Abstract

Perovskite cathodes have emerged as a promising alternative to traditional cathode materials in low-temperature solid oxide fuel cells (LT-SOFCs) due to their exceptional catalytic properties and high oxygen reduction reaction (ORR) activity. Their fast catalytic activity and chemical stability have drawn significant attention to lowering the operating temperature of SOFCs. In this study, Ba2+ and Bi3+ are doped into LaFeO3. The aim is to investigate the catalytic activity and electrochemical performance of LT-SOFCs. The presented cathode material is characterized in terms of phase structure, surface morphology, and interface studies before being applied as a cathode in SOFCs to measure electrochemical performance. The XPS study revealed that La1−2xBaxBixFeO3 (x = 0.1) exhibits enriched surface oxygen vacancies compared to La1−2xBaxBixFeO3 (x = 0.2). La1−2xBaxBixFeO3 with (x = 0.1 and 0.2) delivers a peak power density of 665 and 545 mW cm−2 at 550 °C, respectively. Moreover, impedance spectra confirmed that La1−2xBaxBixFeO3 with x = 0.1 exhibits lower electrode polarization resistance (0.33 Ω cm2) compared to La1−2xBaxBixFeO3 with x = 0.2 (0.57 Ω cm2) at 550 °C. Our findings thus confirm that LBBF cathode-based SOFCs can be considered a potential cathode to operate fuel cells at low temperatures, and it will open up another horizon in the subject of research.

1. Introduction

Solid oxide fuel cells (SOFCs) have received substantial attention in stationary power generation due to their high efficiency, fuel flexibility, and low emissions. SOFCs are made of solid materials, such as ceramic or metallic materials, that provide several advantages. For instance, the solid materials used in SOFCs allow for high-temperature operation, resulting in high thermal efficiency and low greenhouse gas emissions [1]. High operating temperatures hamper current SOFC development, as conventional SOFCs require 800–1200 °C to achieve sufficient ionic conductivity. Furthermore, the catalysts need high temperatures to maintain effective catalytic functionality [2,3]. Lowering the operating temperature of solid oxide fuel cells is beneficial in terms of material selection and choosing a low-cost interconnector favorable for device fabrication. However, electrochemical performance starts to decrease with decreasing operating temperatures. Consequently, the oxygen reduction reaction gets slower and causes electrical loss [4,5,6]. Sluggish catalytic activities hamper the performance of low-temperature solid oxide fuel cells (LT-SOFCs). While SOFCs operating at high temperatures endure plenty of challenges, they also create obstructions in their practical applications. Inadequate lifetime, complexities in device fabrication, and high operating temperatures further increase the challenges for SOFC commercialization [7,8,9]. Therefore, lowering the operating temperature is the utmost requirement for SOFCs. As a matter of fact, to improve electrochemical activities at low temperatures, it is essential to develop new cathode materials with fast ORR functionalities [10,11,12].

The cathode plays an imperative role in accelerating catalytic activities, which are directly associated with electrode polarization resistance. This is because the polarization resistance of the cathode contributes more to the total resistance of SOFCs [13]. Therefore, searching out new cathode materials with low polarization resistance and fast ORR kinetics is one of the foremost requirements for operating SOFCs at low temperatures [14]. Advanced techniques can improve the catalytic functionalities, including spray pyrolysis and pulsed laser deposition (PLD). These microstructural tailoring techniques have been used to improve the performance of SOFC cathodes. Both spray-pyrolysis and PLD have been shown to be effective in enhancing the performance of SOFC cathodes [15,16]. Ferrite-based cathode materials have shown significantly improved performance at an intermediate temperature compared to conventional manganite-based material such as (La0.75Sr0.25)0.95MnO3±δ (LSM) [17]. However, ferrite-based cathode materials, such as Sr-doped lanthanum ferrite (LSF) cathode, La0.25Pr0.25Sr0.5FeO3, (LPSF) (La0.8Sr0.2)0.98Fe0.98Cu0.02O3 (LSFC), Ba0.5Sr0.5Co0.8Fe0.2O3−δ (BSCF), Ln0.5Sr0.5Fe0.9Mo0.1O3–δ (LSFM), La0.7Ba0.3Co0.2Fe0.8O3−δ (LBBCF), Bi0.5Sr0.5Fe0.95P0.05O3−δ, (BSFP) Ca2Fe2O5 (CFO), and Pr0.5Sr0.5FeO3−δ (PSF) [13,18,19,20,21,22,23] cathode materials have shown significantly improved catalytic functionalities at intermediate temperatures, owing to their improved electrochemical performances at intermediate temperatures.

Bismuth oxides are known to exhibit high ionic conductivity for oxygen ions. This property makes them potentially useful as dopants in solid oxide fuel cells (SOFCs), where they can improve the transport of oxygen ions across the electrolyte and thus enhance the electrochemical performance of the cell. Hou, J. et al. have reported that bismuth-doped La0.74Bi0.1Sr0.16MnO3 (LBSM) has shown better performance than pure LSM, and the configured cell delivers 880 mW cm−2 with an OCV of 0.81 V at 650 °C. In addition, the cell exhibits low ohmic resistance [24]. Sarat, S. et al. found that only a two-mol% addition of Bi2O3 in scandia-stabilized zirconia (ScSZ) delivers a maximum conductivity of 0.18 S/cm at 600 °C [25]. Jung, D.W. et al. have reported 0.18 and 0.1 S/cm, respectively, at 600 and 500 °C in new co-doped bismuth oxide electrolyte compounds using dysprosium and gadolinium [26]. Bismuth also shows remarkable improvements in performance when forming a composite with other materials. The composite material La0.8Sr0.20MnO3−δ–Er0.4Bi0.6O3 displays a lower area-specific resistance (ASR) of 0.43 Ω cm2 at 600 °C [27]. These studies reveal that adding bismuth significantly improved the ionic conductivity and enhanced the catalytic performance of the electrode material. Additionally, barium-based cathode material at low temperatures (below 600 °C) has shown considerably less electrode polarization resistance with enhanced fuel cell performance. Ba0.5Sr0.5Co0.8Fe0.2O3−δ, BaCo0.8Fe0.2O3−δ, BaCo0.4Fe0.4Zr0.1Y0.1O3−δ, Pr2BaNiMnO7−δ, and Ba0.3Ca0.7Co0.8Fe0.2O3−δ [28,29,30,31,32] are some renown cathodes owing to their high catalytic kinetics at low temperatures.

Based on the previously reported literature in this work, Ba2+ and Bi3+ are chosen to be doped in La-ferrite. The reason for the selection of Ba2+ and Bi3+ is that barium reduces electrical resistance and bismuth improves conductivity and electrochemical properties, as reported by Yao, C. et al., and Li, L. et al. [33,34]. La1−2xBaxBixFeO3 (x = 0, 0.1, and 0.2) was prepared by using the sol-gel auto-combustion method. It is found that LBBF cathode-based fuel cells exhibit high power densities for La1−2xBaxBixFeO3 (x = 0.1 and 0.2) compared to La1−2xBaxBixFeO3 (x = 0) at 470–550 °C. After evaluating the power densities, the two compositions La1−2xBaxBixFeO3 (x = 0.1 and 0.2) were then characterized in terms of XRD for phase analysis, SEM for surface morphology, and XPS for analyzing surface properties, specifically oxygen vacancies. Furthermore, the LBBF cathode’s electrochemical performances were investigated for assessing ORR catalytic functionalities. The reason behind increasing the dopant concentration to (x = 0.2) was to form a composite phase and compare it with (x = 0.1). La1−2xBaxBixFeO3 (x = 0, 0.1, and 0.2) was then used as a cathode in LT-SOFC.

2. Experimental Section

2.1. Material Synthesis

La1−2xBaxBixFeO3 (x = 0.0, 0.1, and 0.2) was synthesized using the sol-gel auto-combustion method. Stoichiometric amounts of La(NO3)3 (Sigma-Aldrich, China, 99.9%), Ba(NO3)2 (Sigma 99.9%), Bi(NO3)3 (Sigma 99.9%), and Fe(NO₃)₃ (Sigma 99.9%) were dissolved in 300 mL of deionized water, followed by adding citric acid solution, which acts as a chelating agent. Keep the solution stirring at 90 °C. To control the pH of the solution, NH3 (Sigma 99.98%) was added dropwise until it touched pH 8, as NH3 is a weak base and can increase the pH of a solution when added to an acidic solution. NH3 reacts with water to form NH4+ and hydroxide ions. The hydroxide ions generated from this reaction can combine with hydrogen ions in the solution to form water, thus reducing the concentration of H+ in the solution and increasing the pH. After that, the solutions were stirred until they were converted into gel. In the next step, the precursors were dried at 140 °C for 24 h and then calcined at 900 °C for 5 h to obtain the LBBF (x = 0.1 and 0.2) powders. Sm0.2Ce0.8O2−δ (SDC), used as an electrolyte, was synthesized using the co-precipitation method according to the reported reference [35].

