The Effect of Nb2O5 Precursor on KNN-Based Ceramics’ Piezoelectricity and Strain Temperature Stability

Abstract

1. Introduction

2. Materials and Methods

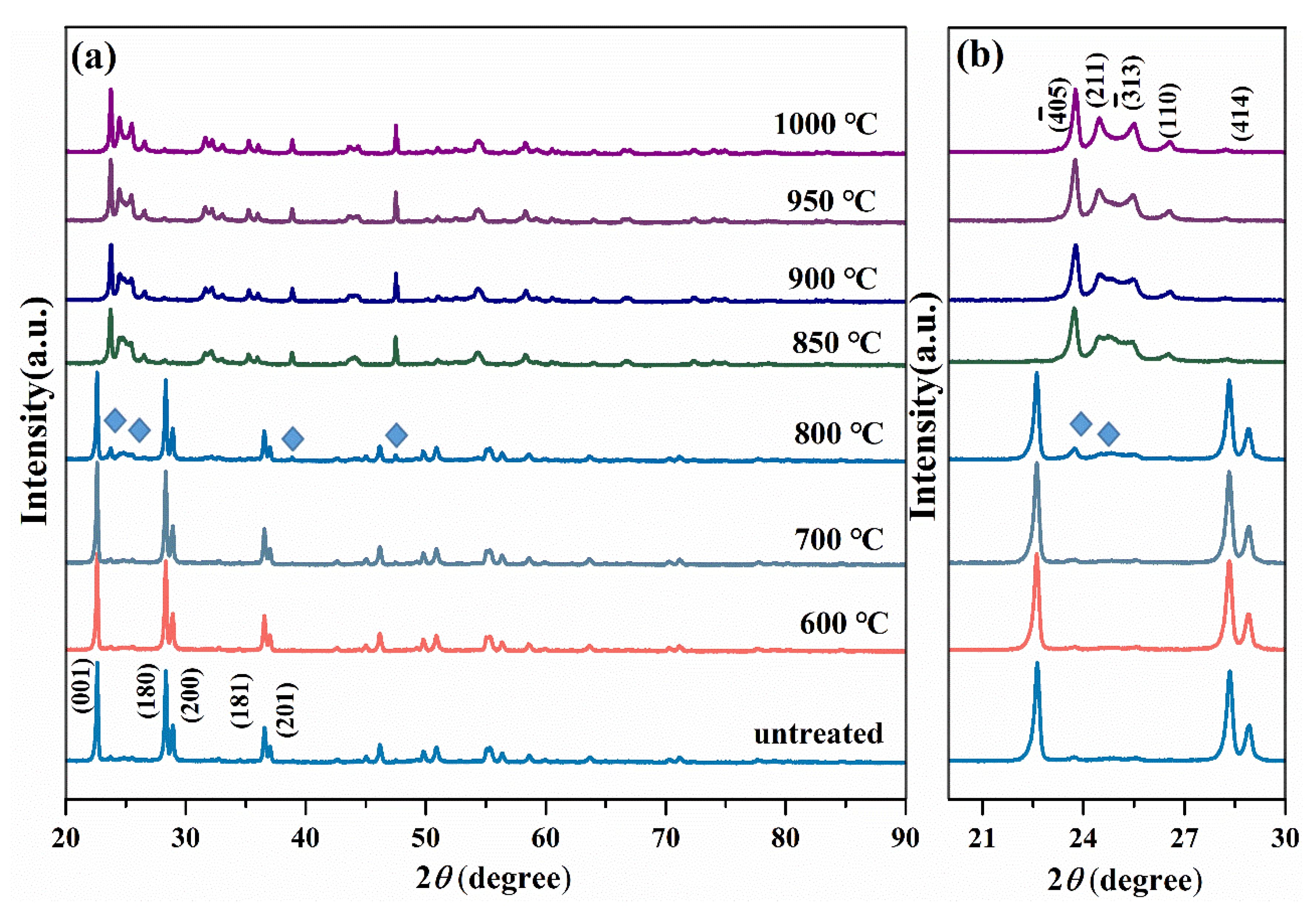

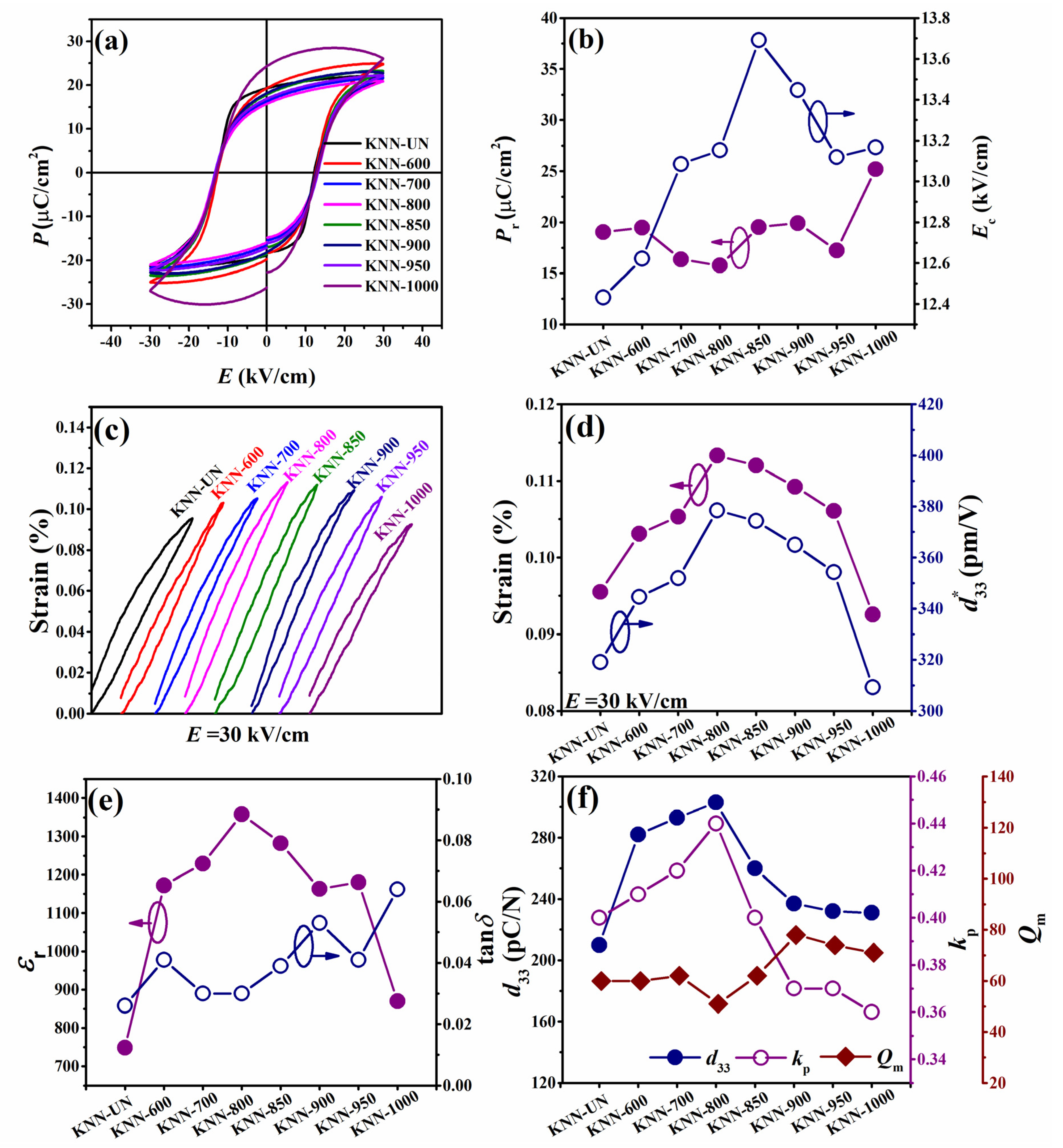

