Penetration Gain Study of a Tungsten-Fiber/Zr-Based Metallic Glass Matrix Composite

Abstract

:1. Introduction

2. Experiment

2.1. Experiment Configuration

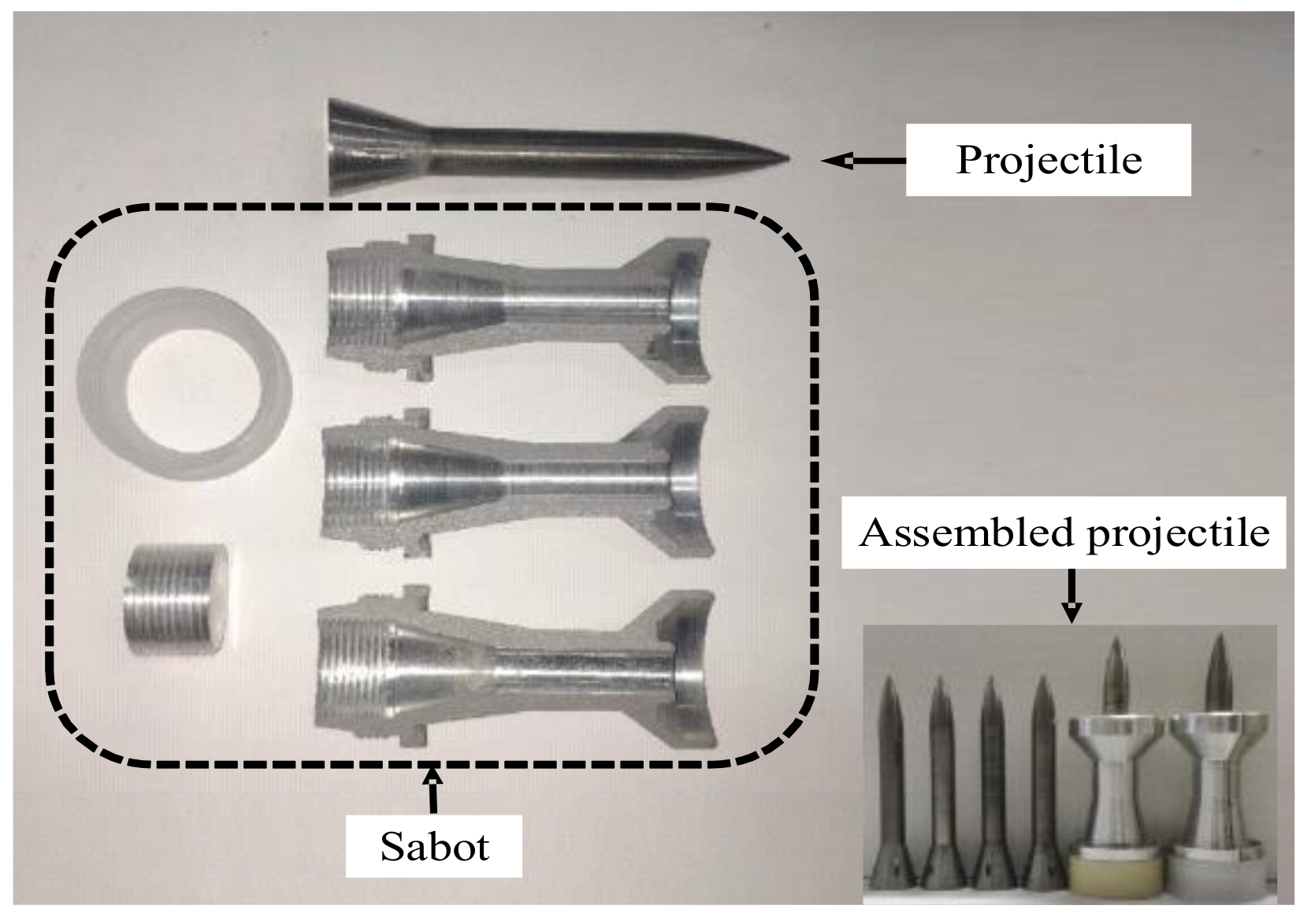

2.2. Projectile Structure

