Influence of X Cation Covalence in the Formation of Ni-O-X Mixed Oxides by Reactive Ion Beam Mixing of Ni/X Interfaces

Abstract

1. Introduction

2. Materials and Methods

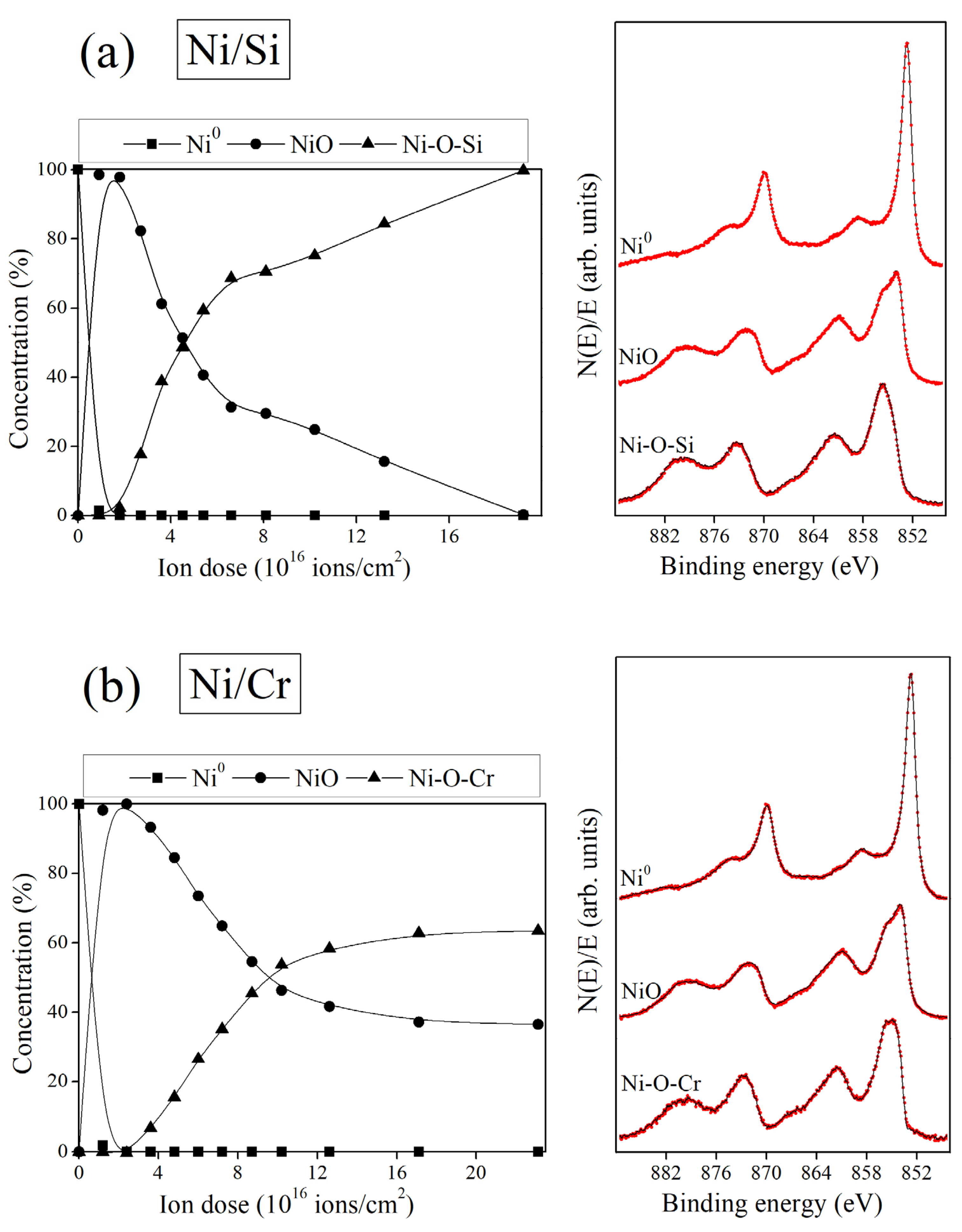

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, Z.; Fang, D.; Liang, Y.; He, Y.; Einaga, H.; Shangguan, W. Catalytic degradation of benzene over non-thermal plasma coupled Co-Ni binary metal oxide nanosheet catalysts. J. Environ. Sci. 2023, 132, 1–11. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, M.; Ren, A.; Huang, Y.; Yan, X.; Feng, R.; Zhao, G. Mesoporous nickel-cobalt oxide for efficient liquid-phase benzyl alcohol oxidation by air. Catal. Today 2022, 405–406, 75–81. [Google Scholar] [CrossRef]