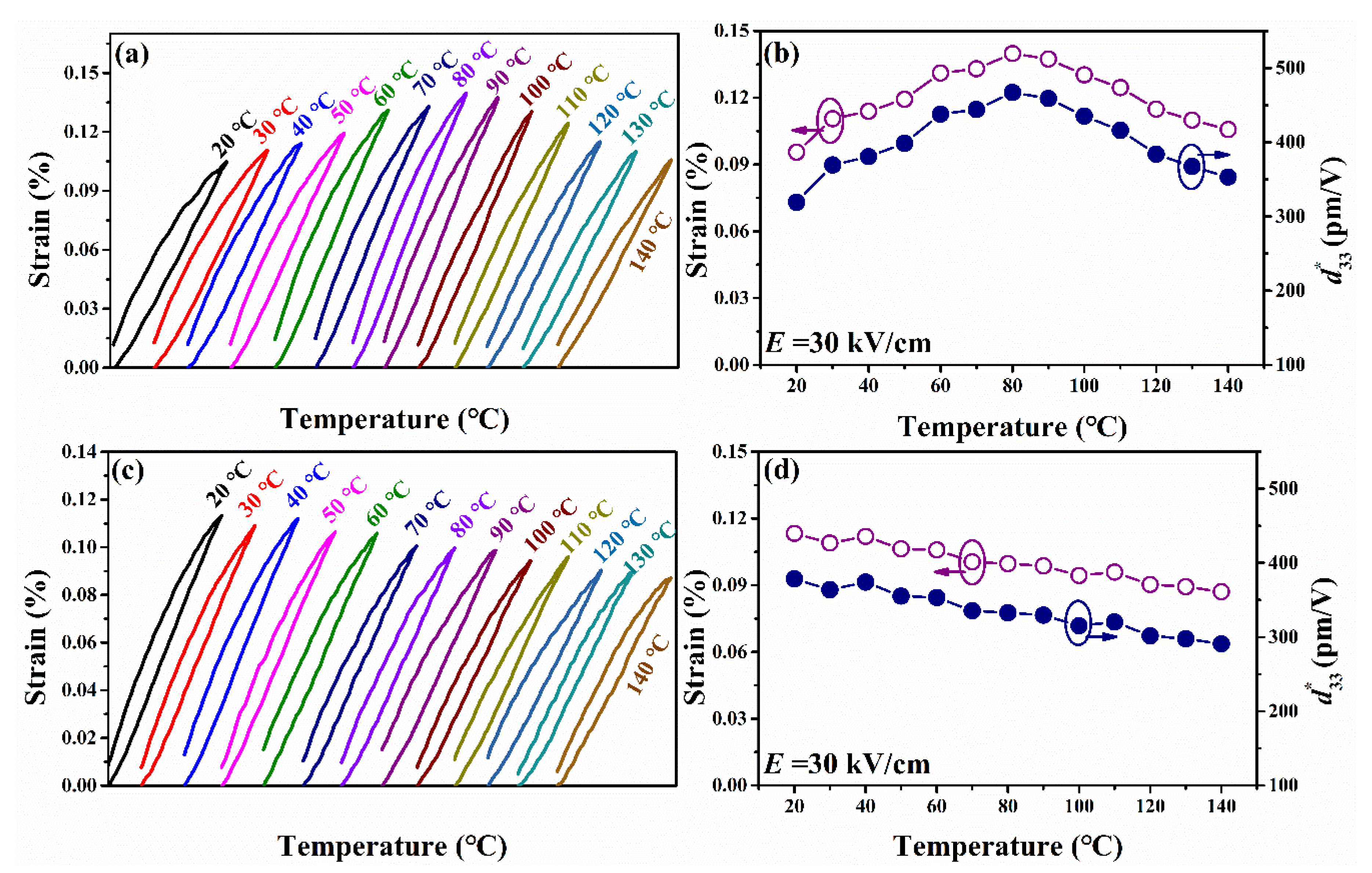

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jaffe, B.; Cook, W.R.; Jaffe, H. Piezoelectric Ceramics; Academic Press: New York, NY, USA, 1971. [Google Scholar]

- Shrout, T.R.; Zhang, S.J. Lead-free piezoelectric ceramics: Alternatives for PZT? J. Electroceram. 2007, 19, 113–126. [Google Scholar] [CrossRef]

- Zhao, C.; Huang, Y.; Wu, J. Multifunctional barium titanate ceramics via chemical modification tuning phase structure. Info. Mat. 2020, 2, 1163–1190. [Google Scholar] [CrossRef]

