Effect of Electrolysis Temperature on the Preparation of FeO by Molten Salt Electrolysis

Abstract

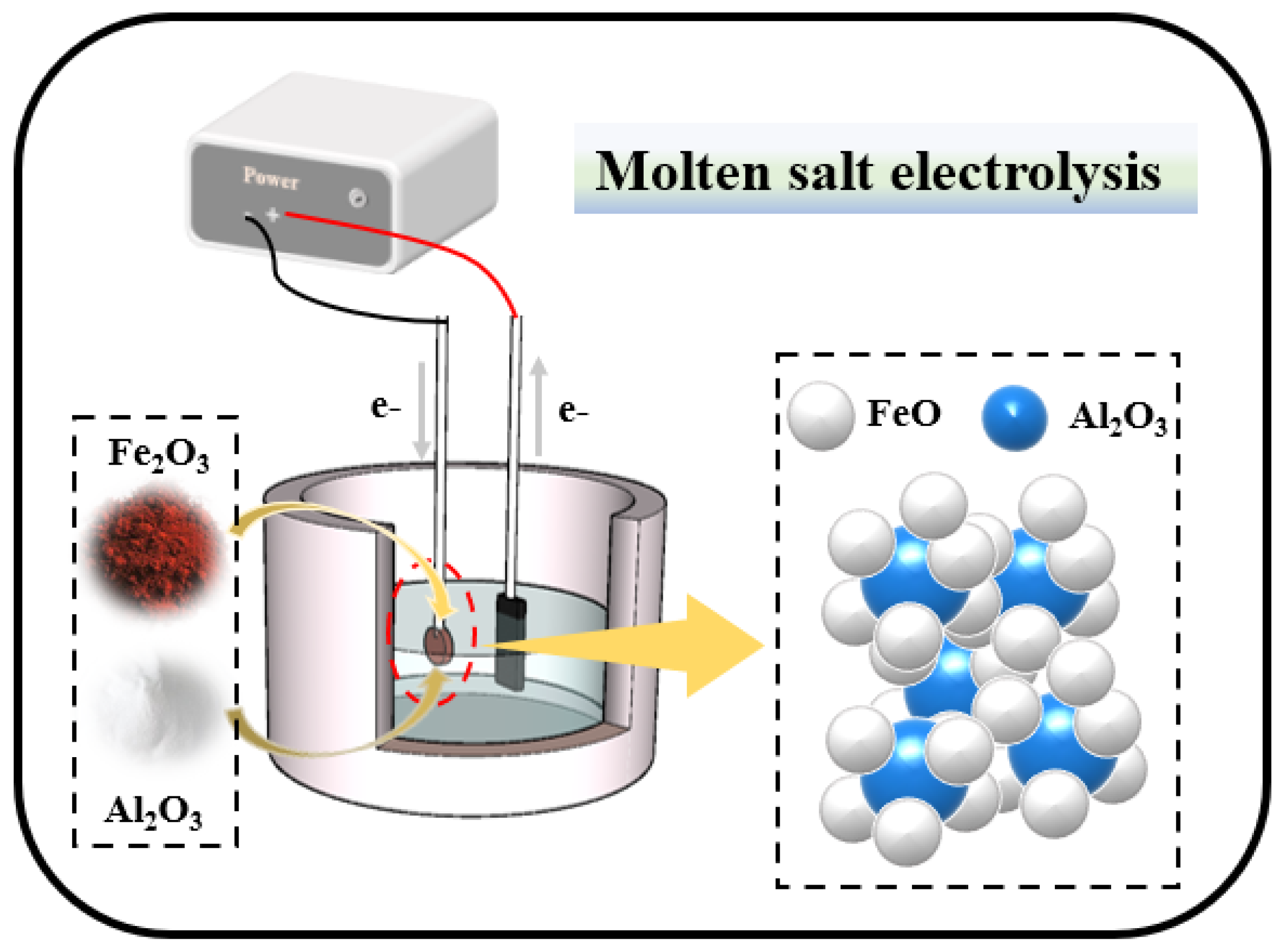

