Effect of Electrical Resistance Heating on Recrystallization of Cold-Rolled Low-Carbon Steel

Abstract

:1. Introduction

1.1. Electric Current Effects on Plastic Flow and Solid-State Transformations

1.2. Gleeble vs. Conventional Heating Studies

1.2.1. 316 Stainless Steel

1.2.2. Copper

1.2.3. Aluminum

1.2.4. Inconel 718

1.3. Objective of Present Study

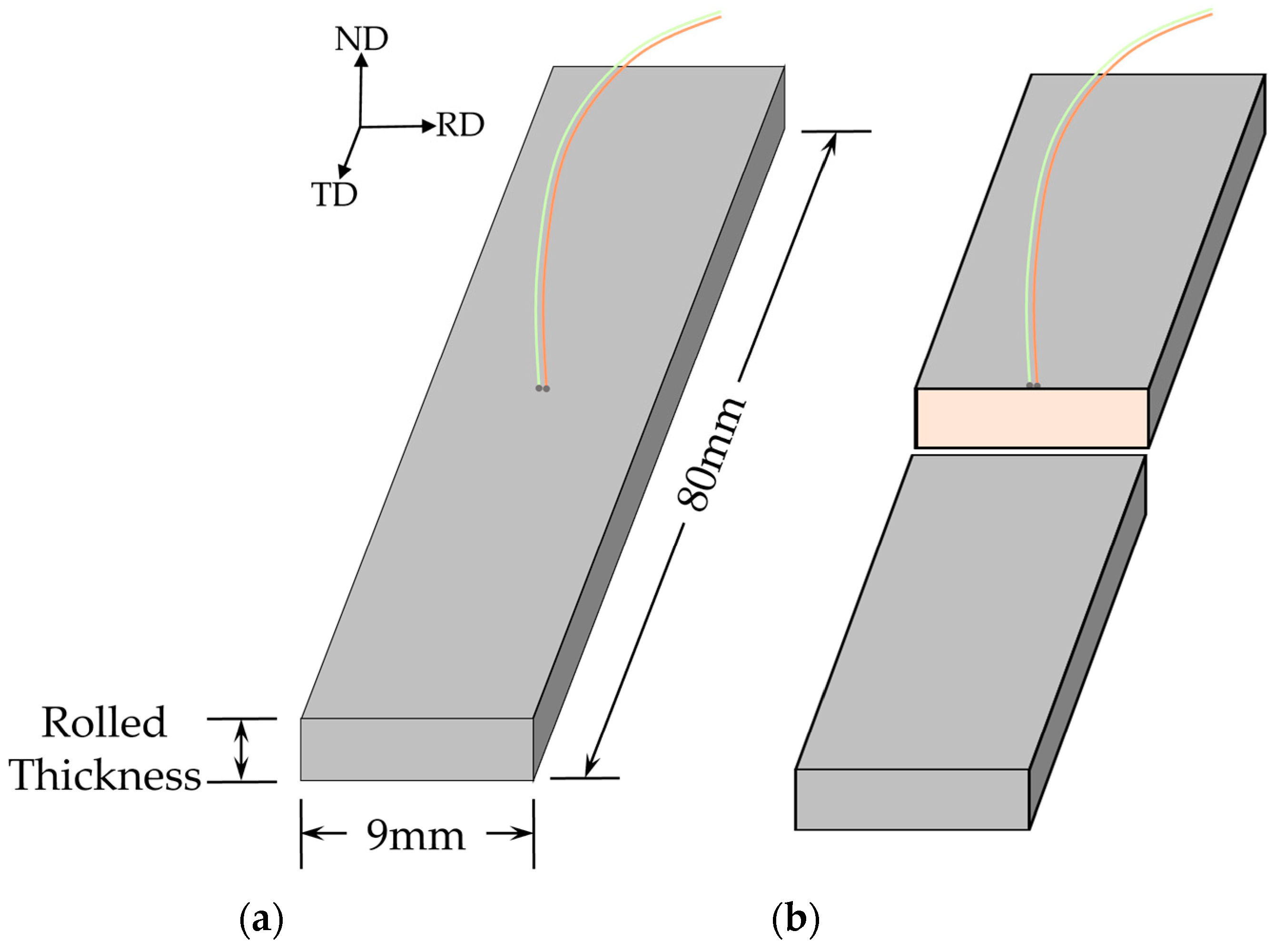

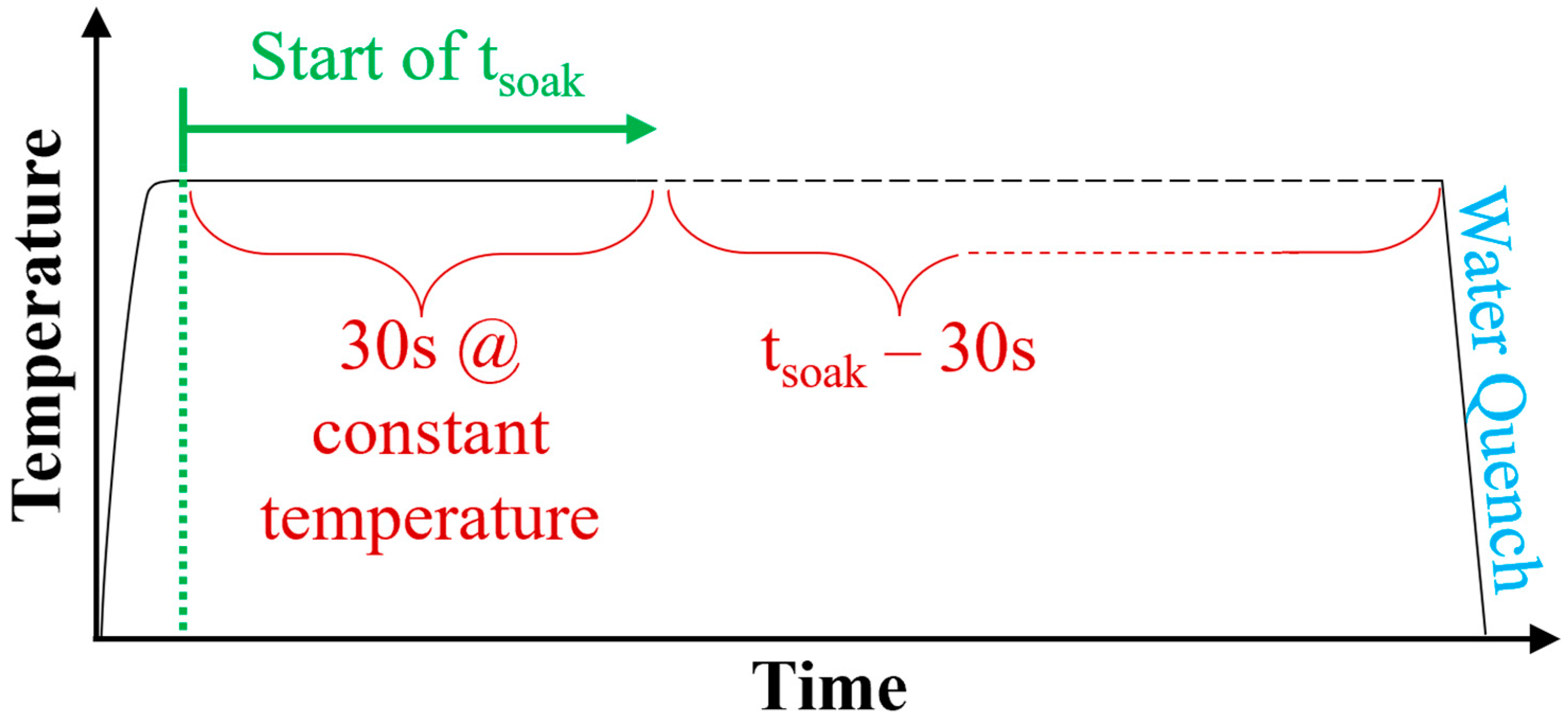

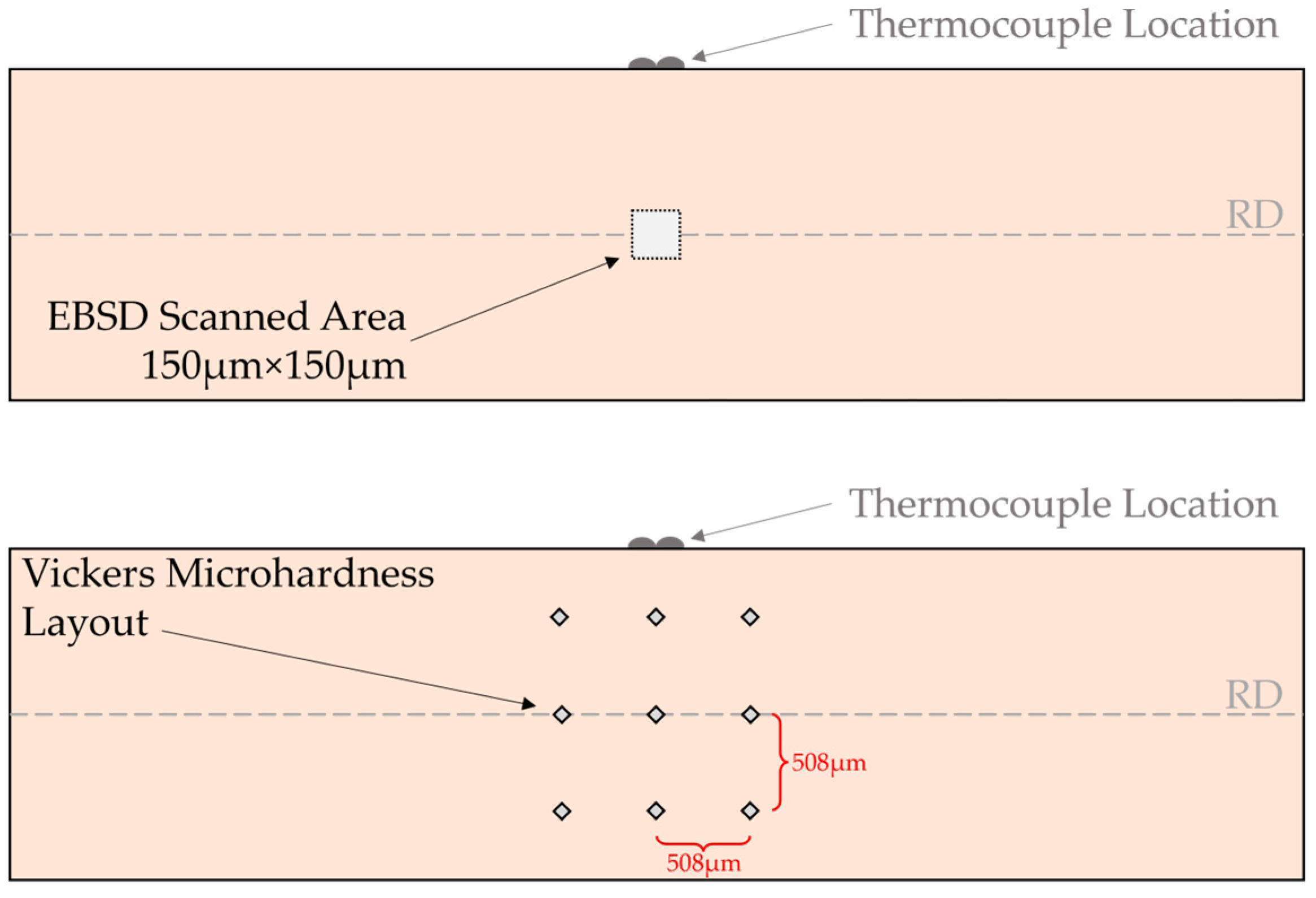

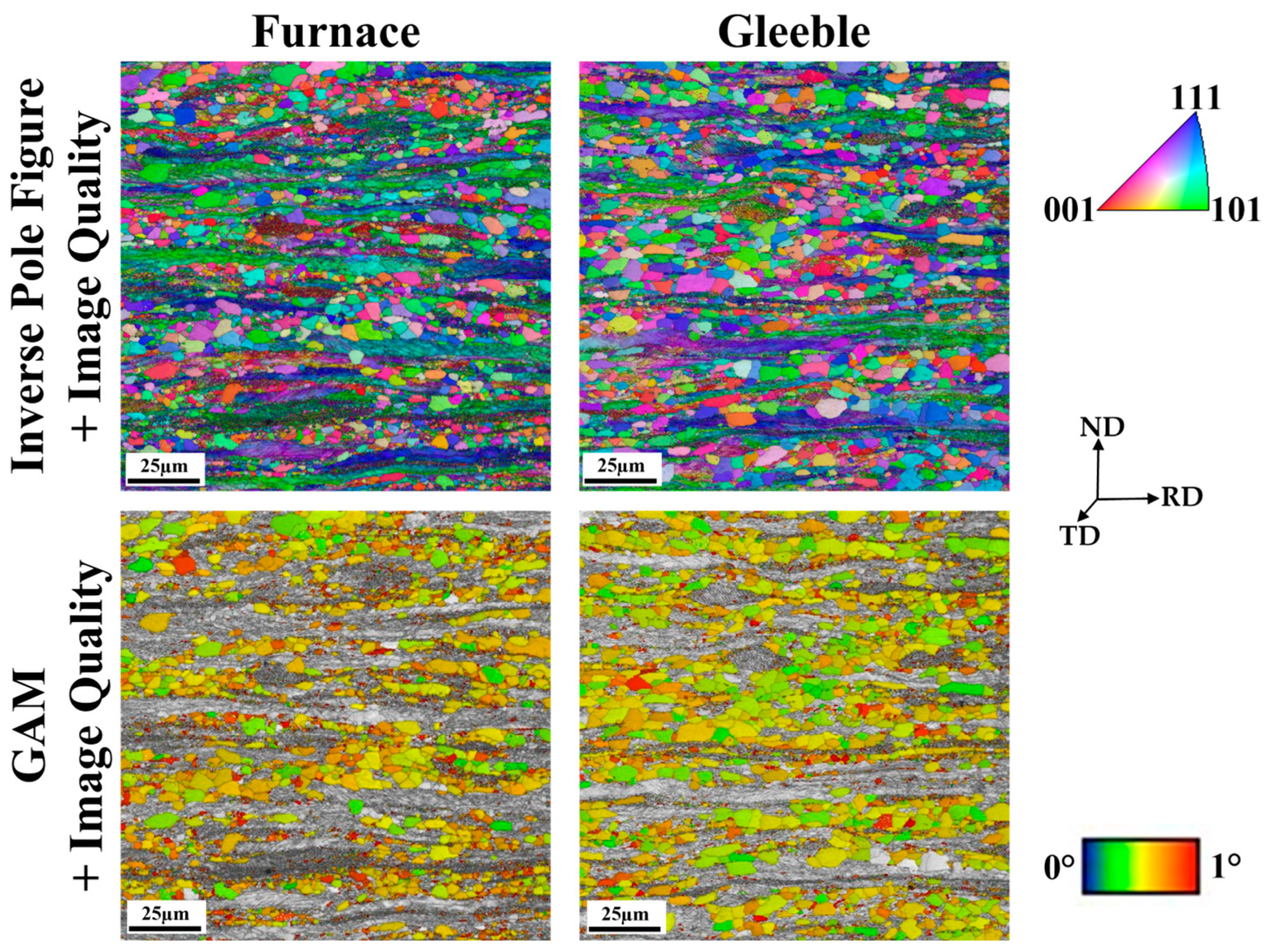

2. Materials and Methods

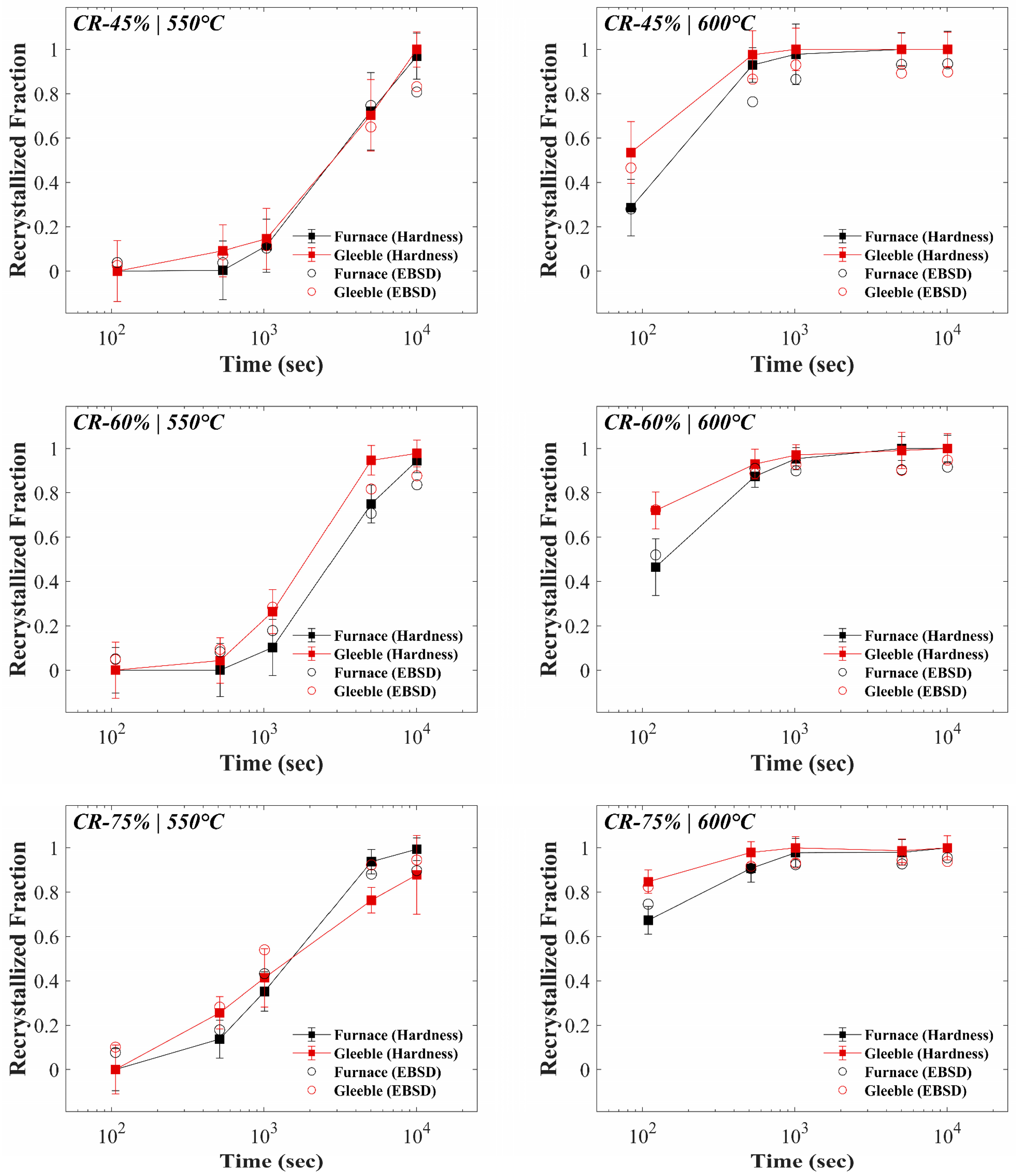

3. Results and Discussion

4. Conclusions

- On aggregate, the Gleeble-treated samples showed a tendency to recrystallize more rapidly than the furnace-treated samples, especially during the initial stages of nucleation and growth. This trend was reflected in recrystallized fractions obtained via both hardness and EBSD.