2.2. Fuel Cell Fabrication

SOFCs based on La1−2xBaxBixFeO3 (x = 0.1 and 0.2) cathodes were assembled by a dry pressing method. Ni0.8Co0.15Al0.05LiO2−δ (NCAL) was used as an anode and Sm0.2Ce0.8O2−δ as an electrolyte. Due to triple charge conduction (O2−/H+/e−), NCAL has reported an efficient symmetrical electrode material at low temperatures [36]. As a symmetrical electrode, NCAL exhibits superior catalytic functionalities for the hydrogen oxidation reaction (HOR) and oxygen reduction reaction (ORR) [37]. Ni-LBBF and Ni-NCAL were formed by pasting the slurry of LBBF and NCAL on Ni-foam. The slurry is formed by mixing the powder with terpineol. After pasting the NCAL slurry on Ni-foam, Ni-NCAL and Ni-LBBF were dried in the oven at 130 °C for 30 min. Using LBBF as a cathode material, SOFCs were fabricated by compacting the SDC powder between two pieces of Ni-LBBF and Ni-NCAL electrodes uniaxially with a pressure load of 250 MPa for 3 min. The obtained pellet, configured as Ni-NCAL/SDC/LBBF-Ni, has a 13 mm diameter and an apparent active area of 0.64 cm−2.

2.3. Characterization of Materials and Electrochemical Measurements

Crystalline structure analysis of the prepared materials was carried out by X-ray diffraction (XRD, Germany, Bruker Corporation) with Cu Kα (λ = 1.54060 Å) as the source over the 2θ range of 10–80°. Surface morphology and microstructure investigations were performed using a JSM7100F field emission scanning electron microscope. X-ray photoelectron spectroscopy (XPS, Thermo Scientific Escalab 250Xi) was used to investigate surface properties. LBBF-based cathode SOFC fuel cell performance was measured by the IT8511 electronic load. Electrochemical impedance spectroscopy (EIS) was performed by a Gamry Reference 3000 in fuel cell conditions. For measuring EIS, the frequency range was fixed from 0.1 Hz to 1 MHz with an amplitude of 10 mV. ZSimpWin (3.2) software was used to evaluate EIS data. H2 as fuel and air as oxidant were used with a flow rate of 110–130 mL min−1.

