Consolidation of Zn-Hydroxyapatite and Zn-Bioactive Glass Composites Using High-Pressure Torsion

Abstract

1. Introduction

2. Materials and Methods

3. Results

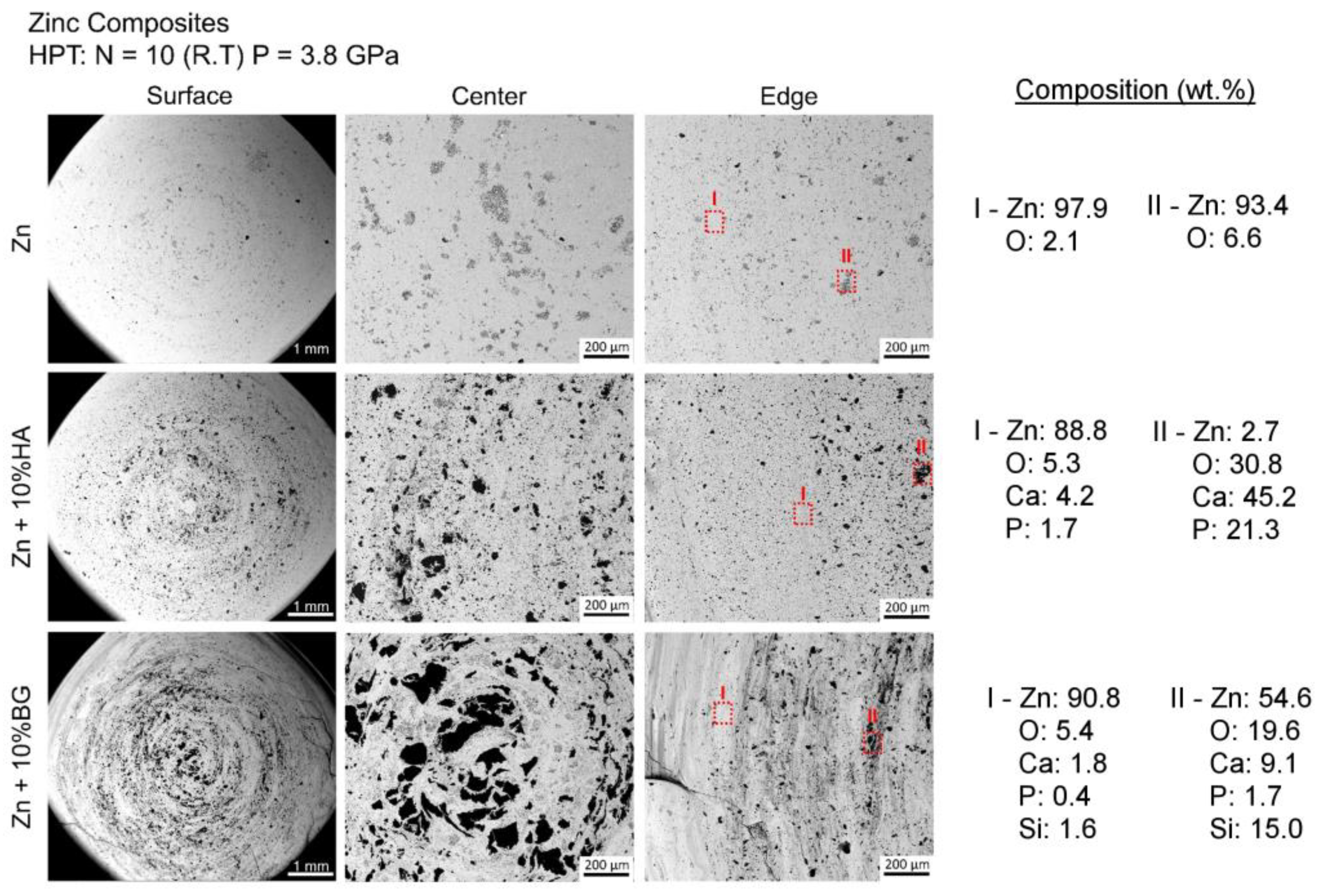

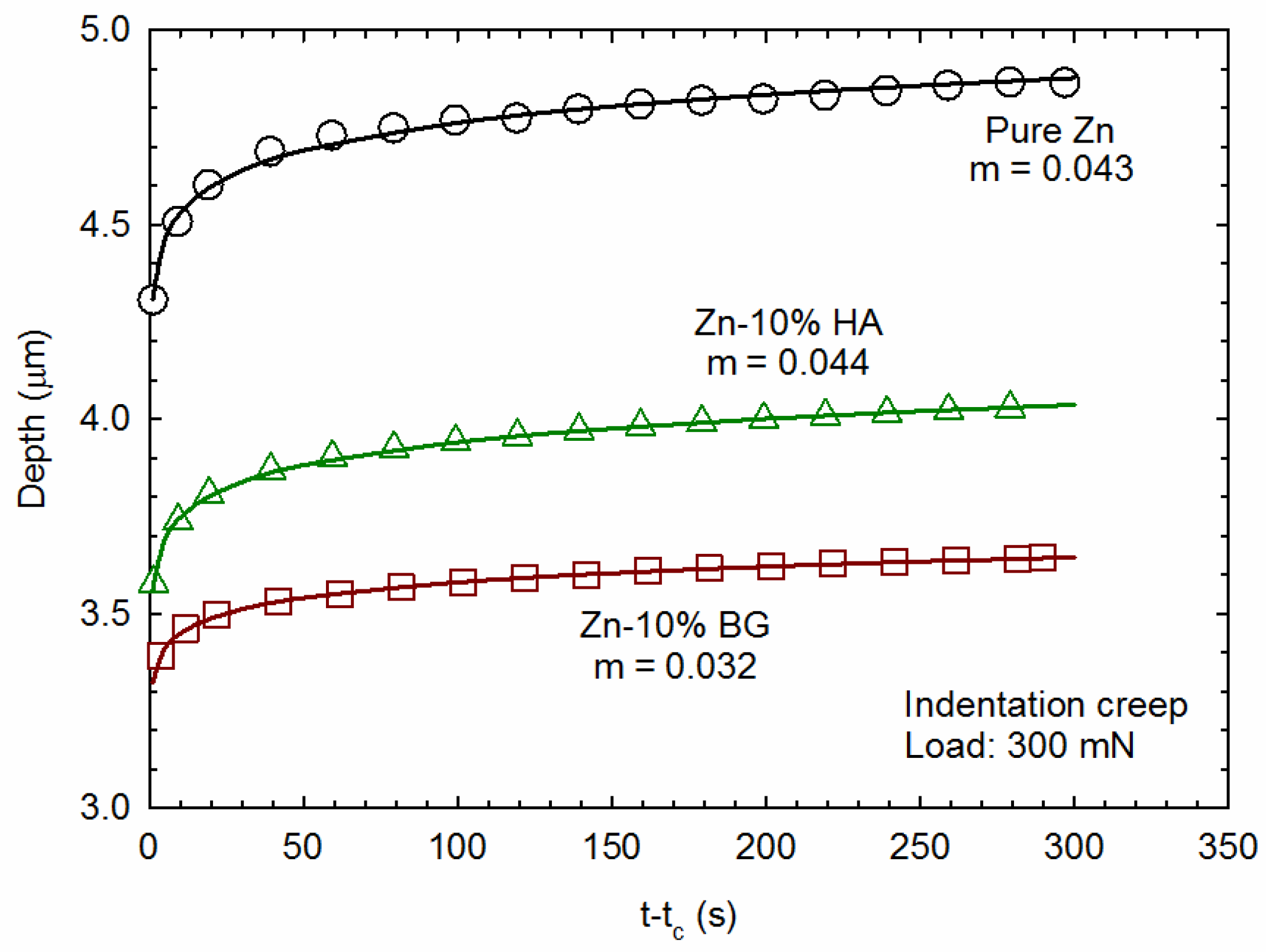

3.1. Consolidation and Mechanical Properties

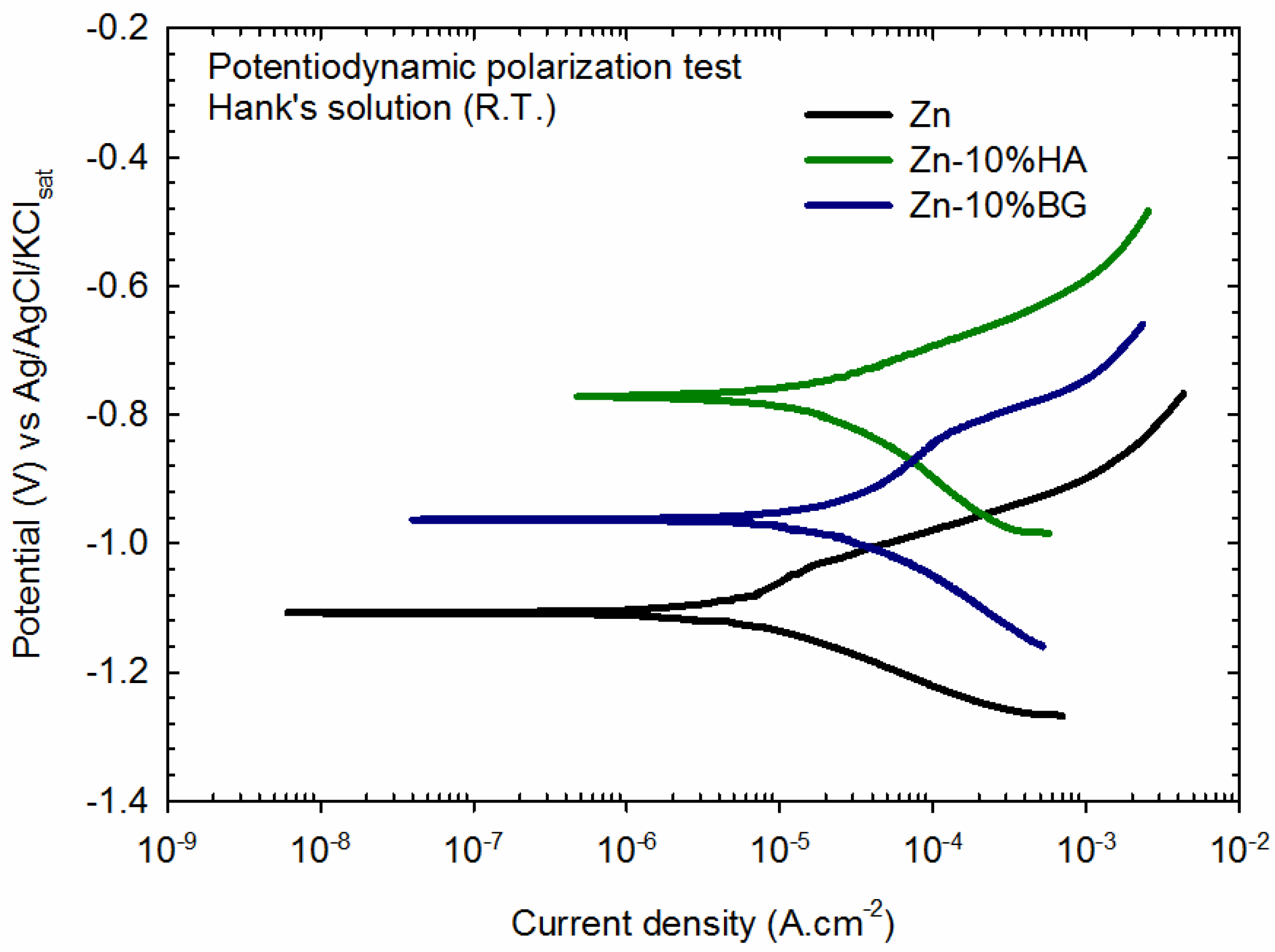

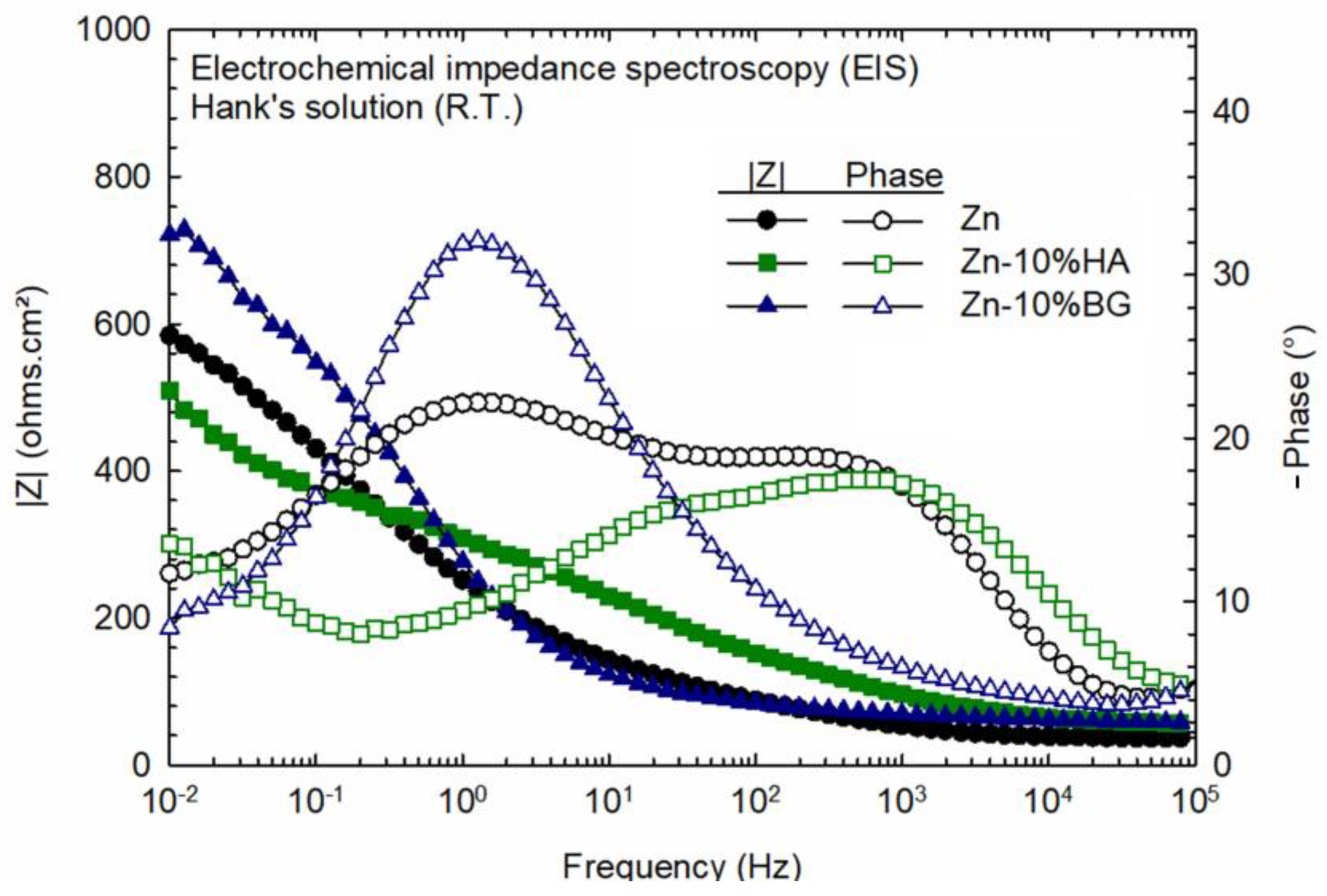

3.2. Corrosion Behavior

4. Discussion

| Composite | Yield Strength (MPa) | Corr. Potential (V) | Corr. Rate (mm/Year) | Corr. Test | Corr. Media | Reference |

|---|---|---|---|---|---|---|

| Zn-10% HA | 156 | −0.760 | 0.258 | Electrochemical | Hank’s | This study |

| Zn-10% BG | 161 | −0.960 | 0.320 | Electrochemical | Hank’s | This study |

| Zn-1% Mg | 258 | −0.946 | 0.040 | Immersion | SBF | [52] |

