Abstract

The high uniform magnetic field combined with pre-deformation and vacuum heat treatment processing is designed for improving the diffusion bonding properties of the 1420 Al-Li alloy. Serial magneto-thermal coupling treatment experiments of 1420 Al-Li alloy and the pure aluminium diffusion couple, together with the gallium interlayer, is carried out in a superconducting high magnetic field device. Various parameter combinations are used to produce different samples on which interface organization and connection performance are studied. Electron microscopic analysis reveals various interface topographies and fracture morphologies after shear strength tests. Influence of diffusion bonding temperature on element diffusion under a high uniform magnetic field is investigated. The diffusion activation energy of Mg element in pure aluminum under a 12 T magnetic field is calculated in this paper. It is found that the bonding quality and bonding performance of the interface are improved greatly after heat treatment with a strong magnetic field, and the bonding temperature is an important factor affecting the interface bonding and bonding strength. The diffusion coefficient of the Mg element in the 1420 Al-Li alloy to L2 pure aluminum increases with the increase of diffusion bonding temperature. Reducing the activation energy of elemental diffusion is beneficial to atomic diffusion.

1. Introduction

Lightweight is the eternal goal of aerospace industry. Materials and structures with higher strength and low density properties enable aerospace devices to have better performance, adapt to more complex service environments, and save strategic energy and maintenance costs [1,2]. Al-Li alloys are considered the most potential candidate for aerospace structural materials as they provide superior significant property improvements over conventional aluminum alloys, such as high strength, specific stiffness, excellent corrosion resistance and superplasticity [3,4,5]. Multi-layer hollow Al-Li alloy structural parts, fabricated by superplastic forming and diffusion bonding technology (SPF/DB) [6,7,8], can effectively solve the lightweight problem in the field of aerospace, and realize the unity of material lightweightedness and structural lightweightedness, which has an important and far-reaching impact on the design and manufacture of modern and future aerospace structures.

Diffusion bonding technology is an advanced solid-phase bonding technology, which realizes interfacial metallurgical bonding through atomic diffusion under certain temperature and pressure conditions. It has the advantages of excellent joint quality, high welding precision, and the connection of internal as well as multi-point or large-area components [9]. The structural weight reduction and cost reduction of titanium alloy structural parts have attracted extensive attention, which is attributed to the easy decomposition of titanium, nickel and other oxide films in the application of DB/SPF technology [10]. However, a dense and stable oxide film is easily formed on the surface of aluminum alloy, which seriously hinders the diffusion of aluminum atoms and the formation of metallurgical bonding, and restricts the development and application of aluminum alloy diffusion bonding technology [11]. Therefore, how to solve the diffusion joint problem of Al-Li alloy and obtain the high quality joint has been a research hotspot in the field of connection technology.

Currently, many studies have focused on different methods to improve the diffusion bonding quality of Al-Li alloys. Xiao et al. [12] found that the electropulsing treatment combined with pre-deformation can influence the ageing behavior and mechanical properties of 5A90 Al-Li alloy. The increase in strength of the alloy was attributed to the combination of the coarsening of δ′ precipitates and the localized Joule heating. Xu et al. [13] found that the pulsed electromagnetic field treatment reduces the dislocation density of the pre-stretching specimen and improves the dislocation uniformity of 2195 Al-Li alloy. Nevertheless, the principle of electrical pulse action is still controversial. Diffusion bonding of 1420 Al-Li alloy assisted by pure aluminum foil was conducted, the results show that the bonding temperatures have direct influence on the interface microstructure and bond strength of joints [14]. In addition, the transient liquid phase diffusion bonding technology can effectively solve the problem of oxide film and achieve high quality metallurgical bonding [15,16], but it takes a long time to complete the isothermal solidification and homogenization process, accompanied by the formation of complex joint structure. Although lots of research work has been carried out on the diffusion bonding process of aluminum alloy, there are still obvious shortcomings and limitations in the related methods.