3. Results and Discussion

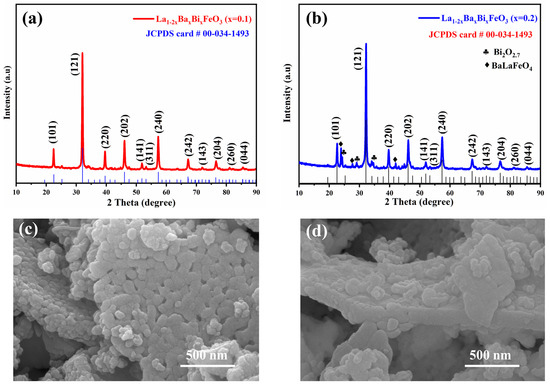

3.1. Crystalline Structure and Surface Morphology Analysis

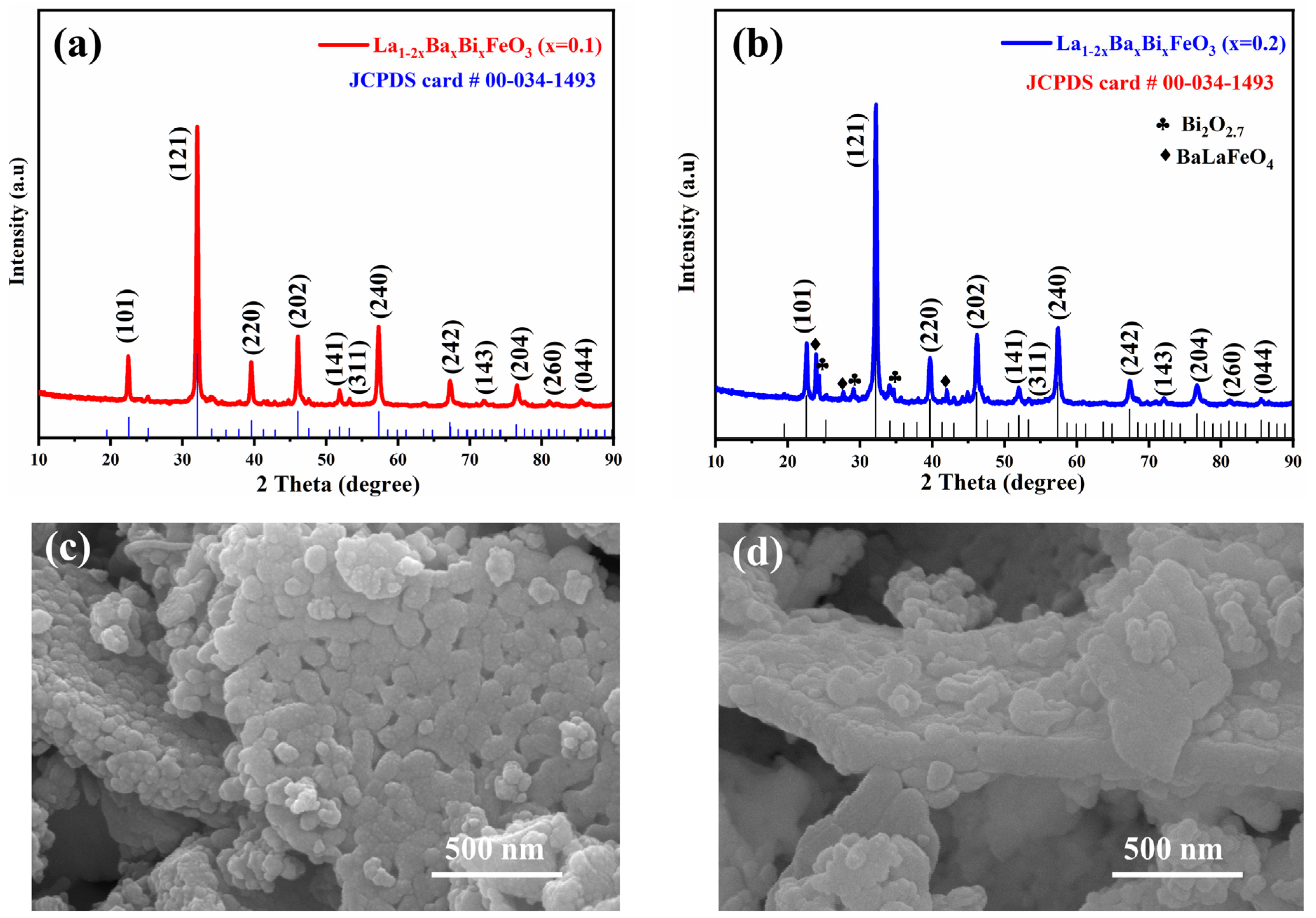

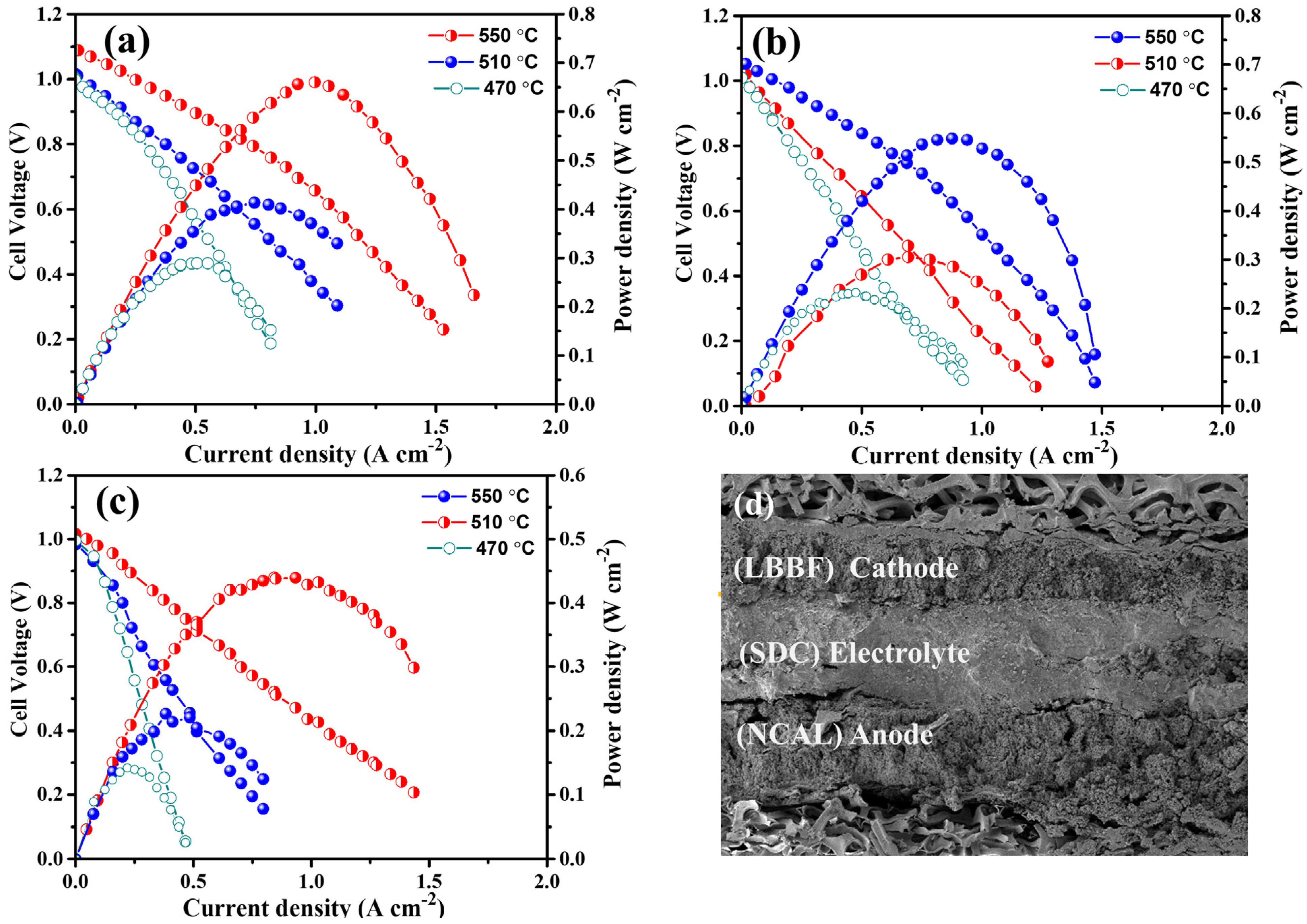

Figure 1a shows the XRD patterns of La1−2xBaxBixFeO3 with (x = 0.1 and 0.2). The XRD pattern of LBBF presented for both samples contains an orthorhombic crystal structure with pace group Pbnm and space group 62. The diffraction peaks are well indexed to JCPDS card # 00-034-1493. La1−2xBaxBixFeO3 (x = 0.1), as shown in Figure 1a, no extra phase appeared, indicating that Bi and Ba were completely doped in LaFeO3. Furthermore, additional peaks were detected in sample La1−2xBaxBixFeO3 (x = 0.2), as shown in Figure 1b. The extra peaks are from Bi2O2.7 and BaLaFeO4. The crystallite size of LBBF was calculated by using Debye-Scherer’s formula as shown in Equation (1).

Figure 1.

(a,b) X-ray diffraction (XRD) pattern of La1−2xBaxBixFeO3 (x = 0.1 and 0.2), showing the crystal structure and phase composition. (c,d) Scanning electron microscopy (SEM) micrograph of La1−2xBaxBixFeO3 (x = 0.1 and 0.2), showing the surface morphology and microstructure.

The average crystallite size of the La1−2xBaxBixFeO3 (x = 0.1) is calculated as 24 nm and La1−2xBaxBixFeO3 (x = 0.2) is calculated as 26 nm.

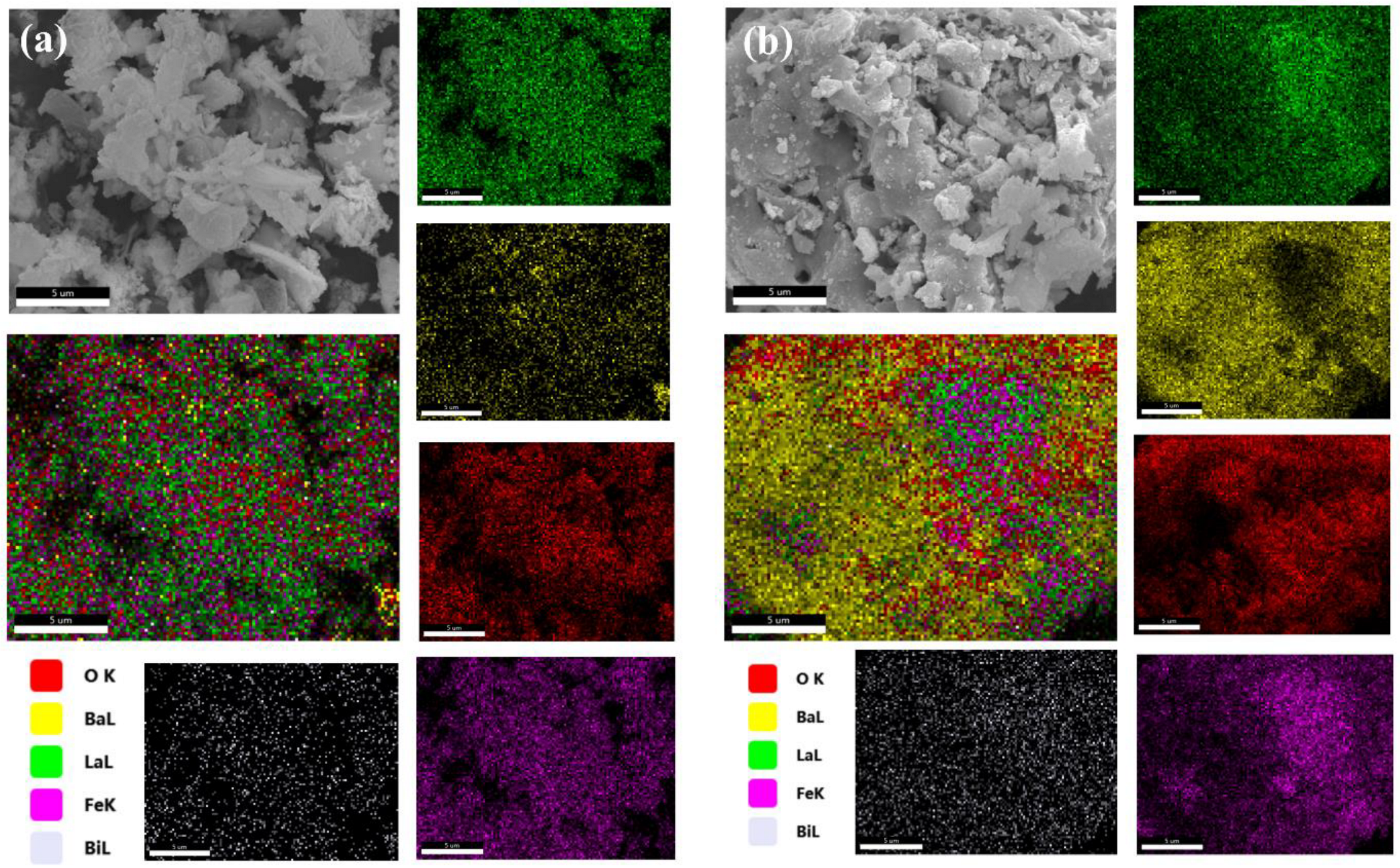

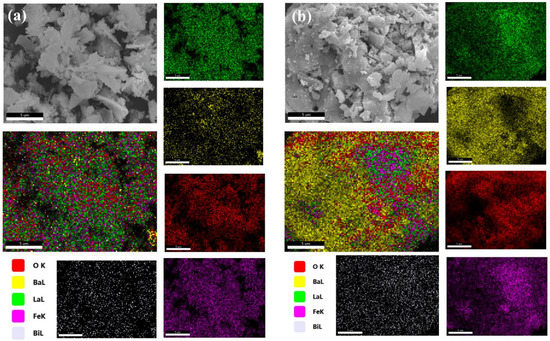

Figure 1c,d presents the surface morphology of the as-prepared La1−2xBaxBixFeO3 with x = 0.1 and La1−2xBaxBixFeO3 with x = 0.2 by scanning electron microscopy (SEM). LBBF (x = 0.1 and 0.2) exhibits irregular shapes with particle sizes varying from 30–60 nm calculated from Imaje-J software. From the SEM images, as shown in Figure 1c, LBBF (x = 0.1) exhibits comparatively less agglomeration than LBBF (x = 0.2). An even distribution of elements can be useful in determining the homogeneity of a sample as well as identifying the presence of certain elements that may be of interest [38]. To access element distribution, an energy-dispersive spectrometer (EDS) was used. Figure 2a,b provides the elemental distribution information for LBBF (x = 0.1 and 0.2) powders. Figure 2a shows an even distribution of elements of La, Ba, Bi, Fe, and O, whereas in Figure 2b, the distribution of these elements is not as even, especially for Fe and Ba. An equal distribution of elements in a cathode sample can improve its performance. In such an even distribution, the available surface area for the ORR increases, and more active sites are available for the reaction to occur. This can improve the overall catalytic activity of the cathode and increase the SOFC’s power density [39,40,41].

Figure 2.

Scanning electron microscope (SEM) micrographs and energy-dispersive X-ray spectroscopy (EDS) images of (a) La1−2xBaxBixFeO3 (x = 0.1) and (b) La1−2xBaxBixFeO3 (x = 0.2) cathode materials. The SEM images show the surface morphology and microstructure of the materials, while the EDS images provide elemental distribution.

