Study on the Influence of Grain Size and Microstructure on the Mechanical Properties of Fe-6.5 wt%Si High Silicon Steel Prepared by CVD Method

Abstract

1. Introduction

2. Experimental and Simulation Modeling

2.1. Sample Preparation and Characterization

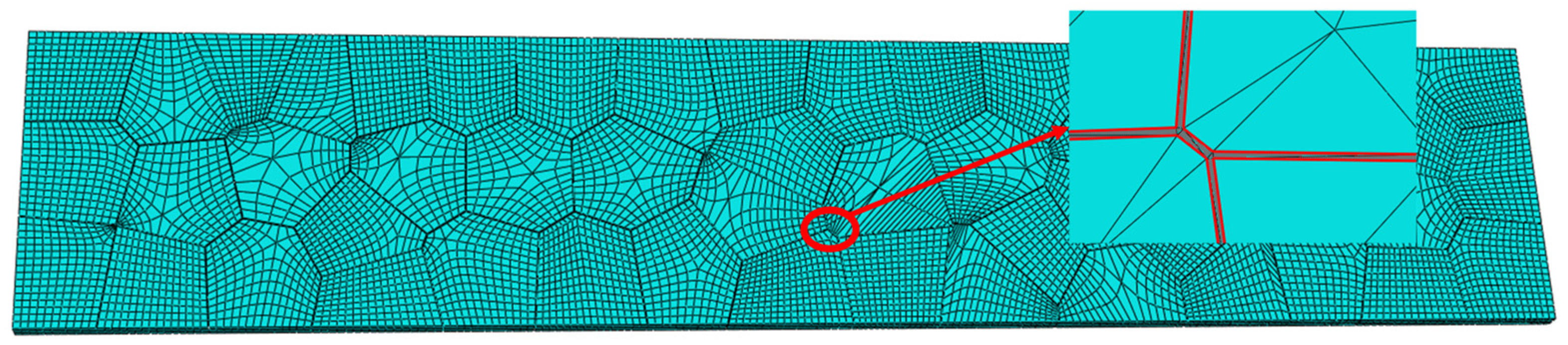

2.2. Simulation Modeling

3. Results and Discussion

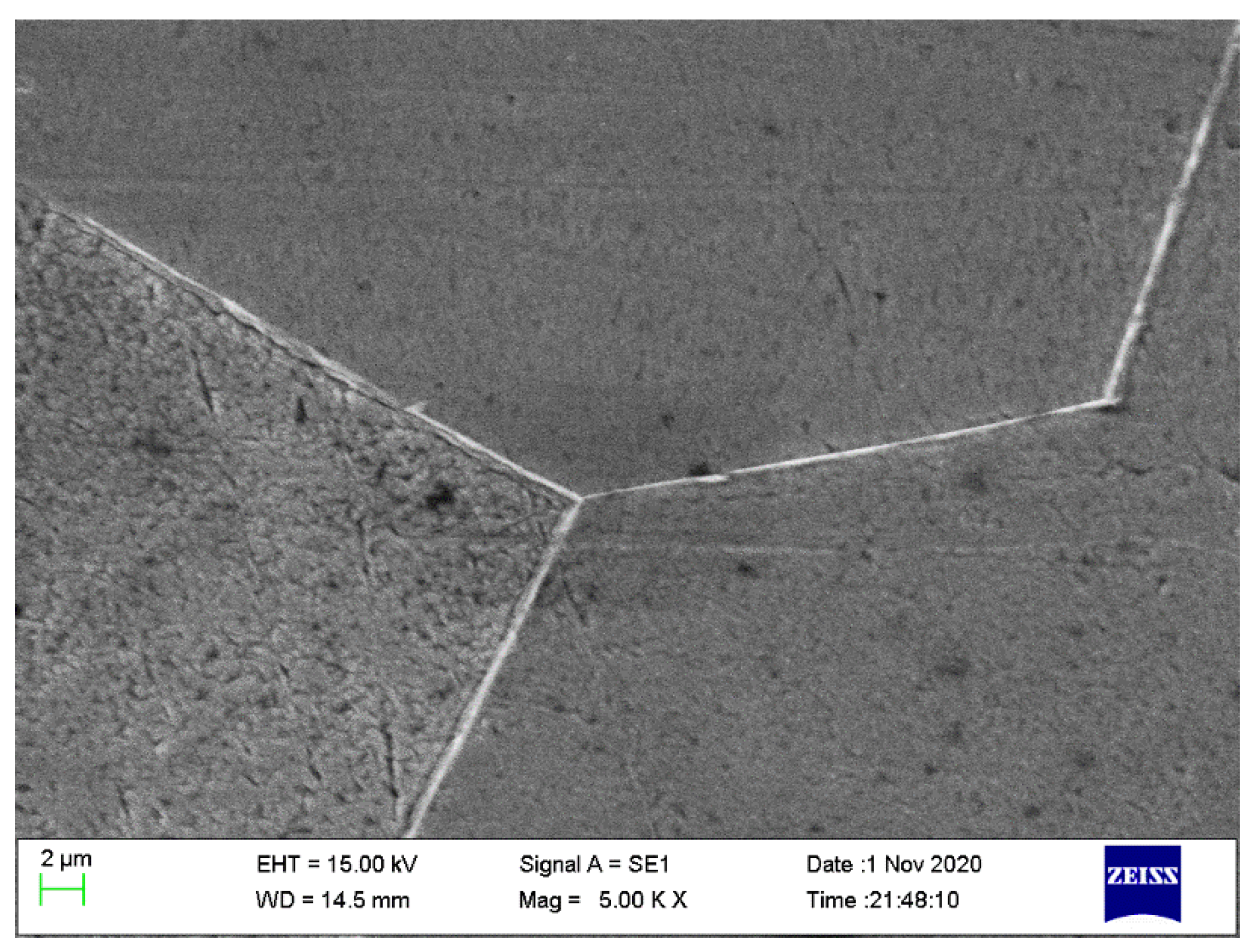

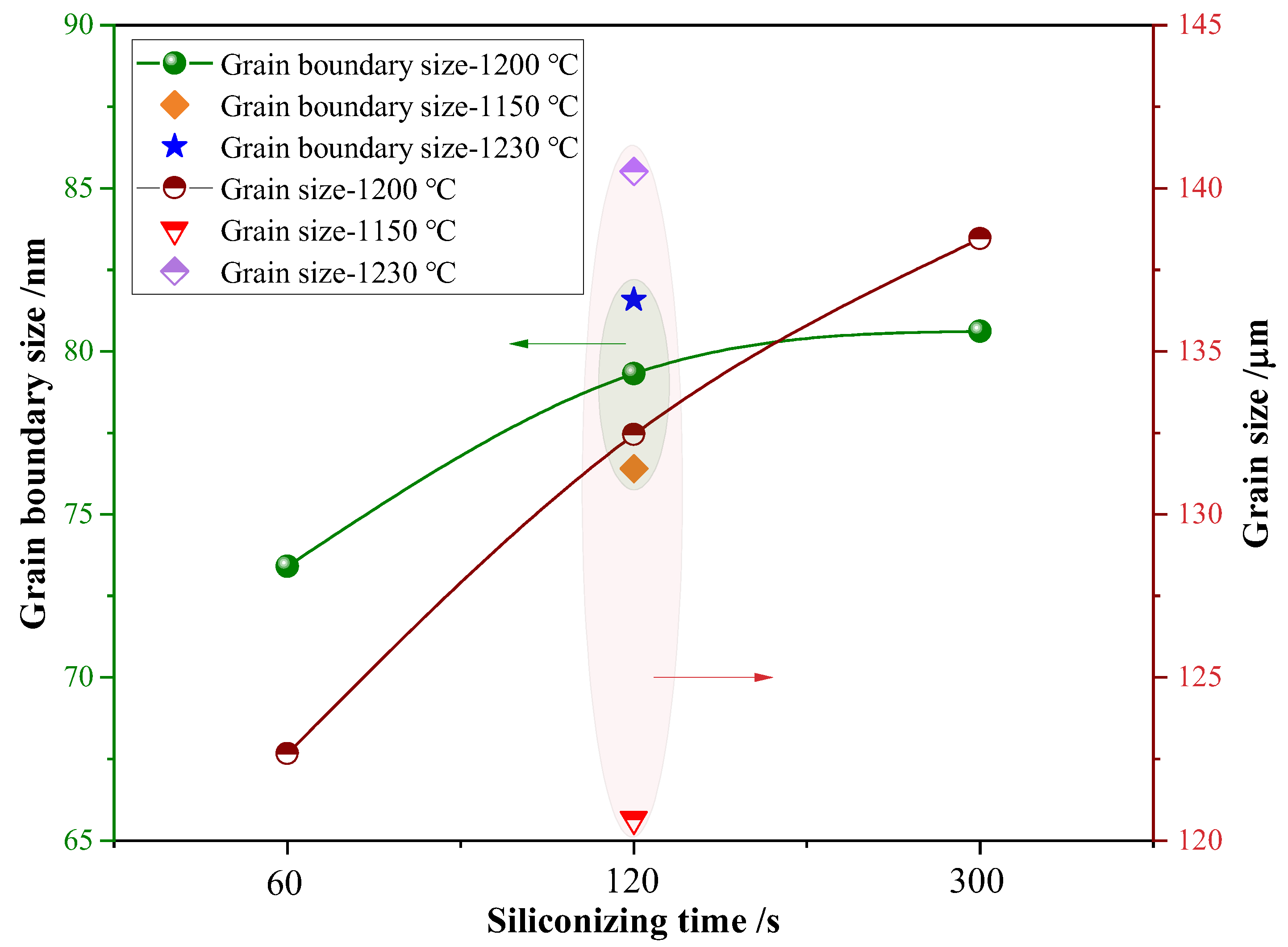

3.1. Influence of Silicon Infiltration Parameters on Grain and Grain Boundary Size

