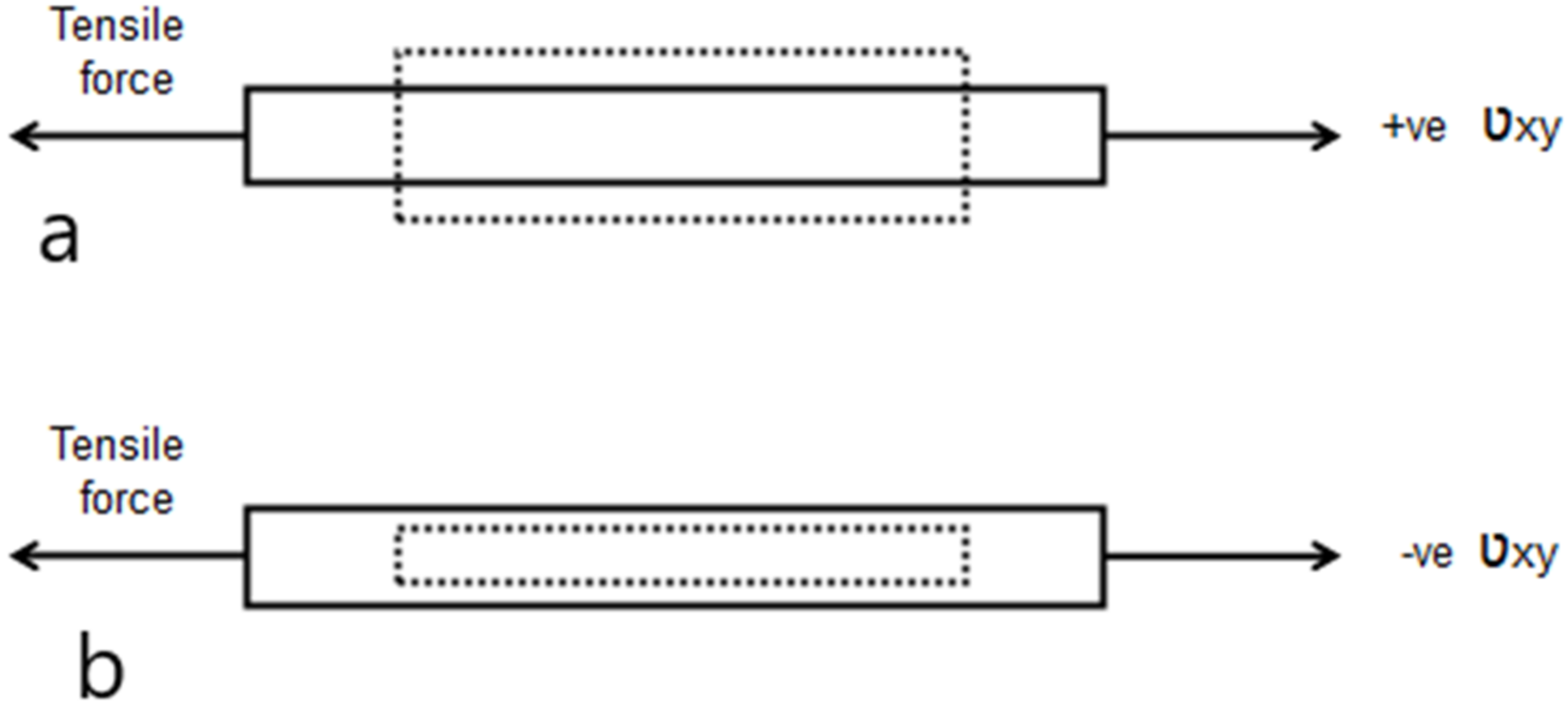

Effects of Braid Angle and Material Modulus on the Negative Poisson’s Ratio of Braided Auxetic Yarns

