Abstract

A numerical simulation has been conducted to investigate the oscillatory mechanism of a solutocapillary convection and the influence of different aspect ratios on the flow characteristics in a liquid bridge. The SIMPLE algorithm is applied to figure out the Navier-Stokes equation and the concentration diffusion equation on the staggered grids, and the level set approach with the conservation of the mass is used to acquire the surface deformation of the liquid bridge. The flow characteristics of the oscillatory solutocapillary convection are analyzed in detail, including the distributions of the concentration, velocity, and transverse displacement of the free surface at the upper corner and intermediate height of the liquid bridge. Moreover, the effects of the aspect ratio on the flow stability and onset time of the oscillations for the concentration and velocity have also been investigated. The results show that the essence of the oscillatory solutocapillary convection is the result of the coupling oscillation of the concentration, velocity and free surface. The upper corner is the origin region of the oscillation, which has an important impact on the overall flow characteristics. Within a definite height range of the liquid bridge, the lower the height, the more stable the flow and the weaker the oscillation. There is a complex relationship between the onset time of the concentration and velocity oscillations and the aspect ratio of the liquid bridge.

1. Introduction

The floating zone method is intensively applied to prepare superior crystals, and the liquid bridge is a scientific idealized model for the floating zone method. The convection along the free surface of the fluid caused by the surface tension gradient is a main flow mode that determines the internal flow characteristics under the microgravity condition [1,2,3]. In practice, the nonuniform concentration distribution of impurities in raw materials on the free surface of the melt zone drives the solutocapillary convection. Streak defects will be formed inside or on the final crystals when the concentration difference exceeds the critical value and the convection begins to oscillate, which will seriously affect the properties of the crystals [4,5]. The study on the flow characteristics and the oscillatory mechanism of the solutocapillary convection in the floating zone is helpful to improve the crystal growth process and quality. The flow characteristics in the liquid bridge with different heights are also different, which are mainly reflected in the stability of the flow. In engineering applications, the oscillatory solutocapillary convection is often a problem that needs to be suppressed. The study on the onset time of the oscillations of the concentration, velocity, and surface can be helpful to the application of some measures.

Campbell et al. [6] researched the effects of a solutocapillary convection in the course of the growth of alloy crystals in the floating zone, indicating that the area dominated by the solutocapillary convection was more susceptible to morphological instabilities. Benz and Dold [7] produced a summary and research work on the crystal growth under microgravity conditions, including the phenomenon of convective mass transfer and flow characteristics, and they proposed the possibility of replacing the microgravity with magnetic fields. Witkowski and Walker [8] investigated the effects of the growth velocity on the steadiness of the solutocapillary convection in the liquid bridge of different aspect ratios, indicating that the base flow was only actuated by the thin solute layer near the crystal-melt interface for a large growth rate. Walker et al. [9] investigated the solutocapillary convection in the floating zone using a high magnetic field, indicating that the solutocapillary convection could be developed by increasing the magnetic field strength and became the main convection under certain conditions. Lin et al. [10] numerically studied the influence of buoyancy and the solutal Marangoni convection on the flow structures in a germanium-silicon floating zone and found that the effect of buoyancy could not be neglected for small Prandtl number fluids. Lyubimova and Scuridyn [11] studied the three-dimensional solutocapillary convection in the floating zone and obtained the flow structure and concentration distributions within the liquid bridge in the unsteady conditions. Minakuchi et al. [12] numerically investigated the solutocapillary convection appearing in the growth of crystal SixGe1−x with the float-zone technique in the absence of gravity, indicating that the strength of the axial flow follows the free surface because the solutal Marangoni convection was much weaker than that of the thermal Marangoni convection, and it still had an important influence on the flow structure. Zhou and Huai [13] numerically investigated the surface change of the liquid bridge in the solutocapillary convection, and they found that the free surface bulged out around the upper disk and bulged in around the lower disk when the solutocapillary convection was dominant. Viviani et al. [14] obtained the critical point of starting the solute capillary convection through experimental research. Mizev et al. [15] studied the initial stage and stability of the buoyancy and solutecapillary convection caused by surface active sources under the interface through experiments and theories, and they concluded that the interaction between the buoyancy and solute capillary convection led to the occurrence of oscillatory convection. Yang et al. [16] discussed the influence of the instability of the surface internal energy on the pure solutocapillary convection under the condition of a certain inclined angle of the liquid bridge through experiments and found that the spatiotemporal transformation of the asymmetric liquid bridge had three periods: namely, the initial period near the upper corner, the development stage towards the middle height and the contraction stage at the lower corner. The imbalance of the curvature of the interface on both sides, arisen from the surface internal energy instability, accelerates the change of the cell flow structure. Lappa et al. [17] investigated the instabilities of a three-dimensional Marangoni convection in the liquid bridge under different aspect ratios, indicating that the lower the aspect ratio, the larger the critical wavenumber and the more complicated the flow field structure, and the aspect ratio played a momentous role in the flow form. Tang and Hu [18] investigated the effect of the aspect ratio, which is at the beginning of the thermocapillary oscillatory convection in a half-floating zone of a large Prandtl number fluid and found that the aspect ratio was not only a main parameter of the oscillatory flow, but also affected the oscillatory mechanism. Yan et al. [19] investigated experimentally the relationship between the aspect ratio and critical Marangoni number and found that the critical Marangoni number generally increased following the increasing aspect ratio of the floating half zone (aspect ratio ≥ 0.4), and then decreased. Fan and Liang [20] carried out a numerical simulation of the thermal-solutal capillary convection of the liquid bridge under different aspect ratios in microgravity conditions, and they obtained the variable mechanism of the cell flow structure and the variable law of the internal flow of the liquid bridge. Finally, they defined the concept of dividing the convection region into strong and weak. Zhang et al. [21] numerically investigated the effects of various aspect ratios on the thermocapillary convection in liquid bridges by a transformable free surface and found that the aspect ratio had a significant influence in the flow and temperature fields. As the aspect ratio increased, the frequency of the temperature fluctuation decreased, and the amplitude increased as well as the deformation ratio. Yano and Nishino [22] investigated the influence of the liquid bridge shape on the oscillatory thermocapillary convection considering the aspect ratio and volume ratio. Mendis et al. [23] discussed the influence of the solutocapillary convection on the hydrodynamic instability in a Si-Ge liquid bridge under different aspect ratios in zero gravity by numerical simulation, and they proposed a parameter region suitable for the stable flow of the small aspect ratio liquid bridge in crystal growth. Kan et al. [24] numerically studied the turbulent statistical characteristics and flow structure of the outlet water of the rotary axial flow pump through their own program. A new immersion boundary method based on the level set of the sharp interface was adopted to acquire the complex geometry of the pump. For the complex surface geometry, they used the unstructured triangular mesh to discretize and applied the ray tracing method to divide the computational domain. They [25] also established a new and accurate prediction model using the VOF method, which can accurately predict the transient characteristics.

There are many factors that cause the change in the surface tension, and we mainly consider the effect of the concentration gradient in the present work. At present, there are a few studies on the oscillatory mechanism of solutocapillary convection and the impact of the aspect ratio on the flow characteristics in the liquid bridge. Most studies assume that the free surface of the liquid bridge is undeformed and that it is always a straight line or a cylindrical surface. It not only affects the accuracy of the final results, but also, to some extent, limits the diversification of the research. Therefore, the flow characteristics at the corner and intermediate height are investigated in detail through the arrangement of monitoring points, and the oscillatory mechanism of the solutocapillary convection is summarized on the basis of considering the dynamic deformation of the free surface. We investigate the distributions of the concentration and flow fields in the liquid bridge with different aspect ratios and analyze the impact of the aspect ratio on the flow stability. The complex interaction among the oscillations of the concentration, velocity, and transverse displacement of the surface is also discussed.

2. Models and Methods

2.1. Geometric Model

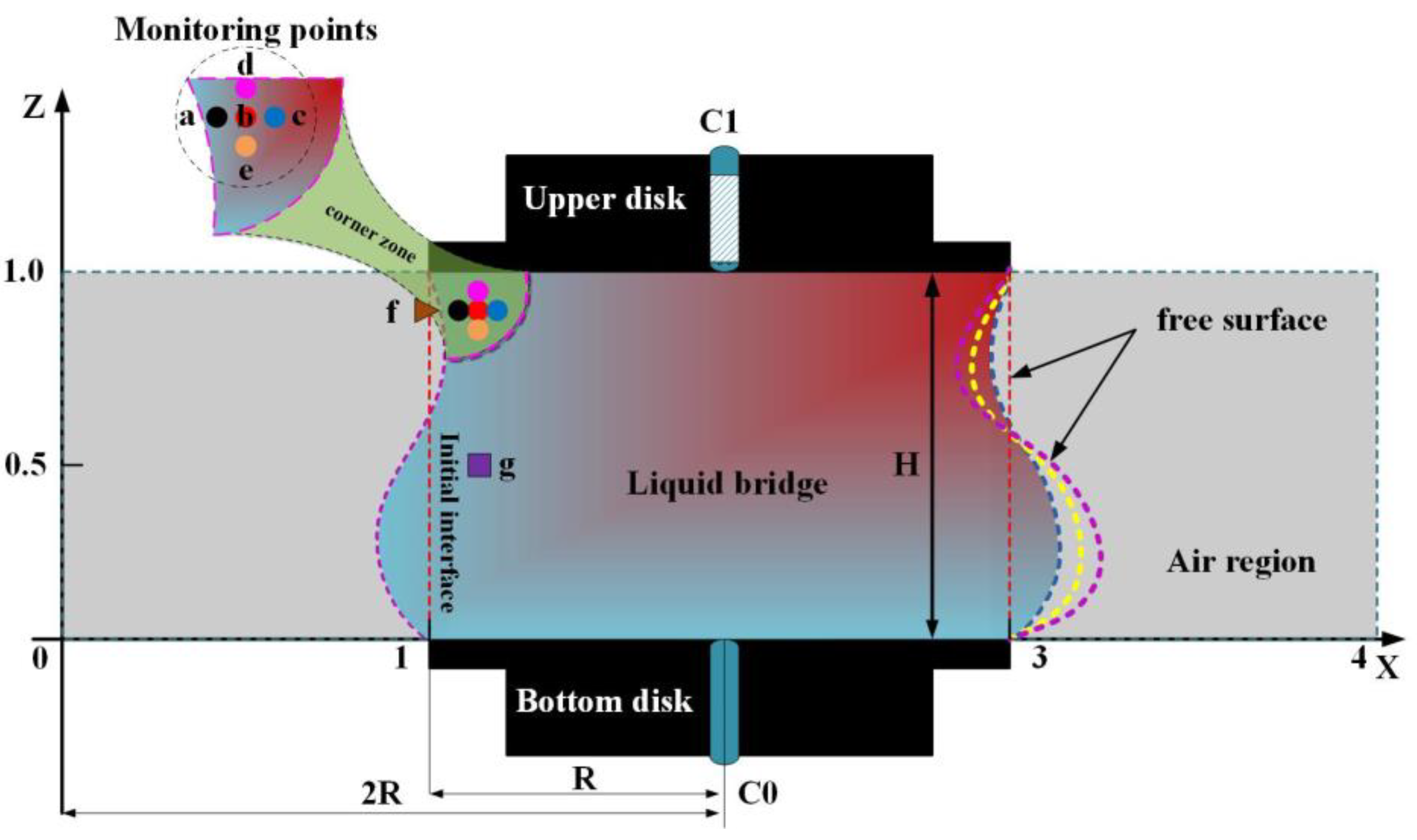

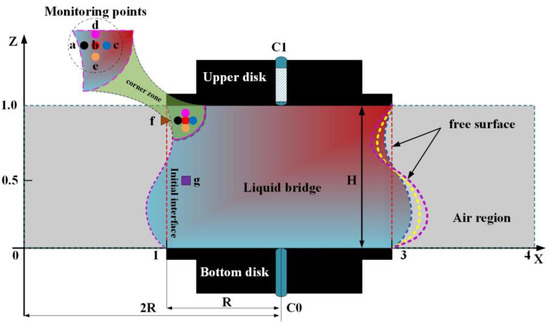

Figure 1 is the schematic diagram of the liquid bridge model. The entire calculation area is a rectangular container with a width of 4R and a height of H. The liquid bridge is located between two disks with the same axis. The selected radius is R and the height is H, and both sides of the liquid bridge are surrounded by air. Toluene/n-hexane mixed solution is selected as the medium, and the ratio is 0.24 to 0.76. The initial shape of the free surface of the liquid bridge is a vertical plane. With the development of the solutocapillary convection, the interface between the liquid and gas is deformable. The concentration difference between the upper and lower discs is ΔC = C1 − C0, in which C1 represents the upper disk of the high concentration area and C0 represents the lower disk of the low concentration area.

Figure 1.

Schematic diagram of liquid bridge model.

