Study on Single-Layer and Single-Channel Microstructure of 304 Stainless Steel Using Joule Heat Additive Manufacturing

Abstract

:1. Introduction

2. Experimental Materials and Methods

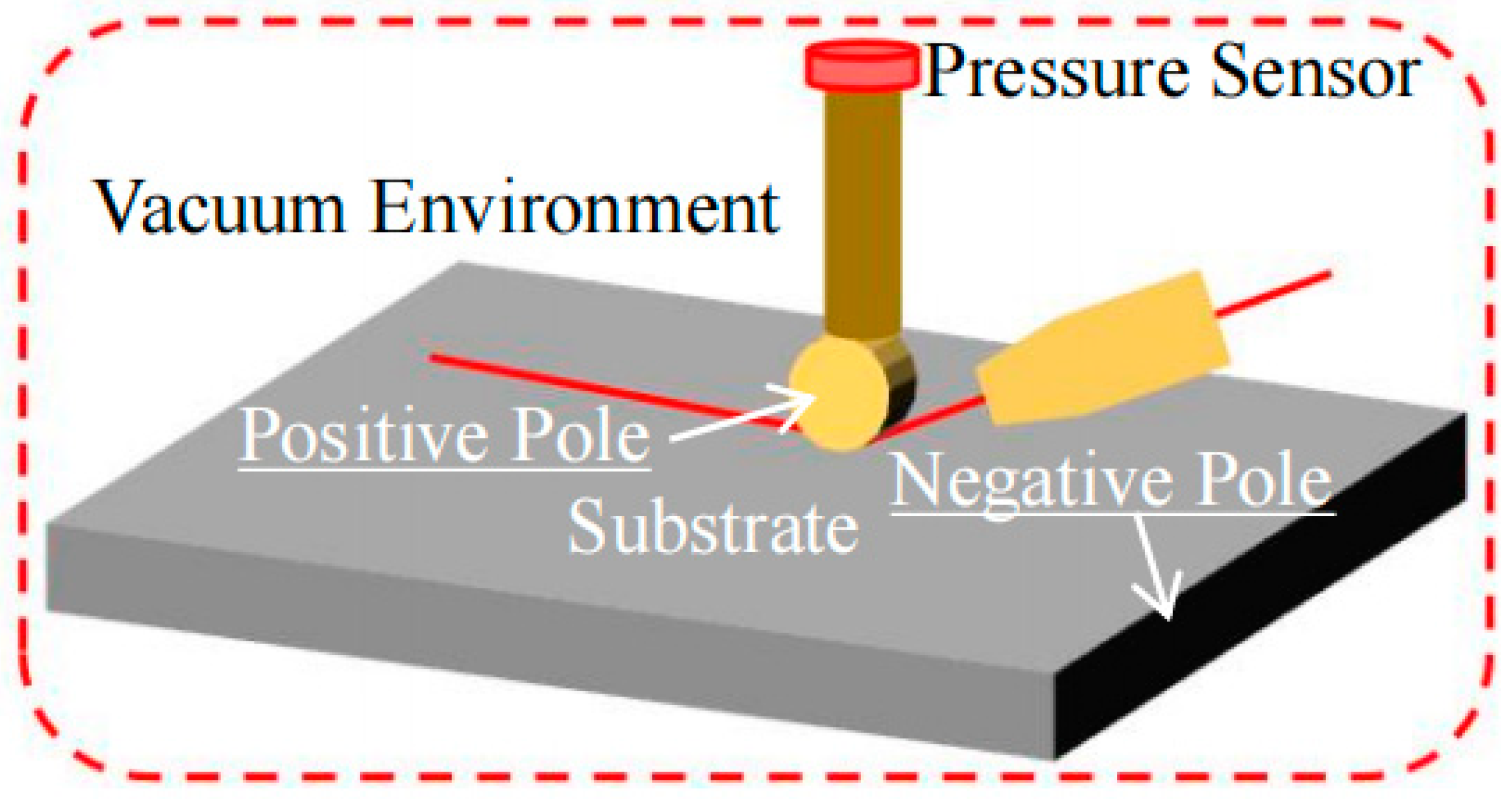

2.1. Experimental Principles and Equipment

2.2. Experimental Materials

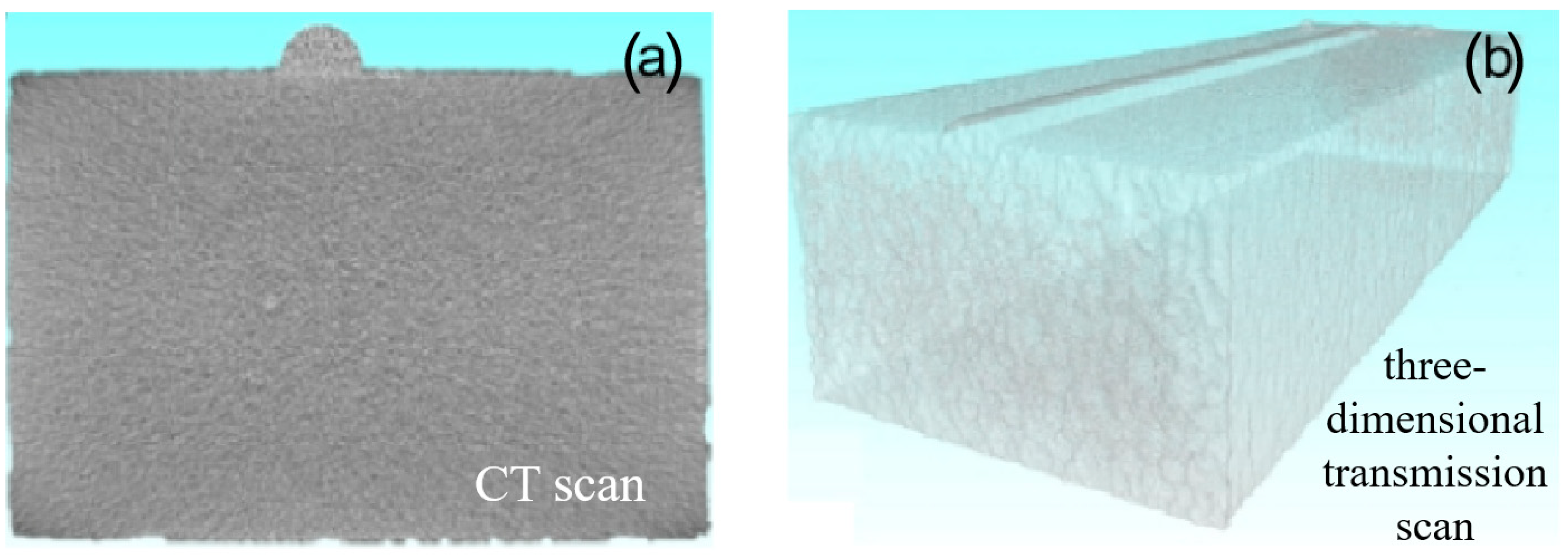

2.3. Detection Method

3. Results and Analysis

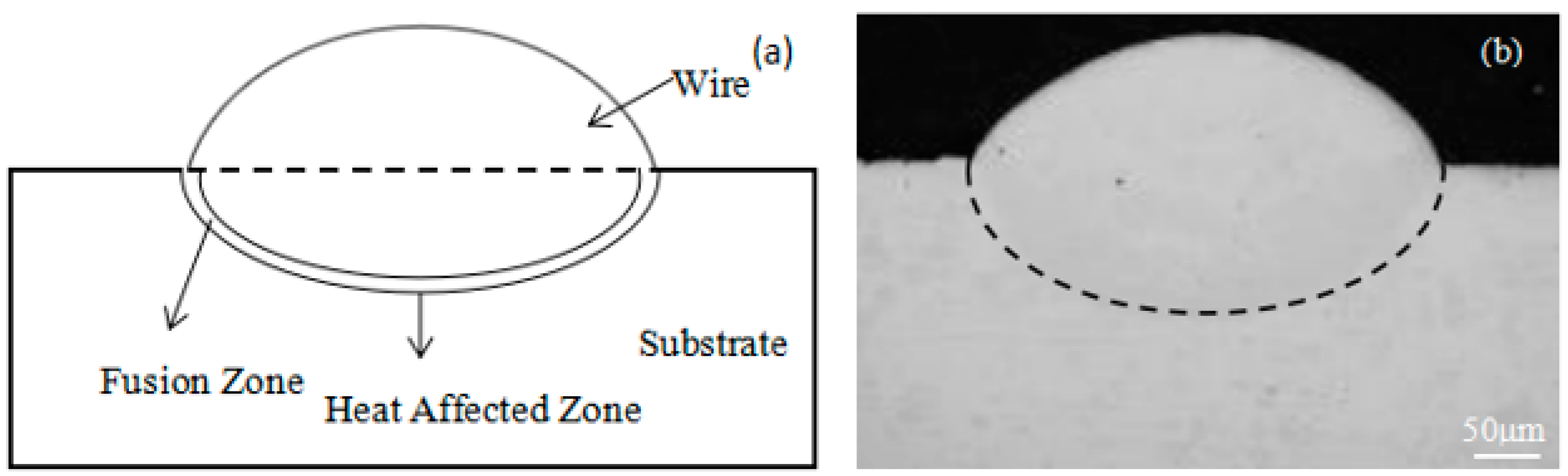

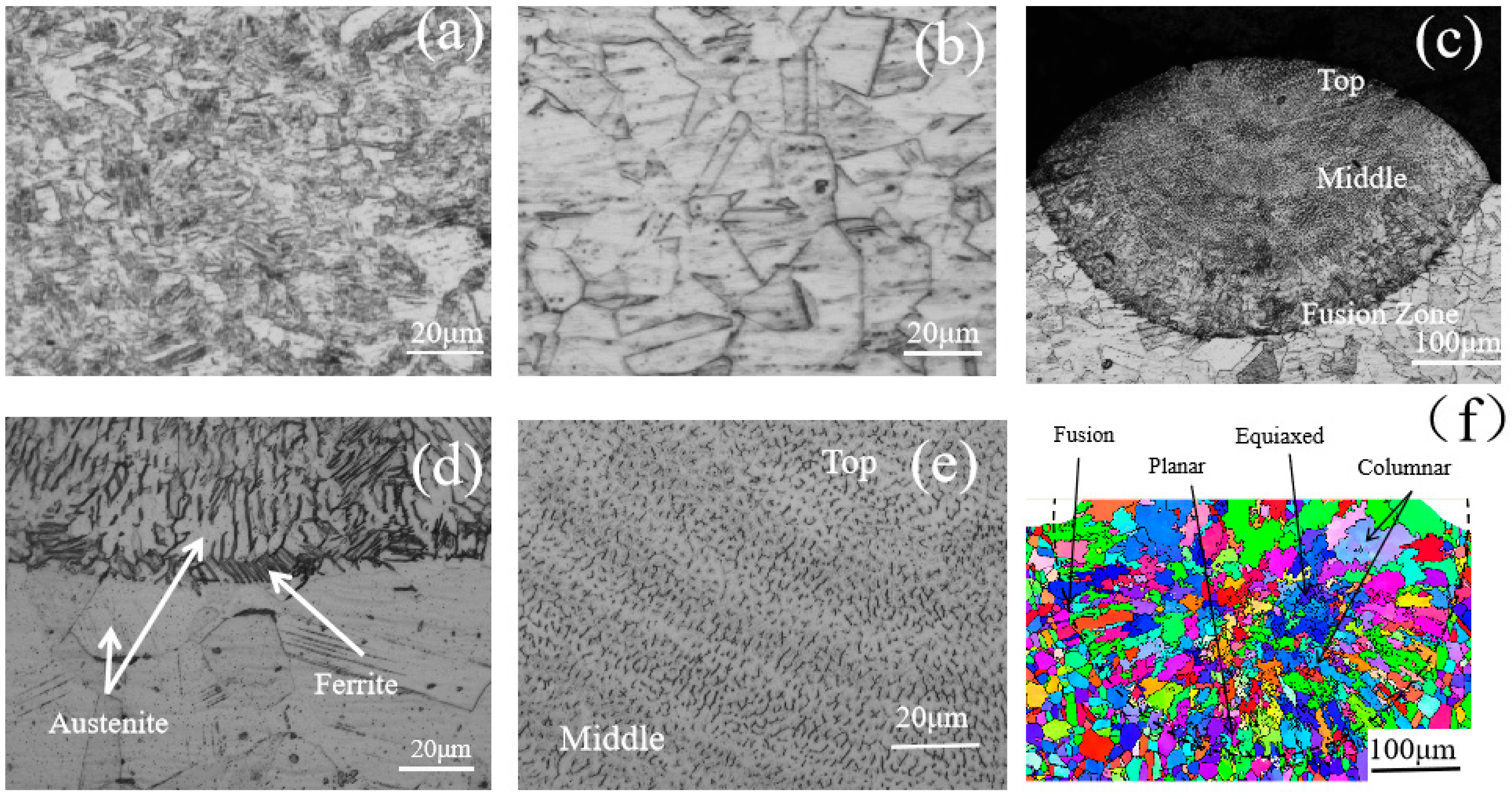

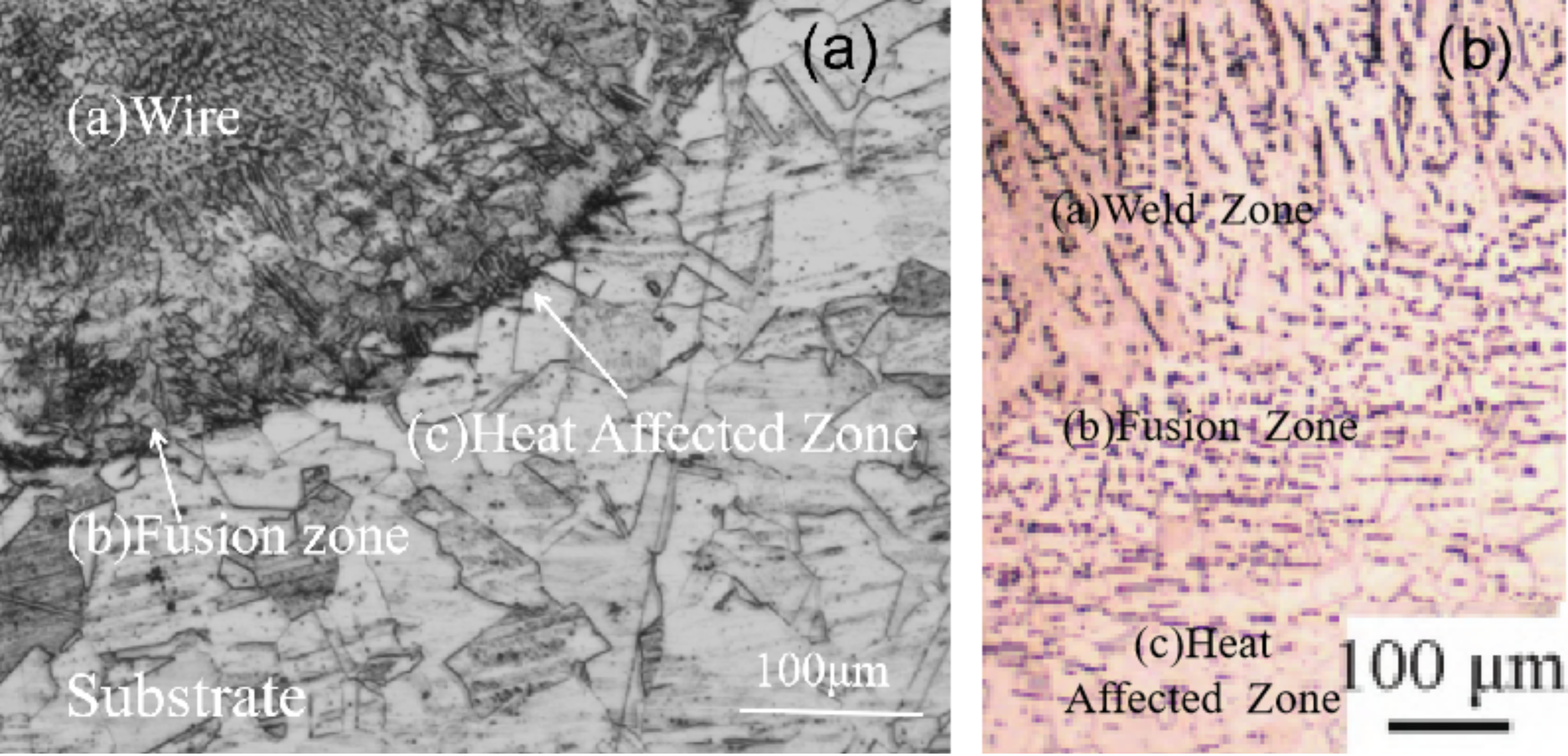

3.1. Microstructure Analysis of Single Layer and Single Channel

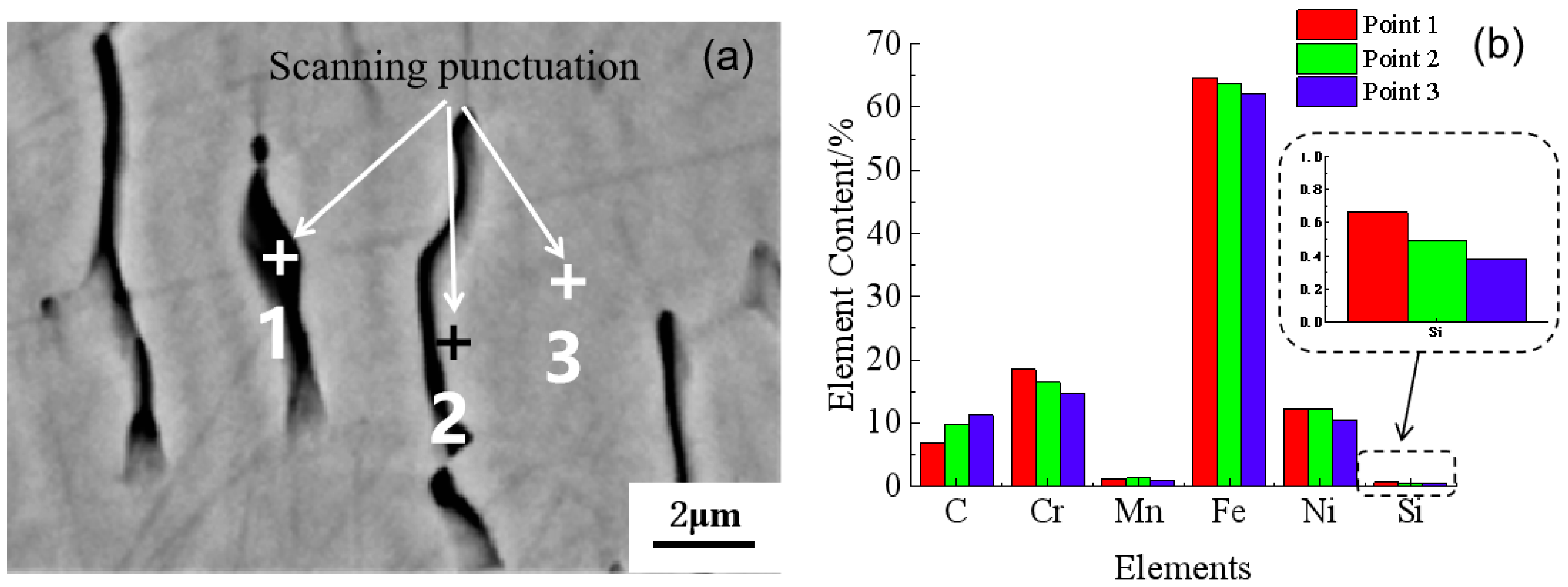

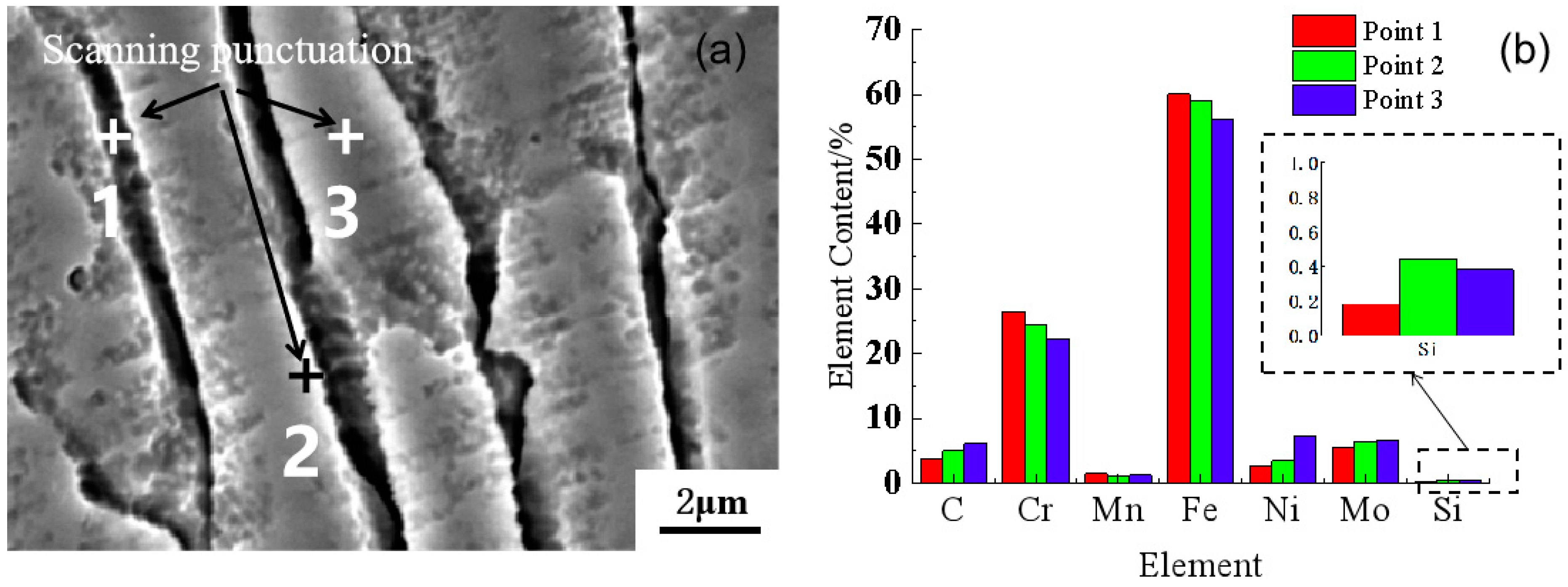

3.2. Element Composition and Distribution of Single Layer and Single Channel