Abstract

:1. Introduction

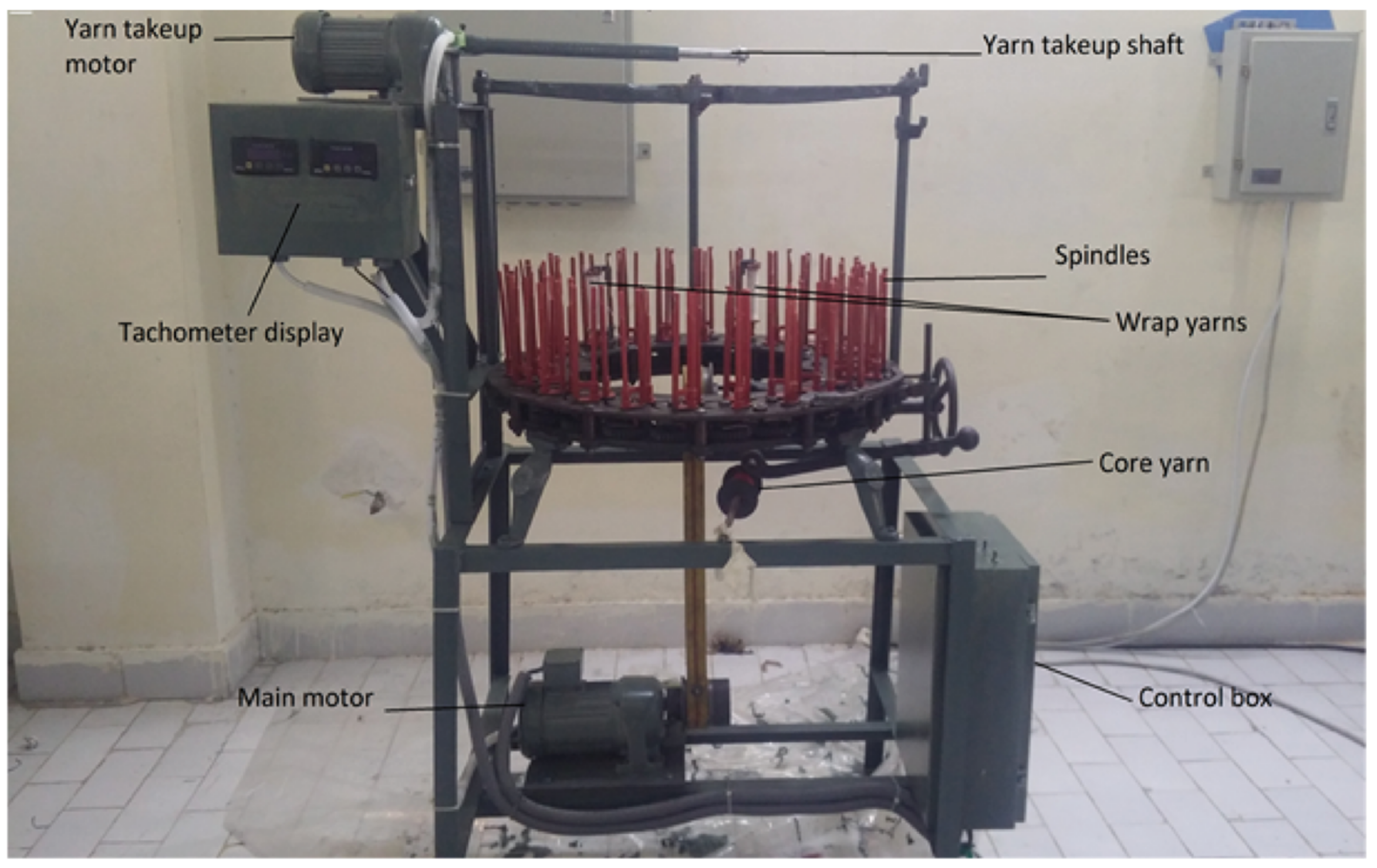

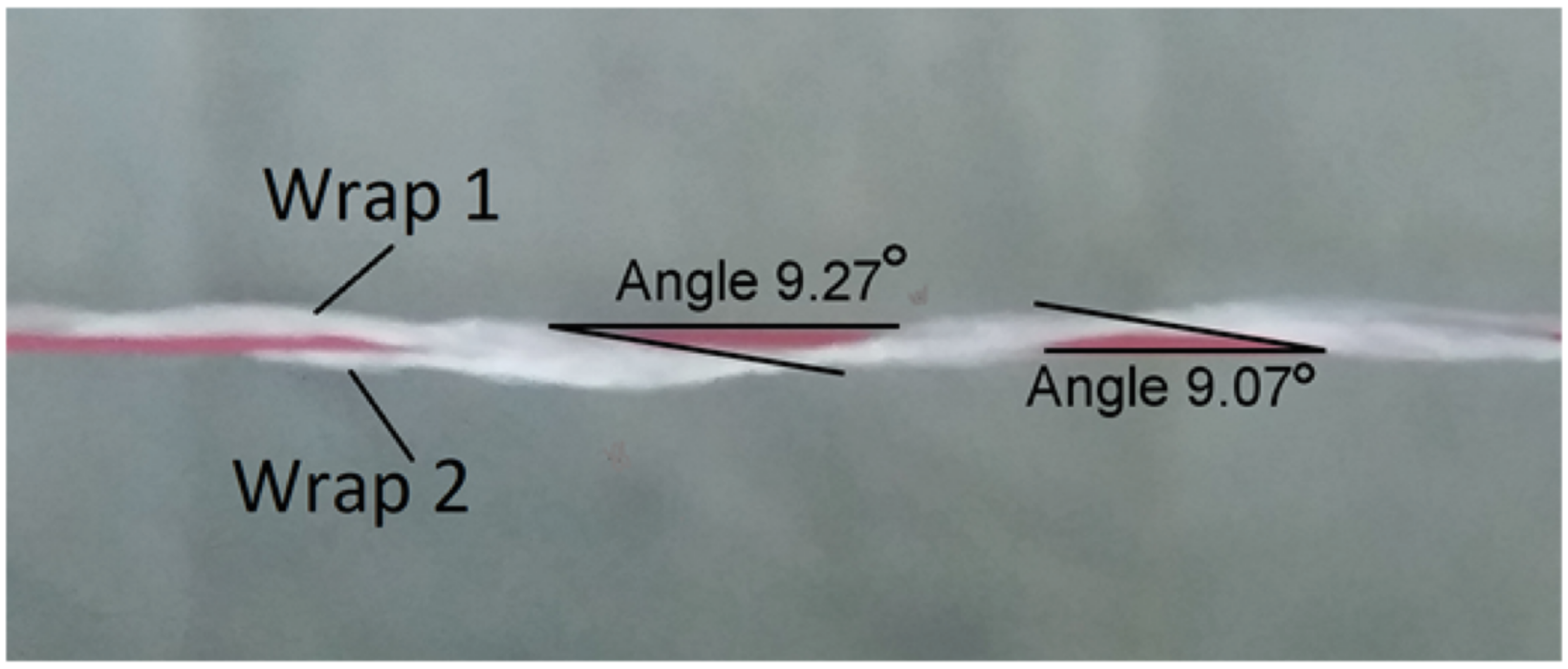

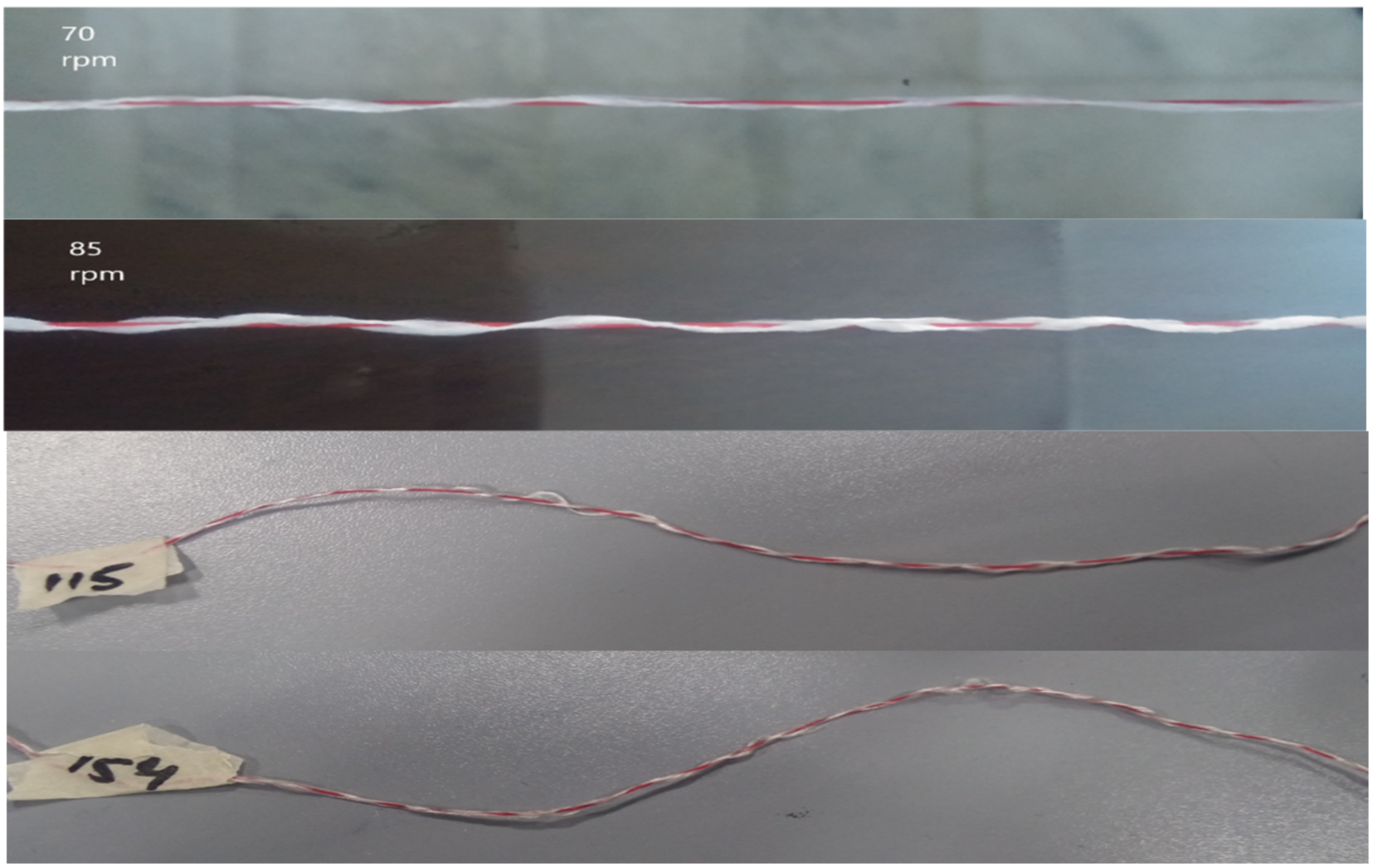

2. Experimental Section

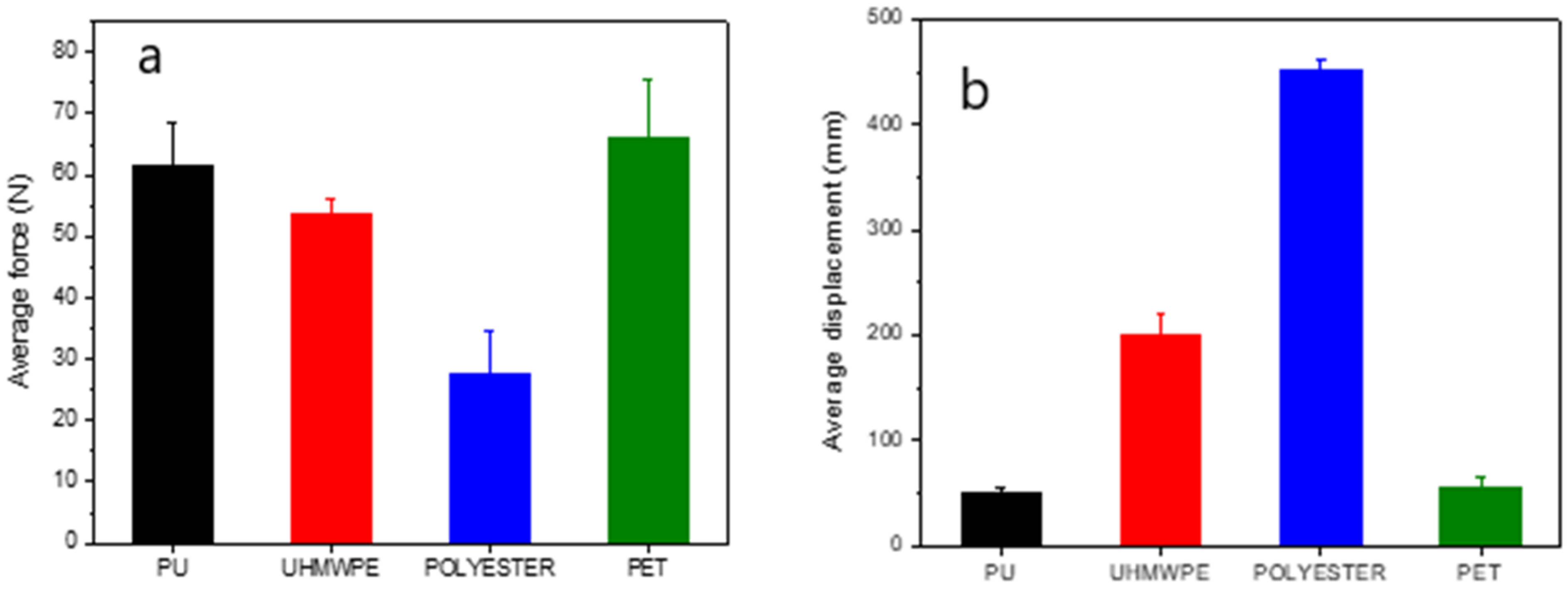

3. Results and Discussion

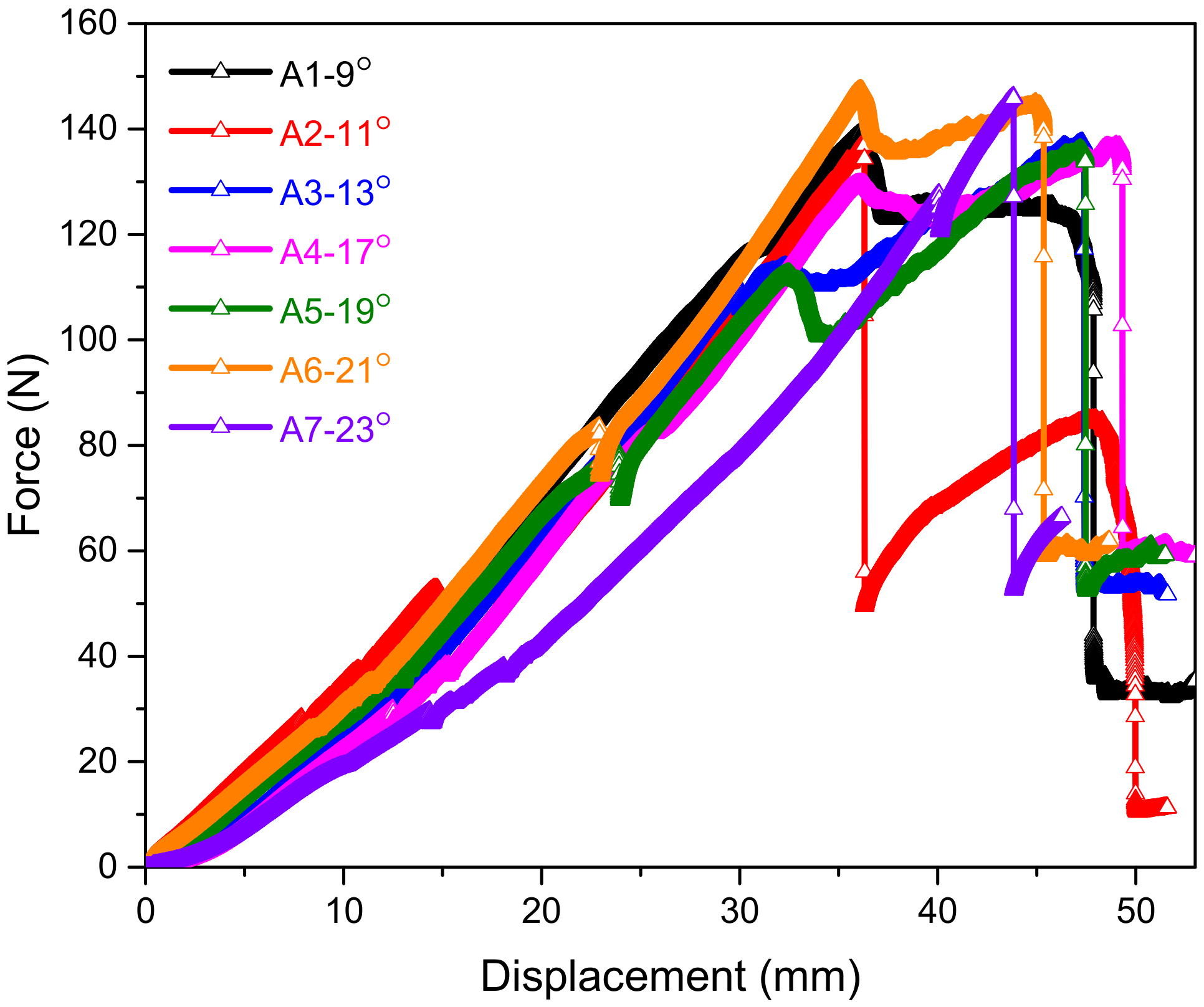

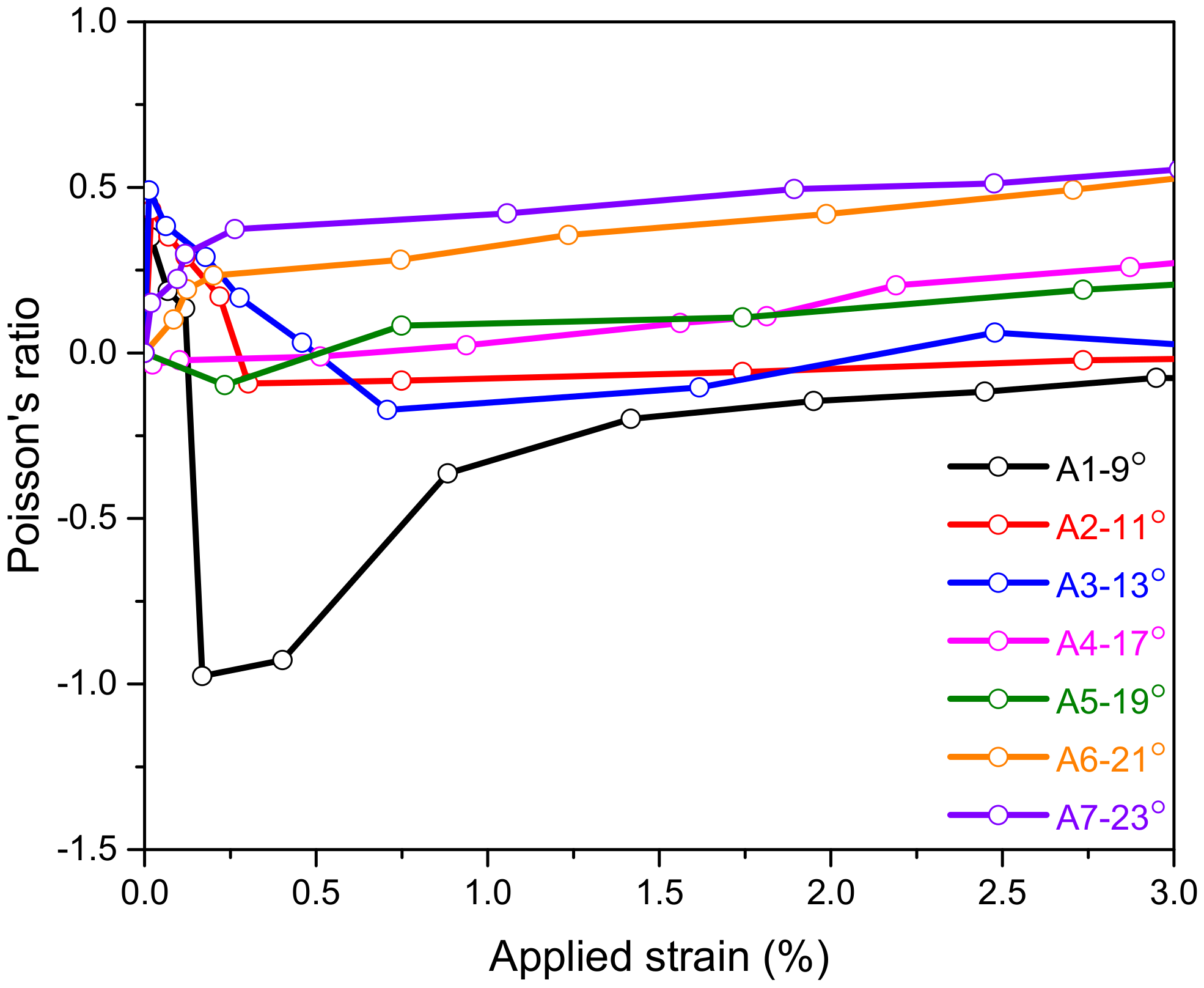

3.1. Braided Yarn with Polyester Core

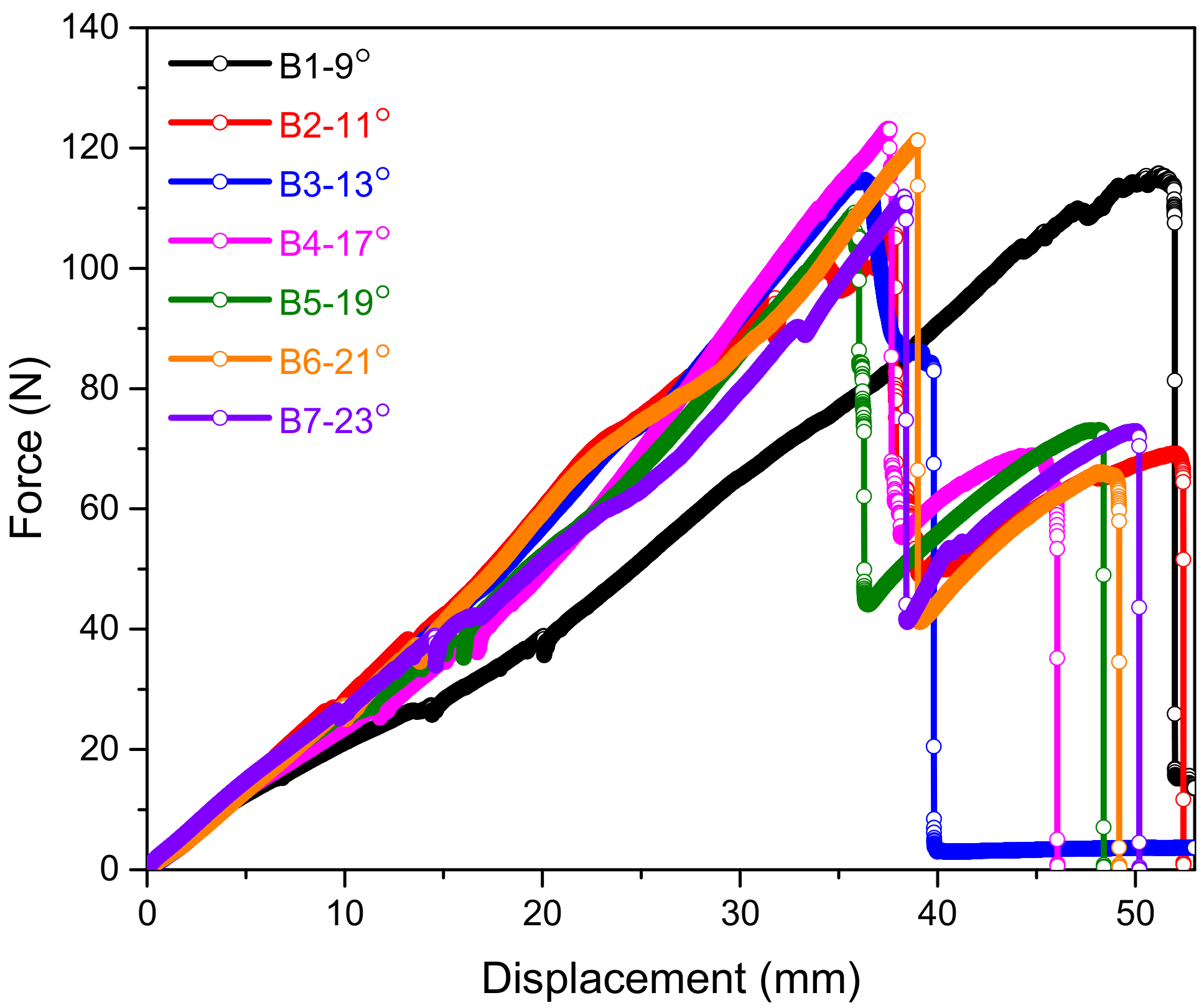

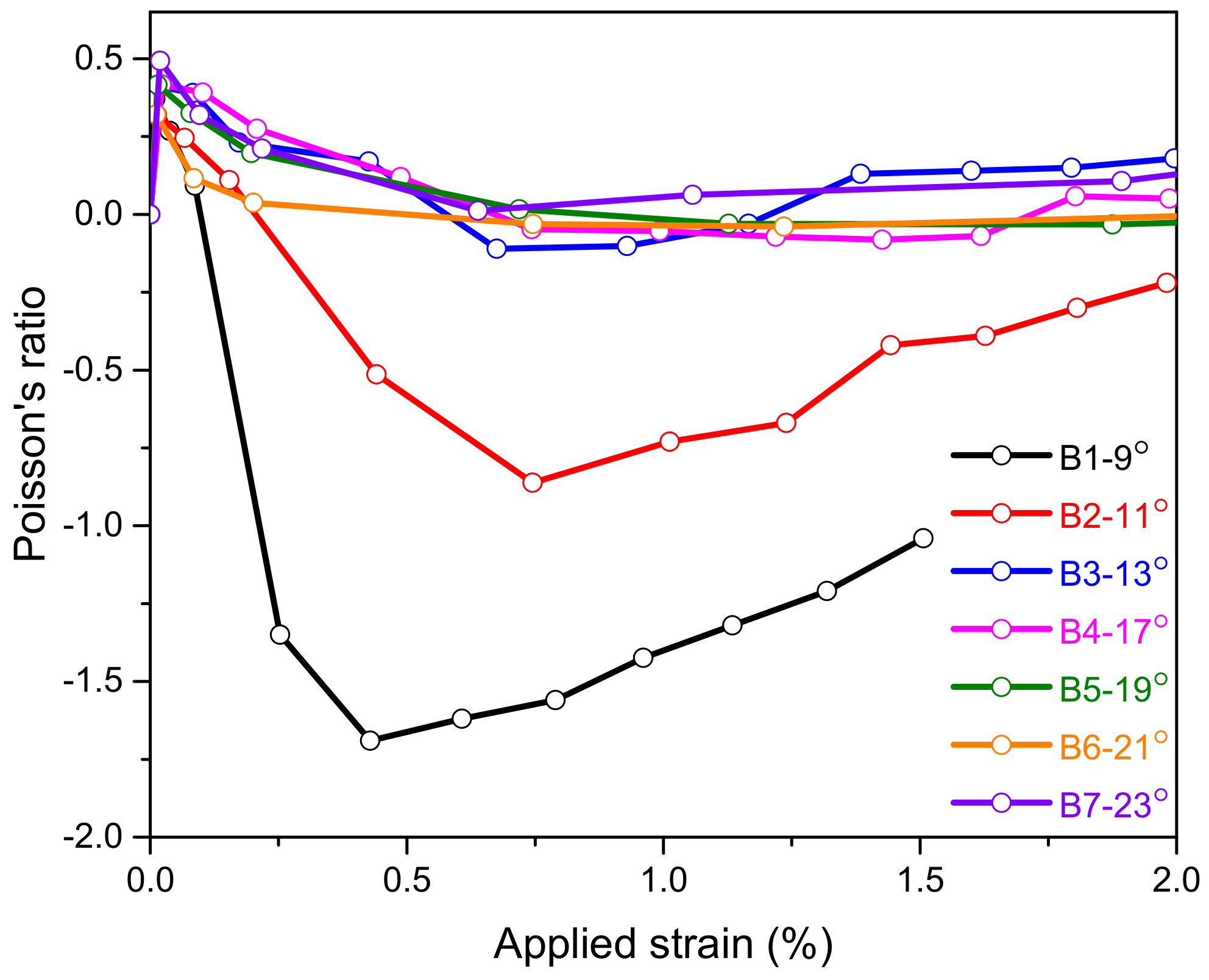

3.2. Braided Yarn with PU Core

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Evans, K.E.; Nkansah, M.A.; Hutchinson, J.I.; Rogers, S.C. Molecular network design. Nature 1991, 353, 124–125. [Google Scholar] [CrossRef]

- Lim, T.C. Auxetic Materials and Structures. Engineering Materials; Springer: Singapore, 2015. [Google Scholar]

- Wojciechowski, K.W. Constant thermodynamic tension Monte Carlo studies of elastic properties of a two-dimensional system of hard cyclic hexamers. Mol. Phys. 1987, 61, 1247–1258. [Google Scholar] [CrossRef]

