Ni-CeO2/SBA-15 Catalyst Prepared by Glycine-Assisted Impregnation Method for Low-Temperature Dry Reforming of Methane

Abstract

:1. Introduction

2. Materials and Methods

2.1. Catalyst Preparation

2.2. Characterization of Catalysts

2.3. Catalytic Test

3. Results and Discussion

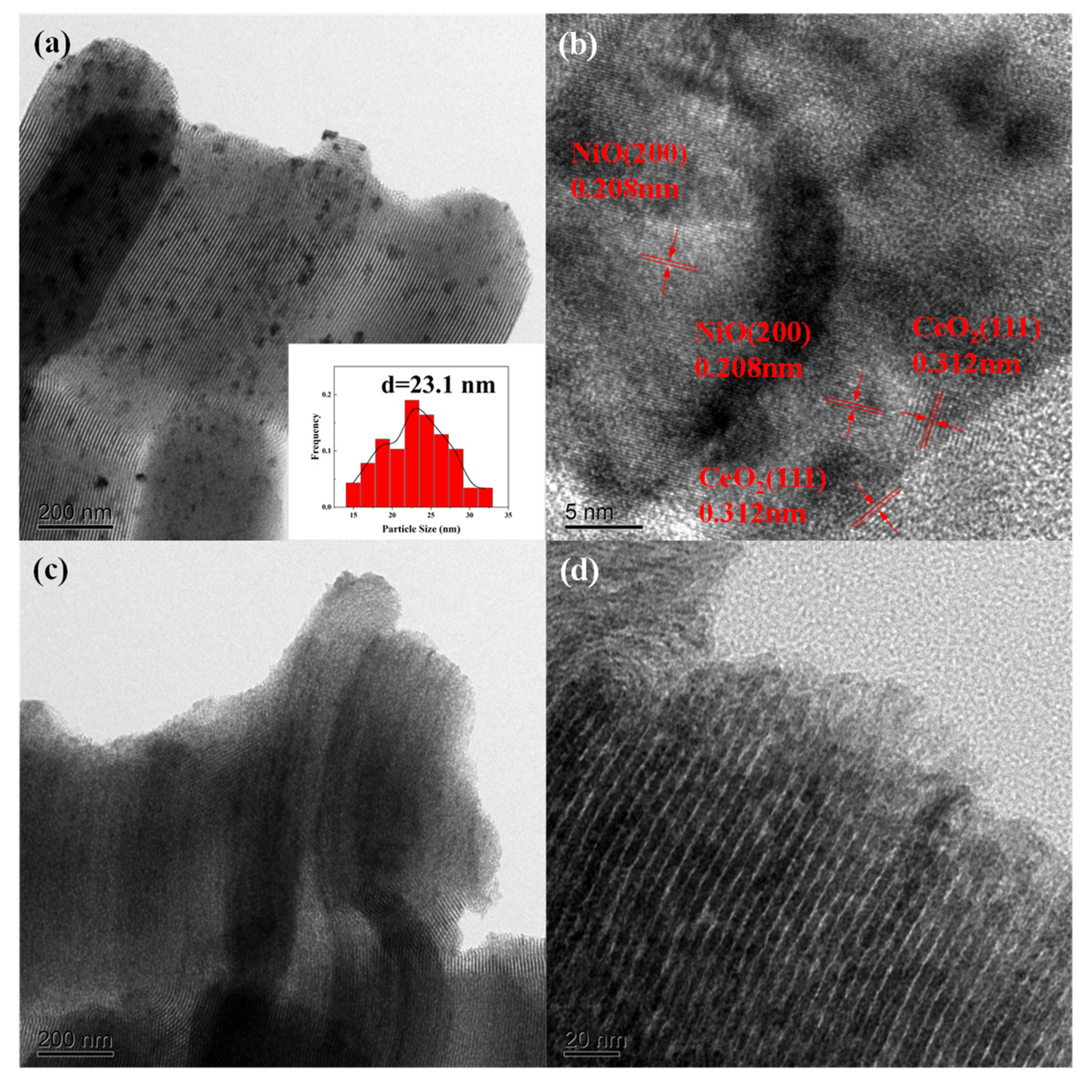

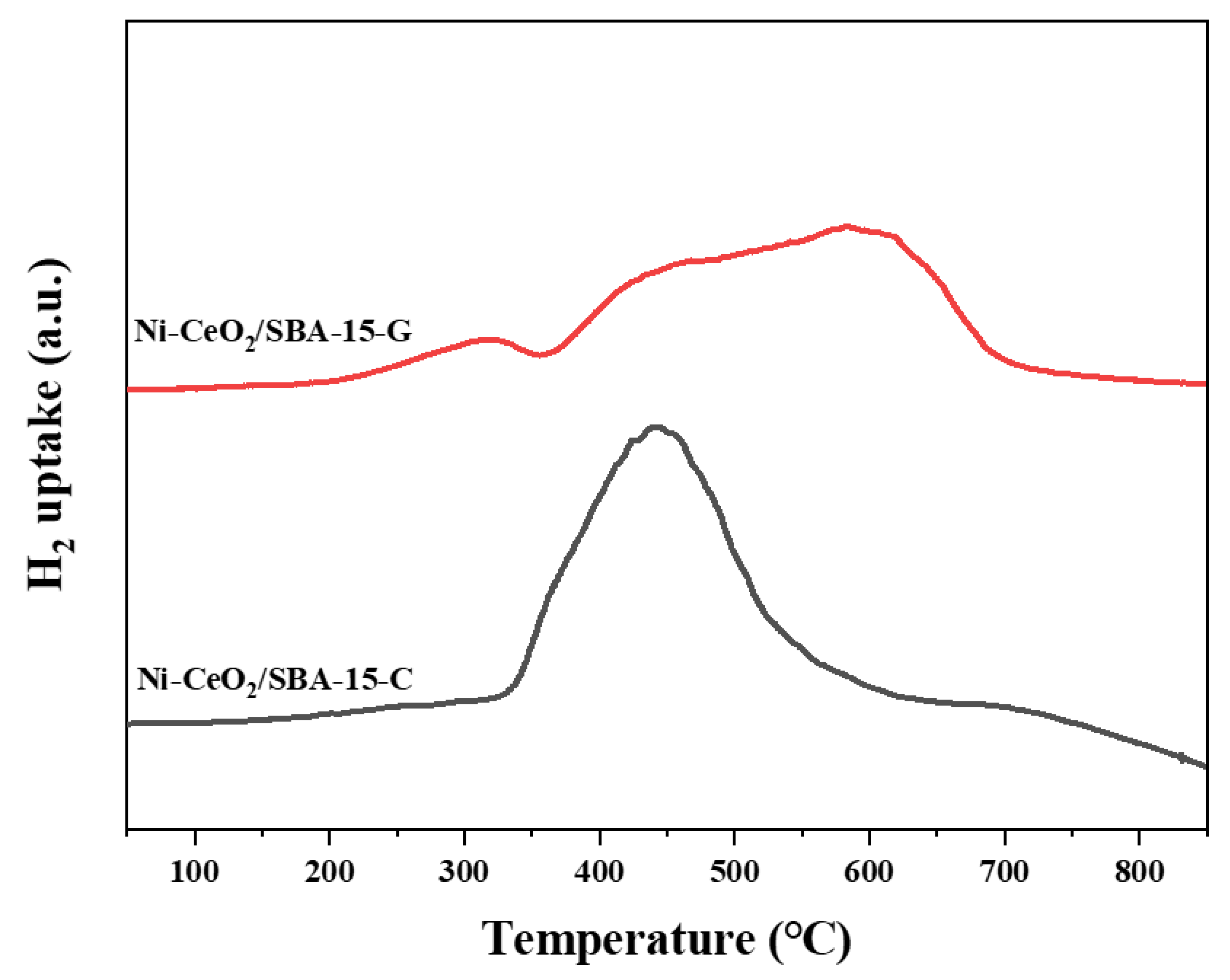

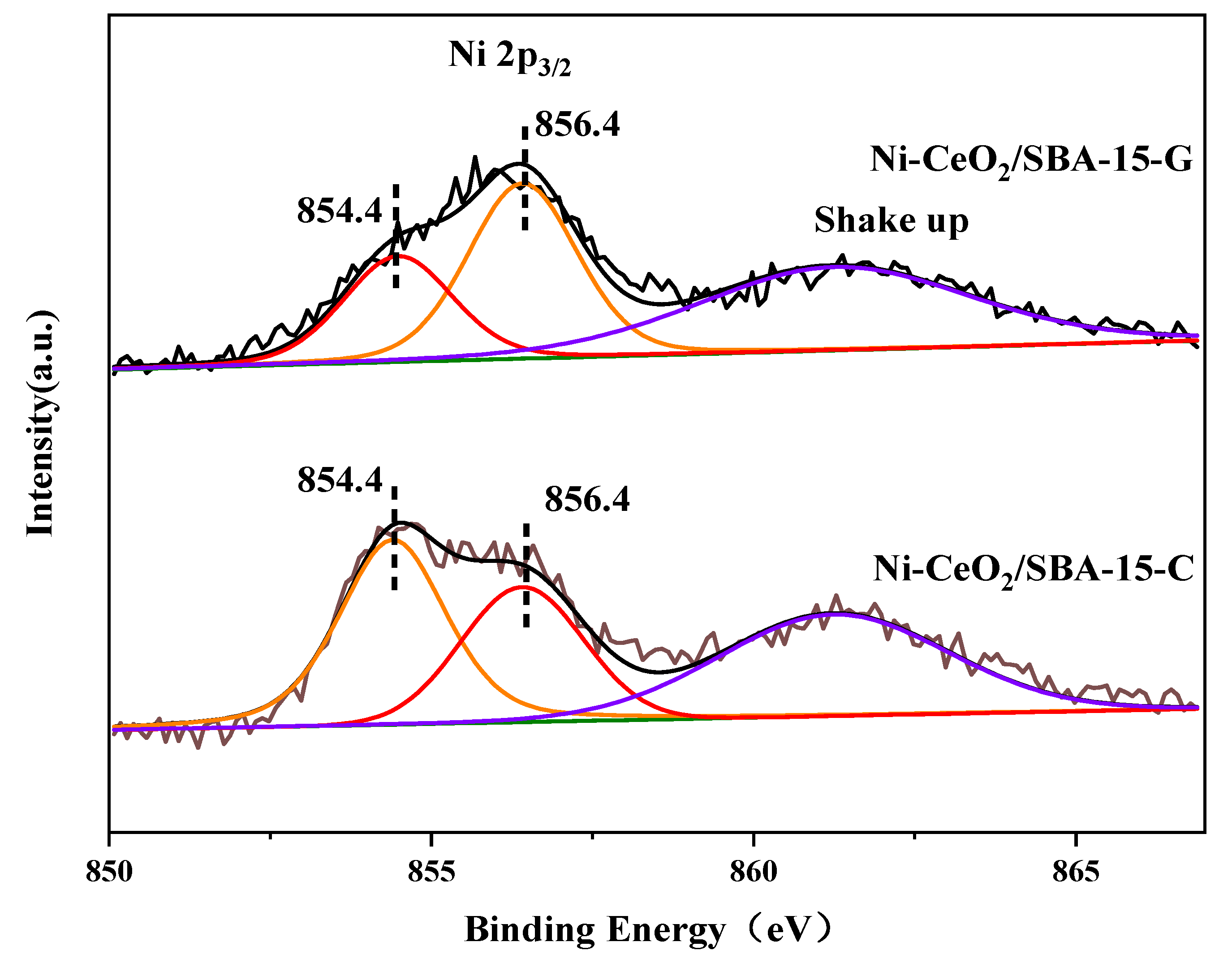

3.1. Characterization of Fresh Catalysts

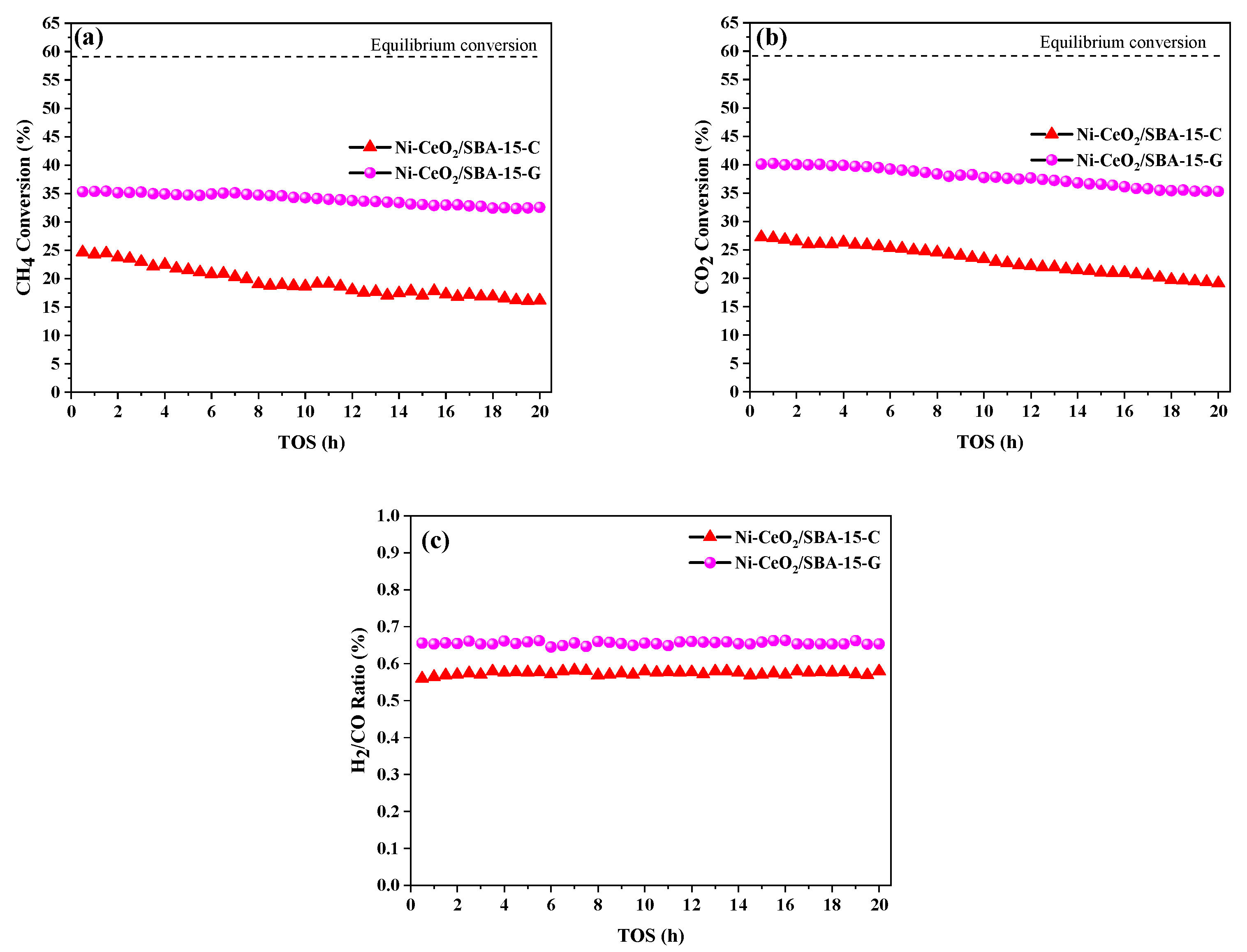

3.2. DRM Performances over Catalysts

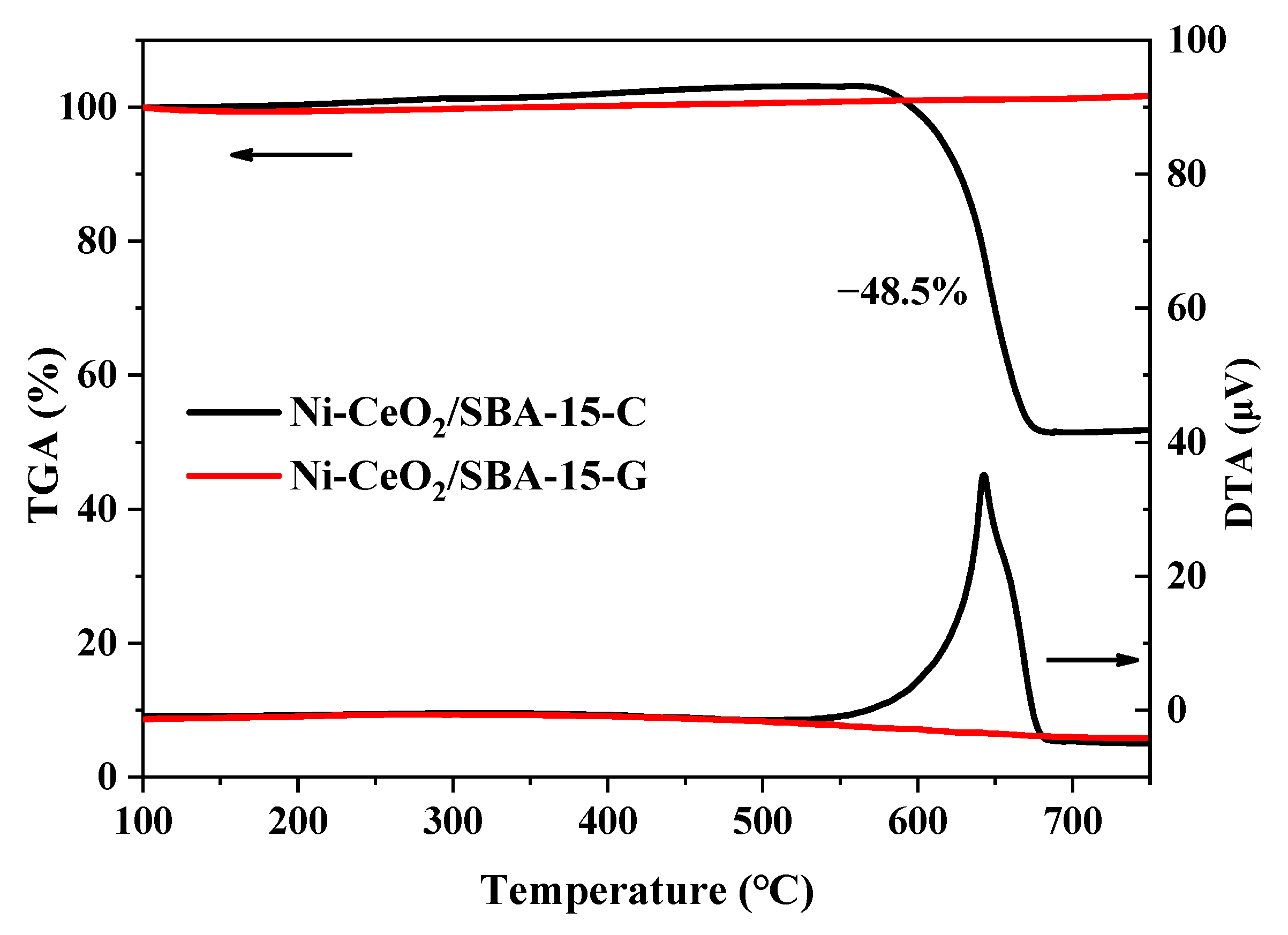

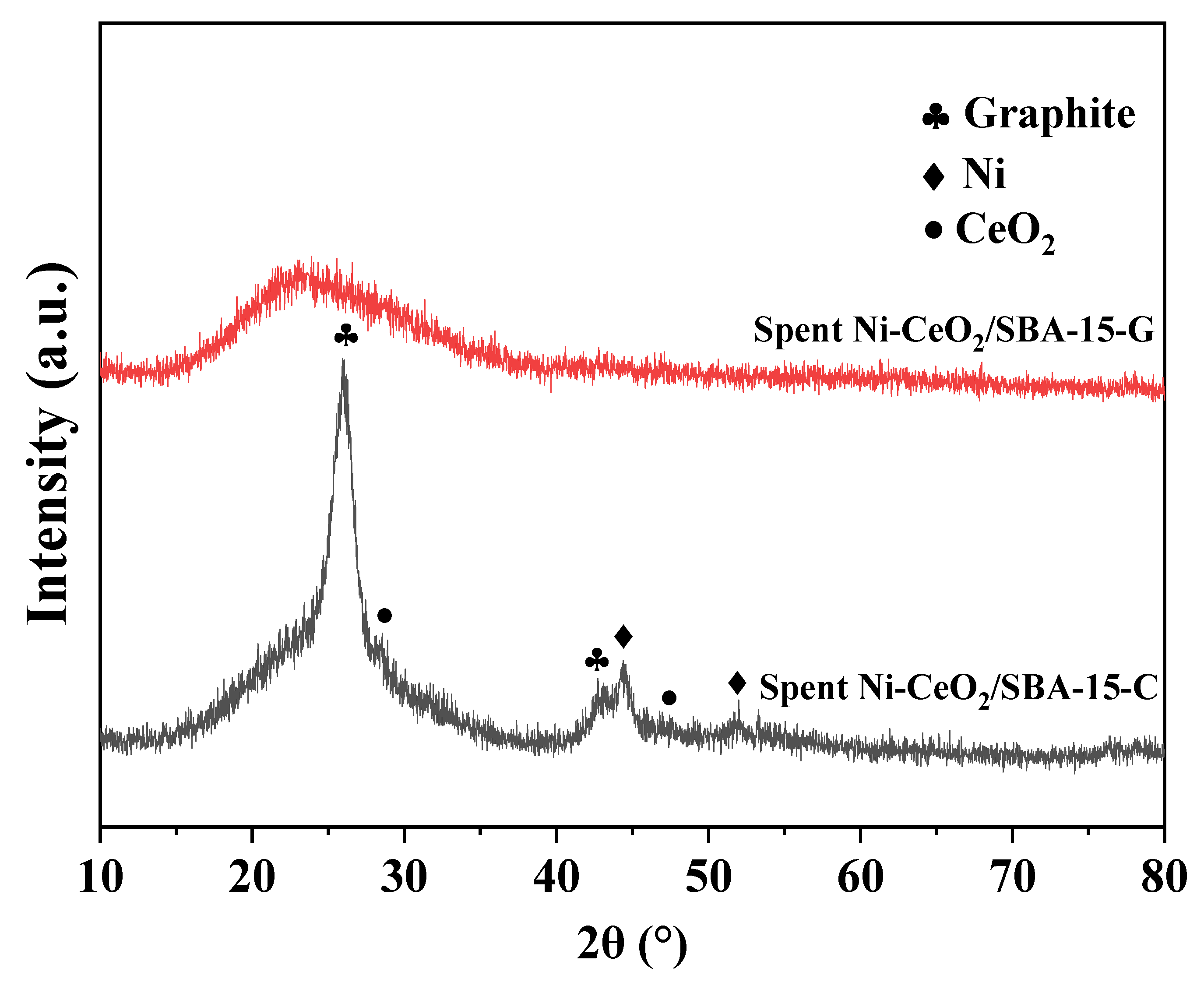

3.3. Characterization of Spent Catalysts

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marinho, A.L.A.; Toniolo, F.S.; Noronha, F.B.; Epron, F.; Duprez, D.; Bion, N. Highly active and stable Ni dispersed on mesoporous CeO2-Al2O3 catalysts for production of syngas by dry reforming of methane. Appl. Catal. B 2021, 281, 119459. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, J.; Xu, Y.; Sun, Y. A review of CH4-CO2 reforming to synthesis gas over Ni-based catalysts in recent years (2010–2017). Int. J. Hydrogen Energy 2018, 43, 15030–15054. [Google Scholar] [CrossRef]

- Gálvez, M.E.; Albarazi, A.; da Costa, P. Enhanced catalytic stability through non-conventional synthesis of Ni/SBA-15 for methane dry reforming at low temperatures. Appl. Catal. A 2015, 504, 143–150. [Google Scholar] [CrossRef]

- Jing, J.-y.; Wei, Z.-h.; Zhang, Y.-b.; Bai, H.-C.; Li, W.-y. Carbon dioxide reforming of methane over MgO-promoted Ni/SiO2 catalysts with tunable Ni particle size. Catal. Today 2020, 356, 589–596. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, L.; Wang, S.; Mao, D.; Hu, C. Low-Temperature catalytic CO2 dry reforming of methane on Ni-based catalysts: A review. Fuel Process. Technol. 2018, 169, 199–206. [Google Scholar] [CrossRef]

- Akri, M.; Zhao, S.; Li, X.; Zang, K.; Lee, A.F.; Isaacs, M.A.; Xi, W.; Gangarajula, Y.; Luo, J.; Ren, Y.; et al. Atomically dispersed nickel as coke-resistant active sites for methane dry reforming. Nat. Commun. 2019, 10, 5181. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Fatesh, A.S.; Fakeeha, A.H.; Ibrahim, A.A.; Abasaeed, A.E. Ni supported on La2O3 + ZrO2 for dry reforming of methane: The impact of surface adsorbed oxygen species. Int. J. Hydrogen Energy 2021, 46, 3780–3788. [Google Scholar] [CrossRef]

- Yang, E.; Nam, E.; Lee, J.; Lee, H.; Park, E.D.; Lim, H.; An, K. Al2O3-Coated Ni/CeO2 nanoparticles as coke-resistant catalyst for dry reforming of methane. Catal. Sci. Technol. 2020, 10, 8283–8294. [Google Scholar] [CrossRef]