| Zn-1% Mg/1β-TCP | 277 | −0.957 | 0.045 | Immersion | SBF | [52] |

| Zn-0.5% SiC | 43 | −1.059 | 0.148 | Electrochemical | SBF | [48] |

| Zn-1% SiC | 75 | −1.107 | 0.163 | Electrochemical | SBF | [48] |

| Zn-2% SiC | 122 | −1.119 | 0.198 | Electrochemical | SBF | [48] |

| Zn-3% SiC | 44 | −1.170 | 0.230 | Electrochemical | SBF | [48] |

| Zn-0.1% GNP | 110 | −1.084 | 0.224 | Electrochemical | Hank’s | [49] |

| Zn-0.2% GNP | 123 | −1.113 | 0.090 | Electrochemical | Hank’s | [49] |

| Zn-0.3% GNP | 119 | −1.061 | 0.143 | Electrochemical | Hank’s | [49] |

| Zn-0.4% GNP | 118 | −1.110 | 0.187 | Electrochemical | Hank’s | [49] |

| Zn-3% MgO | 156 | −0.953 | 0.171 | Electrochemical | SBF | [50] |

| Zn-3% ZnO | 135 | −0.960 | 0.184 | Electrochemical | SBF | [50] |

| Zn-3% CuO | 203 | −0.963 | 0.178 | Electrochemical | SBF | [50] |