- Annealing at the higher soak temperature of 600 °C led to faster recrystallization when measured after the first soak duration of 100 s. Combined with the faster initial transformation during Gleeble treatment, the increased recrystallization activity was further amplified by increased cold reduction, with reduction levels of 45%, 60%, and 75% exhibiting respective recrystallized fractions of 29%, 46%, and 67% during furnace treatment versus 53%, 72%, and 85% during Gleeble treatment.

- Annealing for longer durations led to a convergence of the microstructures and recrystallized fractions from both heating methods, with 550 °C treatments saturating at near-complete recrystallization after 10,000 s and the 600 °C treatments doing so by the 5000 s mark. While the behavior at convergence is equivalent between the two heating methods, the faster initial recrystallization rates in the Gleeble must be taken into consideration when upscaling the processing parameters to large-scale manufacturing using conventional heating methods, particularly when annealing heavily distorted (cold-rolled) microstructures for short durations.

- Analysis of transformation kinetics using the JMAK relationship pointed towards greater transformation activity during Gleeble treatment, with the effects of grain growth becoming dominant at 600 °C.

- Activation energies determined using JMAK coefficients were of similar order of magnitude as other published values for steels and showed an increasing trend with increased cold reduction. Within each reduction level, the activation energy for the Gleeble-heated case was higher than its furnace-heated counterpart, although these computed values inherit the significant contribution of grain growth at 600 °C.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