- Wojciechowski, K.W. Two-dimensional isotropic system with a negative Poisson’s ratio. Phys. Lett. A 1989, 137, 60–64. [Google Scholar] [CrossRef]

- Lakes, R. Foam structures with a negative Poisson’s ratio. Science 1987, 235, 1038–1040. [Google Scholar] [CrossRef] [PubMed]

- Robert, F.A. An isotropic three-dimensional structure with Poisson’s ratio = −1. J. Elast. 1985, 15, 427–430. [Google Scholar]

- Alderson, K.; Evans, K. The fabrication of microporous polyethylene having a negative Poisson’s ratio. Polymer 1992, 33, 4435–4438. [Google Scholar] [CrossRef]

- Alderson, K.; Pickles, A.; Neale, P.; Evans, K. Auxetic polyethylene: The effect of a negative Poisson’s ratio on hardness. Acta Metall. Mater. 1994, 42, 2261–2266. [Google Scholar] [CrossRef]

- Evans, K.; Nkansah, K.; Hutchinson, J.I. Auxetic foams: Modelling negative Poisson’s ratios. Acta Metall. Mater. 1994, 42, 1289–1294. [Google Scholar] [CrossRef]

- Evans, K.; Alderson, A. Auxetic materials: Functional materials and structures from lateral thinking! Adv. Mater. 2000, 12, 617–628. [Google Scholar] [CrossRef]