In order to simplify the problem, a few assumptions are introduced: (1) There is no heat and mass transfer at the outer edge of the ambient air. (2) The upper and lower disks are completely insulated and impermeable. (3) The non-slip condition applies to all of the walls in the calculation area. (4) The viscous dissipation is negligible. (5) The flow is the laminar flow. The binary mixture fluid is assumed to be the incompressible Newtonian fluid. In addition to surface tension, the fluid has constant physical properties. The surface tension is regarded as the linear function of the concentration, which is presented as σ = σ0 − σC (C–C1), where σ0 is the initial surface tension, σC is the concentration coefficient of the surface tension; furthermore, σC is expressed as σC = −∂σ/∂C = constant.

2.2. Governing Equations and Boundary Conditions

In this paper, the solutecapillary convection in the isothermal liquid bridge under microgravity is mainly studied. The gravitational effect is ignored. The surface deformation is taken into account in order to make the final results more accurate. For such a gas-liquid two-phase system, we adopt the Level set method [26] to acquire the displacement of the surface. The governing equations of the liquid bridge part in microgravity are composed of the following mass, Navier-Stokes and concentration diffusion equations:

where u = (u, ν) is the fluid velocity, ρ = ρ (x, t) is the fluid density, μ = μ (x, t) is the fluid dynamic viscosity, D′ is the viscous stress tensor, C is the concentration, p is the pressure, κ is the curvature of the interface, d is the normal distance to the interface, δ is the dirac delta function, n is the unit normal vector at the interface, D is the concentration diffusion coefficient, φ is the level set function.

The governing equations are dimensionless in order to simplify the calculation. L is the characteristic length, taking L = D = 2R. U is the characteristic velocity, taking U = σC ∆C/μl under microgravity, where μl is the dynamic viscosity. The dimensionless parameters used are as follows:

where the physical quantities marked with the symbol “-” refer to dimensionless quantities. and refer to dimensionless distances in the horizontal and vertical directions, respectively. and represent dimensionless radial and axial velocities, respectively. The main parameters are the dimensionless density ratio (ρg/ρl) and the dynamic viscosity ratio (μg/μl), among which ρl and μl are the density and dynamic viscosity of the liquid bridge, ρg and μg are the density and dynamic viscosity of the surrounding air.

Therefore, the dimensionless governing equations are described as follows:

where V represents dimensionless velocity, Reynolds number is Re = ρlUL/μl, Weber number is We = ρlU2L/σ, Concentration capillary number is CaC = σC ∆C/σ0, the dimensionless concentration C′ = (C1−C)/∆C, Schmidt number is Sc = μl/ρlD in which D is the concentration diffusion coefficient.

In the distance function, the gradient on all of the walls is set to zero. The boundary and initial conditions would be satisfied:

2.3. Level Set Method

The Level set method is to change the time-varying material interface into a zero level isosurface of the function (x, t). As long as the value of the function can be obtained at any time, the position of the isosurface can be determined. The function (x, t) is obtained from the following equation:

where u = (u, ν) is the fluid velocity. The governing equation for the level set function is derived from:

In order to suppress the numerical instability on the interface, particularly when the density ratio of the two-phase system is big, it is necessary to smooth the physical properties near the interface. It is assumed that the interface is a thin layer of thickness 2α and the physical properties within the interface layer are continuous and do not change abruptly. The Heaviside function and Dirac function are introduced, which are defined as follows:

The density ρ and dynamic viscosity μ can be signified in the following:

where subscript l is the liquid phase and g is the gas phase.

Sussman et al. [27] proposed that it be reinitialized after calculating each step to ensure that it is always a symbol distance function to prevent its instability. The reconstructed function satisfies the following equation:

where .

Chang et al. [28] proposed to track the area of the calculation domain in real time to avoid the dissipation. The level set function is amended by reinitialization, and the lost part is corrected by the variable ratio so that the area is kept constant in the whole calculation. The area compensation equation is as follows:

where A(t) is the area of liquid bridge at time t with regard to the level set function φ(x, t), A0 is the initial area at t = 0 and F(c) is expressed as the following equation:

where F(c) represents the function of the local curvature, which change with h and n. Set h = n = 0 to facilitate the convergence of the program in the calculation. The convergence criterion is as follows:

The domain of the liquid bridge and the ambient air is divided into the uniform staggered grids. The discretization method of the convection term is the quadratic upstream interpolation (QUICK) method of the convection kinematics, while the discretization method of the other terms is the central difference method. The successive over-relaxation (SOR) method is used to solve the Poisson equation of the pressure, and the continuous surface force (CSF) model is used to deal with the surface tension at the interface. Additionally, the higher essentially non-oscillatory (ENO) scheme is applied to obtain the convection term of the level set function.

Toluene/n-hexane mixture is adopted as the medium of the liquid bridge to investigate the flow characteristics of the oscillatory solutocapillary convection. The specific physical properties (Chen et al. [29]; Semenov and Schimpf [30]) are illustrated in Table 1.

Table 1.

Physical properties of toluene/n-hexane (0.24/0.76) mixture.

Four different grids are used for the test calculation in order to verify the grid independence. The grid refinement study are shown in Table 2. The velocity and concentration distributions at the surface point of the intermediate height of the liquid bridge were considered for the code validation and mesh refinement check. According to the error calculation method, the error values of the second group and the other three groups are 2.1%, 0.5% and 0.5% in the axial velocity comparison, and 4.7%, 2.5% and 1.8% in the radial velocity comparison. Meanwhile, the concentrations comparison are 1.6%, 0.5% and 0.3%. According to these results, the square grid of 81 × 41 is applied, which is enough to accurately capture the free surface, concentration and flow fields.

Table 2.

Dimensionless velocity and concentration distribution at intermediate height surface point of the right liquid bridge (ΔC = 0.025, Sc = 142.8, CaC = −0.01, R = 2.5 mm and Ar = 1.0).

3. Results and discussions

3.1. Code Validation

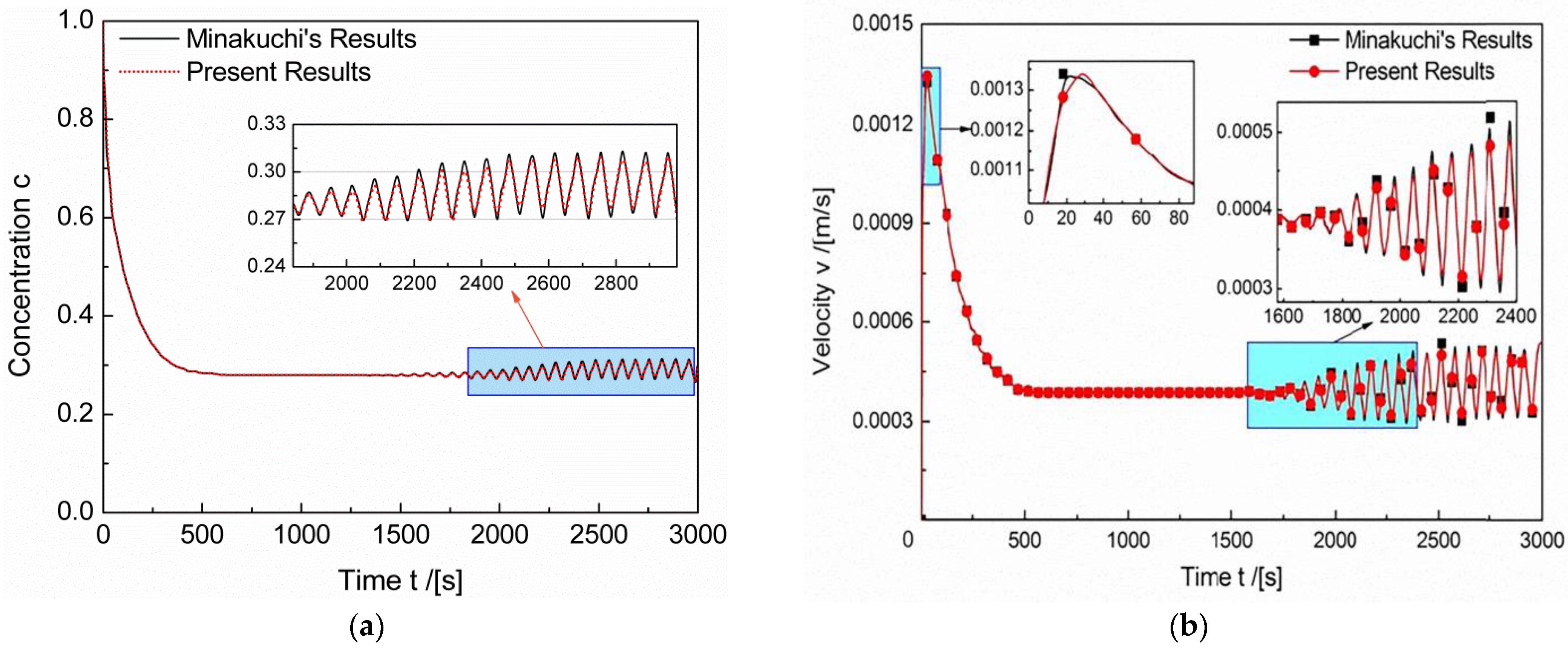

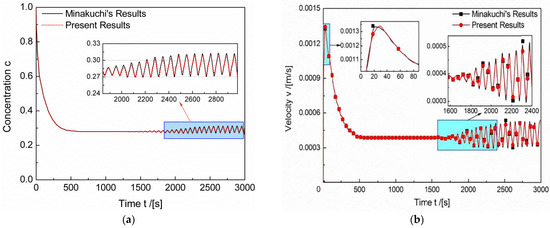

Figure 2 shows the comparison of the concentration and velocity distribution at the monitoring point (0.999R, 0.5H) near the intermediate height of the liquid bridge. The following are the main parameters: the solute Marangoni number MaC = 1107, the Schmidt number Sc = 14, where MaC can be substituted with a corresponding concentration difference according to MaC = σCρl∆CL/μl2 (other parameters can be found in Minakuchi et al. [12]). As shown in Figure 2, the present results are consistent with the results of Minakuchi et al.

Figure 2.

(a,b) Concentration and velocity comparison of monitoring point near intermediate height (MaC = 1107, Sc = 14).

