Reduction of Fluorine Diffusion and Improvement of Dark Current Using Carbon Implantation in CMOS Image Sensor

Abstract

:1. Introduction

2. Principles of Fluorine Diffusion and Image Sensor Operation

2.1. Principle of Fluorine Diffusion

2.2. Principle of Image Sensor Operation

3. Experimentals

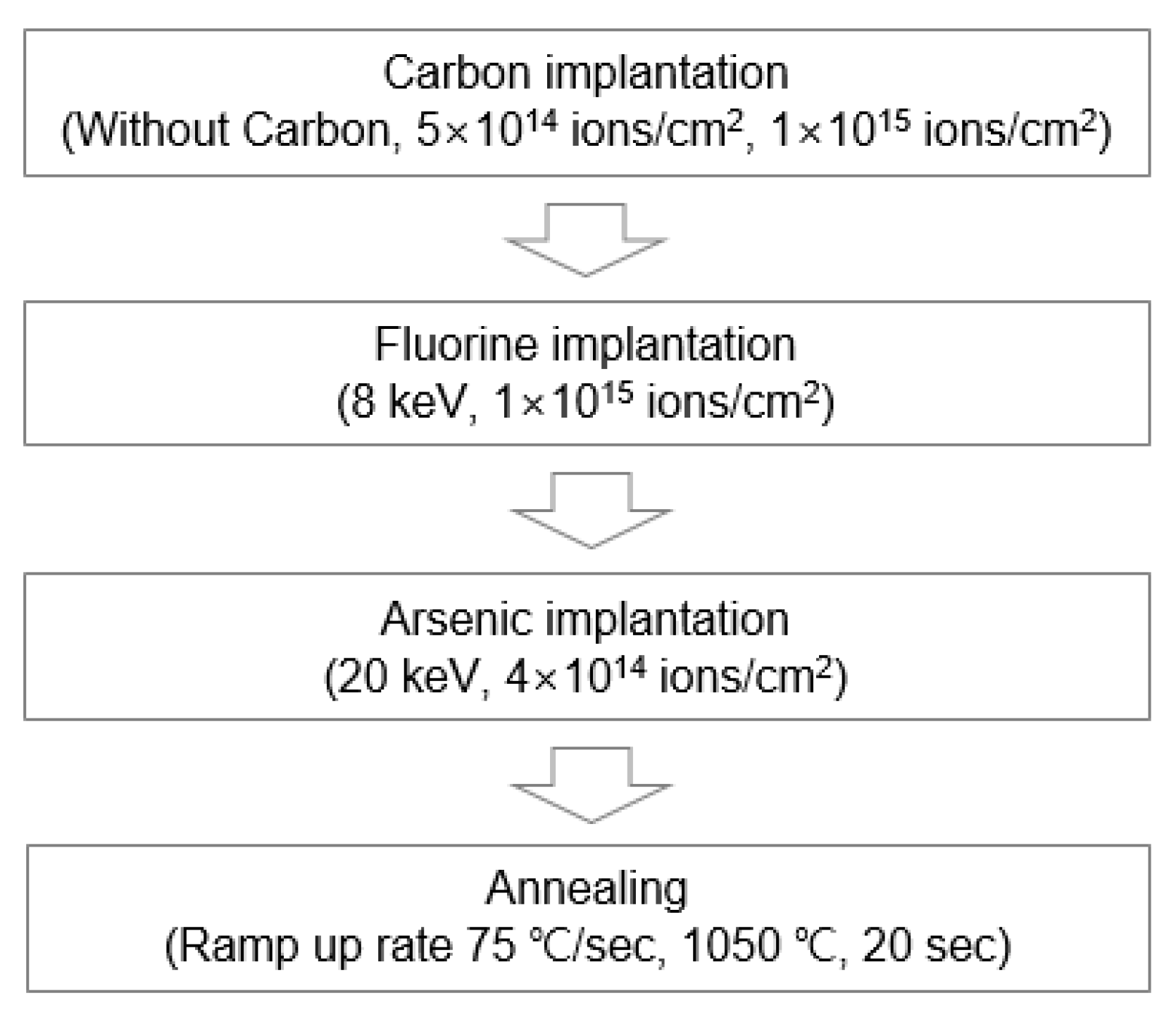

3.1. Implantation Process and Characterization

3.2. Fabrication of Image Sensor

4. Results and Discussion

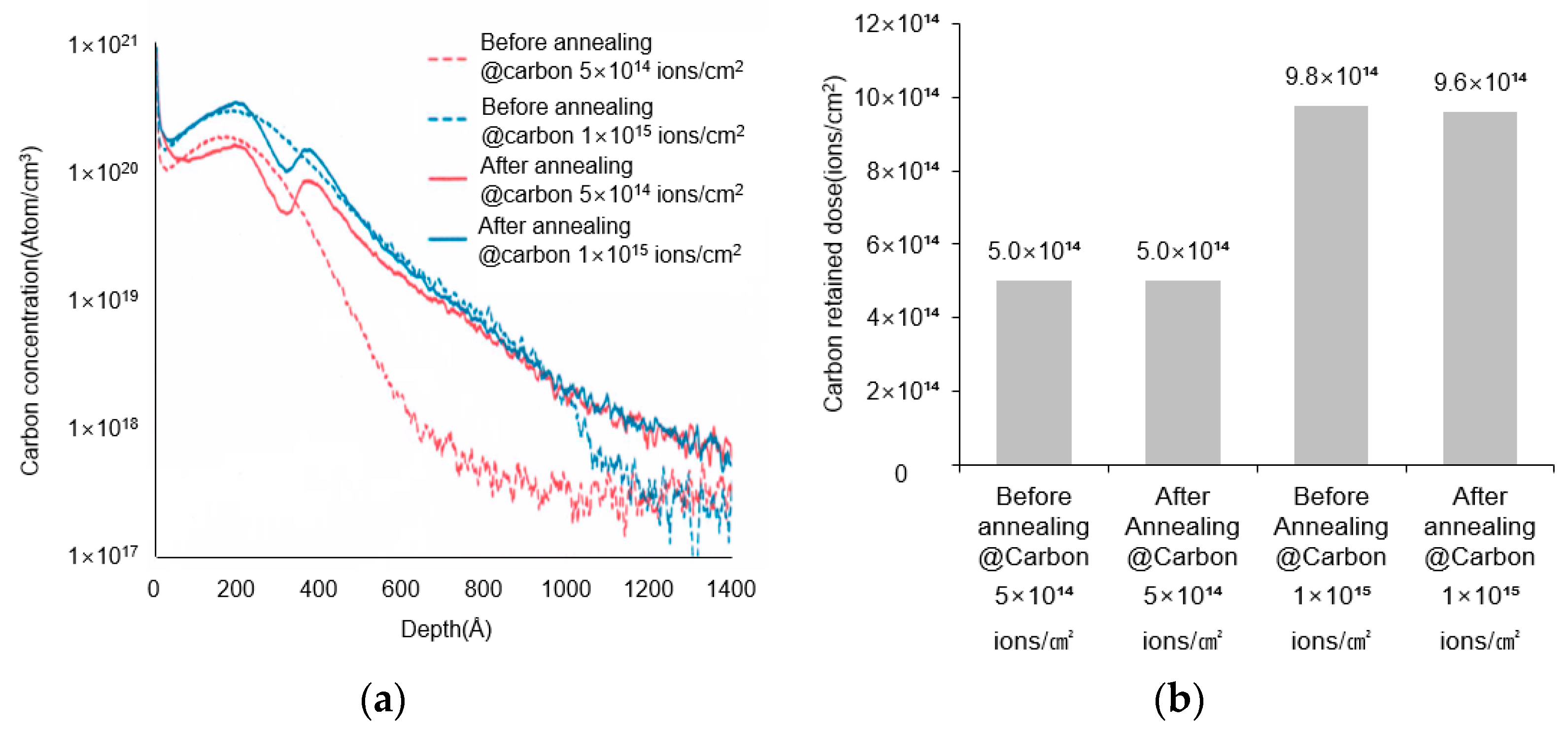

