Unveiling the Transporting Mechanism of (Ti0.2Zr0.2Nb0.2Hf0.2Ta0.2)C at Room Temperature

Abstract

1. Introduction

2. Experimental and Theoretical Methods

2.1. Materials Synthesized

2.2. Properties Characterization

2.3. Density Function Theory Calculations

3. Results and Discussion

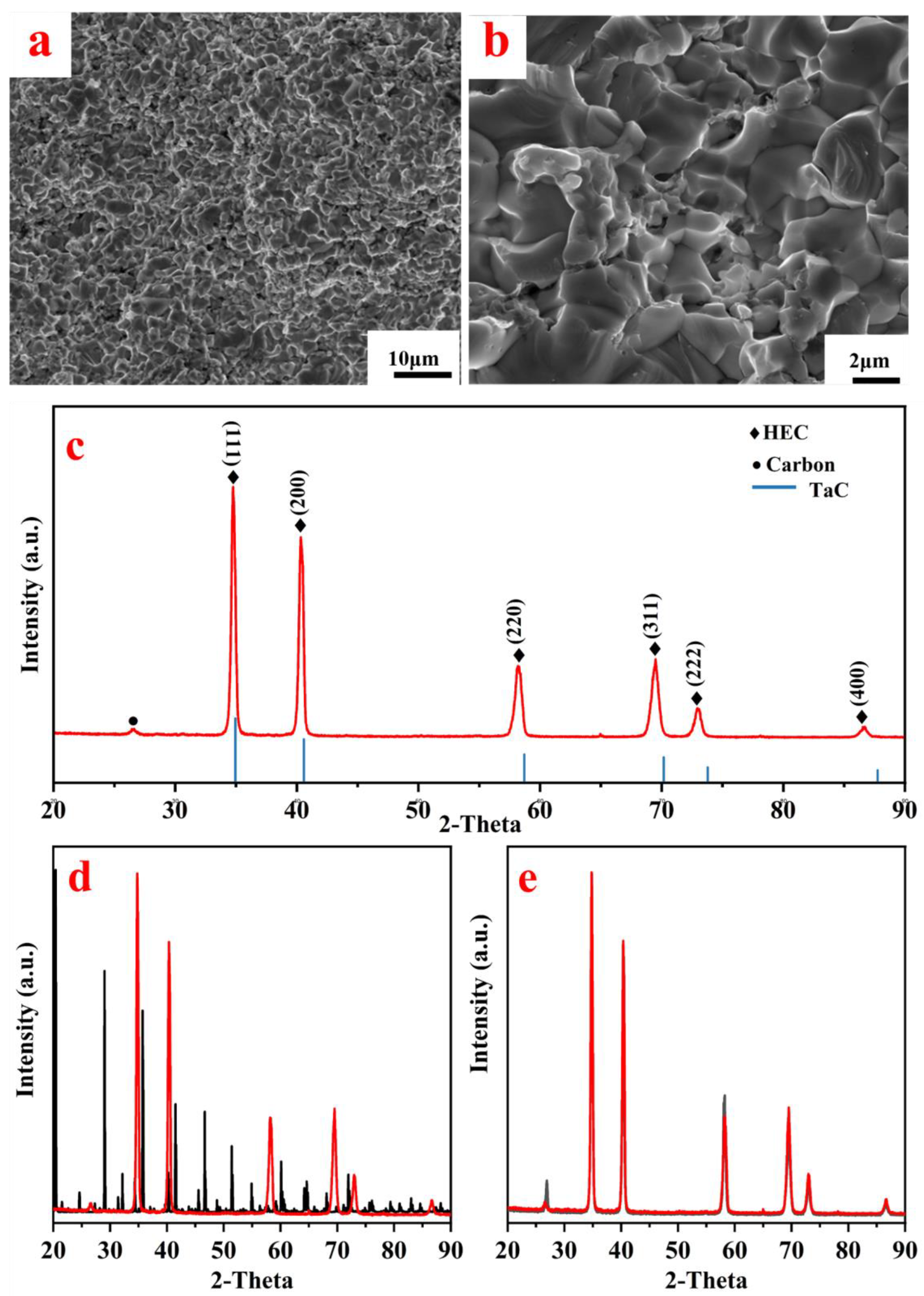