With the rapid development of superconducting high magnetic field technology, magnetic field–assisted metal manufacturing has been widely used [17]. The high uniform magnetic field can accelerate the diffusion speed, reduce the diffusion activation energy and increase the diffusion coefficient [18,19]. Liu et al. [4] showed that the δ′ particles in Al-Li alloy coarsened obviously when imposed upon a high magnetic field, and the average diameters of the δ′ particles were estimated to be 26 nm in the case of 0 T, but 68 nm in the case of 11.5 T. Li et al. [20] and Yuan et al. [21] studied the intermediate phase growth of the Mg–Al diffusion couple and the Ni/Ni-6.3%Al diffusion couple, which is parallel to the direction of the high magnetic field, and found that the thickness of the intermediate phase decreased with the addition of a strong magnetic field. In the solid phase transformation process, the magnetic properties of different constituent phases in the material may have great differences; as such, the strong magnetic field can change the mechanism of phase transformation (such as the phase transformation temperature/degree, microstructure morphology, grain boundary migration and recrystallization, etc.), and also affect the diffusion of atoms in the diffusion connection of alloy materials [22]. Zhou et al. [23] proved that the application of magnetic field retarded the oxide–scale growth of Fe-20Ni binary alloy after measuring the penetrated depths of the oxide precipitates in subscale. Ohtsuka et al. [24] studied the ferrite transition of Fe-1.4C (wt%) and Fe-1.5Mn-0.1C (wt%) steels, as well as the pearlite transition of Fe-1.3Mn-1.0C (wt%) and Fe-0.8C (wt%) steels under a 10 T strong magnetic field. The results showed that the high magnetic field accelerates the ferrite transition process and increases the pearlite transition temperature to a certain extent. However, the effect of heat treatment on Al-Li alloy with a high magnetic field is rarely studied. The diffusion bonding behavior of Al-Li alloy under magnetic–thermal–mechanical coupling is still unclear. It is necessary to systematically explore the influence of heat treatment on diffusion bonding properties and element diffusion of Al-Li alloy under a high uniform magnetic field.

2. Materials and Methods

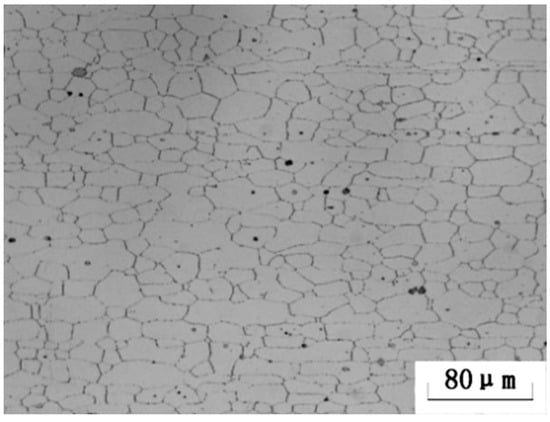

The material of the experimental sample was a 1420 Al-Li alloy superplastic fine crystal plate with a size of 20 mm × 30 mm × 1.8 mm, the chemical composition of which was determined by inductively coupled plasma mass spectrometry (ICP–Thermo iCAP 7400, Thermo Fisher Scientific, Massachusetts, MA, USA), as shown in Table 1. The grains were equiaxed with a grain size in the range of 10–20 μm, as shown in Figure 1. The intermediate layer material was 99.99% purity metal gallium, which can break the barrier of the oxide film on the alloy surface, provide a channel for the mutual diffusion of Al-Li alloy matrix atoms, and form a good diffusion bonding joint [25]. Gallium with a high purity of 99.99% was selected as an intermediate layer material to prevent the growth of oxide films.

Table 1.

Chemical composition of 1420 Al-Li alloy (wt%).

Figure 1.

Microstructure of 1420 Al-Li alloy.