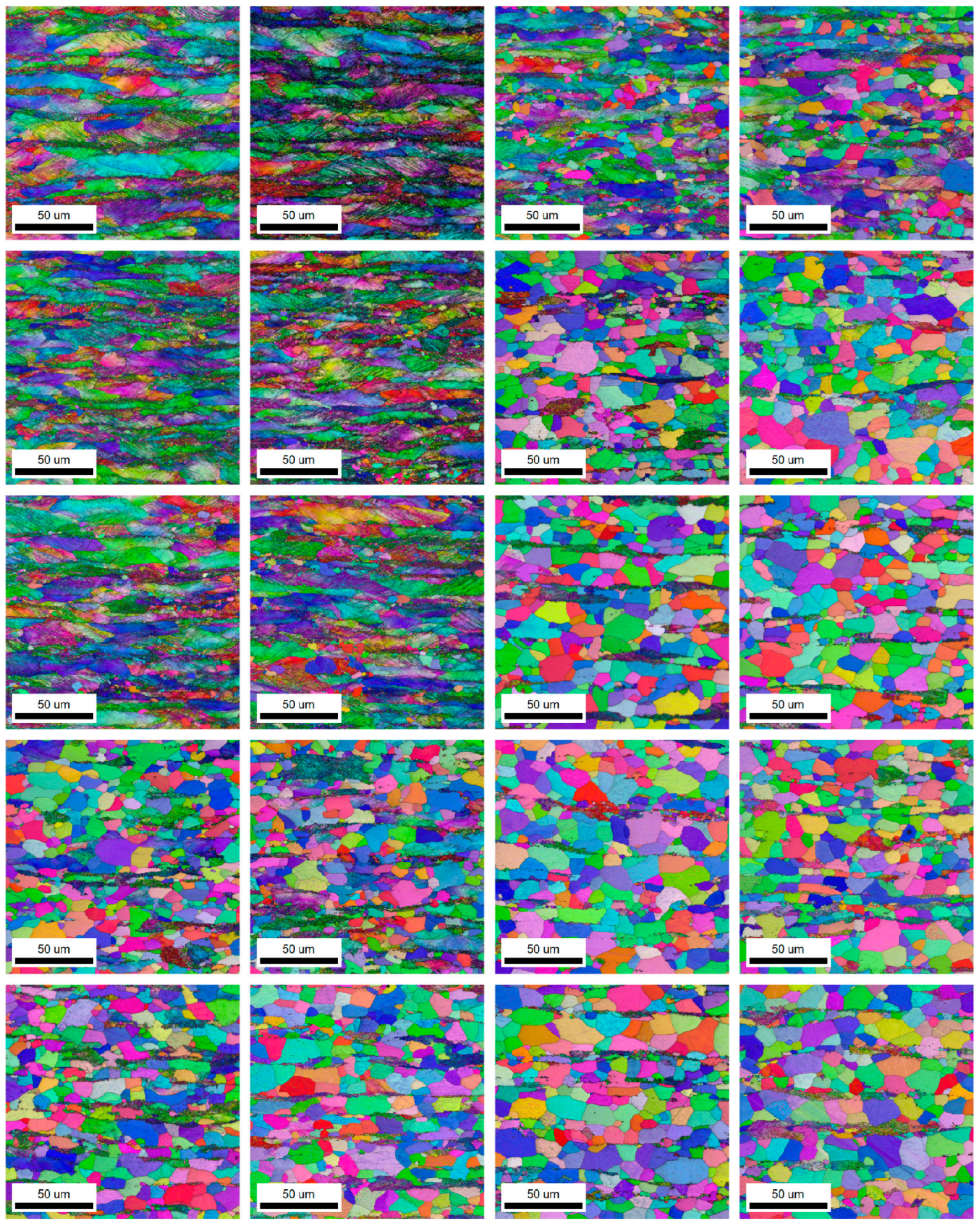

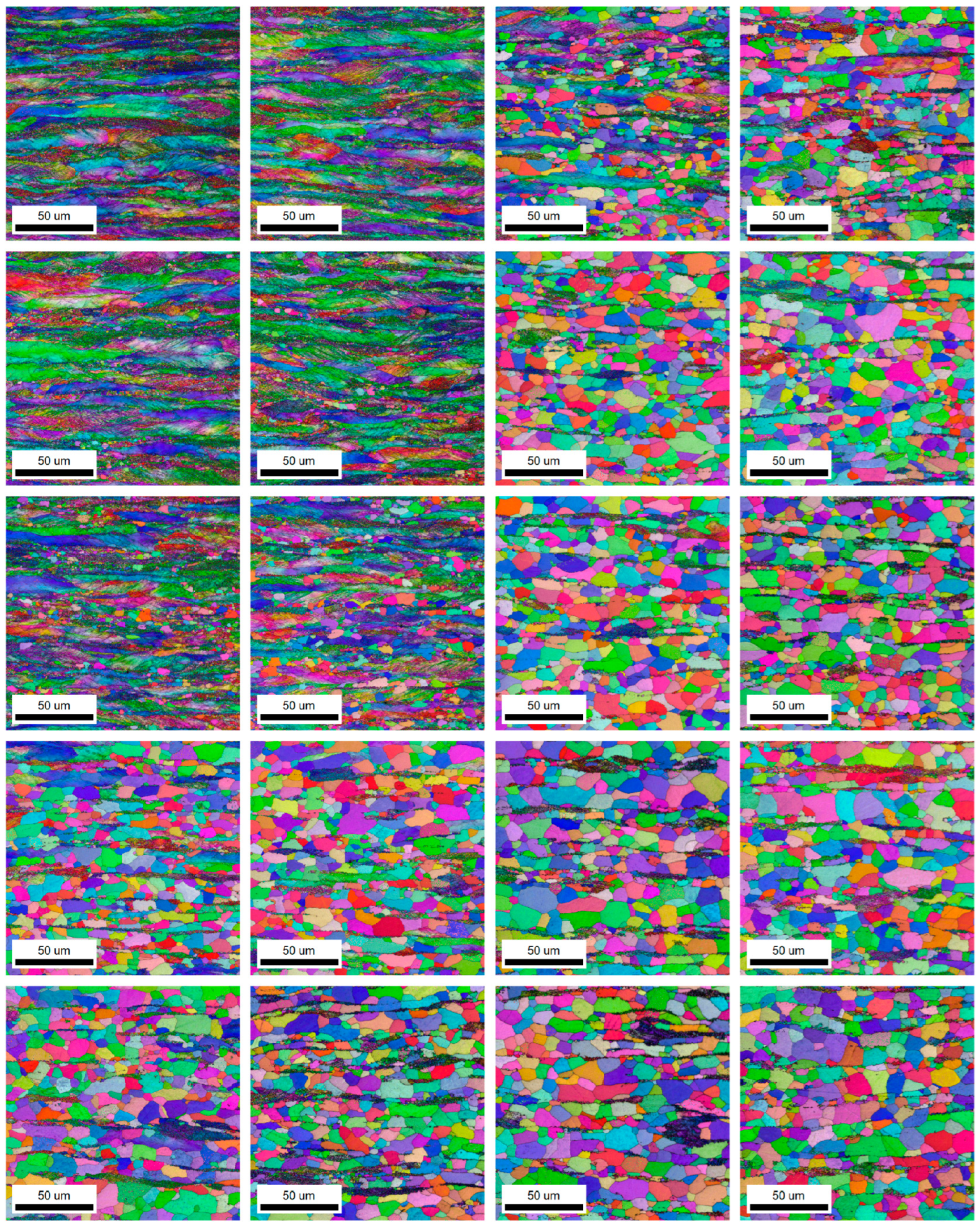

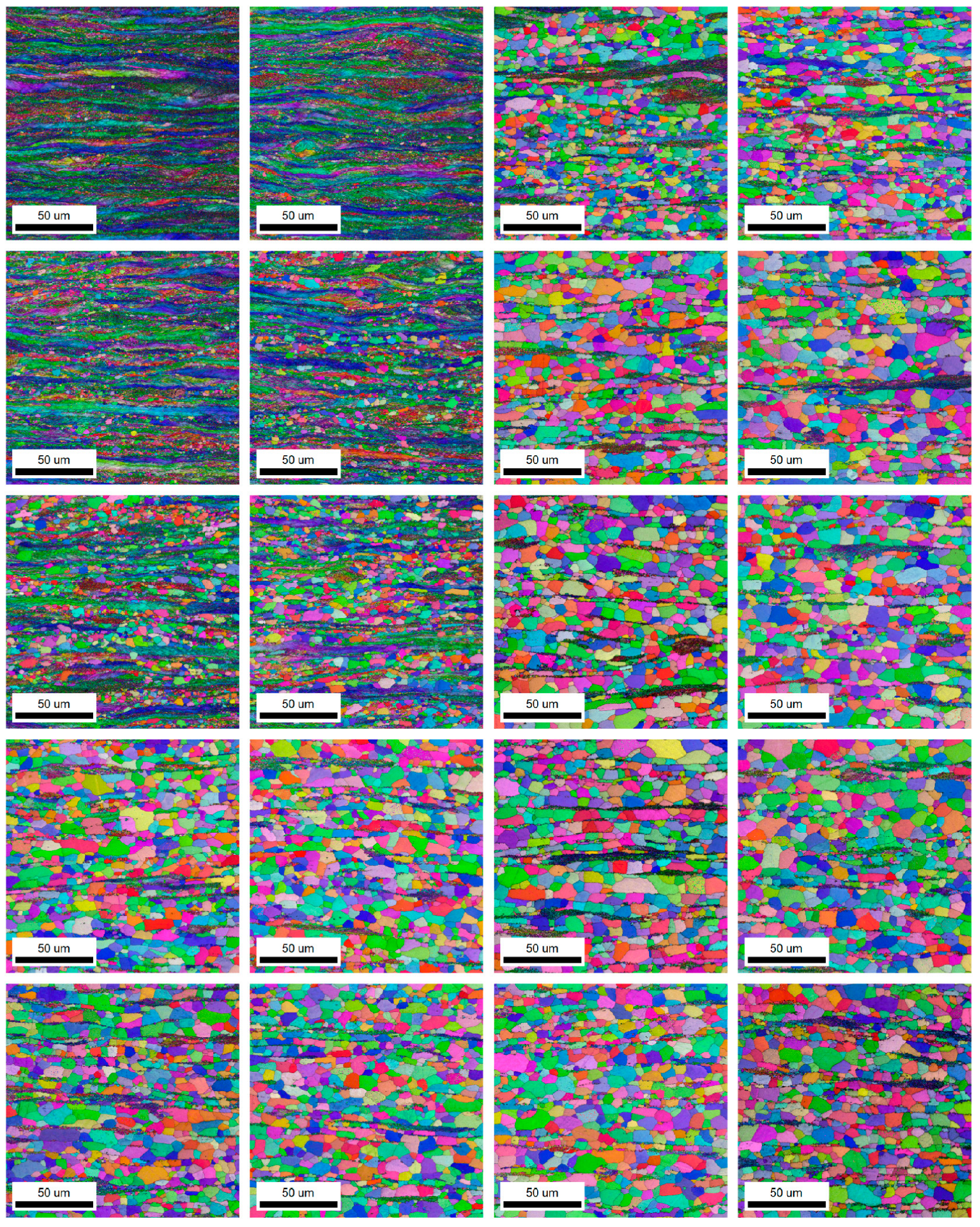

Appendix A. EBSD Maps of All Samples

References

- Gleeble Thermal-Mechanical Simulators. Available online: www.gleeble.com (accessed on 9 December 2021).

- Troitskii, O.A.; Likhtman, V.I. The Effect of the Anisotropy of Electron and γ Radiation on the Deformation of Zinc Single Crystals in the Brittle State. Dokl. Akad. Nauk SSSR 1963, 148, 332–334. [Google Scholar]

- Sprecher, A.F.; Mannan, S.L.; Conrad, H. Overview No. 49: On the Mechanisms for the Electroplastic Effect in Metals. Acta Metall. 1986, 34, 1145–1162. [Google Scholar] [CrossRef]

- Okazaki, K.; Kagawa, M.; Conrad, H. A Study of the Electroplastic Effect in Metals. Scr. Metall. 1978, 12, 1063–1068. [Google Scholar] [CrossRef]

- Conrad, H.; Karam, N.; Mannan, S.; Sprecher, A.F. Effect of Electric Current Pulses on the Recrystallization Kinetics of Copper. Scr. Metall. 1988, 22, 235–238. [Google Scholar] [CrossRef]

