Reversible and Irreversible Laser Interference Patterning of MOF Thin Films

Abstract

:1. Introduction

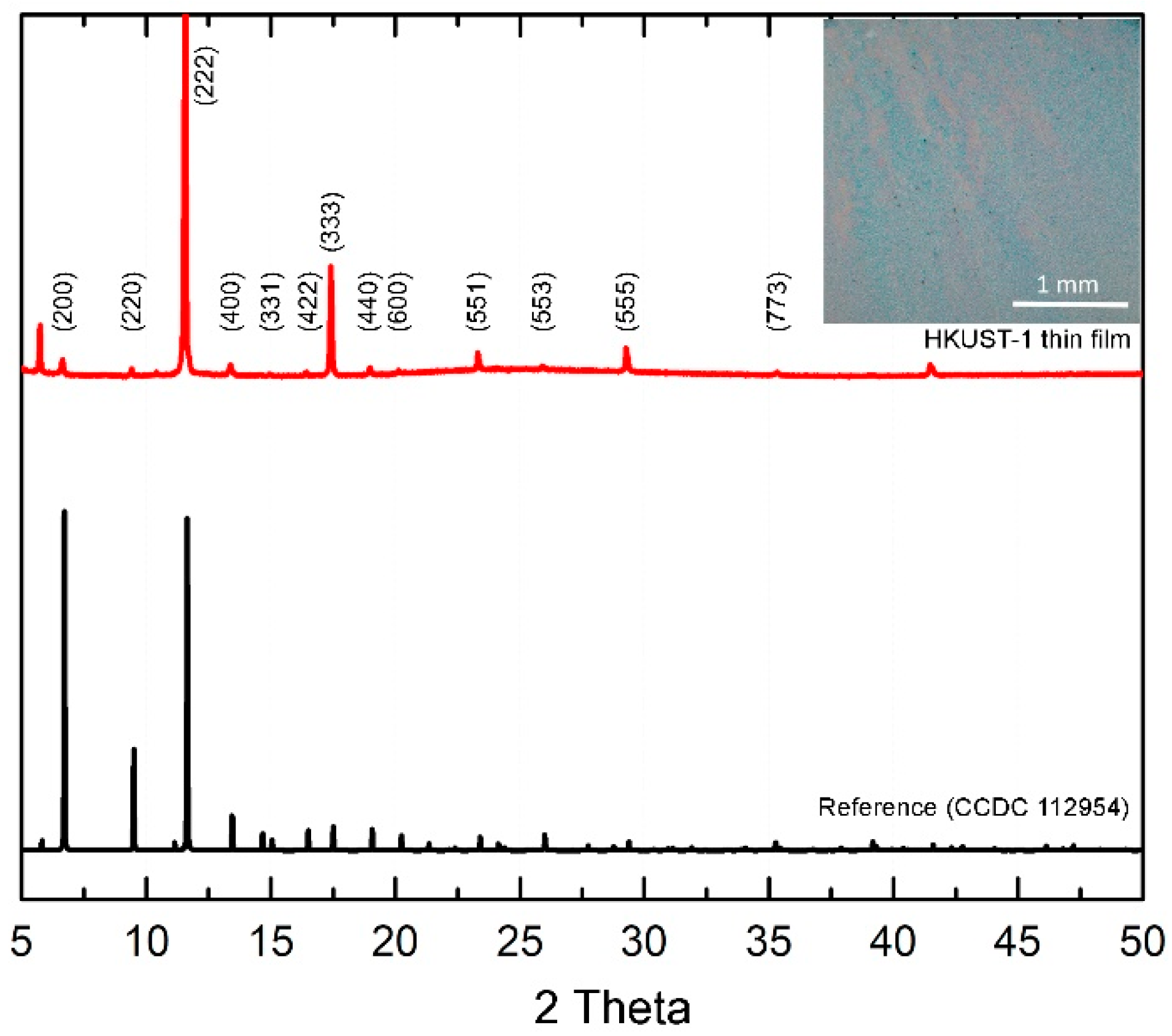

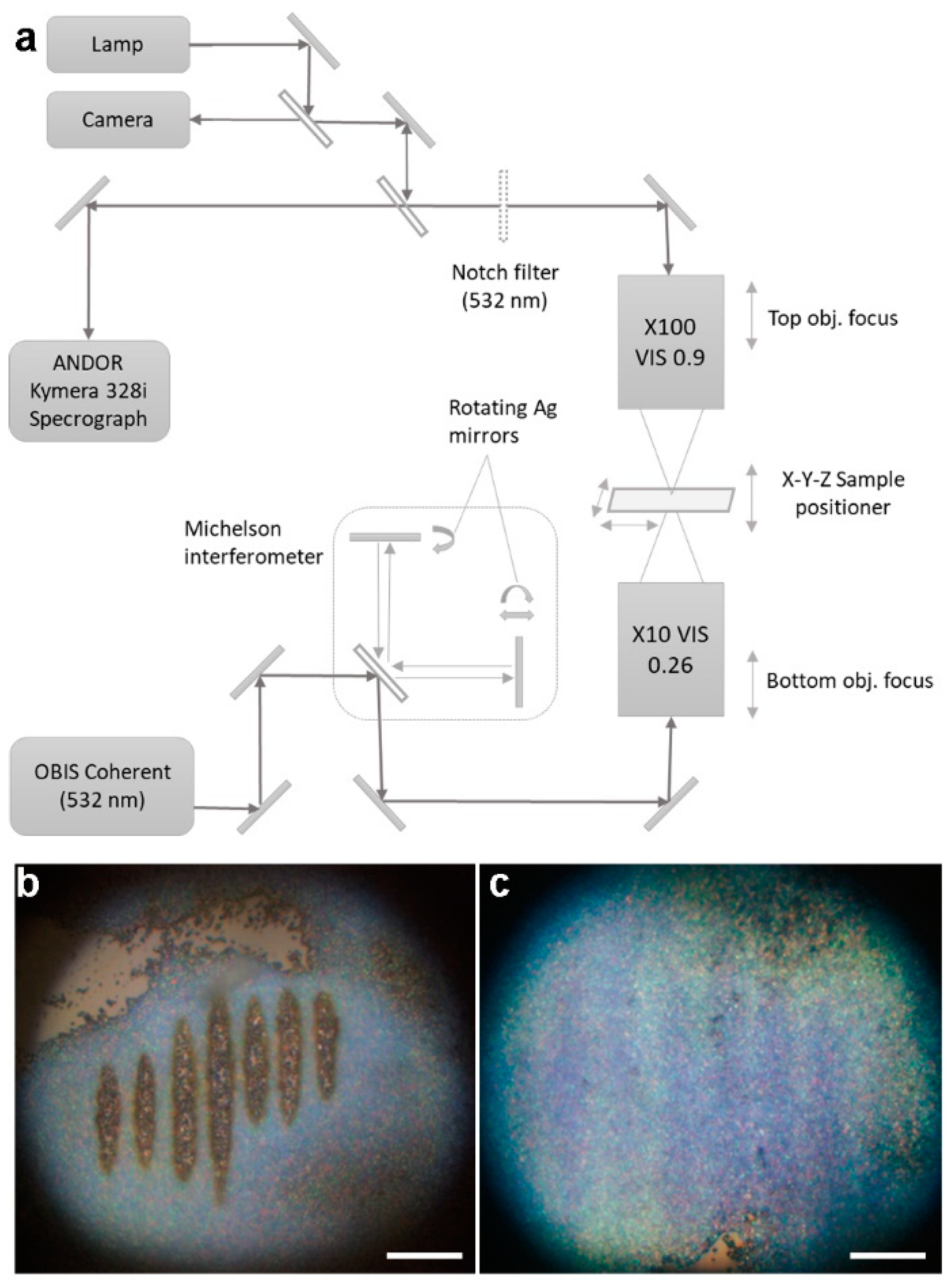

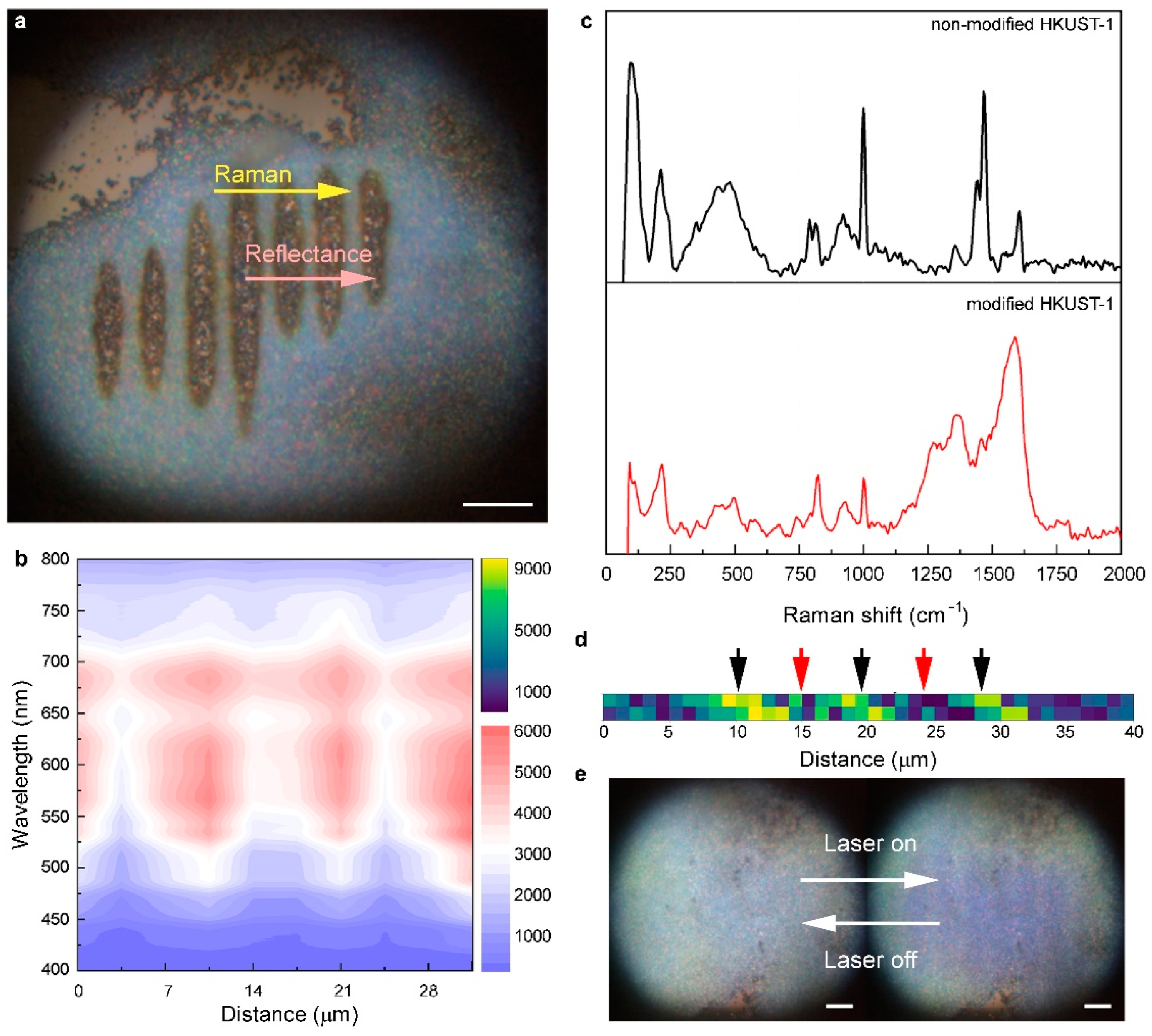

