Phases Reconstruction and Foaming Modification of Basic Oxygen Furnace Slag on Its Grindability

Abstract

:1. Introduction

2. Raw Materials and Methods

2.1. Raw Materials

2.2. Method

3. Results and Discussion

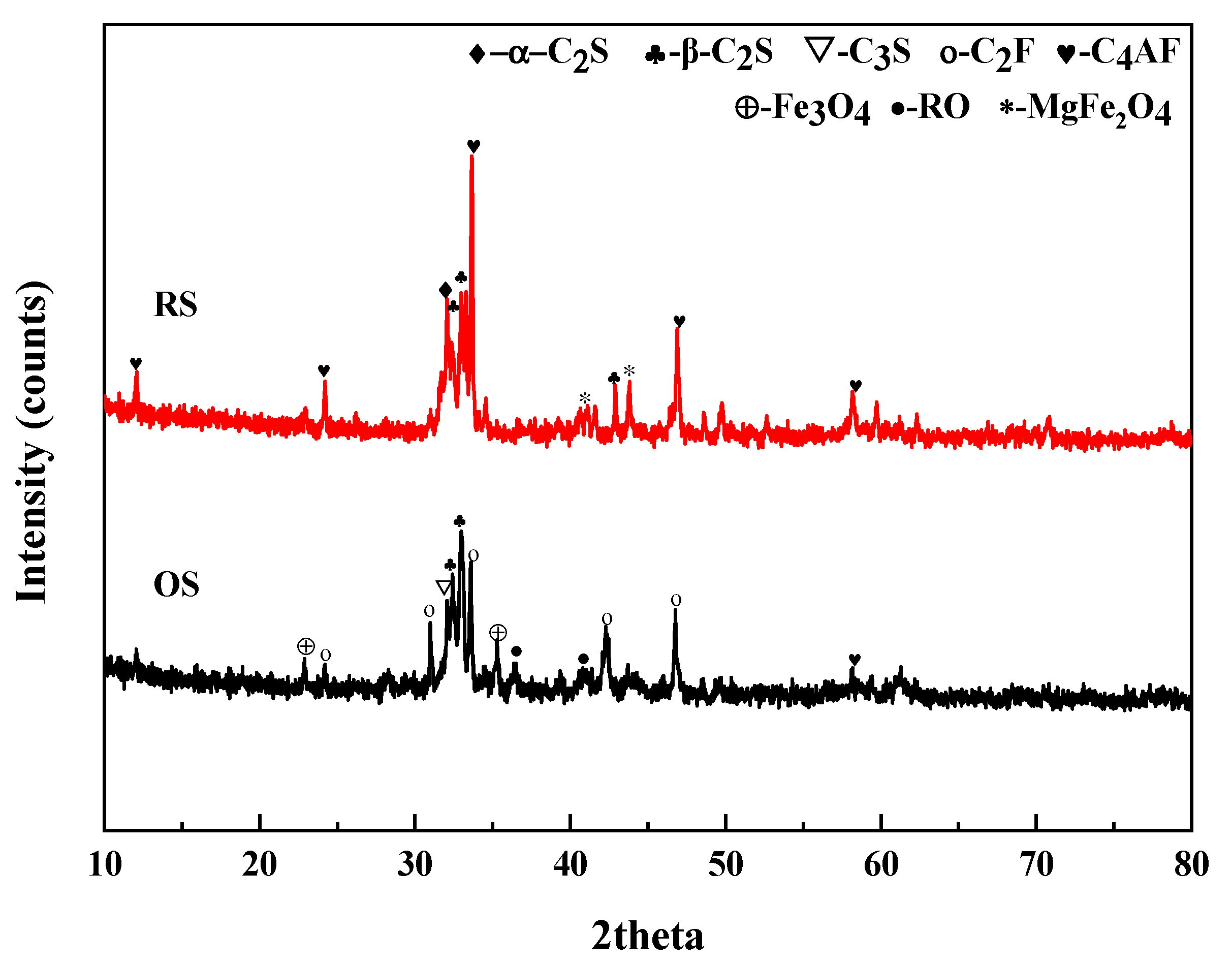

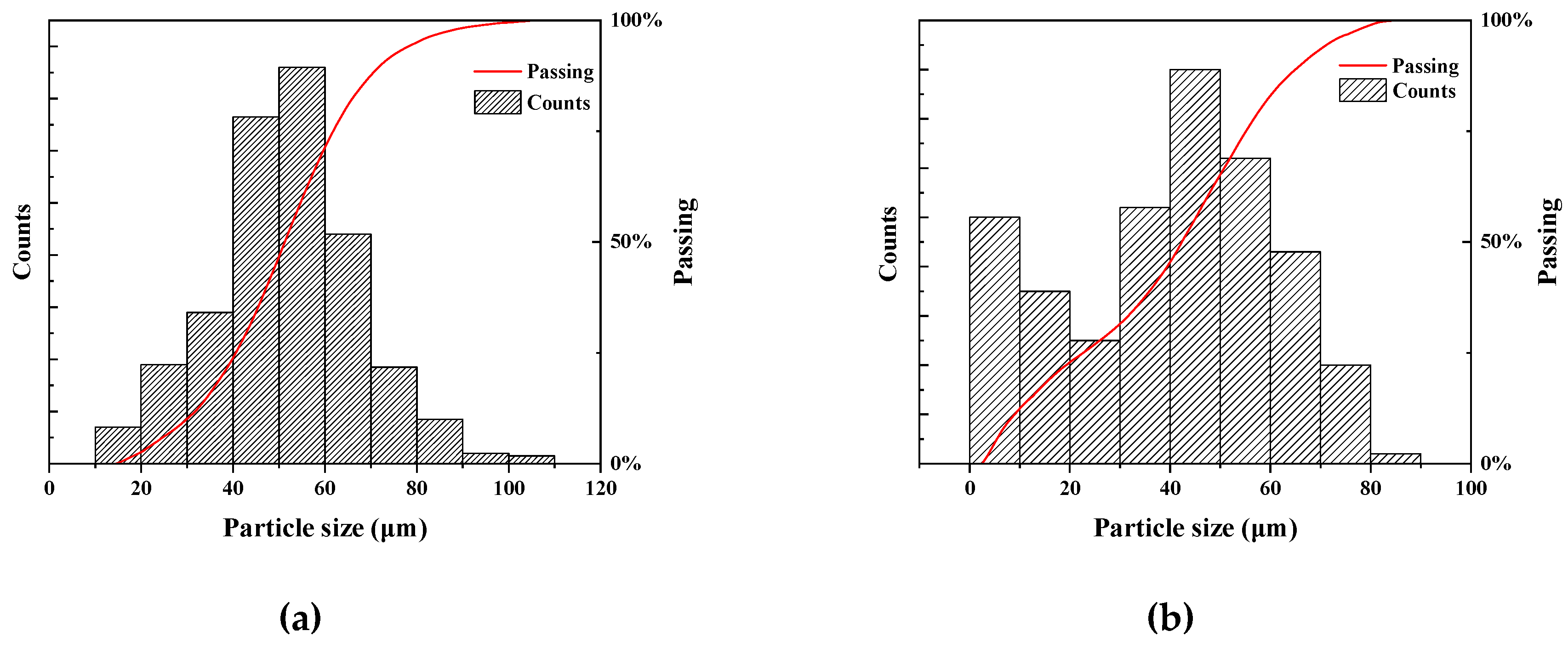

3.1. Reconstruction

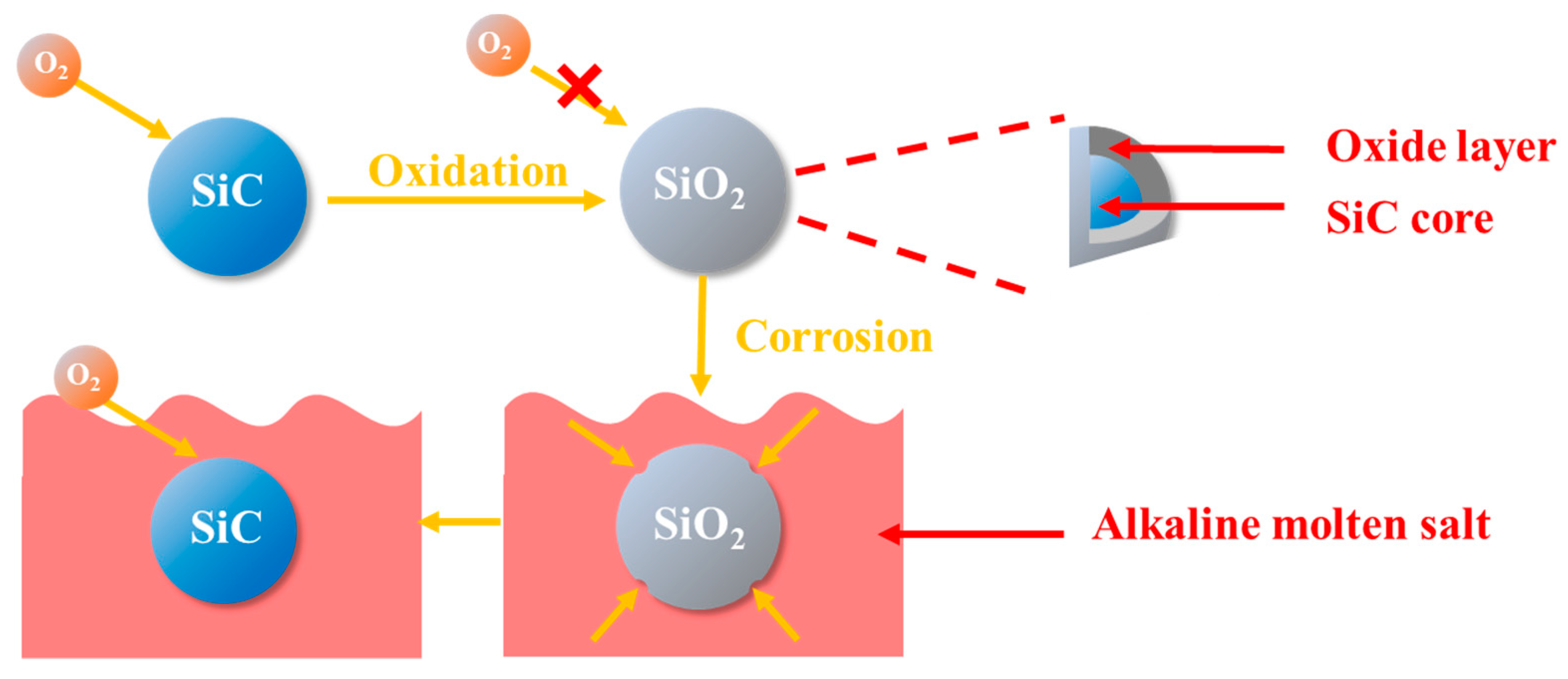

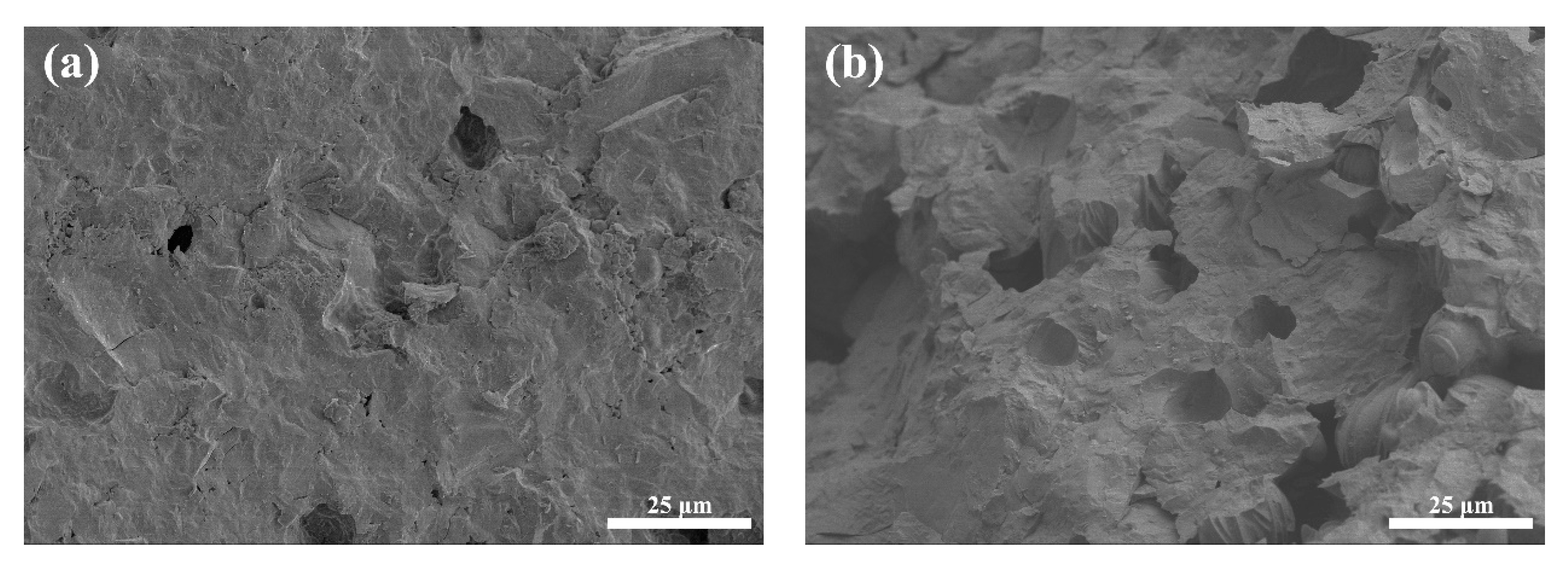

3.2. SiC Foaming Modification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kazemian, A.; Vayghan, A.G.; Rajabipour, F. Quantitative assessment of