The Structure of Lenticular Crystals Formed in Plastically Deformed Titanium Nickelide

Abstract

1. Introduction

2. Methodology

3. Experimental Results

4. Discussion of the Results

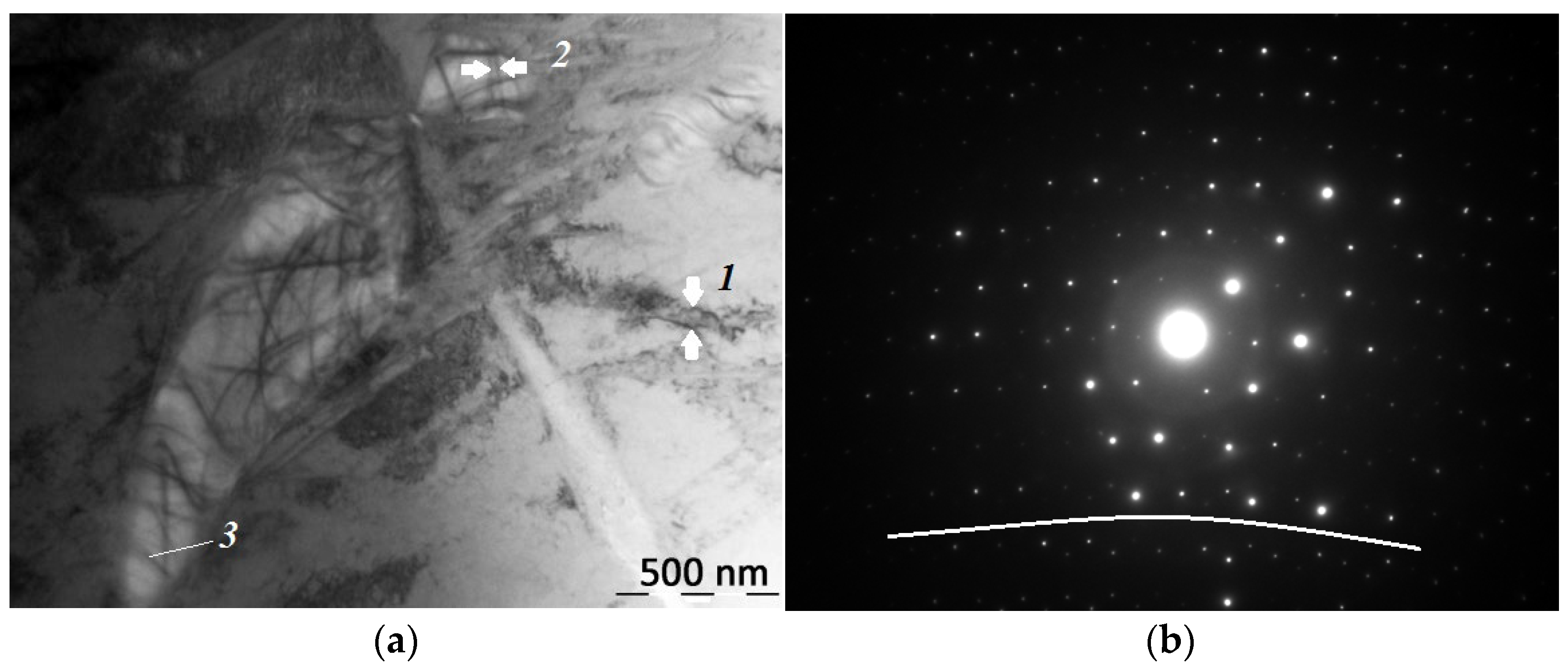

- the presence of areas of local tensile normal stresses, creating increased molar volume, which may occur as local structural transformation (as illustrated as lenticular crystals in the area of the tip of the crack in Figure 2);