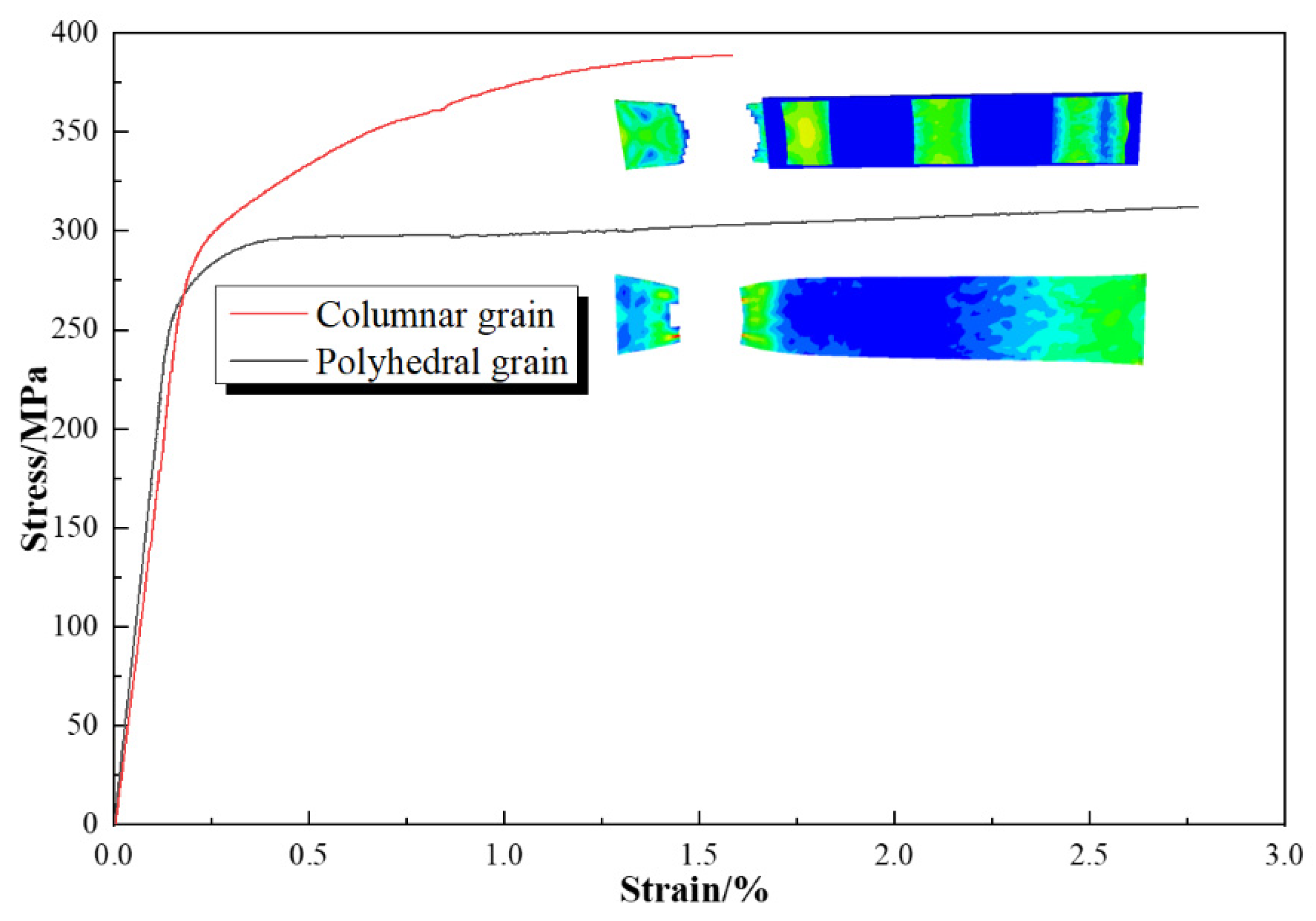

3.2. Simulation Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, H. Analysis of energy-saving transformer core materials. Decis. Inf. J. 2015, 8, 232. [Google Scholar]

- Yang, G.; Sang, Z.; Ge, Y. A new method for transformer vibration and noise research. Sci. Technol. Inno. App. 2014, 35, 3–4. [Google Scholar]

- Littmann, M. Iron and silicon-iron alloys. IEEE Trans. Magn. 1971, 7, 48–60. [Google Scholar] [CrossRef]

- Krings, A.; Boglietti, A.; Cavagnino, A.; Sprague, S. Soft magnetic material status and trends in electric machines. IEEE Trans. Ind. Electron. 2017, 64, 2405–2414. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, F.; Zhu, H.; Pan, H. Effects of temperature and diffusion time on the preparation of high silicon Ssteel by CVD method. Surf. Technol. 2013, 42, 85–87. [Google Scholar]

- Ouyang, G.; Chen, X.; Liang, Y.; Macziewski, C.; Cui, J. Review of Fe-6.5wt%Si high silicon steel—A promising soft magnetic material for sub-kHz application. J. Magn. Magn. Mater. 2019, 481, 234–250. [Google Scholar] [CrossRef]

- Shi, Q.; Yao, X. Prediction simulation of power generation and installed capacity in the world and China. Elec. Power Eng. 2008, 28, 147–151. [Google Scholar]

- Yang, J.; Xie, J.; Zhou, C. Preparation process and development prospect of 6.5%Si high silicon steel. Funct. Mater. 2003, 3, 244–246. [Google Scholar]

