A Machine Learning Approach for Segmentation and Characterization of Microtextured Regions in a Near-α Titanium Alloy

Abstract

:1. Introduction

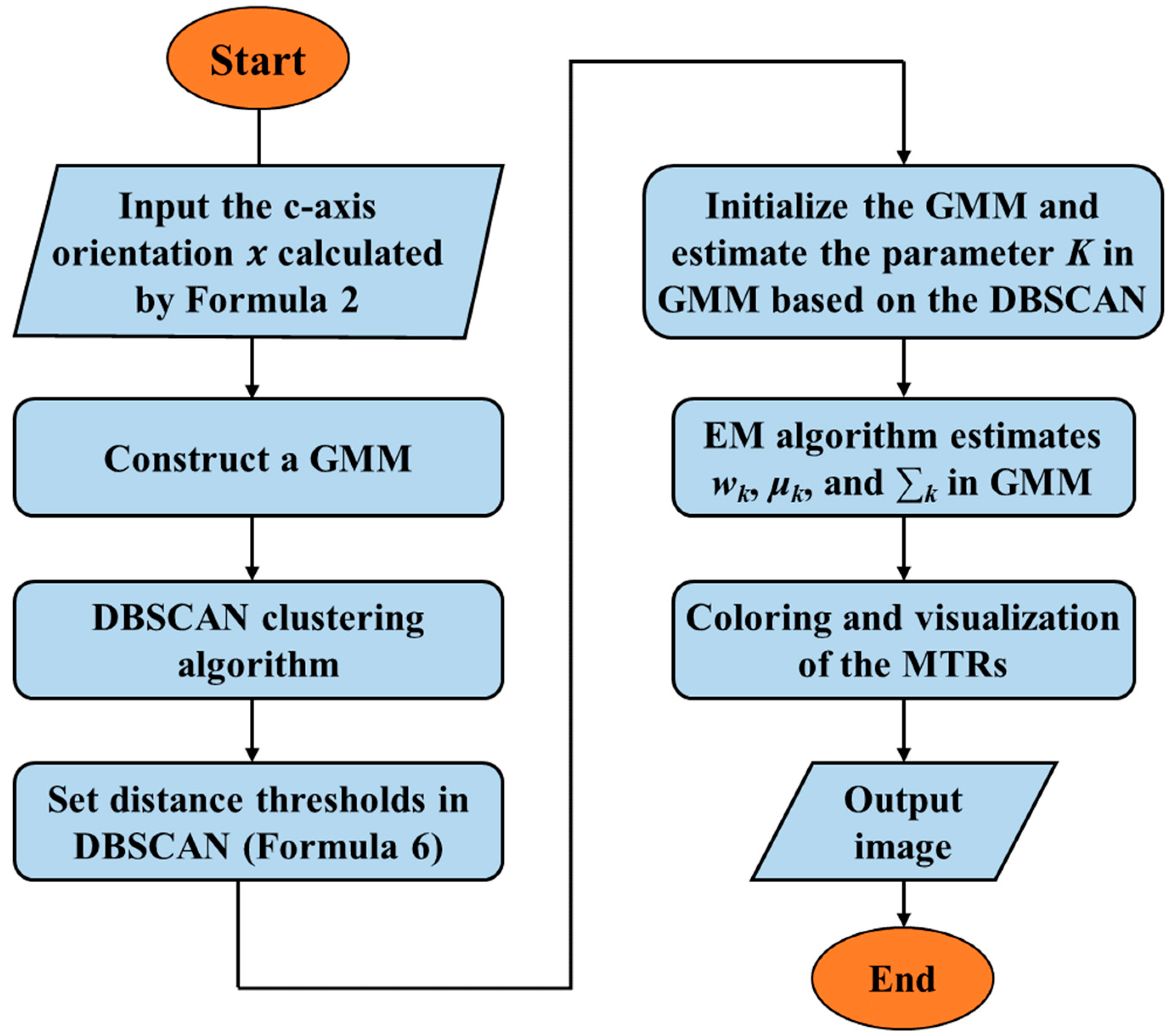

2. Experiments and Methods

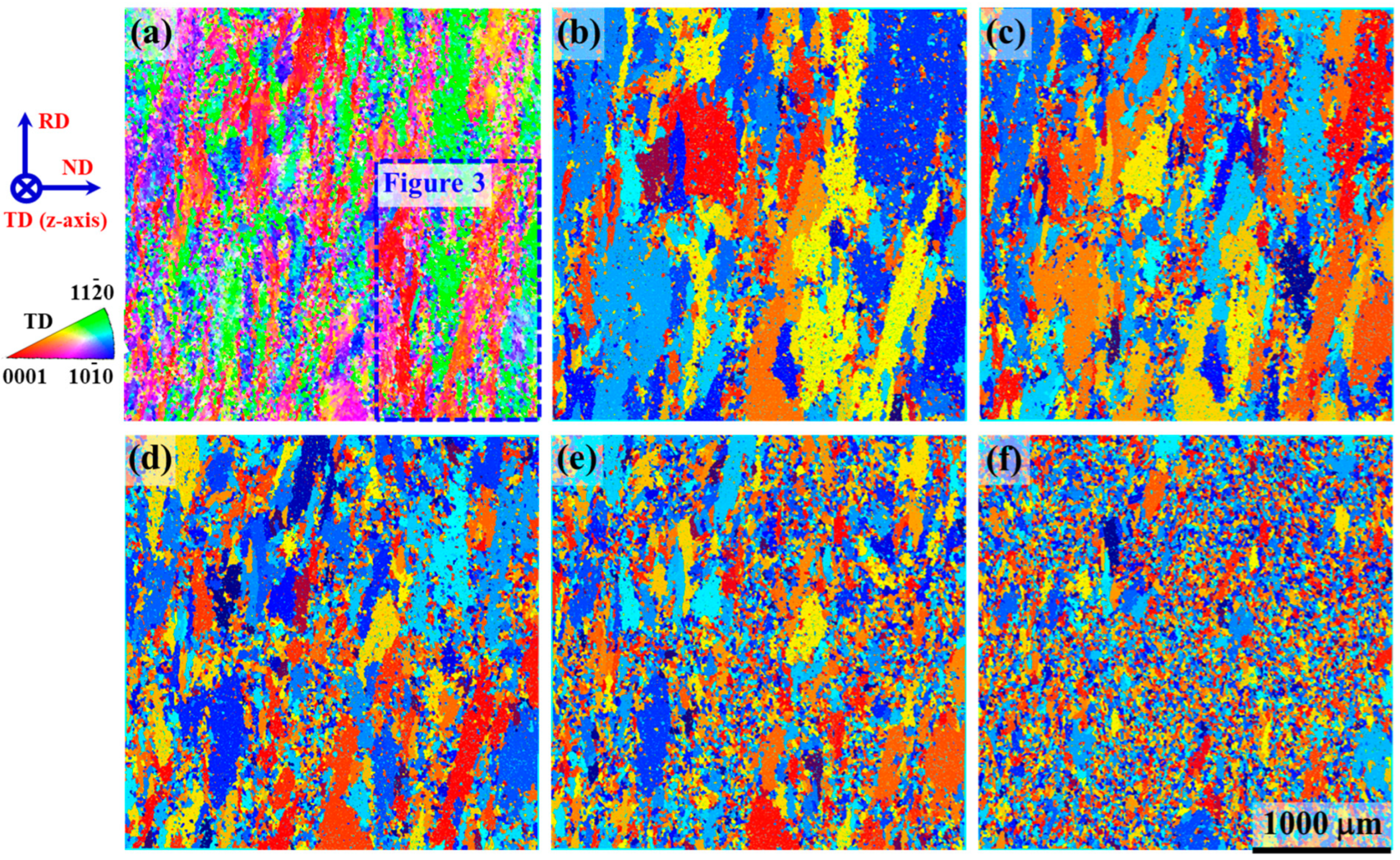

3. Results and Discussion

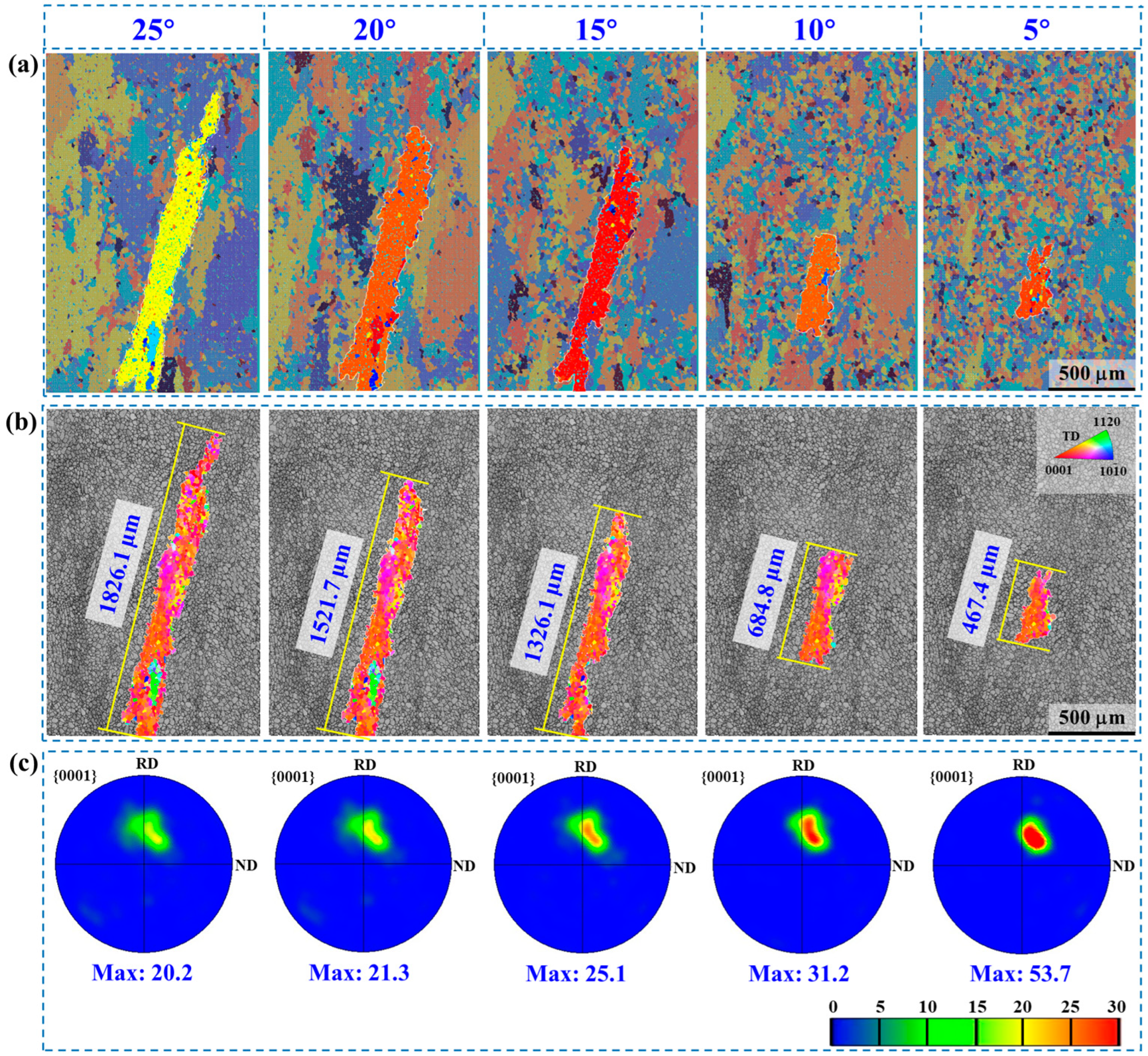