5. Conclusions

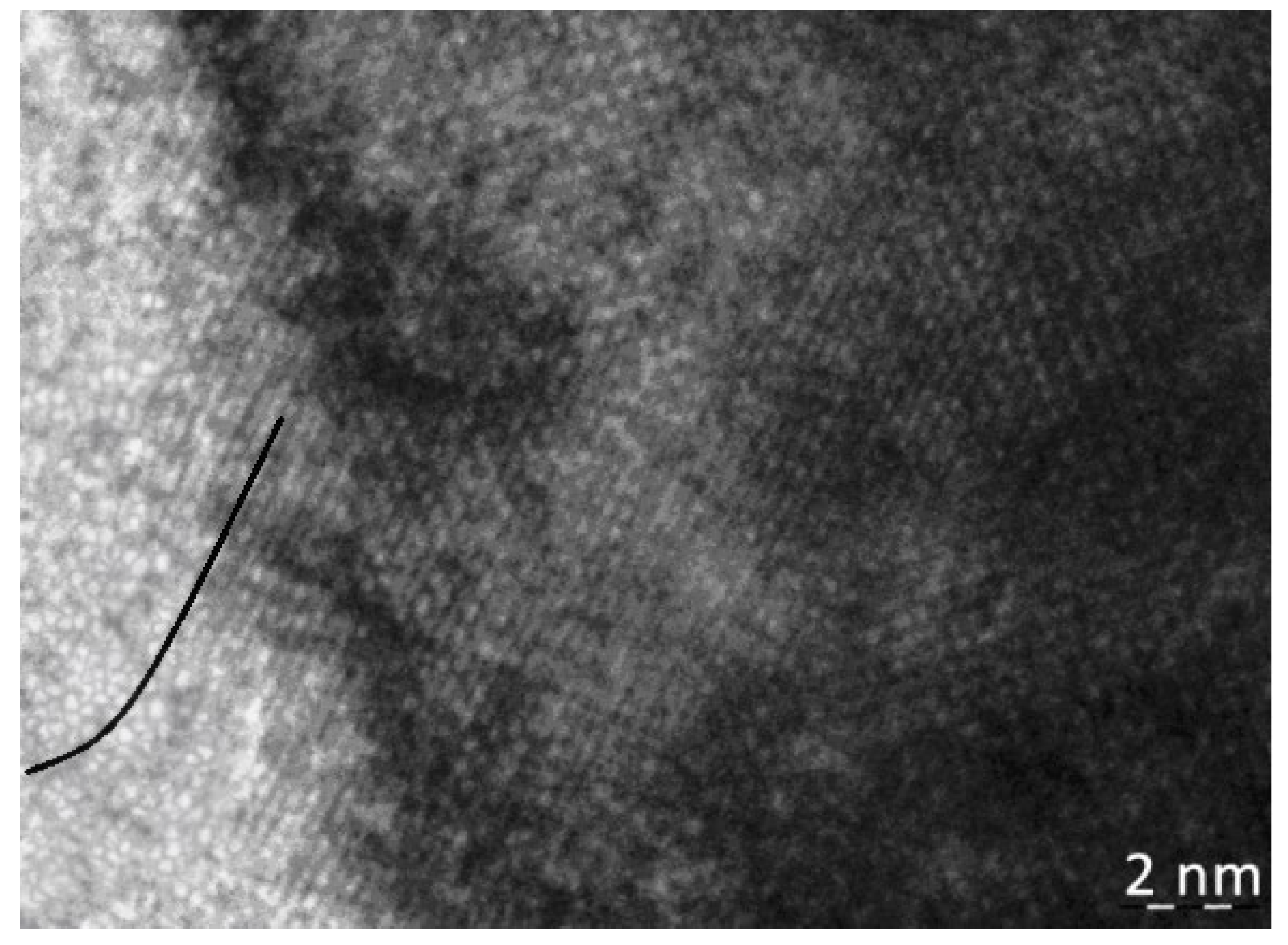

- In titanium nickelide samples subjected to plastic deformation, lenticular crystals of the Ni2Ti3 phase containing bend–extinction contours were found, indicating significant internal stresses in localized areas.