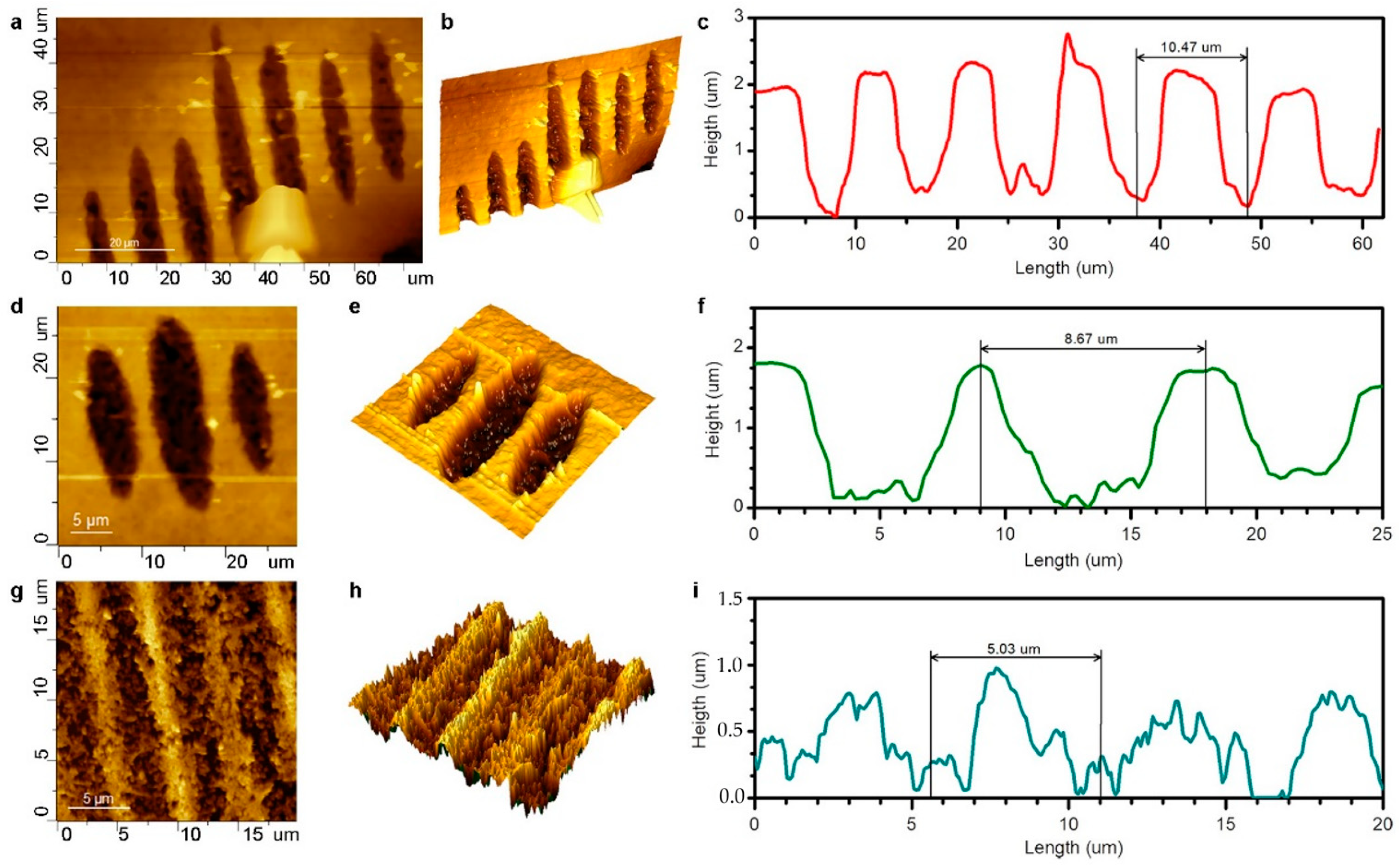

2. Results and Discussion

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, H.-C.; Long, J.R. Introduction to Metal–Organic Frameworks. Chem. Rev. 2012, 112, 673–674. [Google Scholar] [CrossRef] [PubMed]