- Faid, A.Y.; Barnett, A.O.; Seland, F.; Sunde, S. NiCu mixed metal oxide catalyst for alkaline hydrogen evolution in anion exchange membrane water electrolysis. Electrochim. Acta 2021, 371, 137837. [Google Scholar] [CrossRef]

- Dhas, C.R.; Monica, S.E.S.; Jothivenkatachalam, K.; Nathanael, A.J.; Kavinkumar, V.; Venkatesh, R.; Arivukarasan, D. Direct-grown nebulizer-sprayed nickel-copper mixed metal oxide nanocomposite films as bifunctional electrocatalyst for water splitting. Ionics 2021, 28, 383–396. [Google Scholar] [CrossRef]

- Rastegarpanah, A.; Liu, Y.; Deng, J.; Jing, L.; Pei, W.; Zhang, X.; Hou, Z.; Rezaei, M.; Dai, H. Influence of preparation method on catalytic performance of three-dimensionally ordered macroporous NiO-CuO for CO oxidation. J. Solid State Chem. 2021, 297, 122091. [Google Scholar] [CrossRef]

- Awan, I.Z.; Beltrami, G.; Bonincontro, D.; Gimello, O.; Cacciaguerra, T.; Tanchoux, N.; Martucci, A.; Albonetti, S.; Cavani, F.; Di Renzo, F. Copper-nickel mixed oxide catalysts from layered double hydroxides for the hydrogen-transfer valorisation of lignin in organosolv pulping. Appl. Catal. A Gen. 2021, 609, 117929. [Google Scholar] [CrossRef]

- Kong, L.; Li, D.; Bi, J.; Fan, X.; Xie, Z.; Xiao, X.; Zhao, Z. Template-induced mesoporous Ni-Al oxide catalysts with tuned physico-chemical properties for the oxidative dehydrogenation of ethane. J. Chem. Eng. 2023, 452, 139247. [Google Scholar] [CrossRef]

- Nesterov, N.S.; Pakharukova, V.P.; Philippov, A.A.; Gerasimov, E.Y.; Tsybulya, S.V.; Martyanov, O.N. Synthesis of catalytic precursors based on mixed Ni-Al oxides by supercritical antisolvent co-precipitation. Catalysts 2022, 12, 1597. [Google Scholar] [CrossRef]

- Caravaggio, G.; Nossova, L.; Turnbull, M.J. Nickel-magnesium mixed oxide catalyst for low temperature methane oxidation. J. Chem. Eng. 2021, 405, 126862. [Google Scholar] [CrossRef]

- Summa, P.; Gajewska, M.; Li, L.; Hu, C.; Samojeden, B.; Motak, M.; Da Costa, P. Solution combustion synthesis as an alternative synthesis route for novel Ni-Mg-Al mixed-oxide catalyst for CO2 methanation. J. CO2 Util. 2022, 60, 101983. [Google Scholar] [CrossRef]

- Zahra, T.; Ahmad, K.S.; Zequine, C.; Gupta, R.; Malik, M.A.; Niazi, J.H.; Qureshi, A. Bio-inspired NiO/ZrO2 mixed oxides (NZMO) for oxygen evolution reactions: From facile synthesis to electrochemical analysis. J. Chem. Technol. Biotechnol. 2023, 98, 296–305. [Google Scholar] [CrossRef]

- Moschkowitsch, W.; Zion, N.; Honig, H.C.; Levy, N.; Cullen, D.A.; Elbaz, L. Mixed-Metal Nickel-Iron Oxide Aerogels for Oxygen Evolution Reaction. ACS Catal. 2022, 12, 12162–12169. [Google Scholar] [CrossRef]

- Nozari-Asbemarz, M.; Amiri, M.; Imanzadeh, H.; Bezaatpour, A.; Nouhi, S.; Hosseini, P.; Wark, M.; Seifzadeh, D. Mixed metal oxides as efficient electrocatalysts for water oxidation. Int. J. Hydrogen Energy 2022, 47, 5250–5259. [Google Scholar] [CrossRef]

- Devi, S.; Sunaina, R.; Wadhwa, R.; Yadav, K.K.; Jha, M. Understanding the origin of ethanol oxidation from ultrafine nickel manganese oxide nanosheets derived from spent alkaline batteries. J. Clean. Prod. 2022, 376, 134147. [Google Scholar] [CrossRef]