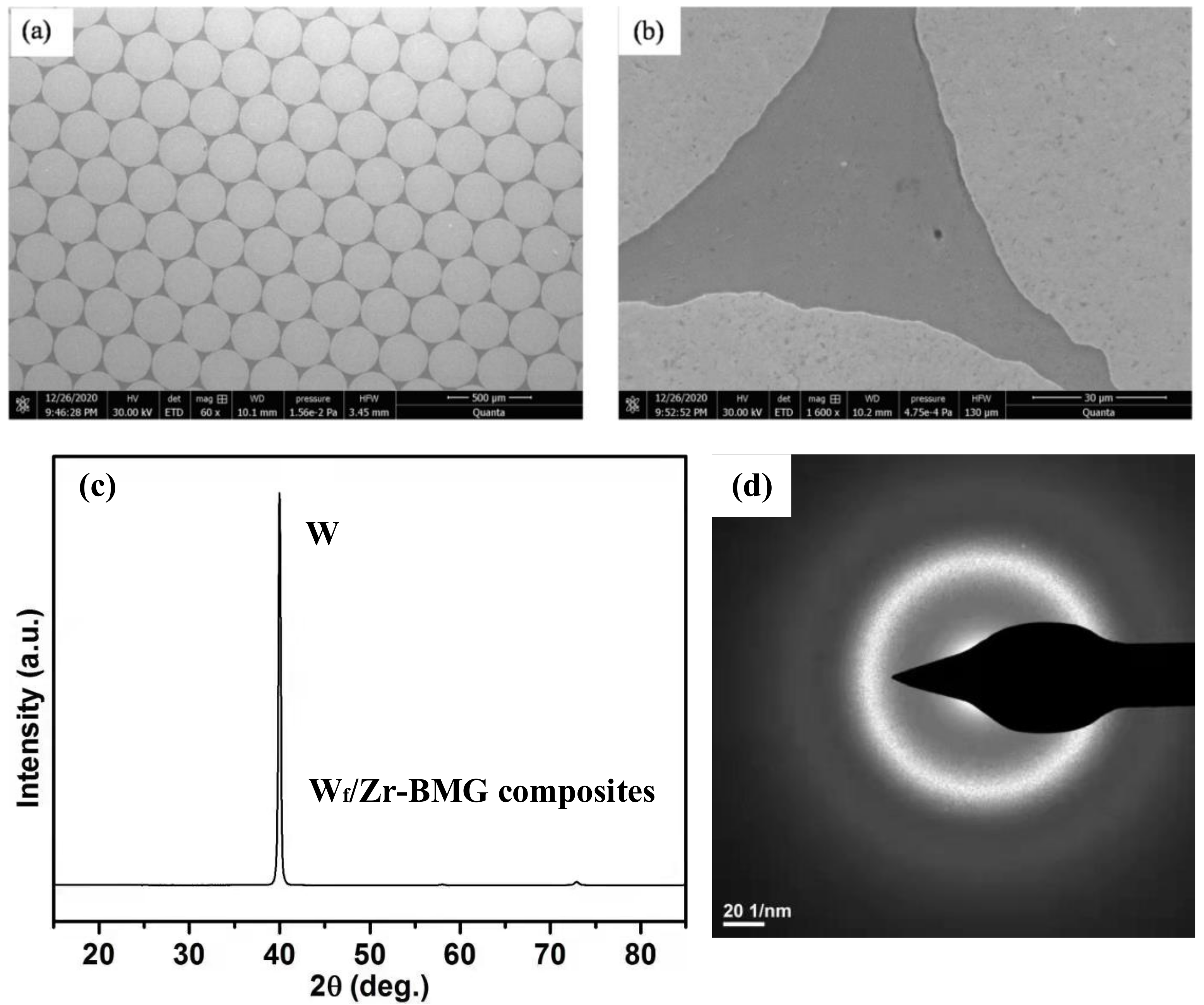

2.3. Projectile and Target Material

3. Penetration Test Result

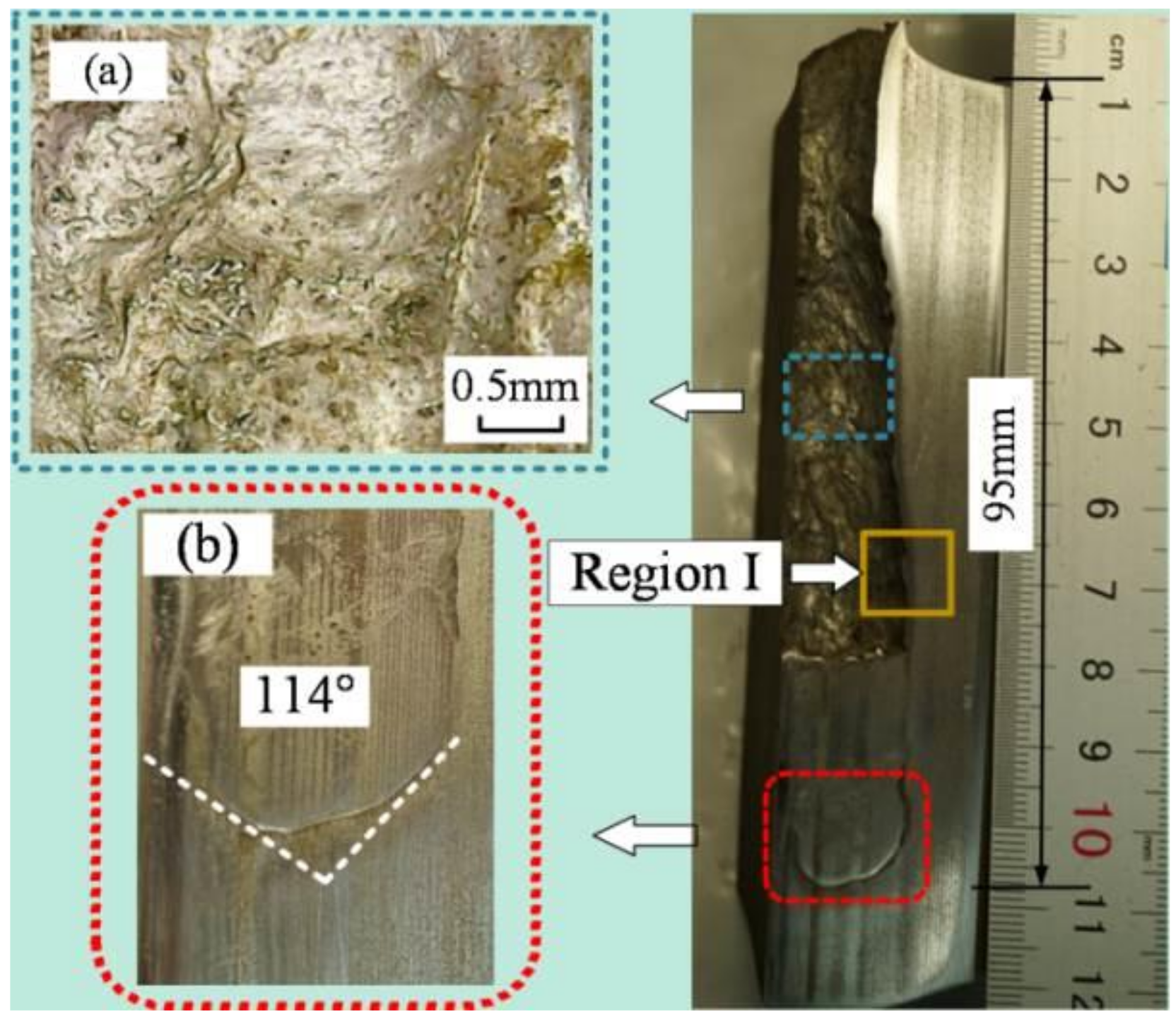

3.1. WHA Rod

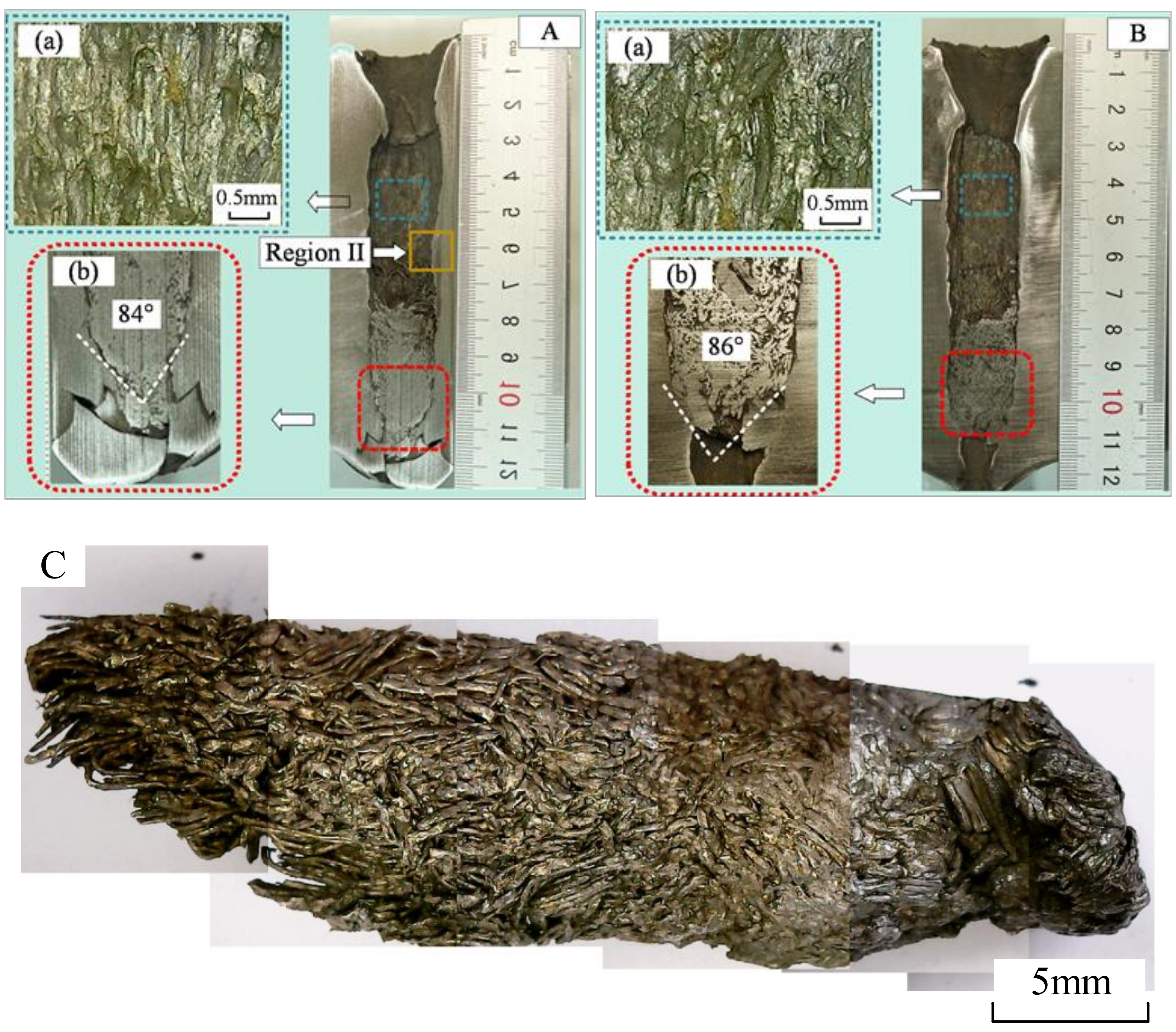

3.2. Wf/Zr-MG Rod