| Zn-3% Mg-0.7Mg2Si | 388 | −0.996 | 0.045 | Immersion | Hank’s | [53] |

| Zn-3% Mg-0.7Mg2Si | 406 | −0.930 | 0.043 | Immersion | Hank’s | [53] |

| Zn–1Mg2Ge | 118 | −0.714 | 0.219 | Electrochemical | Hank’s | [56] |

| Zn–3Mg2Ge | 162 | −0.755 | 0.347 | Electrochemical | Hank’s | [56] |

| Zn–5Mg2Ge | 129 | −0.845 | 0.026 | Electrochemical | Hank’s | [56] |

| Zn/1% TCP | 133 | - | 0.081 | Immersion | SBF | [20] |

| Zn/3% TCP | 141 | - | 0.071 | Immersion | SBF | [20] |

| Zn/5% TCP | 123 | - | 0.081 | Immersion | SBF | [20] |

| Zn/1% TCP | 132 | −0.915 | 0.077 | Electrochemical | SBF | [19] |

| Zn/3% TCP | 142 | −0.928 | 0.148 | Electrochemical | SBF | [19] |

| Zn/5% TCP | 142 | −0.927 | 0.162 | Electrochemical | SBF | [19] |

| Zn-1% Mg | 135 | −1.066 | 0.114 | Immersion | Hank’s | [51] |

| Zn-2% Mg | 152 | −1.101 | 0.209 | Immersion | Hank’s | [51] |

| Zn-5% Mg | 184 | −1.312 | 0.427 | Immersion | Hank’s | [51] |

| Zn-3% HA | 108 | −1.046 | 0.101 | Electrochemical | SBF | [57] |

| Zn-3% HA-2% Fe | 116 | −1.047 | 0.088 | Electrochemical | SBF | [57] |

| Zn-5% HA-2% Fe | 118 | −1.071 | 0.113 | Electrochemical | SBF | [57] |

| Zn-1% HA | 70 | −1.281 | 0.327 | Immersion | Hank’s | [21] |

| Zn-5% HA | 43 | −1.274 | 0.630 | Immersion | Hank’s | [21] |

| Zn-10% HA | 47 | −1.290 | 0.856 | Immersion | Hank’s | [21] |

| Zn-16% HA | 46 | - | 1.520 | Electrochemical | SBF | [22] |

| Zn-8% HA | 113 | - | 0.070 | Electrochemical | SBF | [23] |

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, Y.F.; Gu, X.N.; Witte, F. Biodegradable metals. Mater. Sci. Eng. R Rep. 2014, 77, 1–34. [Google Scholar] [CrossRef]