- Perez, L.C.P.; Chalkley, Z.; Wendt, R.; Ahmet, I.Y.; Wollgarten, M.; Mayer, M.T. CO2 electro reduction activity and dynamic structural evolution of in situ reduced nickel-indium mixed oxides. J. Mat. Chem. A 2022, 10, 20593–20605. [Google Scholar] [CrossRef]

- Aberkane, A.B.; Yeste, M.P.; Djazi, F.; Cauqui, M.A. CO methanation over NiO-CeO2 mixed-oxide catalysts prepared by a modified co-precipitation method: Effect of the preparation pH on the catalytic performance. Nanomaterials 2022, 12, 2627. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Surendran, S.; Lim, Y.; Choi, H.; Lim, J.; Kim, J.Y.; Han, M.; Sim, U. Spinel-type Ni2GeO4 electrocatalyst for electrochemical ammonia synthesis via nitrogen reduction reaction under ambient conditions. Int. J. Energy Res. 2021, 46, 4119–4129. [Google Scholar] [CrossRef]

- Kulal, N.; Vetrivel, R.; Gopinath, C.S.; Ravindran, R.K.; Rao, V.N.; Shetty, M.; Shrikanth, R.; Rangappa, D.; Shanbhag, G.V. Green route for carbonylation of amines by CO2 using Sn-Ni-O bifunctional catalyst and theoretical study for finding best suited active sites. J. Eng. Chem. 2021, 419, 129439. [Google Scholar] [CrossRef]

- Zhao, Z.; Lakshminarayanan, N.; Swartz, S.L.; Arkenberg, G.B.; Felix, L.G.; Slimane, R.B.; Choi, C.C.; Ozkan, U.S. Characterization of olivine-supported nickel silicate as potential catalysts for tar removal from biomass gasification. Appl. Cat. A Gen. 2015, 489, 42–50. [Google Scholar] [CrossRef]

- Bilal, A.; Kasi, J.K.; Kasi, A.K.; Bokhari, M.; Ahmed, S.; Ali, S.W. Environment friendly synthesis of nickel ferrite nanoparticles using Brassica oleracea var. capitate (green cabbage) as a fuel and their structural and magnetic characterizations. Mat. Chem. Phys. 2022, 290, 126483. [Google Scholar] [CrossRef]

- Din, S.U.; Ul Haq, M.; Sajid, M.; Khatoon, R.; Chen, X.; Li, L.; Zhang, M.; Zhu, L. Development of high-performance sensor based on NiO/SnO(2)heterostructures to study sensing properties towards various reducing gases. Nanotechnology 2020, 31, 395502. [Google Scholar] [CrossRef] [PubMed]

- Arranz, A.; Palacio, C. Nanoscale modification of Ni/Al interfaces by low-energy O2+ reactive ion beam mixing. Appl. Phys. A 2011, 103, 309–316. [Google Scholar] [CrossRef]

- Proctor, A.; Sherwood, M.P.A. Data analysis techniques in x-ray photoelectron spectroscopy. Anal. Chem. 1982, 54, 13–19. [Google Scholar] [CrossRef]

- Bell, G.G.; Ley, L. Photoemission study of SiOx (0 ≤ x ≤ 2) alloys. Phys. Rev. B 1998, 37, 8383–8393. [Google Scholar] [CrossRef] [PubMed]

- Guittet, M.J.; Crocombette, J.P.; Gauttier-Soyer, M. Bonding and XPS chemical shifts in ZrSiO4 versus SiO2 and ZrO2: Charge transfer and electrostatic effects. Phys. Rev. B 2001, 63, 125117. [Google Scholar] [CrossRef]

- Ünveren, E.; Kemnitz, E.; Hutton, S.; Lippitz, A.; Unger, W.E.S. Analysis of highly resolved x-ray photoelectron Cr 2p spectra obtained with a Cr2O3 powder sample prepared with adhesive tape. Surf. Interface Anal. 2004, 36, 92–95. [Google Scholar] [CrossRef]

- Biesinger, M.C.; Brown, C.; Mycroft, J.R.; Davidson, R.D.; McIntyre, N.S. X-ray photoelectron spectroscopy studies of chromium compounds. Surf. Interface Anal. 2004, 36, 1550–1563. [Google Scholar] [CrossRef]