- Scarpa, F.; Adhikari, S.; Wang, C. Nanocomposites with auxetic nanotubes. Int. J. Smart Nano Mater. 2010, 1, 83–94. [Google Scholar] [CrossRef] [Green Version]

- Gorodtsov, V.A.; Lisovenko, D.S. Auxetics among materials with cubic anisotropy. Mech. Solids 2020, 55, 461–474. [Google Scholar] [CrossRef]

- Lim, T.C. Mechanics of Metamaterials with Negative Parameters; Springer: Singapore, 2020. [Google Scholar]

- Luo, C.; Han, C.Z.; Zhang, X.Y.; Zhang, X.G.; Ren, X.; Xie, Y.M. Design, manufacturing and applications of auxetic tubular structures: A review. Thin-Walled Struct. 2021, 163, 107682. [Google Scholar] [CrossRef]

- Jopek, H. Finite element analysis of tunable composite tubes reinforced with auxetic structures. Materials 2017, 10, 1359. [Google Scholar] [CrossRef] [Green Version]

- Kelkar, P.U.; Kim, H.S.; Cho, K.H.; Kwak, J.Y.; Kang, C.Y.; Song, H.C. Cellular auxetic structures for mechanical metamaterials: A review. Sensors 2020, 20, 3132. [Google Scholar] [CrossRef]