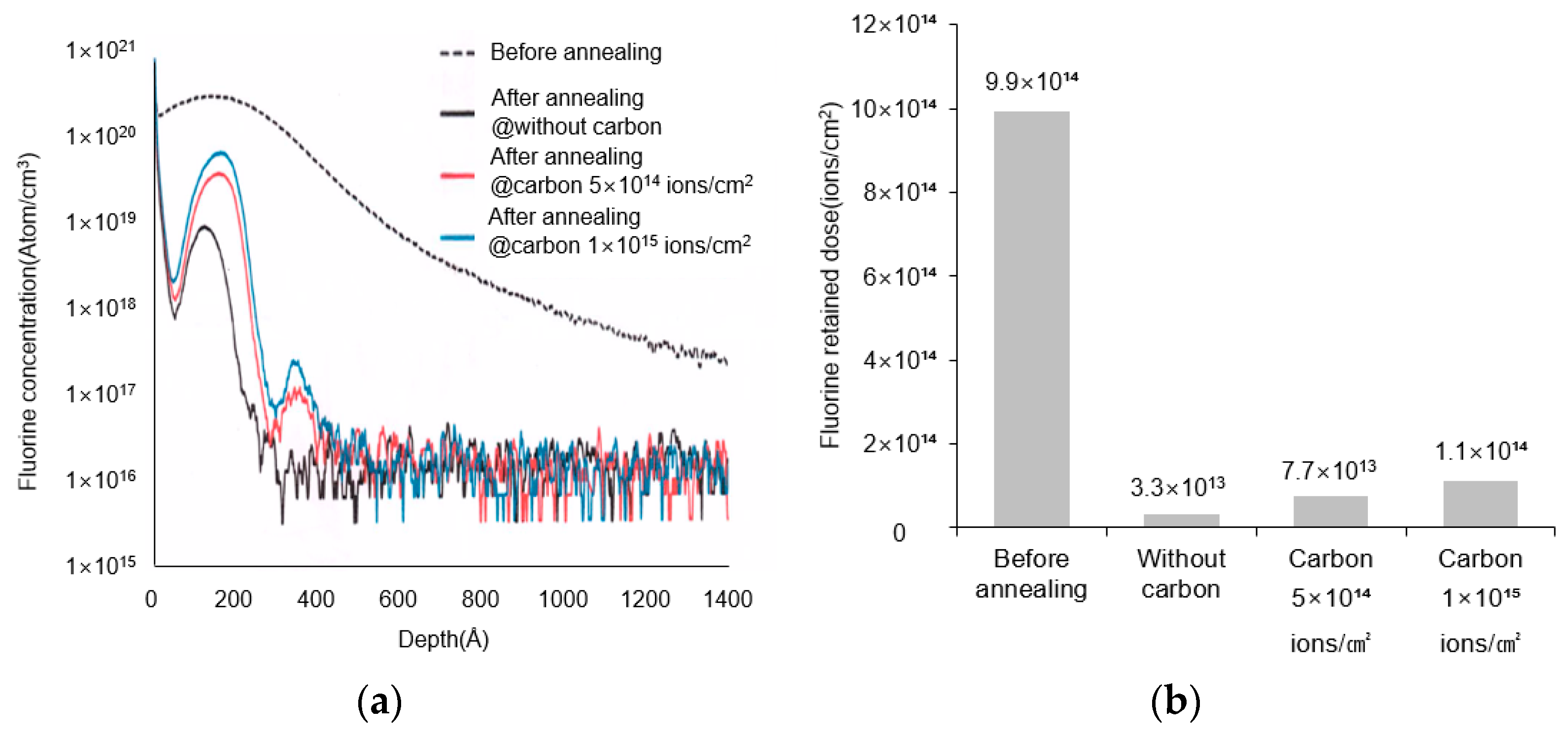

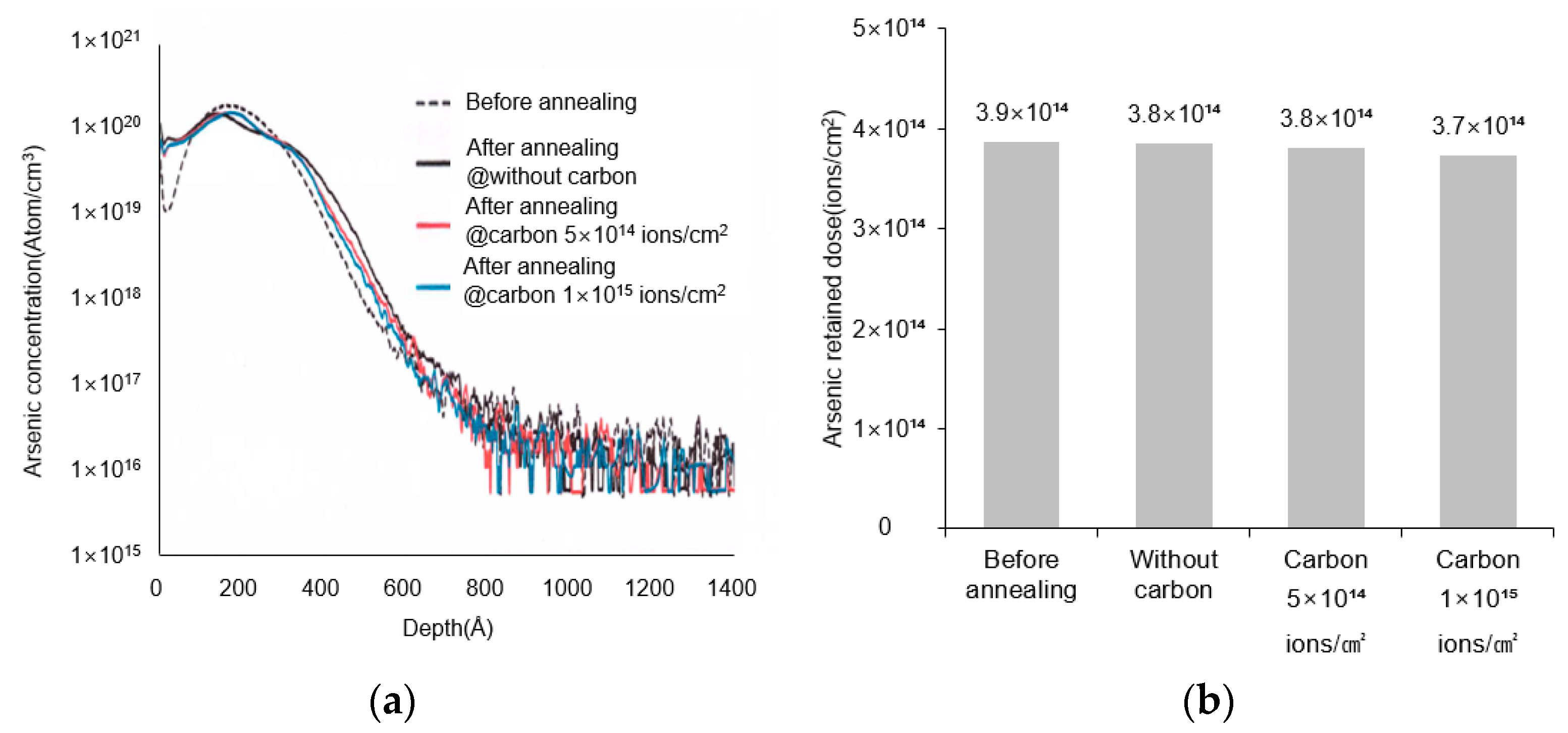

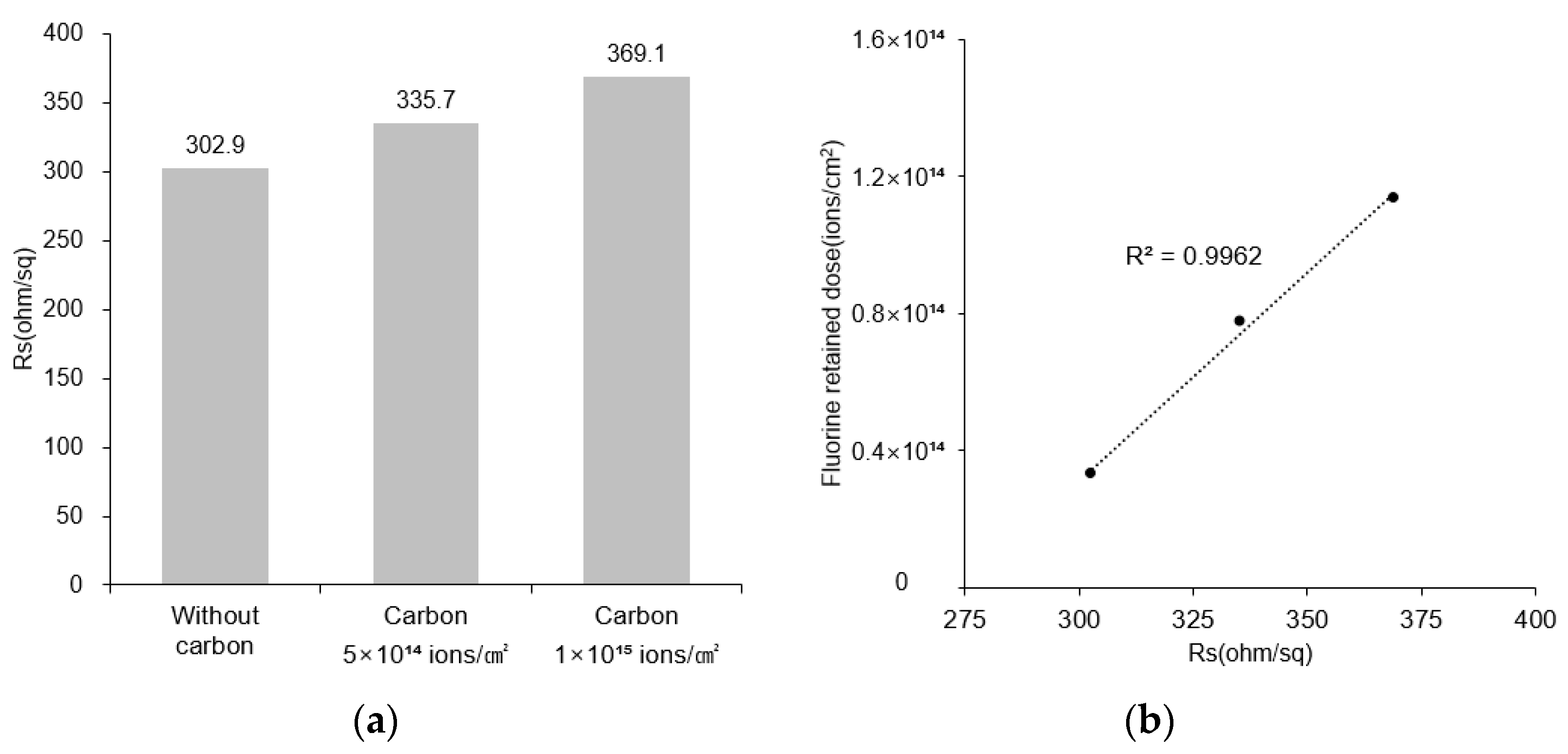

4.1. Measurements of Concentration and Sheet Resistance

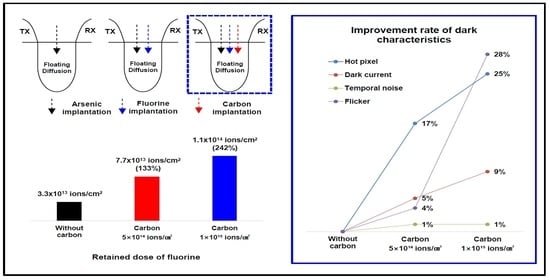

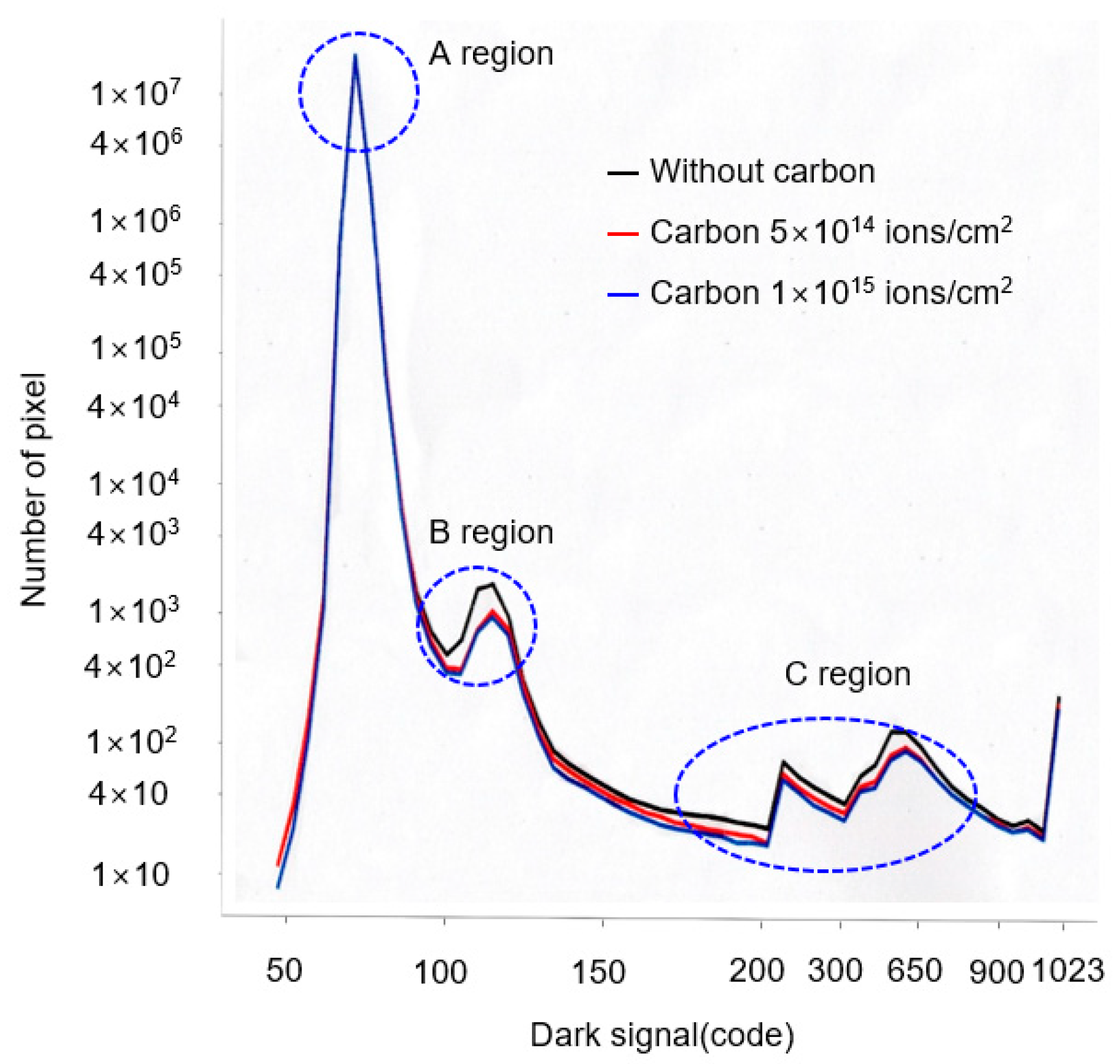