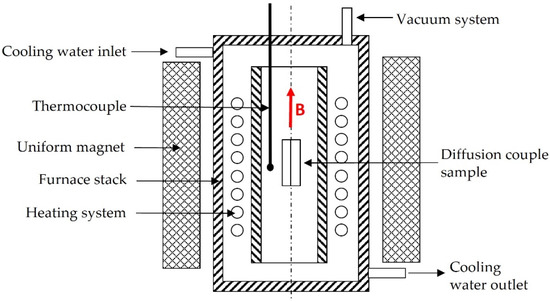

All samples were polished using an automatic polishing machine. Thereafter, the specimens were cleaned in an ultrasonic bath with acetone and then were evenly coated with liquid gallium by the rubbing method. The gallium content in the intermediate layer was controlled at about 1 mg/cm2, considering the sensitivity of the element diffusion. The pre–deformation diffusion couples were prepared by mechanical loading on the electronic universal testing machine with a three–stage resistance furnace heating method. Then, the couple samples were subjected to a high uniform magnetic field combined with vacuum heat treatment processing in a JMTD–12T–φ100 mm superconducting high magnetic field device. As depicted in Figure 2, the diffusion couple interface direction was parallel to the direction of the magnetic field. To investigate the diffusion bonding performance of the samples subjected to different diffusion bonding temperatures under high uniform magnetic field conditions, the single factor experiment was conducted using the parameters (12 T in magnetic induction intensity, 7 MPa in pressure, 1 h in time, and 440 °C~560 °C in temperature), according to existing research results [25]. Further analysis on the interfacial microstructure of the specimens after heat treatment was carried out using an OLYMPUS BX41M light microscope. The shear fracture morphology of the joint obtained by the joint shear strength test in an electronic universal mechanical testing machine was closely observed at the micrometer scale using an LEO–1450 scanning electron microscope (SEM) for all diffusion bonding conditions. SEM/EDS techniques were adopted to assess the content of Mg element near the diffusion interface.

Figure 2.

Schematic view of the superconducting magnetic field heat treatment system.

3. Results and Discussion

3.1. Effect of Bonding Temperature on Interfacial Microstructure and Joints Shear Strength

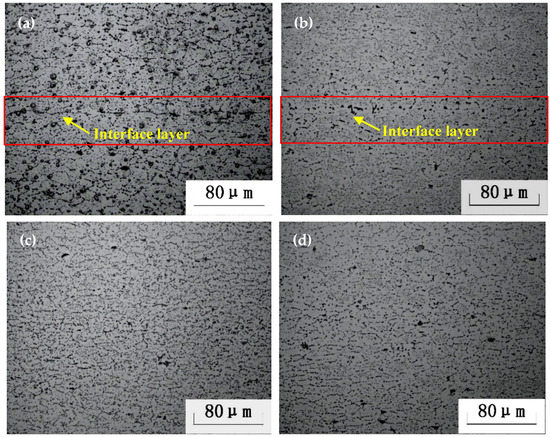

The interface structure of diffusion connection corresponding to different bonding temperatures, under the conditions of magnetic induction intensity 12 T and time 1 h, is shown in Figure 3. After diffusion bonding at 440 °C, the interface between the 1420 Al-Li alloy matrix is obvious, and there are continuous interface holes on the interface. When the diffusion bonding temperature reaches 480 °C, the dense oxide film on the surface of the Al-Li alloy gradually penetrates, and the holes at the interface gather and blend with each other, as shown in Figure 3b. With the increase of the diffusion bonding temperature, the interface quality is obviously improved, and the welding degree gets better and better. When the temperature is greater than 520 °C, the interface completely disappears, and a defectfree diffusion junction joint is obtained (Figure 3d).

Figure 3.

Microstructure of joints under different temperatures. (a) 440 °C; (b) 480 °C; (c) 520 °C; (d) 560 °C.