- De la Cruz-Flores, V.G.; Martinez-Hernandez, A.; Gracia-Pinilla, M.A. Deactivation of Ni-SiO2 catalysts that are synthetized via a modified direct synthesis method during the dry reforming of methane. Appl. Catal. A 2020, 594, 117455. [Google Scholar] [CrossRef]

- Huang, F.; Wang, R.; Yang, C.; Driss, H.; Chu, W.; Zhang, H. Catalytic performances of Ni/mesoporous SiO2 catalysts for dry reforming of methane to hydrogen. J. Energy Chem. 2016, 25, 709–719. [Google Scholar] [CrossRef]

- Abdullah, B.; Abd Ghani, N.A.; Vo, D.-V.N. Recent advances in dry reforming of methane over Ni-based catalysts. J. Clean. Prod. 2017, 162, 170–185. [Google Scholar] [CrossRef] [Green Version]

- Kurlov, A.; Deeva, E.B.; Abdala, P.M.; Lebedev, D.; Tsoukalou, A.; Comas-Vives, A.; Fedorov, A.; Müller, C.R. Exploiting two-dimensional morphology of molybdenum oxycarbide to enable efficient catalytic dry reforming of methane. Nat. Commun. 2020, 11, 4920. [Google Scholar] [CrossRef] [PubMed]

- Joo, S.; Kim, K.; Kwon, O.; Oh, J.; Kim, H.J.; Zhang, L.; Zhou, J.; Wang, J.-Q.; Jeong, H.Y.; Han, J.W.; et al. Enhancing Thermocatalytic Activities by Upshifting the d-Band Center of Exsolved Co-Ni-Fe Ternary Alloy Nanoparticles for the Dry Reforming of Methane. Angew. Chem. Int. Ed. 2021, 60, 15912–15919. [Google Scholar] [CrossRef] [PubMed]

- Marin, C.M.; Popczun, E.J.; Nguyen-Phan, T.-D.; Tafen, D.N.; Alfonso, D.; Waluyo, I.; Hunt, A.; Kauffman, D.R. Designing perovskite catalysts for controlled active-site exsolution in the microwave dry reforming of methane. Appl. Catal. B 2021, 284, 119711. [Google Scholar] [CrossRef]

- Hamzehlouia, S.; Jaffer, S.A.; Chaouki, J. Microwave Heating-Assisted Catalytic Dry Reforming of Methane to Syngas. Sci. Rep. 2018, 8, 8940. [Google Scholar] [CrossRef] [Green Version]