- Park, J.-W.; Jeong, H.-J.; Jin, S.-W.; Kim, M.-J.; Lee, K.; Kim, J.J.; Hong, S.-T.; Han, H.N. Effect of Electric Current on Recrystallization Kinetics in Interstitial Free Steel and AZ31 Magnesium Alloy. Mater. Charact. 2017, 133, 70–76. [Google Scholar] [CrossRef]

- Poliak, E.I.; Lee, S.W.; Seo, D.H.; Choo, W.Y. Effect of Electric Current Heating on Hot Deformation Resistance and Microstructure of Steels. Met. Mater. 1999, 5, 563–570. [Google Scholar] [CrossRef]

- Rahnama, A.; Qin, R. Room Temperature Texturing of Austenite/Ferrite Steel by Electropulsing. Sci. Rep. 2017, 7, 42732. [Google Scholar] [CrossRef] [PubMed]

- Noell, P.J.; Rodelas, J.M.; Ghanbari, Z.N.; Laursen, C.M. Microstructural Modification of Additively Manufactured Metals by Electropulsing. Addit. Manuf. 2020, 33, 101128. [Google Scholar] [CrossRef]

- Conrad, H. Effects of Electric Current on Solid State Phase Transformations in Metals. Mater. Sci. Eng. A 2000, 287, 227–237. [Google Scholar] [CrossRef]

- Kim, M.-J.; Lee, K.; Oh, K.H.; Choi, I.-S.; Yu, H.-H.; Hong, S.-T.; Han, H.N. Electric Current-Induced Annealing during Uniaxial Tension of Aluminum Alloy. Scr. Mater. 2014, 75, 58–61. [Google Scholar] [CrossRef]