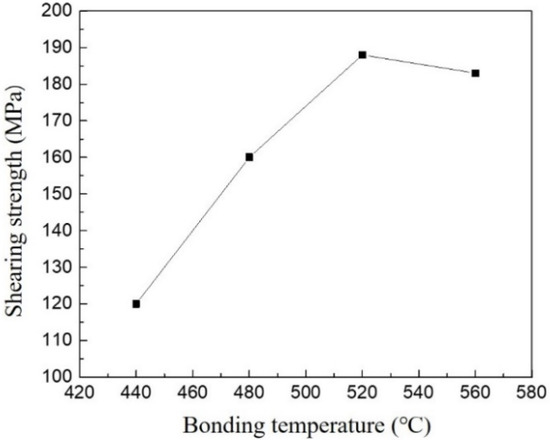

The relation between diffusion bonding temperature and joint shear strength under conditions corresponding to the treatment of diffusion bonded specimens (12 T in magnetic induction intensity and 1 h in time) is observed in Figure 4. With the increase of diffusion bonding temperature under the condition of the same magnetic induction intensity, the shear strength of the joint increases first and then decreases, and the shear strength of the joint reaches a maximum of 188 MPa when the temperature is 520 °C. This is mainly because the diffusion bonding temperature is the main parameter affecting the grain growth. It is more favorable for atomic migration, dislocation and hole movement, nucleation and growth of new grains at the interface correspond with the temperature increases. Therefore, within a certain range, increasing the temperature of diffusion bonding can improve the strength of the joint. Nevertheless, when the temperature is higher than 520 °C, the microstructure of the material is coarse, the performance deteriorates, and the shear strength of the joint decreases slightly, which are attributed to the high temperature. Under the high temperature, the eutectic phase with a low melting point in the Al-Li alloy will undergo local remelting, which will result in overburning, which is irreversible [26]. Meanwhile, the grain boundary will be destroyed together with the intergrain bond decreases, and the grain will crack rapidly when subjected to deformation, which seriously affects the mechanical properties. On the other hand, the secondary dendrite arm spacing (SDAS) decreased and the distribution of the SDAS became uniform under high magnetic fields, which resulted in a finer interfacial structure of the sample. In addition, the area fraction of the grain boundary slightly decreased at first and then increased with increasing magnetic flux density under uniform magnetic fields [4]. Consequently, the interfacial microstructure and joint shear strength are better under the high uniform magnetic field combined with high temperature.

Figure 4.

Shearing strength of joints with different bonding temperatures.

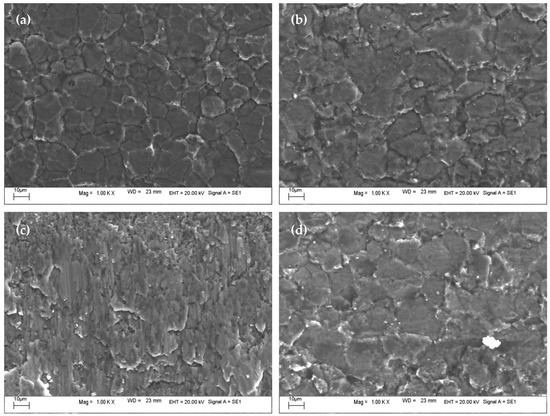

The morphology of the diffusion–bonding shear fracture at different temperatures is revealed by scanning electron microscopy over a wide range of magnifications. The fracture morphology can significantly reveal the performance of diffusion connections, as shown in Figure 5. When the temperature is low, the relatively flat and smooth microstructures of the shear fracture are depicted in Figure 5a and b, respectively. By contrast, in Figure 5c, a coarse–scale surface tearing crack shows an irregular series of material tearing-off from the fracture surface with the increase of diffusion bonding temperature. This is primarily because the shear force exceeding the yield strength of the bonding parts results in an indecisive break trace under proper magneto–thermal coupling where the interfacial material is not sufficiently fractured from the material matrix. The large number of significant tear marks also indicates that the more the area of metallurgical bonding between the samples, the higher the shear strength of bonding parts. As the temperature increased to 560 °C (higher than 520 °C), the bonding fracture tear band gradually decreased and tapered, as shown in Figure 5d, indicating that the bonding performance slightly decreased under corresponding conditions.

Figure 5.

Fracture surface of the shearing test with different temperatures: (a) 440 °C; (b) 480 °C; (c) 520 °C; (d) 560 °C.

