Effect of Al Content on the Microstructure and Tensile Properties of Zr-Co-Al Alloy Prepared by Rapid Solidification

Abstract

1. Introduction

2. Experimental Procedures

3. Results and Discussion

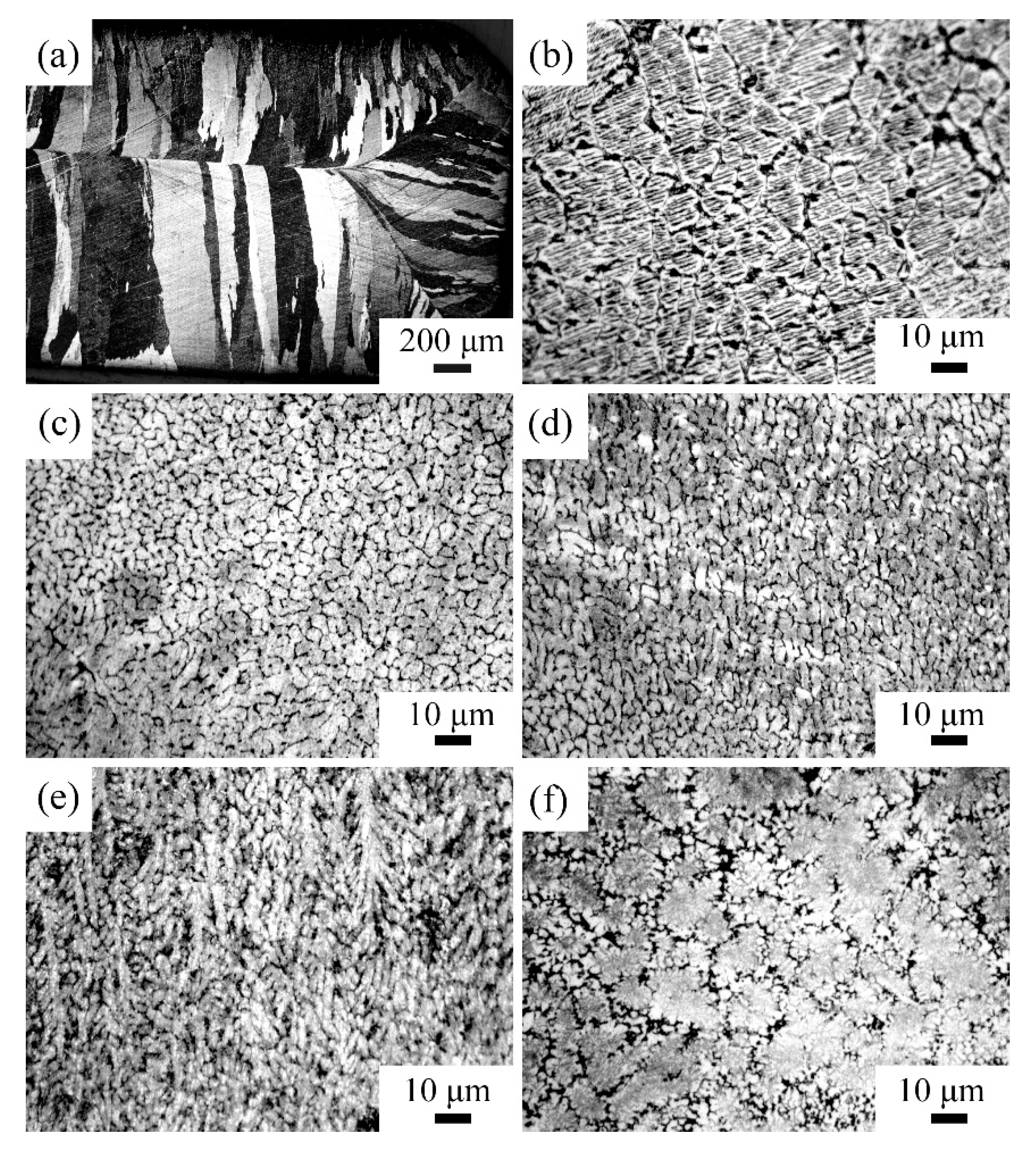