3.3. Analysis of Single Layer and Single Channel EBSD Phase Morphology Characteristics

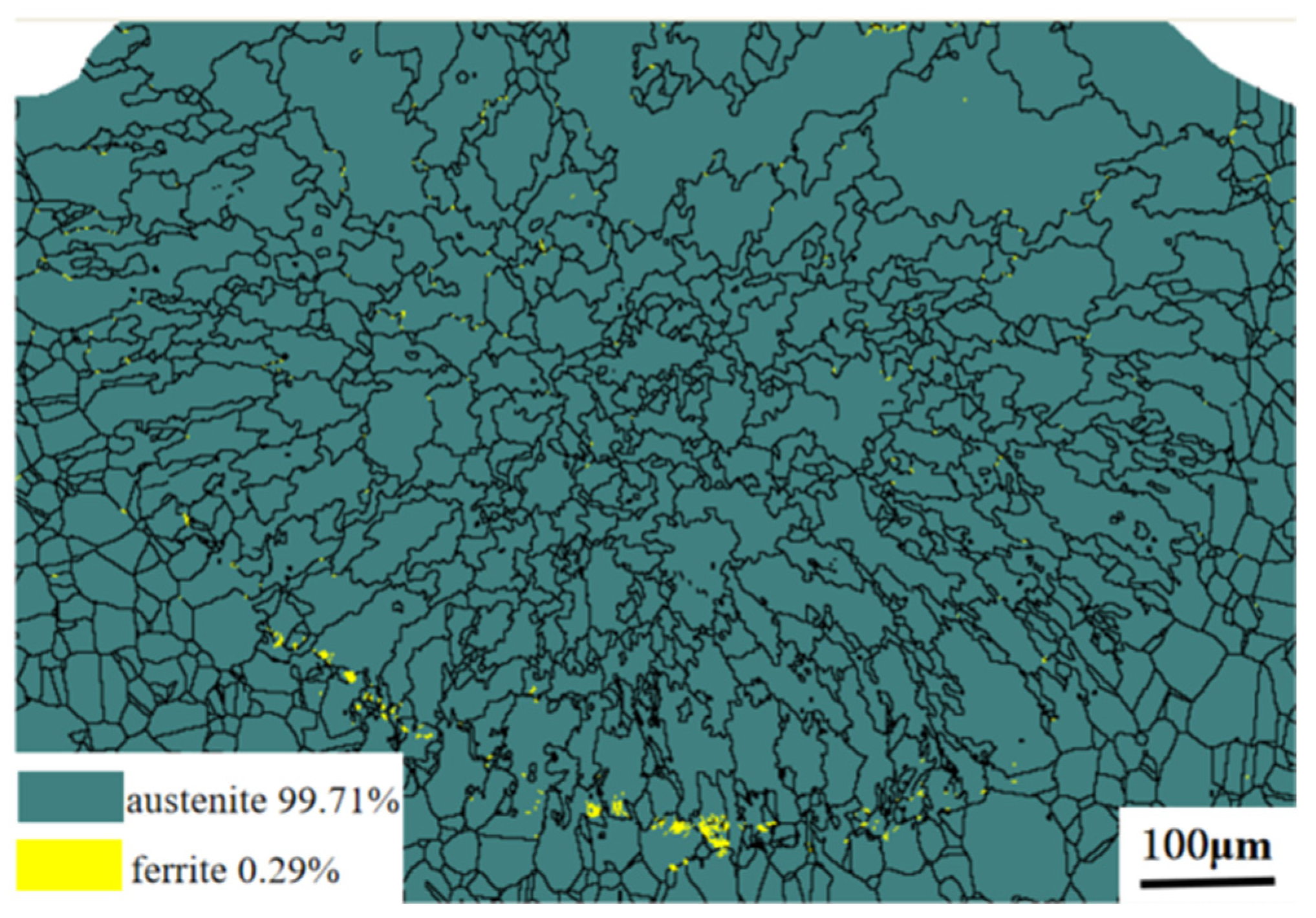

3.3.1. Phase Distribution

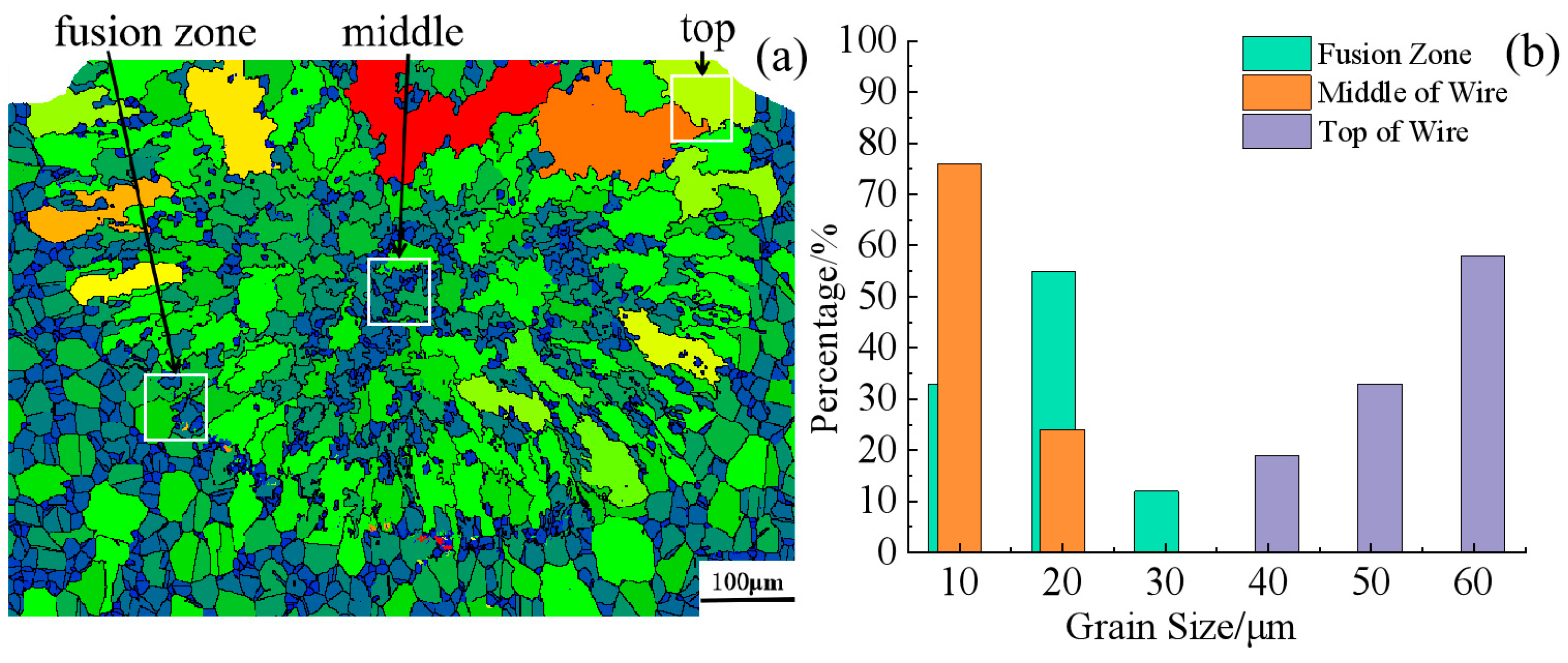

3.3.2. Grain Size Distribution

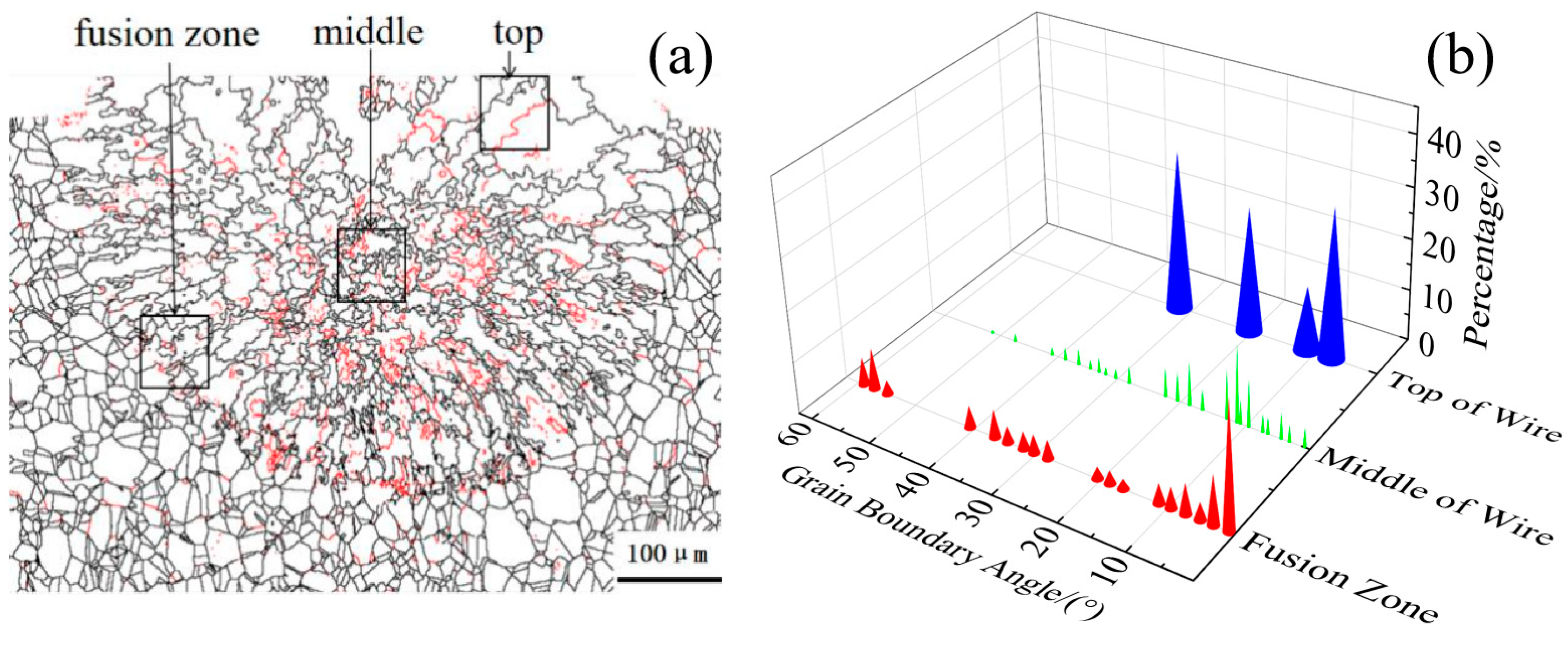

3.3.3. Grain Boundary Angle Distribution

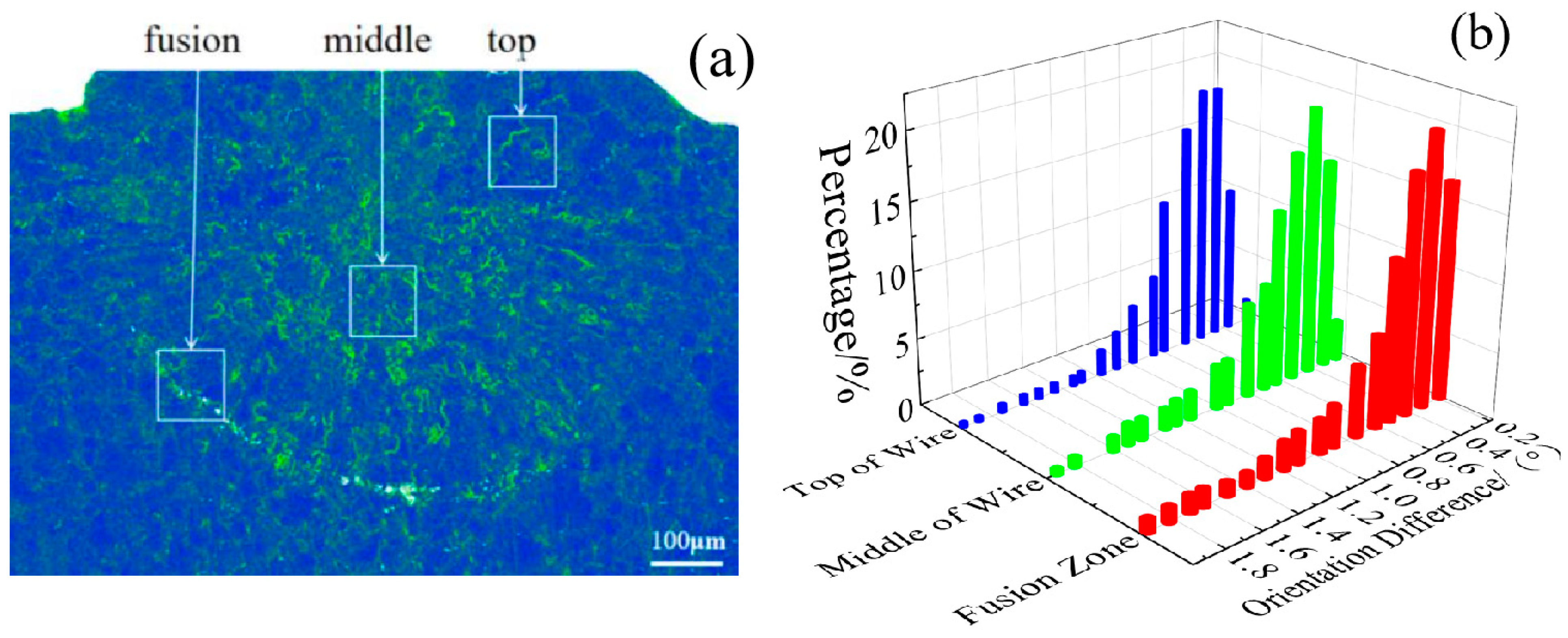

3.3.4. Distribution of Local Grain Orientation Difference

4. Conclusions

- The substrate structure consists of coarse columnar austenite, the fusion zone shows a closely distributed ferrite phase, and the area above the fusion zone is predominantly austenite. Notably, there is a significant difference in grain size between the substrate and the wire. As we