3.2. Effect of High Magnetic Field Heat Treatment on the Distribution and Diffusion of Mg Elements near the Interface

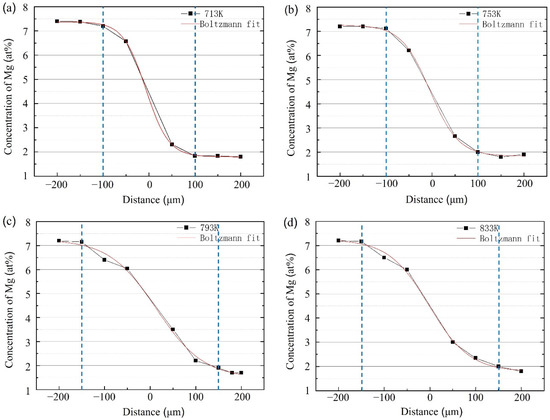

3.2.1. Mg Element Distribution near the Interface

The content of the Mg element near the diffusion interface was measured by SEM+EDS technology. The correspondence contents of the Mg element near the diffusion interface under different experimental conditions are depicted in Figure 6. The diffusion distance of the Mg element in Al-Li alloy into pure aluminum gradually becomes farther with the increase of temperature. It is evident from the four curves in Figure 6 that the diffusion bonding temperature promotes the diffusion velocity of Mg atoms in Al, which is in good agreement with the favorable pattern shown in Section 3.1. It is suggest that the proper diffusion bonding temperature can effectively improve the quality of diffusion connections.

Figure 6.

The content of Mg element near the diffusion interface under different bonding temperatures (a–d).

3.2.2. Diffusion Coefficient of Mg Element in L2 Pure Aluminum

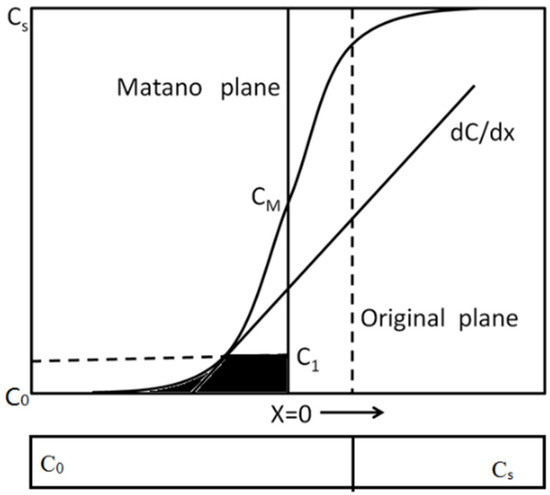

Further investigation of the impacts of bonding temperature on the mutual diffusion coefficient of Mg in pure aluminum was calculated by the Boltzman–Minamano–method [25], of which the solution principle is shown in Figure 7. For a one-dimensional semi-infinite diffusional couple with initial conditions , the concentration distribution curve can be obtained by analyzing the concentration at different positions of the sample when the diffusion time of the sample is t under certain temperature and magnetic field conditions.

Figure 7.

Schematic diagram of the Boltzman–Minamata–method for solving the diffusion coefficient.

If the diffusivity depends on the concentration, the solution of Fick’s second law is a function of the combined variable , under constant source diffusion and one–dimensional semi–infinite diffusivity pairs. Therefore, through the Boltzman–transformation and introducing variable to one–dimensional Fick’s second law, the relational expression can be obtained after simplification as:

By integrating both sides of Equation (1) and simplifying, it can be obtained as follows:

Equation (2) should satisfy the following conditions: , which actually determines the position of the origin of coordinates x = 0, and its physical meaning is that the concentration curves on both sides of x = 0 are equal to the area enclosed by the two lines C = C0 and C = Cs. Therefore, the mathematical relationship can be expressed as Equation (3).

The diffusion coefficient D can be expressed as Equation (4) when any concentration of C1 is experimentally determined.

where t is the diffusion time, is the area enclosed by the concentration curve, C = C0, C = C1 and x = 0 (the Matano plane which is the cross section satisfying Equation (3)), and is the slope of the concentration distribution curve when C = C1.