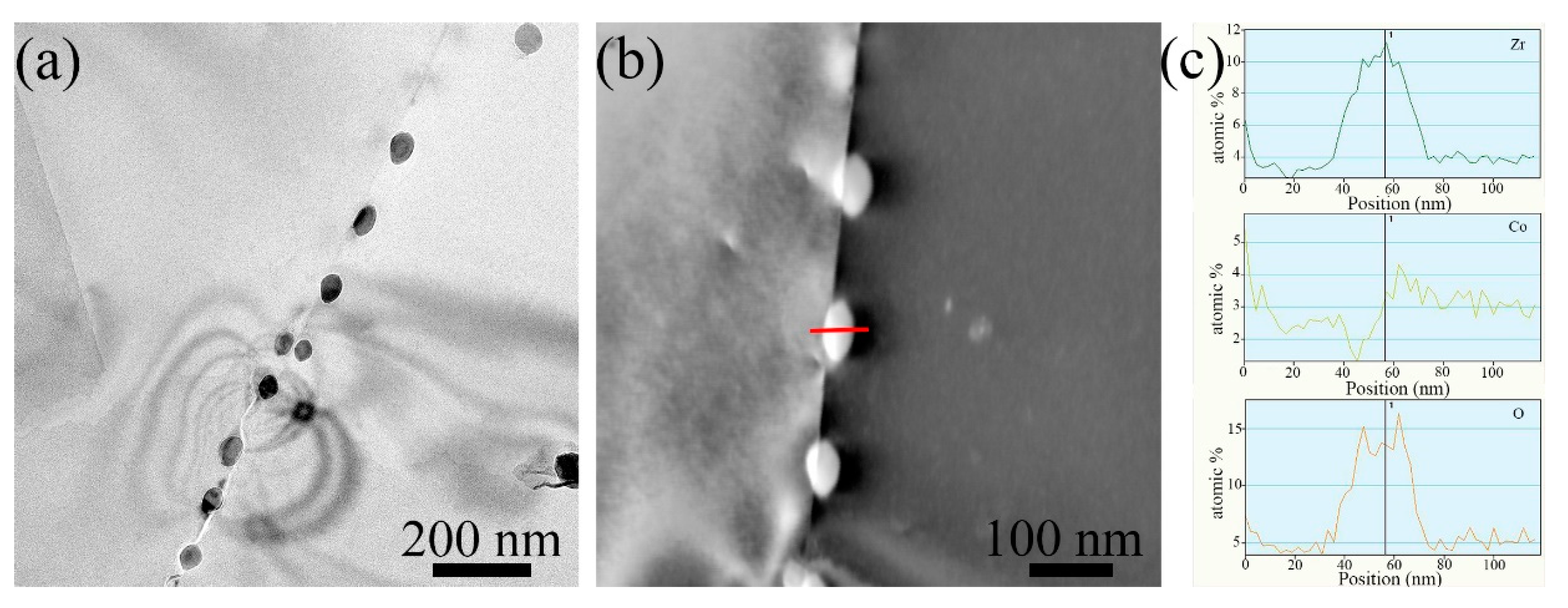

3.1. Microstructure

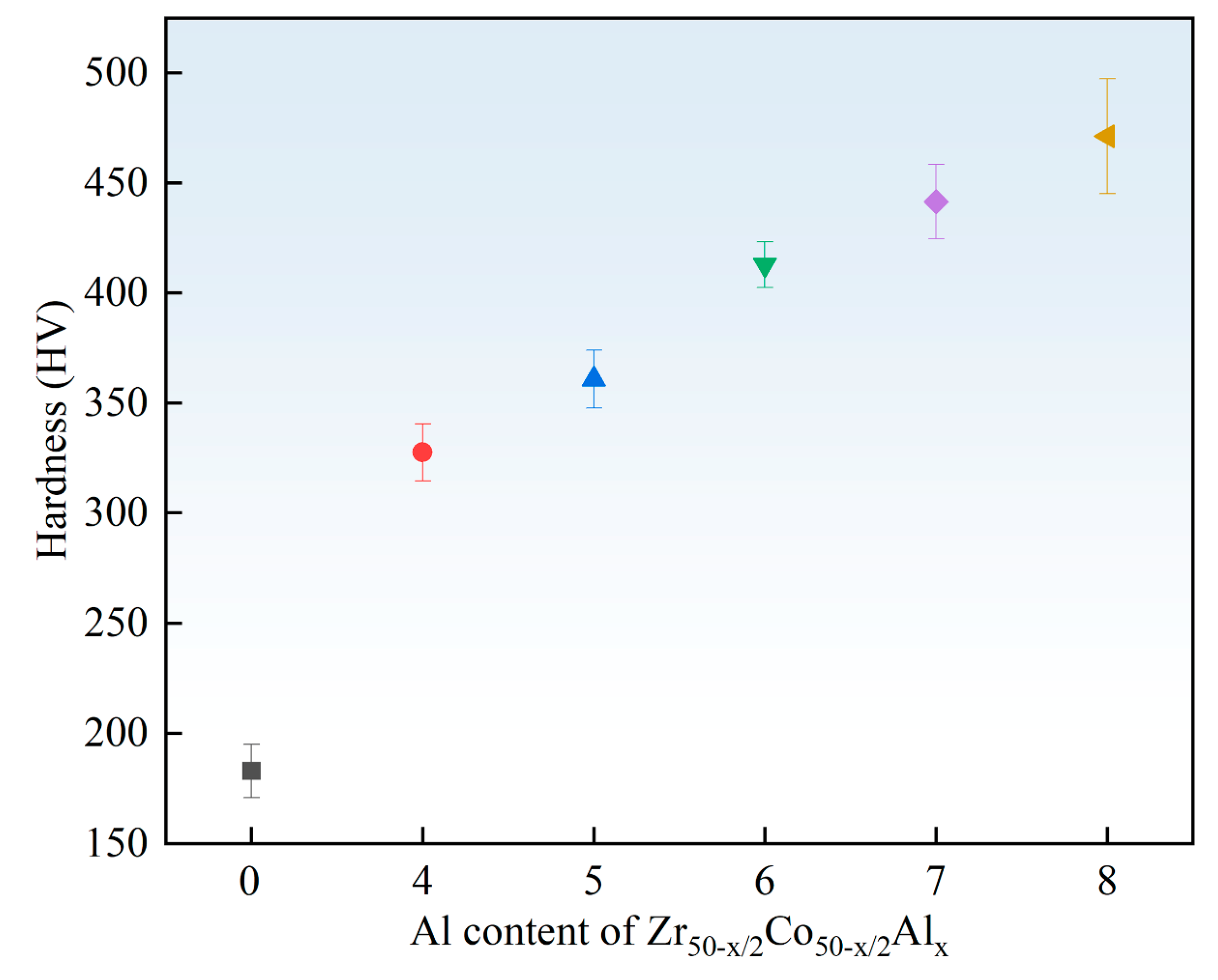

3.2. Hardness

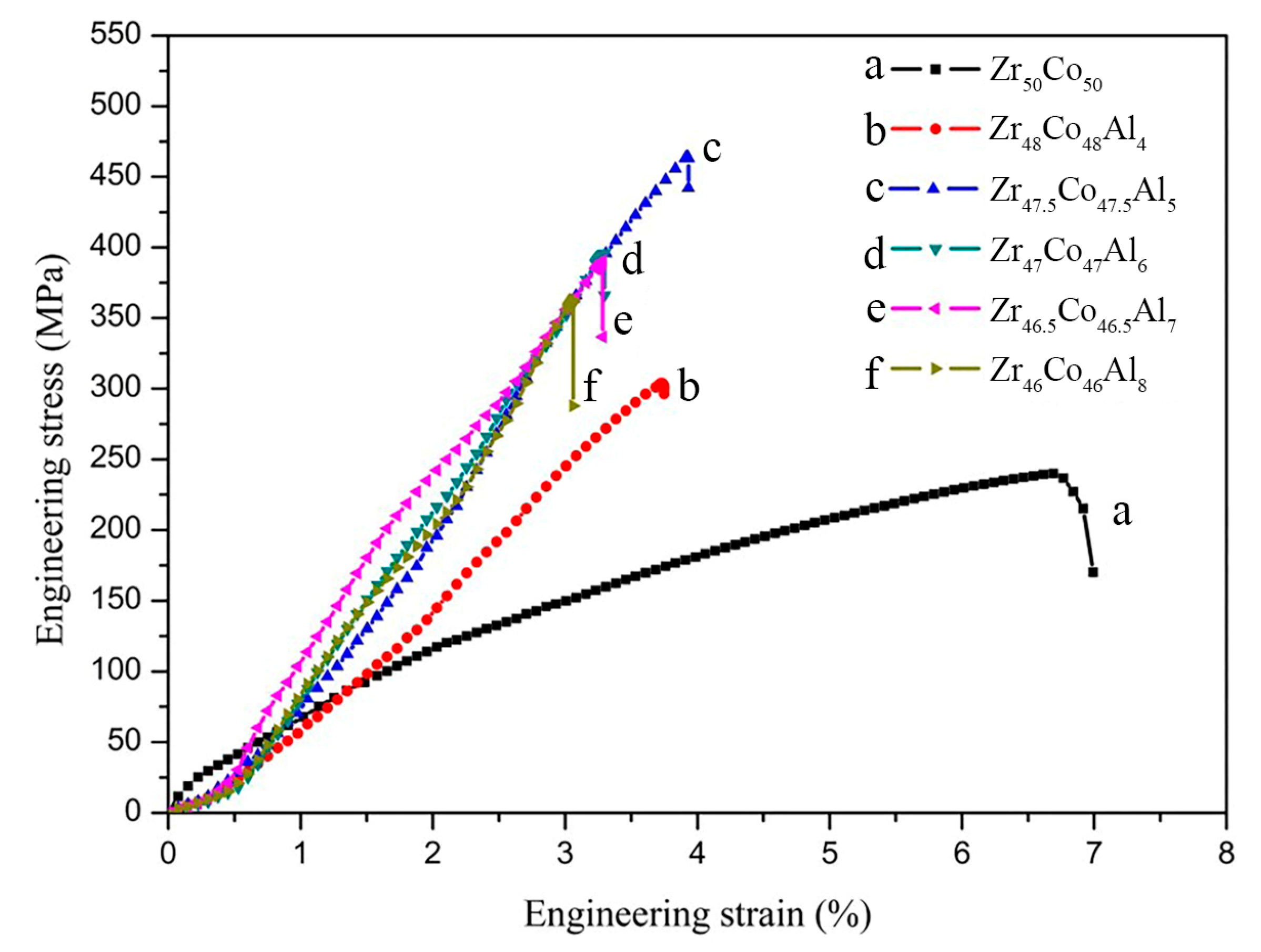

3.3. Tensile Mechanical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hua, N.; Pang, S.; Li, Y.; Wang, J.; Li, R.; Georgarakis, K.; Yavari, A.R.; Vaughan, G.; Zhang, T. Ni- and Cu-free Zr–Al–Co–Ag bulk metallic glasses with superior glass-forming ability. J. Mater. Res. 2011, 26, 539–546. [Google Scholar] [CrossRef]

- Wada, T.; Qin, F.; Wang, X.; Yoshimura, M.; Inoue, A.; Sugiyama, N.; Ito, R.; Matsushita, N. Formation and bioactivation of Zr-Al-Co bulk metallic glasses. J. Mater. Res. 2011, 24, 2941–2948. [Google Scholar] [CrossRef]