- Zhou, C.; Zhang, J.; Yao, W.; Liu, D.; He, G. Remarkably strong piezoelectricity, rhombohedral-orthorhombic-tetragonal phase coexistence and domain structure of (K,Na)(Nb,Sb)O3-(Bi,Na)ZrO3-BaZrO3 ceramics. J. Alloy Compd. 2020, 820, 153411. [Google Scholar] [CrossRef]

- Tao, H.; Wu, H.; Liu, Y.; Zhang, Y.; Wu, J.; Li, F.; Lyu, X.; Zhao, C.; Xiao, D.; Zhu, J.; et al. Ultrahigh Performance in Lead-Free Piezoceramics Utilizing a Relaxor Slush Polar State with Multiphase Coexistence. J. Am. Chem. Soc. 2019, 141, 13987–13994. [Google Scholar] [CrossRef]

- Zhang, M.H.; Wang, K.; Du, Y.J.; Dai, G.; Sun, W.; Li, G.; Hu, D.; Thong, H.C.; Zhao, C.; Xi, X.Q.; et al. High and Temperature-Insensitive Piezoelectric Strain in Alkali Niobate Lead-free Perovskite. J. Am. Chem. Soc. 2017, 139, 3889–3895. [Google Scholar] [CrossRef]

- Cen, Z.; Yu, Y.; Zhao, P.; Chen, L.; Zhu, C.; Li, L.; Wang, X. Grain configuration effect on the phase transition, piezoelectric strain and temperature stability of KNN-based ceramics. J. Mater. Chem. C 2019, 7, 1379–1387. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Y.; Gao, J.; Zhou, Z.; Wang, H.; Wang, K.; Zhang, X.; Li, L.; Li, J.-F. High-performance lead-free piezoelectrics with local structural heterogeneity. Energy Environ. Sci. 2018, 11, 3531–3539. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, X.; Su, W.; Yao, W.; Zhou, C. Superior piezoelectricity and rhombohedral-orthorhombic-tetragonal phase coexistence of (1- x)(K,Na)(Nb,Sb)O3-x(Bi,Na)HfO3 ceramics. Scr. Mater. 2020, 176, 108–111. [Google Scholar] [CrossRef]

- Thong, H.-C.; Zhao, C.; Zhu, Z.-X.; Chen, X.; Li, J.-F.; Wang, K. The impact of chemical heterogeneity in lead-free (K, Na)NbO3 piezoelectric perovskite: Ferroelectric phase coexistence. Acta Mater. 2019, 166, 551–559. [Google Scholar] [CrossRef]

- Lv, X.; Wu, J.; Zhang, X.X. Tuning the Covalency of A-O Bonds to Improve the Performance of KNN-Based Ceramics with Multiphase Coexistence. ACS Appl. Mater. Interfaces 2020, 12, 49795–49804. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, A.; Lu, J.; Xie, B.; Liang, B.; Mao, Y.; Fan, H. Balanced development of dielectric permittivity, loss tangent, and temperature stability in K0.5Na0.5NbO3-based ceramic capacitors. J. Alloy Compd. 2020, 817, 152798. [Google Scholar] [CrossRef]

- Chen, K.; Ma, J.; Shi, C.; Wu, W.; Wu, B. Enhanced temperature stability in high piezoelectric performance of (K, Na)NbO3-based lead-free ceramics trough co-doped antimony and tantalum. J. Alloy Compd. 2021, 852, 156865. [Google Scholar] [CrossRef]

- Liu, Y.-X.; Thong, H.-C.; Cheng, Y.-Y.-S.; Li, J.-W.; Wang, K. Defect-mediated domain-wall motion and enhanced electric-field-induced strain in hot-pressed K0.5Na0.5NbO3 lead-free piezoelectric ceramics. J. Appl. Phys. 2021, 129, 024102. [Google Scholar] [CrossRef]

- Hreščak, J.; Bencan, A.; Rojac, T.; Malič, B. The influence of different niobium pentoxide precursors on the solid-state synthesis of potassium sodium niobate. J. Eur. Ceram. Soc. 2013, 33, 3065–3075. [Google Scholar] [CrossRef]