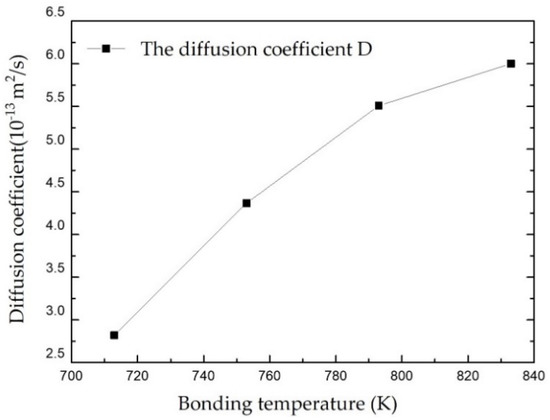

The diffusion coefficients corresponding to different temperatures can be obtained by careful calculation, as shown in Figure 8. It is obvious that the diffusion coefficient of the Mg element in Al increases with the increase of bonding temperature, which is beneficial to increase the diffusion flux of the Mg element in the process of diffusion connection, so as to accelerate the closure of interface holes on the diffusion connection joint and facilitate the interface reaction between the Mg element and oxide film, thus further improving the interface quality of diffusion bonding.

Figure 8.

Plot of the relationship between diffusion coefficient and temperature.

3.2.3. Diffusion Activation Energy of Mg Element in L2 Pure Aluminum

To investigate the diffusion activation energy, a series of calculations were performed according to the Arrhenius Equation (5).

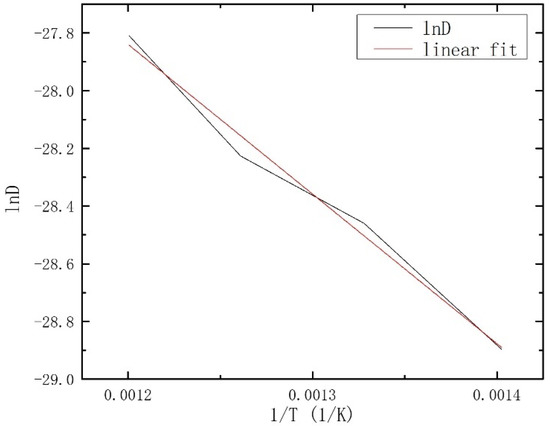

The lnD − curve can be drawn as shown in Figure 9, according to Equation (5), and the diffusion coefficient D can be calculated corresponding to different diffusion connection temperatures T under 12 T magnetic induction intensity. The least square method is adopted to fit the curve, in which the slope is −Q/R, and the intercept is lnD0. It is evident from the curve, after being calculated, that the diffusion activation energy Q is 43.2 kJ/mol and the frequency factor D0 is 4.1 × 10−10 m2/s.

Figure 9.

The curve graph of and 1/T.

Thus, the diffusion activation energy of Mg in pure aluminum is about 131 kJ/mol in the normal absence of the magnetic field, which is 67% higher than that under the 12 T strong magnetic field.

4. Conclusions

In summary, the diffusion bonding properties and element diffusion of 1420 Al-Li alloy are investigated by measuring and calculating bonding samples produced under various magnetic thermal parameter combinations. From the above study, the following main conclusions can be drawn.

A suitable bonding temperature (520 °C) with a high magnetic field (12 T) is crucially important to the interface bonding and bonding strength performance. In general, higher bonding temperature promotes welding degree and interface quality, while an excessively high temperature causes overburning and reduces the mechanical properties.

The diffusion bonding temperature promotes the diffusion of Mg atoms in pure aluminum. In the range below the overburning temperature, the higher the temperature, the farther the diffusion distance of the Mg element and the larger the diffusion coefficient, the better the quality of the diffusion connections.

Under the conditions of a high uniform magnetic field combined with heat treatment, the promotion of atomic diffusion can be attributed to the reduction of elemental diffusion activation energy. A significantly lower (67%) diffusion activation energy of Mg element in pure aluminum under a 12 T strong magnetic field compared with that under 0 T (no magnetic field) is detected.