- Tan, J.; Pan, F.S.; Zhang, Y.; Sun, B.A.; He, J.; Zheng, N.; Stoica, M.; Kühn, U.; Eckert, J. Formation of Zr–Co–Al bulk metallic glasses with high strength and large plasticity. Intermetallics 2012, 31, 282–286. [Google Scholar] [CrossRef]

- Matsuda, M.; Nishimoto, T.; Matsunaga, K.; Morizono, Y.; Tsurekawa, S.; Nishida, M. Deformation structure in ductile B2-type Zr–Co–Ni alloys with martensitic transformation. J. Mater. Sci. 2011, 46, 4221–4227. [Google Scholar] [CrossRef]

- Matsuda, M.; Nishimoto, T.; Morizono, Y.; Tsurekawa, S.; Nishida, M. Enhancement of ductility in B2-type Zr–Co–Pd alloys with martensitic transformation. Intermetallics 2011, 19, 894–899. [Google Scholar] [CrossRef]

- Matsuda, M.; Iwamoto, Y.; Morizono, Y.; Tsurekawa, S.; Takashima, K.; Nishida, M. Enhancement of ductility in B2-type Zr–Co–Ni alloys with deformation-induced martensite and microcrack formation. Intermetallics 2013, 36, 45–50. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, C.; Jiang, J.-Z. Bulk metallic glass composites containing B2 phase. Prog. Mater. Sci. 2021, 121, 100799. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, H.; Wu, Y.; Song, W.; Chen, R.; Tan, C.; Xie, G.; Cao, D.; Wang, H.; Liu, X.; et al. Enhancing dynamic mechanical properties of bulk metallic glass composites via deformation-induced martensitic transformation. Scr. Mater. 2020, 186, 346–351. [Google Scholar] [CrossRef]

- Lu, W.F.; Li, C.J.; Sarac, B.; Şopu, D.; Yi, J.H.; Tan, J.; Stoica, M.; Eckert, J. Structural, elastic and electronic properties of CoZr in B2 and B33 structures under high pressure. J. Alloys Compd. 2017, 705, 445–455. [Google Scholar] [CrossRef]

- Li, X.; Lu, W.F.; Li, C.J.; Yuan, Q.; Wu, Z.X.; Tan, J.; Gao, P.; You, X.; Yi, J.H. Effect of Al content on the mechanical properties and toughening mechanism of Zr-Co-Al alloys prepared by rapid solidification. Mater. Sci. Eng. A 2022, 831, 142237. [Google Scholar] [CrossRef]

- Jansson, K.; Nygren, M.; Östlund, Å. Crystallization behaviour of amorphous Zr1-xCox alloys with 0.20 ≤ x ≤ 0.41. Mater. Res. Bull. 1984, 19, 1091–1104. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, J.-Z. Formation of the B2–ZrCo phase and micro-hardness evolution in Zr–Co–Al BMGs via conventional and flash annealing. J. Alloys Compd. 2020, 834, 154230. [Google Scholar] [CrossRef]

- Kosiba, K.; Scudino, S.; Kobold, R.; Kühn, U.; Greer, A.L.; Eckert, J.; Pauly, S. Transient nucleation and microstructural design in flash-annealed bulk metallic glasses. Acta Mater. 2017, 127, 416–425. [Google Scholar] [CrossRef]

- Li, C.J.; Tan, J.; Zhu, X.K.; Zhang, Y.; Stoica, M.; Kuhn, U.; Eckert, J. On the transformation-induced work-hardening behavior of Zr47.5Co47.5Al5 ultrafine-grained alloy. Intermetallics 2013, 35, 116–119. [Google Scholar] [CrossRef]

- Li, P.Y. Microstructure and mechanical properties of novel B2-type ductile Zr-Co-Cu alloys containing the B33 phase. Mater. Res. Express. 2017, 4, 086505. [Google Scholar] [CrossRef]

- Hossain, D.; Harris, I.R.; Barraclough, K.G. A study of ZrCo and related ternary phases represented by the general formula, Zr50Co50 xNix. J. Less Common Met. 1974, 37, 35–57. [Google Scholar] [CrossRef]