:1. Introduction

2. Experimental

2.1. Thermodynamic Analysis

2.2. Experimental Process

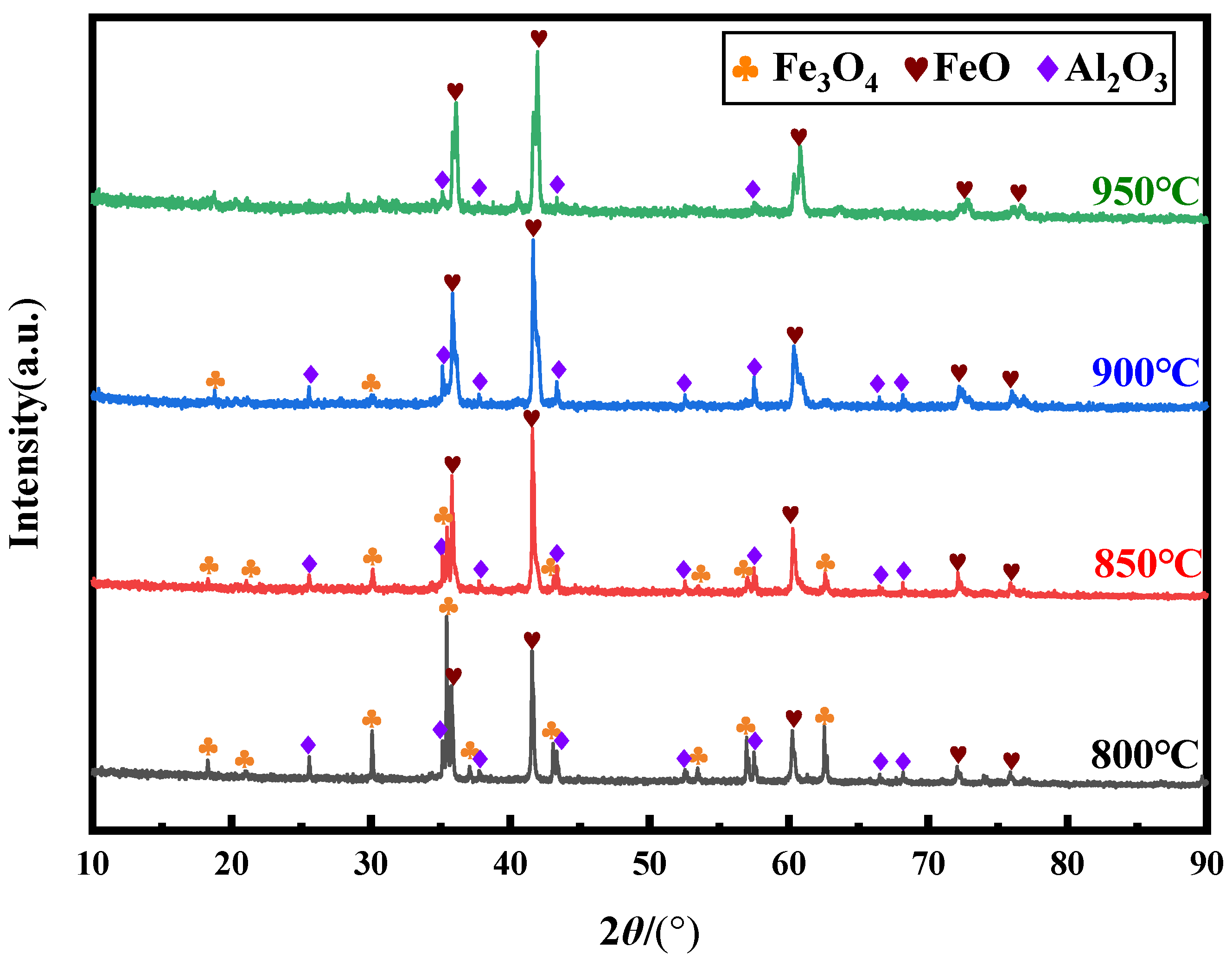

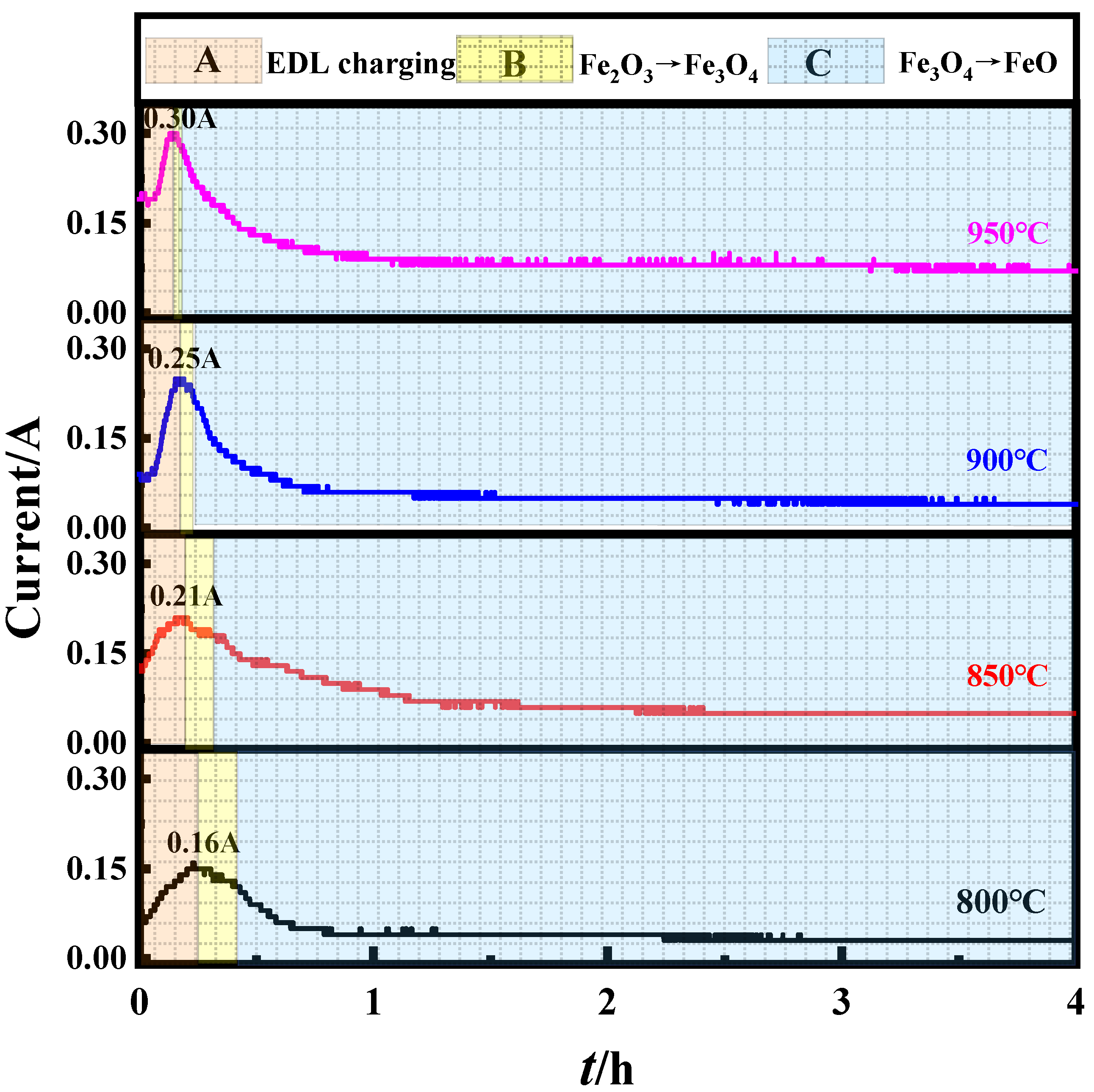