Author Contributions

Methodology, writing—original draft preparation, supervision, H.Z.; investigation, validation, T.N.; visualization, funding acquisition, Y.L.; conceptualization, project administration, M.Y.; writing—review and editing, H.Z. and M.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Foundation of Equipment Pre-research Area, grant number 80923010401; the Research Project Supported by the Shanxi Scholarship Council of China, grant number 2021109 and 2021118; the Fund Program for the Scientific Activities of Selected Returned Overseas Professionals in Shanxi Province, grant number 20210040; the key core technology and generic technology research of Shanxi, grant number 2020XXX005; the Natural Science Foundation of Shanxi Province, China, grant number 20210302124213; and the National Natural Science Foundation of China, grant number 51201155.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rioja, R.J.; Liu, J. The evolution of Al-Li base products for aerospace and space applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Abd El-Aty, A.; Xu, Y.; Guo, X.; Zhang, S.H.; Ma, Y.; Chen, D. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review. J. Adv. Res. 2018, 10, 49–67. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, G. Hot Extrusion Processing of Al-Li Alloy Profiles and Related Issues: A Review. Chin. J. Mech. Eng. 2020, 33, 64. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Q.; Zhang, H.; Wang, K.; Pang, X.; He, J. Effects of high magnetic fields on the microstructures and grain boundaries in binary Al-Li alloy. J. Alloys Compd. 2009, 469, 258–263. [Google Scholar] [CrossRef]

- Kablov, E.N.; Antipov, V.V.; Oglodkova, J.S.; Oglodkov, M.S. Development and Application Prospects of Aluminum-Lithium Alloys in Aircraft and Space Technology. Metallurgist 2021, 65, 72–81. [Google Scholar] [CrossRef]

- Lathashankar, B.; Tejaswini, G.C.; Suresh, R.; Swamy, N.H.S. Advancements in diffusion bonding of aluminium and its alloys: A comprehensive review of similar and dissimilar joints. Adv. Mater. Process. Technol. 2022, 1–19. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Niu, T.; Zhang, H.; Yuan, M. Study on SPF/DB Technology for Two-Sheet Hollow Structure of 1420 Al-Li Alloy. Metals 2022, 12, 389. [Google Scholar] [CrossRef]

- Jiang, S.; Jia, Y.; Lu, Z.; Shi, C.; Zhang, K. Superplastic forming/diffusion bonding without interlayer of 5A90 Al-Li alloy hollow double-layer structure. J. Mater. Eng. Perform. 2017, 26, 4265–4273. [Google Scholar] [CrossRef]

- Silva, M.; Ramos, A.S.; Vieira, M.T.; Simões, S. Diffusion bonding of Ti6Al4V to Al2O3 using Ni/Ti reactive multilayers. Metals 2021, 11, 655. [Google Scholar] [CrossRef]

- Assari, A.H.; Eghbali, B. Solid state diffusion bonding characteristics at the interfaces of Ti and Al layers. J. Alloys Compd. 2019, 773, 50–58. [Google Scholar] [CrossRef]

- Gao, H.; Li, N.; Ho, H.; Zhang, Y.; Zhang, N.; Wang, L.; Lin, J. Determination of a set of constitutive equations for an Al-Li alloy at SPF conditions. Mater. Today Proc. 2015, 2, S408–S413. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, K.; Shi, C.; Lu, Z.; Jiang, J. Influence of electropulsing treatment combined with pre-deformation on ageing behavior and mechanical properties of 5A90 Al-Li alloy. J. Alloys Compd. 2019, 784, 1234–1247. [Google Scholar] [CrossRef]

- Xu, J.; Huang, L.; Xu, Y.; Xie, B.; Zhao, M.; Su, H.; Wang, Y.; Li, J. Effect of pulsed electromagnetic field treatment on dislocation evolution and subsequent artificial aging behavior of 2195 Al-Li alloy. Mater. Charact. 2022, 187, 111872. [Google Scholar] [CrossRef]

