Assessing Strain Rate Sensitivity of Nanotwinned Al–Zr Alloys through Nanoindentation

Abstract

1. Introduction

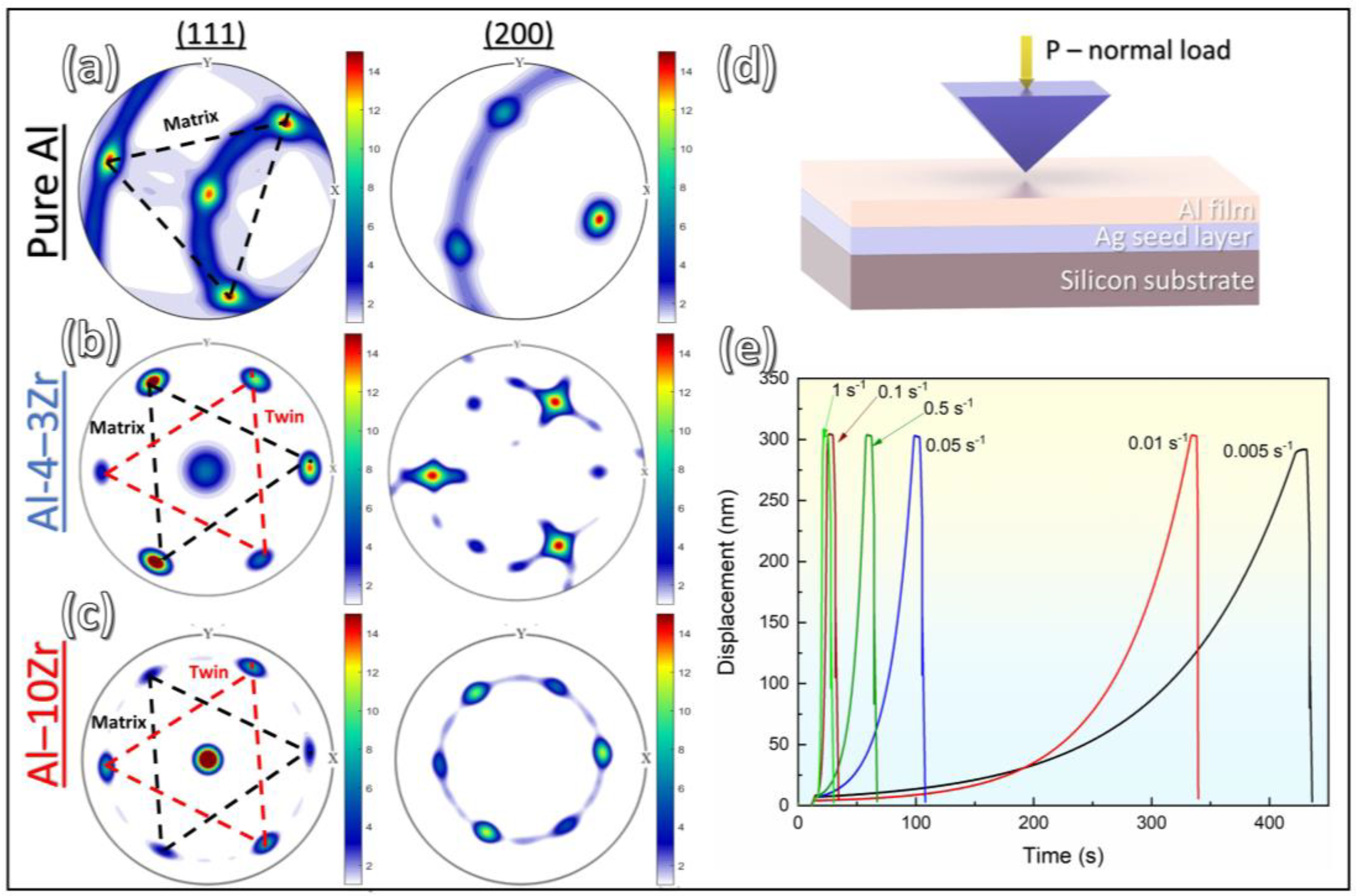

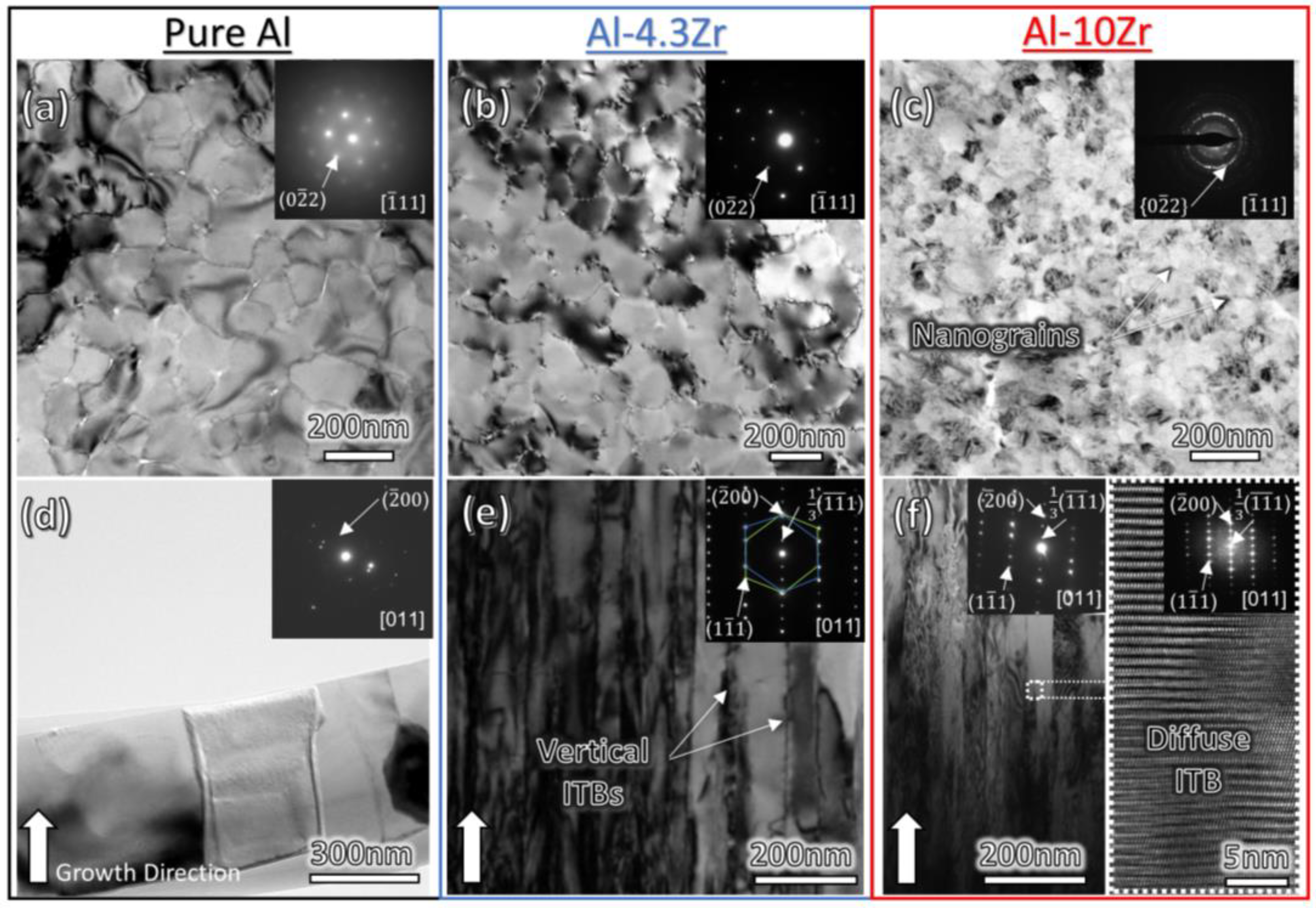

2. Materials and Methods

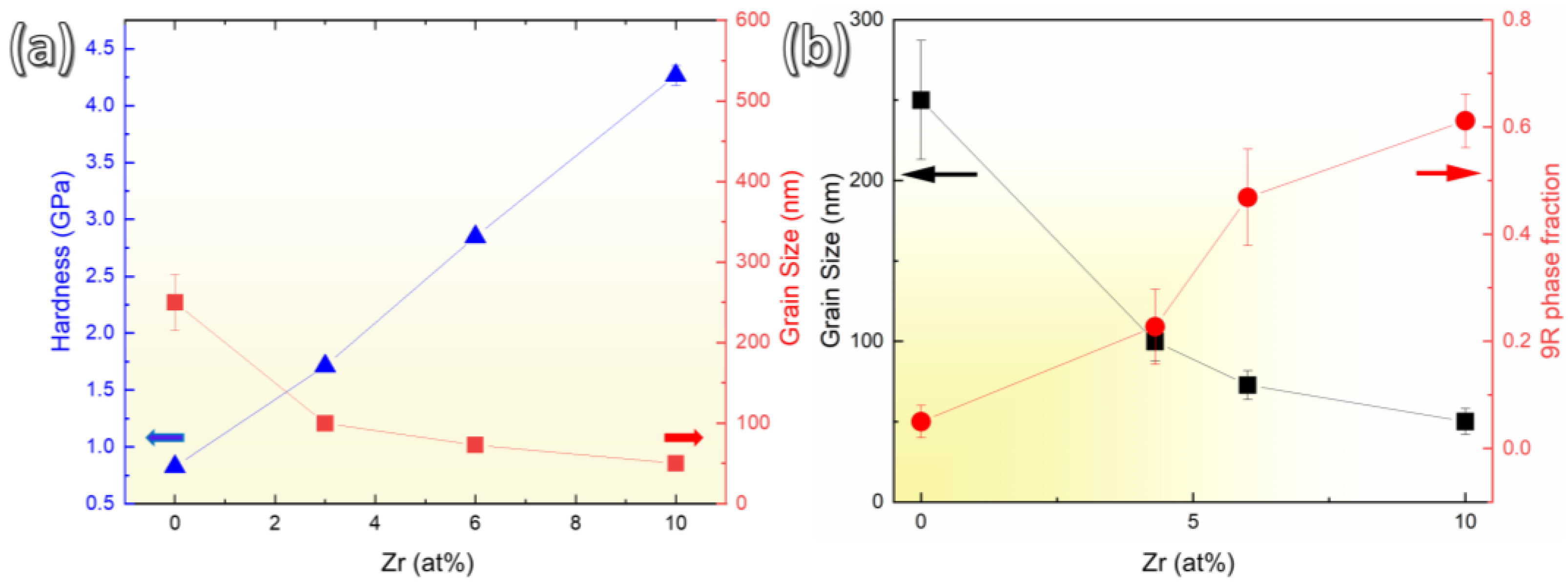

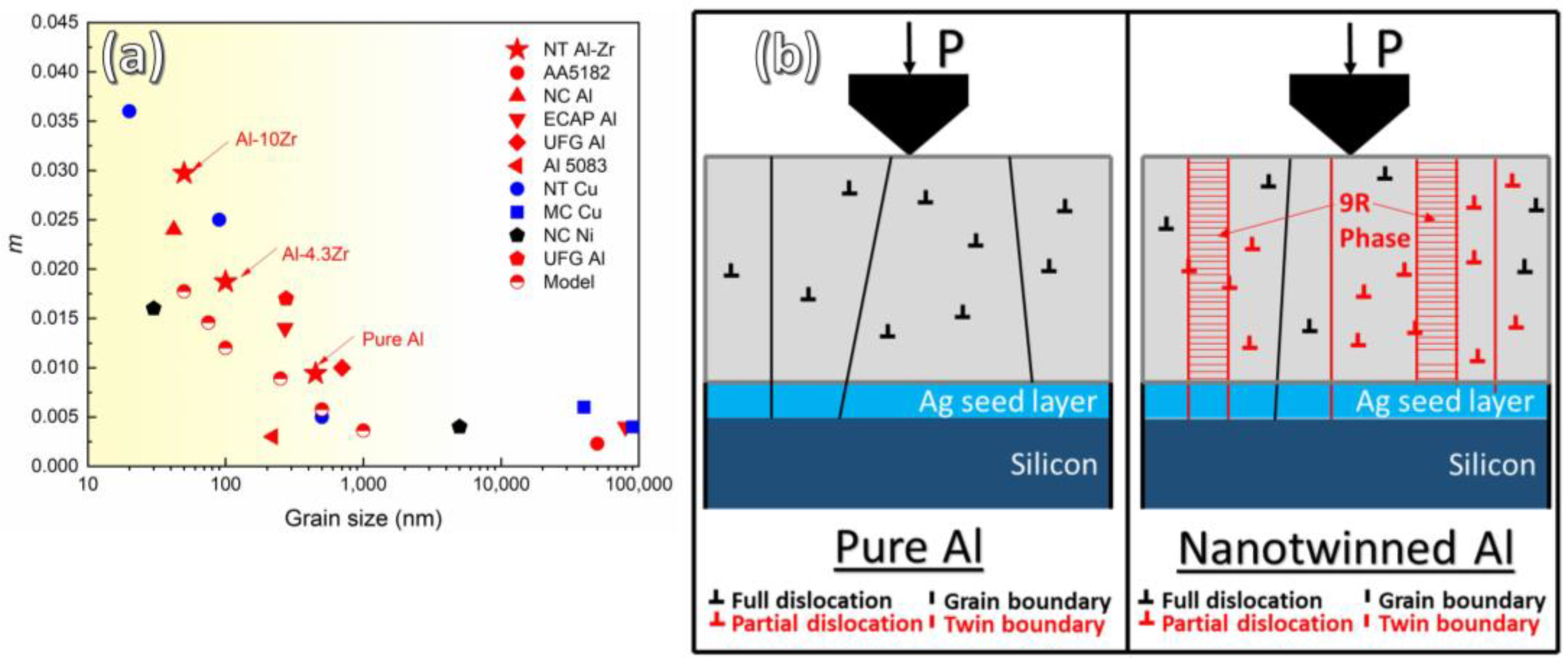

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hansen, N. Hall-Petch Relation and Boundary Strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Petch, N.J. The Cleavage Strength of Polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion and Results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Yang, B.; Shang, Z.; Ding, J.; Lopez, J.; Jarosinski, W.; Sun, T.; Richter, N.; Zhang, Y.; Wang, H.; Zhang, X. Investigation of Strengthening Mechanisms in an Additively Manufactured Haynes 230 Alloy. Acta Mater. 2022, 222, 117404. [Google Scholar] [CrossRef]