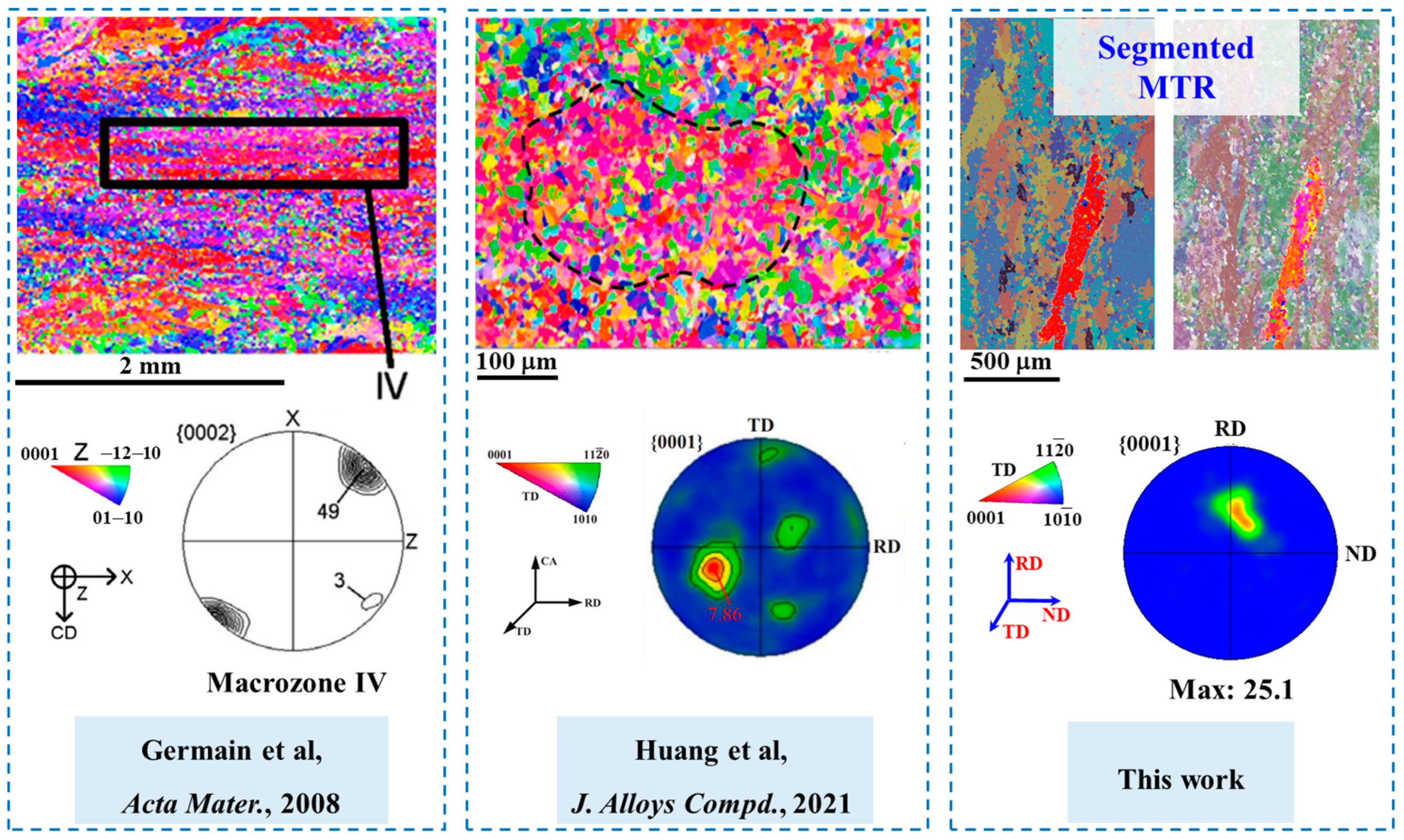

3.1. MTR Segmentation

3.2. Characterization of MTRs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bache, M. A review of dwell sensitive fatigue in titanium alloys: The role of microstructure, texture and operating conditions. Int. J. Fatigue 2003, 25, 1079–1087. [Google Scholar] [CrossRef]