- François, A.; Veyssière, P. A TEM investigation of the deformation microstructure of CoZr and Co40Ni10Zr50 ordered alloys. Intermetallics 1994, 2, 9–22. [Google Scholar] [CrossRef]

- Wu, D.Y.; Song, K.K.; Gargarella, P.; Cao, C.D.; Li, R.; Kaban, I.; Eckert, J. Glass-forming ability, thermal stability of B2 CuZr phase, and crystallization kinetics for rapidly solidified Cu–Zr–Zn alloys. J. Alloys Compd. 2016, 664, 99–108. [Google Scholar] [CrossRef]

- Javid, F.A.; Mattern, N.; Pauly, S.; Eckert, J. Effect of Cobalt on Phase Formation, Microstructure, and Mechanical Properties of Cu50−xCoxZr50 (x = 2, 5, 10, 20 at.%) Alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 43, 2631–2636. [Google Scholar] [CrossRef]

- Ishida, K.; Kainuma, R.; Ueno, N.; Nishizawa, T. Ductility enhancement in NiAl (B2)-base alloys by microstructural control. Metall. Trans. A 1991, 22, 441–446. [Google Scholar] [CrossRef]

- Zeumer, B.; Sauthoff, G. Deformation behaviour of intermetallic NiAl Ta alloys with strengthening Laves phase for high-temperature applications III. Effects of alloying with Cr. Intermetallics 1998, 6, 451–460. [Google Scholar] [CrossRef]

- McKamey, C.G.; Horton, J.A.; Liu, C.T. Effect of chromium on properties of Fe3Al. J. Mater. Res. 2011, 4, 1156–1163. [Google Scholar] [CrossRef]

- Nowak, K.; Kupka, M. High-temperature oxidation behaviour of B2 FeAl based alloy with Cr, Zr and B additions. Mater. Chem. Phys. 2012, 132, 902–908. [Google Scholar] [CrossRef]

- Aoki, K.; Izumi, O. Improvement in Room Temperature Ductility of the Intermetallic Compound Ni3Al by Ternary Trace Element Addition. J. Jpn. Inst. Met. 1979, 43, 358–359. [Google Scholar] [CrossRef]

- Wollmershauser, J.A.; Kabra, S.; Agnew, S.R. In situ neutron diffraction study of the plastic deformation mechanisms of B2 ordered intermetallic alloys: NiAl, CuZn, and CeAg. Acta Mater. 2009, 57, 213–223. [Google Scholar] [CrossRef]

- Mulay, R.P.; Agnew, S.R. The fracture behavior of B2 structured MgR intermetallics. Scr. Mater. 2009, 61, 1036–1039. [Google Scholar] [CrossRef]

- Russell, A.M.; Zhang, Z.; Lograsso, T.A.; Lo, C.C.H.; Pecharsky, A.O.; Morris, J.R.; Ye, Y.; Gschneidner, K.A.; Slager, A.J. Mechanical properties of single crystal YAg. Acta Mater. 2004, 52, 4033–4040. [Google Scholar] [CrossRef]

- Stumphy, B.; Mudryk, Y.; Russell, A.; Herman, D.; Gschneidner, K. Oxidation resistance of B2 rare earth–magnesium intermetallic compounds. J. Alloys Compd. 2008, 460, 363–367. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, H.; Wu, H.H.; Zhang, Z.Y.; Hui, X.D.; Chen, G.L.; Ma, D.; Wang, X.L.; Lu, Z.P. Formation of Cu–Zr–Al bulk metallic glass composites with improved tensile properties. Acta Mater. 2011, 59, 2928–2936. [Google Scholar] [CrossRef]

- Li, C.J.; Tan, J.; Wang, G.; Bednarčík, J.; Zhu, X.K.; Zhang, Y.; Stoica, M.; Kühn, U.; Eckert, J. Enhanced strength and transformation-induced plasticity in rapidly solidified Zr–Co–(Al) alloys. Scr. Mater. 2013, 68, 897–900. [Google Scholar] [CrossRef]