4. Micro-Structure Analyses of the Crater

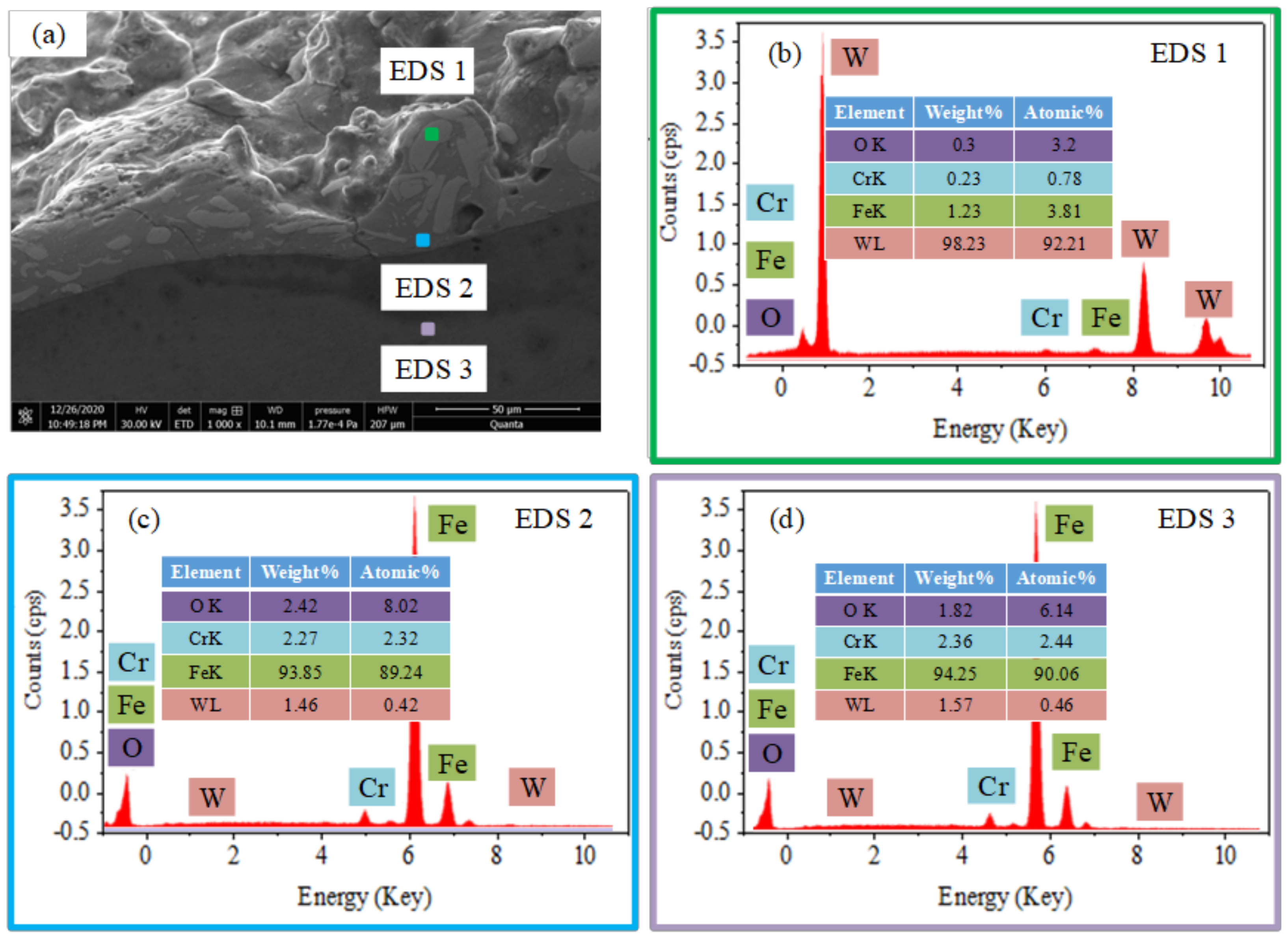

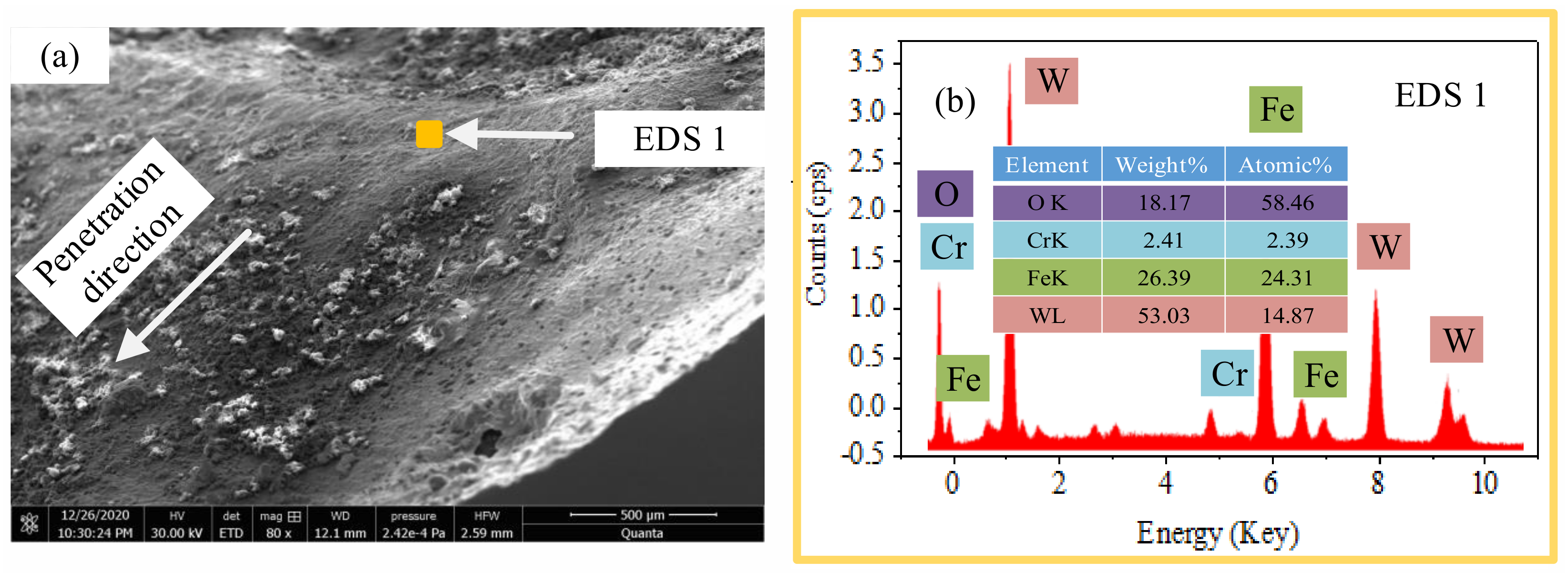

4.1. Tungsten Alloy Penetrating Crater

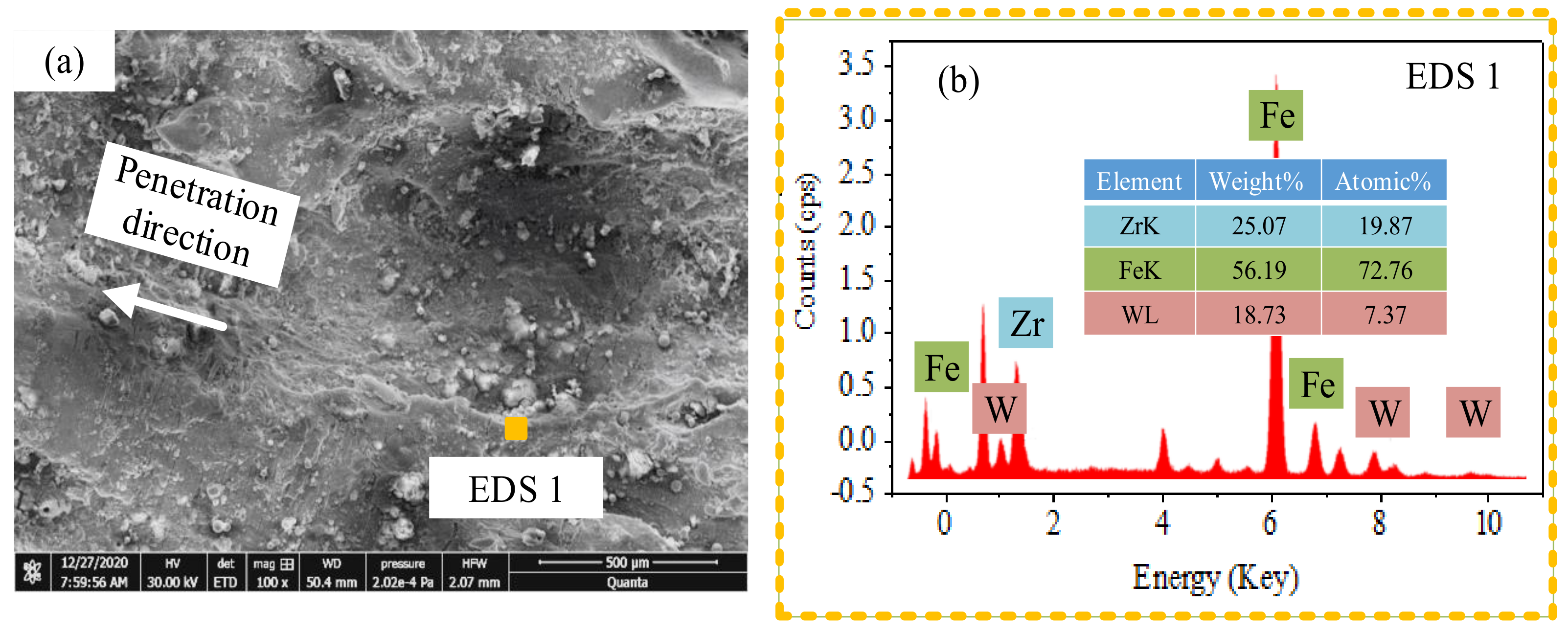