- Edalati, K.; Bachmaier, A.; Beloshenko, V.A.; Beygelzimer, Y.; Blank, V.D.; Botta, W.J.; Bryła, K.; Čížek, J.; Divinski, S.; Enikeev, N.A.; et al. Nanomaterials by severe plastic deformation: Review of historical developments and recent advances. Mater. Res. Lett. 2022, 10, 163–256. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Effect of grain size on strength and strain rate sensitivity in metals. J. Mater. Sci. 2022, 57, 5210–5229. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Deformation mechanisms in ultrafine-grained metals with an emphasis on the Hall-Petch relationship and strain rate sensitivity. J. Mater. Res. Technol. 2021, 14, 137–159. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Kawasaki, M.; Langdon, T.G. Seventy years of Hall-Petch, ninety years of superplasticity and a generalized approach to the effect of grain size on flow stress. Prog. Mater. Sci. 2023, 137, 101131. [Google Scholar] [CrossRef]

- Miyamoto, H.; Yuasa, M.; Rifai, M.; Fujiwara, H. Corrosion Behavior of Severely Deformed Pure and Single-Phase Materials. Mater. Trans. 2019, 60, 1243–1255. [Google Scholar] [CrossRef]

- Miyamoto, H. Corrosion of Ultrafine Grained Materials by Severe Plastic Deformation, an Overview. Mater. Trans. 2016, 57, 559–572. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Processing Magnesium and Its Alloys by High-Pressure Torsion: An Overview. Adv. Eng. Mater. 2019, 21, 1801039. [Google Scholar] [CrossRef]

- Medeiros, M.P.; Lopes, D.R.; Kawasaki, M.; Langdon, T.G.; Figueiredo, R.B. An Overview on the Effect of Severe Plastic Deformation on the Performance of Magnesium for Biomedical Applications. Materials 2023, 16, 2401. [Google Scholar] [CrossRef]

- Hohenwarter, A.; Kammerhofer, C.; Pippan, R. The ductile to brittle transition of ultrafine-grained Armco iron: An experimental study. J. Mater. Sci. 2010, 45, 4805–4812. [Google Scholar] [CrossRef]

- Ivanisenko, Y.; Valiev, R.Z.; Fecht, H.J. Grain boundary statistics in nano-structured iron produced by high pressure torsion. Mater. Sci. Eng. A 2005, 390, 159–165. [Google Scholar] [CrossRef]

- Batista, B.A.; Soares, R.B.; Lins, V.F.C.; Figueiredo, R.B.; Hohenwarter, A.; Matencio, T. Corrosion in Hank’s solution and mechanical strength of ultrafine-grained pure iron. Adv. Eng. Mater. 2020, 22, 2000183. [Google Scholar] [CrossRef]

- Srinivasarao, B.; Zhilyaev, A.P.; Langdon, T.G.; Pérez-Prado, M.T. On the relation between the microstructure and the mechanical behavior of pure Zn processed by high pressure torsion. Mater. Sci. Eng. A 2013, 562, 196–202. [Google Scholar] [CrossRef]

- Bednarczyk, W.; Kawałko, J.; Rutkowski, B.; Wątroba, M.; Gao, N.; Starink, M.J.; Bała, P.; Langdon, T.G. Abnormal grain growth in a Zn-0.8Ag alloy after processing by high-pressure torsion. Acta Mater. 2021, 207, 116667. [Google Scholar] [CrossRef]

- Hernández-Escobar, D.; Unocic, R.R.; Kawasaki, M.; Boehlert, C.J. High-pressure torsion processing of Zn–3Mg alloy and its hybrid counterpart: A comparative study. J. Alloys Compd. 2020, 831, 154891. [Google Scholar] [CrossRef]

- Kawasaki, M.; Langdon, T.G. Developing superplasticity and a deformation mechanism map for the Zn–Al eutectoid alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2011, 528, 6140–6145. [Google Scholar] [CrossRef]

- Kawasaki, M.; Ahn, B.; Langdon, T.G. Microstructural evolution in a two-phase alloy processed by high-pressure torsion. Acta Mater. 2010, 58, 919–930. [Google Scholar] [CrossRef]

- Sun, X.; Yu, X.; Li, W.; Chen, M.; Liu, D. Fabrication and characterization of biodegradable zinc matrix composites reinforced by uniformly dispersed beta-tricalcium phosphate via graphene oxide-assisted hetero-agglomeration. Mater. Sci. Eng. C 2021, 130, 112431. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Liu, D.; Chen, Z.; He, X.; Li, X.; Sun, X. Fabrication, in vitro and in vivo properties of β-TCP/Zn composites. J. Alloys Compd. 2022, 913, 165223. [Google Scholar] [CrossRef]