move from the fusion line to the top of the wire, the grains transition from planar to columnar, then equiaxed, and finally back to columnar.

- The microstructure of the single layer is composed of austenite with a small amount of ferrite, where the austenite phase accounts for 99.71% of the content. Apart from Cr and Mo elements, the element content in the middle of the wire and the fusion zone is similar, resulting in a relatively uniform distribution.

- The grain size in the middle of the wire ranges within 10 μm, with a higher proportion of large-angle grain boundaries, which can improve the material’s toughness. The small-angle grain boundary is predominantly distributed in the middle of the wire, leading to an increase in material anisotropy. Additionally, the local orientation difference distribution for the grains in the three regions is consistent, with the highest proportion of orientation differences falling within 1°.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar, S.P.; Elangovan, S.; Mohanraj, R.; Ramakrishna, J.R. Review on the evolution and technology of State-of-the-Art metal additive manufacturing processes. Mater. Today Proc. 2021, 46, 7907–7920. [Google Scholar] [CrossRef]

- Lu, B. Additive Manufacturing—Current Situation and Future. China Mech. Eng. 2020, 31, 19–23. [Google Scholar]

- Biegler, M.; Graf, B.; Rethmeier, M. In-situ distortions in LMD additive manufacturing walls can be measured with digital image correlation and predicted using numerical simulations. Addit. Manuf. 