- Alderson, A. A triumph of lateral thought. Chem. Ind. 1999, 17, 384–391. [Google Scholar]

- Williams, J.J.; Smith, C.W.; Evans, K.; Lethbridge, Z.A.D.; Walton, R.L. An analytical model for producing negative Poisson’s ratios and its application in explaining off-axis elastic properties of the NAT-type zeolites. Acta Mater. 2007, 55, 5697–5707. [Google Scholar] [CrossRef]

- Grima, J.N.; Cassar, R.N.; Gatt, R.J. On the effect of hydrostatic pressure on the auxetic character of NAT-type silicates. Non-Cryst. Solids 2009, 355, 1307–1312. [Google Scholar] [CrossRef]

- Baughman, R.H.; Shacklette, J.M.; Zakhidov, A.A.; Stafstrom, S. Negative Poisson’s ratios as a common feature of cubic metals. Nature 1998, 392, 362–365. [Google Scholar] [CrossRef]

- Epishin, A.; Fedelich, B.; Finn, M.; Künecke, G.; Rehmer, B.; Nolze, G.; Leistner, C.; Petrushin, N.; Svetlov, L. Investigation of Elastic Properties of the Single-Crystal Nickel-Base Superalloy CMSX-4 in the Temperature Interval between Room Temperature and 1300 °C. Crystals 2021, 11, 152. [Google Scholar] [CrossRef]