- Wu, F.; Chen, W.; Zhao, B.; Hou, H.; Zhou, W.; Li, Z. Diffusion bonding of 1420 Al-Li alloy assisted by pure aluminum foil as interlayer. Materials 2020, 13, 1103. [Google Scholar] [CrossRef] [PubMed]

- Atabaki, M.M.; Idris, J. Low-temperature partial transient liquid phase diffusion bonding of Al/Mg2Si metal matrix composite to AZ91D using Al-based interlayer. Mater. Des. 2012, 34, 832–841. [Google Scholar] [CrossRef]

- Malekan, A.; Farvizi, M.; Mirsalehi, S.; Saito, N.; Nakashima, K. Influence of bonding time on the transient liquid phase bonding behavior of Hastelloy X using Ni-Cr-B-Si-Fe filler alloy. Mater. Sci. Eng. A 2019, 755, 37–49. [Google Scholar] [CrossRef]

- Han, J.; Wang, H.; Xu, A.; Niu, K.; Zheng, W. Externally-Physical-Field-Assisted Aging Precipitation in Aerospace Aluminum Alloys: A Review. Crit. Rev. Solid State Mater. Sci. 2022, 1–26. [Google Scholar] [CrossRef]

- Sarvari, M.; Abdollah-Zadeh, A.; Naffakh-Moosavy, H.; Rahimi, A.; Parsaeyan, H. Investigation of collision surfaces and weld interface in magnetic pulse welding of dissimilar Al/Cu sheets. J. Manuf. Process. 2019, 45, 356–367. [Google Scholar] [CrossRef]

- Li, J.; Pei, Q.; Wang, R.; Zhou, Y.; Zhang, Z.; Cao, Q.; Wang, D.; Mi, W.; Du, Y. Enhanced photocatalytic performance through magnetic field boosting carrier transport. ACS Nano 2018, 12, 3351–3359. [Google Scholar] [CrossRef]

- Li, Z.F.; Dong, J.; Zeng, X.Q.; Lu, C.; Ding, W.J.; Ren, Z.M. Influence of strong static magnetic field on intermediate phase growth in Mg-Al diffusion couple. J. Alloys Compd. 2007, 440, 132–136. [Google Scholar] [CrossRef]

- Yuan, Z.; Ren, Z.; Li, C.; Xiao, Q.; Wang, Q.; Dai, Y.; Wang, H. Effect of high magnetic field on diffusion behavior of aluminum in Ni-Al alloy. Mater. Lett. 2013, 108, 340–342. [Google Scholar] [CrossRef]

- Gubernatorov, V.V.; Sycheva, T.S.; Vladimirov, L.R.; Gundyrev, V.M.; Ivchenko, V.A.; Ovchinnikov, V.V. Effects of ion irradiation and magnetic field on primary recrystallization of metals. Phys. Met. Metallogr. 2009, 107, 68–72. [Google Scholar] [CrossRef]

- Zhou, C.H.; Ma, H.T.; Wang, L.; Li, X.W. Growth of subscale on Fe-20Ni binary alloy in the presence of magnetic field. Corros. Sci. 2013, 77, 292–296. [Google Scholar] [CrossRef]

- Ohtsuka, H.; Xu, Y.; Wada, H. Alignment of ferrite grains during austenite to ferrite transformation in a high magnetic field. Mater. Trans. JIM 2000, 41, 907–910. [Google Scholar] [CrossRef]

- Niu, T.; Hou, H.; Wang, Y.; Zhou, W.; Wu, F. Effect of high uniform magnetic field on joining property and element diffusion of 1420 Al-Li Alloy. Trans. China Weld. Inst. 2016, 37, 1–5. [Google Scholar]

- Wu, Y.; Wang, X.D.; Li, J.L.; Feng, Z.H. Effects of Solution Temperature on Microstructure of 2A66 Al-Cu-Li Alloy. Mater. Sci. Forum 2016, 850, 687–692. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).