4.2. Wf/Zr-MG Alloy Penetrating Crater

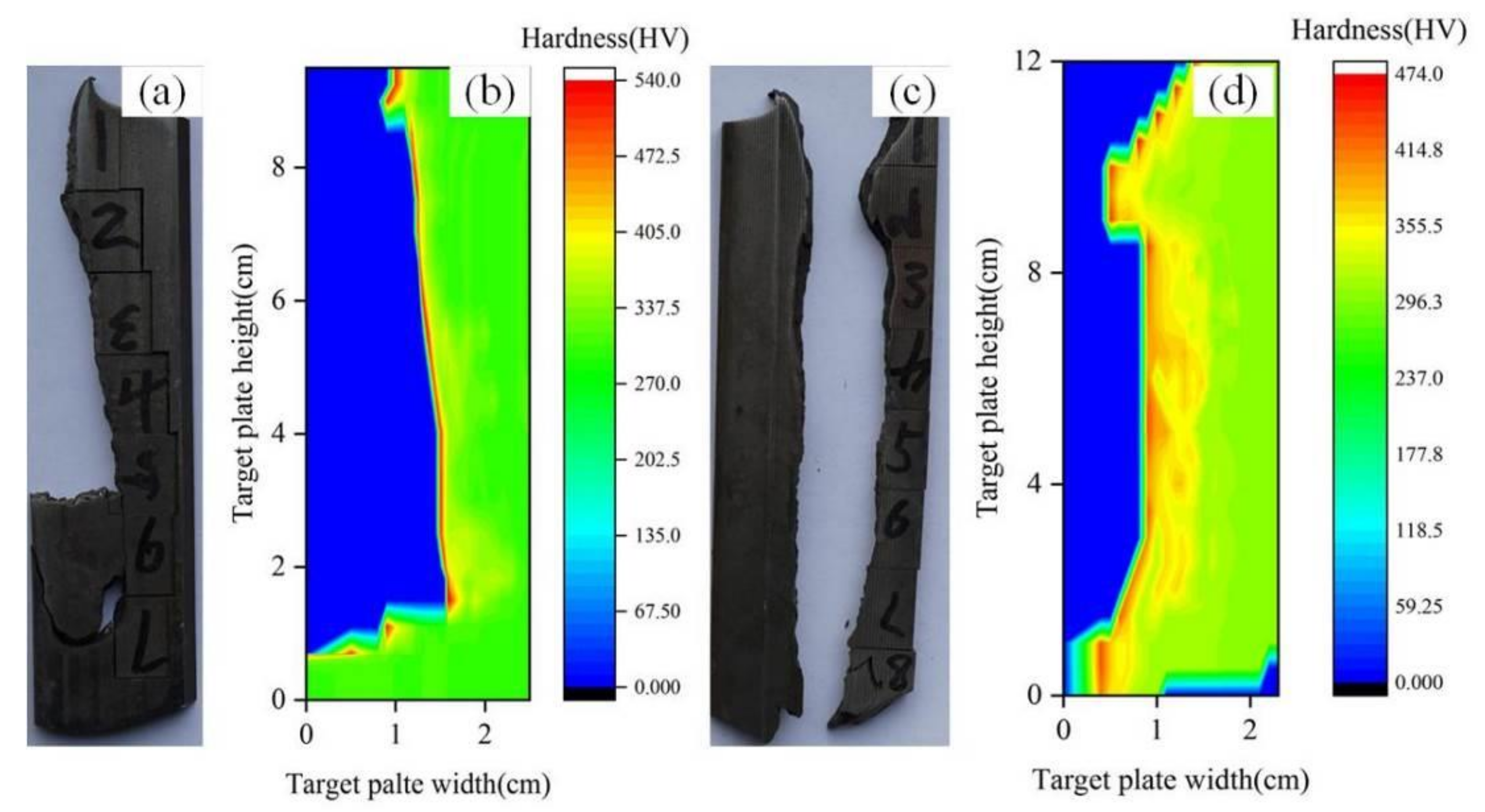

4.3. Target Hardness Distribution

5. Result and Discussion

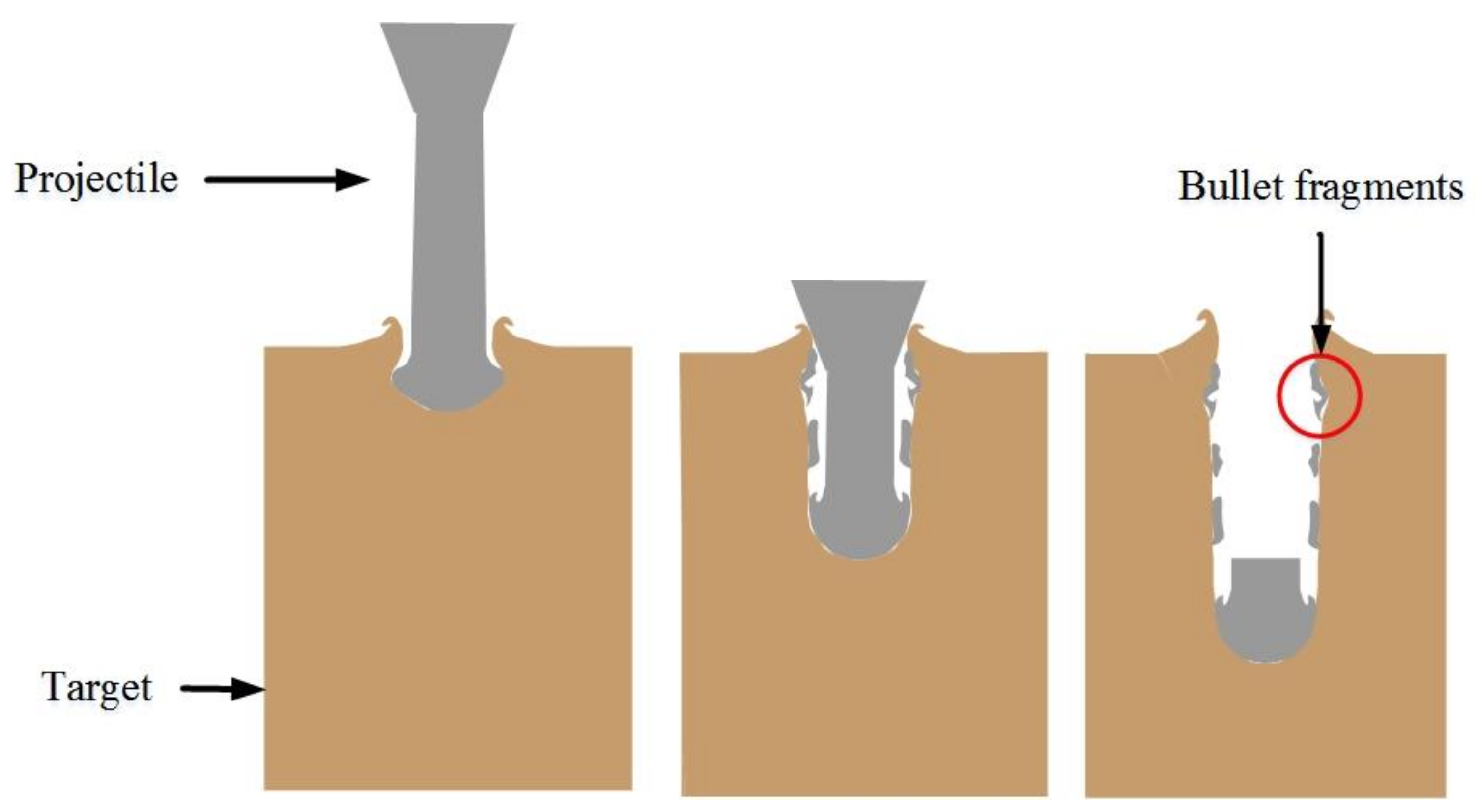

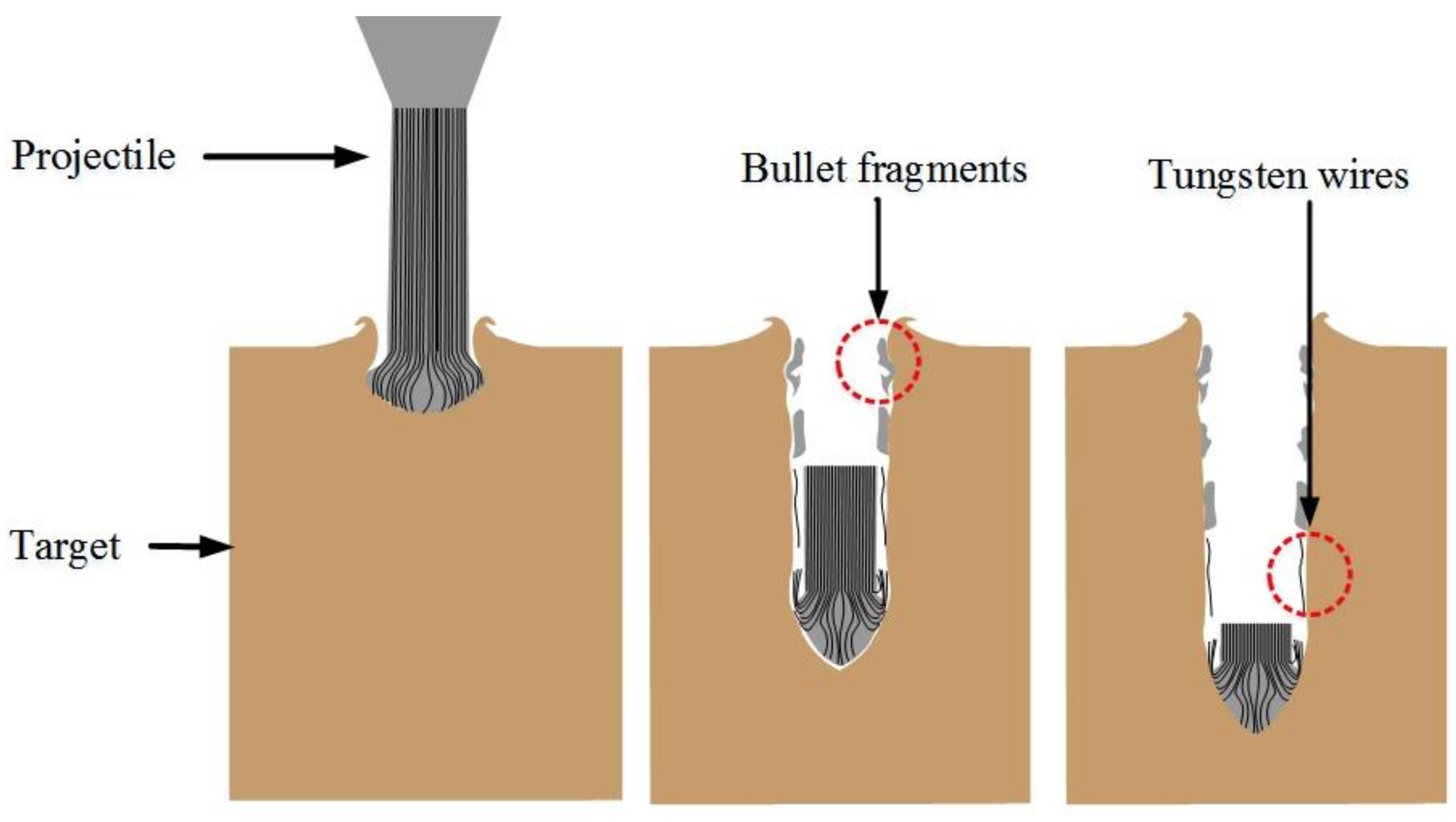

5.1. Rod Erosion Mechanism of Two Materials

5.2. Theoretical Analysis of Penetration Resistance

6. Conclusions

- (1)

- Under the same impact velocity, the self-sharpening effect of the Wf/Zr-MG rod is obvious. The diameter of the crater penetrated by the Wf/Zr-MG rod is smaller, and the penetration resistance is less than that of the 93W rod under the same conditions. The penetration depth is approximately 10% higher than that of the 93W rod.

