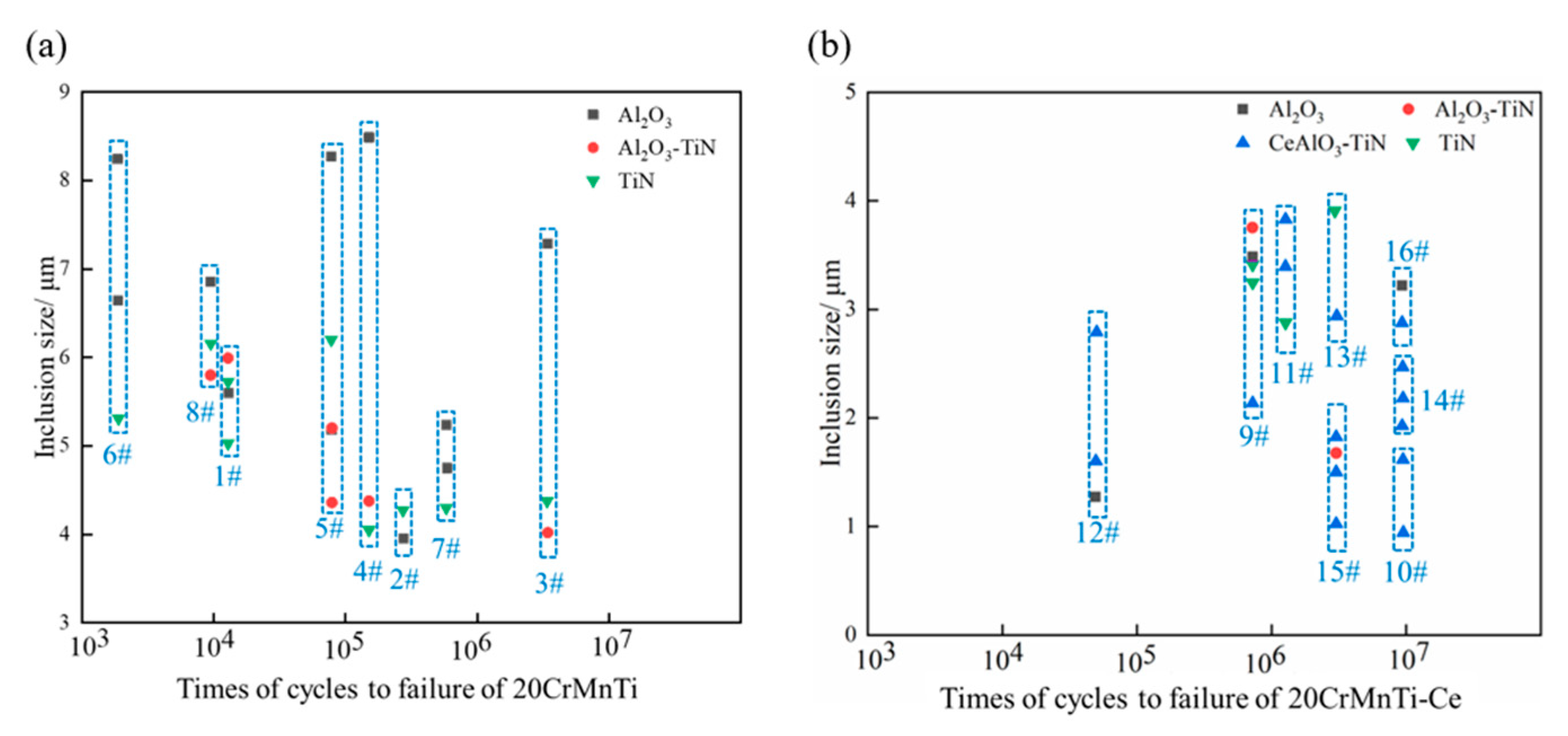

3.4. Relationships between Inclusions and Fatigue Strengths

4. Conclusions

- (1)

- TiN and Al2O3 are the most abundant types of inclusions in 20CrMnTi, accounting for 47% and 34% of the total share of inclusions, respectively. After adding the rare earth element Ce, the main type of titanium-containing inclusion in 20CrMnTi-Ce was CeAlO3-TiN, accounting for 63% of the total share of inclusions. The addition of Ce can serve the purpose of modifying titanium-containing inclusions.

- (2)

- Using the crystallographic theory of “matching edges”, the matching orientation relationships between CeAlO3 and TiN were calculated as [010]TiN//[21] CeAlO3&(002) TiN//. CeAlO3 can serve as a heterogeneous nucleation core for TiN.

- (3)

- The main sources of fatigue failure in 20CrMnTi were TiN and Al2O3 inclusions. Adding Ce led to the formation of spherical CeAlO3-TiN inclusions in 20CrMnTi. The fatigue cycle times of 20CrMnTi did not reach 107, while the fatigue cycle times of 20CrMnTi-Ce reached 107. The fatigue performance of 20CrMnTi-Ce was significantly better than that of 20CrMnTi.