- Furukawa, H.; Cordova, W.E. The Chemistry and Applications of Metal-Organic Frameworks. Science 2013, 341, 6149. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xie, L.S.; Skorupskii, G. Electrically Conductive Metal–Organic Frameworks. Chem. Rev. 2020, 120, 8536–8580. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kulachenkov, N.K.; Haar, Q. MOF-Based Sustainable Memory Devices. Adv. Funct. Mater. 2020, 32, 2107949. [Google Scholar] [CrossRef]

- Lv, Y.; Xiong, Z. Pure Metal–Organic Framework Microlasers with Controlled Cavity Shapes. Nano Lett. 2020, 20, 2020–2025. [Google Scholar] [CrossRef]

- Mingabudinova, L.R.; Vinogradov, V.V. Metal–organic frameworks as competitive materials for non-linear optics. Chem. Soc. Rev. 2016, 45, 5408–5431. [Google Scholar] [CrossRef] [Green Version]

- Danowski, W.; van Leeuwen, T. Unidirectional rotary motion in a metal–organic framework. Nat. Nanotechnol. 2019, 14, 488–494. [Google Scholar] [CrossRef]

- Ribeiro, E.L.; Davis, E.M. MOF-derived PtCo/Co3O4 nanocomposites in carbonaceous matrices as high-performance ORR electrocatalysts synthesized via laser ablation techniques. Catal. Sci. Technol. 2021, 11, 3002–3013. [Google Scholar] [CrossRef]

- Guo, S.; Zhao, Y.; Yuan, H.; Wang, C.; Jiang, H.; Cheng, G.J. Ultrafast Laser Manufacture of Stable, Efficient Ultrafine Noble Metal Catalysts Mediated with MOF Derived High Density Defective Metal Oxides. Small 2020, 16, 2000749. [Google Scholar] [CrossRef]

- Wang, K.-Y.; Feng, L. Rapid Generation of Hierarchically Porous Metal–Organic Frameworks through Laser Photolysis. Angew. Chem. Int. Ed. 2020, 59, 11349–11354. [Google Scholar] [CrossRef]

- Jiang, H.; Tong, L.; Liu, H.; Xu, J.; Jin, S.; Wang, C.; Hu, X.; Ye, L.; Deng, H.; Cheng, G.J. Graphene-Metal-Metastructure Monolith via Laser Shock-Induced Thermochemical Stitching of MOF Crystals. Matter 2020, 2, 1535–1549. [Google Scholar] [CrossRef] [Green Version]

- Ruiqian, M.; Haoqing, J. Multivariate MOFs for Laser Writing of Alloy Nanoparticle Patterns. Chem. Commun. 2020, 56, 2715–2718. [Google Scholar]

- Haoqing, J.; Shengyu, J. Nanoscale Laser Metallurgy and Patterning in Air Using MOFs. J. Am. Chem. Soc. 2019, 141, 5481–5489. [Google Scholar]

- Nakata, Y.; Osawa, K. Utilization of the high spatial-frequency component in adaptive beam shaping by using a virtual diagonal phase grating. Sci. Rep. 2019, 9, 4640. [Google Scholar] [CrossRef]

- Müller, D.W.; Fox, T. Applying Ultrashort Pulsed Direct Laser Interference Patterning for Functional Surfaces. Sci. Rep. 2020, 10, 3647. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mulko, L.; Soldera, M. Structuring and functionalization of non-metallic materials using direct laser interference patterning: A review. Nanophotonics 2022, 11, 203–240. [Google Scholar] [CrossRef]

- Zhang, Y.; Su, Y.; Zhao, Y.; Wang, Z.; Wang, C. Two-Photon 3D Printing in Metal–Organic Framework Single Crystals. Small 2022, 18, 2200514. [Google Scholar] [CrossRef]