3.2. XPS Analysis of the LBBF Cathode

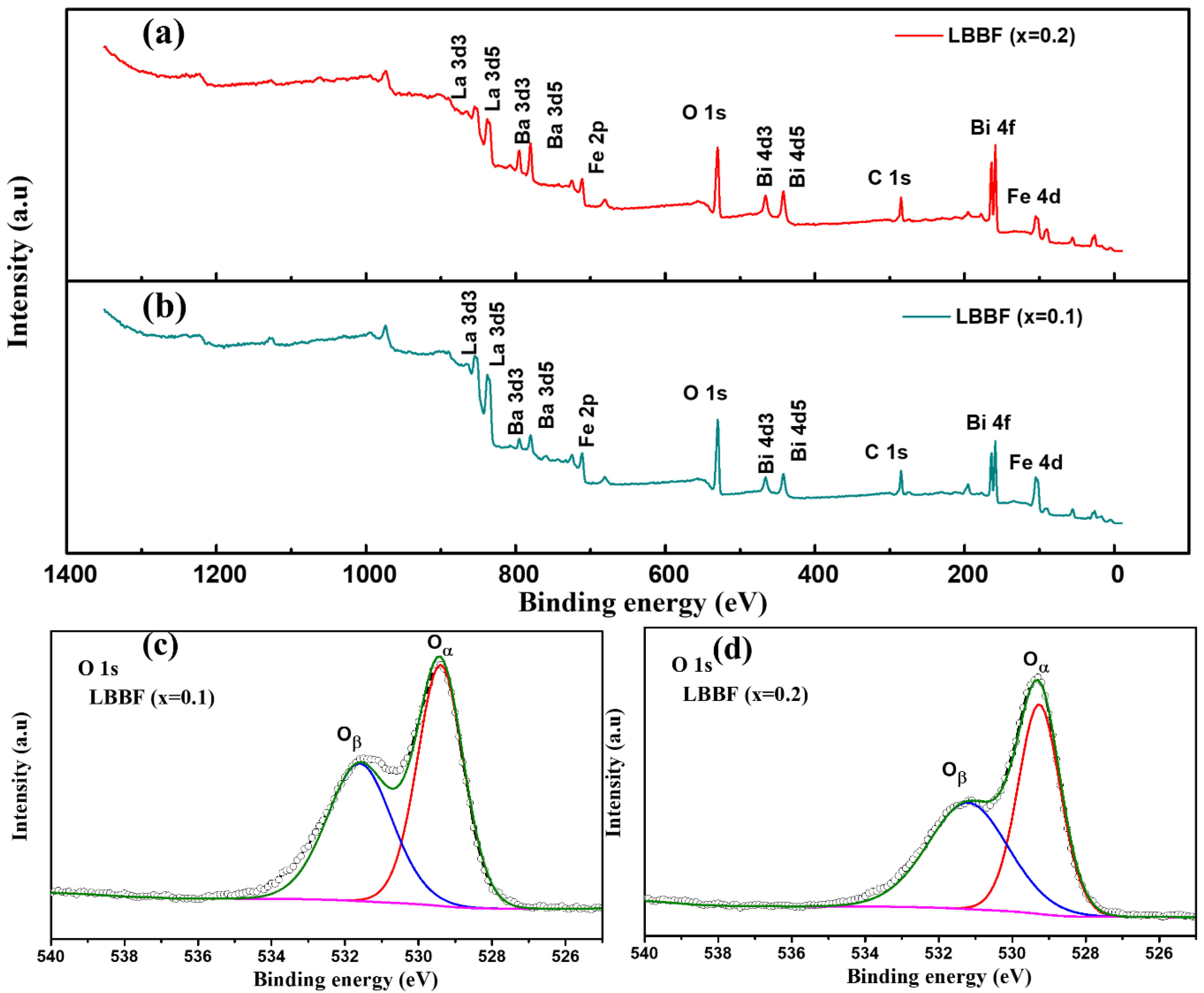

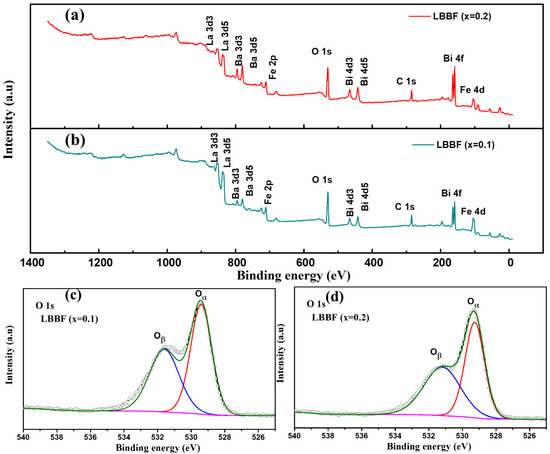

XPS was performed to further investigate La1−2xBaxBixFeO3 (x = 0.1 and 0.2) surface properties and oxygen vacancies. Figure 3a shows the survey spectra of LBBF (x = 0.1 and 0.2). The XPS spectra of LBBF show the characteristic peaks of La, Bi, Ba, Fe, C, and O. The distinct peaks indicate the presence of LBBF without any additional peaks. Furthermore, to identify the chemical state of oxygen (O1s), the spectra of both LBBF cathodes were deconvoluted by Gaussian functions and Shirley background. Figure 3b O1s spectra represent LBBF (x = 0.1), while Figure 3c O1s spectra represent LBBF (x = 0.2). The O1s spectra peaks are deconvoluted into lattice oxygen (Oα) and surface oxygen defects (Oβ). Deconvoluted peaks at a binding energy of 528–529 eV, referred to as lattice oxygen (Oα) spectra, while surface oxide defects (Oβ) peaks are at binding energy 530.5–531.5 eV [42,43]. Surface oxygen defects play a significant role in enhancing oxygen vacancies and subsequently facilitating fast catalytic functionalities. To compare the relative (Oβ), an atomic percentage of the deconvoluted peaks of the O1s spectra is calculated and analyzed in Thermo Avantage software. The relative atomic ratio of Oβ in LBBF (x = 0.1) is 7% higher than in LBBF (x = 0.2). The apparent increase in surface oxygen defects significantly improves oxygen vacancies. These vacancies create oxygen ion diffusion pathways, which can facilitate the oxygen reduction reaction at the cathode. The enriched surface oxygen vacancies promote fast ion mobility [44,45].

Figure 3.

(a,b) Illustration of the X-ray photoelectron spectroscopy (XPS) spectra of La1−2xBaxBixFeO3 (x = 0.1 and 0.2) for investigation of the surface properties of the samples. The O 1s spectra for each composition are also shown in (c,d) to further examine the oxygen-related species present in.