3.1. Crystal Structure and Morphology Characteristic

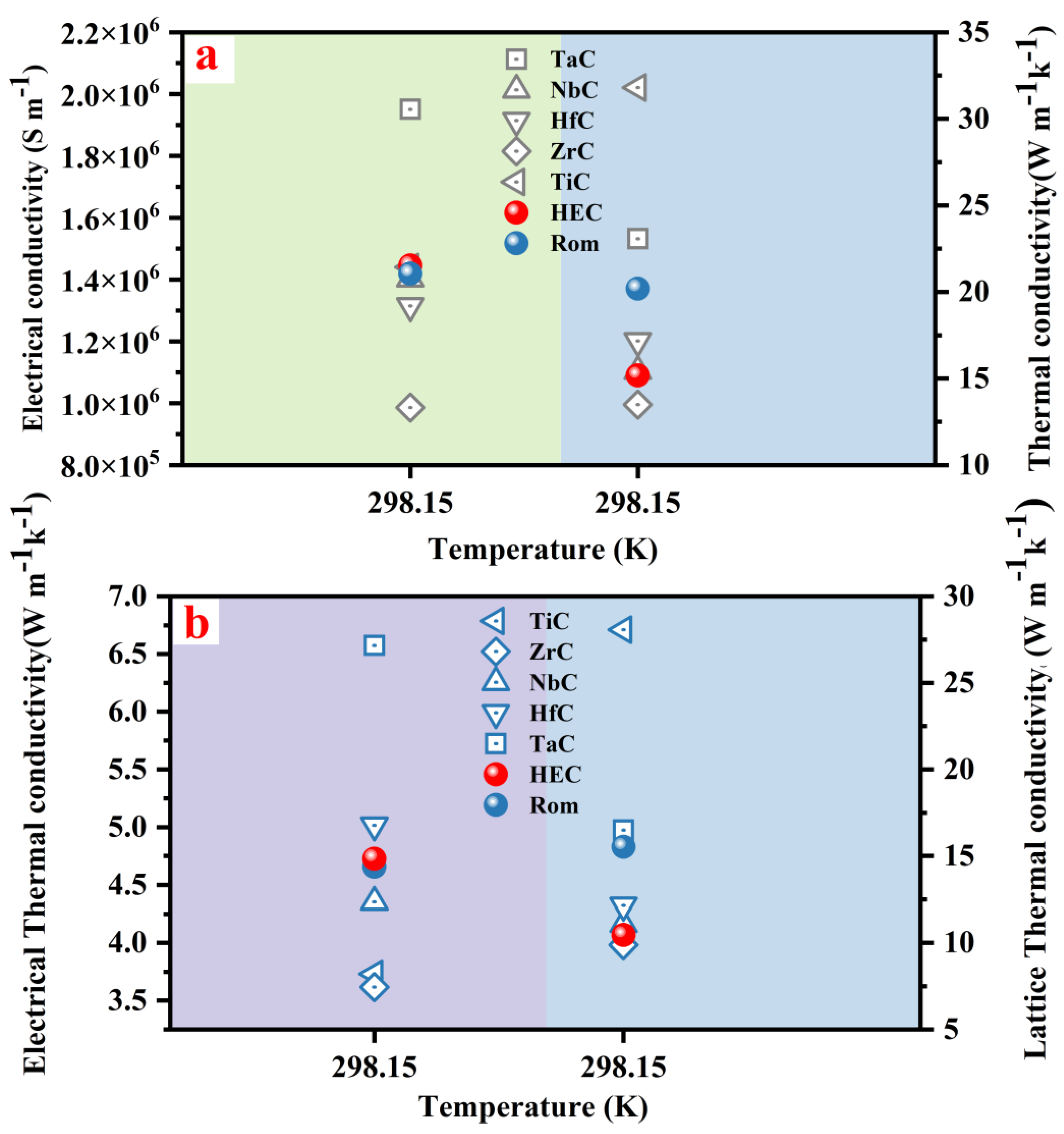

3.2. Thermal and Electrical Conductivity of HEC

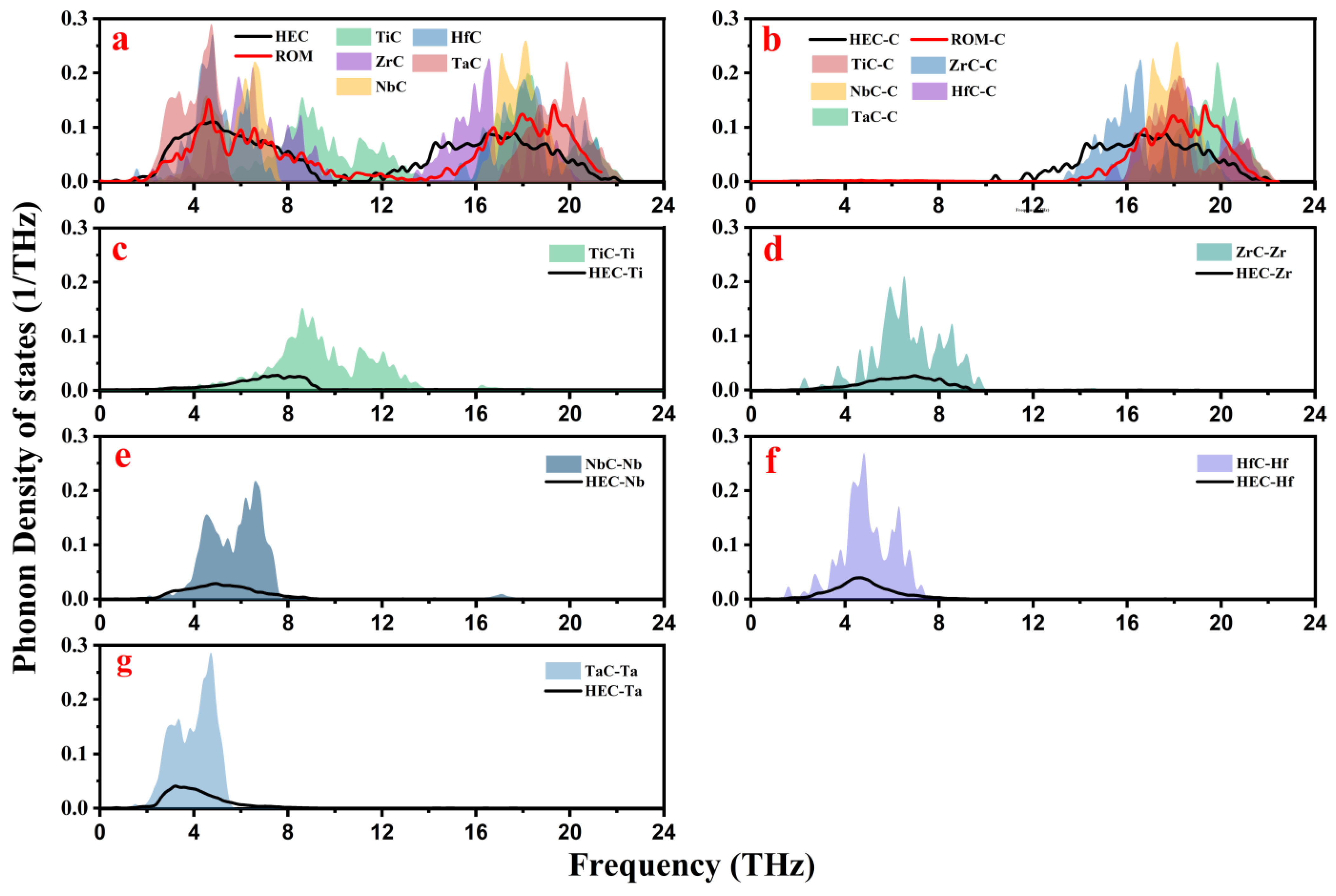

3.3. Phonon Properties of HEC and Individual Carbides

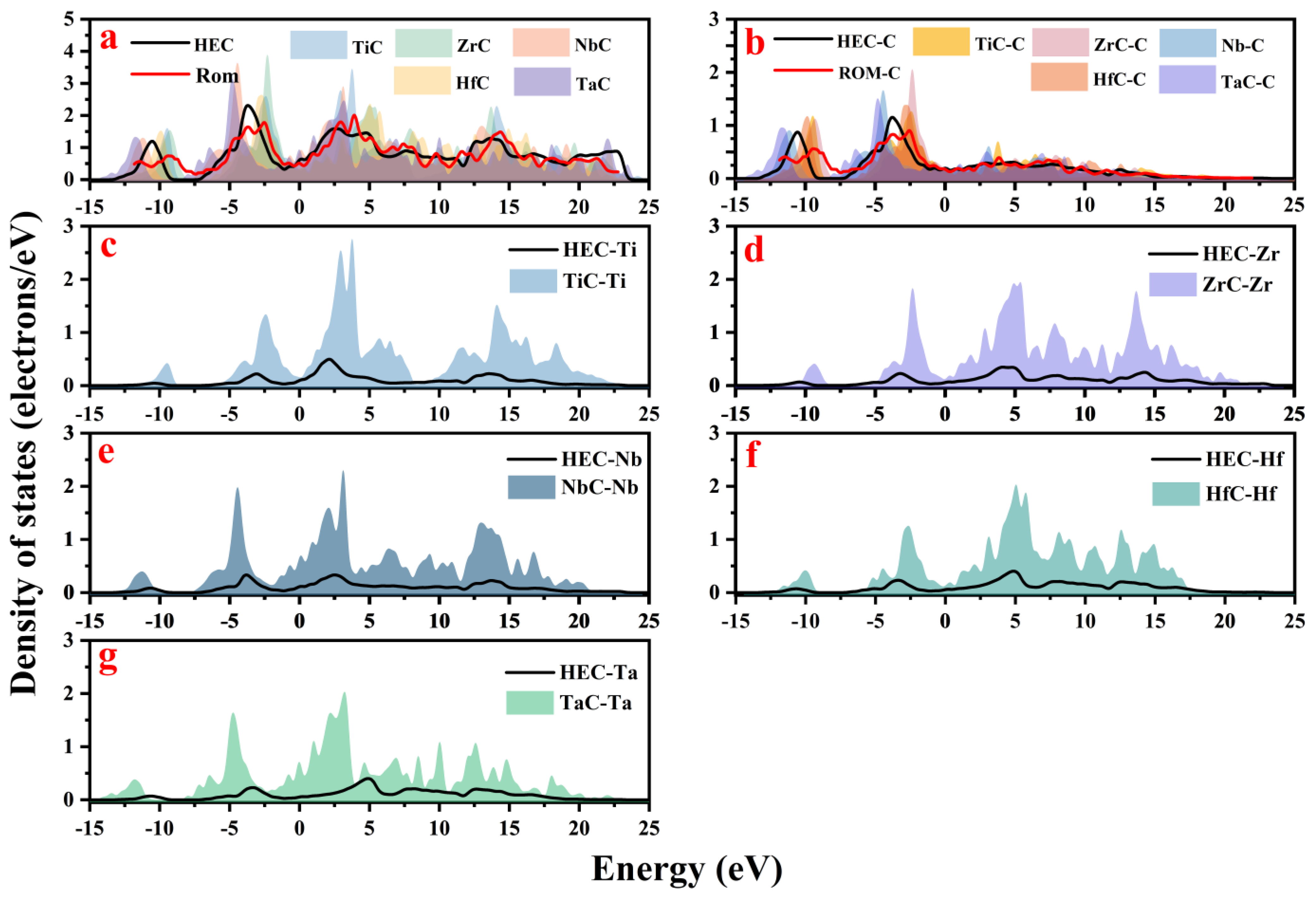

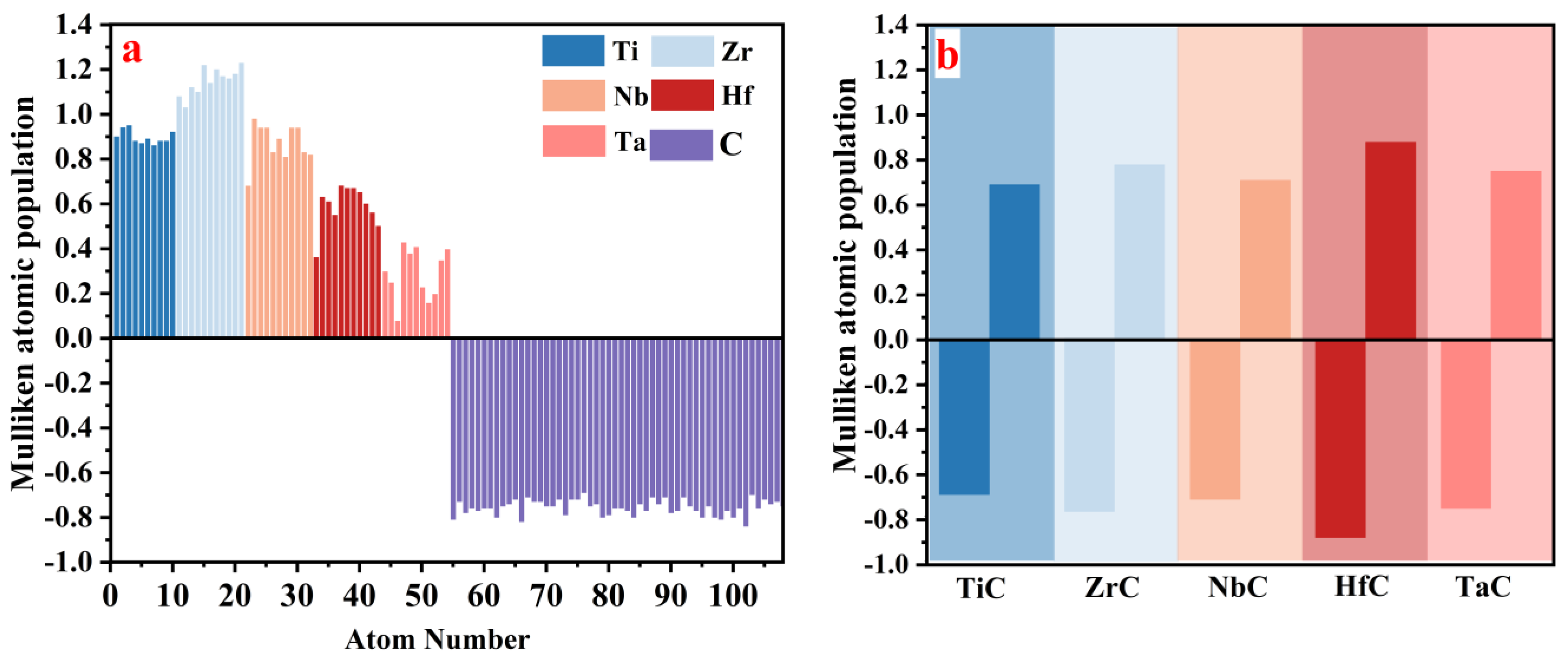

3.4. Electric Structure of HEC and Individual Carbides