- Xie, Y.; Xing, J.; Tan, Z.; Xie, L.; Cheng, Y.; Wu, X.; Han, R.; Chen, Q.; Zhu, J. High mechanical quality factor and piezoelectricity in potassium sodium niobate ceramics. Ceram. Int. 2022, 48, 6565–6573. [Google Scholar] [CrossRef]

- Kim, B.-H.; Yang, S.-A.; Lee, M.-K.; Lee, G.-J. Properties of (Bi,M)ZrO3 (M: Alkali metals)-modified (K,Na)NbO3 lead-free piezoceramics. Ceram. Int. 2017, 43, 15880–15885. [Google Scholar] [CrossRef]

- Batra, K.; Sinha, N.; Kumar, B. Effect of Nd-doping on 0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3 ceramics: Enhanced electrical properties and piezoelectric energy harvesting capability. J. Phys. Chem. Solids 2022, 170, 110953. [Google Scholar] [CrossRef]

- Wang, D.; Hussain, F.; Khesro, A.; Feteira, A.; Tian, Y.; Zhao, Q.; Reaney, I.M. Composition and temperature dependence of structure and piezoelectricity in (1−x)(K1−yNay)NbO3-x(Bi1/2Na1/2)ZrO3 lead-free ceramics. J. Am. Ceram. Soc 2017, 100, 627–637. [Google Scholar] [CrossRef]

- Tang, X.; Chen, T.; Liu, Y.; Zhang, J.; Zhang, T.; Wang, G.; Zhou, J. Composition dependence of phase structure and electrical properties in (0.98-x)K0.35Na0.65NbO3–0.02BaZrO3–xBi0.5Na0.5ZrO3 ternary ceramics. J. Alloy Compd. 2016, 672, 277–281. [Google Scholar] [CrossRef]

- Batra, K.; Sinha, N.; Kumar, B. Lead-free 0.95(K0.6Na0.4)NbO3-0.05(Bi0.5Na0.5)ZrO3 ceramic for high temperature dielectric, ferroelectric and piezoelectric applications. J. Alloy Compd. 2020, 818, 152874. [Google Scholar] [CrossRef]

- Bongkarn, T.; Chootin, S.; Pinitsoontorn, S.; Maensiri, S. Excellent piezoelectric and ferroelectric properties of KNLNTS ceramics with Fe2O3 doping synthesized by the solid state combustion technique. J. Alloy Compd. 2016, 682, 14–21. [Google Scholar] [CrossRef]

- Guo, J.; Xu, F.; Shang, X.; Lu, Y.; Li, P.; Zhou, T.; Zhang, Z.; He, Y.; Damjanovic, D. High-Performance Small-Amount Fe2O3-Doped (K,Na)NbO3-Based Lead-Free Piezoceramics with Irregular Phase Evolution. J. Am. Ceram. Soc 2016, 99, 2341–2346. [Google Scholar] [CrossRef]

- Cheng, Y.; Xing, J.; Li, X.; Xie, L.; Xie, Y.; Tan, Z.; Zhu, J. Meticulously tailoring phase boundary in KNN-based ceramics to enhance piezoelectricity and temperature stability. J. Am. Ceram. Soc. 2022, 105, 5213–5221. [Google Scholar] [CrossRef]

- Yashima, M.; Omoto, K.; Chen, J.; Kato, H.; Xing, X. Evidence for (Bi,Pb)–O Covalency in the High TC Ferroelectric PbTiO3–BiFeO3 with Large Tetragonality. Chem. Mat. 2011, 23, 3135–3137. [Google Scholar] [CrossRef]

- Eichel, R.-A. Structural and dynamic properties of oxygen vacancies in perovskite oxides-analysis of defect chemistry by modern multi-frequency and pulsed EPR techniques. Phys. Chem. Chem. Phys. 2011, 13, 368–384. [Google Scholar] [CrossRef]

- Malic, B.; Jenko, D.; Holc, J.; Hrovat, M.; Kosec, M. Synthesis of Sodium Potassium Niobate: A Diffusion Couples Study. J. Am. Ceram. Soc. 2008, 91, 1916–1922. [Google Scholar] [CrossRef]