- Bodyako, M.N.; Loiko, Y.M.; Pavlyukevich, B.L.; Parkhimovich, V.I. Recrystallization Diagrams for Induction Heating. Met. Sci. Heat Treat. 1962, 2, 57–59. [Google Scholar] [CrossRef]

- Shahmir, H.; Nili-Ahmadabadi, M.; Razzaghi, A.; Mohammadi, M.; Wang, C.T.; Jung, J.M.; Kim, H.S.; Langdon, T.G. Using Dilatometry to Study Martensitic Stabilization and Recrystallization Kinetics in a Severely Deformed NiTi Alloy. J. Mater. Sci. 2015, 50, 4003–4011. [Google Scholar] [CrossRef]

- Oberdorfer, B.; Steyskal, E.-M.; Sprengel, W.; Pippan, R.; Zehetbauer, M.; Puff, W.; Würschum, R. Recrystallization Kinetics of Ultrafine-Grained Ni Studied by Dilatometry. J. Alloys Compd. 2011, 509, S309–S311. [Google Scholar] [CrossRef]

- Liu, G.; Li, J.; Zhang, S.; Wang, J.; Meng, Q. Dilatometric Study on the Recrystallization and Austenization Behavior of Cold-Rolled Steel with Different Heating Rates. J. Alloys Compd. 2016, 666, 309–316. [Google Scholar] [CrossRef]

- Krawczynska, A.T.; Lewandowska, M.; Kuziak, R.; Kurzydłowski, K.J. Recrystallization and Grain Growth in Nano-Structured Austenitic Stainless Steel under Electric Current Heating. Phys. Status Solidi (C) 2010, 7, 1380–1383. [Google Scholar] [CrossRef]