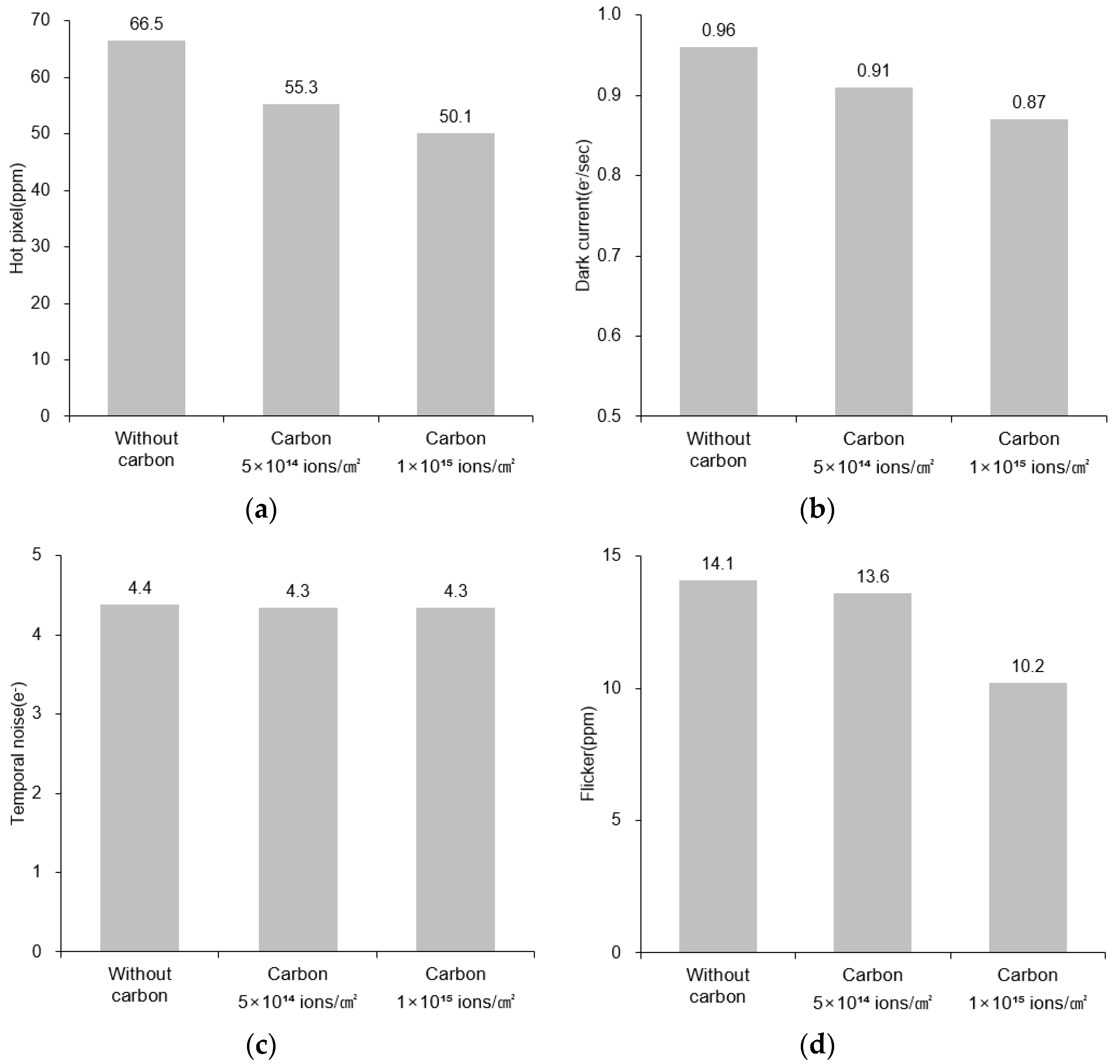

4.2. Evaluation of Dark Current of Image Sensor

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Market Breakdown of Camera Phone—2nd Half 2019 & 1st Half 2020 Forecast; Techno Systems Research: Tokyo, Japan, 2020; pp. 1–4. Available online: https://www.t-s-r.co.jp/en/report/3115/ (accessed on 10 September 2021). (In Japanese)

- Sukhavasi, S.B.; Sukhavasi, S.B.; Elleithy, K.; Abuzneid, S.; Elleithy, A. CMOS Image Sensors in Surveillance System Applications. Sensors 2021, 21, 488. [Google Scholar] [CrossRef] [PubMed]

- Park, S.-S.; Shin, B.-J.; Uh, H.-S. Recent Technology Trends and Future Prospects for Image Sensor. J. Microelectron. Packag. Soc. 2020, 27, 1–10. [Google Scholar]