- Renda, S.; Cortese, M.; Iervolino, G.; Martino, M.; Meloni, E.; Palma, V. Electrically driven SiC-based structured catalysts for intensified reforming processes. Catal. Today 2022, 383, 31–43. [Google Scholar] [CrossRef]

- Meloni, E.; Martino, M.; Ricca, A.; Palma, V. Ultracompact methane steam reforming reactor based on microwaves susceptible structured catalysts for distributed hydrogen production. Int. J. Hydrogen Energy 2021, 46, 13729–13747. [Google Scholar] [CrossRef]

- Rieks, M.; Bellinghausen, R.; Kockmann, N.; Mleczko, L. Experimental study of methane dry reforming in an electrically heated reactor. Int. J. Hydrogen Energy 2015, 40, 15940–15951. [Google Scholar] [CrossRef]

- Wismann Sebastian, T.; Engbæk Jakob, S.; Vendelbo Søren, B.; Bendixen Flemming, B.; Eriksen Winnie, L.; Aasberg-Petersen, K.; Frandsen, C.; Chorkendorff, I.; Mortensen Peter, M. Electrified methane reforming: A compact approach to greener industrial hydrogen production. Science 2019, 364, 756–759. [Google Scholar] [CrossRef] [Green Version]

- Sokolov, S.; Radnik, J.; Schneider, M.; Rodemerck, U. Low-Temperature CO2 reforming of methane over Ni supported on ZnAl mixed metal oxides. Int. J. Hydrogen Energy 2017, 42, 9831–9839. [Google Scholar] [CrossRef]

- Károlyi, J.; Németh, M.; Evangelisti, C.; Sáfrán, G.; Schay, Z.; Horváth, A.; Somodi, F. Carbon dioxide reforming of methane over Ni–In/SiO2 catalyst without coke formation. J. Ind. Eng. Chem. 2018, 58, 189–201. [Google Scholar] [CrossRef] [Green Version]

- Abdulrasheed, A.; Jalil, A.A.; Gambo, Y.; Ibrahim, M.; Hambali, H.U.; Shahul Hamid, M.Y. A review on catalyst development for dry reforming of methane to syngas: Recent advances. Renew. Sustain. Energy Rev. 2019, 108, 175–193. [Google Scholar] [CrossRef]

- Wang, F.; Han, B.; Zhang, L.; Xu, L.; Yu, H.; Shi, W. CO2 reforming with methane over small-sized Ni@SiO2 catalysts with unique features of sintering-free and low carbon. Appl. Catal. B 2018, 235, 26–35. [Google Scholar] [CrossRef]

- Wang, F.; Han, K.; Xu, L.; Yu, H.; Shi, W. Ni/SiO2 Catalyst Prepared by Strong Electrostatic Adsorption for a Low-Temperature Methane Dry Reforming Reaction. Ind. Eng. Chem. Res. 2021, 60, 3324–3333. [Google Scholar] [CrossRef]

- Da Silva, F.D.A.R.; dos Santos, R.C.R.; Nunes, R.S.; Valentini, A. Role of tin on the electronic properties of Ni/Al2O3 catalyst and its effect over the methane dry reforming reaction. Appl. Catal. A 2021, 618, 118129. [Google Scholar] [CrossRef]

- Cichy, M.; Pańczyk, M.; Słowik, G.; Zawadzki, W.; Borowiecki, T. Ni–Re alloy catalysts on Al2O3 for methane dry reforming. Int. J. Hydrogen Energy 2022, 47, 16528–16543. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, J.; Zhang, X.; Zhou, Z.; Song, F.; Zhang, Q.; Tan, Y.; Han, Y. How the reflux treatment stabilizes the metastable structure of ZrO2 and improves the performance of Ni/ZrO2 catalyst for dry reforming of methane? Energy Convers. Manag. 2020, 216, 112950. [Google Scholar] [CrossRef]

- Hu, X.; Jia, X.; Zhang, X.; Liu, Y.; Liu, C.-j. Improvement in the activity of Ni/ZrO2 by cold plasma decomposition for dry reforming of methane. Catal. Commun. 2019, 128, 105720. [Google Scholar] [CrossRef]

- Liu, Z.; Grinter, D.C.; Lustemberg, P.G.; Nguyen-Phan, T.-D.; Zhou, Y.; Luo, S.; Waluyo, I.; Crumlin, E.J.; Stacchiola, D.J.; Zhou, J.; et al. Dry Reforming of Methane on a Highly-Active Ni-CeO2 Catalyst: Effects of Metal-Support Interactions on C−H Bond Breaking. Angew. Chem. Int. Ed. 2016, 55, 7455–7459. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Wei, Y.; Wang, Z.; Zhang, S.; Li, Y.; Nguyen, L.; Li, Y.; Zhou, Y.; Shen, W.; Tao, F.F.; et al. Synergy of Single-Atom Ni1 and Ru1 Sites on CeO2 for Dry Reforming of CH4. J. Am. Chem. Soc. 2019, 141, 7283–7293. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Wu, Y.; Li, J.; Wei, S.; Gao, X.; Wang, P. Combustion-Impregnation preparation of Ni/SiO2 catalyst with improved low-temperature activity for CO2 methanation. Int. J. Hydrogen Energy 2021, 46, 20919–20929. [Google Scholar] [CrossRef]

- Dębek, R.; Zubek, K.; Motak, M.; Galvez, M.E.; da Costa, P.; Grzybek, T. Ni–Al hydrotalcite-like material as the catalyst precursors for the dry reforming of methane at low temperature. C. R. Chim. 2015, 18, 1205–1210. [Google Scholar] [CrossRef]