- (4)

- With the same inclusion sizes, the high-stress and low-life regions of the square TiN were larger than those of the circular TiN. As the sizes of the TiN inclusions increase, the maximum stress of the steel matrix increases. Also, the high-stress and low-life regions noticeably increase, thus increasing the likelihood of a fatigue fracture.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hong, Y.S.; Lei, Z.Q.; Sun, C.Q.; Zhao, A.G. Propensities of crack interior initiation and early growth for very-high-cycle fatigue of high strength steels. J. Int. J. Fatigue 2014, 58, 144–151. [Google Scholar] [CrossRef]

- Li, W.; Deng, H.L.; Sun, Z.D.; Zhang, Z.Y.; Lu, L.T.; Sakai, T. Subsurface inclusion induced crack nucleation and growth behaviors of high strength steels under very high cycle fatigue: Characterization and microstructure-based modeling. J. Mater. Sci. Eng. A 2015, 641, 10–20. [Google Scholar] [CrossRef]

- Li, Y.D.; Guo, W.M.; Xu, N.; Wu, X.F.; Shi, J.B.; Ma, H. Crack growth process in GBF area of SUJ2 bearing steel in very high cycle fatigue regime. J. Mater. Sci. Technol. 2013, 29, 1463–1469. [Google Scholar] [CrossRef]

- Yamashita, Y.; Murakami, Y. Small crack growth model from low to very high cycle fatigue regime for internal fatigue failure of high strength steel. J. Int. J. Fatigue 2016, 93, 406–414. [Google Scholar] [CrossRef]

- Ding, W.H.; Li, M.Q. Application of Alloy Elements and Thermomechanical Control Process in Trial production of Pipeline Steel. Mater. Rev. 2007, 21, 67. [Google Scholar]

- Hui, W.J.; Dong, H.; Chen, S.L. Inclusion and surface condition on Fatigue property of High strength spring steel. J. Spec. Steel 1998, 19, 8–14. [Google Scholar]

- Xiang, C.Y. Alloy Structural Steel M.; China Machine Press: Beijing, China, 1999. [Google Scholar]

- Sakai, T.; Sato, Y.; Oguma, N. Characteristic S-N properties of high-carbon-chromium-bearing steel under axial loading in long-life fatigue. Fatigue Fract. Eng. M 2010, 25, 765–773. [Google Scholar] [CrossRef]

- Sakai, T.; Takeda, M.; Shiozawa, K.; Ochi, Y.; Nakajima, M.; Nakamura, Y.; Oguma, N. Experimental reconfirmation of characteristic S-N property for high carbon chromium bearing steel in wide life region in rotating bending. J. Soc. Mater. Sci. Jpn. 2000, 49, 779–785. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Wang, L.J.; Chou, K.C. Effect of cerium on the cleanliness of spring steel used in fastener of high-speed railway. J. Rare Earth 2014, 8, 759–766. [Google Scholar] [CrossRef]

- Liu, H.H.; Fu, P.X.; Liu, H.W.; Sun, C.; Sun, M.Y.; Li, D.Z. A novel large cross-section quenching and tempering mold steel matching excellent strength-hardness-toughness properties. J. Mater. Sci. Eng. A 2018, 737, 274–285. [Google Scholar] [CrossRef]

- Yang, C.Y.; Luan, Y.K.; Li, D.Z.; Li, Y.Y. Effects of rare earth elements on inclusions and impact toughness of high-carbon chromium bearing steel. J. Mater. Sci. Technol. 2019, 35, 1298–1308. [Google Scholar] [CrossRef]

- Ahn, J.H.; Jung, H.D.; Im, J.H.; Jung, K.H.; Moon, B.M. Influence of the addition of gadolinium on the microstructure and mechanical properties of duplex stainless steel. J. Mater. Sci. Eng. A 2016, 658, 255–262. [Google Scholar] [CrossRef]

- Bao, D.H.; Cheng, G.G.; Huang, Y.; Qiao, T.; Dai, W.X. Refinement of solidification structure of H13 steel by rare earth sulfide. Steel Res. Int. 2022, 93, 2100304. [Google Scholar] [CrossRef]

- Zheng, L.L. Development of Mo-Ti-Ce Micro-Alloyed New Air-Cold Bainite Steel for Shovel Teeth; Inner Mongolia University of Science and Technology: Baotou, China, 2020. [Google Scholar]

- Li, H.W.; Yang, J.C.; Zhang, J. Precipitation behaviors of titaniferous inclusions in cerium-containing IF steel. J. Iron Steel Res. 2015, 27, 49–52. [Google Scholar]

- Mu, X.G.; Hideaki, S. Influence of Dissolved Cerium and Primary Inclusion Particles of Ce2O3 and CeS on Solidification Behavior of Fe-0.20 mass%C-0.02 mass%P Alloy. ISIJ Int. 1999, 39, 722–729. [Google Scholar]

- Chen, X.; Li, Y.X.; Zhang, H.M. Microstructure and mechanical properties of high boron white cast iron with about 4 wt% chromium. J. Mater. Sci. 2011, 46, 112–116. [Google Scholar] [CrossRef]