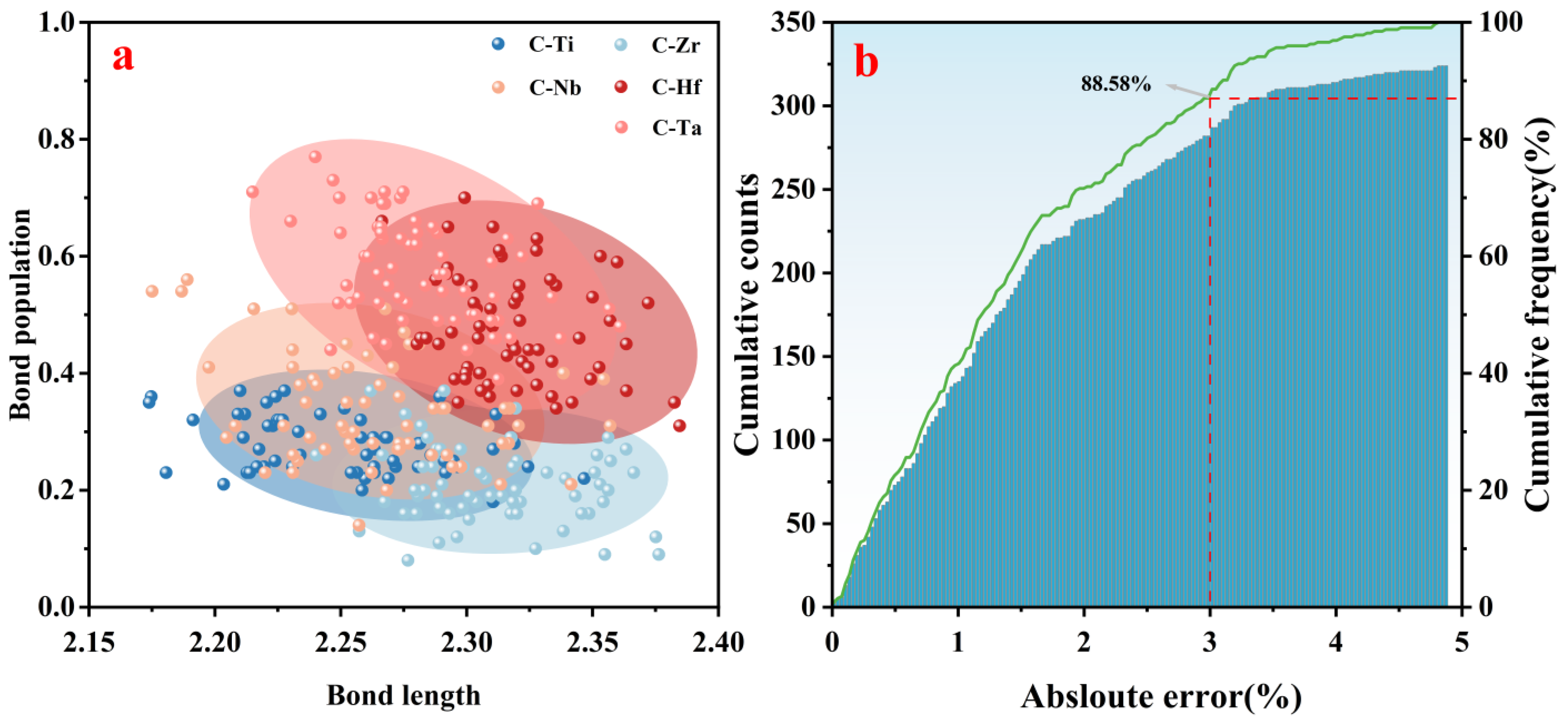

3.5. Bond Characters

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rost, C.M.; Sachet, E.; Borman, T.; Moballegh, A.; Dickey, E.C.; Hou, D.; Jones, J.L.; Curtarolo, S.; Maria, J.P. Entropy-stabilized oxides. Nat. Commun. 2015, 6, 8485. [Google Scholar] [CrossRef]

- Talluri, B.; Yoo, K.; Kim, J. High entropy spinel metal oxide (CoCrFeMnNi)3O4 nanoparticles as novel efficient electrocatalyst for methanol oxidation and oxygen evolution reactions. J. Environ. Chem. Eng. 2022, 10, 106932. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y.; Yu, H.; Zou, D. High-entropy oxides for catalysis: Status and perspectives. Appl. Catal. A Gen. 2022, 631, 118478. [Google Scholar] [CrossRef]

- Yu, P.; Ma, Z.; Liu, C.; Liu, W.; Zhao, S.; Han, Z.; Shao, T.; Gao, P.; Jiang, B.; Gu, X. Preparation of high entropy (Ba0.2Mg0.2Ca0.2Sr0.2Pb0.2)TiO3 perovskite oxide powders by a sol-hydrothermal method. Ceram. Int. 2022, 48, 15992–15999. [Google Scholar] [CrossRef]