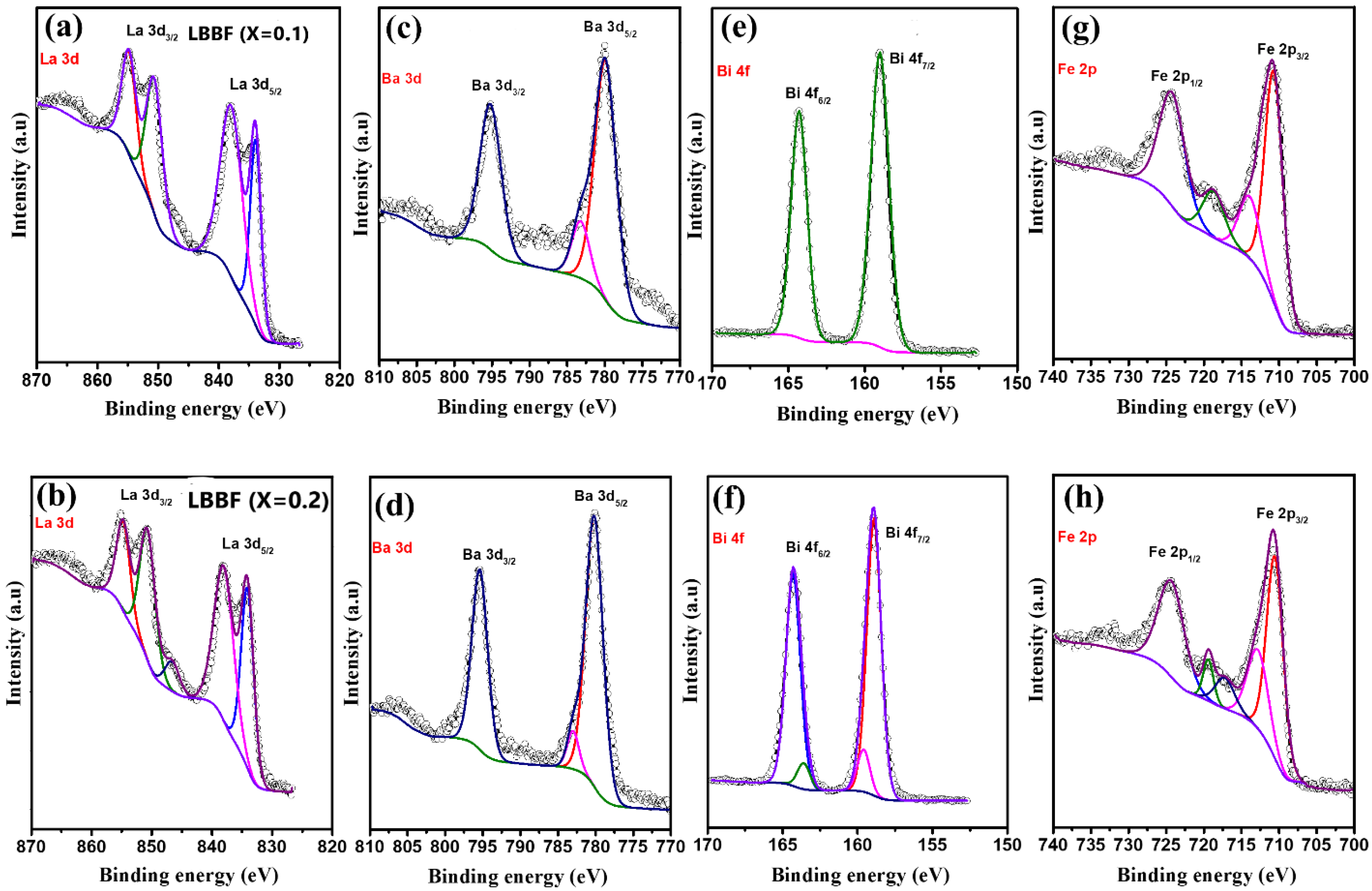

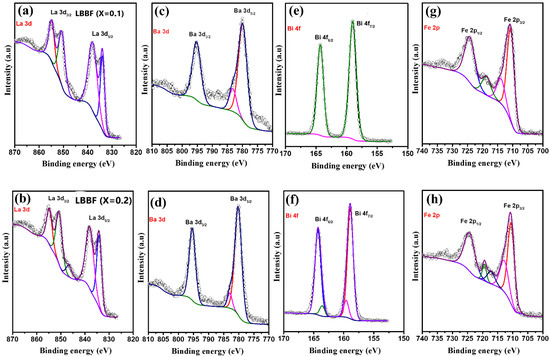

Furthermore, individual core-level spectra of La, Bi, Ba, and Fe are shown in Figure 4a–h. From the deconvoluted core-level spectra, it is found that La 3d5/2 peaks exhibit clear doublet structures at binding energies of 834 and 837 eV, while La 3d5/2 peaks arise at binding energies of 850 and 855 eV, as shown in Figure 4a,b. The obtained La 3d core-level spectra are well matched with the reported literature [46]. Ba core level spectra indicate that Ba is composed of Ba 3d3/2 and 3d5/2 peaks corresponding to binding energies of 779.8 and 795.1 eV. The presence of the pink band in the deconvolution of Ba 3d5/2 core level spectra is the appearance of an unknown peak, which is also reported in the literature [47,48]. The reported results for Ba 3d agree with previous results [49]. Bi 4f peaks are collected at binding energies of 149 eV and 164 eV. Two small satellite peaks appear for cathode LBBF (x = 0.2); however, these two peaks were not noticed in cathode LBBF (x = 0.1). The peaks are consistent with previous studies [50]. Figure 4g,f shows the Fe 2p core-level spectra. Fe 2p XPS core-level spectra excitation gives rise to a peak at 710.6 eV and 724.3 eV, including a shoulder and satellite peak as well. This finding for Fe 2p agrees with the previously reported result [51]. The following core-level spectra of La, Bi, Ba, and Fe presented in Figure 4 agree with previous literature depicting no chemical change occurring while the synthesis of LBBF material gives rise to any extra phase or impurities in both LBBF samples.

Figure 4.

XPS core-level spectra of La1−2xBaxBixFeO3 (x = 0.1) and (x = 0.2) showing (a,b) La 3d spectra, (c,d) Ba 3d spectra, (e,f) Bi 4f spectra, and (g,h) Fe 2p spectra.

3.3. Electrochemical Performances

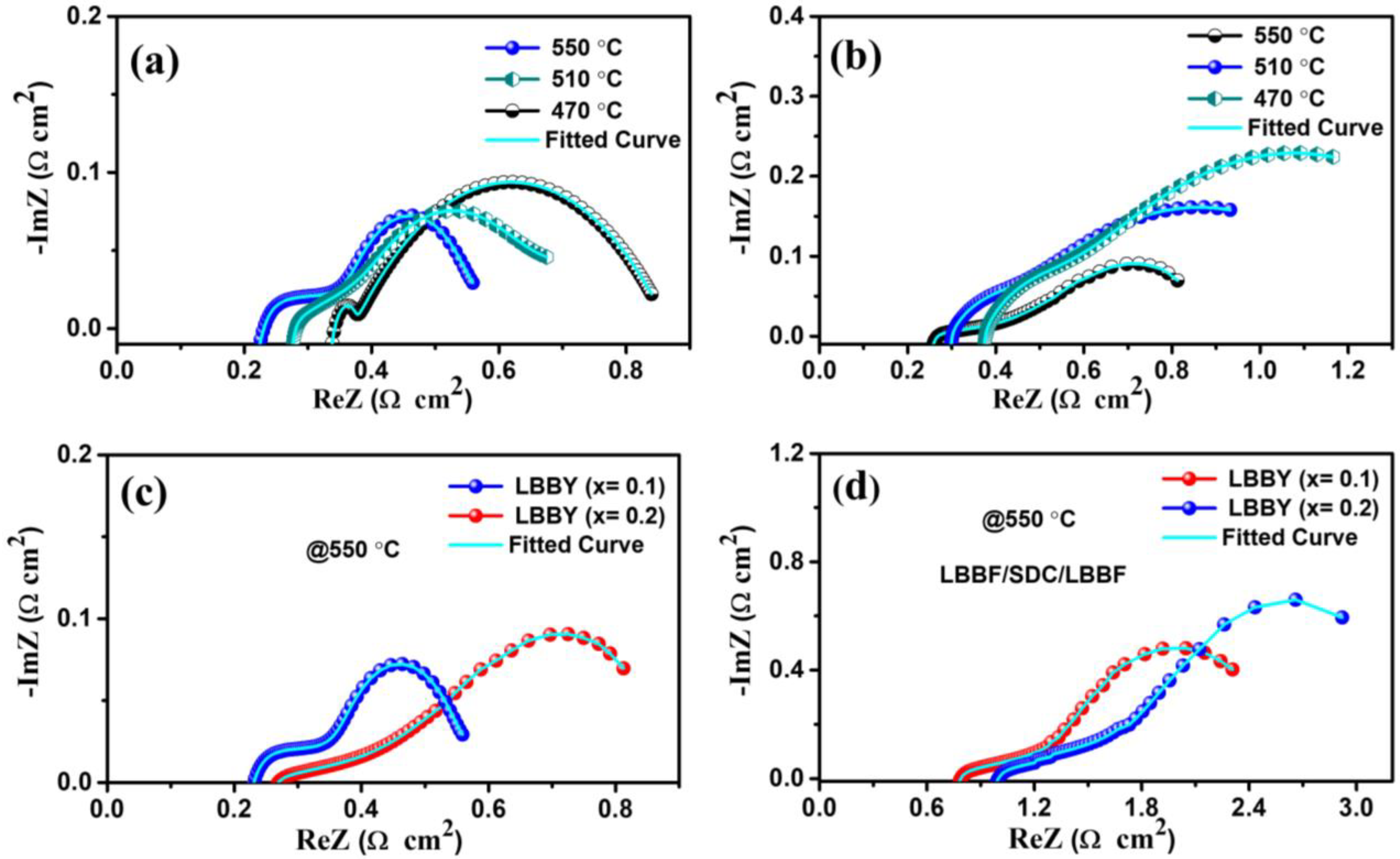

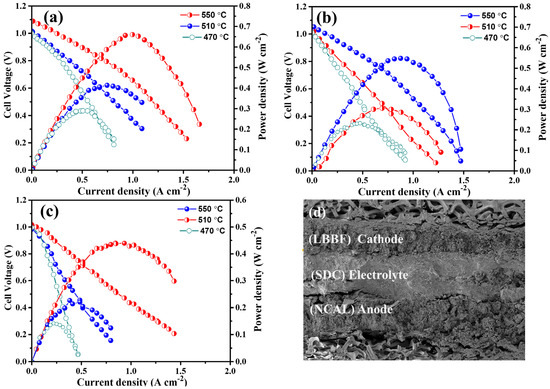

To evaluate the ORR functionality of the developed materials, three LBBF-based SOFCs were operated at low temperatures of 470–550 °C with Sm0.2C0.8O2−δ (SDC) as an electrolyte and Ni-NCAL as an anode. The configured Ni-NCAL/SDC/LBBF-Ni operated at temperature ranges from 470–550 °C in open circuit voltages (OCVs) and maximum power densities (Pmax). Figure 5a presents current-voltage and current-power characteristics measured for LBBF cathode-based SOFCs. Before fuel cell performance, the cell was preheated at 550 °C for 1.5 h for mechanical stability, followed by supplying hydrogen as a fuel and oxygen as an oxidant. Fuel cell performance was measured when the OCV got stable. LBBF-based SOFC (x = 0.1) delivers a peak power density of 665–286 mW cm−2 and an OCV of 1.1–1.00 V at 550–470 °C, respectively. It can be seen from Figure 5b that, on increasing the contents of Ba and Bi doping, the performance starts to decrease. LBBF cathode with x = 0.2 delivers an OCV of 1.054 V along with a peak power density of 548 mW cm−2 at 550 °C, which is almost 117 mW cm−2 less than LBBF (x = 0.1). From fuel cell performance, it is found that LBBF (x = 0.1) delivers a higher power output than the composite phase structure of LBBF. As shown in Figure 5c, La1−2xBaxBixFeO3 (x = 0) delivers a Pmax of 439 mW cm−2 along with an OCV of 1.01 V at 550 °C, which is almost 226 mW cm −2 less than from LBBF (x = 0.1). The enhancement in power density is more prominent when compared with La1−2xBaxBixFeO3 (x= 0.1 and 0.2). These results further verified that Bi and Ba additions prompt electrochemical performance at low operating temperatures. Our configured LBBF-based SOFC delivers higher performances at 550 °C compared to previous literature with pure SDC as an electrolyte as well as composite electrolytes with different anodes and cathodes reported in the literature [52,53,54,55,56]. The improved number of surface oxygen defects mentioned in XPS analysis, as shown in Figure 3, is one of the reasons for achieving high performance. Enriching oxygen vacancies improves electrochemical performance; as a result, ion mobility gets faster, substantially improving the fuel cell’s performance and ORR kinetics. These results can also manifest a substantial decrease in electrode polarization resistance, which we will evaluate and discuss in the EIS portion later. Furthermore, the cross-sectional SEM image of the best-performing SOFC device is presented in Figure 5d. From a cross-sectional view, the electrolyte is well compacted with the electrode, demonstrating better mechanical strength. Some cracks were found, as shown in the image, which occurred while scissoring the pellet for the cross-sectional image. Ni-foam is a highly porous material with a high volume of interconnected voids or pores that can facilitate gas transport and electrolyte infiltration in SOFCs. When the LBBF slurry is pasted on the Ni-foam, the porous structure of the Ni-foam allows the slurry to infiltrate into the pores and coat the surface, forming a highly porous electrode.