2018, 20, 101–110. [Google Scholar] [CrossRef]

- Montoya-Zapata, D.; Creus, C.; Ortizc, I.; Alvarez, P.; Moreno, A.; Posada, J.; Ruiz, O.E. Generation of 2.5D Deposition Strategies for LMD-based Additive Manufacturing. Procedia Comput. Sci. 2021, 180, 280–289. [Google Scholar] [CrossRef]

- Fuchs, J.; Schneider, C.; Enzinger, N. Wire-based additive manufacturing using an electron beam as heat source. Weld. Word 2018, 62, 267–275. [Google Scholar] [CrossRef]

- Panchenko, M.; Maier, G.; Moskvina, V.; Astafurov, S.; Melnikov, E.; Reunova, K.; Kolubaev, E.; Astafurova, E. Microstructure and mechanical properties of Nb-alloyed austenitic CrNi steel fabricated by wire-feed electron beam additive manufacturing. Mater. Charact. 2022, 190, 112063. [Google Scholar] [CrossRef]

- Li, Q.; Wang, G.; Dong, M.; Feng, C.; Luo, Z. Influence of wire compositions on the microstructure and mechanical properties of WAAM Al-Cu aluminum alloy. Rare Met. Mater. Eng. 2021, 50, 1649–1655. [Google Scholar]

- Chen, S.; Yuan, C.; Jiang, F.; Yan, Z.; Zhang, P. Study on Heat Generation Mechanism and Melting Behavior of Droplet Transition in Resistive Heating Metal Wires. Acta Metall. Sin. 2018, 54, 1297–1310. [Google Scholar]

- Li, S.; Ma, K.; Xu, C.; Yang, L.; Lu, B. Numerical Analysis and Experimental Verification of Resistance Additive Manufacturing. Crystals 2022, 12, 193. [Google Scholar] [CrossRef]

- Ma, K.; Li, S.; Xu, C.; Gao, Z.; Yang, L.; Lu, B. Study on the Process Characteristics Based on Joule Heat of Sliding-Pressure Additive Manufacturing. Materials 2023, 16, 2017. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.; Huang, D.; Wang, J.; Li, K.; Sun, Q. Effect of Low-Temperature ECAP with Extended Route and Aging Heat Treatment on Structure and Properties of Cu0.6Cr Alloy. Rare Met. Mater. Eng. 2022, 51, 3204–3213. [Google Scholar]

- Lai, Y.; Ning, L.; Liu, Y.; Liu, N.; Meng, X.; Tan, Z.; Tong, J.; Zheng, Z. Effect of Heat Treatment on Microstructures and Stress Rupture Properties of a Hot-Corrosion Resistant Single Crystal Superalloy. Rare Met. Mater. Eng. 2023, 52, 2243–2252. [Google Scholar]