- Rost, C.M.; Rak, Z.; Brenner, D.W.; Maria, J.P. Local structure of the MgxNixCoxCuxZnxO(x = 0.2) entropy-stabilized oxide: An EXAFS study. J. Am. Ceram. Soc. 2017, 100, 2732–2738. [Google Scholar] [CrossRef]

- Wang, C.; Qin, M.; Lei, T.; He, Y.; Kisslinger, K.; Rupert, T.J.; Luo, J.; Xin, H.L. Synergic grain boundary segregation and precipitation in W- and W-Mo-containing high-entropy borides. J. Eur. Ceram. Soc. 2021, 41, 5380–5387. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Z.-B.; Sun, S.-K.; Guo, W.-M.; Chen, Q.-S.; Qiu, J.-X.; Plucknett, K.; Lin, H.-T. Microstructure and mechanical properties of high-entropy borides derived from boro/carbothermal reduction. J. Eur. Ceram. Soc. 2019, 39, 3920–3924. [Google Scholar] [CrossRef]

- Barbarossa, S.; Orrù, R.; Garroni, S.; Licheri, R.; Cao, G. Ultra high temperature high-entropy borides: Effect of graphite addition on oxides removal and densification behaviour. Ceram. Int. 2021, 47, 6220–6231. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, J.-C.; Liu, J.-X.; Wei, X.-F.; Li, F.; Zhang, G.-J.; Jing, C.; Zhao, J.; Wu, H. High-entropy silicide ceramics developed from (TiZrNbMoW)Si2 formulation doped with aluminum. J. Eur. Ceram. Soc. 2020, 40, 2752–2759. [Google Scholar] [CrossRef]

- Kuang, J.; Zhang, P.; Wang, Q.; Hu, Z.; Liang, X.; Shen, B. Formation and oxidation behavior of refractory high-entropy silicide (NbMoTaW)Si2 coating. Corros. Sci. 2022, 198, 110134. [Google Scholar] [CrossRef]

- Liu, D.; Huang, Y.; Liu, L.; Zhang, L. A novel of MSi2 high-entropy silicide: Be expected to improve mechanical properties of MoSi2. Mater. Lett. 2020, 268, 127629. [Google Scholar] [CrossRef]

- Kavak, S.; Bayrak, K.G.; Bellek, M.; Mertdinç, S.; Muhaffel, F.; Gökçe, H.; Ayas, E.; Derin, B.; Öveçoğlu, M.L.; Ağaoğulları, D. Synthesis and characterization of (HfMoTiWZr)C high entropy carbide ceramics. Ceram. Int. 2022, 48, 7695–7705. [Google Scholar] [CrossRef]

- Zhang, P.-X.; Ye, L.; Chen, F.-H.; Han, W.-J.; Wu, Y.-H.; Zhao, T. Stability, mechanical, and thermodynamic behaviors of (TiZrHfTaM)C (M = Nb, Mo, W, V, Cr) high-entropy carbide ceramics. J. Alloys Compd. 2022, 903, 163868. [Google Scholar] [CrossRef]

- Yan, X.; Constantin, L.; Lu, Y.; Silvain, J.F.; Nastasi, M.; Cui, B. (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics with low thermal conductivity. J. Am. Ceram. Soc. 2018, 101, 4486–4491. [Google Scholar] [CrossRef]

- Dusza, J.; Švec, P.; Girman, V.; Sedlák, R.; Castle, E.G.; Csanádi, T.; Kovalčíková, A.; Reece, M.J. Microstructure of (Hf-Ta-Zr-Nb)C high-entropy carbide at micro and nano/atomic level. J. Eur. Ceram. Soc. 2018, 38, 4303–4307. [Google Scholar] [CrossRef]

- Castle, E.; Csanadi, T.; Grasso, S.; Dusza, J.; Reece, M. Processing and Properties of High-Entropy Ultra-High Temperature Carbides. Sci. Rep. 2018, 8, 8609. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, A.; Jia, J.; Meng, J.; Su, B. Phase evolution and properties of (VNbTaMoW)C high entropy carbide prepared by reaction synthesis. J. Eur. Ceram. Soc. 2020, 40, 2746–2751. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Hsu, S.-Y.; Song, R.-W.; Lo, W.-L.; Lai, Y.-T.; Tsai, S.-Y.; Duh, J.-G. Improving the hardness of high entropy nitride (Cr0.35Al0.25Nb0.12Si0.08V0.20)N coatings via tuning substrate temperature and bias for anti-wear applications. Surf. Coat. Technol. 2020; 403, 126417. [Google Scholar] [CrossRef]

- Ye, B.; Wen, T.; Huang, K.; Wang, C.Z.; Chu, Y. First-principles study, fabrication, and characterization of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramic. J. Am. Ceram. Soc. 2019, 102, 4344–4352. [Google Scholar] [CrossRef]