- Fabrègue, D.; Mouawad, B.; Hutchinson, C.R. Enhanced Recovery and Recrystallization of Metals Due to an Applied Current. Scr. Mater. 2014, 92, 3–6. [Google Scholar] [CrossRef]

- Huang, K.; Cayron, C.; Logé, R.E. The Surprising Influence of Continuous Alternating Electric Current on Recrystallization Behaviour of a Cold-Rolled Aluminium Alloy. Mater. Charact. 2017, 129, 121–126. [Google Scholar] [CrossRef]

- Nicolaÿ, A.; Franchet, J.M.; Cormier, J.; Logé, R.E.; Fiorucci, G.; Fausty, J.; Van Der Meer, M.; Bozzolo, N. Influence of Joule Effect Heating on Recrystallization Phenomena in Inconel 718. Met. Mater. Trans. A 2021, 52, 4572–4596. [Google Scholar] [CrossRef]

- Van Iderstine, D.; Mujahid, S.; Paudel, Y.; Rhee, H. Effects of Direct Resistance Heating on Recrystallization in Cold-Worked Steels. In Report of the 2022 Department of Defense Steels Summit; Limmer, K.R., Field, D.M., Sebeck, K.M., Gonzales, M., Soto-Medina, S., Draper, M.C., Nath, M., Kudzal, A., Payton, E.J., Eds.; DEVCOM Army Research Laboratory: Adelphi, MD, USA, 2023; p. 37. [Google Scholar]

- McMaster-Carr. Available online: https://www.mcmaster.com/ (accessed on 2 August 2023).

- Thermo-Calc Software TCFE9 Steels/Fe-Alloys Database. Available online: https://thermocalc.com/products/databases/steel-and-fe-alloys/ (accessed on 24 January 2022).

- ASM International (Ed.) Heat Treating. In ASM Handbook; ASM International: Materials Park, OH, USA, 1991; Volume 4, ISBN 978-0-87170-379-8. [Google Scholar]

- Metal Forming Equipment & Machines. Available online: https://www.fenn-torin.com/ (accessed on 30 October 2023).

- Ushioda, K.; Hutchinson, W.B.; Ågren, J.; Von Schlippenbach, U. Investigation of Structure and Texture Development during Annealing of Low-Carbon Steel. Mater. Sci. Technol. 1986, 2, 807–815. [Google Scholar] [CrossRef]

- Scanning Electron Microscopes (SEM) For Applications in Academia and Industry. Available online: https://www.zeiss.com/microscopy/en/products/sem-fib-sem/sem.html (accessed on 30 October 2023).

- Electron Backscatter Diffraction (EBSD). Available online: https://www.edax.com/products/ebsd/ (accessed on 30 October 2023).

- Dziaszyk, S.; Payton, E.J.; Friedel, F.; Marx, V.; Eggeler, G. On the Characterization of Recrystallized Fraction Using Electron Backscatter Diffraction: A Direct Comparison to Local Hardness in an IF Steel Using Nanoindentation. Mater. Sci. Eng. A 2010, 527, 7854–7864. [Google Scholar] [CrossRef]

- Wilson® VH3100 Vickers & Knoop Hardness Testers. Available online: https://www.buehler.com/products/hardness-testing/vickers-knoop-hardness-testers/wilson-vh3100-vickers-knoop-hardness-testers/ (accessed on 30 October 2023).

- E28 Committee ASTM E92; Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- E04 Committee ASTM E384; Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- EDAX OIM Analysis. Available online: https://www.edax.com/products/ebsd/oim-analysis (accessed on 30 October 2023).

- Huang, J.; Poole, W.J.; Militzer, M. Austenite Formation during Intercritical Annealing. Met. Mat. Trans. A 2004, 35, 3363–3375. [Google Scholar] [CrossRef]

- Purcek, G.; Saray, O.; Karaman, I.; Maier, H.J. High Strength and High Ductility of Ultrafine-Grained, Interstitial-Free Steel Produced by ECAE and Annealing. Met. Mat. Trans. A 2012, 43, 1884–1894. [Google Scholar] [CrossRef]

- Dieter, G.E. McGraw-Hill series in materials science and engineering. In Mechanical Metallurgy, 3rd ed.; McGraw-Hill: New York, NY, USA, 1986; ISBN 978-0-07-016893-0. [Google Scholar]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, the Netherlands; Boston, MA, USA, 2004; ISBN 978-0-08-044164-1. [Google Scholar]

- Porter, D.A.; Easterling, K.E.; Sherif, M.Y. Phase Transformations in Metals and Alloys, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2009; ISBN 978-1-4200-6210-6. [Google Scholar]

- Vandermeer, R.A.; Gordon, P. Recovery and Recrystallization of Metals; Interscience Publishers: New York, NY, USA, 1963. [Google Scholar]

- Samajdar, I.; Verlinden, B.; Van Houtte, P.; Vanderschueren, D. Recrystallisation Kinetics in IF-Steel: A Study on the Sluggish Recrystallisation Behaviour. Scr. Mater. 1997, 37, 869–874. [Google Scholar] [CrossRef]

- Raabe, D. Recovery and Recrystallization: Phenomena, Physics, Models, Simulation. In Physical Metallurgy; Elsevier: Amsterdam, The Netherlands, 2014; pp. 2291–2397. ISBN 978-0-444-53770-6. [Google Scholar]

- Etesami, S.A.; Enayati, M.H. Microstructural Evolution and Recrystallization Kinetics of a Cold-Rolled, Ferrite-Martensite Structure During Intercritical Annealing. Met. Mater. Trans. A 2016, 47, 3271–3276. [Google Scholar] [CrossRef]

- Dutta, S.; Panda, A.K.; Mitra, A.; Chatterjee, S.; Roy, R.K. Microstructural Evolution, Recovery and Recrystallization Kinetics of Isothermally Annealed Ultra Low Carbon Steel. Mater. Res. Express 2020, 7, 016554. [Google Scholar] [CrossRef]