- (2)

- Under the same impact velocity, the failure modes of the two rod materials are completely different. The penetration failure mode of the Wf/Zr-MG rods into RHA is the bending, backflow, and fracture of the WFs. The bottom of the crater penetrated by Wf/Zr-MG rods is conical. The failure mode of the 93W rod is the area with a large deformation on both sides of the “mushroom nose,” which is constantly broken and peeled during the penetration process. The bottom of the crater is hemispherical.

- (3)

- Under the same impact velocity, the extrusion ability of the two kinds of rod materials to the side wall of the crater are evidently different. The MRSL formed by 93W in the process of penetration shows a wavy change. It increases the backflow resistance of the rod and target materials and increases the pressure of the rod on the side wall of target plate and the penetration resistance. By contrast, the MRSL is more relatively straight and smooth when formed by the Wf/Zr-MG rods, and the backflow of projectile and target materials is easy. The pressure of the rod on the side wall of the crater is lower, which reduces the penetration resistance and significantly improves the penetration ability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fras, T.; Roth, C.C.; Mohr, D. Dynamic perforation of ultra-hard high-strength armor steel: Impact experiments and modeling. Int. J. Impact Eng. 2019, 131, 256–271. [Google Scholar] [CrossRef]

- Jo, M.C.; Kim, S.; Suh, D.W.; Hong, S.S.; Kim, H.K.; Sohn, S.S.; Lee, S. Effect of tempering conditions on adiabatic shear banding during dynamic compression and ballistic impact tests of ultra-high-strength armor steel. Mater. Sci. Eng. A 2020, 792, 139818. [Google Scholar] [CrossRef]

- Xinde, B.; Zuozhong, J.; Wei, L.; Jian, X.; Wenjun, M.; Yonggang, R. Review on the Development and Prospect of Du Munitions. Rare Metal. Mater. Eng. 2003, 32, 412–416. [Google Scholar]

- Zhu, F.-L.; Chen, Y.; Zhu, G.-L. Numerical simulation study on penetration performance of depleted Uranium (DU) alloy fragments. Def. Technol. 2020, 17, 50–55. [Google Scholar] [CrossRef]

- Luo, D.; Wang, Y.; Wang, F.; Cheng, H.; Zhang, B.; Zhu, Y. The influence of metal cover plates on ballistic performance of silicon carbide subjected to large-scale tungsten projectile. Mater. Des. 2020, 191, 108659. [Google Scholar] [CrossRef]

- Wang, M.; Huang, D.; Luo, R. Shear failure of tungsten alloy at mesoscale modeled by Movable cellular Automata. Theor. Appl. Fract. Mech. 2011, 56, 162–168. [Google Scholar] [CrossRef]

- Cai, W.D.; Li, Y.; Dowding, R.J.; Mohamed, F.A.; Lavernia, E.J. A review of tungsten-based alloys as kinetic energy penetrator materials. Rev. Part. Mater. 1995, 3, 71–132. [Google Scholar]

- Danesi, P.R. Radiological and Depleted Uranium Weapons: Environmental and Health Consequences. In Encyclopedia of Environmental Health; Elsevier Inc.: Amsterdam, The Netherlands, 2011; pp. 728–744. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, L.; Huang, P.; Xu, K.; Wang, F.; Lu, T. Clarification on shear transformation zone size and its correlation with plasticity for Zr-based bulk metallic glass in different structural states. Mater. Sci. Eng. A 2016, 677, 349–355. [Google Scholar] [CrossRef]

- Hua, N.; Li, G.; Lin, C.; Ye, X.; Wang, W.; Chen, W. Chemistry effects on the compressive property and Weibull modulus of Zr-based bulk metallic glasses. J. Non-Cryst. Solids 2015, 432, 342–347. [Google Scholar] [CrossRef]

- Greer, A.; Cheng, Y.; Ma, E. Shear bands in metallic glasses. Mater. Sci. Eng. R Rep. 2013, 74, 71–132. [Google Scholar] [CrossRef]

- Inoue, A.; Takeuchi, A. Recent development and application products of bulk glassy alloys. Acta Mater. 2011, 59, 2243–2267. [Google Scholar] [CrossRef]

- Rafique, M.M.A. Bulk Metallic Glasses and Their Composites: Additive Manufacturing and Modeling and Simulation; Momentum Press: New York, NY, USA, 2018. [Google Scholar]

- Kecskes, L.J.; Edwards, B.T.; Woodman, R.H. Hafnium-Based Bulk Metallic Glasses for Kinetic Energy Penetrators. In Transformational Science and Technology for the Current and Future Force: (with CD-ROM); World Scientific: Singapore, 2006. [Google Scholar] [CrossRef] [Green Version]

- Dandliker, R.B. Bulk Metallic Glass Matrix Composites: Processing, Microstructure, and Application as a Kinetic Energy Penetrator. Ph.D. Thesis, California Institute of Technology, Pasadena, CA, USA, 1998. [Google Scholar] [CrossRef]

- Ma, W.; Kou, H.; Chen, C.; Li, J.; Chang, H.; Zhou, L.; Fu, H. Compressive deformation behaviors of tungsten fiber reinforced Zr-based metallic glass composites. Mater. Sci. Eng. A 2008, 486, 308–312. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; Wang, Z. Deformation and damage evolution of tungsten fiber reinforced metallic glass matrix composite induced by compression. Mater. Sci. Eng. A 2008, 483–484, 164–167. [Google Scholar] [CrossRef]

- Conner, R.; Dandliker, R.; Johnson, W. Mechanical properties of tungsten and steel fiber reinforced Zr41.25Ti13.75Cu12.5Ni10Be22.5 metallic glass matrix composites. Acta Mater. 1998, 46, 6089–6102. [Google Scholar] [CrossRef]