- Milstein, F.; Huang, K. Existence of a negative Poisson ratio in fcc crystals. Phys. Rev. B. 1979, 19, 2030–2033. [Google Scholar] [CrossRef]

- Friis, E.A.; Lakes, R.S.; Park, J.B. Negative Poisson’s ratio polymeric and metallic foams. Mater. Sci. 1988, 12, 4406–4414. [Google Scholar] [CrossRef]

- Goldstein, R.V.; Gorodtsov, V.A.; Lisovenko, D.S.; Volkov, M.A. Negative Poisson’s ratio for cubic crystals and nano/microtubes. Phys. Mesomech. 2014, 17, 97–115. [Google Scholar] [CrossRef]

- Goldstein, R.V.; Gorodtsov, V.A.; Lisovenko, D.S. Auxetic mechanics of crystalline materials. Mech. Solids 2010, 45, 529–545. [Google Scholar] [CrossRef]

- Lees, C.; Vincent, J.E.V.; Hillerton, J.E. Poisson’s ratio in skin. Biomed. Mater. Eng. 1991, 1, 19–23. [Google Scholar] [CrossRef] [PubMed]

- Frohlich, L.M.; Labarbera, M.; Stevens, W.P.J. Poisson’s ratio of a crossed fibre sheath: The skin of aquatic salamanders. Zoology 1994, 232, 231–252. [Google Scholar] [CrossRef]

- Gaspar, N.; Ren, X.J.; Smith, C.W.; Grima, J.N.; Evans, K. Novel honeycombs with auxetic behaviour. Acta Mater. 2005, 53, 2439–2445. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, H. A review on auxetic structures and polymeric materials. Sci. Res. Essays 2010, 5, 1052–1063. [Google Scholar]

- Attard, D.; Manicaro, E.; Gatt, R.; Grima, J.N. On the properties of auxetic rotating stretching squares. Phys. Status Sol. B 2009, 246, 2045–2054. [Google Scholar] [CrossRef]

- Lim, T.C.; Acharya, R.U. An hexagonal array of fourfold interconnected hexagonal nodules for modeling auxetic microporous polymers: A comparison of 2D and 3D models. J. Mater. Sci. 2009, 44, 4491–4494. [Google Scholar] [CrossRef]

- Chan, N.; Evans, K.J. Indentation resilience of conventional and auxetic foams. Cell. Plast. 1998, 34, 231–260. [Google Scholar] [CrossRef]

- Lim, T.C. Auxeticity of concentric auxetic-conventional foam rods with high modulus interface adhesive. Materials 2018, 11, 223. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Evans, K.; Donoghue, J.P.; Alderson, K.L. The Design, Matching and Manufacture of Auxetic Carbon Fibre Laminates. J. Compos. Mater. 2004, 38, 95–106. [Google Scholar] [CrossRef]

- Miller, W.; Hook, P.B.; Smith, C.W.; Wang, X.; Evans, K. The manufacture and characterisation of a novel, low modulus, negative Poisson’s ratio composite. Compos. Sci. Technol. 2009, 69, 651–655. [Google Scholar] [CrossRef]

- Kocer, C.; McKenzie, D.R.; Bilek, M.M. Elastic properties of a material composed of alternating layers of negative and positive Poisson’s ratio. Mater. Sci. Eng. A 2009, 505, 111–115. [Google Scholar] [CrossRef]

- Bezazi, A.; Boukharouba, W.; Scarpa, F. Mechanical properties of auxetic carbon/epoxy composites: Static and cyclic fatigue behaviour. Phys. Status Sol. B 2009, 246, 2102–2110. [Google Scholar] [CrossRef]

- Cicala, G.; Recca, G.; Oliveri, L.; Grube, D.J.; Scarpa, F.; Perikleous, Y. Auxetic Hexachiral Truss Core Reinforced with Twisted Hemp Yarns: Out of Plane Shear Properties. In Proceedings of the 16th International Conference on Composite Structures (ICCS 16), Porto, Portugal, 28–30 June 2011. [Google Scholar]

- Alderson, A.; Alderson, K.L.; Ravirala, N. Design and Modelling of Mechanical and Thermal Responses of Novel Auxetic Honeycomb Cores for Structural Composites. In Proceedings of the 16th International Conference on Composite Structures (ICCS 16), Porto, Portugal, 28–30 June 2011. [Google Scholar]

- Gorodtsov, V.A.; Lisovenko, D.S. Out-of-Plane Tension of Thin Two-Layered Plates of Identically Oriented Hexagonal Crystals. Phys. Mesomech. 2021, 24, 146–154. [Google Scholar] [CrossRef]

- Volkov, M.A.; Demin, A.I.; Gorodtsov, V.A.; Lisovenko, D.S. Effective elastic properties variability for two-layered plates of hexagonal and cubic crystals under longitudinal tension. Compos. Struct. 2021, 274, 114300. [Google Scholar] [CrossRef]

- Caddock, B.; Evans, K.J. Microporous materials with negative Poisson’s ratios. I. Microstructure and mechanical properties. Phys. D Appl. Phys. 1989, 22, 1877. [Google Scholar] [CrossRef]

- Pickles, A.P.; Alderson, K.L.; Evans, K. The effects of powder morphology on the processing of auxetic polypropylene (PP of negative Poisson’s ratio). Polym. Eng. Sci. 1996, 36, 636–642. [Google Scholar] [CrossRef]

- Alderson, K.L.; Webber, R.S.; Evans, K. Novel variations in the microstructure of auxetic ultra-high molecular weight polyethylene. Part 2: Mechanical properties. Polym. Eng. Sci. 2000, 40, 1906–1914. [Google Scholar] [CrossRef]

- Ravirala, N.; Alderson, K.L.; Davies, P.J.; Simkins, V.R.; Alderson, A. Negative Poisson’s ratio polyester fibers. Text. Res. J. 2006, 76, 540–546. [Google Scholar] [CrossRef]

- Shanahan, M.E.R.; Piccirelli, N. Elastic behaviour of a stretched woven cloth. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1059–1064. [Google Scholar] [CrossRef]

- Ugbolue, S.C.; Kim, Y.K.; Warner, S.B.; Fan, Q.; Yang, C.L.; Kyzymchuk, O.; Feng, Y.J. The formation and performance of auxetic textiles. Part I: Theoretical and technical considerations. Text. Inst. 2010, 101, 660–667. [Google Scholar] [CrossRef]

- Hoover, W.G.; Hoover, C.G. Searching for auxetics with DYNA3D and ParaDyn. Phys. Stat. Sol. B 2005, 242, 585–594. [Google Scholar] [CrossRef] [Green Version]

- Pikhitsa, P.V. Architecture of cylinders with implications for materials with negative Poisson ratio. Phys. Status Sol. B 2007, 244, 1004–1007. [Google Scholar] [CrossRef]

- Shah, I.A.; Khan, R.; Koloor, S.S.R.; Petrů, M.; Badshah, S.; Ahmad, S.; Amjad, M. Finite Element Analysis of the Ballistic Impact on Auxetic Sandwich Composite Human Body Armor. Materials 2022, 15, 2064. [Google Scholar] [CrossRef]

- Liu, H.; Kollosche, M.; Yan, J.; Zellner, E.M.; Bentil, S.A.; Rivero, I.V.; Wiersema, C.; Laflamme, S. Numerical investigation of auxetic textured soft strain gauge for monitoring animal skin. Sensors 2020, 20, 4185. [Google Scholar] [CrossRef]