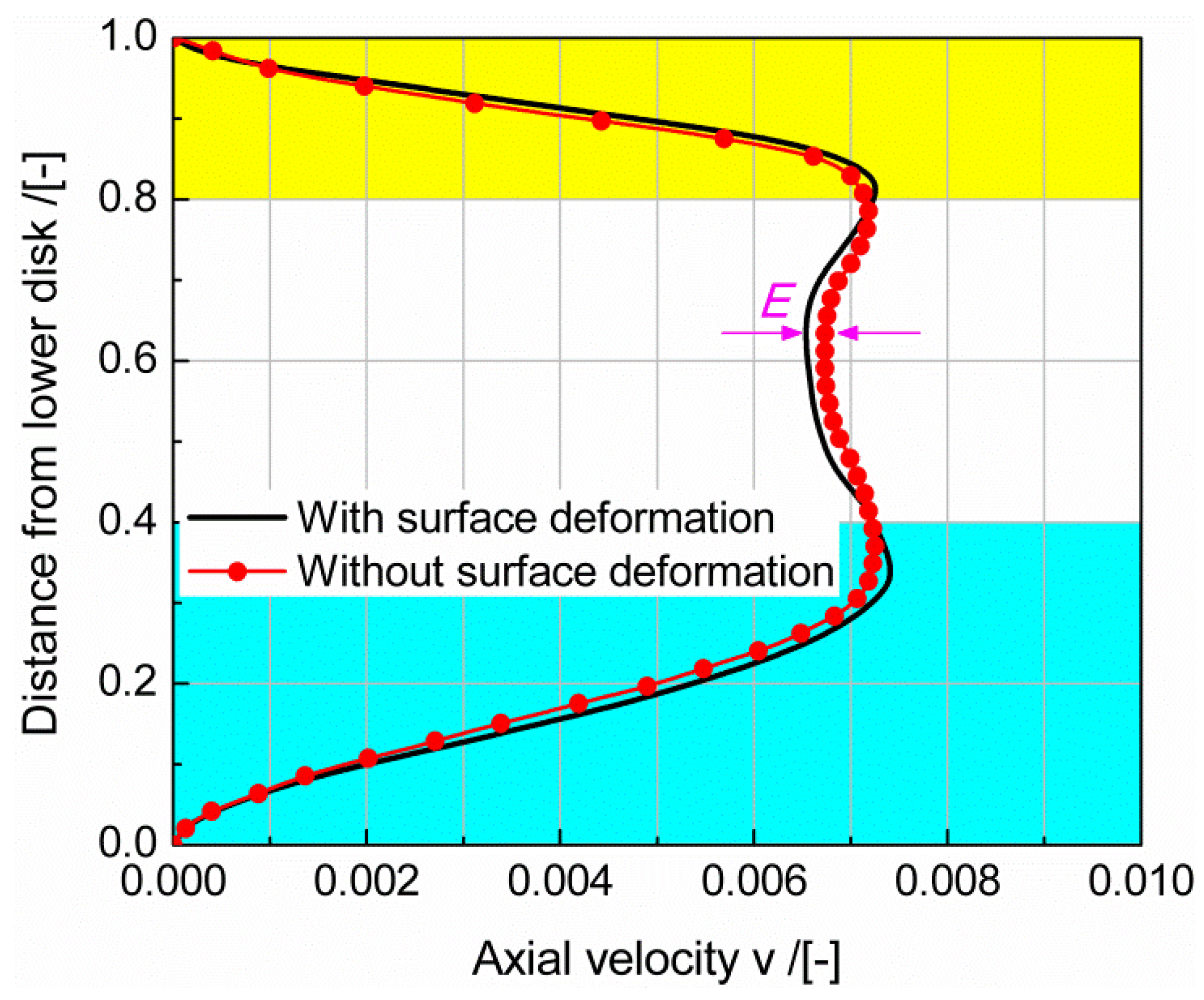

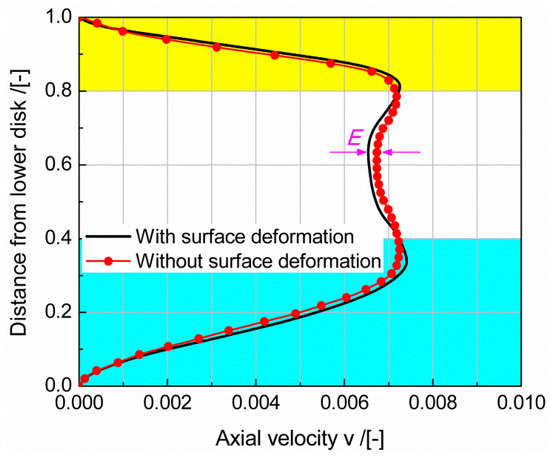

The distribution of the axial velocity on the surface with and without considering dynamic surface deformation is demonstrated in Figure 3. The following are the parameters: ∆C = 0.015, CaC = −0.006, R = 2.5 mm, H/R = 1.0, Vr = 1.0. It can be found that the axial velocity without surface deformation is less than that with surface deformation around the upper and lower disks. The reasons are that the thickness of the surface boundary layer varies with the surface deformation and the concentration gradient increases to accelerate the flow. Meanwhile, the axial flow is weakened by the transverse oscillation of the surface, to some extent, so that the axial velocity without surface deformation is greater than that with surface deformation near the intermediate height. According to the error formula Error = , where d is the difference between the corresponding points on the two curves, is the average of these differences, n is the number of selected points, dmax and dmin are the maximum and minimum in the differences, respectively. The error of the axial velocity distribution considering the dynamic surface deformation or not is approximately 5.377%. Therefore, the dynamic deformation needs to be considered in the study of the solutecapillary convection in the liquid bridge, which can improve the accuracy of the results.

Figure 3.

Distribution of axial velocity on free surface (∆C = 0.015, CaC = −0.006, H/R = 1.0, Vr = 1.0).

3.2. Oscillatory Mechanism of Solutocapillary Convection in Liquid Bridge

The monitoring points are arranged in the internal and surface areas of the liquid bridge. The location information of every monitoring point is illustrated in Table 3, and the specific location can refer to Figure 1. The monitoring points a, b and c are located in one horizontal direction and stay off the free surface in turn. The monitoring points d, b and e are in one vertical direction and stay off the upper disk in turn. The monitoring point f is on the surface of the corner, and point g is at the intermediate height and in the same vertical direction as point d. The parameters are as follows: concentration difference ∆C = 0.025, solute capillary number CaC = −0.01, diameter R = 2.5 mm, aspect ratio H/R = 1.0, volume ratio Vr = 1.0.

Table 3.

Layout of monitoring points in liquid bridge.

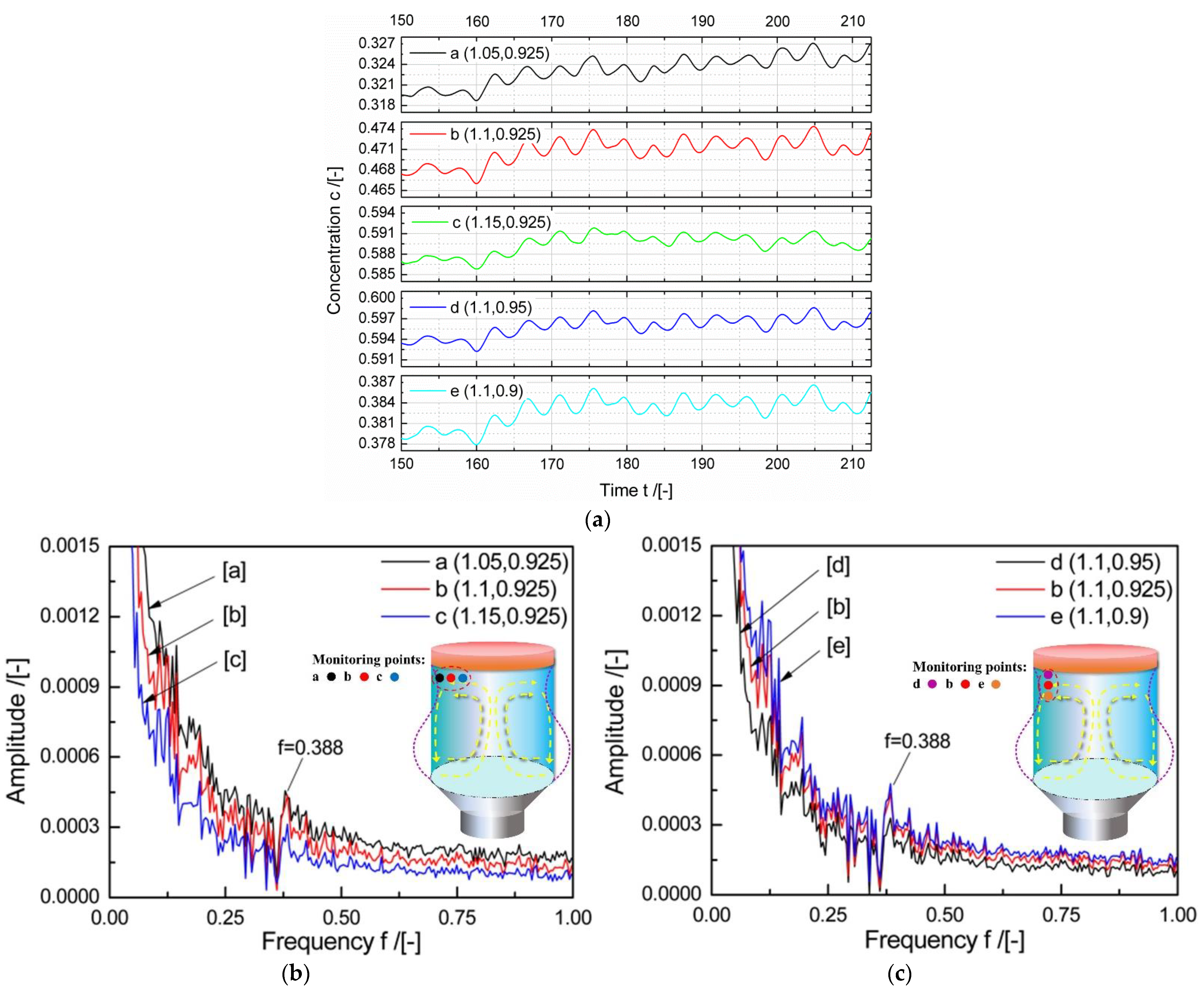

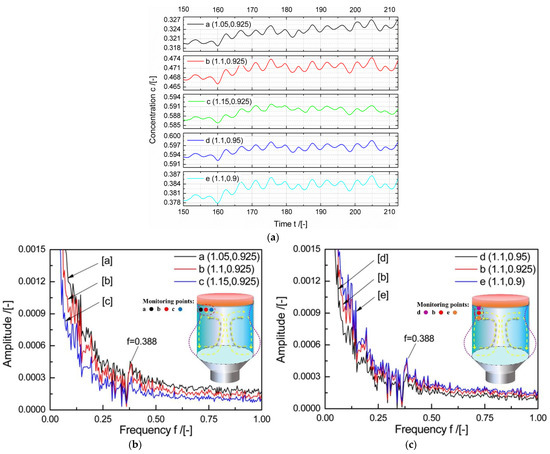

Figure 4 shows the variation of the concentration at five monitoring points within the upper corner and the FFT spectra of the concentration oscillation in the horizontal and vertical directions. It can be seen from the figure that the average period of the concentration oscillation at each monitoring point is basically the same and there is no obvious regularity of the amplitude variation with time. In the horizontal direction, the change in the concentration at the monitoring point a tends to increase with time, the average concentration at point b remains basically unchanged, and the change in the concentration at point c tends to decrease with time. As Figure 4b illustrates, the oscillation amplitude at point a is greater than that at points b and c inside the liquid bridge (Aa > Ab > Ac), which states that the closer the concentration is to the surface, the stronger the fluctuation will be, and the fluctuation will gradually transfer to the inside. The amplitudes at the three monitoring points are increased significantly with the effect of the velocity oscillation at f = 0.388, and then the change in the amplitude gradually becomes stable, indicating that the internal oscillation is influenced by the disturbance in the initial stage and the amplitude gradient change is large. As the convection development, the mutual coupled effect of the oscillations of the concentration and velocity causes the oscillation to be a high-frequency and stable oscillation. Vertically, Figure 4c illustrates that monitoring points d, b and e stay off the upper disk in turn, and the fluctuation is transmitted downwards due to the concentration diffusion. The change law of the amplitude is Ae > Ab > Ad, indicating that the intensity of the concentration oscillation at point e is slightly greater. At the top of the corner, the major return flow driven by the surface flow is limited under the constraint of the upper disk and the flow velocity is less than that in the lower position of the corner, where the concentration oscillation excited by the coupled effect of the velocity and surface is more intense. The change in the amplitude in the vertical direction is similar to that in the horizontal direction at f = 0.388.

Figure 4.

(a) Concentration variation of monitoring points in upper corner area; (b,c) FFT spectra of concentration oscillation in horizontal and vertical directions (CaC = −0.01, R = 2.5 mm, H/R = 1.0, Vr = 1.0).

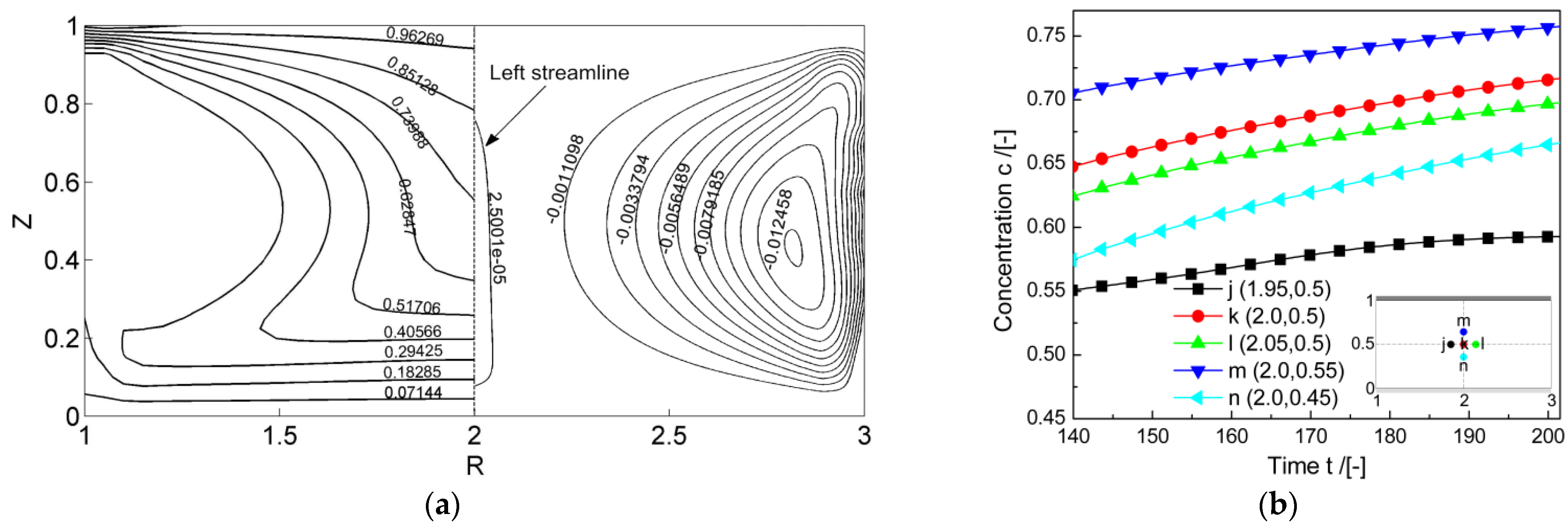

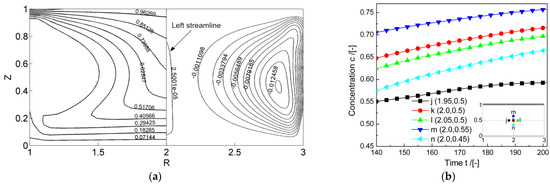

The distributions of the concentration and flow fields at t = 150 and the concentration distribution at the central monitoring points are shown in Figure 5. The internal cell flow structures and concentration contours are no longer symmetrical when the solutocapillary convection oscillates. The outermost streamline of the cell flow in the clockwise direction (value of flow function is greater than zero) on the left side has crossed the centerline, as shown in Figure 5a, indicating that the cell flow in the counterclockwise direction on the right has been invaded, and the concentration contours have been tilted to the right accordingly. The cell flow encroachment is mainly reflected in the middle and lower part because the oscillation disrupts the equilibrium state of the cell flow structures on both sides in the stable phase. As convection development, the vortex center remains near the intermediate height, and the concentration distribution at the central monitoring points is given. Figure 5b is illustrates that the concentration diffuses down slowly, and the concentration is Cm > Ck > Cn in the vertical direction. In the horizontal direction, the concentration at monitoring points j and l is Cj < Cl, and the high-concentration fluid is transported to the right. Compared with the concentration oscillation at the high-concentration corner, the distribution of the concentration at these monitoring points does not oscillate. The reason is that the corner is a sensitive area and it is susceptible to disturbance in the solutocapillary convection. The concentration development near the center is mainly downward diffusion. Due to the long diffusion time, the slow velocity of the central fluid, and the interaction of the flow of two cells, there will be a certain resistance in the center. Therefore, under the effect of the concentration difference and the resistance, the concentration will not oscillate.