- Sinha, V.; Mills, M.J.; Williams, J.C.; Spowart, J.E. Observations on the faceted initiation site in the dwell-fatigue tested ti-6242 alloy: Crystallographic orientation and size effects. Met. Mater. Trans. A 2006, 37, 1507–1518. [Google Scholar] [CrossRef]

- Cappola, J.; Stinville, J.-C.; Charpagne, M.-A.; Callahan, P.G.; Echlin, M.P.; Pollock, T.M.; Pilchak, A.; Kasemer, M. On the Localization of Plastic Strain in Microtextured Regions of Ti-6Al-4V. Acta Mater. 2020, 204, 116492. [Google Scholar] [CrossRef]

- Kasemer, M.; Echlin, M.P.; Stinville, J.C.; Pollock, T.M.; Dawson, P. On slip initiation in equiaxed α/β Ti-6Al-4V. Acta Mater. 2017, 136, 288–302. [Google Scholar] [CrossRef]

- Zhang, K.; Yang, K.V.; Lim, S.; Wu, X.; Davies, C.H.J. Effect of the presence of macrozones on short crack propagation in forged two-phase titanium alloys. Int. J. Fatigue 2017, 104, 1–11. [Google Scholar] [CrossRef]

- Zhang, K.; Wu, X.; Davies, C.H.J. Effect of microtexture on short crack propagation in two-phase titanium alloys. Int. J. Fatigue 2017, 104, 206–220. [Google Scholar] [CrossRef]

- Nait-Ali, A.; Hémery, S.; Gueguen, M. How macrozone size and morphology influence yield in titanium alloys investigated using fast Fourier transform-based crystal plasticity simulations. Int. J. Solids Struct. 2021, 216, 1–16. [Google Scholar] [CrossRef]

- Bieler, T.R.; Semiatin, S.L. The origins of heterogeneous deformation during primary hot working of Ti–6Al–4V. Int. J. Plast. 2002, 18, 1165–1189. [Google Scholar] [CrossRef]

- Glavicic, M.G.; Bartha, B.B.; Jha, S.K.; Szczepanski, C.J. The origins of microtexture in duplex Ti alloys. Mater. Sci. Eng. A 2009, 513–514, 325–328. [Google Scholar] [CrossRef]

- Germain, L.; Gey, N.; Humbert, M.; Bocher, P.; Jahazi, M. Analysis of sharp microtexture heterogeneities in a bimodal IMI 834 billet. Acta Mater. 2005, 53, 3535–3543. [Google Scholar] [CrossRef]

- Germain, L.; Gey, N.; Humbert, M.; Vo, P.; Jahazi, M.; Bocher, P. Texture heterogeneities induced by subtransus processing of near α titanium alloys. Acta Mater. 2008, 56, 4298–4308. [Google Scholar] [CrossRef]

- Zhao, Z.B.; Wang, Q.J.; Liu, J.R.; Yang, R. Characterizations of microstructure and crystallographic orientation in a near-α titanium alloy billet. J. Alloys Compd. 2017, 712, 179–184. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S. Orientation dependent spheroidization response and macro-zone formation during sub β-transus processing of Ti-6Al-4V alloy. Acta Mater. 2017, 134, 283–301. [Google Scholar] [CrossRef]

- Huang, L.; Sun, Z.; Cao, J.; Yin, Z. The formation and evolution of macrozone in Ti-6242S alloy during thermo-mechanical processing. J. Alloys Compd. 2021, 861, 158533. [Google Scholar] [CrossRef]