- Yu, J.; Cui, Y.; Wu, C.D.; Yang, Y.; Chen, B.; Qian, G. Two-Photon Responsive Metal–Organic Framework. J. Am. Chem. Soc. 2015, 137, 4026–4029. [Google Scholar] [CrossRef]

- Ameloot, R.; Roeffaers, M.B.J.; De Cremer, G.; Vermoortele, F.; Hofkens, J.; Sels, B.F.; De Vos, D.E. Metal–Organic Framework Single Crystals as Photoactive Matrices for the Generation of Metallic Microstructures. Adv. Mater. 2011, 23, 1788–1791. [Google Scholar] [CrossRef]

- Zhang, W.; Li, R.; Zheng, H.; Bao, J.; Tang, Y.; Zhou, K. Laser-Assisted Printing of Electrodes Using Metal–Organic Frameworks for Micro-Supercapacitors. Adv. Funct. Mater. 2021, 31, 2009057. [Google Scholar] [CrossRef]

- Pečinka, L.; Peña-Méndez, E.M.; Conde-González, J.E.; Havel, J. Laser ablation synthesis of metal-doped gold clusters from composites of gold nanoparticles with metal organic frameworks. Sci. Rep. 2021, 11, 4656. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Huang, Z.; Jiang, H.; Wang, C.; Zhou, Y.; Shen, W.; Xu, H.; Deng, H. Facile Synthesis of Uniform Metal Carbide Nanoparticles from Metal–Organic Frameworks by Laser Metallurgy. ACS Appl. Mater. Interfaces 2019, 11, 44573–44581. [Google Scholar] [CrossRef] [PubMed]

- Lam, D.V.; Dung, D.T.; Kim, J.H.; Kim, H.; Lee, S.M. Laser-induced sulfurization of nickel-based metal-organic frameworks for highly stable phase-engineered energy materials. Chem. Eng. J. 2022, 437, 135237. [Google Scholar] [CrossRef]

- Tang, Y.J.; Zheng, H.; Wang, Y.; Zhang, W.; Zhou, K. Laser-Induced Annealing of Metal–Organic Frameworks on Conductive Substrates for Electrochemical Water Splitting. Adv. Funct. Mater. 2021, 31, 2102648. [Google Scholar] [CrossRef]

- Kulachenkov, N.K.; Bruyere, S. Ultrafast Melting of Metal–Organic Frameworks for Advanced Nanophotonics. Adv. Funct. Mater. 2020, 30, 1908292. [Google Scholar] [CrossRef]

- Kulachenkov, N.K.; Sun, D. Photochromic Free MOF-Based Near-Infrared Optical Switch. Angew. Chem. Int. Ed. 2020, 59, 15522–15526. [Google Scholar] [CrossRef]

- Chui, S.S.-Y.; Lo, S.M.-F. A Chemically Functionalizable Nanoporous Material [Cu3(TMA)2(H2O)3]n. Science 1999, 283, 1148–1150. [Google Scholar] [CrossRef]

- Xu, S.; Chansai, S.; Stere, C.; Inceesungvorn, B.; Goguet, A.; Wangkawong, K.; Taylor, S.F.R.; Al-Janabi, N.; Hardacre, C.; Martin, P.A.; et al. Sustaining metal–organic frameworks for water–gas shift catalysis by non-thermal plasma. Nat. Catal. 2019, 2, 142–148. [Google Scholar] [CrossRef] [Green Version]

- He, C.; Liu, L. Volatile Organic Compound Vapour Measurements Using a Localised Surface Plasmon Resonance Optical Fibre Sensor Decorated with a Metal-Organic Framework. Sensors 2021, 21, 1420. [Google Scholar] [CrossRef]