- Barr, T.L. Recent advances in x-ray photoelectron spectroscopy studies of oxides. J. Vac. Sci. Technol. A 1991, 9, 1793–1805. [Google Scholar] [CrossRef]

- Maiti, K.; Mahadevan, P.; Sarma, D.D. Evolution of electronic structure with dimensionality in divalent nickelates. Phys. Rev. B 1999, 59, 12457–12469. [Google Scholar] [CrossRef]

- Altieri, S.; Tjeng, L.H.; Tanaka, A.; Sawatzky, G.A. Core-level x-ray photoemission on NiO in the impurity limit. Phys Rev. B 2000, 61, 13403–13409. [Google Scholar] [CrossRef]

- Malinowski, E.R.; Howery, D.C. Factor Analysis in Chemistry; Krieger: Malabar, FL, USA, 1989. [Google Scholar]

- Palacio, C.; Mathieu, H.J. Application of factor analysis to the AES and XPS study of the oxidation of chromium. Surf. Interface Anal. 1990, 16, 178–182. [Google Scholar] [CrossRef]

- Fiedor, J.N.; Proctor, A.; Houalla, M.; Hercules, D.M. Determination of the distribution of molybdenum oxidation states in reduced Mo/TiO2 catalysts by factor analysis and curve fitting. Surf. Interface Anal. 1993, 20, 1–9. [Google Scholar] [CrossRef]

- Arranz, A.; Palacio, C. Composition of tantalum nitride thin films grown by low-energy nitrogen implantation: A factor analysis study of the Ta 4f XPS core level. Appl. Phys. A 2005, 81, 1405–1410. [Google Scholar] [CrossRef]

- Lenglet, M.; d’Huysser, A.; Arsène, J.; Bonnelle, J.P.; Jørgensen, C.K. XANES, x-ray photoelectron and optical spectra of divalent nickel at the crystallographic transition in NiCr2O4 and the Ni1-xCuxCr2O4 system: Correlation with the Jahn-Teller effect. J. Phys. C Solid State Phys. 1986, 19, L363–L368. [Google Scholar] [CrossRef]

- Lorenz, P.; Finster, J.; Wendt, G.; Salyn, J.V.; Zumadilov, E.K.; Nefedov, V.I. Esca investigations of some NiO/SiO2 and NiO-Al2O3/SiO2 catalysts. J. Electron Spectrosc. Relat. Phenom. 1979, 16, 267–276. [Google Scholar] [CrossRef]

- Shalvoy, R.B.; Reucroft, P.J.; Davis, B.H. Characterization of coprecipitated nickel on silica methanation catalysts by X-ray photoelectron spectroscopy. J. Catal 1979, 56, 336–348. [Google Scholar] [CrossRef]

- Malherbe, J.B.; Hofmann, S.; Sanz, J.M. Preferential sputtering of oxides. A comparison of model predictions with experimental data. Appl. Surf. Sci. 1986, 27, 355–365. [Google Scholar] [CrossRef]

- Benito, N.; Palacio, C. Nanostructuring of Ta2O5 surfaces by low energy Ar+ bombardment. Appl. Surf. Sci. 2015, 351, 753–759. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Biersack, J.B.; Littmark, U. The Stopping and Range of Ions in Matter Vol 1; Pergamon: New York, NY, USA, 1985; Available online: https://www.SRIM.org (accessed on 4 February 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arranz, A.; Palacio, C. Influence of X Cation Covalence in the Formation of Ni-O-X Mixed Oxides by Reactive Ion Beam Mixing of Ni/X Interfaces. Crystals 2023, 13, 345. https://doi.org/10.3390/cryst13020345

Arranz A, Palacio C. Influence of X Cation Covalence in the Formation of Ni-O-X Mixed Oxides by Reactive Ion Beam Mixing of Ni/X Interfaces. Crystals. 2023; 13(2):345. https://doi.org/10.3390/cryst13020345

Chicago/Turabian StyleArranz, Antonio, and Carlos Palacio. 2023. "Influence of X Cation Covalence in the Formation of Ni-O-X Mixed Oxides by Reactive Ion Beam Mixing of Ni/X Interfaces" Crystals 13, no. 2: 345. https://doi.org/10.3390/cryst13020345

APA StyleArranz, A., & Palacio, C. (2023). Influence of X Cation Covalence in the Formation of Ni-O-X Mixed Oxides by Reactive Ion Beam Mixing of Ni/X Interfaces. Crystals, 13(2), 345. https://doi.org/10.3390/cryst13020345