Figure 5.

(a) Distributions of concentration and velocity fields at t = 150; (b) Concentration distribution at monitoring points in the center of liquid bridge (CaC = −0.01, R = 2.5 mm, H/R = 1.0, Vr = 1.0).

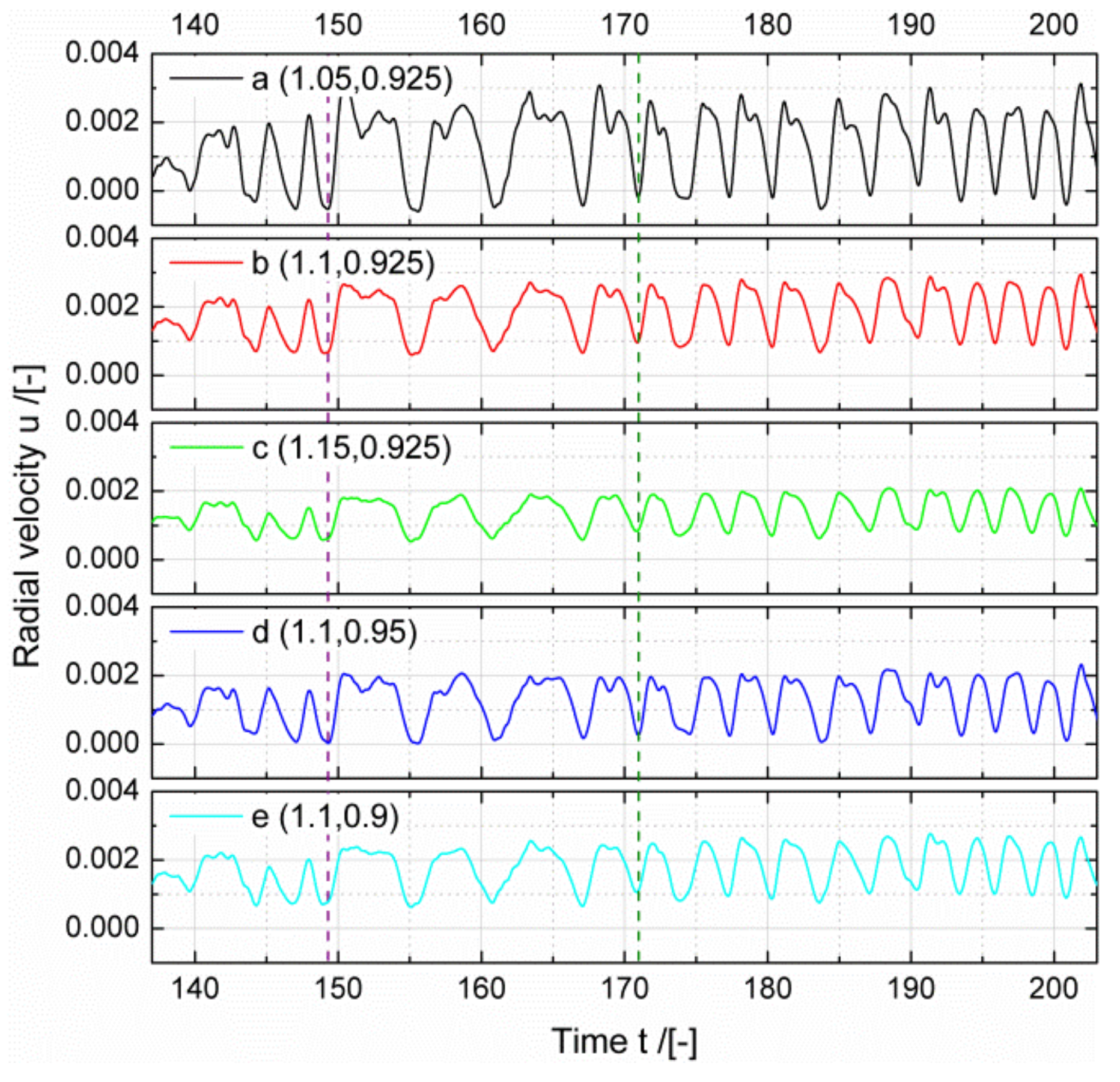

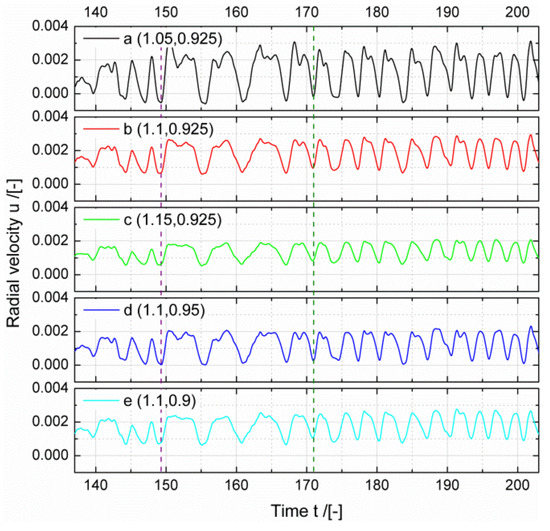

Figure 6 and Figure 7 represent the oscillations of the radial and axial velocities at the monitoring points in the high-concentration corner, respectively. On the whole, the law of radial velocity oscillation is relatively obvious, while the axial velocity oscillation is relatively disordered, showing certain pulsation characteristics. The radial velocity is greater than the axial velocity and the oscillation is more intense, and the oscillation of the velocity occurs prior to the oscillation of the concentration. As shown in Figure 6, the radial velocity begins to oscillate at t = 149 after a high-frequency disturbance, and the average oscillation period is T = 5. At t = 171, the oscillation period begins to decrease and the frequency increases, but the amplitude basically remains unchanged and begins to enter a stable high-frequency oscillation stage. In the horizontal direction, the velocity oscillation at point a is the most intense, and the oscillation is transmitted from the surface to the inside in terms of the amplitude and attenuation direction (Aa = 0.0028® Ab = 0.002® Ac = 0.0014). As shown in Figure 7, the axial velocity of each monitoring point presents certain pulsation characteristics after the disturbance, and the oscillation period and amplitude are small, indicating that the oscillation of the radial velocity is dominant at the corner. The transmission direction of the axial velocity oscillation is the same as that of the radial velocity. The further away from the high-concentration corner, the more intense the oscillation in the vertical direction. The transmission direction of the fluctuation is from the bottom to the top (Ae = 0.0011®Ab = 0.0008®Ad = 0.0003). In general, the oscillation of the velocity is mainly affected by the variety of the solutocapillary convection on the surface and the motion of the cell flow structure on both sides, which will directly affect the redistribution and rebalance of the concentration with a long diffusion time. The oscillation of the concentration lags behind that of the velocity eventually, which also shows that the oscillatory principle of the velocity and concentration is different.

Figure 6.

Variation of radial velocity at monitoring points (CaC = −0.01, R = 2.5 mm, H/R = 1.0, Vr = 1.0).

Figure 7.

Variation of axial velocity at monitoring points (CaC = −0.01, R = 2.5 mm, H/R = 1.0, Vr = 1.0).

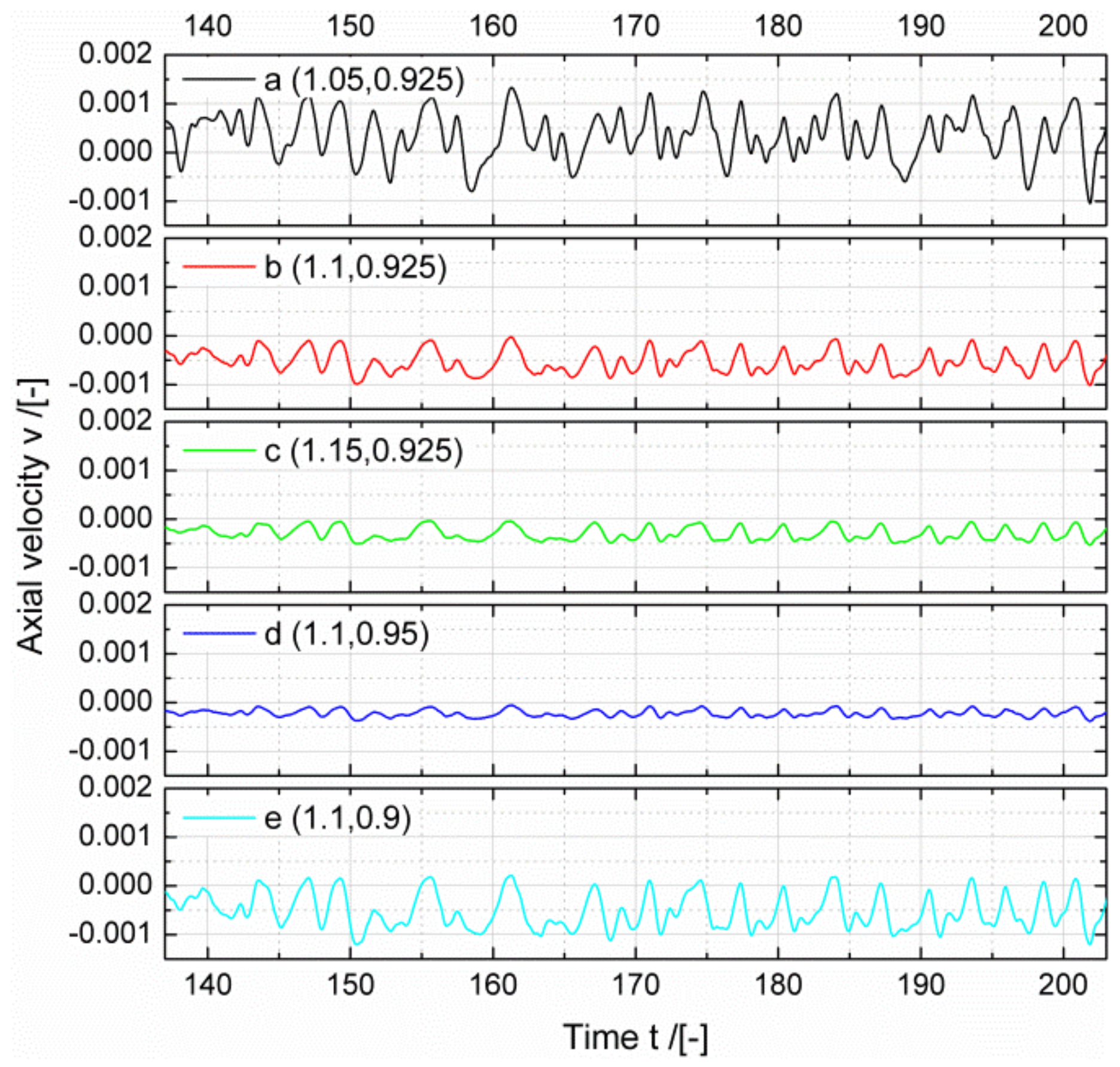

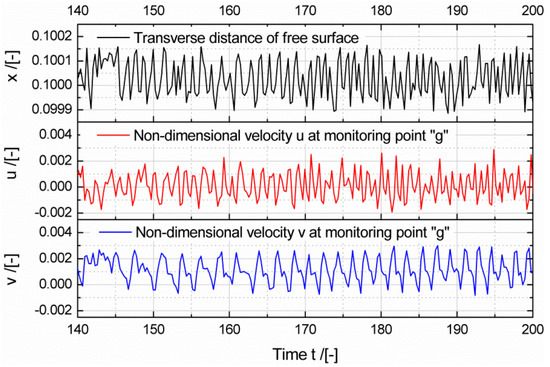

The velocity and transverse displacement oscillations of monitoring point f (1.0, 0.925) on the free surface of the corner area are shown in Figure 8, and the oscillation will gradually show certain pulsating characteristics. The transverse displacement is less than zero, indicating that the flow direction of the fluid medium is from the gas side to the liquid side; that is to say, the free surface is concave to the inside of the liquid bridge near the upper disk. After a period of disturbance, the average oscillation period is basically the same as that of the radial velocity (T ≈ 5). In contrast to the oscillation of the radial velocity, the transverse displacement of the surface enters the high-frequency disordered oscillation period at the later stage of the oscillation, which indicates that the different forms of the oscillation interaction of the radial and axial velocities in the corner region lead to the surface instability. The oscillatory pattern of axial velocity is similar to that of the radial velocity, which gradually changes from the low-frequency oscillation to the high-frequency oscillation, and the amplitude is basically unchanged. As a whole, the oscillatory pattern of the velocity on the surface is the same as that inside the corner. The change of the radial velocity is dominant, and the oscillation is relatively intense.

