Effect of Short-Range Ordering on the Grain Boundary Character Distribution Optimization of FCC Metals with High Stacking Fault Energy: A Case Study on Ni-Cr Alloys

Abstract

:1. Introduction

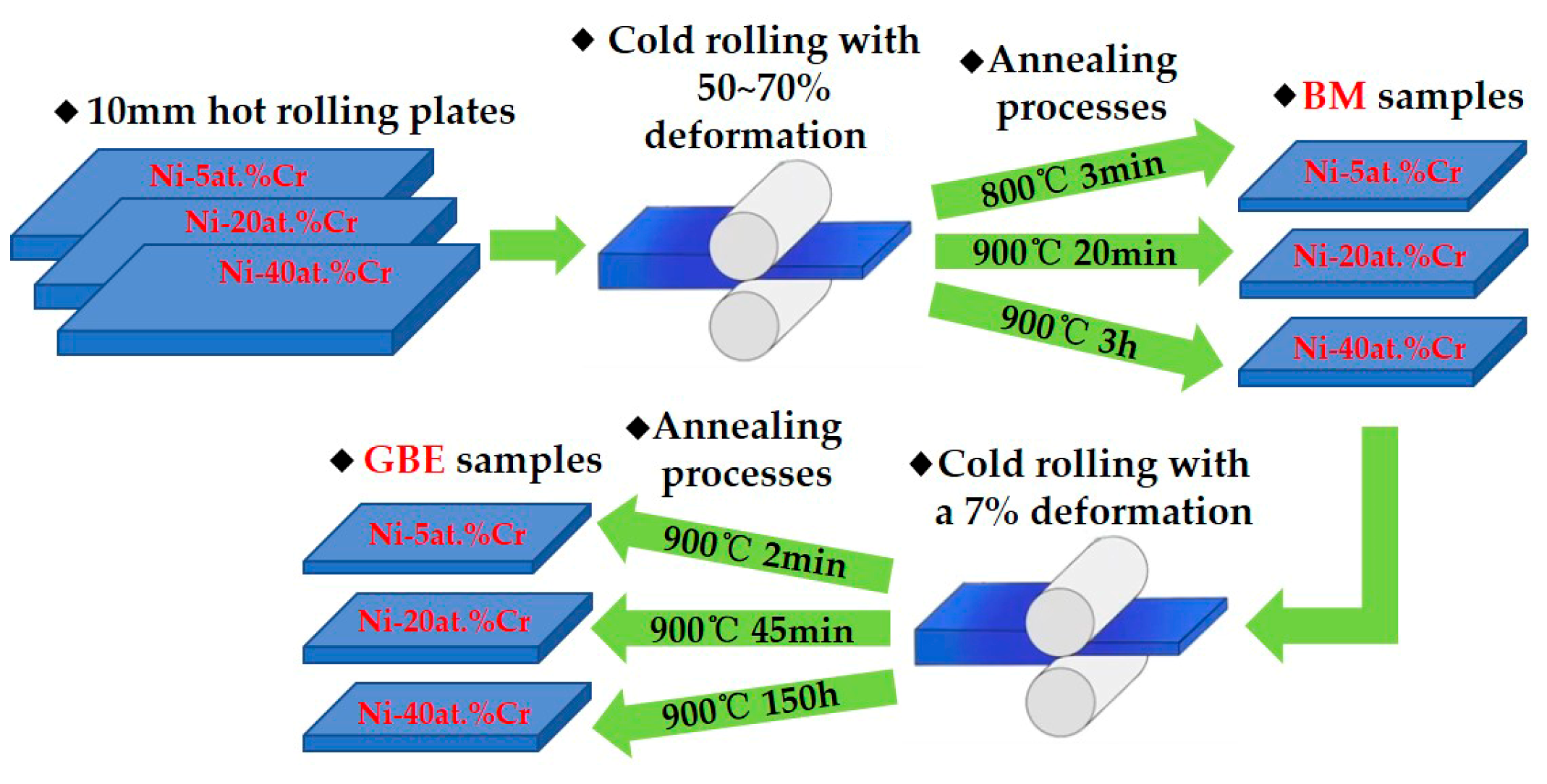

2. Materials and Methods

3. Results

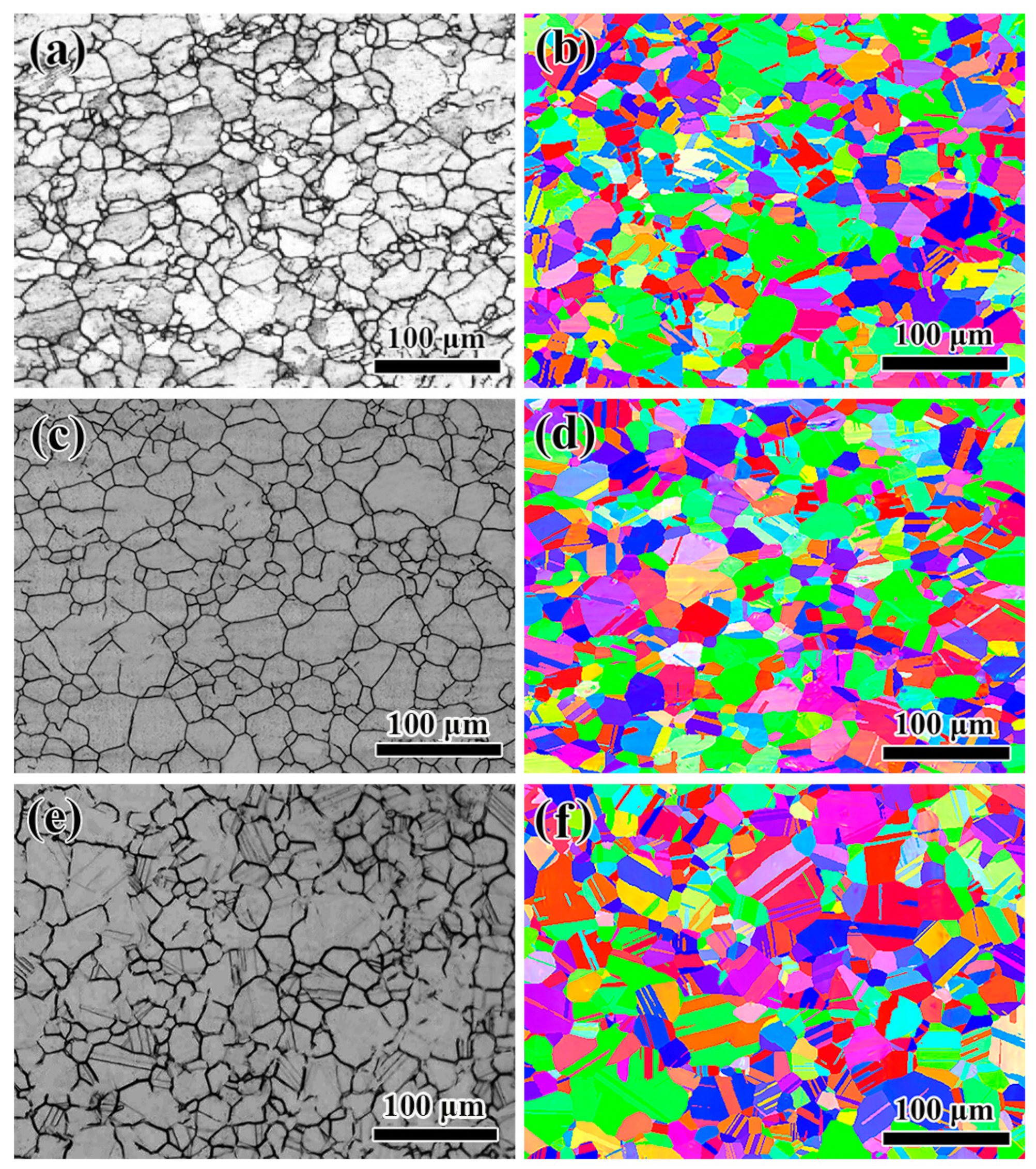

3.1. Microstructures of BM Samples

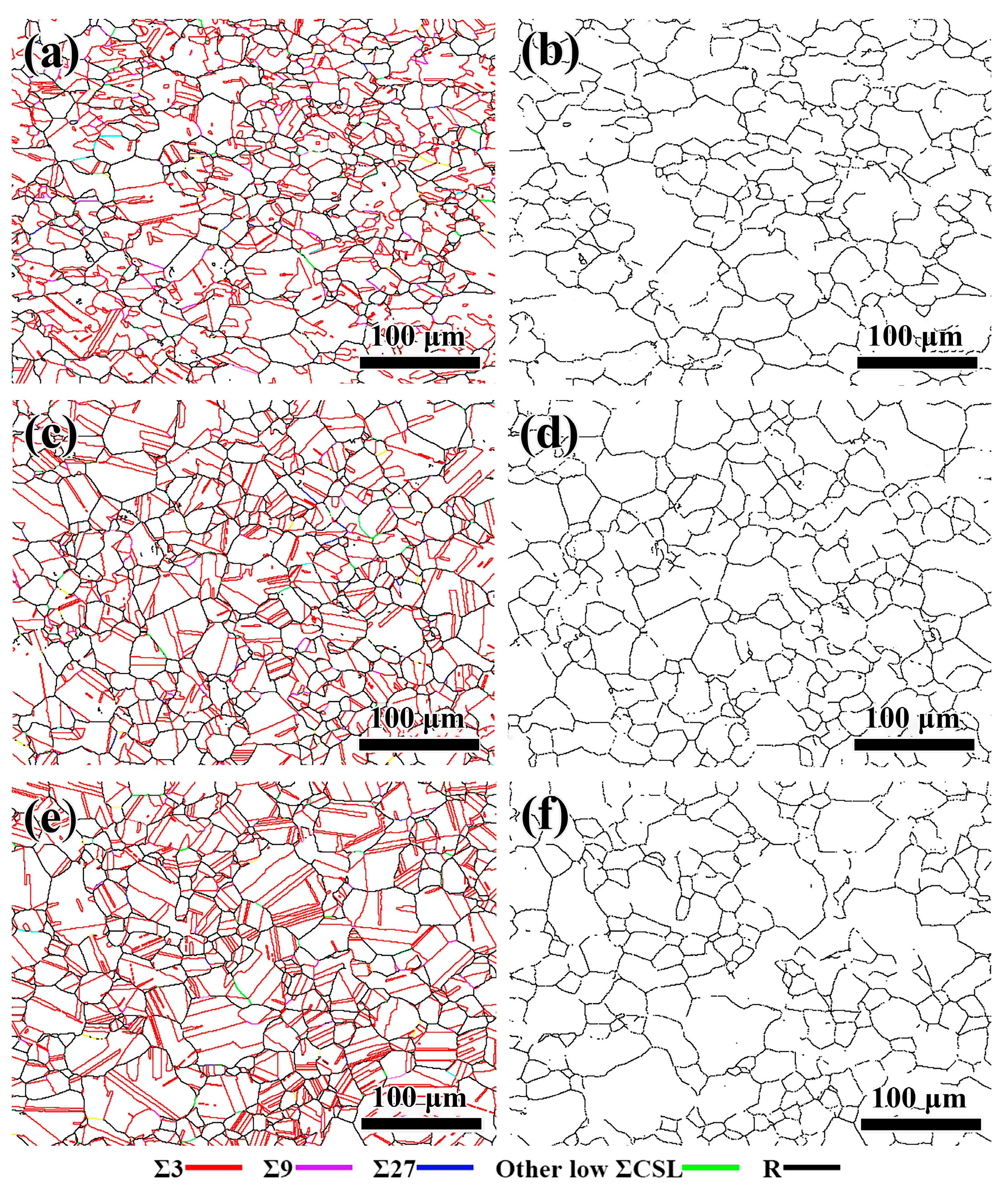