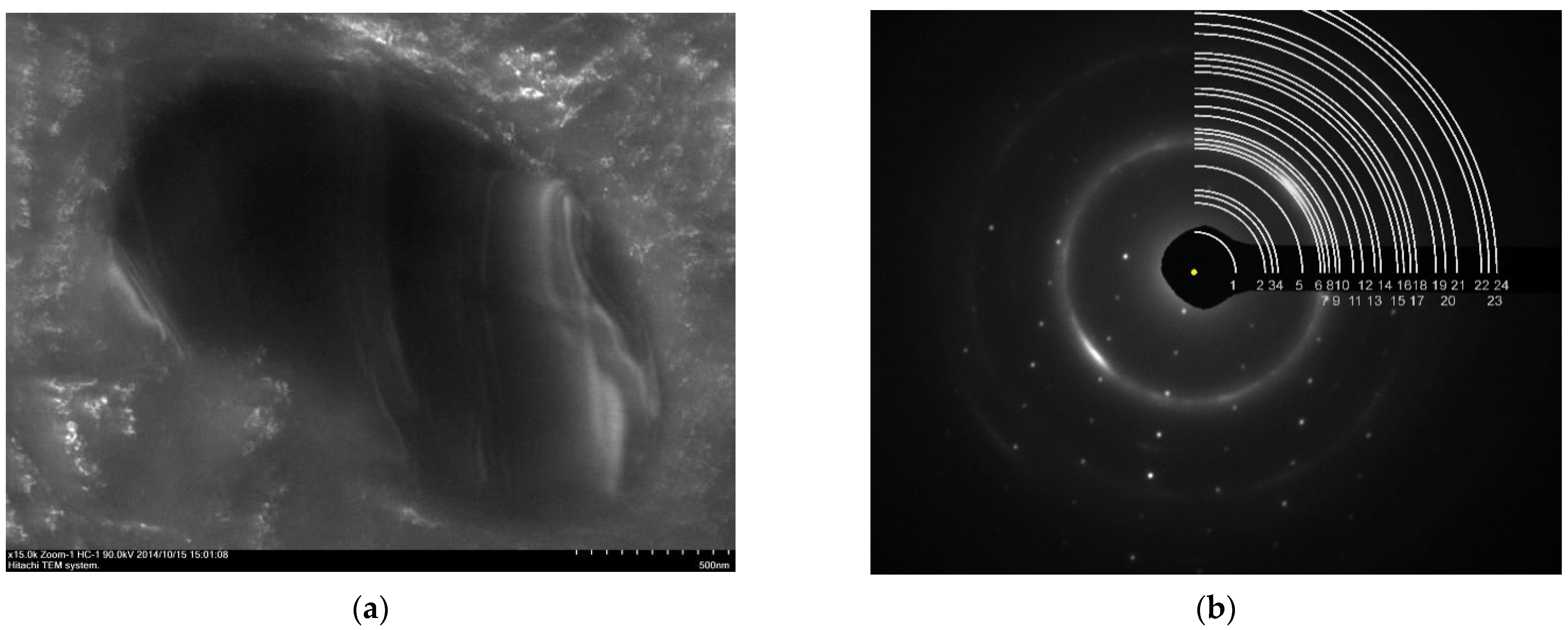

- The crystal structure of lenticular crystals Ni2Ti3 is in a phase having a spinel structural type with a crystal lattice parameter of 11.53 ± 0.03 Å.

- The studied Ni51Ti49 alloy samples that have undergone plastic deformation have a significant magnetization caused by the growth of a new ferromagnetic phase Ni2Ti3.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Likhachev, V.A.; Kuzmin, S.L.; Kamentsova, Z.P. The Shape Memory Effect; LSU: Leningrad, Russia, 1987; p. 216. [Google Scholar]

- Gunter, V.E.; Khodorenko, V.N.; Yasenchuk, Y.F. Titanium Nickelide. New Generation Medical Material; MIT: Tomsk, Russia, 2006; p. 296. [Google Scholar]

- Malygin, G.A. Diffuse martensitic transitions and the plasticity of crystals with a shape memory effect. Phys.-Uspekhi 2001, 44, 173. [Google Scholar] [CrossRef]

- Potekaev, A.I.; Klopotov, A.A.; Kozlov, E.V.; Kulagina, V.V. Weakly Stable Pre-Transition Structures in Titanium Nickelide; Publishing House of NTL: Tomsk, Russia, 2004; p. 296. [Google Scholar]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Otsuka, K.; Suzuki, Y.; Shimizu, K. Alloys with Shape Memory Effect; Metallurgiya: Moscow, Russia, 1990; p. 224. [Google Scholar]

- Zel’Dovich, V.; Sobyanina, G.; Novoselova, T.V. Martensitic transformations in TiNi alloys with Ti3Ni4 precipitates. J. Phys. 1997, 7, 299–304. [Google Scholar] [CrossRef][Green Version]

- Bataillard, L.; Bidaux, J.-E.; Gotthardt, R. Interaction between microstructure and multiple-step transformation in binary NiTi alloys using in-situ transmission electron microscopy observations. Philos. Mag. A 1998, 78, 327–344. [Google Scholar] [CrossRef]