- Liu, H.; Wierzbicki, D.; Debek, R.; Motak, M.; Grzybek, T.; da Costa, P.; Gálvez, M.E. La-Promoted Ni-hydrotalcite-derived catalysts for dry reforming of methane at low temperatures. Fuel 2016, 182, 8–16. [Google Scholar] [CrossRef]

- Omoregbe, O.; Danh, H.T.; Nguyen-Huy, C.; Setiabudi, H.D.; Abidin, S.Z.; Truong, Q.D.; Vo, D.-V.N. Syngas production from methane dry reforming over Ni/SBA-15 catalyst: Effect of operating parameters. Int. J. Hydrogen Energy 2017, 42, 11283–11294. [Google Scholar] [CrossRef]

- Panduro, E.A.C.; Granlund, H.; Sztucki, M.; Konovalov, O.; Breiby, D.W.; Gibaud, A. Using Three-Dimensional 3D Grazing-Incidence Small-Angle X-ray Scattering (GISAXS) Analysis To Probe Pore Deformation in Mesoporous Silica Films. ACS Appl. Mater. Interfaces 2014, 6, 2686–2691. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Liu, D.; Guo, Z.; Xi, S.; Chu, W.; Liu, Y. Insights into Ni and (Ce)SBA-15-CTA interaction and syngas formation rate. Mol. Catal. 2021, 514, 111850. [Google Scholar] [CrossRef]

- Yan, X.; Hu, T.; Liu, P.; Li, S.; Zhao, B.; Zhang, Q.; Jiao, W.; Chen, S.; Wang, P.; Lu, J.; et al. Highly efficient and stable Ni/CeO2-SiO2 catalyst for dry reforming of methane: Effect of interfacial structure of Ni/CeO2 on SiO2. Appl. Catal. B 2019, 246, 221–231. [Google Scholar] [CrossRef]

- Ren, H.-P.; Hao, Q.-Q.; Ding, S.-Y.; Zhao, Y.-Z.; Zhu, M.; Tian, S.-P.; Ma, Q.; Song, W.-Q.; Miao, Z.; Liu, Z.-T. A High-Performance Ni/SiO2 Prepared by the Complexed-Impregnation Method with Citric Acid for Carbon Dioxide Reforming of Methane. Ind. Eng. Chem. Res. 2018, 57, 16257–16263. [Google Scholar] [CrossRef]

- Bian, L.; Zhang, L.; Zhu, Z.; Li, Z. Methanation of carbon oxides on Ni/Ce/SBA-15 pretreated with dielectric barrier discharge plasma. Mol. Catal. 2018, 446, 131–139. [Google Scholar] [CrossRef]

- Liu, H.; Li, Y.; Wu, H.; Liu, J.; He, D. Effects of α- and γ-cyclodextrin-modified impregnation method on physicochemical properties of Ni/SBA-15 and its catalytic performance in CO2 reforming of methane. Chin. J. Catal. 2015, 36, 283–289. [Google Scholar] [CrossRef]

- Yang, Y.; Ochoa-Hernández, C.; Pizarro, P.; de la Peña O’shea, V.A.; Coronado, J.M.; Serrano, D.P. Ce-Promoted Ni/SBA-15 catalysts for anisole hydrotreating under mild conditions. Appl. Catal. B 2016, 197, 206–213. [Google Scholar] [CrossRef]

- Tapia-Parada, K.; Valverde-Aguilar, G.; Mantilla, A.; Valenzuela, M.A.; Hernández, E. Synthesis and characterization of Ni/Ce–SiO2 and Co/Ce–TiO2 catalysts for methane decomposition. Fuel 2013, 110, 70–75. [Google Scholar] [CrossRef]

- Setiabudi, H.D.; Chong, C.C.; Abed, S.M.; Teh, L.P.; Chin, S.Y. Comparative study of Ni-Ce loading method: Beneficial effect of ultrasonic-assisted impregnation method in CO2 reforming of CH4 over Ni-Ce/SBA-15. J. Environ. Chem. Eng. 2018, 6, 745–753. [Google Scholar] [CrossRef]

- Emamdoust, A.; la Parola, V.; Pantaleo, G.; Testa, M.L.; Farjami Shayesteh, S.; Venezia, A.M. Partial oxidation of methane over SiO2 supported Ni and NiCe catalysts. J. Energy Chem. 2020, 47, 1–9. [Google Scholar] [CrossRef]

- Yi, H.; Xue, Q.; Lu, S.; Wu, J.; Wang, Y.; Luo, G. Effect of pore structure on Ni/Al2O3 microsphere catalysts for enhanced CO2 methanation. Fuel 2022, 315, 123262. [Google Scholar] [CrossRef]

- Ashok, J.; Ang, M.L.; Kawi, S. Enhanced activity of CO2 methanation over Ni/CeO2-ZrO2 catalysts: Influence of preparation methods. Catal. Today 2017, 281, 304–311. [Google Scholar] [CrossRef]

- Lee, S.M.; Lee, Y.H.; Moon, D.H.; Ahn, J.Y.; Nguyen, D.D.; Chang, S.W.; Kim, S.S. Reaction Mechanism and Catalytic Impact of Ni/CeO2–x Catalyst for Low-Temperature CO2 Methanation. Ind. Eng. Chem. Res. 2019, 58, 8656–8662. [Google Scholar] [CrossRef]

- Kang, W.; Guo, H.; Varma, A. Noble-metal-free NiCu/CeO2 catalysts for H2 generation from hydrous hydrazine. Appl. Catal. B 2019, 249, 54–62. [Google Scholar] [CrossRef]

- Guo, D.; Lu, Y.; Ruan, Y.; Zhao, Y.; Zhao, Y.; Wang, S.; Ma, X. Effects of extrinsic defects originating from the interfacial reaction of CeO2-x-nickel silicate on catalytic performance in methane dry reforming. Appl. Catal. B 2020, 277, 119278. [Google Scholar] [CrossRef]