- Liu, L.; He, Y.; Li, Z.; Zhang, Z. Research on microstructure and mechanical properties of 316 stainless steel fabricated by arc additive manufacturing in different paths. Trans. China Weld. Inst. 2020, 41, 13–19+97–98. [Google Scholar]

- Unnikrishnan, R.; Satish, K.; Ismail, T.; Bhadauria, A.; Shekhawat, S.K.; Khatirkar, R.K.; Sapate, S. Effect of Heat Input on the Microstructure, Residual Stresses and Corrosion Resistance of 304 L Austenitic Stainless Steel Weldments. Mater. Charact. 2014, 93, 10–23. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, S.; Jiang, F.; Yang, F. Electro-thermal-mechanical response analysis of plastic deformation of resistance heating metal wire. Trans. China Weld. Inst. 2020, 41, 1–6. [Google Scholar]

- Asl, H.; Vatani, A. Numerical analysis of the burn-through at in-service welding of 316 stainless steel pipeline. Int. J. Press. Vessel. Pip. 2013, 105, 49–59. [Google Scholar] [CrossRef]

- Nie, D.; Lu, Z.; Zhang, K. Hot bending behavior of SUS 304 stainless steel sheet assisted by resistance heating: Multi-field coupling numerical simulation and experimental investigation. Int. J. Adv. Manuf. Technol. 2016, 87, 2763–2774. [Google Scholar] [CrossRef]

- Li, Y.; Liu, S.; Chang, Z.; Xu, J.; Luo, S.; Li, J. Study on microstructure of 304 stainless steel made by MIG arc additive. Weld. Technol. 2023, 52, 7–11. [Google Scholar]

- Fan, D.; He, C.; Chen, X.; Lian, J. Effect of CO2 partial pressure on corrosion behavior of 2205 duplex stainless steel in acidic oil and gas fields. Hot Work. Technol. 2019, 48, 50–55. [Google Scholar]

- Zhao, H. The Effect of Heat Aging on Microstructure and Corrosion Resistance of 316L Stainless Steel Welds; Xi’an University of Technology: Xi’an, China, 2018. [Google Scholar]

- Chen, X.; Li, W.; Ren, P.; Cao, W.; Liu, Q. Effects of C Content on Microstructure and Properties ofFe-Mn-Al-C Low-Density Steels. Acta Metall. Sin. 2019, 55, 951–957. [Google Scholar]

| CNC Milling Machine | Parameter | Work Travel (mm × mm × mm) | Dimensions (mm × mm × mm) | Repeat Positioning Accuracy (mm) | Max. Moving Speed (mm/min) | Spindle Motor Power (kW) | Max. Spindle Speed (rpm) |

| Value | 90 × 65 × 65 | 380 × 240 × 410 | ±0.002 | 5000 | 0.1 | 3000 | |

| Power Supply | Parameter | Dimensions (mm × mm × mm) | Voltage Range (V) | Current Range (A) | Output Power Range (kW) | Power Supply Regulation Rate (%) | Setting Accuracy (%) |

| Value | 435 × 640 × 85 | 0~10 | 0~1020 | 0~10.2 | ≤0.01 | ≤0.02 |

| Parameter | Pumping Speed (L/s) | Gas Throughput (L/s) | Compression Ratio (mm) | Rotational Speed (rpm) | Maximum Foreline Pressure (mbar) | Ultimate Pressure (mbar) | Weight (kg) | |

|---|---|---|---|---|---|---|---|---|

| Value | 90i Molecular Pump | 435 × 640 × 85 | 0~10 | 0~1020 | 0~10.2 | ≤0.01 | ≤0.02 | ≤2 |

| D60T Mechanical Pump | 17.5 | \ | \ | 1400 | \ | 0.3 | 70 | |

| Material | Fe | Cr | Mn | Mo | Ni | Si | C | P | S |

|---|---|---|---|---|---|---|---|---|---|

| 304 | 69.34 | 18.01 | 0.77 | 0.03 | 8.03 | 0.47 | 0.052 | 0.027 | 0.003 |

| 316 L | 68.33 | 16.38 | 0.86 | 2.11 | 10.11 | 0.44 | 0.018 | 0.026 | 0.007 |

| Material | Density (g/cm3) | Specific Heat Capacity (kJ/kg·°C) | Melting Point (°C) | Thermal Conductivity (W/m·°C) | Electrical Resistivity (Ω·mm2/m) |

|---|---|---|---|---|---|

| 304 | 7.93 | 0.50 | 1400 | 14.63 | 0.73 |

| 316 L | 7.98 | 0.502 | 1400 | 13.31 | 0.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Gao, Z.; Xiong, J.; Fan, L.; Chen, J.; Ma, K.; Yang, L.; Lu, B. Study on Single-Layer and Single-Channel Microstructure of 304 Stainless Steel Using Joule Heat Additive Manufacturing. Crystals 2023, 13, 1573. https://doi.org/10.3390/cryst13111573

Li S, Gao Z, Xiong J, Fan L, Chen J, Ma K, Yang L, Lu B. Study on Single-Layer and Single-Channel Microstructure of 304 Stainless Steel Using Joule Heat Additive Manufacturing. Crystals. 2023; 13(11):1573. https://doi.org/10.3390/cryst13111573

Chicago/Turabian StyleLi, Suli, Zhuang Gao, Jie Xiong, Longfei Fan, Jichao Chen, Kaiyue Ma, Laixia Yang, and Bingheng Lu. 2023. "Study on Single-Layer and Single-Channel Microstructure of 304 Stainless Steel Using Joule Heat Additive Manufacturing" Crystals 13, no. 11: 1573. https://doi.org/10.3390/cryst13111573

APA StyleLi, S., Gao, Z., Xiong, J., Fan, L., Chen, J., Ma, K., Yang, L., & Lu, B. (2023). Study on Single-Layer and Single-Channel Microstructure of 304 Stainless Steel Using Joule Heat Additive Manufacturing. Crystals, 13(11), 1573. https://doi.org/10.3390/cryst13111573