- Yang, H.; Qu, X.; Lin, W.; Wang, C.; Zhu, D.; Dai, K.; Zheng, Y. In vitro and in vivo studies on zinc-hydroxyapatite composites as novel biodegradable metal matrix composite for orthopedic applications. Acta Biomater. 2018, 71, 200–214. [Google Scholar] [CrossRef] [PubMed]

- Pinc, J.; Čapek, J.; Kubásek, J.; Průša, F.; Hybášek, V.; Veřtát, P.; Sedlářová, I.; Vojtěch, D. Characterization of a Zn-Ca5(PO4)3(OH) Composite with a High Content of the Hydroxyapatite Particles Prepared by the Spark Plasma Sintering Process. Metals 2020, 10, 372. [Google Scholar] [CrossRef]

- Pinc, J.; Čapek, J.; Hybášek, V.; Průša, F.; Hosová, K.; Maňák, J.; Vojtěch, D. Characterization of Newly Developed Zinc Composite with the Content of 8 wt.% of Hydroxyapatite Particles Processed by Extrusion. Materials 2020, 13, 1716. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Escobar, D.; Kawasaki, M.; Boehlert, C.J. Metal hybrids processed by high-pressure torsion: Synthesis, microstructure, mechanical properties and developing trends. Int. Mater. Rev. 2022, 67, 231–265. [Google Scholar] [CrossRef]

- Hernández-Escobar, D.; Marcus, J.; Han, J.-K.; Unocic, R.R.; Kawasaki, M.; Boehlert, C.J. Effect of post-deformation annealing on the microstructure and micro-mechanical behavior of Zn–Mg hybrids processed by High-Pressure Torsion. Mater. Sci. Eng. A 2020, 771, 138578. [Google Scholar] [CrossRef]

- Hernández-Escobar, D.; Rahman, Z.U.; Yilmazer, H.; Kawasaki, M.; Boehlert, C.J. Microstructural evolution and intermetallic formation in Zn-Mg hybrids processed by High-Pressure Torsion. Philos. Mag. 2019, 99, 557–584. [Google Scholar] [CrossRef]

- Castro, M.M.; Montoro, L.A.; Isaac, A.; Kawasaki, M.; Figueiredo, R.B. Mechanical mixing of Mg and Zn using high-pressure torsion. J. Alloys Compd. 2021, 869, 159302. [Google Scholar] [CrossRef]

- Hench, L.L. Bioceramics. J. Am. Ceram. Soc. 1998, 81, 1705–1728. [Google Scholar] [CrossRef]

- dos Santos, D.M.M.; de Carvalho, S.M.; Pereira, M.M.; Houmard, M.; Nunes, E.H.M. Freeze-cast composite scaffolds prepared from sol-gel derived 58S bioactive glass and polycaprolactone. Ceram. Int. 2019, 45, 9891–9900. [Google Scholar] [CrossRef]

- Pereira, P.H.R.; Figueiredo, R.B.; Huang, Y.; Cetlin, P.R.; Langdon, T.G. Modeling the temperature rise in high-pressure torsion. Mater. Sci. Eng. A 2014, 593, 185–188. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Szommer, P. Mathematical description of indentation creep and its application for the determination of strain rate sensitivity. Mater. Sci. Eng. A 2014, 611, 333–336. [Google Scholar] [CrossRef]

- Carvalho, A.P.; Reis, L.M.; Pinheiro, R.P.R.P.; Pereira, P.H.R.; Langdon, T.G.; Figueiredo, R.B. Using Plane Strain Compression Test to Evaluate the Mechanical Behavior of Magnesium Processed by HPT. Metals 2022, 12, 125. [Google Scholar] [CrossRef]

- Su, Y.; Wang, K.; Gao, J.; Yang, Y.; Qin, Y.-X.; Zheng, Y.; Zhu, D. Enhanced cytocompatibility and antibacterial property of zinc phosphate coating on biodegradable zinc materials. Acta Biomater. 2019, 98, 174–185. [Google Scholar] [CrossRef]

- Mollaei, N.; Razavi, S.; Aboutalebi, M.; Fatemi, S. Effect of Mn addition on the microstructure, mechanical, and corrosion properties of an extruded biodegradable Zn-0.2 Mg alloy. J. Mater. Res. Technol. 2023, 22, 1983–1998. [Google Scholar] [CrossRef]

- Hing, K.; Best, S.; Bonfield, W. Characterization of porous hydroxyapatite. J. Mater. Sci. Mater. Med. 1999, 10, 135–145. [Google Scholar] [CrossRef]

- Chen, Q.Z.; Thompson, I.D.; Boccaccini, A.R. 45S5 Bioglass®-derived glass–ceramic scaffolds for bone tissue engineering. Biomaterials 2006, 27, 2414–2425. [Google Scholar] [CrossRef]

- Wagoner, R.H. Strain-rate sensitivity of zinc sheet. Metall. Mater. Trans. A 1984, 15, 1265–1271. [Google Scholar] [CrossRef]