- Qiu, D.; Zhang, M.X.; Taylor, J.A.; Kelly, P.M. A new approach to designing a grain refiner for Mg casting alloys and its use in Mg-Y-based alloys. J. Acta Mater. 2009, 57, 3052–3059. [Google Scholar] [CrossRef]

- Wang, F.; Qiu, D.; Liu, Z.L.; Taylor, J.A.; Easton, M.A.; Zhang, M.X. Crystallographic study of grain refinement of Al by Nb addition. J. Appl. Crystallogr. 2014, 47, 770–779. [Google Scholar] [CrossRef]

- Zhang, M.X.; Kelly, P.M.; Easton, M.A. Crystallographic study of grain refinement in aluminum alloys using the edge-to-edge matching model. J. Acta Mater. 2005, 53, 1427–1438. [Google Scholar] [CrossRef]

- Zhang, M.X.; Kelly, P.M. Crystallographic features of phase transformations in solids. J. Prog. Mater. Sci. 2009, 54, 1101–1170. [Google Scholar] [CrossRef]

- Zhao, H.; Chu, H.D.; Zhang, Z.J. Experimental Study on the Measurement of Poisson’s Ratio of Elastic Modulus to Shear Modulus of 20CrMnTi Alloy Steel. J. Test Technol. Test. Mach. 2003, 4, 23–24. [Google Scholar]

- Brooksbank, D.; Andrews, K.W. Tessellated stresses associated with some inclusions in steel. J. Iron Steel Inst. 1969, 207, 474. [Google Scholar]

- Gu, C.; Liu, W.Q.; Lian, J.H.; Bao, Y.P. In-depth analysis of the fatigue mechanism induced by inclusions for high-strength bearing steels. Int. J. Miner. Metall. Mater. 2021, 28, 826–834. [Google Scholar] [CrossRef]

| Sample | C | Si | Mn | Al | Cr | Ti | Ce | N | O |

|---|---|---|---|---|---|---|---|---|---|

| (wt./%) | (ppm) | ||||||||

| 20CrMnTi | 0.23 | 0.18 | 0.95 | 0.042 | 1.02 | 0.065 | 48 | 42 | |

| 20CrMnTi-Ce | 0.22 | 0.20 | 0.89 | 0.046 | 1.05 | 0.061 | 52 | 55 | 39 |

| Phase | Crystal Structure | Space Group | Lattice Parameter/nm |

|---|---|---|---|

| TiN | FCC | Fmm | a = 0.4235 |

| CeAlO3 | Cubic | m | a = 0.3802 |

| Phase | CP Row | Interatomic Spacing/nm | Type | CP Plane | Interatomic Spacing/nm |

|---|---|---|---|---|---|

| TiN | <010> | 0.212 | Straight rows | {002} | 0.212 |

| <> | 0.300 | Straight rows | {022} | 0.150 | |

| <> | 0.367 | Straight rows | {222} | 0.122 | |

| CeAlO3 | 1} | 0.220 | |||

| <1> | 0.233 | Straight rows | 0} | 0.190 | |

| <1101> | 0.269 | Straight rows | 2} | 0.134 | |

| 1} | 0.115 |

| Matching Rows | Misfit fr/% | Matching Planes | Misfit fd/% |

|---|---|---|---|

| 9.01 | 3.63 | ||

| 8.96 | |||

| 6.09 |

| Material | Young’s Modulus, E/GPa | Poisson’s Ratio, ν |

|---|---|---|

| 20CrMnTi | 206 | 0.27 |

| Titanium nitride | 320 | 0.19 |

| Aluminium oxide | 375 | 0.22 |

| Inclusion Radius/μm | The Maximum Stress in the Steel Matrix/MPa |

|---|---|

| 1.5 | 1133 |

| 3 | 1170 |

| 5 | 1182 |

| 10 | 1185 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Peng, J.; Zhang, F.; Li, Y.; Zhang, X.; An, S. Effects of Ce-Modified TiN Inclusions on the Fatigue Properties of Gear Steel 20CrMnTi. Crystals 2023, 13, 1071. https://doi.org/10.3390/cryst13071071

Wang J, Peng J, Zhang F, Li Y, Zhang X, An S. Effects of Ce-Modified TiN Inclusions on the Fatigue Properties of Gear Steel 20CrMnTi. Crystals. 2023; 13(7):1071. https://doi.org/10.3390/cryst13071071

Chicago/Turabian StyleWang, Jian, Jun Peng, Fang Zhang, Yujie Li, Xin Zhang, and Shengli An. 2023. "Effects of Ce-Modified TiN Inclusions on the Fatigue Properties of Gear Steel 20CrMnTi" Crystals 13, no. 7: 1071. https://doi.org/10.3390/cryst13071071

APA StyleWang, J., Peng, J., Zhang, F., Li, Y., Zhang, X., & An, S. (2023). Effects of Ce-Modified TiN Inclusions on the Fatigue Properties of Gear Steel 20CrMnTi. Crystals, 13(7), 1071. https://doi.org/10.3390/cryst13071071