Figure 8.

Oscillation of velocity and lateral displacement of monitoring point f on the free surface of corner area (CaC = −0.01, R = 2.5 mm, H/R = 1.0, Vr = 1.0).

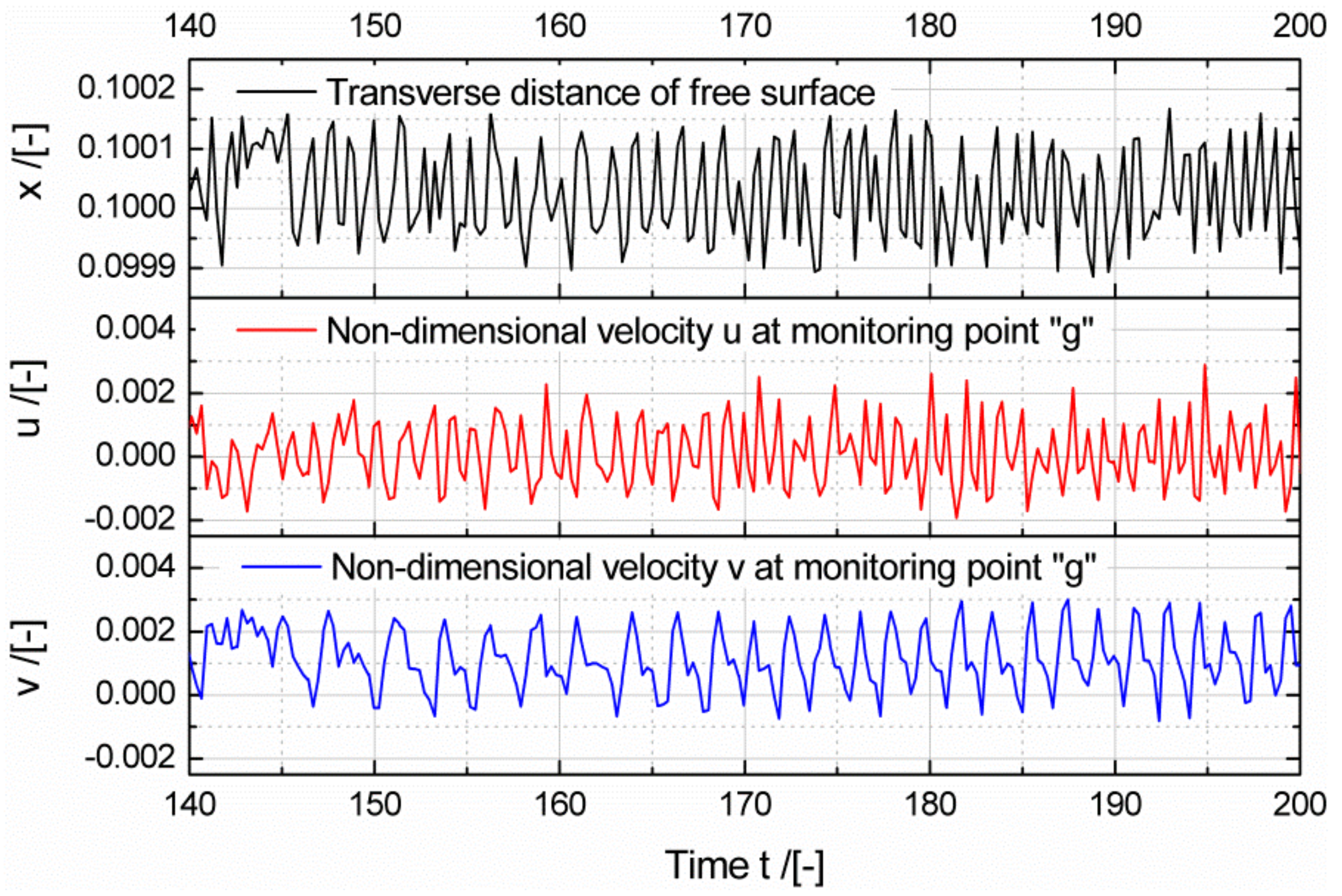

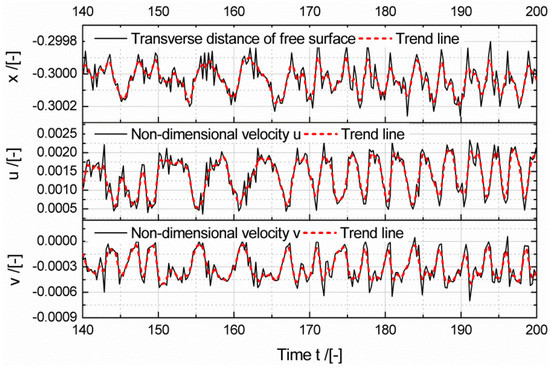

Figure 9 shows the change of surface transverse displacement, radial velocity and axial velocity with time at the monitoring point g (1.1, 0.5). For the onset time of oscillations, the velocity and the transverse displacement start to oscillate regularly in turn. In terms of the oscillation forms, the radial velocity and transverse displacement belong to the high-frequency oscillation, and both have the same average oscillation period. In the later period of oscillation, the transverse displacement and velocity express a tendency of decreased period and increased frequency. On the whole, the oscillation frequency of the velocity and transverse displacement at the intermediate height is higher than that at the monitoring point f. At the same time, the transverse displacement is also smaller than that at the corner area, indicating that the deformation degree is small. The magnitude and amplitude of the axial velocity are greater than the radial velocity, and the oscillation law is more apparent at the intermediate height, indicating that the oscillation of the axial velocity is more intense.

Figure 9.

Variations of velocity and corresponding displacement of free surface at monitoring point g (CaC = −0.01, R = 2.5 mm, H/R = 1.0, Vr = 1.0).

Based on the above analysis of the flow characteristics, it can be concluded that the oscillatory mechanism of the solutocapillary convection under microgravity is as follows: in the case where the concentration difference between the upper and lower disks is constant, the concentration diffusion takes a long time, and the surface tension non-uniformity exists for a long time. The high-concentration corner is vulnerable to disturbance. Although the corner area is small in scale, its fluctuation will affect the overall flow of the liquid bridge. Due to the high concentration and large velocity, the flow in the corner area is primarily affected by the surface flow and the acceleration process of the return flow when considering the surface dynamic deformation. In other words, when the thickness of the surface boundary layer changes, the concentration gradient will increase accordingly, resulting in accelerated flow. As the degree of the surface deformation is reflected in the surface pressure affected by the radial velocity, the surface oscillation in this region is followed by the oscillation of the velocity. The coupling effect of the oscillating solutecapillary convection originating from the high concentration corner region through the velocity, free surface and concentration oscillation will present the above unique oscillation characteristics in the liquid bridge.

3.3. Influence of Aspect Ratio on Flow Characteristics of Oscillatory Solutocapillary Convection in Liquid Bridge

The solutocapillary convection in the liquid bridge presents some unique characteristics, including the long-term existence of concentration non-uniformity, the slow, weak and extremely unstable development of the convection, and the concentration rebalance phenomenon on the surface. This section mainly discusses the effect of the aspect ratio on the characteristics of the oscillating solute capillary convection flow. The specific aspect ratios are settled as 0.9, 0.95, 1.05 and 1.1. The other parameters are as follows: ∆C = 0.025, CaC = −0.01, D = 5.0 mm, Vr = 1.0.

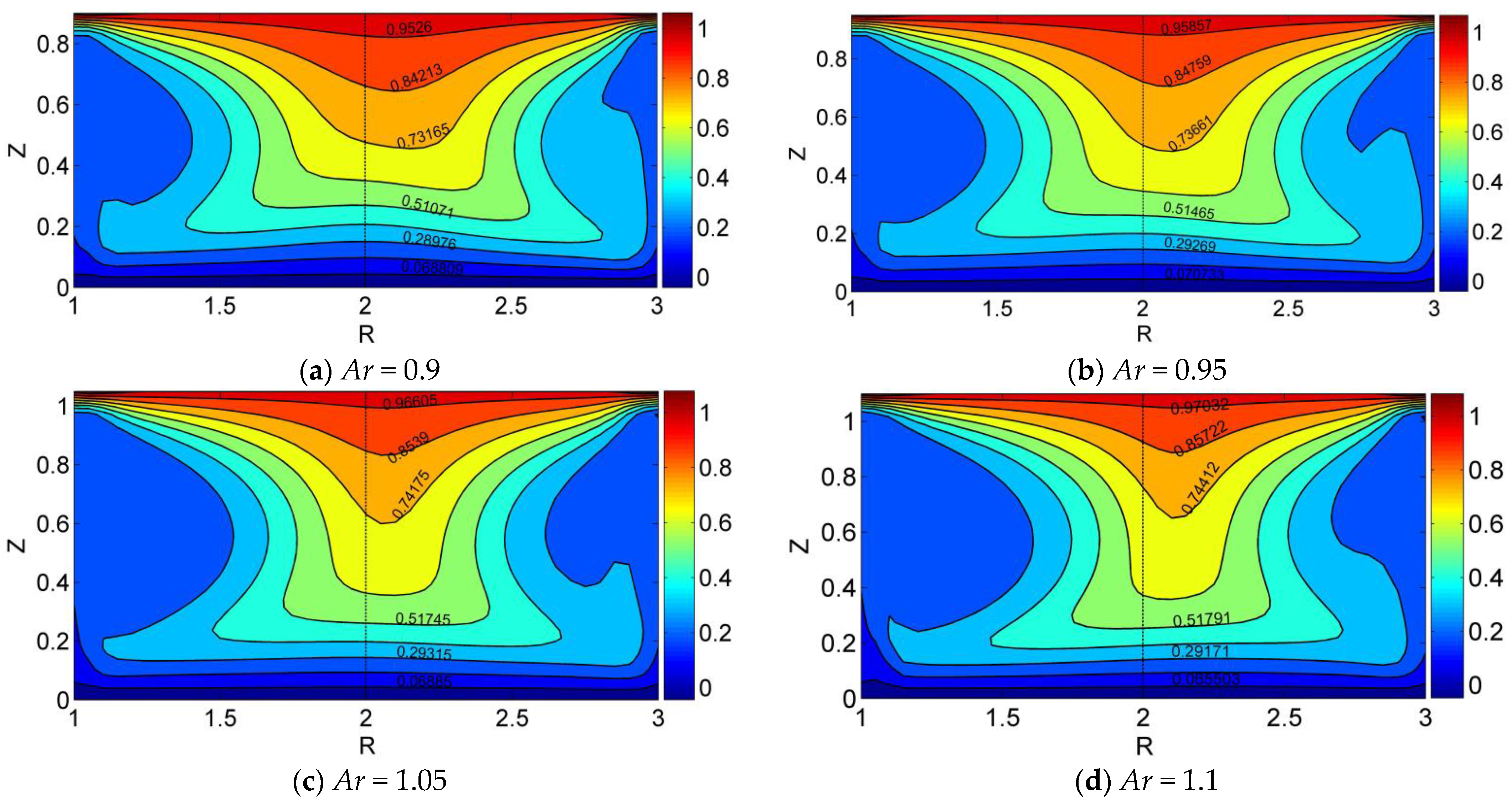

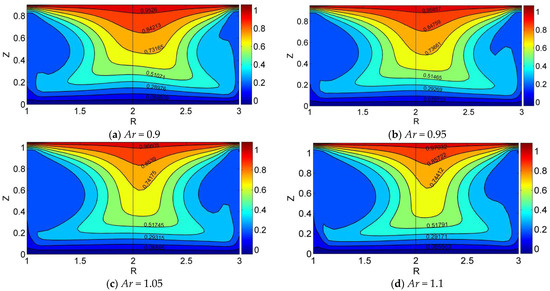

Figure 10 shows the concentration contour distribution inside the liquid bridge under different aspect ratios at the same time. Through comparison, it is found that the higher the liquid bridge height is, the higher the concentration level in the middle and upper parts is. The concentration gradient on the surface of the upper corner and inside the liquid bridge near the lower disk is large. There is no obvious regularity of the concentration change near the lower disk, and the asymmetry of the contour is prominent. The asymmetry of the contour lines indicates that the left-right oscillation and the mutual encroachment of the cell flow structures on both sides are more intense. The concentration contour gradually moves closer to the center and forms a large radial concentration gradient with the increase in the height, which intensifies the convection movement. On the contrary, the smaller the height, the more uniform the internal concentration distribution.