- Gleiter, H. Nanostructured Materials: Basic Concepts and Microstructure. Acta Mater. 2000, 48, 1–29. [Google Scholar] [CrossRef]

- Kumar, K.S.; Van Swygenhoven, H.; Suresh, S. Mechanical Behavior of Nanocrystalline Metals and Alloys. Acta Mater. 2003, 51, 5743–5774. [Google Scholar] [CrossRef]

- Ding, J.; Xue, S.; Shang, Z.; Li, J.; Zhang, Y.; Su, R.; Niu, T.; Wang, H.; Zhang, X. Characterization of Precipitation in Gradient Inconel 718 Superalloy. Mater. Sci. Eng. A 2021, 804, 140718. [Google Scholar] [CrossRef]

- Sun, T.; Shang, Z.; Cho, J.; Ding, J.; Niu, T.; Zhang, Y.; Yang, B.; Xie, D.; Wang, J.; Wang, H.; et al. Ultra-Fine-Grained and Gradient FeCrAl Alloys with Outstanding Work Hardening Capability. Acta Mater. 2021, 215, 117049. [Google Scholar] [CrossRef]

- Sergueeva, A.V.; Song, C.; Valiev, R.Z.; Mukherjee, A.K. Structure and Properties of Amorphous and Nanocrystalline NiTi Prepared by Severe Plastic Deformation and Annealing. Mater. Sci. Eng. A 2003, 339, 159–165. [Google Scholar] [CrossRef]

- Liao, X.Z.; Zhao, Y.H.; Srinivasan, S.G.; Zhu, Y.T.; Valiev, R.Z.; Gunderov, D.V. Deformation Twinning in Nanocrystalline Copper at Room Temperature and Low Strain Rate. Appl. Phys. Lett. 2004, 84, 592–594. [Google Scholar] [CrossRef]

- Pinto, E.M.; Ramos, A.S.; Vieira, M.T.; Brett, C.M.A. A Corrosion Study of Nanocrystalline Copper Thin Films. Corros. Sci. 2010, 52, 3891–3895. [Google Scholar] [CrossRef]

- Simoes, S.; Calinas, R.; Vieira, M.T.F.; Vieira, M.T.F.; Ferreira, P.J. In Situ TEM Study of Grain Growth in Nanocrystalline Copper Thin Films. Nanotechnology 2010, 21, 145701. [Google Scholar] [CrossRef]

- Gai, P.L.; Mitra, R.; Weertman, J.R. Structural Variations in Nanocrystalline Nickel Films. Pure Appl. Chem. 2002, 74, 1519–1526. [Google Scholar] [CrossRef]

- Li, Q.; Shang, Z.; Sun, X.; Fan, C.; Su, R.; Richter, N.A.; Fan, Z.; Zhang, Y.; Xue, S.; Wang, H.; et al. High-Strength and Tunable Plasticity in Sputtered Al–Cr Alloys with Multistage Phase Transformations. Int. J. Plast. 2021, 137, 102915. [Google Scholar] [CrossRef]

- Niu, T.; Zhang, Y.; He, Z.; Sun, T.; Richter, N.A.; Wang, H.; Zhang, X. Texture Development in Cu-Ag-Fe Triphase Immiscible Nanocomposites with Superior Thermal Stability. Acta Mater. 2023, 244, 118545. [Google Scholar] [CrossRef]

- Ganapathi, S.K.; Aindow, M.; Fraser, H.L.; Rigney, D.A. A Comparative Study of the Nanocrystalline Material Produced by Sliding Wear and Inert Gas Condensation. Mater. Res. Soc. Symp. Proc. 1991, 206, 593–598. [Google Scholar] [CrossRef]

- Nieman, G.W.; Weertman, J.R.; Siegel, R.W. Microhardness of Nanocrystalline Palladium and Copper Produced by Inert-Gas Condensation. Scr. Metall. 1989, 23, 2013–2018. [Google Scholar] [CrossRef]

- Wu, X.J.; Du, L.G.; Zhang, H.F.; Liu, J.F.; Zhou, Y.S.; Li, Z.Q.; Xiong, L.Y.; Bai, Y.L. Synthesis and Tensile Property of Nanocrystalline Metal Copper. Nanostructured Mater. 1999, 12, 221–224. [Google Scholar] [CrossRef]