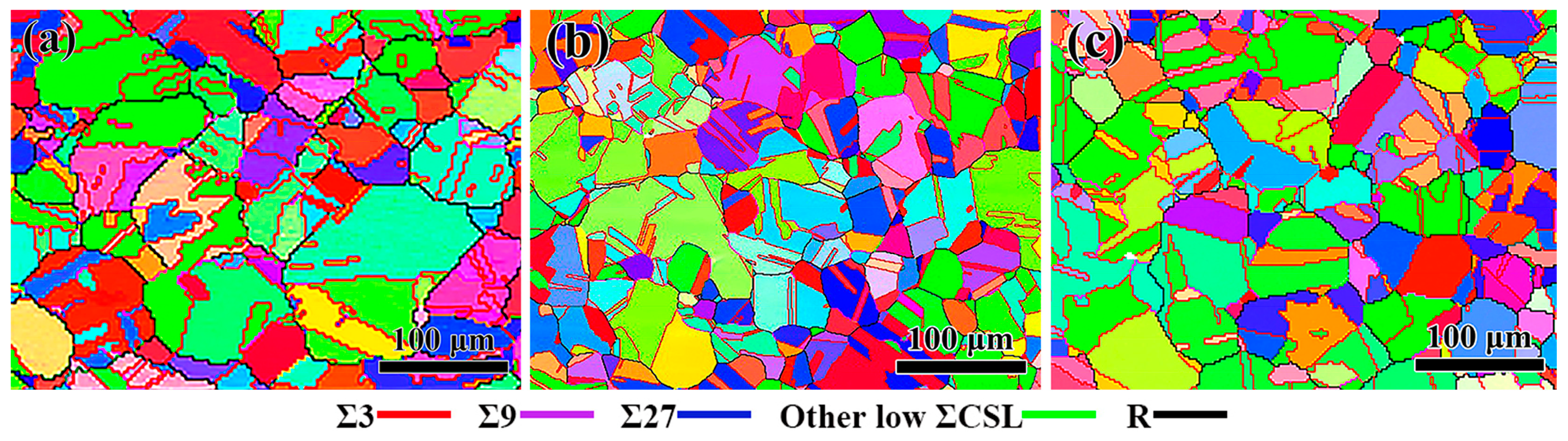

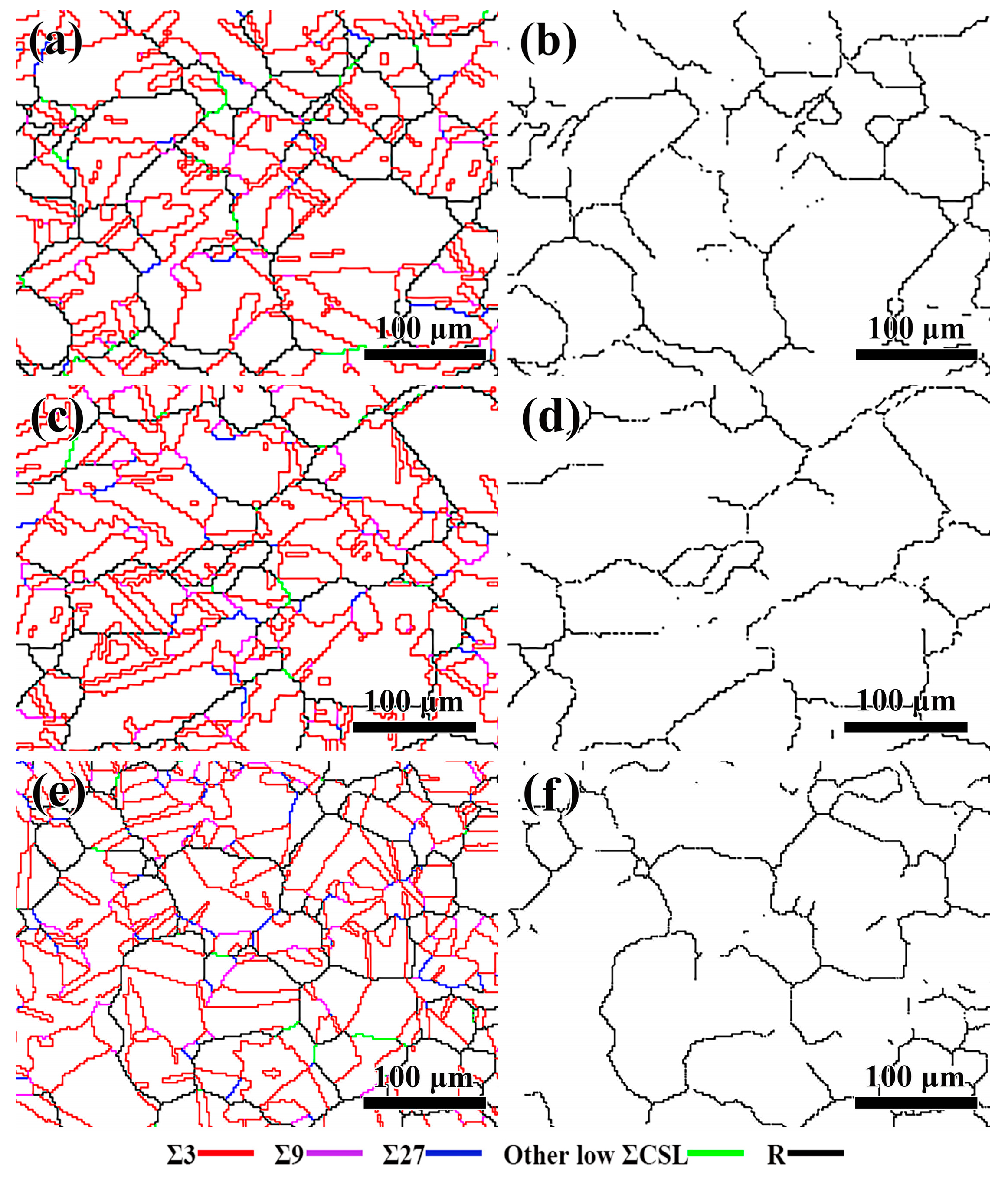

3.2. Microstructure of TMPed Samples

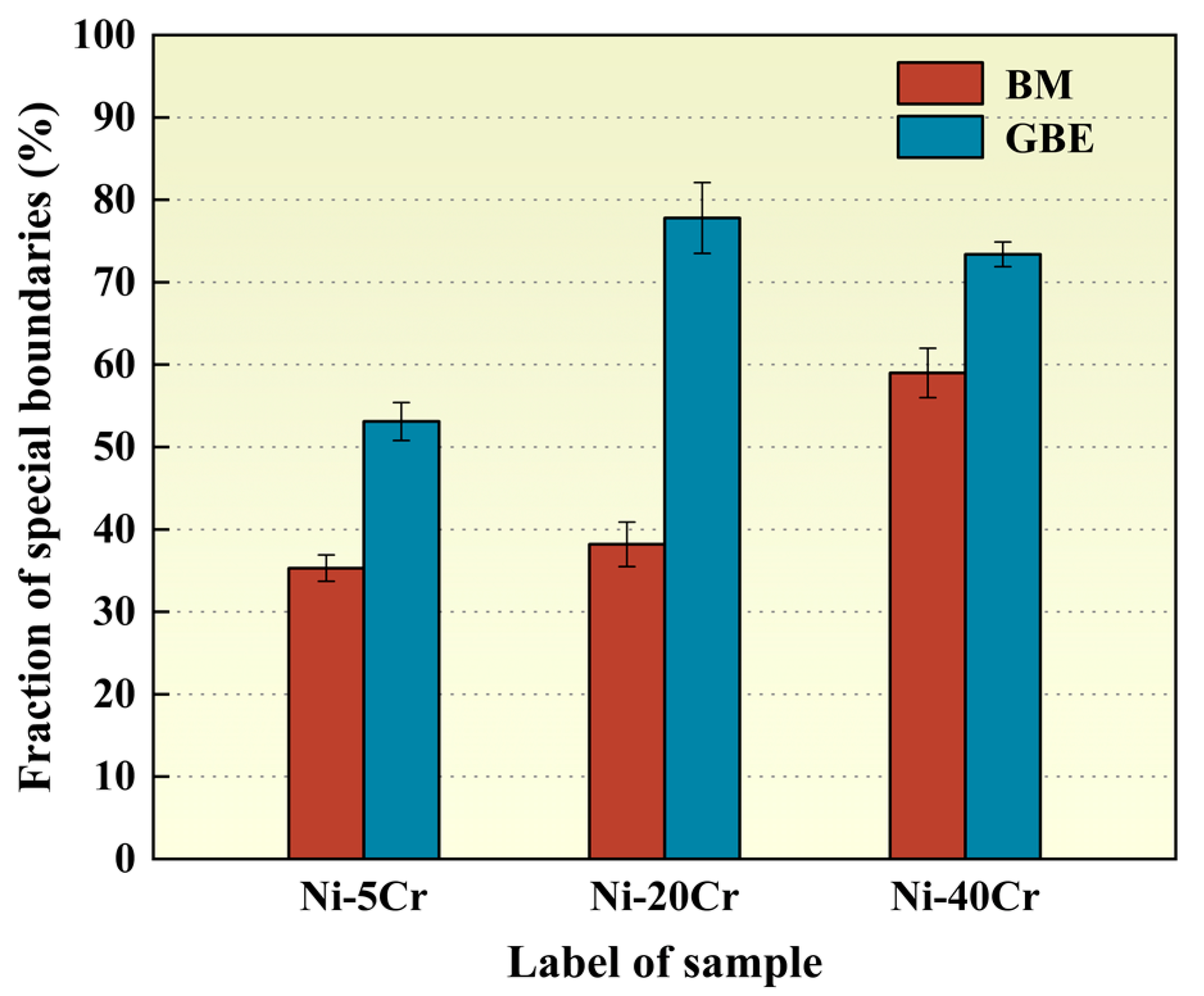