- Conner, R.; Dandliker, R.; Scruggs, V.; Johnson, W. Dynamic deformation behavior of tungsten-fiber/metallic-glass matrix composites. Int. J. Impact Eng. 2000, 24, 435–444. [Google Scholar] [CrossRef]

- Rong, G.; Huang, D.W.; Wang, J. Research on penetration mechanism of tungsten fiber composite reinforced penetrators. In Proceedings of the 25th International Symposium on Ballistics, Beijing, China, 17–21 May 2010; pp. 1180–1186. [Google Scholar]

- Rong, G.; Huang, D.; Yang, M. Penetrating behaviors of Zr-based metallic glass composite rods reinforced by tungsten fibers. Theor. Appl. Fract. Mech. 2012, 58, 21–27. [Google Scholar] [CrossRef]

- Chen, X.; Chen, G. Experimental research on the penetration of tungsten-fiber/metallic-glass matrix composite material bullet into steel target. EPJ Web Conf. 2012, 26, 01049. [Google Scholar] [CrossRef]

- Du, Z.; Du, C.; Zhu, Z.; Xia, L. An experimental study on perforation behavior of pole penetrator prepared from Wf/Zr-based bulk metallic glass matrix composite. Rare Met. Mater. Eng. 2016, 45, 1308–1313. (In Chinese) [Google Scholar]

- Du, C.; Du, Z.; Zhu, Z. Effect of impact velocity and diameter of tungsten fiber on penetration ability of Wf/Zr-based metallic glass composite penetrator. Rare Met. Mater. Eng. 2017, 46, 1632–1637. (In Chinese) [Google Scholar]

- Cheng, C.; Du, Z.-H.; Chen, X.; Xu, L.-Z.; Du, C.-X.; Han, J.-L.; Wang, X.-D. Damage of multi-layer spaced metallic target plates impacted by radial layered PELE. Def. Technol. 2019, 16, 201–207. [Google Scholar] [CrossRef]

- Terentyev, D.; Riesch, J.; Lebediev, S.; Bakaeva, A.; Coenen, J. Mechanical properties of as-fabricated and 2300 °C annealed tungsten wire tested up to 600 °C. Int. J. Refract. Met. Hard Mater. 2017, 66, 127–134. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, G.; Jiang, F.; Du, Y.; Chen, G. Effect of volume fraction on quasistatic compressive characteristics of tungsten fiber/Zr-based bulk metallic glass matrix composites. Rare Met. Mater. Eng. 2006, 35, 1568–1571. [Google Scholar] [CrossRef]

- Li, J.; Chen, X.; Huang, F. FEM analysis on the deformation and failure of fiber reinforced metallic glass matrix composite. Mater. Sci. Eng. A 2016, 652, 145–166. [Google Scholar] [CrossRef]

- Li, J.; Chen, X.; Huang, F. FEM analysis on the “self-sharpening” behavior of tungsten fiber/metallic glass matrix composite long rod. Int. J. Impact Eng. 2015, 86, 67–83. [Google Scholar] [CrossRef]

- Chen, X.; Wei, L.; Li, J. Experimental research on the long rod penetration of tungsten-fiber/Zr-based metallic glass matrix composite into Q235 steel target. Int. J. Impact Eng. 2015, 79, 102–116. [Google Scholar] [CrossRef]

- Luo, R.-M.; Huang, D.-W.; Yang, M.-C.; Huang, H.; Yang, F.Y. Research on Melted and Rapidly Solidified Layer on the Surface of Crater Penetrated by Long Tungsten Rod. Acta Armamentarii 2015, 48, 1191–1200. (In Chinese) [Google Scholar]

- Chen, X.W.; Li, Q.M. Deep penetration of a non-deformable projectile with different geometrical characteristics. Int. J. Impact Eng. 2002, 27, 619–637. [Google Scholar] [CrossRef]

| WHA [25] | Wf [26] | Zr-MG [27] | RHA [28,29] | |

|---|---|---|---|---|

| Density/(g·cm−3) | 17.6 | 19.22 | 6.68 | 7.85 |

| Poisson’s ratio | 0.3 | 0.28 | 0.36 | 0.3 |

| Modulus of elasticity/GPa | 360 | 370 | 96 | 210 |

| Yield stress/MPa | 1300 | 1725 | 1900 | 900 |

| Penetrator | Impact Velocity (m/s) | Target Plate | Penetration Depth Ratio (P/L) | ||||

|---|---|---|---|---|---|---|---|

| Penetrator No. | Projectile Type | Mass of Rod (g) | Penetration Depth (mm) | Average Diameter of Crater (mm) | Thickness of Target (mm) | ||

| 1 | Tungsten alloy | 122.7 | 1585.8 | 95 | 18.7 | 110 | 0.98 |

| 2 | Wf/Zr-MG alloy A | 121.6 | 1553.1 | Perforated | 16.4 | 110 | 1.13 |

| 3 | Wf/Zr-MG alloy B | 121.9 | 1584.7 | Perforated | 17.1 | 110 | 1.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, F.; Du, C.; Du, Z.; Gao, G.; Cheng, C.; Wang, X. Penetration Gain Study of a Tungsten-Fiber/Zr-Based Metallic Glass Matrix Composite. Crystals 2022, 12, 284. https://doi.org/10.3390/cryst12020284

Zhou F, Du C, Du Z, Gao G, Cheng C, Wang X. Penetration Gain Study of a Tungsten-Fiber/Zr-Based Metallic Glass Matrix Composite. Crystals. 2022; 12(2):284. https://doi.org/10.3390/cryst12020284

Chicago/Turabian StyleZhou, Feng, Chengxin Du, Zhonghua Du, Guangfa Gao, Chun Cheng, and Xiaodong Wang. 2022. "Penetration Gain Study of a Tungsten-Fiber/Zr-Based Metallic Glass Matrix Composite" Crystals 12, no. 2: 284. https://doi.org/10.3390/cryst12020284

APA StyleZhou, F., Du, C., Du, Z., Gao, G., Cheng, C., & Wang, X. (2022). Penetration Gain Study of a Tungsten-Fiber/Zr-Based Metallic Glass Matrix Composite. Crystals, 12(2), 284. https://doi.org/10.3390/cryst12020284