- Wang, J.; Wu, S.; Fu, S.; Liu, S.; Yan, M.; Lai, Q.; Lan, S.; Hahn, H.; Feng, T. Ultrahigh Hardness with Exceptional Thermal Stability of a Nanocrystalline CoCrFeNiMn High-Entropy Alloy Prepared by Inert Gas Condensation. Scr. Mater. 2020, 187, 335–339. [Google Scholar] [CrossRef]

- Hull, R.; Gibson, J.M.; Brus, L.E.; Norris, D.J.; Bawendi, M.G.; Zunger, A.; Zunger, A.; Whaley, K.B.; Williamson, A.J.; Reboredo, F.A.; et al. Grain Boundary–Mediated Plasticity in Nanocrystalline Nickel. Science 2004, 305, 654–658. [Google Scholar]

- Liang, R.; Khan, A.S. A Critical Review of Experimental Results and Constitutive Models for BCC and FCC Metals over a Wide Range of Strain Rates and Temperatures. Int. J. Plast. 1999, 15, 963–980. [Google Scholar] [CrossRef]

- Liu, Y.; Hay, J.; Wang, H.; Zhang, X. A New Method for Reliable Determination of Strain-Rate Sensitivity of Low-Dimensional Metallic Materials by Using Nanoindentation. Scr. Mater. 2014, 77, 5–8. [Google Scholar] [CrossRef]

- Hayes, R.W.; Witkin, D.; Zhou, F.; Lavernia, E.J. Deformation and Activation Volumes of Cryomilled Ultrafine-Grained Aluminum. Acta Mater. 2004, 52, 4259–4271. [Google Scholar] [CrossRef]

- Chen, J.; Lu, L.; Lu, K. Hardness and Strain Rate Sensitivity of Nanocrystalline Cu. Scr. Mater. 2006, 54, 1913–1918. [Google Scholar] [CrossRef]

- Wei, Q.; Cheng, S.; Ramesh, K.T.; Ma, E. Effect of Nanocrystalline and Ultrafine Grain Sizes on the Strain Rate Sensitivity and Activation Volume: Fcc versus Bcc Metals. Mater. Sci. Eng. A 2004, 381, 71–79. [Google Scholar] [CrossRef]

- Wei, Y.; Bower, A.F.; Gao, H. Enhanced Strain-Rate Sensitivity in Fcc Nanocrystals Due to Grain-Boundary Diffusion and Sliding. Acta Mater. 2008, 56, 1741–1752. [Google Scholar] [CrossRef]

- Malygin, G.A. Analysis of the Strain-Rate Sensitivity of Flow Stresses in Nanocrystalline FCC and BCC Metals. Phys. Solid State 2007, 49, 2266–2273. [Google Scholar] [CrossRef]

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh Strength and High Electrical Conductivity in Copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef]

- Lu, L.; Chen, X.; Huang, X.; Lu, K. Revealing the Maximum Strength in Nanotwinned Copper. Science 2009, 323, 607–610. [Google Scholar] [CrossRef]

- Fang, Q.; Sansoz, F. Columnar Grain-Driven Plasticity and Cracking in Nanotwinned FCC Metals. Acta Mater. 2021, 212, 116925. [Google Scholar] [CrossRef]

- Anderoglu, O.; Misra, A.; Wang, H.; Ronning, F.; Hundley, M.F.; Zhang, X. Epitaxial Nanotwinned Cu Films with High Strength and High Conductivity. Appl. Phys. Lett. 2008, 93, 5–8. [Google Scholar] [CrossRef]

- Zhang, X.; Anderoglu, O.; Misra, A.; Wang, H. Influence of Deposition Rate on the Formation of Growth Twins in Sputter-Deposited 330 Austenitic Stainless Steel Films. Appl. Phys. Lett. 2007, 90, 2007–2009. [Google Scholar] [CrossRef]

- Yu, K.Y.; Bufford, D.; Chen, Y.; Liu, Y.; Wang, H.; Zhang, X. Basic Criteria for Formation of Growth Twins in High Stacking Fault Energy Metals. Appl. Phys. Lett. 2013, 103, 181903. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Su, R.; Niu, T.J.; Richter, N.A.; Xue, S.; Li, Q.; Ding, J.; Yang, B.; Wang, H.; Zhang, X. Thermal Stability and Deformability of Annealed Nanotwinned Al/Ti Multilayers. Scr. Mater. 2020, 186, 219–224. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Li, Q.; Gong, M.; Xue, S.; Ding, J.; Li, J.; Cho, J.; Niu, T.; Su, R.; Richter, N.A.; et al. Deformation Behavior and Phase Transformation of Nanotwinned Al/Ti Multilayers. Appl. Surf. Sci. 2020, 527, 146776. [Google Scholar] [CrossRef]

- Xiao, J.; Deng, C. Mitigating the Hall-Petch Breakdown in Nanotwinned Cu by Amorphous Intergranular Films. Scr. Mater. 2021, 194, 113682. [Google Scholar] [CrossRef]