parameters that affect strength development in alkali activated fly ash binders. Constr. Build. Mater. 2015, 93, 869–876. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Abdollahnejad, Z.; Camoes, A.F.; Jamshidi, M.; Ding, Y. Durability of alkali-activated binders: A clear advantage over Portland cement or an unproven issue? Constr. Build. Mater. 2012, 30, 400–405. [Google Scholar] [CrossRef] [Green Version]

- Kourounis, S.; Tsivilis, S.; Tsakiridis, P.E.; Papadimitriou, G.D.; Tsibouki, Z. Properties and hydration of blended cements with steelmaking slag. Cem. Concr. Res. 2007, 37, 815–822. [Google Scholar] [CrossRef]

- Belhadj, E.; Diliberto, C.; Lecomte, A. Characterization and activation of Basic Oxygen Furnace slag. Cem. Concr. Compos. 2012, 34, 34–40. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.Y. Hydration properties of basic oxygen furnace steel slag. Constr. Build. Mater. 2010, 24, 1134–1140. [Google Scholar] [CrossRef]

- Xue, P.; Xu, A.J.; He, D.F.; Yang, Q.X.; Liu, G.Q.; Engstrom, F.; Bjorkman, B. Research on the sintering process and characteristics of belite sulphoaluminate cement produced by BOF slag. Constr. Build. Mater. 2016, 122, 567–576. [Google Scholar] [CrossRef]

- Wu, Q.S.; Wu, Y.; Tong, W.H.; Ma, H.E. Utilization of nickel slag as raw material in the production of Portland cement for road construction. Constr. Build. Mater. 2018, 193, 426–434. [Google Scholar] [CrossRef]

- Zhang, Z.S.; Xv, L.H.; Yu, G.W.; Tang, W.J.; Saiyin, B.; Sun, P.H.; Hao, H.S.; Zhai, W. Influences of the powder of steel slag and granulated blast furnace slag by mechanical activation. Concrete 2010, 10, 92–94. (In Chinese) [Google Scholar]