- Lobanov, M.L.; Rusakov, G.M.; Redikul’Tsev, A.A. Electrotechnical anisotropic steel. Part 1. History of development. Met. Sci. Heat Treat. 2011, 53, 326–332. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Liang, J. Progress in Preparation Technology of 6.5%Si Silicon Steel Sheet. Spec. Stl. 2008, 6, 31–33. [Google Scholar]

- Abe, M.; Takada, Y.; Murakamt, T.; Tanaka, Y.; Mihara, Y. Magnetic properties of commercially produced Fe-6.5wt% Si sheet. J. Mater. Eng. 1989, 11, 109–116. [Google Scholar] [CrossRef]

- Crottier-combe, S.; Audisio, S.; Degauque, J.; Porteseil, J.L.; Ferrara, E.; Pasquale, M.; Fiorillo, F. The magnetic properties of Fe-Si 6.5wt% alloys obtained by a SiCl4-based CVD process. J. Magn. Magn. Mater. 1996, 160, 151–153. [Google Scholar] [CrossRef]

- Su, C.; Zhao, G.; Xiao, H.; Huang, F. Microstructure and texture evolution of high temperature nitriding hi-b steel during secondary recrystallization. J. Iron Steel Res. 2018, 30, 461–468. [Google Scholar]

- Wang, H.; Li, C.; Cai, B.; Chukwuchekwa, N. Effect of ball notch method on the magnetism of high magnetic inductance-oriented silicon steel. J. NEU (Nat Sci. Ed. ) 2013, 34, 1571–1574. [Google Scholar]

- Chen, Q.Y.; Chen, J.; Ren, J.K.; Wang, Z.H.; Liu, Z.Y. Effect of Si content on microstructure and cryogenic toughness of heat affected zone of low nickel steel. Mater. Sci. Eng. A 2020, 771, 138621. [Google Scholar] [CrossRef]

- Kazuhisa, Q.; Tsunehiro, Y.; Katsushi, K. Basic investigation of CVD method for manufacturing 6.5% Si steel sheet. ISIJ Int. 1996, 36, 706–713. [Google Scholar]

- Kusaka, K.; Imaoka, T.; Kondo, T. Relationship between properties and Si-content sintering conditions of Fe-Si type mag-netic alloys. J. Japan Soc. Powder Powder Metall. 2000, 42, 195–202. [Google Scholar] [CrossRef][Green Version]

- Fu, Y.; Su, H.; Liao, Q.; Lei, J.; Zhao, D.; Zhang, Y. Research progress on preparation technology of high silicon steel rolling method. Funct. Mater. 2018, 49, 12084–12090, 12095. [Google Scholar]

- Yuan, W.; Shen, Q.; Zhang, L. Research on Fe-6.5%Si silicon steel produced by powder rolling technique. Powder Metall. Tech. 2007, 25, 32–34. [Google Scholar]

- Haiji, H.; Okada, K.; Hiratani, T.; Abe, M.; Ninomiya, M. Magnetic properties and workability of 6.5% Si steel sheet. J. Magn. Magn. Mater. 1996, 160, 109–114. [Google Scholar] [CrossRef]

- Tatsuhiko, H.; Misao, N.; Hironori, N.; Yoshihiko, O.; Hiroaki, T. Magnetization mechanism of Si-gradient steel sheet manufactured by CVD siliconizing process. Electr. Eng. Jpn. 2015, 193, 18–29. [Google Scholar]

- Fujita, K.; Namikawa, M.; Takada, Y. Magnetic properties and workability of 6.5% Si steel sheet manufactured by siliconizing process. J. Mater. Sci. Technol. 2000, 16, 137–140. [Google Scholar]

- Kim, K.; Pan, L.; Lin, J.; Wang, Y.; Lin, Z.; Chen, G. The effect of boron content on the processing for Fe-6.5wt% Si electrical steel sheets. J. Magn. Magn. Mater. 2004, 277, 331–336. [Google Scholar] [CrossRef]