- Stobbs, W.M.; Sworn, C.H. The Weak Beam Technique as Applied to the Determination of the Stacking-Fault Energy of Copper. Philos. Mag. 1971, 24, 1365–1381. [Google Scholar] [CrossRef]

- Bufford, D.; Wang, H.; Zhang, X. High Strength, Epitaxial Nanotwinned Ag Films. Acta Mater. 2011, 59, 93–101. [Google Scholar] [CrossRef]

- Howie, A.; Swann, P.R. Direct Measurements of Stacking-Fault Energies from Observations of Dislocation Nodes. Philos. Mag. 1961, 6, 1215–1226. [Google Scholar] [CrossRef]

- Vitos, L.; Nilsson, J.O.; Johansson, B. Alloying Effects on the Stacking Fault Energy in Austenitic Stainless Steels from First-Principles Theory. Acta Mater. 2006, 54, 3821–3826. [Google Scholar] [CrossRef]

- Frøseth, A.G.; Derlet, P.M.; Van Swygenhoven, H. Twinning in Nanocrystalline Fcc Metals. Adv. Eng. Mater. 2005, 7, 16–20. [Google Scholar] [CrossRef]

- Xue, S.; Kuo, W.; Li, Q.; Fan, Z.; Ding, J.; Su, R.; Wang, H.; Zhang, X. Texture-Directed Twin Formation Propensity in Al with High Stacking Fault Energy. Acta Mater. 2018, 144, 226–234. [Google Scholar] [CrossRef]

- Xue, S.; Fan, Z.; Chen, Y.; Li, J.; Wang, H.; Zhang, X. The Formation Mechanisms of Growth Twins in Polycrystalline Al with High Stacking Fault Energy. Acta Mater. 2015, 101, 62–70. [Google Scholar] [CrossRef]

- Richter, N.A.; Zhang, Y.F.; Gong, M.; Niu, T.; Yang, B.; Xue, S.; Wang, J.; Wang, H.; Zhang, X. Solute Synergy Induced Thermal Stability of High-Strength Nanotwinned Al-Co-Zr Alloys. Mater. Sci. Eng. A 2023, 862, 144477. [Google Scholar] [CrossRef]

- Richter, N.A.; Zhang, Y.F.; Xie, D.Y.; Su, R.; Li, Q.; Xue, S.; Niu, T.; Wang, J.; Wang, H.; Zhang, X.; et al. Microstructural Evolution of Nanotwinned Al-Zr Alloy with Significant 9R Phase. Mater. Res. Lett. 2020, 9, 91–98. [Google Scholar] [CrossRef]

- Richter, N.A.; Gong, M.; Zhang, Y.F.; Niu, T.; Yang, B.; Wang, J.; Wang, H.; Zhang, X. Exploring the Deformation Behavior of Nanotwinned Al–Zr Alloy via in Situ Compression. J. Appl. Phys. 2022, 132, 065104. [Google Scholar] [CrossRef]

- Gong, M.; Wu, W.; Xie, D.; Richter, N.A.; Li, Q.; Zhang, Y.; Xue, S.; Zhang, X.; Wang, J.; Gong, M.; et al. First-Principles Calculations for Understanding Microstructures and Mechanical Properties of Co-Sputtered Al Alloys. Nanoscale 2021, 13, 14987–15001. [Google Scholar] [CrossRef]

- Li, Q.; Xue, S.; Wang, J.; Shao, S.; Kwong, A.H.; Giwa, A.; Fan, Z.; Liu, Y.; Qi, Z.; Ding, J.; et al. High-Strength Nanotwinned Al Alloys with 9R Phase. Adv. Mater. 2018, 30, 1704629. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Xue, S.; Li, Q.; Fan, C.; Su, R.; Ding, J.; Wang, H.; Wang, H.; Zhang, X. Microstructure and Mechanical Behavior of Nanotwinned AlTi Alloys with 9R Phase. Scr. Mater. 2018, 148, 5–9. [Google Scholar] [CrossRef]

- Zhang, Y.; Niu, T.; Richter, N.A.; Sun, T.; Li, N.; Wang, H.; Zhang, X. Tribological Behaviors of Nanotwinned Al Alloys. Appl. Surf. Sci. 2022, 600, 154108. [Google Scholar] [CrossRef]

- Li, Q.; Xue, S.; Fan, C.; Richter, N.A.; Zhang, Y.; Chen, Y.; Wang, H.; Zhang, X. Epitaxial Nanotwinned Metals and Alloys: Synthesis-Twin Structure–Property Relations. CrystEngComm 2021, 23, 6637–6649. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Li, Q.; Xue, S.C.; Ding, J.; Xie, D.Y.; Li, J.; Niu, T.; Wang, H.; Wang, H.; Wang, J.; et al. Ultra-Strong Nanotwinned Al–Ni Solid Solution Alloys with Significant Plasticity. Nanoscale 2018, 10, 22025–22034. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Su, R.; Xie, D.Y.; Niu, T.J.; Xue, S.; Li, Q.; Shang, Z.; Ding, J.; Richter, N.A.; Wang, J.; et al. Design of Super-Strong and Thermally Stable Nanotwinned Al Alloys: Via Solute Synergy. Nanoscale 2020, 12, 20491–20505. [Google Scholar] [CrossRef] [PubMed]