Figure 10.

Concentration distribution in oscillatory stage (CaC = −0.01, R = 2.5 mm, (a) H/R = 0.9, (b) H/R = 0.95, (c) H/R = 1.05, (d) H/R = 1.1, Vr = 1.0).

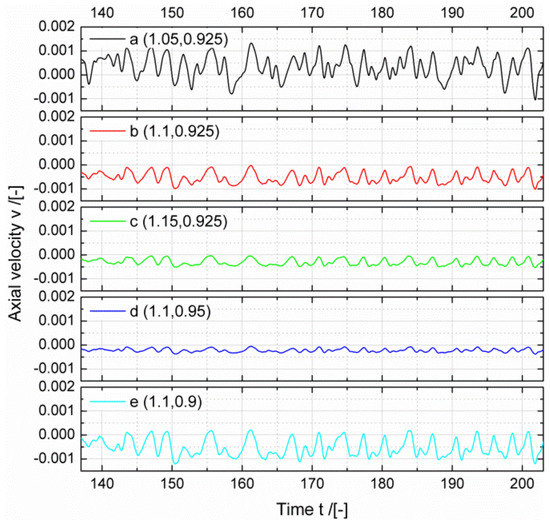

From the above, the radial velocity oscillation is relatively intense and has obvious regularity in the corner area of high concentration, and the axial velocity oscillation is relatively intense and has obvious regularity near the intermediate height of the liquid bridge surface. Therefore, the specific velocity oscillation distribution of the corner region and the intermediate height monitoring points of the liquid bridge under different aspect ratios will be given next, where the position information of the monitoring points expresses the same section of the liquid bridge at different heights, as shown in Table 4.

Table 4.

Layout of monitoring points in liquid bridge under different aspect ratios.

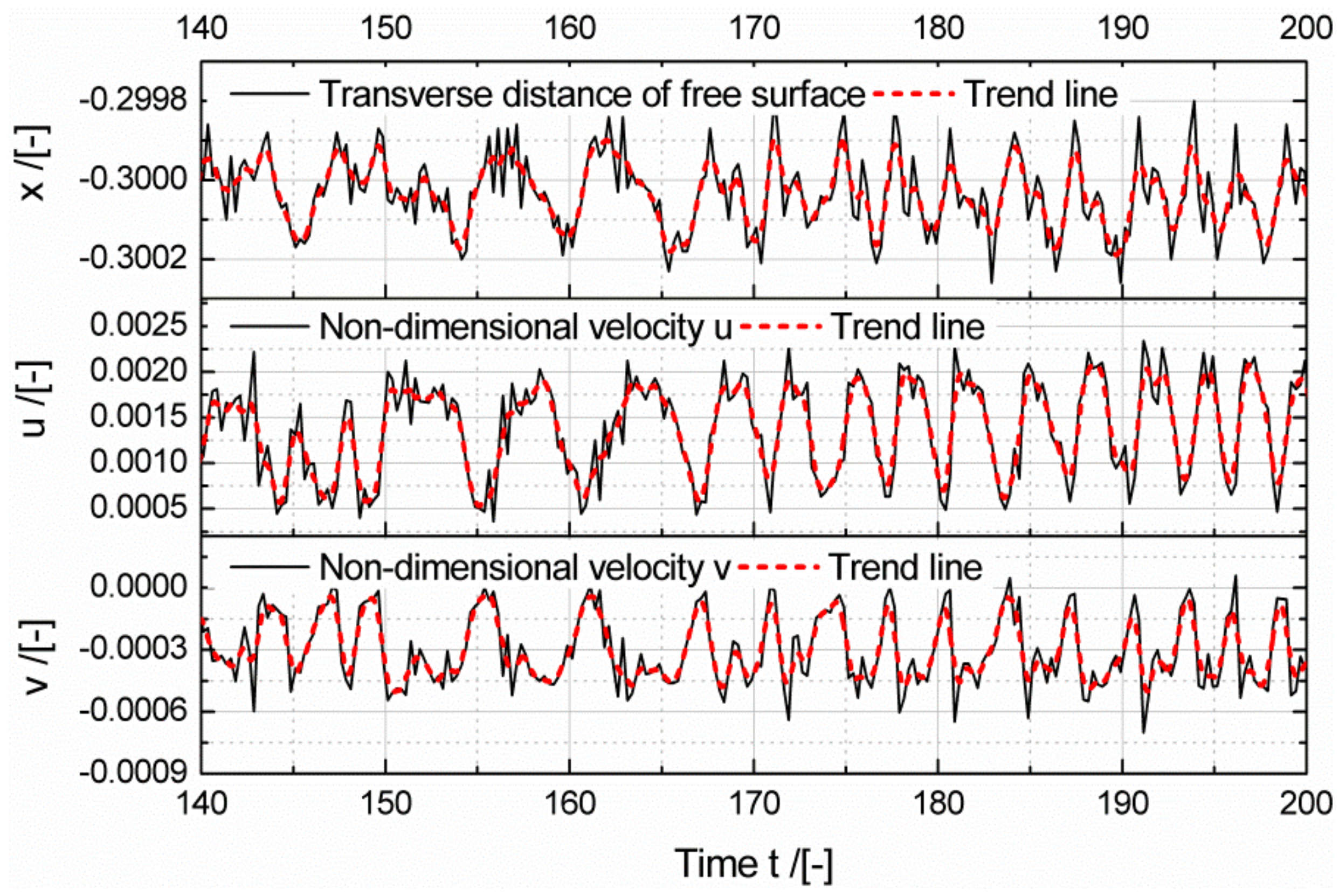

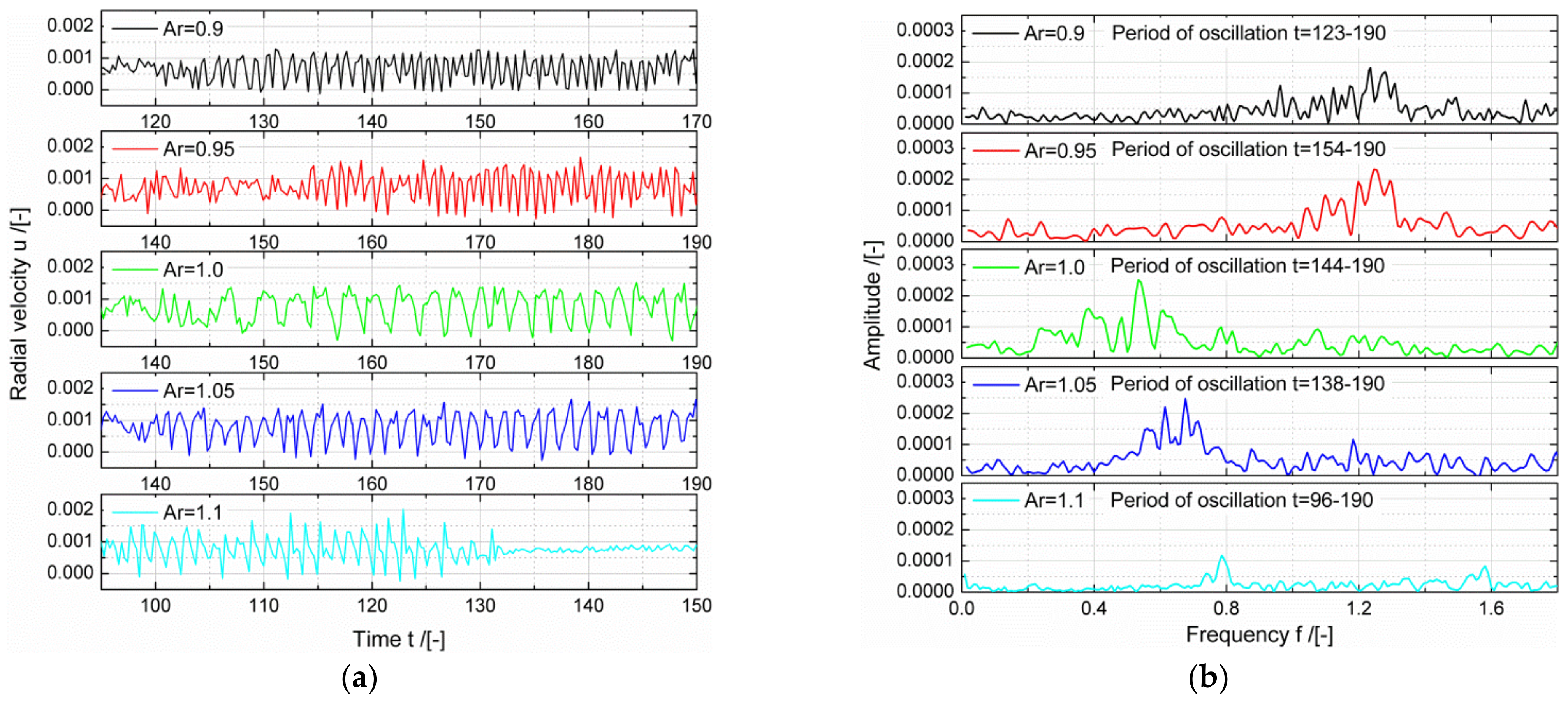

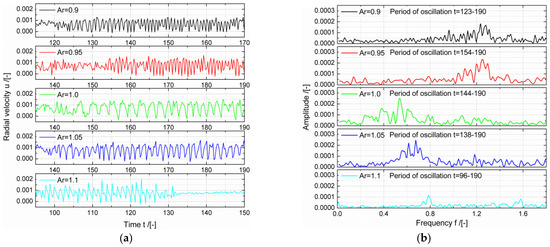

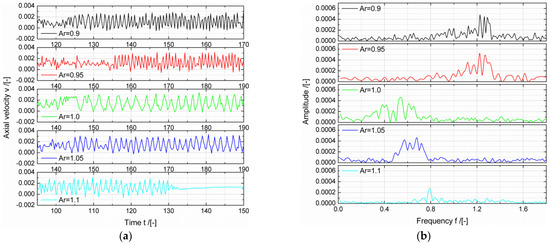

The distribution of the radial velocity oscillations and FFT spectra at the monitoring point h in the liquid bridge with different heights is shown in Figure 11. It can be found that the oscillation in the other four cases is high-frequency compared with Ar = 1.0. The oscillation onset time of Ar = 0.95 is later than Ar = 1.0, while the other onset time is earlier, and the velocity at Ar = 1.1 starts to oscillate first. In the case of coupled oscillations of concentration, velocity, and surface, there is a complex relationship between the onset time of oscillation and the height, which is not simply similar to the relationship that the larger the height of the liquid bridge, the slower the concentration diffusion and the later the oscillation onset time. In terms of the amplitude of the oscillation, the bigger the height is, the bigger the amplitude of the radial velocity at the corner within a certain height range is, indicating that the more intense the oscillation, the more unstable the convection. However, due to the mutual dissipation between the internal convection and the oscillation energy of the liquid bridge, the variation of the radial velocity becomes steady after a period of oscillation. From the FFT spectra, the amplitude of the oscillation expands with the increase in the aspect ratio. As the onset time of oscillation is different under different aspect ratios, the frequency range of sharp amplitude changes is also different. The amplitude change becomes stable at Ar = 1.1 due to the relationship of mutual dissipation mentioned above.

Figure 11.

(a) Radial velocity oscillations at monitoring point h with different aspect ratios; (b) FFT spectra of radial velocity oscillations (CaC = −0.01, R = 2.5 mm, H/R = 0.9, 0.95, 1.0, 1.05 and 1.1, Vr = 1.0).