3.3. Comparison of GBE Quantifying Parameters

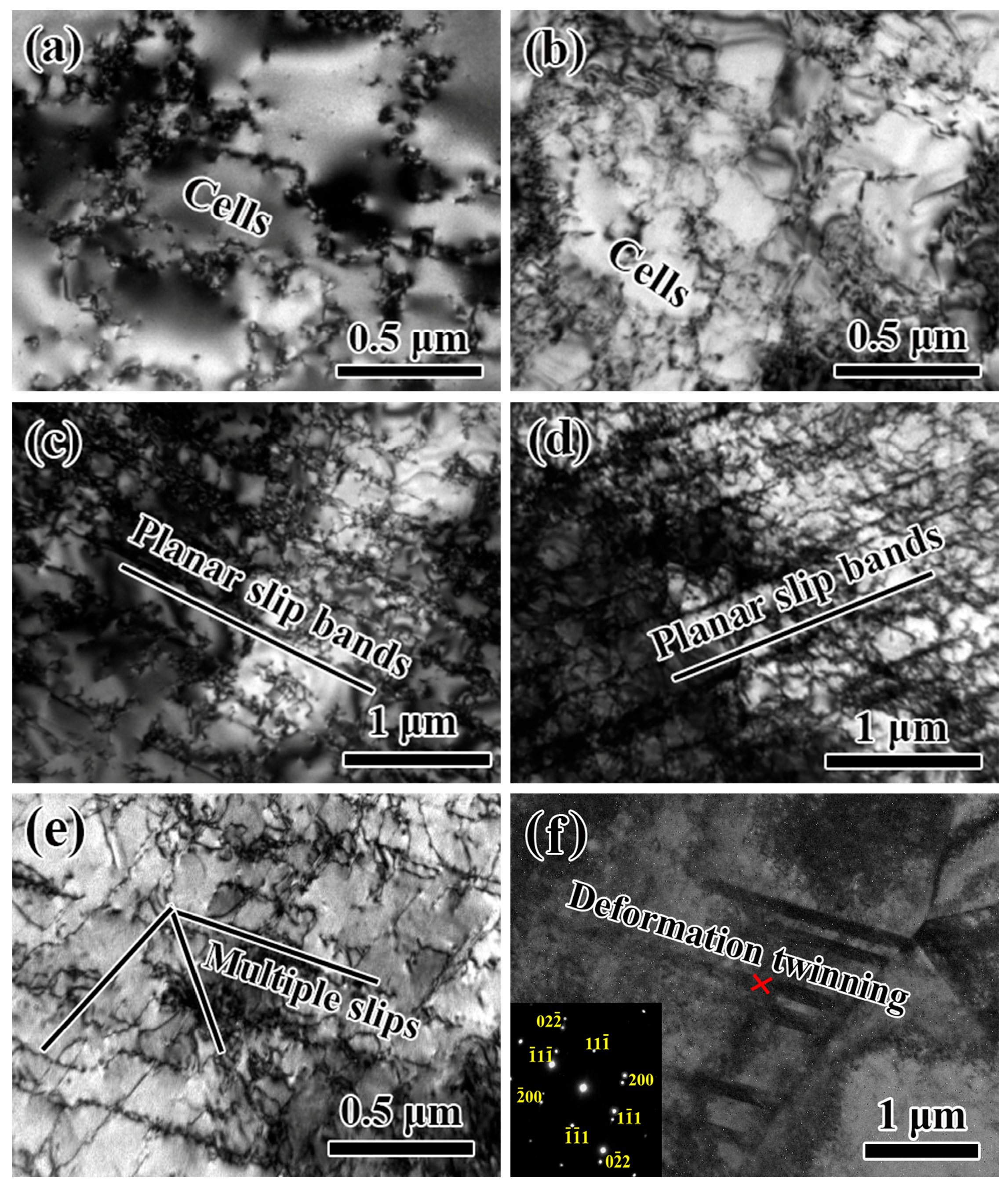

3.4. Deformation Microstructures of Cold-Rolled Ni-Cr Alloys

4. Discussion

4.1. Influence of SRO on Dislocation Slip Mode

4.2. Influence of Planar Slip on GBCD Optimization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kobayashi, S.; Kobayashi, R.; Watanabe, T. Control of grain boundary connectivity based on fractal analysis for improvement of intergranular corrosion resistance in SUS316L austenitic stainless steel. Acta Mater. 2016, 102, 397–405. [Google Scholar] [CrossRef]