- Khalil-Allafi, J.; Dlouhy, A.; Eggeler, G. Ni4Ti3-precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations. Acta Mater. 2002, 50, 4255–4274. [Google Scholar] [CrossRef]

- Filip, P.; Mazanec, K. On precipitation kinetics in TiNi shape memoryalloys. Scr. Mater. 2001, 45, 701–707. [Google Scholar] [CrossRef]

- Tirry, W.; Schryvers, D.; Jorissen, K.; Lamoen, D. Electron-diffraction structure refinement of Ni4Ti3 precipitates in Ni52Ti48. Acta Crystallogr. 2006, 62, 966–971. [Google Scholar] [CrossRef]

- Li, Z.Q.; Sun, Q.P. The initiation and growth of macroscopic martensite band in nano-grained NiTi microtube under tension. Int. J. Plast. 2002, 18, 1481–1498. [Google Scholar] [CrossRef]

- Efstathiou, C.; Sehitoglu, H. Local transformation strain measurements in precipitated NiTi single crystals. Scr. Mater. 2008, 59, 1263–1266. [Google Scholar] [CrossRef]

- Klopotov, A.A.; Gunter, V.E.; Marchenko, E.S.; Yasenchuk, Y.F.; Klopotov, V.D.; Kozlov, E.V. Crystallogeometry of structures in Ti-Ni, Ti-Fe and Ti-Ni-Fe systems. Fundam. Probl. Mod. Mater. Sci. 2009, 6, 81–90. [Google Scholar]

- Tadaki, T.; Nakata, Y.; Shimizu, K.; Otsuka, K. Crystal Structure, Composition and Morphology of a Precipitate in an aged Ti-51 at%Ni Shape Memory Alloy. Trans. Jpn. Inst. Met. 1986, 27, 731–740. [Google Scholar] [CrossRef]

- Nishida, M.; Wayman, C.M.; Honma, T. Precipitation processes in near-equiatomic TiNi shape memory alloys. Met. Trans. 1986, 17, 1505–1515. [Google Scholar] [CrossRef]

- Nishida, M.; Wayman, C.M. Electron microscopy studies of precipitation processes in near-aquiatomic TiNi shape memory alloys. Mater. Sci. Eng. 1987, 93, 191–203. [Google Scholar] [CrossRef]

- Plotnikov, V.A. Acoustic Energy Dissipation During Thermoelastic Martensitic Transformations in Titanium Nickelide-Based Alloys: Monograph; Publishing House AGU: Barnaul, Russia, 2013; p. 204. [Google Scholar]

- Kolosov, V.Y.; Thölén, A.R. Transmission electron microscopy studies of the specific structure of crystals formed by phase transition in iron oxide amorphous films. Acta Mater. 2000, 48, 1829–1840. [Google Scholar] [CrossRef]

- Bagmut, A.G. Electron Microscopy of Films Deposited by Laser Evaporation; Publishing House NTU “KhPI”: Kharkiv, Russia, 2014; p. 304. [Google Scholar]

- Kveglis, L.I. Structure Formation in Amorphous and Nanocrystalline Films of Alloys Based on Transition Metals: Dissertation. Ph.D. Thesis, Kirensky Institute of Physics, Krasnoyarsk, Russia, 2005; p. 280. [Google Scholar]

- Bolotov, I.E.; Kolosov, V.Y. Electron microscope investigation of crystals based on bend-contour arrangement. I. Relationship between bend contour arrangement and bend geometry. Phys. Status Solidi A 1982, 69, 85–96. [Google Scholar] [CrossRef]

- Korotaev, A.D.; Tyumentsev, A.N.; Sukhovarov, V.F. Dispersion Hardening of Refractory Metals; Nauka: Novosibirsk, Russia, 1989; p. 210. [Google Scholar]

- Abylkalykova, R.B.; Tazhibaeva, G.B.; Noskov, F.M.; Kveglis, L.I. The features of the martensitic transformation in titanium nickelide. Bull. Russ. Acad. Sci. Phys. 2009, 73, 1542–1544. [Google Scholar] [CrossRef]