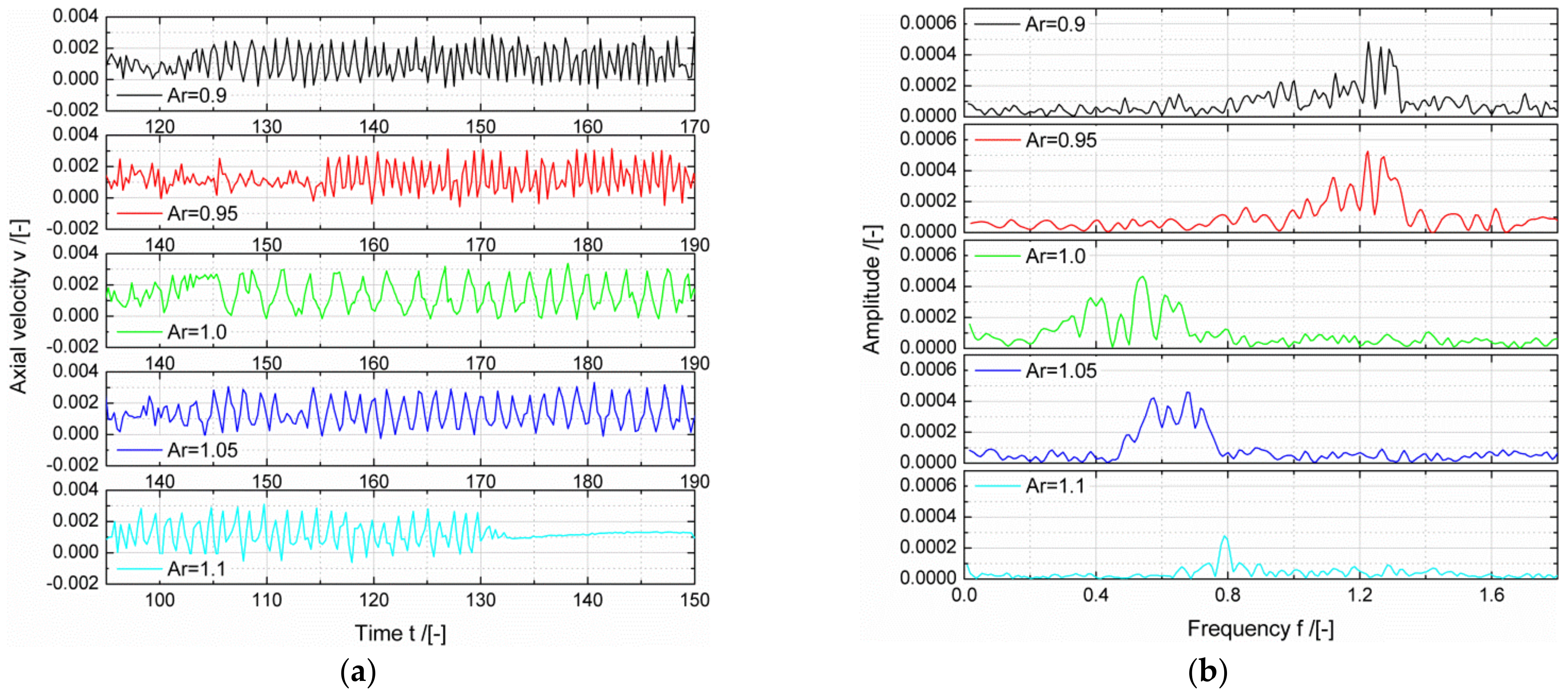

Figure 12 shows the distribution of the axial velocity oscillations and FFT spectra at the monitoring point i under different heights. The variation rule of the oscillation onset time and oscillation amplitude is the same as the radial velocity at the monitoring point h in the corner area, and the effect of the different aspect ratios on the flow stability is also the same.

Figure 12.

(a) Axial velocity oscillations at monitoring point i with different aspect ratios; (b) FFT spectra of axial velocity oscillations (CaC = −0.01, R = 2.5 mm, H/R = 0.9, 0.95, 1.0, 1.05 and 1.1, Vr = 1.0).

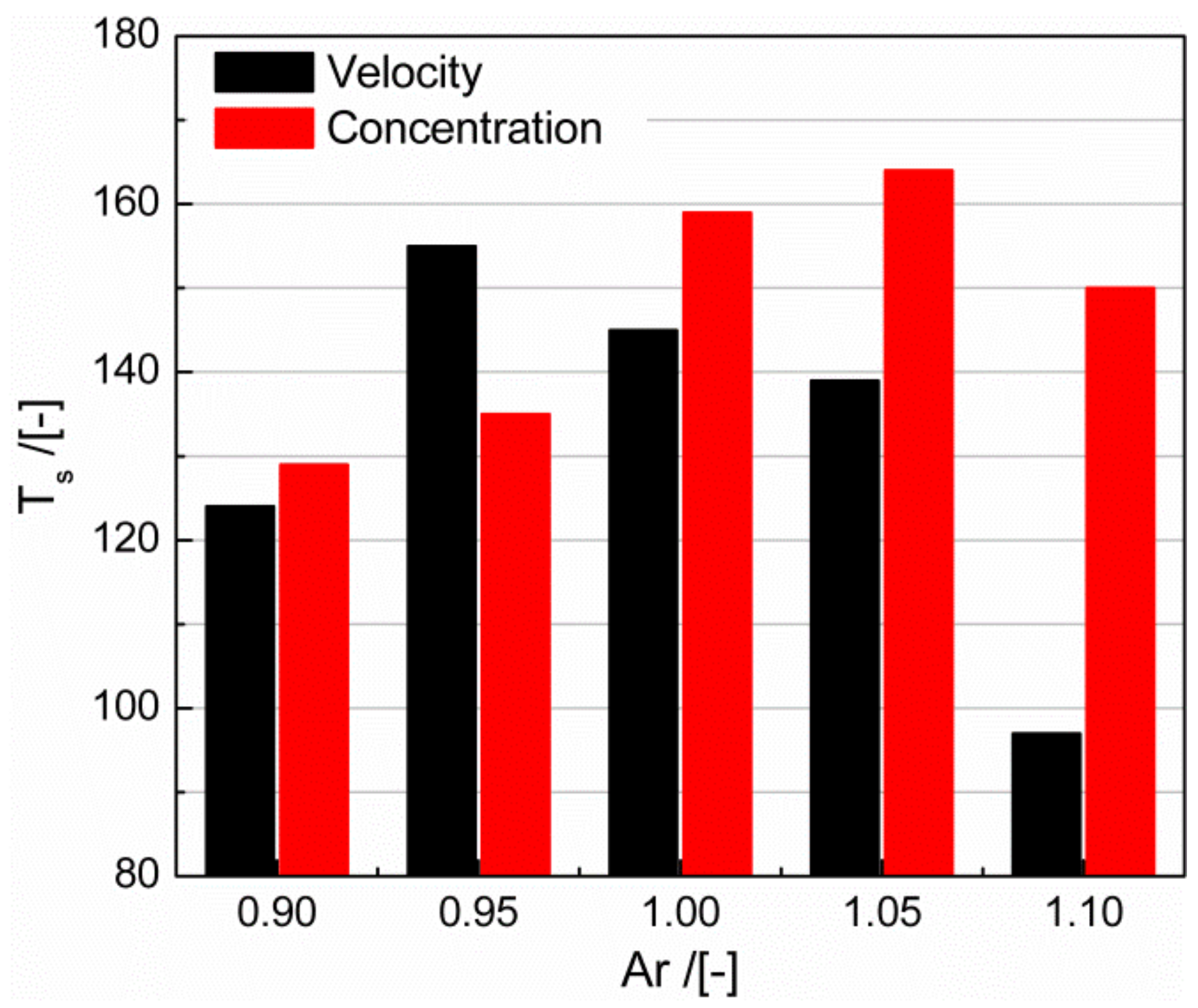

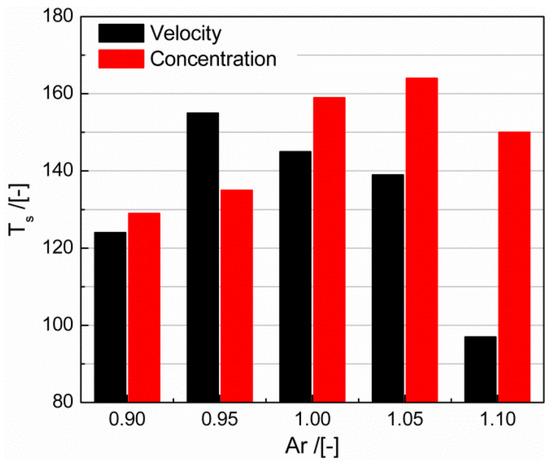

In the above study, as the onset time of the oscillation of the velocity and transverse displacement at the corner area is close to that of the intermediate height, the onset time of the velocity and concentration is plotted uniformly for comparison. Figure 13 shows the onset time of the oscillations of the velocity and concentration at the corner area with five aspect ratios. The trend of the onset time changing with the aspect ratio is approximately parabolic. The red part in the figure demonstrates that the diffusion time is longer when the size becomes larger. The onset time of the concentration extends with the increase in the aspect ratio, and the extension begins to decrease when Ar > 1.0, and suddenly decreases when Ar = 1.1. This means that the left-right swing of the surface and the internal convection offset each other, resulting in the rapid development of the concentration and the reduction in the time when the concentration level tends to be uniform. At the same aspect ratio, compare the onset time of the red and black parts. At Ar = 0.9, 1.0, 1.05 and 1.1, the initial time of the concentration oscillation is greater than the initial time of velocity, which verifies the above oscillating mechanism of the solute capillary convection. The situation is reversed at Ar = 0.95, indicating that the coupling oscillations of velocity, surface and concentration can promote and offset each other. There is a critical liquid bridge aspect ratio Arc between the two cases. Meanwhile, the complex interaction mechanism inside the small-scale liquid bridge and the corresponding critical aspect ratio need to be further discussed because the concentration diffusion is slow and the convection is relatively weak. Compared with the onset time of the velocity oscillation in the black part, the oscillation at Ar = 0.9 is significantly earlier than that at Ar = 1.0. The main reason is that the concentration diffusion accelerates with the decrease in the height, which makes the evolution of the solutocapillary convection faster. There is still a downward trend in the onset time of the velocity oscillation at 1.0 ≤ Ar ≤ 1.05, which indicates that the flow instability caused by the strong convection inside the liquid bridge is the main reason for the advance of the velocity oscillation.

Figure 13.

Onset time of oscillations of velocity and concentration with different aspect ratios (CaC = −0.01, R = 2.5 mm, H/R = 0.9, 0.95, 1.0, 1.05 and 1.1, Vr = 1.0).

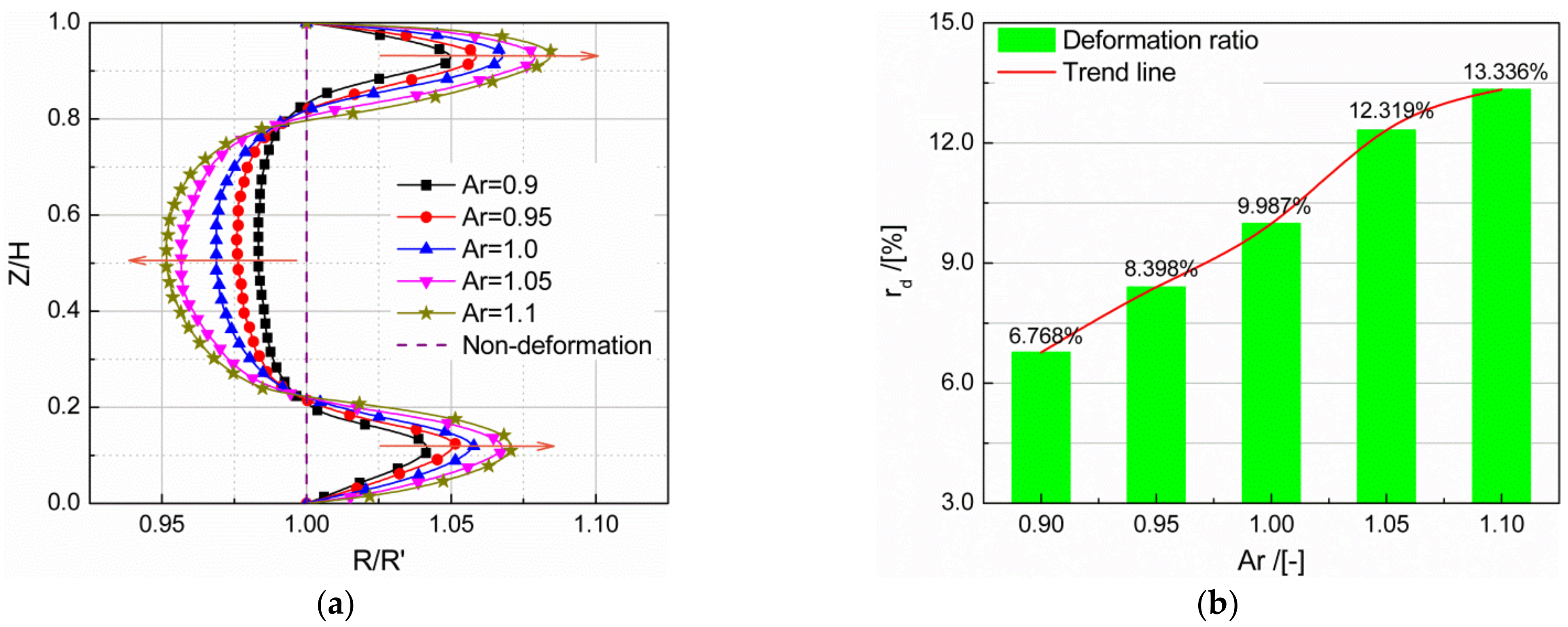

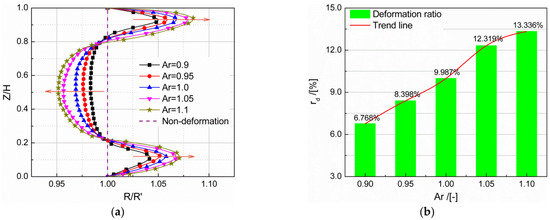

Figure 14 shows the deformation of the left surface of the liquid bridge under five aspect ratios and the corresponding deformation rate, where R’ is the transverse distance from the deformable free surface to the central axis of the liquid bridge. Figure 14a illustrates that the surface deformation trend of the different aspect ratios is the same, and the surface is concave near the upper and lower disks, whereas it is convex in the middle part. The positions of the maximum contraction points are Z/H = 0.12 and Z/H = 0.93, respectively, and the axial position of the maximum bulge point is Z/H = 0.52. The area of the concave surface is equal to that of the convex surface, indicating that the area of the liquid phase is conserved in the calculation. In the horizontal direction, the curvature of the surface expands with the increase in the aspect ratio (see the orange arrows in Figure 14a), which is related to the phenomenon that the radial concentration gradient increases with the increase in the aspect ratio, as illustrated in Figure 10. As shown in Figure 14b, according to the deformation rate rd = (R’max − R’min)/R, the deformation rate increases monotonically, from 6.768% to 13.336%, when the aspect ratio gradually increases from 0.9 to 1.1, which also indicates that the deformation degree of the surface gradually increases.