- Jeong, K.; Jin, S.-W.; Kang, S.-G.; Park, J.-W.; Jeong, H.-J.; Hong, S.-T.; Cho, S.H.; Kim, M.-J.; Han, H.N. Athermally Enhanced Recrystallization Kinetics of Ultra-Low Carbon Steel via Electric Current Treatment. Acta Mater. 2022, 232, 117925. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | Cr | Cu | Mo | Ni | V | P | S |

|---|---|---|---|---|---|---|---|---|---|---|

| Amount (wt%) | 0.190 | 0.760 | 0.010 | 0.050 | 0.020 | 0.002 | 0.010 | 0.001 | 0.019 | 0.007 |

| Pass | CR-45% | CR-60% | CR-75% |

|---|---|---|---|

| 0 (Initial Thickness) | 6.303 | 6.167 | 6.153 |

| 1 | 5.847 | 5.847 | 5.792 |

| 2 | 5.483 | 5.497 | 5.470 |

| 3 | 5.119 | 5.138 | 5.116 |

| 4 | 4.765 | 4.774 | 4.755 |

| 5 | 4.401 | 4.428 | 4.392 |

| 6 | 4.034 | 4.060 | 4.016 |

| 7 | 3.664 | 3.684 | 3.675 |

| 8 | 3.447 | 3.437 | 3.443 |

| 9 | - | 3.172 | 3.160 |

| 10 | - | 2.845 | 2.845 |

| 11 | - | 2.548 | 2.537 |

| 12 | - | - | 2.153 |

| 13 | - | - | 1.801 |

| 14 | - | - | 1.554 |

| 15 | - | - | 1.499 |

| Reduction % | 45.3% | 58.7% | 75.6% |

| Cold Reduction | Annealing Time (s) | 550 °C | 600 °C | ||

|---|---|---|---|---|---|

| Furnace | Gleeble | Furnace | Gleeble | ||

| 45% | 100 | 223.5 ± 4.3 | 217.2 ± 5.9 | 195.2 ± 7.5 | 177.1 ± 9.6 |

| 500 | 215.9 ± 5.4 | 209.4 ± 4.3 | 148.3 ± 4.4 | 144.9 ± 7.2 | |

| 1000 | 207.8 ± 5.0 | 205.5 ± 7.5 | 144.8 ± 9.6 | 135.3 ± 5.5 | |

| 5000 | 163.6 ± 12.9 | 164.9 ± 11.7 | 134.8 ± 2.7 | 131.4 ± 2.7 | |

| 10,000 | 145.4 ± 6.8 | 131.6 ± 3.3 | 135.1 ± 4.0 | 131.7 ± 2.9 | |

| 60% | 100 | 231.5 ± 3.8 | 226.6 ± 8.0 | 182.4 ± 10.6 | 160.8 ± 6.8 |

| 500 | 224.8 ± 7.3 | 217.9 ± 5.7 | 147.8 ± 3.6 | 143.1 ± 5.3 | |

| 1000 | 213.0 ± 9.0 | 199.3 ± 6.8 | 141.1 ± 3.5 | 139.7 ± 3.2 | |

| 5000 | 158.4 ± 7.1 | 141.7 ± 5.3 | 133.5 ± 3.8 | 138.0 ± 6.7 | |

| 10,000 | 141.9 ± 4.0 | 139.1 ± 4.5 | 136.0 ± 4.5 | 134.8 ± 5.1 | |

| 75% | 100 | 244.9 ± 4.1 | 243.5 ± 7.3 | 175.1 ± 5.5 | 158.1 ± 4.7 |

| 500 | 227.6 ± 4.9 | 216.0 ± 4.1 | 152.2 ± 5.8 | 145.1 ± 4.2 | |

| 1000 | 206.6 ± 7.2 | 200.6 ± 12.6 | 145.3 ± 6.1 | 142.8 ± 4.5 | |

| 5000 | 149.3 ± 5.0 | 166.3 ± 5.2 | 145.1 ± 5.3 | 144.5 ± 4.8 | |

| 10,000 | 143.7 ± 4.5 | 155.1 ± 18.1 | 142.4 ± 4.9 | 142.0 ± 4.9 | |

| Cold Reduction | Heating Method-Temperature | n | k |

|---|---|---|---|

| 45% | F-550 °C | 2.36 | 2.23 × 10−9 |

| G-550 °C | 2.29 | 8.97 × 10−9 | |

| F-600 °C | 0.69 | 2.40 × 10−2 | |

| G-600 °C | 0.51 | 1.28 × 10−1 | |

| 60% | F-550 °C | 2.57 | 2.23 × 10−10 |

| G-550 °C | 2.28 | 9.65 × 10−9 | |

| F-600 °C | 0.63 | 3.50 × 10−2 | |

| G-600 °C | 0.40 | 1.95 × 10−1 | |

| 75% | F-550 °C | 2.21 | 2.27 × 10−8 |

| G-550 °C | 1.95 | 1.26 × 10−7 | |

| F-600 °C | 0.40 | 1.85 × 10−1 | |

| G-600 °C | 0.27 | 7.02 × 10−1 |

| Cold Reduction | Heating Method | Activation Energy (kJ/mol) |

|---|---|---|

| 45% | Furnace | 405.79 |

| Gleeble | 550.74 | |

| 60% | Furnace | 449.48 |

| Gleeble | 574.09 | |

| 75% | Furnace | 539.02 |

| Gleeble | 955.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Iderstine, D.; Mujahid, S.; Paudel, Y.; Rhee, H. Effect of Electrical Resistance Heating on Recrystallization of Cold-Rolled Low-Carbon Steel. Crystals 2023, 13, 1650. https://doi.org/10.3390/cryst13121650

Van Iderstine D, Mujahid S, Paudel Y, Rhee H. Effect of Electrical Resistance Heating on Recrystallization of Cold-Rolled Low-Carbon Steel. Crystals. 2023; 13(12):1650. https://doi.org/10.3390/cryst13121650

Chicago/Turabian StyleVan Iderstine, Dawn, Shiraz Mujahid, YubRaj Paudel, and Hongjoo Rhee. 2023. "Effect of Electrical Resistance Heating on Recrystallization of Cold-Rolled Low-Carbon Steel" Crystals 13, no. 12: 1650. https://doi.org/10.3390/cryst13121650

APA StyleVan Iderstine, D., Mujahid, S., Paudel, Y., & Rhee, H. (2023). Effect of Electrical Resistance Heating on Recrystallization of Cold-Rolled Low-Carbon Steel. Crystals, 13(12), 1650. https://doi.org/10.3390/cryst13121650