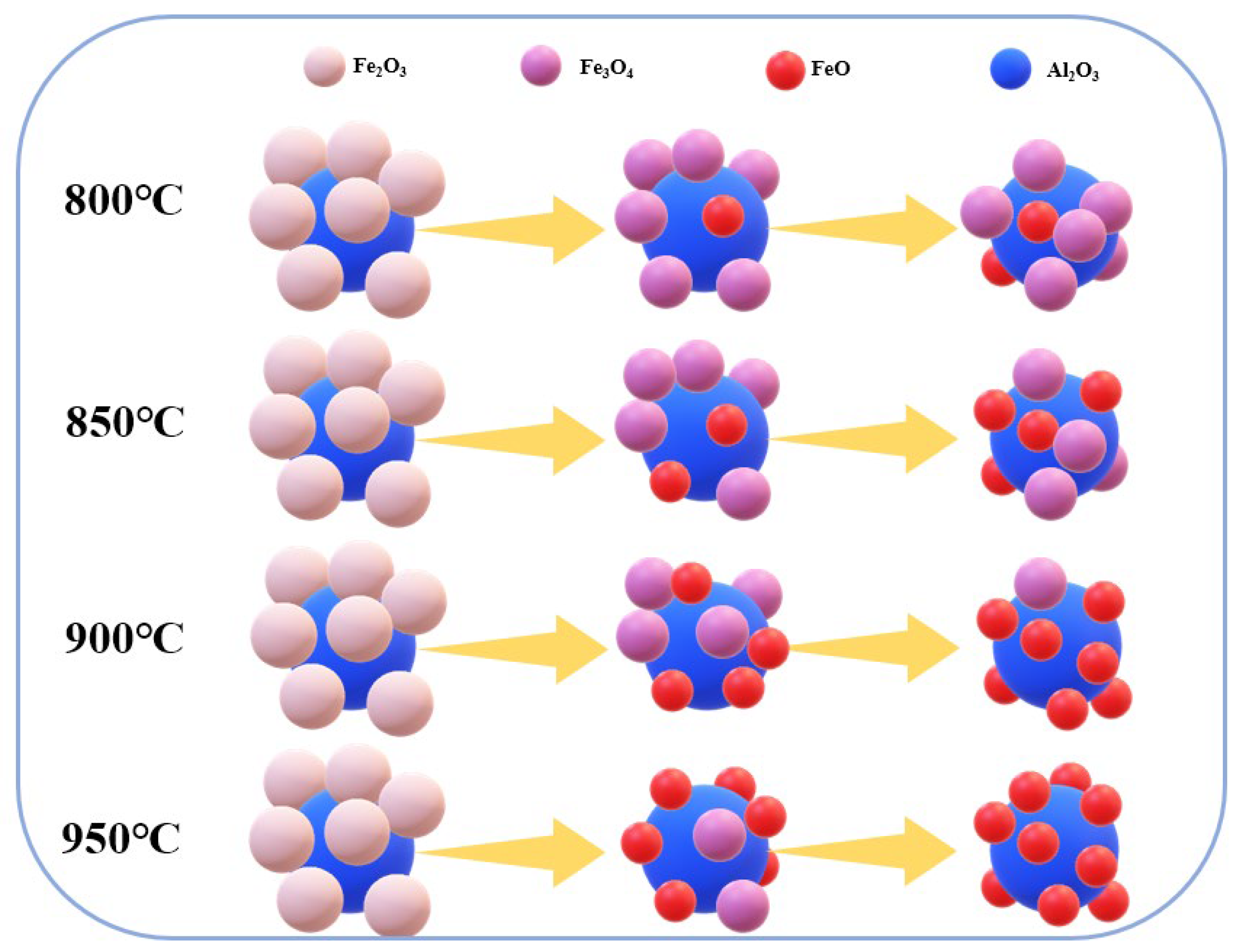

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Z.S.; Zhou, G.; Yin, L.C.; Ren, W.; Li, F.; Cheng, H.M. Graphene/metal oxide composite electrode materials for energy storage. Nano Energy 2012, 1, 107–131. [Google Scholar] [CrossRef]