- Su, F.; Gao, C.; Xiang, Y.; Chen, J. Study on High Temperature Mutual Diffusion Behavior of Fe/Si Alloy. Shanghai Met. 2015, 37, 9–13. [Google Scholar]

- Yamaji, T.; Abe, M.; Takada, Y.; Okada, K.; Hiratani, T. Magnetic properties and workability of 6.5% silicon steel sheet man-ufactured in continuous CVD siliconizing line. J. Magn. Magn. Mater. 1994, 133, 187–189. [Google Scholar] [CrossRef]

- Qian, Y. Development Status of Near-final Shaping Technology—Application of Double Roll Thin Belt Continuous Casting Process in High Si Electrical Steel. Shanghai ISRI 2002, 2, 33–39. [Google Scholar]

- Ouyang, G.; Macziewski, C.; Jensen, B.; Ma, T.; Cui, J. Effects of solidification cooling rates on microstructures and physical properties of Fe-6.5%Si alloys. Acta Mater. 2020, 205, 116575. [Google Scholar] [CrossRef]

- Rouhollahi, A.; Zendehdel, S.; Khaleghi, M.; Fazlolahzadeh, O. Pulsed electrodeposition of platinum nanoparticles on fluorine doped tin oxide in molten salt and its high electrocatalytic activity towards ethanol oxidation. Anal. Bioanal. Chem. 2014, 6, 120–130. [Google Scholar]

- Kang, S. Research on jet forming technology of high silicon steel sheet. Powder Metal. Indus. 2009, 19, 30–33. [Google Scholar]

- Gao, C.; Su, F.; Xiang, Y.; Sun, Q.; Chen, J. Brittleness of silicon steel with a mass fraction of 6.5% by chemical vapor deposition. Mech. Eng. Mater. 2015, 39, 12–16. [Google Scholar]

- Pan, J.; Wang, H.; Daniel, Z.; Chen, B.; Liu, X.; Pan, J. Effect of rare earth grain boundaries on the resilience of three thermal deformations of NdFeB alloys. Chin. J. Rare Earth 2018, 36, 61–68. [Google Scholar]

- Xu, Z.; Chen, J.; Ye, D.; Yin, C.; Qin, Z.; Zhang, Q. Effect of microstructure on silicon diffusion in 6.5%Si silicon steel prepared by CVD method. Surf. Technol. 2021, 50, 247–254. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, D.; Xu, Z.; Yin, C.; Wu, Y.; Chen, J.; Chen, R.; Pan, J.; Chen, Y.; Li, R. Study on the Influence of Grain Size and Microstructure on the Mechanical Properties of Fe-6.5 wt%Si High Silicon Steel Prepared by CVD Method. Crystals 2022, 12, 1470. https://doi.org/10.3390/cryst12101470

Ye D, Xu Z, Yin C, Wu Y, Chen J, Chen R, Pan J, Chen Y, Li R. Study on the Influence of Grain Size and Microstructure on the Mechanical Properties of Fe-6.5 wt%Si High Silicon Steel Prepared by CVD Method. Crystals. 2022; 12(10):1470. https://doi.org/10.3390/cryst12101470

Chicago/Turabian StyleYe, Dongdong, Zhou Xu, Changdong Yin, Yiwen Wu, Jianjun Chen, Rui Chen, Jiabao Pan, Yajuan Chen, and Rui Li. 2022. "Study on the Influence of Grain Size and Microstructure on the Mechanical Properties of Fe-6.5 wt%Si High Silicon Steel Prepared by CVD Method" Crystals 12, no. 10: 1470. https://doi.org/10.3390/cryst12101470

APA StyleYe, D., Xu, Z., Yin, C., Wu, Y., Chen, J., Chen, R., Pan, J., Chen, Y., & Li, R. (2022). Study on the Influence of Grain Size and Microstructure on the Mechanical Properties of Fe-6.5 wt%Si High Silicon Steel Prepared by CVD Method. Crystals, 12(10), 1470. https://doi.org/10.3390/cryst12101470