Figure 14.

(a) Surface deformation with different aspect ratios; (b) Variation of deformation rate rd with Ar (CaC = −0.01, R = 2.5 mm, H/R = 0.9, 0.95, 1.0, 1.05 and 1.1, Vr = 1.0).

4. Conclusions

In this paper, the oscillatory solutocapillary convection in the liquid bridge is numerically investigated, the oscillating mechanism is revealed, and the influence of the aspect ratio on the flow stability is investigated in detail. Simultaneously, the relationship between the concentration, velocity and surface of the onset time of the surface oscillation under different aspect ratios, as well as the complex mutual promotion and offset of the three coupled oscillations are analyzed. The main conclusions are as follows:

- The complex coupling effect of the oscillation among the concentration, velocity and surface leads to the oscillating solutecapillary convection starting from the high concentration corner area. The oscillation at the middle height is later than that in the corner area, and the oscillation of the concentration and velocity is stronger because it is closer to the surface. The oscillation intensity of the concentration in the corner area is relatively larger than that in the middle height. The oscillation of the radial velocity is stronger than that of the axial velocity and has obvious regularity, while the oscillation of the axial velocity at the middle height is significantly stronger than that of the radial velocity and has obvious regularity. The oscillation on the free surface belongs to high-frequency oscillation, and the oscillation of the transverse displacement of the free surface in the corner region is stronger than that of the free surface at the intermediate height.

- Within a certain height range, the smaller the height of the liquid bridge (corresponding to 0.9 ≤ Ar ≤ 1.0), the more stable the solutocapillary convection. The larger the height (corresponding to 1.0 ≤ Ar ≤ 1.05), the greater the amplitudes of the oscillations for the concentration, velocity, and surface. At a constant concentration difference, there is no obvious positive correlation between the onset time of the velocity and concentration oscillation and different aspect ratios. There is a relationship of mutual promotion and offset between the coupling oscillations of the concentration, velocity and surface transverse displacement.

Author Contributions

Project administration, R.L. and S.Y.; Conceptualization, R.L.; Methodology, R.L.; Validation, S.Z. and S.Y.; Writing—original draft preparation, S.Z.; Writing—review and editing, R.L. and S.Y. All authors have read and agreed to the published version of the manuscript.

Funding

The present work is supported financially by the National Natural Science Foundation of China under the grant of 51976087 and 51906163, the Science and Technology Program Foundation of Liaoning Province (2021-MS-270 and LIKZZ20220138), Shenyang Science and Technology Project (No. 21-108-9-08 and No. RC210010) and Postgraduate Education and Teaching Reform Research Project in Liaoning Province.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| A | Amplitude |

| Ar | aspect ratio, H/R |

| C′ | dimensionless concentration, (C1-C)/(C1-C0) |

| ∆C | concentration difference, C1-C0 |

| CaC | concentration capillary, σC ∆C/σ0 |

| D | concentration diffusion coefficient |

| D′ | viscous stress tensor |

| f | frequency |

| H | liquid bridge height |

| L | characteristic length |

| n | unit normal vector of gas-liquid interface |

| p | dimensionless pressure, p/(ρlU2) |

| R | liquid bridge radius |

| Re | Reynolds number, ρlUL/μl |

| Sc | Schmidt number |

| T | period |

| t | time |

| U | characteristic velocity |

| u | fluid velocity |

| V | dimensionless velocity |

| We | Weber number, ρlU2L/σ |

| u,v | velocity in the X and Z directions |

| X,Z | radial and axial coordinates |

| - | dimensionless |

| Greek symbols | |

| μ | dynamic viscosity |

| ρ | density |

| κ | curvature of gas-liquid interface |

| δ(d) | dirac trigonometric function |

| σ0 | initial surface tension |

| σC | concentration coefficient of surface tension |

| φ | level set function |

| Subscripts | |

| 0 | lower disk |

| 1 | upper disk |

| g | gas |

| l | liquid |

References

- Laknath, R.; Mendis, A.; Sekimoto, A.; Okano, Y.; Minakuchi, H.; Dost, S. A numerical study on the exact onset of flow instabilities in thermo-solutal Marangoni convection driven by opposing forces in a half-zone liquid bridge under zero gravity. J. Chem. Eng. JPN. 2021, 54, 424–430. [Google Scholar] [CrossRef]

- Kawaji, M.; Liang, R.Q.; Nasr-Esfahany, M.; Simic-Stefani, S.; Yodab, S. The effect of small vibrations on Marangoni convection and the free surface of a liquid bridge. Acta Astronaut. 2006, 58, 622–632. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z.; Liu, H.; Zhang, L.Q.; Yin, L.M.; Xiao, Y.; Liu, Y. Flow instabilities in thermocapillary liquid bridges between two coaxial disks with different radii. Int. J. Heat Mass Tran. 2022, 183, 122182. [Google Scholar] [CrossRef]

- Liang, R.Q.; Zhou, J.L.; Yang, S.; Zhang, Y.Y.; Shi, J.H.; Xiao, S. Experimental study on transition characteristics of theremo-solutocapillary convection under buoyancy. Exp. Therm. Fluid Sci. 2019, 106, 38–47. [Google Scholar] [CrossRef]

- Bratukhin, Y.K.; Kostarev, K.G.; Viviani, A.; Zuev, A.L. Experimental study of Marangoni bubble migration in normal gravity. Exp. Fluids 2005, 38, 594–605. [Google Scholar] [CrossRef]

- Campbell, T.A.; Schweizer, M.; Dold, P.; Cröll, A.; Benz, K.W. Float zone growth and characterization of Ge1−xSix (x ≤ 10 at %) single crystals. J. Cryst. Growth 2001, 226, 231–239. [Google Scholar] [CrossRef]

- Benz, K.W.; Dold, P. Crystal growth under microgravity: Present results and future prospects towards the International Space Station. J. Cryst. Growth 2002, 237, 1638–1645. [Google Scholar] [CrossRef]

- Witkowski, L.M.; Walker, J.S. Solutocapillary instabilities in liquid bridges. Phys. Fluids 2002, 14, 2647–2656. [Google Scholar] [CrossRef]

- Walker, J.S.; Dold, P.; Cröll, A.; Volz, M.P.; Szofran, F.R. Solutocapillary convection in the float-zone process with a strong magnetic field. Int J Heat Mass Tran. 2002, 45, 4695–4702. [Google Scholar] [CrossRef]

- Lin, K.; Dold, P.; Benz, K.W. Numerical study of influences of buoyancy and solutal Marangoni convection on flow structures in a germanium-silicon floating zone. Cryst. Res. Technol. 2005, 40, 550–556. [Google Scholar] [CrossRef]

- Lyubimova, T.P.; Scuridyn, R.V. Numerical modelling of three-dimensional thermo- and solutocapillary-induced flows in a floating zone during crystal growth. Eur. Phys. J.-Spec. Top. 2011, 192, 41–46. [Google Scholar] [CrossRef]

- Minakuchi, H.; Takagi, Y.; Okano, Y.; Gima, S. The relative contributions of thermo-solutal Marangoni convections on flow patterns in a liquid bridge. J. Cryst. Growth 2014, 385, 61–65. [Google Scholar] [CrossRef]

- Zhou, X.M.; Huai, X.L. Free surface deformation of thermo-solutocapillary convection in axisymmetric liquid bridge. Microgravity Sci. Technol. 2015, 27, 39–47. [Google Scholar] [CrossRef]

- Viviani, A.; Denisova, M.; Kostarev, K.; Zuev, A. The threshold origin of solutocapillary Marangoni convection on a bounded free surface. Acta Astronaut. 2014, 102, 200–206. [Google Scholar] [CrossRef]

- Mizev, A.; Birikh, R. Interaction between buoyant and solutocapillary convections induced by a surface-active source placed under the free surface. Eur. Phys. J-Spec. Top. 2011, 192, 145–153. [Google Scholar] [CrossRef]

- Yang, S.; Qin, D.C.; Zhang, Y.P.; Xu, L.; Fu, Y.D.; Cui, J.; Pan, H. Experimental study on the influence of gravitational tilt angle on the spatio-temporal evolution of solutocapillary convection. Symmetry 2022, 12, 2485. [Google Scholar] [CrossRef]

- Lappa, M.; Savino, R.; Monti, R. Three-dimensional numerical simulation of Marangoni instabilities in liquid bridges: Influence of geometrical aspect ratio. Int. J. Numer. Meth Fluids 2001, 36, 53–90. [Google Scholar] [CrossRef]

- Tang, Z.M.; Hu, W.R. Influence of aspect ratio on the onset of thermocapillary oscillatory convection in a floating half zone of large Prandtl number fluid. Chin. Phys. Lett. 2003, 20, 526–528. [Google Scholar]

- Yan, A.A.; Li, K.; Cao, Z.H.; Hu, W.R. Aspect-ratio dependent oscillatory thermocapillary convection in the floating half zone. Sci. China-Phys. Mech. 2011, 54, 338–341. [Google Scholar] [CrossRef]

- Fan, J.G.; Liang, R.Q. Thermal-solutal capillary convection in binary mixture liquid bridge with various aspect ratios under microgravity. J. Cryst. Growth 2022, 586, 126630. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, H.L.; Zhang, X.D.; Zou, Y.; Tang, S.J. The effect of aspect ratio and axial magnetic field on thermocapillary convection in liquid bridges with a deformable free-surface. Eng. Appl. Comp. Fluid. 2015, 10, 16–28. [Google Scholar] [CrossRef]

- Yano, T.; Nishino, K. Effect of liquid bridge shape on the oscillatory thermal Marangoni convection. Eur. Phys. J-Spec. Top. 2015, 224, 289–298. [Google Scholar] [CrossRef]

- Mendis, R.L.A.; Sekimoto, A.; Okano, Y.; Minakuchi, H.; Dost, S. The relative Contribution of solutal Marangoni convection to thermal Marangoni flow instabilities in a liquid bridge of smaller aspect ratios under zero gravity. Crystals 2021, 11, 116. [Google Scholar] [CrossRef]

- Kan, K.; Yang, Z.X.; Lyu, P.; Zheng, Y.; Shen, L. Numerical study of turbulent flow past a rotating axial-flow pump based on a level-set immersed boundary method. Renew. Energ. 2020, 168, 960–971. [Google Scholar] [CrossRef]

- Kan, K.; Chen, H.X.; Zheng, Y.; Zhou, D.Q.; Binama, M.; Dai, J. Transient characteristics during power-off process in a shaft extension tubular pump by using a suitable numerical model. Renew. Energ. 2020, 164, 109–121. [Google Scholar] [CrossRef]

- Osher, S.; Sethian, J.A. Fronts propagating with curvature-dependent speed: Algorithms based on Hamilton-Jacobi formulations. J. Comput. Phys. 1988, 79, 12–49. [Google Scholar] [CrossRef]

- Sussman, M.; Smereka, P.; Osher, S. A level set approach for computing solutions to incompressible two-phase flow. J. Comput. Phys. 1994, 114, 146–159. [Google Scholar] [CrossRef]

- Chang, Y.C.; Hou, T.Y.; Merriman, B.; Osher, S. A level set formulation of Eulerian interface capturing methods for incompressible fluid flows. J. Comput. Phys. 1996, 124, 449–464. [Google Scholar] [CrossRef]

- Chen, J.C.; Zhang, L.; Li, Y.R.; Yu, J.J. Three-dimensional numerical simulation of pure solutocapillary flow in a shallow annular pool for mixture fluid with high Schmidt number. Microgravity Sci. Technol. 2016, 28, 49–57. [Google Scholar] [CrossRef]

- Semenov, S.N.; Schimpf, M.E. Molecular thermodiffusion (thermophoresis) in liquid mixtures. Phys. Rev. E 2005, 72, 041202. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).