- Kveglis, L.I.; Noskov, F.M.; Volochaev, M.N.; Nyavro, A.V.; Filarowski, A. Magnetic Properties of Nickel-Titanium Alloy during Martensitic Transformations under Plastic and Elastic Deformation. Symmetry 2021, 13, 665. [Google Scholar] [CrossRef]

- Yener, T.; Siddique, S.; Walther, F.; Zeytin, S. Effect of electric current on the production of NiTi intermetallics via electric-current-activated sintering. MTAEC9 Mater. Technol. 2015, 49, 721–724. [Google Scholar] [CrossRef]

- Ergin, N.; Ozdemir, O. An Investigation on TiNi Intermetallic Produced by Electric Current Activated Sintering. Acta Phys. Pol. A 2013, 123, 248–249. [Google Scholar] [CrossRef]

- Xinxin, C.; Liqun, M.; Meng, Y.; Xiangyu, Z.; Yi, D. Electrochemical Properties of the Amorphous Ti3Ni2 Alloy in Ni/MH Batteries. Rare Met. Mater. Eng. 2012, 41, 1511–1515. [Google Scholar] [CrossRef]

- Han, X.; Zou, W.; Wang, R.; Jin, S.; Zhang, Z.; Li, T.; Yang, D. Microstructure of TiNi shape-memory alloy synthesized by explosive shock-wave compression of Ti-Ni powder mixture. J. Mater. Sci. 1997, 32, 4723–4729. [Google Scholar] [CrossRef]

- Bahador, A.; Hamzah, E.; Kondoh, K.; Abubakar, T.A.; Yusof, F.; Umeda, J.; Saud, S.; Ibrahim, M.K. Microstructure and superelastic properties of free forged Ti-Ni shape-memory alloy. Trans. Nonferrous Met. Soc. China 2018, 28, 502–514. [Google Scholar] [CrossRef]

- Panin, V.E.; Egorushkin, V.E. Fundamentals of physical mesomechanics of plastic deformation and destruction of solids as nonlinear hierarchically organized systems. Phys. Mesomech. 2015, 18, 100–113. [Google Scholar] [CrossRef]

- Panin, V.E.; Egorushkin, V.E.; Derevyagina, L.S.; Deryugin, E.E. Nonlinear wave processes of crack propagation in brittle and brittle-ductile fracture. Phys. Mesomech. 2013, 16, 183–190. [Google Scholar] [CrossRef]

- Moiseenko, D.D.; Pochivalov, Y.I.; Maksimov, P.V.; Panin, V.E. Rotational deformation modes in near-boundary regions of grain structure in a loaded polycrystal. Phys. Mesomech. 2013, 16, 248–258. [Google Scholar] [CrossRef]

- Gorelik, S.S.; Skakov, Y.A.; Rastorguev, L.N. X-ray and Electron-Optical Analysis; MISIS: Moscow, Russia, 1994; p. 328. [Google Scholar]

- Yurko, G.A.; Barton, J.W.; Parr, J.G. The crystal structure of Ti2Ni. Acta Crystallogr. 1959, 12, 909–911. [Google Scholar] [CrossRef]

- Lipson, H.; Parker, A.M.B. Structure of Martensite. J. Iron Steel Inst. 1944, 149, 123–141. [Google Scholar]

- Pushin, V.G.; Kondratiev, V.V.; Khachin, V.N. Pre-Transition Phenomena and Martensitic Transformations; Ural Branch of the Russian Academy of Sciences: Yekaterinburg, Russia, 1998; p. 367. [Google Scholar]

- Surikova, N.S. Regularities and Mechanisms of Plastic Deformation and Structural-Phase Transformations in Single Crystals of TiNi(Fe, Mo) and TiNi(Fe) Alloys: Dissertation. Ph.D. Thesis, Tomsk State University, Tomsk, Russia, 2011; p. 343. [Google Scholar]

- Kornev, V.M. On diagrams of destruction of bodies with short macro cracks. Embrittlement of the material during fatigue failure. Phys. Mesomech. 2016, 19, 80–99. [Google Scholar]