- Kasal, A.; Kuskun, T.; Smardzews, J. Experimental and numerical study on withdrawal strength of different types of auxetic dowels for furniture joints. Materials 2020, 13, 4252. [Google Scholar] [CrossRef]

- Narojczyk, J.W.; Wojciechowski, K.W.; Smardzewski, J.; Imre, A.R.; Grima, J.N.; Bilski, M. Cancellation of auxetic properties in fcc hard sphere crystals by hybrid layer-channel nanoinclusions filled by hard spheres of another diameter. Materials 2021, 14, 3008. [Google Scholar] [CrossRef]

- Degabriele, E.P.; Attard, D.; Grima-Cornish, J.N.; Caruana-Gauci, R.; Gatt, R.; Evans, K.E.; Grima, J.N. On the Compressibility Properties of the Wine-Rack-Like Carbon Allotropes and Related Poly (phenylacetylene) Systems. Phys. Status Sol. B 2019, 256, 1800572. [Google Scholar] [CrossRef] [Green Version]

- Rysaeva, L.K.; Lisovenko, D.S.; Gorodtsov, V.A.; Baimova, J.A. Stability, elastic properties and deformation behaviour of graphene-based diamond-like phases. Comput. Mater. Sci. 2020, 172, 109355. [Google Scholar] [CrossRef]

- Poźniak, A.A.; Wojciechowski, K.W.; Grima, J.N.; Mizzi, L. Planar auxeticity from elliptic inclusions. Compos. Part B 2016, 94, 379–388. [Google Scholar] [CrossRef]

- Wright, J.R.; Sloan, M.R.; Evans, K.J. Tensile properties of helical auxetic structures: A numerical study. Appl. Phys. 2010, 108, 044905. [Google Scholar] [CrossRef]

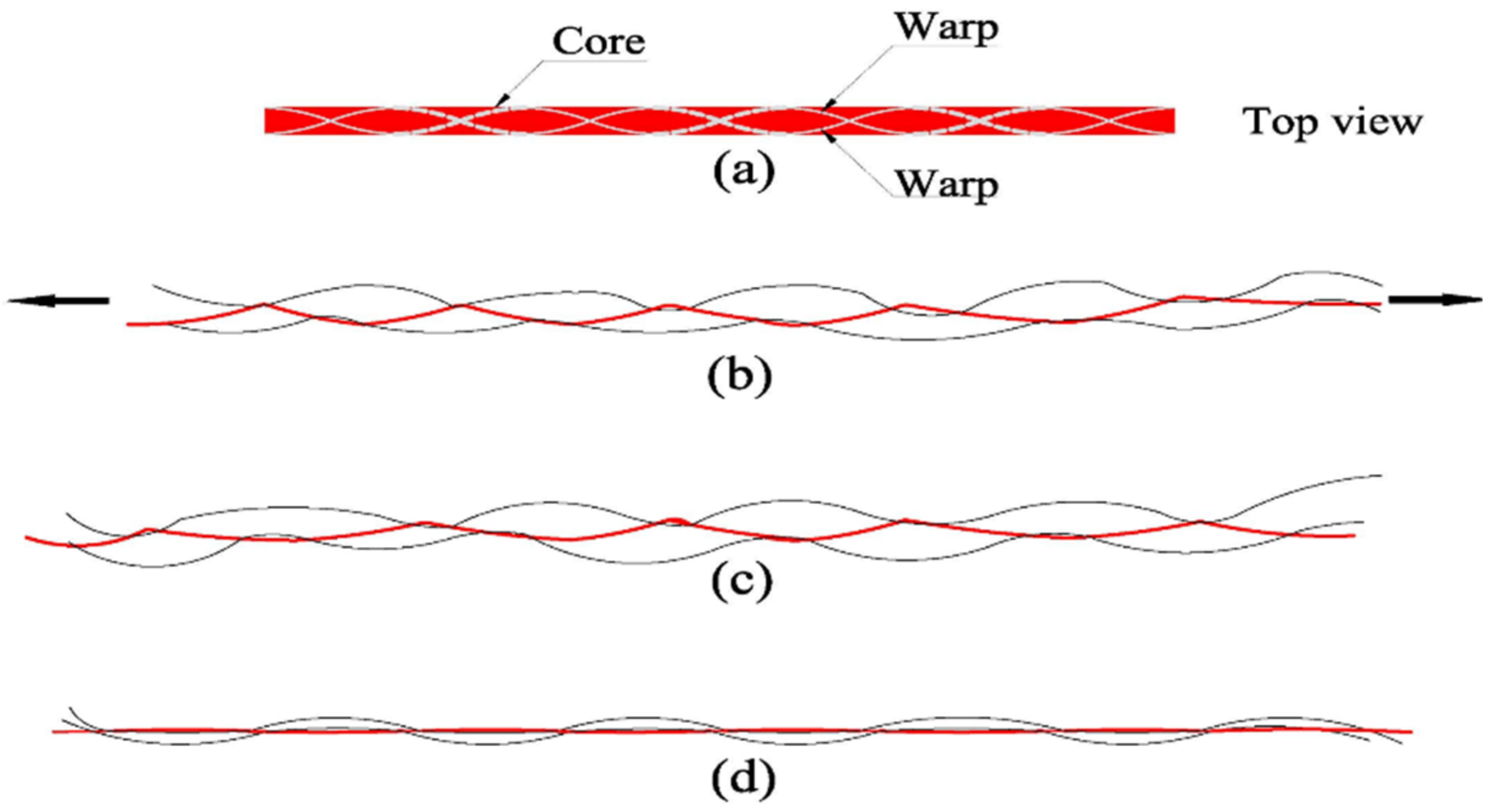

- Sloan, M.R.; Wright, J.R.; Evans, K. The helical auxetic yarn—A novel structure for composites and textiles; geometry, manufacture and mechanical properties. Mech. Mater. 2011, 43, 476–486. [Google Scholar] [CrossRef]

- Iftekhar, H.; Waseem Ullah Khan, R.M.; Nawab, Y.; Hamdani, S.T.A.; Panchal, S. Numerical Analysis of Binding Yarn Float Length for 3D Auxetic Structures. Phys. Status Sol. B 2020, 257, 2000440. [Google Scholar] [CrossRef]

- Sibal, A.R. Design strategy for auxetic dual helix yarn systems. Mater. Lett. 2015, 161, 740–742. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Zhang, G.H.; Ghita, O.; Evans, K. The variation in Poisson’s ratio caused by interactions between core and wrap in helical composite auxetic yarns. Compos. Sci. Technol. 2014, 102, 87–93. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y. Negative Poisson’s ratio weft-knitted fabrics. Text. Res. J. 2010, 80, 856–863. [Google Scholar]

- Zulifqar, A.; Hua, T.; Hu, H. Development of uni-stretch woven fabrics with zero and negative Poisson’s ratio. Text. Res. J. 2018, 88, 2076–2092. [Google Scholar] [CrossRef]

- Nazir, M.U.; Shaker, K.; Hussain, R.; Nawab, Y. Performance of novel auxetic woven fabrics produced using Helical Auxetic Yarn. Mater. Res. Express 2019, 6, 085703. [Google Scholar] [CrossRef]

- Chen, J.; Du, Z.; Li, T. Performance of novel auxetic woven fabrics produced using Helical Auxetic Yarn. Text. Res. J. 2020, 90, 809–823. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, S.; Wu, M.; Chen, X.; Studd, R. Manufacture and Evaluation of Auxetic Yarns and Woven Fabrics. Phys. Status Sol. B 2020, 257, 1900112. [Google Scholar] [CrossRef]