- Park, S.-S. CCD/CMOS Image Sensor; Dooyangsa: Seoul, Korea, 2010; pp. 43–140. [Google Scholar]

- Teranishi, N.; Kohono, A.; Ishihara, Y.; Oda, E.; Arai, K. No Image Lag Photodiode Structure in the Interline CCD Image Sensor. In Proceedings of the International Electron Devices Meeting, San Francisco, CA, USA, 13–15 December 1982; pp. 324–327. [Google Scholar]

- Fossum, E.R.; Hondongwa, D.B. A Review of the Pinned Photodiode for CCD and CMOS Image Sensors. IEEE J. Electron Devices Soc. 2014, 2, 33–43. [Google Scholar] [CrossRef]

- Teranishi, N. Effect and Limitation of Pinned Photodiode. IEEE Trans. Electron Devices 2015, 63, 10–15. [Google Scholar] [CrossRef]

- Teranishi, N. Ion Implantation Technology for Image Sensors. In Proceedings of the 21st International Conference on Ion Implantation Technology (IIT), Tainan, Taiwan, 26–30 September 2016; pp. 1–6. [Google Scholar]

- Teranishi, N.; Fuse, G.; Sugitani, M. A Review of Ion Implantation Technology for Image Sensors. Sensors 2018, 18, 2358. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chern, H.-N.; Lee, C.-L.; Lei, T.-F. The Effect of Fluorine Passivation on Polysilicon Thin-Film Transistors. IEEE Trans. Electron Devices 1994, 41, 698–702. [Google Scholar] [CrossRef]

- Kwon, S.-K.; Kwon, H.-M.; Han, I.-S.; Jang, J.-H.; Oh, S.-H.; Song, H.-S.; Park, B.-S.; Chung, Y.-S.; Lee, J.-H.; Kim, S.-B.; et al. Effects of Fluorine on the NBTI Reliability and Low-Frequency Noise Characteristics of p-MOSFETs. IEEE J. Electron Devices Soc. 2018, 6, 808–814. [Google Scholar] [CrossRef]

- Maegawa, S.; Ipposhi, T.; Maeda, S.; Nishimura, H.; Ichiki, T.; Ashida, M.; Tanina, O.; Inoue, Y.; Nishimura, T.; Tsubouchi, N. Performance and Reliability Improvements in Poly-Si TFT’s by Fluorine Implantation into Gate Poly-Si. IEEE Trans. Electron Devices 1995, 42, 1106–1112. [Google Scholar] [CrossRef]

- Ha, M.-L.; Kang, M.-K.; Yoon, S.-W.; Han, C.-H.; Lee, J.; Lee, Y.-J. Temporal Noise Improvement Using the Selective Application of the Fluorine Implantation in the CMOS Image Sensor. In Proceedings of the International Image Sensors Workshop (IISW), Hiroshima, Japan, 30 May–2 June 2017; pp. 32–35. [Google Scholar]

- Mastromatteo, M. Mechanism of Fluorine redistribution and Incorporation During Sold Phase Epitaxial Regrowth of Pre-Amorphized Silicon. Ph.D. Thesis, University of Padova, Padua, Italy, 31 January 2010. [Google Scholar]

- Jeng, S.-P.; Ma, T.-P.; Canteri, R.; Anderle, M.; Rubloff, G.W. Anomalous Diffusion of Fluorine in Silicon. Appl. Phys. Lett. 1992, 61, 1310–1312. [Google Scholar] [CrossRef] [Green Version]

- Vanderpool, A.; Taylor, M. Reducing Ultra-Shallow Boron Diffusion Using Carbon and Fluorine Co-implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms. 2005, 237, 142–147. [Google Scholar] [CrossRef]

- Williams, J.S. Solid phase epitaxial regrowth phenomena in silicon. Nucl. Instr. Meth. Res. 1983, 209–210, 219–228. [Google Scholar] [CrossRef]

- Nakamura, J. Image Sensors and Signal Processing for Digital Still Cameras; Taylor & Francis Group Publisher: London, UK, 2006; pp. 156–157. [Google Scholar]

- Diebel, M.; Chakravarthi, S.; Dunham, S.T.; Machala, C.F.; Ekbote, S.; Jain, A. Investigation and Modeling of Fluorine Co-implantation Effects on Dopant Redistribution. MRS Online Proc. Libr. (OPL) 2003, 765, D6.15.1–D6.15.6. [Google Scholar] [CrossRef] [Green Version]

- Diebel, M.; Dunham, S.T. Ab-initio Calculations to Model Anomalous Fluorine Behavior. MRS Online Proc. Libr. (OPL) 2002, 717, C4.5.1–C4.5.6. [Google Scholar] [CrossRef]