- Bayoumy, D.; Schliephake, D.; Dietrich, S.; Wu, X.H.; Zhu, Y.M.; Huang, A.J. Intensive Processing Optimization for Achieving Strong and Ductile Al-Mn-Mg-Sc-Zr Alloy Produced by Selective Laser Melting. Mater. Des. 2021, 198, 109317. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Kang, N.; Chen, J.; Tang, Y.; Tan, H.; Yu, X.; Yang, H.; Huang, W. Directed Energy Deposition Additive Manufacturing of a Sc/Zr-Modified Al–Mg Alloy: Effect of Thermal History on Microstructural Evolution and Mechanical Properties. Mater. Sci. Eng. A 2021, 802, 140606. [Google Scholar] [CrossRef]

- Ma, R.; Peng, C.; Cai, Z.; Wang, R.; Zhou, Z.; Li, X.; Cao, X. Manipulating the Microstructure and Tensile Properties of Selective Laser Melted Al–Mg-Sc-Zr Alloy through Heat Treatment. J. Alloy. Compd. 2020, 831, 154773. [Google Scholar] [CrossRef]

- Dao, M.; Lu, L.; Shen, Y.F.; Suresh, S. Strength, Strain-Rate Sensitivity and Ductility of Copper with Nanoscale Twins. Acta Mater. 2006, 54, 5421–5432. [Google Scholar] [CrossRef]

- Choi, I.C.; Kim, Y.J.; Wang, Y.M.; Ramamurty, U.; Jang, J.-I. Nanoindentation Behavior of Nanotwinned Cu: Influence of Indenter Angle on Hardness, Strain Rate Sensitivity and Activation Volume. Acta Mater. 2013, 61, 7313–7323. [Google Scholar] [CrossRef]

- Chu, J.P.; Lai, Y.W.; Lin, T.N.; Wang, S.F. Deposition and Characterization of TiNi-Base Thin Films by Sputtering. Mater. Sci. Eng. A 2000, 277, 11–17. [Google Scholar] [CrossRef]

- Wang, J.; Li, N.; Anderoglu, O.; Zhang, X.; Misra, A.; Huang, J.Y.; Hirth, J.P. Detwinning Mechanisms for Growth Twins in Face-Centered Cubic Metals. Acta Mater. 2010, 58, 2262–2270. [Google Scholar] [CrossRef]

- Wang, J.; Anderoglu, O.; Hirth, J.P.; Misra, A.; Zhang, X. Dislocation Structures of Σ3 {112} Twin Boundaries in Face Centered Cubic Metals. Appl. Phys. Lett. 2009, 95, 93–96. [Google Scholar] [CrossRef]

- Li, N.; Wang, J.; Zhang, X.; Misra, A. In-Situ TEM Study of Dislocation-Twin Boundaries Interaction in Nanotwinned Cu Films. Jom 2011, 63, 62. [Google Scholar] [CrossRef]

- Bufford, D.; Bi, Z.; Jia, Q.X.; Wang, H.; Zhang, X. Nanotwins and Stacking Faults in High-Strength Epitaxial Ag/Al Multilayer Films. Appl. Phys. Lett. 2012, 101, 223112. [Google Scholar] [CrossRef]

- Bufford, D.; Liu, Y.; Wang, J.; Wang, H.; Zhang, X. In Situ Nanoindentation Study on Plasticity and Work Hardening in Aluminium with Incoherent Twin Boundaries. Nat. Commun. 2014, 5, 4864. [Google Scholar] [CrossRef]

- Su, R.; Neffati, D.; Xue, S.; Li, Q.; Fan, Z.; Liu, Y.; Wang, H.; Kulkarni, Y.; Zhang, X. Deformation Mechanisms in FCC Co Dominated by High-Density Stacking Faults. Mater. Sci. Eng. A 2018, 736, 12–21. [Google Scholar] [CrossRef]

- Follansbee, P.S.; Kocks, U.F. A Constitutive Description of the Deformation of Copper Based on the Use of the Mechanical Threshold Stress as an Internal State Variable. Acta Metall. 1988, 36, 81–93. [Google Scholar] [CrossRef]

- Picu, R.C.; Vincze, G.; Ozturk, F.; Gracio, J.J.; Barlat, F.; Maniatty, A.M. Strain Rate Sensitivity of the Commercial Aluminum Alloy AA5182-O. Mater. Sci. Eng. A 2005, 390, 334–343. [Google Scholar] [CrossRef]