Figure 5.

(a) Fuel cell performance of La1−2xBaxBixFeO3 (x = 0.1) 550–470 °C; (b) fuel cell performance of La1−2xBaxBixFeO3 (x = 0.2) at 550–470 °C; (c) fuel cell performance La1−2xBaxBixFeO3 (x = 0.0); (d) cross-sectional SEM image of the configured SOFC device.

3.4. Electrochemical Impedance Spectra Analysis

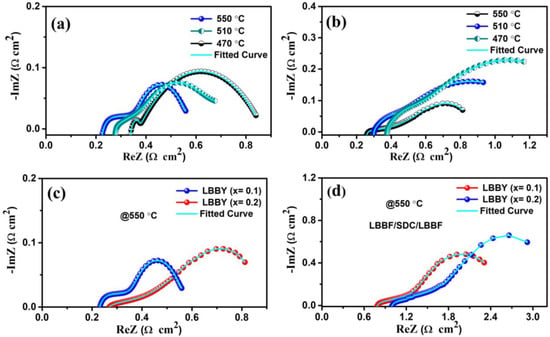

To investigate the electrochemical properties of LBBF-based SOFC, electrochemical impedance spectroscopy (EIS) was carried out. EIS Nyquist plots of La1−2xBaxBixFeO3 (x = 0.1 and 0.2) were measured in open circuit voltage (OCV) in a frequency domain from 0.01 MHz to 1 MHz with an applied 10 mV AC signal. Figure 6 shows the impedance spectra of Ni-NCAL/SDC/LBBF-Ni. An equivalent circuit of Ro (RctQct and RmtQmt) was applied for fitting the EIS data, in which Rct and Rmt represented the charge transfer and mass transfer resistances, respectively. At the same time, Q is the corresponding constant phase element (CPE), representing a non-ideal capacitor [57]. The corresponding characteristic capacitance (Ci) for each process is calculated by:

Figure 6.

(a) Electrochemical impedance spectroscopy (EIS) of La1−2xBaxBixFeO3 (x = 0.1) at 550–470 °C; (b) EIS of La1−2xBaxBixFeO3 (x = 0.2) at 550–470 °C; (c) comparison EIS of La1−2xBaxBixFeO3 x = 0.1 and 0.2 at 550 °C; (d) symmetrical EIS (Ni-LBBF/SDC/LBBF-Ni) of LBBF (x = 0.1) and LBBF (x = 0.2) at 550 °C in a reducing atmosphere.

The R1 and R2 resistance sums show the electrode polarization resistance of the cell. Less electrode resistance is a result of fast catalytic functionalities. Polarization resistance in a fabricated SOFC indicates the HOR and ORR catalytic kinetics, responsible for electrochemical performances [58]. EIS-simulated data from Figure 6 is presented in Table 1. It can be seen that LBBF with x = 0.1 delivers the least electrode polarization resistance of 0.33 Ω cm2, while LBBF with x = 0.2 exhibits 0.57 Ω cm2 at 550 °C. The least electrode polarization resistance of 0.33 Ω cm2 in LBBF (x = 0.1) infers a fast catalytic reaction in the as-fabricated LBBF cathode-based SOFC. As a result, the mobility of ions gets faster, which results in enhancements in catalytic functionalities. When the temperature decreases to 470 °C, the best-performing cell still exhibits the least electrode polarization of 0.57 Ω cm2, which shows fast catalytic activities and the well-computability and chemical stability of the LBBF cathode with the electrolyte and anode. The increment in electrode polarization resistance for LBBF with (x = 0.2) is mainly due to a decrease in surface oxygen vacancies coherent with the XPS analysis of O1s spectra as shown in Figure 3, where surface oxygen defects are comparatively less. The prepared LBBF-based SOFC delivers much less electrode polarization resistance as compared to the reported literature at low temperatures. The electrode polarization resistance of 0.33 Ω cm2 at 550 °C in LBBF portrays it as a potential cathode. Another reason for fast catalytic activities is the addition of barium and bismuth, which significantly improve the ionic/electronic conductivity and oxygen vacancies; as a result, electrode polarization resistance decreases. After all, on performing EIS of a symmetrical cell with cell configuration Ni-LBBF/SDC/LBBF-Ni, it is found that the best performing cell exhibits a low polarization resistance of 0.74 Ω cm2 at 550 °C, further certifying LBBF as a potential cathode at low operating temperatures. While LBBF (x = 0.2) delivers cathode polarization resistance of 0.94 Ω cm2 at 550 °C, which is comparatively higher than LBBF (x = 0.1).

Table 1.

The fitting parameters of La1−2xBaxBixFeO3 (x = 0.1 and 0.2) EIS based on the equivalent circuit models. R and Q have the units of Ω cm2 and S Secn cm−2, respectively. While capacitance has the unit of farads (F).

Future Outlook

This study has demonstrated promising electrochemical performance and enhanced ORR catalytic activities in the LBBF cathode. However, there are several areas where future research could build upon these findings, such as the long-term stability of the cathode material in fuel cell conditions, which needs to be evaluated. Secondly, a detailed study of microstructure using advanced characterization such as HR-TEM should be further investigated. Additionally, different electrolyte and anode materials should be optimized further to enhance the cathode material’s electrochemical performance and stability. Overall, the findings of this study have important implications for the development of high-performance cathodes for solid oxide fuel cells operated at low temperatures.

4. Conclusions

In summary, we have demonstrated La1−2xBaxBixFeO3 (x = 0.1 and 0.2) as a potential cathode at low operating temperatures (470–550 °C). X-ray diffraction (XRD) and scanning electron microscopy (SEM) confirm the phase structure and surface morphology. On performing X-ray photoelectron spectroscopy (XPS), we have found that La1−2xBaxBixFeO3 (x = 0.1) shows a noticeable 7% higher increment of surface oxygen defects in La1−2xBaxBixFeO3 (x = 0.1) compared to La1−2xBaxBixFeO3 (x = 0.2), portraying enhanced oxygen vacancies and subsequently improved ORR functionalities of the LBBF cathode. La1−2xBaxBixFeO3 with (x = 0.1 and 0.2) delivers a peak power density of 665 and 545 mW cm−2 at 550 °C, respectively. Both compositions deliver an open circuit voltage (OCV) > 1 V, depicting them as high-performing electrodes when operating the SOFC at low temperatures. The results of EIS showed that both La1−2xBaxBixFeO3 (x = 0.1 and 0.2) compositions exhibited low electrode polarization resistance of 0.33 Ω.cm2 and 0.57 Ω.cm2 at 550 °C. This low resistance value suggests that the LBBF cathode has fast oxygen reduction reaction (ORR) catalytic activities, which are desirable for efficient SOFC performance. Our study thus authenticates that La1−2xBaxBixFeO3 can be an alternative high-performing cathode with fast ORR functionalities at low operating temperatures.

Author Contributions

Conceptualization, N.S., Z.C. and L.L.; methodology, Y.N., T.S. and M.Y.; software, T.S.; formal analysis, M.Y.; writing—original draft, N.S.; writing—review and editing, N.S., Z.C., Y.L. and L.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the National Natural Science Foundation of the People’s Republic of China (Grant No. U2006224), the Guagxi Natural Science Foundation, China (No. 2022GXNSFFA035035), and the Natural Science Foundation of Jiangsu Higher Education Institutions of China (Grant No. 119KJD420002).

Data Availability Statement

The data that support the findings of this study are available within this article.

Acknowledgments

The authors would like to acknowledge all those mentioned above for their invaluable contributions. We would also like to acknowledge the financial support provided by National Natural Science Foundation of the People’s Republic of China (Grant No. U2006224), the Guagxi Natural Science Foundation, China (No. 2022GXNSFFA035035), and the Natural Science Foundation of Jiangsu Higher Education Institutions of China (Grant No. 119KJD420002).

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal influences reported in this paper.