- Tan, J.; Zhang, Y.; Stoica, M.; Kuhn, U.; Mattern, N.; Pan, F.S.; Eckert, J. Study of mechanical property and crystallization of a ZrCoAl bulk metallic glass. Intermetallics 2011, 19, 567–571. [Google Scholar] [CrossRef]

- Dong, Q.; Pan, Y.J.; Tan, J.; Qin, X.M.; Li, C.J.; Gao, P.; Feng, Z.X.; Calin, M.; Eckert, J. A comparative study of glass-forming ability, crystallization kinetics and mechanical properties of Zr55Co25Al20 and Zr52Co25Al23 bulk metallic glasses. J. Alloys Compd. 2019, 785, 422–428. [Google Scholar] [CrossRef]

- Matsuda, M.; Hayashi, K.; Nishida, M. Ductility Enhancement in B2-Type Zr-Co-Ni Alloys with Martensitic Transformation. Mater. Trans. 2009, 50, 2335–2340. [Google Scholar] [CrossRef]

- Guan, H.D.; Li, C.J.; Peng, Y.Z.; Gao, P.; Feng, Z.X.; Liu, Y.C.; Li, J.N.; Tao, J.M.; Yi, J.H. Fe-based metallic glass particles carry carbon nanotubes to reinforce Al matrix composites. Mater. Charact. 2022, 189, 112006. [Google Scholar] [CrossRef]

- Liu, J.; Fan, G.; Tan, Z.; Guo, Q.; Su, Y.; Li, Z.; Xiong, D.-B. Mechanical properties and failure mechanisms at high temperature in carbon nanotube reinforced copper matrix nanolaminated composite. Compos. Part A Appl. Sci. Manuf. 2019, 116, 54–61. [Google Scholar] [CrossRef]

- Deng, H.; Yi, J.; Xia, C.; Yi, Y. Mechanical properties and microstructure characterization of well-dispersed carbon nanotubes reinforced copper matrix composites. J. Alloys Compd. 2017, 727, 260–268. [Google Scholar] [CrossRef]

| Alloys | UTS (MPa) | UFS (%) |

|---|---|---|

| Zr50Co50 | 240 ± 20 | 6.99 |

| Zr48Co48Al4 | 304 ± 20 | 3.75 |

| Zr47.5Co47.5Al5 | 464 ± 20 | 3.93 |

| Zr47Co47Al6 | 396 ± 20 | 3.30 |

| Zr46.5Co46.5Al7 | 390 ± 20 | 3.28 |

| Zr46Co46Al8 | 363 ± 20 | 3.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Lu, W.; Li, C.; Gao, P.; You, X.; Tan, J. Effect of Al Content on the Microstructure and Tensile Properties of Zr-Co-Al Alloy Prepared by Rapid Solidification. Crystals 2022, 12, 1483. https://doi.org/10.3390/cryst12101483

Wu Z, Lu W, Li C, Gao P, You X, Tan J. Effect of Al Content on the Microstructure and Tensile Properties of Zr-Co-Al Alloy Prepared by Rapid Solidification. Crystals. 2022; 12(10):1483. https://doi.org/10.3390/cryst12101483

Chicago/Turabian StyleWu, Zixiang, Wenfei Lu, Caiju Li, Peng Gao, Xin You, and Jun Tan. 2022. "Effect of Al Content on the Microstructure and Tensile Properties of Zr-Co-Al Alloy Prepared by Rapid Solidification" Crystals 12, no. 10: 1483. https://doi.org/10.3390/cryst12101483

APA StyleWu, Z., Lu, W., Li, C., Gao, P., You, X., & Tan, J. (2022). Effect of Al Content on the Microstructure and Tensile Properties of Zr-Co-Al Alloy Prepared by Rapid Solidification. Crystals, 12(10), 1483. https://doi.org/10.3390/cryst12101483