- Lee, J.D.; Niessen, P. Superplasticity in a new dispersion strengthened zinc alloy. Metall. Trans. 1973, 4, 949–957. [Google Scholar] [CrossRef]

- Li, H.; Xie, X.; Zheng, Y.F.; Cong, Y.; Zhou, F.; Qiu, K.; Wang, X.; Chen, S.; Huang, L.; Tian, L. Development of biodegradable Zn-1X binary alloys with nutrient alloying elements Mg, Ca and Sr. Sci. Rep. 2015, 5, 10719. [Google Scholar] [CrossRef] [PubMed]

- Harai, Y.; Edalati, K.; Horita, Z.; Langdon, T.G. Using ring samples to evaluate the processing characteristics in high-pressure torsion. Acta Mater. 2009, 57, 1147–1153. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z. Scaling-Up of High Pressure Torsion Using Ring Shape. Mater. Trans. 2009, 50, 92–95. [Google Scholar] [CrossRef]

- Harai, Y.; Ito, Y.; Horita, Z. High-pressure torsion using ring specimens. Scr. Mater. 2008, 58, 469–472. [Google Scholar] [CrossRef]

- Huang, T.; Liu, Z.; Wu, D.; Yu, H. Microstructure, mechanical properties, and biodegradation response of the grain-refined Zn alloys for potential medical materials. J. Mater. Res. Technol. 2021, 15, 226–240. [Google Scholar] [CrossRef]

- Liu, X.; Sun, J.; Yang, Y.; Pu, Z.; Zheng, Y. In vitro investigation of ultra-pure Zn and its mini-tube as potential bioabsorbable stent material. Mater. Lett. 2015, 161, 53–56. [Google Scholar] [CrossRef]

- Mostaed, E.; Sikora-Jasinska, M.; Mostaed, A.; Loffredo, S.; Demir, A.; Previtali, B.; Mantovani, D.; Beanland, R.; Vedani, M. Novel Zn-based alloys for biodegradable stent applications: Design, development and in vitro degradation. J. Mech. Behav. Biomed. Mater. 2016, 60, 581–602. [Google Scholar] [CrossRef] [PubMed]

- Bagha, P.S.; Khaleghpanah, S.; Sheibani, S.; Khakbiz, M.; Zakeri, A. Characterization of nanostructured biodegradable Zn-Mn alloy synthesized by mechanical alloying. J. Alloys Compd. 2018, 735, 1319–1327. [Google Scholar] [CrossRef]

- Čapek, J.; Jablonská, E.; Lipov, J.; Kubatík, T.F.; Vojtěch, D. Preparation and characterization of porous zinc prepared by spark plasma sintering as a material for biodegradable scaffolds. Mater. Chem. Phys. 2018, 203, 249–258. [Google Scholar] [CrossRef]

- Gao, C.; Yao, M.; Shuai, C.; Peng, S.; Deng, Y. Nano-SiC reinforced Zn biocomposites prepared via laser melting: Microstructure, mechanical properties and biodegradability. J. Mater. Sci. Technol. 2019, 35, 2608–2617. [Google Scholar] [CrossRef]

- Kabir, H.; Munir, K.; Wen, C.; Li, Y. Microstructures, mechanical and corrosion properties of graphene nanoplatelet–reinforced zinc matrix composites for implant applications. Acta Biomater. 2023, 157, 701–719. [Google Scholar] [CrossRef]

- Sun, X.; Yu, X.; Li, W.; Chen, M.; Liu, D. Mechanical properties, degradation behavior and cytocompatibility of biodegradable 3vol% X (X = MgO, ZnO and CuO)/Zn matrix composites with excellent dispersion property fabricated by graphene oxide-assisted hetero-aggregation. Biomater. Adv. 2022, 134, 112722. [Google Scholar] [CrossRef]

- Yang, H.; Qu, X.; Lin, W.; Chen, D.; Zhu, D.; Dai, K.; Zheng, Y. Enhanced osseointegration of Zn-Mg composites by tuning the release of Zn ions with sacrificial Mg-rich anode design. ACS Biomater. Sci. Eng. 2018, 5, 453–467. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Z.; Liu, D.; Zhao, Y.; Sun, X. Microstructure and properties of β-TCP/Zn-1Mg composites processed by hot extrusion combination of multi-pass ECAP. J. Alloys Compd. 2022, 903, 163988. [Google Scholar] [CrossRef]

- Tong, X.; Cai, W.; Lin, J.; Wang, K.; Jin, L.; Shi, Z.; Zhang, D.; Lin, J.; Li, Y.; Dargusch, M. Biodegradable Zn− 3Mg− 0.7 Mg2Si composite fabricated by high-pressure solidification for bone implant applications. Acta Biomater. 2021, 123, 407–417. [Google Scholar] [CrossRef] [PubMed]

- Ghaebi Panah, N.; Atkin, R.; Sercombe, T.B. Bioactivity and biodegradability of high temperature sintered 58S ceramics. J. Eur. Ceram. Soc. 2022, 42, 3614–3623. [Google Scholar] [CrossRef]