- Das, S.; Ashok, J.; Bian, Z.; Dewangan, N.; Wai, M.H.; Du, Y.; Borgna, A.; Hidajat, K.; Kawi, S. Silica–Ceria sandwiched Ni core–shell catalyst for low temperature dry reforming of biogas: Coke resistance and mechanistic insights. Appl. Catal. B 2018, 230, 220–236. [Google Scholar] [CrossRef]

- Albarazi, A.; Beaunier, P.; da Costa, P. Hydrogen and syngas production by methane dry reforming on SBA-15 supported nickel catalysts: On the effect of promotion by Ce0.75Zr0.25O2 mixed oxide. Int. J. Hydrogen Energy 2013, 38, 127–139. [Google Scholar] [CrossRef]

- Yao, L.; Zhu, J.; Peng, X.; Tong, D.; Hu, C. Comparative study on the promotion effect of Mn and Zr on the stability of Ni/SiO2 catalyst for CO2 reforming of methane. Int. J. Hydrogen Energy 2013, 38, 7268–7279. [Google Scholar] [CrossRef]

- Wang, F.; Han, K.; Yu, W.; Zhao, L.; Wang, Y.; Wang, X.; Yu, H.; Shi, W. Low Temperature CO2 Reforming with Methane Reaction over CeO2-Modified Ni@SiO2 Catalysts. ACS Appl. Mater. Interfaces 2020, 12, 35022–35034. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Sibudjing, K. Facile Synthesis of Multi-Ni-Core@Ni Phyllosilicate@CeO2 Shell Hollow Spheres with High Oxygen Vacancy Concentration for Dry Reforming of CH4. ChemCatChem 2018, 10, 2994–3001. [Google Scholar] [CrossRef]

- Wolfbeisser, A.; Sophiphun, O.; Bernardi, J.; Wittayakun, J.; Föttinger, K.; Rupprechter, G. Methane dry reforming over ceria-zirconia supported Ni catalysts. Catal. Today 2016, 277, 234–245. [Google Scholar] [CrossRef] [Green Version]

- Made Joni, I.; Vanith, M.; Camellia, P.; Balasubramanian, N. Augmentation of graphite purity from mineral resources and enhancing % graphitization using microwave irradiation: XRD and Raman studies. Diam. Relat. Mater. 2018, 88, 129–136. [Google Scholar]

| Catalysts | NiO Crystal Size 1 (nm) | CeO2 Crystal Size 1 (nm) | Ce3+-Ce4+ 2 | Carbon Deposited 3 (%) |

|---|---|---|---|---|

| Ni-CeO2/SBA-15-C | 9.5 | 5.3 | 31–69% | 48.5 |

| Ni-CeO2/SBA-15-G | n.d.4 | n.d. 4 | 49–51% | n.d. 4 |

| Catalysts | GHSV (mL/gcat/h) | CH4:CO2:N2(Ar) | Specific Rate 1 (×10−4 molCH4/gNi/s) | Specific Rate 1 (×10−5 molCH4/gcat/s) | Note |

|---|---|---|---|---|---|

| Ni-CeO2/SBA-15-C | 600,000 | 3:3:14 | 34.9 | 17.4 | This work |

| Ni-CeO2/SBA-15-G | 600,000 | 3:3:14 | 70.5 | 35.2 | This work |

| Ni-SiO2@CeO2 | 200,000 | 3:2:0 | 20 | 10.6 | [50] |

| Ni/SBA-15-RM | 20,000 | 1:1:0 | 12.1 | 9.7 | [3] |

| Ni/SBA-15 | 20,000 | 1:1:8 | 1.3 | 1.3 | [51] |

| Ni-Zr/SiO2 | 14,400 | 1:1:0 | 3.6 | 3.4 | [52] |

| Ni@SiO2-CeO2-W | 60,000 | 3:3:4 | 1.4 | 0.19 | [53] |

| Ni@SiO2-CeO2-E | 60,000 | 3:3:4 | 1.1 | 0.14 | [53] |

| Ni@NiPhy | 36,000 | 1:1:1 | 1.6 | 5.1 | [54] |

| Ni@NiPhy@CeO2 | 36,000 | 1:1:1 | 2.1 | 4.0 | [54] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Gong, D.; Lu, X.; Han, C.; Liu, H.; Wang, L. Ni-CeO2/SBA-15 Catalyst Prepared by Glycine-Assisted Impregnation Method for Low-Temperature Dry Reforming of Methane. Crystals 2022, 12, 713. https://doi.org/10.3390/cryst12050713

Yang J, Gong D, Lu X, Han C, Liu H, Wang L. Ni-CeO2/SBA-15 Catalyst Prepared by Glycine-Assisted Impregnation Method for Low-Temperature Dry Reforming of Methane. Crystals. 2022; 12(5):713. https://doi.org/10.3390/cryst12050713

Chicago/Turabian StyleYang, Jiliang, Dandan Gong, Xinkang Lu, Cui Han, Hui Liu, and Luhui Wang. 2022. "Ni-CeO2/SBA-15 Catalyst Prepared by Glycine-Assisted Impregnation Method for Low-Temperature Dry Reforming of Methane" Crystals 12, no. 5: 713. https://doi.org/10.3390/cryst12050713

APA StyleYang, J., Gong, D., Lu, X., Han, C., Liu, H., & Wang, L. (2022). Ni-CeO2/SBA-15 Catalyst Prepared by Glycine-Assisted Impregnation Method for Low-Temperature Dry Reforming of Methane. Crystals, 12(5), 713. https://doi.org/10.3390/cryst12050713