- Zhang, O.G.H.; Ghita, O.; Evans, K. The fabrication and mechanical properties of a novel 3-component auxetic structure for composites. Compos. Sci. Technol. 2015, 117, 257–267. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Du, Z.; Xie, K.; Liu, G.; Yang, S. A novel interlaced-helical wrapping yarn with negative Poisson’s ratio. Fibers Polym. 2018, 19, 2411–2417. [Google Scholar] [CrossRef]

- Liu, S.; Pan, X.; Zheng, D.; Du, Z.; Liu, G.; Yang, S. Study on the structure formation and heat treatment of helical auxetic complex yarn. Text. Res. J. 2019, 89, 1003–1012. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, X.; Studd, R. Experimental and numerical study of helical auxetic yarns. Text. Res. J. 2021, 91, 11–12. [Google Scholar] [CrossRef]

- Ali, M.; Zeeshan, M.; Qadir, M.B.; Riaz, R.; Ahmad, S.; Nawad, Y.; Anjum, A.S. Development and mechanical characterization of weave design based 2D woven auxetic fabrics for protective textiles. Fibers Polym. 2018, 19, 2431–2438. [Google Scholar] [CrossRef]

- Liu, S.; Gao, Y.; Chen, X.; Du, Z. A theoretical study on the effect of structural parameter on tensile properties of helical auxetic yarns. Fibers Polym. 2019, 20, 1742–1748. [Google Scholar] [CrossRef]

- Kabir, S.; Kim, H.; Lee, S. Characterization of 3D printed auxetic sinusoidal patterns/nylon composite fabrics. Fibers Polym. 2020, 20, 1372–1381. [Google Scholar] [CrossRef]

- Gao, Y.; Ma, P.; Li, K.; Xu, J. Characterization of a 3D Auxetic Warp-knitted Spacer Fabric by Synchrotron Radiation X-ray Computed Tomography. Fibers Polym. 2020, 21, 930–933. [Google Scholar] [CrossRef]

- Xin, X.; Liu, L.; Liu, Y.; Leng, J. 4D printing auxetic metamaterials with tunable, programmable, and reconfigurable mechanical properties. Adv. Funct. Mater. 2020, 30, 2004226. [Google Scholar] [CrossRef]

- Ali, M.N.; Rehman, I.U. An Auxetic structure configured as oesophageal stent with potential to be used for palliative treatment of oesophageal cancer; development and in vitro mechanical analysis. J. Mater. Sci. Mater. Med. 2011, 22, 2573–2581. [Google Scholar] [CrossRef] [PubMed]

- Vinay, C.V.; Varma, D.S.M.; Chandan, M.R.; Sivabalan, P.; Jaiswal, A.K.; Swetha, S.; Sionkowska, A.; Kaczmarek, B. Study of castor oil-based auxetic polyurethane foams for cushioning applications. Polym. Int. 2020, 70, 1631–1639. [Google Scholar] [CrossRef]

| Type of Fiber/Yarn | Fiber/Yarn Diameter (µm) | Linear Density | Elongation at Break (%) | Breaking Load (N) | Young’s Modulus (MPa) | |

|---|---|---|---|---|---|---|

| g/m | dtex | |||||

| PU Elastomer, TROFIL® Monofil Technik GmbH, Hennef, Germany | 600 | 0.36 | 3560 | 650 | 50 | 114 ± 2 |

| PET, Morssinkhof® Sustainable Products, Emmen, Netherlands | 24 | 0.11 | 1120 | 13.8 | 84.3 | 420 ± 30 |

| UHMWPE, Dyneema® SK-75, Almere, Netherlands | 13 | 0.04 | 411 | 2.56 | 140 | 22,500 |

| Polyester cord, Beads Park China, Guangzhou, China | 800 | 0.03 | 3360 | 80 | 54.2 | 630 |

| Sample ID | Core Material | Planned Braid Angle (°) | Measured Braid Angle (°) | Sample ID | Core Material | Planned Braid Angles (°) | Measured Braid Angle (°) |

|---|---|---|---|---|---|---|---|

| A-1 | Polyester cord | 9 | 9 + 0.09 | B-1 | PU elastomer | 9 | 9 + 0.17 |

| A-2 | 11 | 11 + 0.09 | B-2 | 11 | 11 + 0.21 | ||

| A-3 | 13 | 13 + 0.17 | B-3 | 13 | 13 + 0.13 | ||

| A-4 | 17 | 17 − 0.05 | B-4 | 17 | 17 + 0.40 | ||

| A-5 | 19 | 19 + 0.25 | B-5 | 19 | 19 + 0.23 | ||

| A-6 | 21 | 21 + 0.21 | B-6 | 21 | 21 − 0.11 | ||

| A-7 | 23 | 23 + 0.32 | B-7 | 23 | 23 + 0.19 |

| Sample ID | Measured Braid Angle (°) | Strain Value | Poisson’s Ratio |

|---|---|---|---|

| A-1 | 9 + 0.09 | 0.17 | −0.98 |

| A-2 | 11 + 0.09 | 0.31 | −0.09 |

| A-3 | 13 + 0.17 | 0.71 | −0.17 |

| A-4 | 17 + 0.21 | 0.512 | −0.01 |

| A-5 | 19 + 0.12 | 0.234 | −0.09 |

| A-6 | 21 + 0.41 | 0.08 | +0.10 |

| A-7 | 23 + 0.14 | 0.019 | +0.15 |

| Sample ID | Measured Braid Angle (°) | Strain Value | Poisson’s Ratio |

|---|---|---|---|

| B-1 | 9 + 0.17 | 0.427 | −1.70 |

| B-2 | 11 + 0.21 | 0.75 | −0.86 |

| B-3 | 13 + 0.13 | 0.71 | −0.11 |

| B-4 | 17 + 0.09 | 1.426 | −0.081 |

| B-5 | 19 + 0.27 | 1.875 | −0.032 |

| B-6 | 21 + 0.35 | 1.235 | −0.039 |

| B-7 | 23 + 0.14 | 0.639 | +0.012 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, A.A.; Shahid, M.; Hardy, J.G.; Siddiqui, N.A.; Kennedy, A.R.; Gul, I.H.; Rehman, S.U.; Nawab, Y. Effects of Braid Angle and Material Modulus on the Negative Poisson’s Ratio of Braided Auxetic Yarns. Crystals 2022, 12, 781. https://doi.org/10.3390/cryst12060781

Shah AA, Shahid M, Hardy JG, Siddiqui NA, Kennedy AR, Gul IH, Rehman SU, Nawab Y. Effects of Braid Angle and Material Modulus on the Negative Poisson’s Ratio of Braided Auxetic Yarns. Crystals. 2022; 12(6):781. https://doi.org/10.3390/cryst12060781

Chicago/Turabian StyleShah, Arif A., Muhammad Shahid, John G. Hardy, Naveed A. Siddiqui, Andrew R. Kennedy, Iftikhar H. Gul, Shafi Ur Rehman, and Yasir Nawab. 2022. "Effects of Braid Angle and Material Modulus on the Negative Poisson’s Ratio of Braided Auxetic Yarns" Crystals 12, no. 6: 781. https://doi.org/10.3390/cryst12060781

APA StyleShah, A. A., Shahid, M., Hardy, J. G., Siddiqui, N. A., Kennedy, A. R., Gul, I. H., Rehman, S. U., & Nawab, Y. (2022). Effects of Braid Angle and Material Modulus on the Negative Poisson’s Ratio of Braided Auxetic Yarns. Crystals, 12(6), 781. https://doi.org/10.3390/cryst12060781