- Du, R.L.; Chang, J.; Ni, S.Y.; Zhai, W.Y.; Wang, J.Y. Characterization and in vitro bioactivity of zinc-containing bioactive glass and glass-ceramics. J. Biomater. Appl. 2006, 20, 341–360. [Google Scholar] [CrossRef]

- Tong, X.; Wang, H.; Zhu, L.; Han, Y.; Wang, K.; Li, Y.; Ma, J.; Lin, J.; Wen, C.; Huang, S. A biodegradable in situ Zn–Mg2Ge composite for bone-implant applications. Acta Biomater. 2022, 146, 478–494. [Google Scholar] [CrossRef] [PubMed]

- Pathak, D.K.; Pandey, P.M. Evaluation of in vitro corrosion behavior of zinc–hydroxyapatite and zinc–hydroxyapatite–iron as biodegradable composites. J. Biomed. Mater. Res. Part B Appl. Biomater. 2021, 109, 436–450. [Google Scholar] [CrossRef] [PubMed]

| Sample | E (VvsAg/AgCl/KClsat) | I (μA/cm2) |

|---|---|---|

| Zn | −1.12 ± 0.02 | 6.28 ± 1.59 |

| Zn-HA | −0.80 ± 0.07 | 16.24 ± 5.10 |

| Zn-BG | −1.00 ± 0.06 | 20.05 ± 2.62 |

| Processing | Hardness (Hv) | Corr. Rate (mm/Year) | Corr. Test | Corr. Media | Reference |

|---|---|---|---|---|---|

| HPT | 47.7 | 0.094 | Electrochemical | Hank’s | Present study |

| Casting | 41.4 | 0.019 | Immersion | Hank’s | [43] |

| Rolling | 42.7 | 0.011 | Immersion | Hank’s | [43] |

| Extrusion-drawing | 41.4 | 0.036 | Immersion | Hank’s | [44] |

| Rolling | 40.0 | 0.135 | Electrochemical | Hank’s | [39] |

| Casting | 30.0 | 0.137 | Immersion | Hank’s | [45] |

| Extrusion | 34.0 | 0.134 | Immersion | Hank’s | [45] |

| Ball milling + Sintering | 18.0 | 2.710 | Electrochemical | Hank’s | [46] |

| Extrusion | 34.9 | 0.410 | Immersion | SBF | [47] |

| Sintering | 18.7 | 0.610 | Immersion | SBF | [47] |

| Sintering | 14.4 | 0.750 | Immersion | SBF | [47] |

| Spark Plasma Sintering | 43.9 | 0.073 | Immersion | Hank’s | [21] |

| Spark Plasma Sintering | 33.0 | 0.850 | Electrochemical | SBF | [22] |

| Extrusion | 45.6 | 0.13 | Electrochemical | SBF | [23] |

| Laser Melting System | 40.7 | 0.114 | Electrochemical | SBF | [48] |

| Sintering | 58.0 | 0.264 | Electrochemical | Hank’s | [49] |

| Spark Plasma Sintering | 47.4 | 0.105 | Electrochemical | SBF | [50] |

| Sintering | 47.3 | 0.191 | Electrochemical | SBF | [19] |

| Sintering | 43.7 | 0.085 | Electrochemical | Hank’s | [51] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carvalho, A.P.; Assunção, A.C.d.O.; Braga, J.d.O.; Lopes, D.R.; dos Santos, D.M.M.; Nunes, E.H.M.; Cotting, F.; Figueiredo, R.B. Consolidation of Zn-Hydroxyapatite and Zn-Bioactive Glass Composites Using High-Pressure Torsion. Crystals 2023, 13, 949. https://doi.org/10.3390/cryst13060949

Carvalho AP, Assunção ACdO, Braga JdO, Lopes DR, dos Santos DMM, Nunes EHM, Cotting F, Figueiredo RB. Consolidation of Zn-Hydroxyapatite and Zn-Bioactive Glass Composites Using High-Pressure Torsion. Crystals. 2023; 13(6):949. https://doi.org/10.3390/cryst13060949

Chicago/Turabian StyleCarvalho, Amanda P., Andressa C. de O. Assunção, Jorgimara de O. Braga, Débora R. Lopes, Diogo M. M. dos Santos, Eduardo Henrique M. Nunes, Fernando Cotting, and Roberto B. Figueiredo. 2023. "Consolidation of Zn-Hydroxyapatite and Zn-Bioactive Glass Composites Using High-Pressure Torsion" Crystals 13, no. 6: 949. https://doi.org/10.3390/cryst13060949

APA StyleCarvalho, A. P., Assunção, A. C. d. O., Braga, J. d. O., Lopes, D. R., dos Santos, D. M. M., Nunes, E. H. M., Cotting, F., & Figueiredo, R. B. (2023). Consolidation of Zn-Hydroxyapatite and Zn-Bioactive Glass Composites Using High-Pressure Torsion. Crystals, 13(6), 949. https://doi.org/10.3390/cryst13060949