- Abylkalykova, R.B.; Kveglis, L.I.; Kalitova, A.A.; Noskov, F.M. Abnormally Fast Migration of Substance at Shock Loadings. Adv. Mater. Res. 2013, 871, 231–234. [Google Scholar] [CrossRef]

| at.% | Area 1 | Area 2 |

|---|---|---|

| Ni | 51.3 | 41.7 |

| Ti | 48.7 | 58.3 |

| Line Number | d, Å | Matrix B2, hkl (Δd, Å) | Indexes of the Orientation [110] Spinel Structure, hkl (Δd, Å) |

|---|---|---|---|

| 1. | 6,65 | 111 (0,00) | |

| 2. | 5,61 | 200 (+0,15); ½20 (−0,03) | |

| 3. | 4,05 | 220 (+0,02) | |

| 4. | 3,38 | 311 (+0,11) | |

| 5. | 2,85 | 400 (+0,03) | |

| 6. | 2,62 | 331 (+0,02) | |

| 7. | 2,34 | 422 (+0,01) | |

| 8. | 2,22 | 511 (0,00) | |

| 9. | 2,12 | 110 (0,00) | |

| 10. | 2,01 | 440 (+0,02) | |

| 11. | 1,91 | 442 (+0,01) | |

| 12. | 1,71 | 533 (+0,05) | |

| 13. | 1,65 | 444 (+0,01) | |

| 14. | 1,59 | 551 (+0,02) | |

| 15. | 1,49 | 553 (+0,01) | |

| 16. | 1,40 | 644 (0,00) | |

| 17. | 1,33 | 751(0,00) | |

| 18. | 1,23 | 211 (0,00) | 911 (+0,03) |

| 19. | 1,15 | 933(+0,01) | |

| 20. | 1,09 | 10 4 0 (−0,02) | |

| 21. | 1,07 | 220(−0,01) | 10 4 2 (−0,02) |

| 22. | 0,99 | 10 6 0 (0,00) |

| Line Number | d, Å | Matrix B2, hkl (Δd, Å) | Indexes of the Orientation [110] Spinel Structure, hkl (Δd, Å) |

|---|---|---|---|

| 1. | 6,67 | 111 (0,00) | |

| 2. | 3,91 | 220 (+0,17); 221 (−0,06) | |

| 3. | 3,53 | 311 (−0,05) | |

| 4. | 3,31 | 222 (+0,02) | |

| 5. | 2,56 | 331 (+0,09) | |

| 6. | 2,19 | 511 (+0,03) | |

| 7. | 2,12 | 110 (0,00) | |

| 8. | 2,04 | 440 (0,00) | |

| 9. | 1,95 | 531 (0,00) | |

| 10. | 1,90 | 442 (−0,03) | |

| 11. | 1,74 | 533 (+0,02) | |

| 12. | 1,64 | 444 (+0,03) | |

| 13. | 1,53 | 642 (+0,01) | |

| 14. | 1,48 | 200(+0,03) | |

| 15. | 1,36 | 660 (0,00) | |

| 16. | 1,32 | 751 (+0,01) | |

| 17. | 1,27 | 911 (0,00) | |

| 18. | 1,24 | 211(−0,01) | |

| 19. | 1,14 | 933 (+0,02) | |

| 20. | 1,10 | 10 4 0 (−0,03) | |

| 21. | 1,05 | 220(+0,01) | |

| 22. | 0,96 | 971(+0,06) | |

| 23. | 0,94 | 10 6 0 (+0,05) | |

| 24. | 0,91 | 10 6 2 (+0,07) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noskov, F.M.; Kveglis, L.I.; Abkaryan, A.K.; Sakenova, R.Y. The Structure of Lenticular Crystals Formed in Plastically Deformed Titanium Nickelide. Crystals 2022, 12, 145. https://doi.org/10.3390/cryst12020145

Noskov FM, Kveglis LI, Abkaryan AK, Sakenova RY. The Structure of Lenticular Crystals Formed in Plastically Deformed Titanium Nickelide. Crystals. 2022; 12(2):145. https://doi.org/10.3390/cryst12020145

Chicago/Turabian StyleNoskov, Fedor M., Ludmila I. Kveglis, Artur K. Abkaryan, and Rimma Y. Sakenova. 2022. "The Structure of Lenticular Crystals Formed in Plastically Deformed Titanium Nickelide" Crystals 12, no. 2: 145. https://doi.org/10.3390/cryst12020145

APA StyleNoskov, F. M., Kveglis, L. I., Abkaryan, A. K., & Sakenova, R. Y. (2022). The Structure of Lenticular Crystals Formed in Plastically Deformed Titanium Nickelide. Crystals, 12(2), 145. https://doi.org/10.3390/cryst12020145