- Issa, B.; Obaidat, I.M.; Albiss, B.A.; Haik, Y. Magnetic nanoparticles: Surface effects and properties related to biomedicine applications. Int. J. Mol. Sci. 2013, 14, 21266–21305. [Google Scholar] [CrossRef] [PubMed]

- Roeb, M.; Gathmann, N.; Neises, M.; Sattler, C.; Pitz-Paal, R. Thermodynamic analysis of two-step solar water splitting with mixed iron oxides. Int. J. Energy. Res. 2009, 33, 893–902. [Google Scholar] [CrossRef]

- Ahmed, A.T.A.; Pawar, S.M.; Inamdar, A.I.; Im, H.; Kim, H. Fabrication of FeO@ CuCo2S4 multifunctional electrode for ultrahigh-capacity supercapacitors and efficient oxygen evolution reaction. Int. J. Energy Res. 2020, 44, 1798–1811. [Google Scholar] [CrossRef]

- Wang, H.; Cao, M.; Mao, T.; Fu, J.; Pan, W.; Hao, H.; Liu, H. Fabrication of BaTiO3@ FeO core-shell nanoceramics for dielectric capacitor applications. Scr. Mater. 2021, 196, 113753. [Google Scholar] [CrossRef]

- Wang, H.; Cao, M.; Tao, C.; Hao, H.; Yao, Z.; Liu, H. Tuning the microstructure of BaTiO3@ FeO core-shell nanoparticles with low temperatures sintering dense nanocrystalline ceramics for high energy storage capability and stability. J. Alloys Compd. 2021, 864, 158644. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Peng, W.; Wang, Z.; Li, X.; Guo, H.; Shih, K. Synthesis of FeO-nanowires/NiCo2O4-nanopellets core/shell heterostructure as free-standing electrode with enhanced lithium storage properties. Ceram. Int. 2016, 42, 15099–15103. [Google Scholar] [CrossRef]

- Harshiny, M.; Samsudeen, N.; Kameswara, R.J.; Matheswaran, M. Biosynthesized FeO nanoparticles coated carbon anode for improving the performance of microbial fuel cell. Int. J. Hydrogen Energy 2017, 42, 26488–26495. [Google Scholar] [CrossRef]

- Harshiny, M.; Iswarya, C.N.; Matheswaran, M. Biogenic synthesis of iron nanoparticles using Amaranthus dubius leaf extract as a reducing agent. Powder. Technol. 2015, 286, 744–749. [Google Scholar] [CrossRef]

- Laurent, S.; Bridot, J.L.; Elst, L.V.; Muller, R.N. Magnetic iron oxide nanoparticles for biomedical applications. Future. Med. Chem. 2010, 2, 427–449. [Google Scholar] [CrossRef]

- Tatarǒlu, A.; Hendi, A.A.; Alorainy, R.H.; Yakuphanǒlu, F. A new aluminum iron oxide Schottky photodiode designed via sol—gel coating method. Chin. Phys. B 2014, 23, 057504. [Google Scholar] [CrossRef]

- Wu, W.D.; Liu, S.M.; Hong, H.X.; Chen, S.X. Stability analysis of water-based nanofluids prepared by using supersonic dispersion method. Adv. Mater. Res. 2012, 383, 6174–6180. [Google Scholar] [CrossRef]

- Zhang, J.B.; Zhang, G.; Xiao, G.Q. Preparation of hercynite. Bull. Chin. Ceram. Soc. 2007, 26, 4. [Google Scholar]

- Botta, P.M.; Aglietti, E.F.; López, J.M.P. Mechanochemical synthesis of hercynite. Mater. Chem. Phys. 2002, 76, 104–109. [Google Scholar] [CrossRef]