- Zhang, N.; Zheng, T.; Li, N.; Zhao, C.; Yin, J.; Zhang, Y.; Wu, H.; Pennycook, S.J.; Wu, J. Symmetry of the Underlying Lattice in (K,Na)NbO3-Based Relaxor Ferroelectrics with Large Electromechanical Response. ACS Appl. Mater. Interfaces 2021, 13, 7461–7469. [Google Scholar] [CrossRef]

- Fu, J.; Zuo, R.; Xu, Z. High piezoelectric activity in (Na,K)NbO3 based lead-free piezoelectric ceramics: Contribution of nanodomains. Appl. Phys. Lett. 2011, 99, 062901. [Google Scholar] [CrossRef]

- Lin, D.; Zhang, S.; Cai, C.; Liu, W. Domain size engineering in 0.5%MnO2-(K0.5Na0.5)NbO3 lead free piezoelectric crystals. J. Appl. Phys. 2015, 117, 074103. [Google Scholar] [CrossRef]

- Zuo, R.; Fu, J.; Wang, X.; Li, L. Phase transition and domain variation contributions to piezoelectric properties of alkaline niobate based lead-free systems. J. Mater. Sci. Mater. Electron. 2009, 21, 519–522. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J. Electric field compensation effect driven strain temperature stability enhancement in potassium sodium niobate ceramics. Acta Mater. 2020, 182, 1–9. [Google Scholar] [CrossRef]

- Tao, H.; Yin, J.; Wu, W.; Zhao, L.; Ma, J.; Wu, B. Sharpening polycrystalline phase boundary for potassium sodium niobate ceramics with MnF2 modification. J. Am. Ceram. Soc. 2022, 105, 5003–5010. [Google Scholar]

- Tan, Z.; Peng, Y.; An, J.; Zhang, Q.; Zhu, J. Critical Role of Order-Disorder Behavior in Perovskite Ferroelectric KNbO3. Inorg. Chem. 2021, 60, 7961–7973. [Google Scholar] [CrossRef]

- Jin, L.; Li, F.; Zhang, S.; Green, D.J. Decoding the Fingerprint of Ferroelectric Loops: Comprehension of the Material Properties and Structures. J. Am. Ceram. Soc. 2014, 97, 1–27. [Google Scholar] [CrossRef]

- Cen, Z.; Bian, S.; Xu, Z.; Wang, K.; Guo, L.; Li, L.; Wang, X. Simultaneously improving piezoelectric properties and temperature stability of Na0.5K0.5NbO3 (KNN)-based ceramics sintered in reducing atmosphere. J. Adv. Ceram. 2021, 10, 820–831. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, R.; Gao, T.; Xie, Y.; Xie, L.; Cheng, Y.; Li, X.; Chen, H.; Xing, J.; Zhu, J. The Effect of Nb2O5 Precursor on KNN-Based Ceramics’ Piezoelectricity and Strain Temperature Stability. Crystals 2022, 12, 1778. https://doi.org/10.3390/cryst12121778

Han R, Gao T, Xie Y, Xie L, Cheng Y, Li X, Chen H, Xing J, Zhu J. The Effect of Nb2O5 Precursor on KNN-Based Ceramics’ Piezoelectricity and Strain Temperature Stability. Crystals. 2022; 12(12):1778. https://doi.org/10.3390/cryst12121778

Chicago/Turabian StyleHan, Ruilin, Tingting Gao, Yining Xie, Lixu Xie, Yuan Cheng, Xu Li, Hao Chen, Jie Xing, and Jianguo Zhu. 2022. "The Effect of Nb2O5 Precursor on KNN-Based Ceramics’ Piezoelectricity and Strain Temperature Stability" Crystals 12, no. 12: 1778. https://doi.org/10.3390/cryst12121778

APA StyleHan, R., Gao, T., Xie, Y., Xie, L., Cheng, Y., Li, X., Chen, H., Xing, J., & Zhu, J. (2022). The Effect of Nb2O5 Precursor on KNN-Based Ceramics’ Piezoelectricity and Strain Temperature Stability. Crystals, 12(12), 1778. https://doi.org/10.3390/cryst12121778