- May, J.; Höppel, H.W.; Göken, M. Strain Rate Sensitivity of Ultrafine-Grained Aluminium Processed by Severe Plastic Deformation. Scr. Mater. 2005, 53, 189–194. [Google Scholar] [CrossRef]

- Varam, S.; Rajulapati, K.V.; Bhanu Sankara Rao, K. Strain Rate Sensitivity Studies on Bulk Nanocrystalline Aluminium by Nanoindentation. J. Alloy. Compd. 2014, 585, 795–799. [Google Scholar] [CrossRef]

- Dalla Torre, F.; Van Swygenhoven, H.; Victoria, M. Nanocrystalline Electrodeposited Ni: Microstructure and Tensile Properties. Acta Mater. 2002, 50, 3957–3970. [Google Scholar] [CrossRef]

- Lu, L.; Schwaiger, R.; Shan, Z.W.; Dao, M.; Lu, K.; Suresh, S. Nano-Sized Twins Induce High Rate Sensitivity of Flow Stress in Pure Copper. Acta Mater. 2005, 53, 2169–2179. [Google Scholar] [CrossRef]

- Izadi, E.; Rajagopalan, J. Texture Dependent Strain Rate Sensitivity of Ultrafine-Grained Aluminum Films. Scr. Mater. 2016, 114, 65–69. [Google Scholar] [CrossRef]

- Miyamoto, H.; Ota, K.; Mimaki, T. Viscous Nature of Deformation of Ultra-Fine Grain Aluminum Processed by Equal-Channel Angular Pressing. Scr. Mater. 2006, 54, 1721–1725. [Google Scholar] [CrossRef]

- Wei, Q. Strain Rate Effects in the Ultrafine Grain and Nanocrystalline Regimes-Influence on Some Constitutive Responses. J. Mater. Sci. 2007, 42, 1709–1727. [Google Scholar] [CrossRef]

- Bailey, J.E.; Hirsch, P.B. The Dislocation Distribution, Flow Stress, and Stored Energy in Cold-Worked Polycrystalline Silver. Philos. Mag. 1960, 5, 485–497. [Google Scholar] [CrossRef]

- Li, N.; Wang, J.; Misra, A.; Zhang, X.; Huang, J.Y.; Hirth, J.P. Twinning Dislocation Multiplication at a Coherent Twin Boundary. Acta Mater. 2011, 59, 5989–5996. [Google Scholar] [CrossRef]

- Li, N.; Wang, J.; Huang, J.Y.; Misra, A.; Zhang, X. Influence of Slip Transmission on the Migration of Incoherent Twin Boundaries in Epitaxial Nanotwinned Cu. Scr. Mater. 2011, 64, 149–152. [Google Scholar] [CrossRef]

- Li, Q.; Xie, D.; Shang, Z.; Sun, X.; Cho, J.; Zhang, Y.; Xue, S.; Wang, H.; Wang, J.; Zhang, X. Coupled Solute Effects Enable Anomalous High-Temperature Strength and Stability in Nanotwinned Al Alloys. Acta Mater. 2020, 200, 378–388. [Google Scholar] [CrossRef]

- Li, Q.; Xue, S.; Zhang, Y.; Sun, X.; Wang, H.; Zhang, X. Plastic Anisotropy and Tension-Compression Asymmetry in Nanotwinned Al–Fe Alloys: An in-Situ Micromechanical Investigation. Int. J. Plast. 2020, 132, 102760. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Richter, N.A.; Sheng, X.; Yang, B.; Stegman, B.T.; Wang, H.; Zhang, X. Assessing Strain Rate Sensitivity of Nanotwinned Al–Zr Alloys through Nanoindentation. Crystals 2023, 13, 276. https://doi.org/10.3390/cryst13020276

Richter NA, Sheng X, Yang B, Stegman BT, Wang H, Zhang X. Assessing Strain Rate Sensitivity of Nanotwinned Al–Zr Alloys through Nanoindentation. Crystals. 2023; 13(2):276. https://doi.org/10.3390/cryst13020276

Chicago/Turabian StyleRichter, Nicholas Allen, Xuanyu Sheng, Bo Yang, Benjamin Thomas Stegman, Haiyan Wang, and Xinghang Zhang. 2023. "Assessing Strain Rate Sensitivity of Nanotwinned Al–Zr Alloys through Nanoindentation" Crystals 13, no. 2: 276. https://doi.org/10.3390/cryst13020276

APA StyleRichter, N. A., Sheng, X., Yang, B., Stegman, B. T., Wang, H., & Zhang, X. (2023). Assessing Strain Rate Sensitivity of Nanotwinned Al–Zr Alloys through Nanoindentation. Crystals, 13(2), 276. https://doi.org/10.3390/cryst13020276