- Al-Janabi, N.; Hill, P.; Murciano, L.T.; Garforth, A.; Gorgojo, P.; Siperstein, F.; Fan, X. Mapping the Cu-BTC metal–organic framework (HKUST-1) stability envelope in the presence of water vapour for CO 2 adsorption from flue gases. Chem. Eng. J. 2015, 281, 669–677. [Google Scholar] [CrossRef] [Green Version]

- Qi, Y.; Lin, S. Increased proton conductivity of metal–organic framework micro-film prepared by a facile salt-free approach. J. Mater. Chem. A 2014, 2, 8849–8853. [Google Scholar] [CrossRef]

- Kenzhebayeva, Y.; Bachinin, S.; Solomonov, A.I.; Gilemkhanova, V.; Shipilovskikh, S.A.; Kulachenkov, N.; Fisenko, S.P.; Rybin, M.V.; Milichko, V.A. Light-Induced Color Switching of Single Metal–Organic Framework Nanocrystals. J. Phys. Chem. Lett. 2022, 13, 777–783. [Google Scholar] [CrossRef] [PubMed]

- Mezenov, Y.A.; Bruyere, S. Probing the dynamics of Cu nanoparticle growth inside metal-organic frameworks upon electron beam irradiation. Photonics Nanostruct.—Fundam. Appl. 2020, 41, 100832. [Google Scholar] [CrossRef]

- Vinogradov, V.V.; Drozdov, A.S. Composites based on heparin and MIL-101(Fe): The drug releasing depot for anticoagulant therapy and advanced medical nanofabrication. J. Mater. Chem. B 2018, 6, 2450–2459. [Google Scholar] [CrossRef]

- Prestipino, C.; Regli, L.; Vitillo, J.G.; Bonino, F.; Damin, A.; Lamberti, C.; Zecchina, A.; Solari, P.L.; Kongshaug, K.O.; Bordiga, S. Local Structure of Framework Cu(II) in HKUST-1 Metallorganic Framework: Spectroscopic Characterization upon Activation and Interaction with Adsorbates. Chem. Mater. 2006, 18, 1337–1346. [Google Scholar] [CrossRef]

- Koryakina, I.; Kuznetsova, D.S. Optically responsive delivery platforms: From the design considerations to biomedical applications. Nanophotonics 2020, 9, 39–74. [Google Scholar] [CrossRef]

- Yin, Y.; Rogers, J.A. Introduction: Smart Materials. Chem. Rev. 2022, 122, 4885–4886. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhestkij, N.; Efimova, A.; Rzhevskiy, S.; Kenzhebayeva, Y.; Bachinin, S.; Gunina, E.; Sergeev, M.; Dyachuk, V.; Milichko, V.A. Reversible and Irreversible Laser Interference Patterning of MOF Thin Films. Crystals 2022, 12, 846. https://doi.org/10.3390/cryst12060846

Zhestkij N, Efimova A, Rzhevskiy S, Kenzhebayeva Y, Bachinin S, Gunina E, Sergeev M, Dyachuk V, Milichko VA. Reversible and Irreversible Laser Interference Patterning of MOF Thin Films. Crystals. 2022; 12(6):846. https://doi.org/10.3390/cryst12060846

Chicago/Turabian StyleZhestkij, Nikolaj, Anastasiia Efimova, Sergey Rzhevskiy, Yuliya Kenzhebayeva, Semyon Bachinin, Ekaterina Gunina, Maxim Sergeev, Vyacheslav Dyachuk, and Valentin A. Milichko. 2022. "Reversible and Irreversible Laser Interference Patterning of MOF Thin Films" Crystals 12, no. 6: 846. https://doi.org/10.3390/cryst12060846

APA StyleZhestkij, N., Efimova, A., Rzhevskiy, S., Kenzhebayeva, Y., Bachinin, S., Gunina, E., Sergeev, M., Dyachuk, V., & Milichko, V. A. (2022). Reversible and Irreversible Laser Interference Patterning of MOF Thin Films. Crystals, 12(6), 846. https://doi.org/10.3390/cryst12060846