- Liu, T.G.; Xia, S.; Du, D.H.; Bai, Q.; Zhang, L.F.; Lu, Y.H. Grain boundary engineering of large-size 316 stainless steel via warm-rolling for improving resistance to intergranular attack. Mater. Lett. 2019, 234, 201–204. [Google Scholar] [CrossRef]

- Telang, A.; Gill, A.S.; Kumar, M.; Teysseyre, S.; Qian, D. Iterative thermomechanical processing of alloy 600 for improved resistance to corrosion and stress corrosion cracking. Acta Mater. 2016, 113, 180–193. [Google Scholar] [CrossRef] [Green Version]

- Guan, X.J.; Shi, F.; Ji, H.M.; Li, X.W. A possibility to synchronously improve the high-temperature strength and ductility in face-centered cubic metals through grain boundary engineering. Scr. Mater. 2020, 187, 216–220. [Google Scholar] [CrossRef]

- Guan, X.J.; Jia, Z.P.; Liang, S.M.; Shi, F.; Li, X.W. A pathway to improve low-cycle fatigue life of face-centered cubic metals via grain boundary engineering. J. Mater. Sci. Technol. 2022, 113, 82–89. [Google Scholar] [CrossRef]

- Shimada, M.; Kokawa, H.; Wang, Z.J.; Sato, Y.S.; Karibe, I. Optimization of grain boundary character distribution for intergranular corrosion resistant 304 stainless steel by twin-induced grain boundary engineering. Acta Mater. 2002, 50, 2331–2341. [Google Scholar] [CrossRef]

- Lehockey, E.M.; Brennenstuhl, A.M.; Thompson, I. On the relationship between grain boundary connectivity, coincident site lattice boundaries, and intergranular stress corrosion cracking. Corros. Sci. 2004, 46, 2383–2404. [Google Scholar] [CrossRef]

- Barr, C.M.; Leff, A.C.; Demott, R.W.; Doherty, R.D.; Taheri, M.L. Unraveling the origin of twin related domains and grain boundary evolution during grain boundary engineering. Acta Mater. 2018, 144, 281–291. [Google Scholar] [CrossRef]

- Guan, X.J.; Shi, F.; Ji, H.M.; Li, X.W. Gain boundary character distribution optimization of Cu-16at.%Al alloy by thermomechanical process: Critical role of deformation microstructure. Mater. Sci. Eng. A 2019, 765, 138299. [Google Scholar] [CrossRef]

- Guan, X.J.; Shi, F.; Jia, Z.P.; Li, X.W. Grain boundary engineering of AL6XN super-austenitic stainless steel: Distinctive effects of planar-slip dislocations and deformation twins. Mater. Charact. 2020, 170, 110689. [Google Scholar] [CrossRef]

- Han, D.; Wang, Z.Y.; Yan, Y.; Shi, F.; Li, X.W. A good strength-ductility match in Cu-Mn alloys with high stacking fault energies: Determinant effect of short range ordering. Scr. Mater. 2017, 133, 59–64. [Google Scholar] [CrossRef]

- Han, D.; Zhang, Y.J.; Li, X.W. A crucial impact of short-range ordering on the cyclic deformation and damage behavior of face-centered cubic alloys: A case study on Cu-Mn alloys. Acta Mater. 2021, 205, 116559. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Han, D.; Li, X.W. A unique two-stage strength-ductility match in low solid-solution hardening Ni-Cr alloys: Decisive role of short range ordering. Scr. Mater. 2020, 178, 269–273. [Google Scholar] [CrossRef]

- Gerold, V.; Karnthaler, H.P. On the origin of planar slip in f.c.c. alloys. Acta Metall. 1989, 37, 2177–2183. [Google Scholar] [CrossRef]

- Pfeiler, W. Investigation of short-range order by electrical resistivity measurement. Acta Metall. 1988, 36, 2417–2434. [Google Scholar] [CrossRef]