- Hu, Z.; Zhou, X.; Liu, H.; Yi, D. The formation of microtextured region during thermo-mechanical processing in a near-β titanium alloy Ti-5Al-5Mo-5V-1Cr-1Fe. J. Alloys Compd. 2020, 853, 156964. [Google Scholar] [CrossRef]

- Ozturk, D.; Pilchak, A.L.; Ghosh, S. Experimentally validated dwell and cyclic fatigue crack nucleation model for α–titanium alloys. Scr. Mater. 2017, 127, 15–18. [Google Scholar] [CrossRef]

- Liu, Y.; Dunne, F.P.E. The mechanistic link between macrozones and dwell fatigue in titanium alloys. Int. J. Fatigue 2021, 142, 105971. [Google Scholar] [CrossRef]

- Ramprasad, R.; Batra, R.; Pilania, G.; Mannodi-Kanakkithodi, A.; Kim, C. Machine learning in materials informatics: Recent applications and prospects. NPJ Comput. Mater. 2017, 3, 54. [Google Scholar] [CrossRef]

- Morgan, D.; Jacobs, R. Opportunities and Challenges for Machine Learning in Materials Science. Annu. Rev. Mater. Res. 2020, 50, 71–103. [Google Scholar] [CrossRef]

- Schneider, Y.; Prabhu, V.; Höss, K.; Wasserbäch, W.; Schmauder, S.; Zhou, Z. Many-Scale Investigations of the Deformation Behavior of Polycrystalline Composites: I-Machine Learning Applied for Image Segmentation. Materials 2022, 15, 2486. [Google Scholar] [CrossRef]

- Staub, A.; Brunner, L.; Spierings, A.B.; Wegener, K. A Machine-Learning-Based Approach to Critical Geometrical Feature Identification and Segmentation in Additive Manufacturing. Technologies 2022, 10, 102. [Google Scholar] [CrossRef]

- Nguyen, T.M.; Wu, Q.M.J. Fast and Robust Spatially Constrained Gaussian Mixture Model for Image Segmentation. IEEE Trans. Circuits Syst. Video Technol. 2013, 23, 621–635. [Google Scholar] [CrossRef]

- Riaz, F.; Rehman, S.; Ajmal, M.; Hafiz, R.; Hassan, A.; Aljohani, N.R.; Nawaz, R.; Young, R.; Coimbra, M. Gaussian Mixture Model Based Probabilistic Modeling of Images for Medical Image Segmentation. IEEE Access 2020, 8, 16846–16856. [Google Scholar] [CrossRef]

- Hanafi, N.; Saadatfar, H. A fast DBSCAN algorithm for big data based on efficient density calculation. Expert Syst. Appl. 2022, 203, 117501. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, H.; Liu, D.; Jin, F.; Lv, N.; Nan, J.; Wang, H.; Yang, Y.; Wang, J. A Machine Learning Approach for Segmentation and Characterization of Microtextured Regions in a Near-α Titanium Alloy. Crystals 2023, 13, 1422. https://doi.org/10.3390/cryst13101422

Rao H, Liu D, Jin F, Lv N, Nan J, Wang H, Yang Y, Wang J. A Machine Learning Approach for Segmentation and Characterization of Microtextured Regions in a Near-α Titanium Alloy. Crystals. 2023; 13(10):1422. https://doi.org/10.3390/cryst13101422

Chicago/Turabian StyleRao, Haodong, Dong Liu, Feng Jin, Nan Lv, Jungang Nan, Haiping Wang, Yanhui Yang, and Jianguo Wang. 2023. "A Machine Learning Approach for Segmentation and Characterization of Microtextured Regions in a Near-α Titanium Alloy" Crystals 13, no. 10: 1422. https://doi.org/10.3390/cryst13101422

APA StyleRao, H., Liu, D., Jin, F., Lv, N., Nan, J., Wang, H., Yang, Y., & Wang, J. (2023). A Machine Learning Approach for Segmentation and Characterization of Microtextured Regions in a Near-α Titanium Alloy. Crystals, 13(10), 1422. https://doi.org/10.3390/cryst13101422