- Ye, B.; Wen, T.; Nguyen, M.C.; Hao, L.; Wang, C.-Z.; Chu, Y. First-principles study, fabrication and characterization of (Zr0.25Nb0.25Ti0.25V0.25)C high-entropy ceramics. Acta Mater. 2019, 170, 15–23. [Google Scholar] [CrossRef]

- Liu, S.-Y.; Zhang, S.; Liu, S.; Li, D.-J.; Li, Y.; Wang, S. Phase stability, mechanical properties and melting points of high-entropy quaternary metal carbides from first-principles. J. Eur. Ceram. Soc. 2021, 41, 6267–6274. [Google Scholar] [CrossRef]

- Lu, W.; Chen, L.; Zhang, W.; Su, W.; Wang, Y.; Fu, Y.; Zhou, Y. Single-phase formation and mechanical properties of (TiZrNbTaMo)C high-entropy ceramics: First-principles prediction and experimental study. J. Eur. Ceram. Soc. 2022, 42, 2021–2027. [Google Scholar] [CrossRef]

- Schwind, E.C.; Reece, M.J.; Castle, E.; Fahrenholtz, W.G.; Hilmas, G.E. Thermal and electrical properties of a high entropy carbide (Ta, Hf, Nb, Zr) at elevated temperatures. J. Am. Ceram. Soc. 2022, 105, 4426–4434. [Google Scholar] [CrossRef]

- Liu, D.; Hou, Y.; Meng, J.; Zhang, A.; Han, J.; Zhang, J. The significant influence of carbon content on mechanical and thermal properties of (VNbTaMoW)0.5Cx high entropy carbides. J. Eur. Ceram. Soc. 2022, 42, 5262–5272. [Google Scholar] [CrossRef]

- Dai, F.-Z.; Wen, B.; Sun, Y.; Xiang, H.; Zhou, Y. Theoretical prediction on thermal and mechanical properties of high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C by deep learning potential. J. Mater. Sci. Technol. 2020, 43, 168–174. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhang, J.; Fu, Z.; Wang, D. Microstructure and Mechanical Property of (TiNbTaZrHf)C Synthesized by In-situ Reaction. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2022, 37, 177–183. [Google Scholar] [CrossRef]

- Clark, S.J.; Segall, M.D.; Pickard, C.J.; Hasnip, P.J.; Probert, M.I.J.; Refson, K.; Payne, M.C. First principles methods using CASTEP. Z. Für Krist.-Cryst. Mater. 2005, 220, 567–570. [Google Scholar] [CrossRef]

- Segall, M.D.; Lindan, P.J.D.; Probert, M.J.; Pickard, C.J.; Hasnip, P.J.; Clark, S.J.; Payne, M.C. First-principles simulation: Ideas, illustrations and the CASTEP code. J. Phys. Condens. Matter 2002, 14, 2717–2744. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef]

- Yu, D.; Yin, J.; Zhang, B.; Liu, X.; Reece, M.J.; Liu, W.; Huang, Z. Pressureless sintering and properties of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics: The effect of pyrolytic carbon. J. Eur. Ceram. Soc. 2021, 41, 3823–3831. [Google Scholar] [CrossRef]

- Wang, F.; Yan, X.; Wang, T.; Wu, Y.; Shao, L.; Nastasi, M.; Lu, Y.; Cui, B. Irradiation damage in (Zr0.25Ta0.25Nb0.25Ti0.25)C high-entropy carbide ceramics. Acta Mater. 2020, 195, 739–749. [Google Scholar] [CrossRef]

- Liang, X.; Wang, H.; Wang, C. Lattice thermal conductivity of transition metal carbides: Evidence of a strong electron-phonon interaction above room temperature. Acta Mater. 2021, 216, 117160. [Google Scholar] [CrossRef]

- Liu, R.; Chen, H.; Zhao, K.; Qin, Y.; Jiang, B.; Zhang, T.; Sha, G.; Shi, X.; Uher, C.; Zhang, W.; et al. Entropy as a Gene-Like Performance Indicator Promoting Thermoelectric Materials. Adv. Mater. 2017, 29, 1702712. [Google Scholar] [CrossRef] [PubMed]

- Rost, C.M.; Borman, T.; Hossain, M.D.; Lim, M.; Quiambao-Tomko, K.F.; Tomko, J.A.; Brenner, D.W.; Maria, J.-P.; Hopkins, P.E. Electron and phonon thermal conductivity in high entropy carbides with variable carbon content. Acta Mater. 2020, 196, 231–239. [Google Scholar] [CrossRef]

- Makinson, R.E.B. The thermal conductivity of metals. Math. Proc. Camb. Philos. Soc. 2008, 34, 474–497. [Google Scholar] [CrossRef]

- Kojda, D.; Mitdank, R.; Handwerg, M.; Mogilatenko, A.; Albrecht, M.; Wang, Z.; Ruhhammer, J.; Kroener, M.; Woias, P.; Fischer, S.F. Temperature-dependent thermoelectric properties of individual silver nanowires. Phys. Rev. B 2015, 91, 024302. [Google Scholar] [CrossRef]