References

- Peng, J.; Huang, J.; Wu, X.; Xu, Y.; Chen, H.; Li, X. Solid Oxide Fuel Cell (SOFC) Performance Evaluation, Fault Diagnosis and Health Control: A Review. J. Power Sources 2021, 505, 230058. [Google Scholar] [CrossRef]

- Al-Khori, K.; Bicer, Y.; Koc, M. Integration of Solid Oxide Fuel Cells into Oil and Gas Operations: Needs, Opportunities, and Challenges. J. Clean. Prod. 2020, 245, 118924. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Yan, M. A Review on the Preparation of Thin-Film YSZ Electrolyte of SOFCs by Magnetron Sputtering Technology. Sep. Purif. Technol. 2022, 298, 121627. [Google Scholar] [CrossRef]

- Duan, C.; Hook, D.; Chen, Y.; Tong, J.; O’Hayre, R. Zr and Y Co-Doped Perovskite as a Stable, High Performance Cathode for Solid Oxide Fuel Cells Operating below 500 C. Energy Environ. Sci. 2017, 10, 176–182. [Google Scholar] [CrossRef]

- Rehman, A.U.; Li, M.; Knibbe, R.; Khan, M.S.; Peterson, V.K.; Brand, H.E.A.; Li, Z.; Zhou, W.; Zhu, Z. Enhancing Oxygen Reduction Reaction Activity and CO2 Tolerance of Cathode for Low-Temperature Solid Oxide Fuel Cells by in Situ Formation of Carbonates. ACS Appl. Mater. Interfaces 2019, 11, 26909–26919. [Google Scholar] [CrossRef]

- Fleig, J. Solid Oxide Fuel Cell Cathodes: Polarization Mechanisms and Modeling of the Electrochemical Performance. Annu. Rev. Mater. Res. 2003, 33, 361–382. [Google Scholar] [CrossRef]

- Ioannidou, E.; Neofytidis, C.; Sygellou, L.; Niakolas, D.K. Au-Doped Ni/GDC as an Improved Cathode Electrocatalyst for H2O Electrolysis in SOECs. Appl. Catal. B Environ. 2018, 236, 253–264. [Google Scholar] [CrossRef]

- Aliotta, C.; Liotta, L.; Deganello, F.; La Parola, V.; Martorana, A. Direct Methane Oxidation as Potential Anode for Intermediate Temperature Solid Oxide Fuel Cells. Appl. Catal. B Environ. 2016, 180, 424–433. [Google Scholar] [CrossRef]

- Chiara, A.; Giannici, F.; Pipitone, C.; Longo, A.; Aliotta, C.; Gambino, M.; Martorana, A. Solid–Solid Interfaces in Protonic Ceramic Devices: A Critical Review. ACS Appl. Mater. Interfaces 2020, 12, 55537–55553. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Belotti, A.; Ciucci, F. P-Substituted Ba0. 95La0. 05FeO3− δ as a Cathode Material for SOFCs. ACS Appl. Energy Mater. 2019, 2, 5472–5480. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, W.; Ding, D.; Liu, M.; Ciucci, F.; Tade, M.; Shao, Z. Advances in Cathode Materials for Solid Oxide Fuel Cells: Complex Oxides without Alkaline Earth Metal Elements. Adv. Energy Mater. 2015, 5, 1500537. [Google Scholar] [CrossRef]

- Jun, A.; Kim, J.; Shin, J.; Kim, G. Perovskite as a Cathode Material: A Review of Its Role in Solid-oxide Fuel Cell Technology. ChemElectroChem 2016, 3, 511–530. [Google Scholar]

- Wu, M.; Cai, H.; Jin, F.; Sun, N.; Xu, J.; Zhang, L.; Han, X.; Wang, S.; Su, X.; Long, W. Assessment of Cobalt–Free Ferrite–Based Perovskite Ln0.5Sr0. 5Fe0.9Mo0.1O3–δ (Ln= Lanthanide) as Cathodes for IT-SOFCs. J. Eur. Ceram. Soc. 2021, 41, 2682–2690. [Google Scholar] [CrossRef]

- Li, M.; Wang, Y.; Wang, Y.; Chen, F.; Xia, C. Bismuth Doped Lanthanum Ferrite Perovskites as Novel Cathodes for Intermediate-Temperature Solid Oxide Fuel Cells. ACS Appl. Mater. Interfaces 2014, 6, 11286–11294. [Google Scholar] [CrossRef] [PubMed]

- dos Santos-Gómez, L.; Zamudio-García, J.; Porras-Vázquez, J.M.; Losilla, E.R.; Marrero-López, D. Recent Progress in Nanostructured Electrodes for Solid Oxide Fuel Cells Deposited by Spray Pyrolysis. J. Power Sources 2021, 507, 230277. [Google Scholar] [CrossRef]

- Xu, M.; Yu, J.; Song, Y.; Ran, R.; Wang, W.; Shao, Z. Advances in Ceramic Thin Films Fabricated by Pulsed Laser Deposition for Intermediate-Temperature Solid Oxide Fuel Cells. Energy Fuels 2020, 34, 10568–10582. [Google Scholar] [CrossRef]

- Ralph, J.M.; Rossignol, C.; Kumar, R. Cathode Materials for Reduced-Temperature SOFCs. J. Electrochem. Soc. 2003, 150, A1518. [Google Scholar] [CrossRef]

- Lee, S.J.; Yong, S.-M.; Kim, D.S.; Kim, D.K. Cobalt-Free Composite Cathode for SOFCs: Brownmillerite-Type Calcium Ferrite and Gadolinium-Doped Ceria. Int. J. Hydrog. Energy 2012, 37, 17217–17224. [Google Scholar] [CrossRef]

- Gao, J.; Li, Q.; Zhang, Z.; Lü, Z.; Wei, B. A Cobalt-Free Bismuth Ferrite-Based Cathode for Intermediate Temperature Solid Oxide Fuel Cells. Electrochem. Commun. 2021, 125, 106978. [Google Scholar] [CrossRef]

- Kim, Y.-M.; Kim-Lohsoontorn, P.; Bae, J. Effect of Unsintered Gadolinium-Doped Ceria Buffer Layer on Performance of Metal-Supported Solid Oxide Fuel Cells Using Unsintered Barium Strontium Cobalt Ferrite Cathode. J. Power Sources 2010, 195, 6420–6427. [Google Scholar] [CrossRef]

- Simner, S.; Anderson, M.; Bonnett, J.; Stevenson, J. Enhanced Low Temperature Sintering of (Sr, Cu)-Doped Lanthanum Ferrite SOFC Cathodes. Solid State Ionics 2004, 175, 79–81. [Google Scholar] [CrossRef]

- Wang, W.G.; Mogensen, M. High-Performance Lanthanum-Ferrite-Based Cathode for SOFC. Solid State Ionics 2005, 176, 457–462. [Google Scholar] [CrossRef]

- Ma, J.; Tao, Z.; Kou, H.; Fronzi, M.; Bi, L. Evaluating the Effect of Pr-Doping on the Performance of Strontium-Doped Lanthanum Ferrite Cathodes for Protonic SOFCs. Ceram. Int. 2020, 46, 4000–4005. [Google Scholar] [CrossRef]

- Hou, J.; Bi, L.; Qian, J.; Zhu, Z.; Zhang, J.; Liu, W. High Performance Ceria–Bismuth Bilayer Electrolyte Low Temperature Solid Oxide Fuel Cells (LT-SOFCs) Fabricated by Combining Co-Pressing with Drop-Coating. J. Mater. Chem. A 2015, 3, 10219–10224. [Google Scholar] [CrossRef]

- Sarat, S.; Sammes, N.; Smirnova, A. Bismuth Oxide Doped Scandia-Stabilized Zirconia Electrolyte for the Intermediate Temperature Solid Oxide Fuel Cells. J. Power Sources 2006, 160, 892–896. [Google Scholar] [CrossRef]

- Jung, D.W.; Lee, K.T.; Wachsman, E.D. Dysprosium and Gadolinium Double Doped Bismuth Oxide Electrolytes for Low Temperature Solid Oxide Fuel Cells. J. Electrochem. Soc. 2016, 163, F411. [Google Scholar] [CrossRef]

- Lee, K.T.; Jung, D.W.; Yoon, H.S.; Lidie, A.A.; Camaratta, M.A.; Wachsman, E.D. Interfacial Modification of La0.80Sr0.20MnO3−δ–Er0.4Bi0.63 Cathodes for High Performance Lower Temperature Solid Oxide Fuel Cells. J. Power Sources 2012, 220, 324–330. [Google Scholar] [CrossRef]

- Afzal, M.; Raza, R.; Du, S.; Lima, R.B.; Zhu, B. Synthesis of Ba0.3Ca0.7Co0.8Fe0.2O3-δ Composite Material as Novel Catalytic Cathode for Ceria-Carbonate Electrolyte Fuel Cells. Electrochim. Acta 2015, 178, 385–391. [Google Scholar] [CrossRef]

- Wang, Q.; Hou, J.; Fan, Y.; Xi, X.; Li, J.; Lu, Y.; Huo, G.; Shao, L.; Fu, X.-Z.; Luo, J.-L. Pr 2 BaNiMnO 7− δ Double-Layered Ruddlesden–Popper Perovskite Oxides as Efficient Cathode Electrocatalysts for Low Temperature Proton Conducting Solid Oxide Fuel Cells. J. Mater. Chem. A 2020, 8, 7704–7712. [Google Scholar] [CrossRef]

- Qi, H.; Zhao, Z.; Tu, B.; Cheng, M. Reaction Tuned Formation of Hierarchical BaCo0.4Fe0.4Zr0.1Y0.1O3-δ Cathode. J. Power Sources 2020, 455, 227971. [Google Scholar] [CrossRef]

- Yan, A.; Yang, M.; Hou, Z.; Dong, Y.; Cheng, M. Investigation of Ba1−XSrxCo0.8Fe0. 2O3−δ as Cathodes for Low-Temperature Solid Oxide Fuel Cells Both in the Absence and Presence of CO2. J. Power Sources 2008, 185, 76–84. [Google Scholar] [CrossRef]