- Clément, N.; Coulomb, P. Energies de défaut d’empilement et mécanismes de déformation dans les alliages nickel-chrome. Philos. Mag. A 1974, 30, 663–672. [Google Scholar] [CrossRef]

- Carter, C.B.; Holmes, S.M. The stacking-fault energy of nickel. Philos. Mag. A 2006, 35, 1161–1172. [Google Scholar] [CrossRef]

- Schwander, P.; Schönfeld, B.; Kostorz, G. Configurational energy change caused by slip in short-range ordered Ni-Mo. Phys. Status Solidi B 1992, 172, 73–85. [Google Scholar] [CrossRef]

- Cao, W.; Xia, S.; Bai, Q.; Zhang, W.Z.; Zhou, B.X.; Li, Z.J.; Jiang, L. Effects of initial microstructure on the grain boundary network during grain boundary engineering in Hastelloy N alloy. J. Alloys Compd. 2017, 704, 724–733. [Google Scholar] [CrossRef] [Green Version]

- Grace, F.I.; Inman, M.C. Influence of stacking fault energy on dislocation configurations in shock-deformed metals. Metallography 1970, 3, 89–98. [Google Scholar] [CrossRef]

- Gallagher, P.C.J. The influence of alloying, temperature, and related effects on the stacking fault energy. Metall. Trans. 1970, 1, 2429–2461. [Google Scholar] [CrossRef]

- Wolf, K.; Gudladt, H.J.; Calderon, H.A. Transition between planar and wavy slip in cyclically deformed short-range ordered alloys. Acta Metall. Mater. 1994, 42, 3759–3765. [Google Scholar] [CrossRef]

- Pettinari-Sturmel, F.; Coujou, A.; Clément, N. The fluctuation of short-range order evidenced by mobile dislocations in the γ-phase of a nickel-based superalloy. Mater. Sci. Eng. A 2005, 400, 114–117. [Google Scholar] [CrossRef]

- Han, D.; Guan, X.J.; Yan, Y.; Shi, F.; Li, X.W. Anomalous recovery of work hardening rate in Cu-Mn alloys with high stacking fault energies under uniaxial compression. Mater. Sci. Eng. A 2019, 743, 745–754. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Smith, D.A. On the mechanisms of grain boundary migration. Philos. Mag. A 1980, 41, 477–492. [Google Scholar] [CrossRef]

- Jhan, R.; Bristowe, P.D. A molecular dynamics study of grain boundary migration without the participation of secondary grain boundary dislocations. Scr. Metall. Mater. 1990, 24, 1313–1318. [Google Scholar] [CrossRef]

- Merkle, K.L.; Thompson, L.J.; Phillipp, F. In-situ HREM studies of grain boundary migration. Interface Sci. 2004, 12, 277–292. [Google Scholar] [CrossRef]

- Randle, V. Mechanism of twinning-induced grain boundary engineering in low stacking fault energy materials. Acta Mater. 1999, 47, 4187–4196. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Guan, X.; Zhang, Y.; Jia, Z.; Liang, S.; Li, X. Effect of Short-Range Ordering on the Grain Boundary Character Distribution Optimization of FCC Metals with High Stacking Fault Energy: A Case Study on Ni-Cr Alloys. Crystals 2022, 12, 1822. https://doi.org/10.3390/cryst12121822

Liu Y, Guan X, Zhang Y, Jia Z, Liang S, Li X. Effect of Short-Range Ordering on the Grain Boundary Character Distribution Optimization of FCC Metals with High Stacking Fault Energy: A Case Study on Ni-Cr Alloys. Crystals. 2022; 12(12):1822. https://doi.org/10.3390/cryst12121822

Chicago/Turabian StyleLiu, Yifan, Xianjun Guan, Yanjie Zhang, Zipeng Jia, Simin Liang, and Xiaowu Li. 2022. "Effect of Short-Range Ordering on the Grain Boundary Character Distribution Optimization of FCC Metals with High Stacking Fault Energy: A Case Study on Ni-Cr Alloys" Crystals 12, no. 12: 1822. https://doi.org/10.3390/cryst12121822

APA StyleLiu, Y., Guan, X., Zhang, Y., Jia, Z., Liang, S., & Li, X. (2022). Effect of Short-Range Ordering on the Grain Boundary Character Distribution Optimization of FCC Metals with High Stacking Fault Energy: A Case Study on Ni-Cr Alloys. Crystals, 12(12), 1822. https://doi.org/10.3390/cryst12121822