- Avery, A.D.; Mason, S.J.; Bassett, D.; Wesenberg, D.; Zink, B.L. Thermal and electrical conductivity of approximately 100-nm permalloy, Ni, Co, Al, and Cu films and examination of the Wiedemann-Franz Law. Phys. Rev. B 2015, 92, 214410. [Google Scholar] [CrossRef]

- Körmann, F.; Ikeda, Y.; Grabowski, B.; Sluiter, M.H.F. Phonon broadening in high entropy alloys. npj Comput. Mater. 2017, 3, 36. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, S.; Liu, Y.; Liu, L.; Ma, Z. Phase structure, mechanical properties and thermal properties of high-entropy diboride (Hf0.25Zr0.25Ta0.25Sc0.25)B2. J. Eur. Ceram. Soc. 2022, 42, 5303–5313. [Google Scholar] [CrossRef]

- Delaire, O.; Ma, J.; Marty, K.; May, A.F.; McGuire, M.A.; Du, M.H.; Singh, D.J.; Podlesnyak, A.; Ehlers, G.; Lumsden, M.D.; et al. Giant anharmonic phonon scattering in PbTe. Nat. Mater. 2011, 10, 614–619. [Google Scholar] [CrossRef]

- Rubel, M.H.K.; Hossain, K.M.; Mitro, S.K.; Rahaman, M.M.; Hadi, M.A.; Islam, A.K.M.A. Comprehensive first-principles calculations on physical properties of ScV2Ga4 and ZrV2Ga4 in comparison with superconducting HfV2Ga4. Mater. Today Commun. 2020, 24, 100935. [Google Scholar] [CrossRef]

- Xiong, K.; You, L.; Zhang, S.; Yang, L.; Jin, C.; Guo, L.; Wang, Y.; Mao, Y. Pressure and temperature effects on (TiZrTa)C medium-entropy carbide from first-principles. J. Mater. Res. Technol. 2023, 23, 2288–2300. [Google Scholar] [CrossRef]

- Uporov, S.A.; Ryltsev, R.E.; Sidorov, V.A.; Estemirova, S.K.; Sterkhov, E.V.; Balyakin, I.A.; Chtchelkatchev, N.M. Pressure effects on electronic structure and electrical conductivity of TiZrHfNb high-entropy alloy. Intermetallics 2022, 140, 107394. [Google Scholar] [CrossRef]

- Hong, D.; Zeng, W.; Liu, F.-S.; Tang, B.; Liu, Q.-J. The structural, mechanical and electronic properties of NbXSi (X = Fe, Co, Ni, Ru, Rh, Pd, Os, Ir and Pt) compounds from first-principles calculations. Mater. Chem. Phys. 2021, 259, 124029. [Google Scholar] [CrossRef]

- Esters, M.; Oses, C.; Hicks, D.; Mehl, M.J.; Jahnatek, M.; Hossain, M.D.; Maria, J.P.; Brenner, D.W.; Toher, C.; Curtarolo, S. Settling the matter of the role of vibrations in the stability of high-entropy carbides. Nat. Commun. 2021, 12, 5747. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Ravichandran, N.K.; Lindsay, L.; Broido, D. Fermi Surface Nesting and Phonon Frequency Gap Drive Anomalous Thermal Transport. Phys. Rev. Lett. 2018, 121, 175901. [Google Scholar] [CrossRef]

- Yang, J.-Y.; Zhang, W.; Xu, C.; Liu, J.; Liu, L.; Hu, M. Strong electron-phonon coupling induced anomalous phonon transport in ultrahigh temperature ceramics ZrB2 TiB2. Int. J. Heat. Mass. Transf. 2020, 152, 119481. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Lei, L.; Zhang, J.; Li, N. Unveiling the Transporting Mechanism of (Ti0.2Zr0.2Nb0.2Hf0.2Ta0.2)C at Room Temperature. Crystals 2023, 13, 708. https://doi.org/10.3390/cryst13040708

Liu T, Lei L, Zhang J, Li N. Unveiling the Transporting Mechanism of (Ti0.2Zr0.2Nb0.2Hf0.2Ta0.2)C at Room Temperature. Crystals. 2023; 13(4):708. https://doi.org/10.3390/cryst13040708

Chicago/Turabian StyleLiu, Tao, Liwen Lei, Jinyong Zhang, and Neng Li. 2023. "Unveiling the Transporting Mechanism of (Ti0.2Zr0.2Nb0.2Hf0.2Ta0.2)C at Room Temperature" Crystals 13, no. 4: 708. https://doi.org/10.3390/cryst13040708

APA StyleLiu, T., Lei, L., Zhang, J., & Li, N. (2023). Unveiling the Transporting Mechanism of (Ti0.2Zr0.2Nb0.2Hf0.2Ta0.2)C at Room Temperature. Crystals, 13(4), 708. https://doi.org/10.3390/cryst13040708