- Kumar, R.V.; Khandale, A.P. A Review on Recent Progress and Selection of Cobalt-Based Cathode Materials for Low Temperature-Solid Oxide Fuel Cells. Renew. Sustain. Energy Rev. 2022, 156, 111985. [Google Scholar] [CrossRef]

- Li, L.; Qin, H.; Shi, C.; Zhang, L.; Chen, Y.; Hu, J. CO 2 Sensing Properties of La1−xBaxFeO3 Thick Film and Packed Powder Sensors. RSC Adv. 2015, 5, 103073–103081. [Google Scholar] [CrossRef]

- Yao, C.; Meng, J.; Liu, X.; Zhang, X.; Meng, F.; Wu, X.; Meng, J. Effects of Bi Doping on the Microstructure, Electrical and Electrochemical Properties of La2-XBixCu0.5Mn1.5O6 (X= 0, 0.1 and 0.2) Perovskites as Novel Cathodes for Solid Oxide Fuel Cells. Electrochim. Acta 2017, 229, 429–437. [Google Scholar] [CrossRef]

- Cai, Y.; Chen, Y.; Akbar, M.; Jin, B.; Tu, Z.; Mushtaq, N.; Wang, B.; Qu, X.; Xia, C.; Huang, Y. A Bulk-Heterostructure Nanocomposite Electrolyte of Ce0.8Sm0.2O2-δ–SrTiO3 for Low-Temperature Solid Oxide Fuel Cells. Nano-Micro Lett. 2021, 13, 46. [Google Scholar] [CrossRef]

- Lin, B.; Chen, J.; Ling, Y.; Zhang, X.; Jiang, Y.; Zhao, L.; Liu, X.; Meng, G. Low-Temperature Solid Oxide Fuel Cells with Novel La0. 6Sr0. 4Co0. 8Cu0. 2O3− δ Perovskite Cathode and Functional Graded Anode. J. Power Sources 2010, 195, 1624–1629. [Google Scholar] [CrossRef]

- Lu, Y.; Akbar, M.; Xia, C.; Mi, Y.; Ma, L.; Wang, B.; Zhu, B. Catalytic Membrane with High Ion–Electron Conduction Made of Strongly Correlated Perovskite LaNiO3 and Ce0.8Sm0.2O2-δfor Fuel Cells. J. Catal. 2020, 386, 117–125. [Google Scholar] [CrossRef]

- Akbar, M.; Qu, G.; Yang, W.; Gao, J.; Yousaf, M.; Mushtaq, N.; Wang, X.; Dong, W.; Wang, B.; Xia, C. Fast Ionic Conduction and Rectification Effect of NaCo0.5Fe0.5O2-CeO2 Nanoscale Heterostructure for LT-SOFC Electrolyte Application. J. Alloys Compd. 2022, 924, 166565. [Google Scholar] [CrossRef]

- Marinha, D.; Hayd, J.; Dessemond, L.; Ivers-Tiffée, E.; Djurado, E. Performance of (La, Sr)(Co, Fe) O3−x Double-Layer Cathode Films for Intermediate Temperature Solid Oxide Fuel Cell. J. Power Sources 2011, 196, 5084–5090. [Google Scholar] [CrossRef]

- Xiong, C.; Taillon, J.A.; Pellegrinelli, C.; Huang, Y.-L.; Salamanca-Riba, L.G.; Chi, B.; Jian, L.; Pu, J.; Wachsman, E.D. Long-Term Cr Poisoning Effect on LSCF-GDC Composite Cathodes Sintered at Different Temperatures. J. Electrochem. Soc. 2016, 163, F1091. [Google Scholar] [CrossRef]

- Ding, D.; Li, X.; Lai, S.Y.; Gerdes, K.; Liu, M. Enhancing SOFC Cathode Performance by Surface Modification through Infiltration. Energy Environ. Sci. 2014, 7, 552–575. [Google Scholar] [CrossRef]

- Tekale, S.U.; Pagore, V.P.; Kauthale, S.S.; Pawar, R.P. La2O3/TFE: An Efficient System for Room Temperature Synthesis of Hantzsch Polyhydroquinolines. Chinese Chem. Lett. 2014, 25, 1149–1152. [Google Scholar] [CrossRef]

- Akbar, M.; Jin, B.; Tu, Z.; Gao, J.; Yousaf, M.; Mushtaq, N.; Wang, X.; Dong, W.; Wang, B.; Cai, Y. High-Performing and Stable Non-Doped Ceria Electrolyte with Amorphous Carbonate Coating Layer for Low-Temperature Solid Oxide Fuel Cells. Electrochim. Acta 2021, 393, 139067. [Google Scholar] [CrossRef]

- Yousaf, M.; Akbar, M.; Shah, M.A.K.Y.; Noor, A.; Lu, Y.; Akhtar, M.N.; Mushtaq, N.; Hu, E.; Yan, S.; Zhu, B. Enhanced ORR Catalytic Activity of Rare Earth-Doped Gd Oxide Ions in a CoFe2O4 Cathode for Low-Temperature Solid Oxide Fuel Cells (LT-SOFCs). Ceram. Int. 2022, 48, 28142–28153. [Google Scholar] [CrossRef]

- Tu, Z.; Tian, Y.; Liu, M.; Jin, B.; Akbar, M.; Mushtaq, N.; Wang, X.; Dong, W.; Wang, B.; Xia, C. Remarkable Ionic Conductivity in a LZO-SDC Composite for Low-Temperature Solid Oxide Fuel Cells. Nanomaterials 2021, 11, 2277. [Google Scholar] [CrossRef]

- Khaled, A.; Pireaux, J.-J.; Khelili, S. Synthesis and Characterization of Ca and Ba Doped LAMOX Materials and Surface Study by X-Ray Photoelectron Spectroscopy. Acta Chim. Slov 2012, 59, 766–778. [Google Scholar]

- Craciun, V.; Singh, R.K. Characteristics of the Surface Layer of Barium Strontium Titanate Thin Films Deposited by Laser Ablation. Appl. Phys. Lett. 2000, 76, 1932–1934. [Google Scholar] [CrossRef]

- Rioult, M. Hematite-Based Epitaxial Thin Films as Photoanodes for Solar Water Splitting. Theses. Hal. Sci. 2015, 3709, 2240. [Google Scholar]

- Zhang, W.H.; Chen, L.; Tao, Y.T.; Chen, J.; Zhang, J.X. Raman Study of Barium Titanate with Oxygen Vacancies. Phys. B Condens. Matter 2011, 406, 4630–4633. [Google Scholar] [CrossRef]

- Felhi, H.; Smari, M.; Bajorek, A.; Nouri, K.; Dhahri, E.; Bessais, L. Controllable Synthesis, XPS Investigation and Magnetic Property of Multiferroic BiMn2O5 System: The Role of Neodyme Doping. Prog. Nat. Sci. Mater. Int. 2019, 29, 198–209. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, Q.; He, Q.; He, T. Double-Perovskites A2FeMoO6−δ (A = Ca, Sr, Ba) as Anodes for Solid Oxide Fuel Cells. J. Power Sources 2010, 195, 6356–6366. [Google Scholar] [CrossRef]

- Ji, Y.; Liu, J.; He, T.; Wang, J.; Su, W. The Effect of Pr Co-Dopant on the Performance of Solid Oxide Fuel Cells with Sm-Doped Ceria Electrolyte. J. Alloys Compd. 2005, 389, 317–322. [Google Scholar] [CrossRef]

- Liu, M.; Ding, D.; Bai, Y.; He, T.; Liu, M. An Efficient SOFC Based on Samaria-Doped Ceria (SDC) Electrolyte. J. Electrochem. Soc. 2012, 159, B661. [Google Scholar] [CrossRef]

- Saebea, D.; Authayanun, S.; Patcharavorachot, Y.; Chatrattanawet, N.; Arpornwichanop, A. Electrochemical Performance Assessment of Low-Temperature Solid Oxide Fuel Cell with YSZ-Based and SDC-Based Electrolytes. Int. J. Hydrogen Energy 2018, 43, 921–931. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, X.; Nikumb, S.; Decès-Petit, C.; Hui, R.; Maric, R.; Ghosh, D. Low Temperature Solid Oxide Fuel Cells with Pulsed Laser Deposited Bi-Layer Electrolyte. J. Power Sources 2007, 164, 182–188. [Google Scholar] [CrossRef]

- Xia, C.; Chen, F.; Liu, M. Reduced-Temperature Solid Oxide Fuel Cells Fabricated by Screen Printing. Electrochem. Solid-State Lett. 2001, 4, A52. [Google Scholar] [CrossRef]

- Akbar, M.; Tu, Z.; Jin, B.; Mushtaq, N.; He, Z.; Dong, W.; Wang, B.; Wang, X.; Xia, C. Demonstrating the Dual Functionalities of CeO2–CuO Composites in Solid Oxide Fuel Cells. Int. J. Hydrogen Energy 2021, 46, 9938–9947. [Google Scholar] [CrossRef]

- Dai, H.; Da’as, E.H.; Shafi, S.P.; Wang, H.; Bi, L. Tailoring Cathode Composite Boosts the Performance of Proton-Conducting SOFCs Fabricated by a One-Step Co-Firing Method. J. Eur. Ceram. Soc. 2018, 38, 2903–2908. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).