- Liu, J.X.; He, G.; Lu, N.; Li, J.T. High infrared emission property of FeAl2O4 fabricated by combustion synthesis. J. Ceram. 2017, 38, 179–183. [Google Scholar]

- Mu, H.Y.; Li, F.T.; An, X.T.; Liu, R.H.; Li, Y.L.; Qian, X.; Hu, Y.Q. One-step synthesis, electronic structure, and photocatalytic activity of earth-abundant visible-light-driven FeAl2O4. Phys. Chem. Chem. Phys. 2017, 19, 9392–9401. [Google Scholar] [CrossRef]

- Kamijo, C. Method of Estimation of Reduction Rate Constant in Ishida-Wen’s Model for FeO-Al2O3 Briquette. ISIJ Inter. 2017, 57, 1797–1803. [Google Scholar] [CrossRef]

- Pelton, A.D.; Gabriel, A.; Sangster, J. Liquidus measurements and coupled thermodynamic–phase-diagram analysis of the NaCl–KCl system. J. Chem. Soc. Faraday Trans. 1 Phys. Chem. Condens. Phases. 1985, 81, 1167–1172. [Google Scholar] [CrossRef]

- Li, H.; Jia, L.; Liang, J.L.; Yan, H.Y.; Cai, Z.Y.; Reddy, R.G. Study on the direct electrochemical reduction of Fe2O3 in NaCl-CaCl2 melt. Int. J. Electrochem. Sci. 2019, 14, 11267–11278. [Google Scholar] [CrossRef]

- Chen, G.Z.; Fray, D.J.; Farthing, T.W. Direct electrochemical reduction of titanium dioxide to titanium in molten calcium chloride. J. Nat. 2000, 407, 361–364. [Google Scholar] [CrossRef]

- Li, H.; Zhang, L.; Liang, J.; Reddy, R.G.; Yan, H.; Yin, Y. Electrochemical Behavior of Fe3O4 in NaCl-CaCl2 Melts. Int. J. Chem. React. Eng. 2019, 17, 1–10. [Google Scholar] [CrossRef]

- Xu, Y.K.; Yan, H.Y.; Jing, Z.W.; Qi, X.; Li, H.; Liang, J.L. Effect of Fe2O3 on Electro-Deoxidation in Fe2O3-Al2O3-NaCl-KCl System. Crystals 2021, 11, 1026. [Google Scholar] [CrossRef]

| Temperature | Stage A Slope | Stage B Slope |

|---|---|---|

| 800 °C | 1.234 | 5.051 |

| 850 °C | 1.603 | 5.722 |

| 900 °C | 4.552 | 7.764 |

| 950 °C | 4.992 | 8.031 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, Z.; Luo, C.; Yan, H.; Meng, J.; Li, C.; Li, H.; Liang, J. Effect of Electrolysis Temperature on the Preparation of FeO by Molten Salt Electrolysis. Crystals 2022, 12, 1130. https://doi.org/10.3390/cryst12081130

Jing Z, Luo C, Yan H, Meng J, Li C, Li H, Liang J. Effect of Electrolysis Temperature on the Preparation of FeO by Molten Salt Electrolysis. Crystals. 2022; 12(8):1130. https://doi.org/10.3390/cryst12081130

Chicago/Turabian StyleJing, Zhenwei, Chao Luo, Hongyan Yan, Ju Meng, Chenxiao Li, Hui Li, and Jinglong Liang. 2022. "Effect of Electrolysis Temperature on the Preparation of FeO by Molten Salt Electrolysis" Crystals 12, no. 8: 1130. https://doi.org/10.3390/cryst12081130

APA StyleJing, Z., Luo, C., Yan, H., Meng, J., Li, C., Li, H., & Liang, J. (2022). Effect of Electrolysis Temperature on the Preparation of FeO by Molten Salt Electrolysis. Crystals, 12(8), 1130. https://doi.org/10.3390/cryst12081130