- Dunham, S.T. The Process Modeling Hierarchy: Connecting Atomistic Calculations to Nanoscale Behavior. In Proceedings of the International Conference on Simulation of Semiconductor Processes and Devices (SISPAD), Kobe, Japan, 4–6 September 2002; pp. 213–216. [Google Scholar]

- Pi, X.D.; Burrows, C.P.; Coleman, P.G. Fluorine in Silicon: Diffusion, Trapping, and Precipitation. Phys. Rev. Lett. 2003, 90, 155901. [Google Scholar] [CrossRef]

- Mubarek, H.A.W.E.; Ashburn, P. Reduction of Boron Diffusion in Silicon-Germanium by Fluorine Implantation. IEEE Electron Device Lett. 2004, 25, 535–537. [Google Scholar] [CrossRef]

- Titov, A.I.; Karabeshkin, K.V.; Karaseov, P.A.; Struchkov, A.I. Do chemical effects affect the accumulation of structural damage during the implantation of fluorine ions into GaN? Semiconductors 2019, 53, 1415–1418. [Google Scholar] [CrossRef]

- Carrère, J.P.; Place, S.; Oddou, J.P.; Benoit, D.; Roy, F. CMOS Image Sensor: Process Impact on Dark Current. In Proceedings of the 2014 IEEE International on Reliability Physics Symposium, Waikoloa, HI, USA, 1–5 June 2014; pp. 3C.1.1–3C.1.6. [Google Scholar]

- Domengie, F.; Regolini, J.L.; Bauza, D.; Morin, P. Impact on Device Performance and Monitoring of Low Dose of Tungsten Contamination by Dark Current Spectroscopy. In Proceedings of the 2010 IEEE International Reliability Physics Symposium (IRPS 2010), Anaheim, CA, USA, 2–6 May 2010; pp. 259–264. [Google Scholar]

- Virmontois, C.; Goiffon, V.; Magnan, P.; Girard, S.; Saint-Pé, O.; Petit, S.; Rolland, G.; Bardoux, A. Influence of Displacement Damage Dose on Dark Current Distributions of Irradiated CMOS Image Sensors. In Proceedings of the 2011 12th European Conference on Radiation and Its Effects on Components and Systems, Seville, Spain, 19–23 September 2011; pp. 329–335. [Google Scholar]

- Janesick, J. Photon Transfer DN→λ; SPIE Press: Bellingham, WA, USA, 2007; pp. 35–38. [Google Scholar]

| Process Order | Process Item & Condition | Without Carbon | Carbon 5 × 1014 Ions/cm2 | Carbon 1 × 1015 Ions/cm2 | |||||

|---|---|---|---|---|---|---|---|---|---|

| ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ | |||

| 1 | Carbon implantation | 5 keV, 5 × 1014 ions/cm2, Tilt 0°, Twist 0° | ○ | ○ | |||||

| 5 keV, 1 × 1015 ions/cm2, Tilt 0°, Twist 0° | ○ | ○ | |||||||

| 2 | Fluorine implantation | 8 keV, 1 × 1015 ions/cm2, Tilt 15°, Twist 90° | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 3 | Arsenic implantation | 20 keV, 4 × 1014 ions/cm2, Tilt 0°, Twist 0° | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| 4 | Annealing | Ramp up rate 75 °C/s, 1050 °C, 20 s | ○ | ○ | ○ | ○ | ○ | ○ | |

| 5 | Rs | 4-point probe, 49 point | ○ | ○ | ○ | ||||

| 6 | SIMS | Carbon, fluorine, arsenic | ○ | ○ | ○ | ○ | |||

| 7 | Dark characteristics | Hot pixel, dark current, temporal noise, flicker | ○ | ○ | ○ | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, S.-Y.; Choa, S.-H. Reduction of Fluorine Diffusion and Improvement of Dark Current Using Carbon Implantation in CMOS Image Sensor. Crystals 2021, 11, 1106. https://doi.org/10.3390/cryst11091106

Chai S-Y, Choa S-H. Reduction of Fluorine Diffusion and Improvement of Dark Current Using Carbon Implantation in CMOS Image Sensor. Crystals. 2021; 11(9):1106. https://doi.org/10.3390/cryst11091106

Chicago/Turabian StyleChai, Su-Young, and Sung-Hoon Choa. 2021. "Reduction of Fluorine Diffusion and Improvement of Dark Current Using Carbon Implantation in CMOS Image Sensor" Crystals 11, no. 9: 1106. https://doi.org/10.3390/cryst11091106

APA StyleChai, S.-Y., & Choa, S.-H. (2021). Reduction of Fluorine Diffusion and Improvement of Dark Current Using Carbon Implantation in CMOS Image Sensor. Crystals, 11(9), 1106. https://doi.org/10.3390/cryst11091106