- Choi, H.; Lee, W.; Kim, D.U.; Kumar, S.; Kim, S.S.; Chung, H.S.; Kim, J.H.; Ahn, Y.C. Effect of grinding aids on the grinding energy consumed during grinding of calcite in a stirred ball mill. Miner. Eng. 2010, 23, 54–57. [Google Scholar] [CrossRef]

- Hou, G.H.; Li, W.F.; Wang, J.G. Difference of grindability and cementitious performance among minerals in steel slag. J. Chin. Ceram. Society 2009, 10, 1613–1617. (In Chinese) [Google Scholar]

- Zhao, J.H.; Wang, D.M.; Yan, P.Y.; Zhao, S.J.; Zhang, D.W. Particle characteristics and hydration activity of ground granulated blast furnace slag powder containing industrial crude glycerol-based grinding aids. Constr. Build. Mater. 2016, 104, 134–141. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, D.; Yan, P.; Li, W. Comparison of Grinding Characteristics of Converter Steel Slag with and without Pretreatment and Grinding Aids. Appl. Sci. 2016, 6, 237–251. [Google Scholar] [CrossRef] [Green Version]

- Chen, K.L. Study on the Activation of Divalent Oxide for Steel Slag and Cementitious Properties. Master’s Thesis, Guilin University of Technology, Guilin, China, 2017. [Google Scholar]

- Hou, X.K.; He, N.; Yuan, J.S.; Dong, Y.B.; Yang, H.Y. Separation of Divalent Metal Oxides Solid Solution from Steel Slag. J. Chin. Ceram. Soc. 2013, 41, 1142–1150. (In Chinese) [Google Scholar]

- Wang, Q.; Zhang, L.A.; Bai, J.R.; Liu, H.P.; Li, S.H. The influence of microwave drying on physicochemical properties of Liushuhe oil shale. Oil Shale 2011, 28, 29–41. [Google Scholar]

- Qin, Y.H.; Han, Y.X.; Gao, P.; Li, Y.J.; Yuan, S. Pre-weakening behavior of magnetite quartzite based on high-voltage pulse discharge. Miner. Eng. 2021, 160, 106662. [Google Scholar] [CrossRef]

- China Building Materials Company; Zhejiang Chengjian Group Co., Ltd.; China Isosand Co., Ltd.; Beijing Xin′ao Concrete Group Co., Ltd. GB/T 208-2014 Test Method for Determining Cement Density; General Administration of Quality Supervision; Inspection and Quarantine of the People’s Republic of China: Beijing, China; Standardization Administration of China: Beijing, China, 2014. (In Chinese) [Google Scholar]

- China Building Materials Company. GB/T 8074-2008 Testing Method for Specific Surface of Cement—Blaine Method; General Administration of Quality Supervision; Inspection and Quarantine of the People’s Republic of China: Beijing, China; Standardization Administration of China: Beijing, China, 2008. (In Chinese) [Google Scholar]

- Doremus, R.H. Transport of oxygen in silicate glasses. J. Non-Cryst. Solids. 2004, 349, 242–247. [Google Scholar] [CrossRef]

- Bernardo, E. Micro- and macro-cellular sintered glass-ceramics from wastes. J. Eur. Ceram. Soc. 2007, 27, 2415–2422. [Google Scholar] [CrossRef]

- Orts, M.J.; Amorós, J.L.; Escardino, A.; Gozalbo, A.; Feliu, C. Kinetic model for the isothermal sintering of low porosity floor tiles. Appl. Clay Sci. 1993, 8, 231–245. [Google Scholar] [CrossRef]

- Bernardo, E.; Cedro, R.; Florean, M.; Hreglich, S. Reutilization and stabilization of wastes by the production of glass foams. Ceram. Int. 2007, 33, 963–968. [Google Scholar] [CrossRef]

- Chayasombat, B.; Kato, T.; Hirayama, T.; Tokunaga, T.; Sasaki, K.; Kuroda, K. Oxidation kinetics of single crystal silicon carbide using electron microscopy. J. Ceram. Soc. Jpn. 2012, 120, 181–185. [Google Scholar] [CrossRef] [Green Version]

- Kingery, W.D.; Bowen, H.K.; Uhlmann, D.R. Introduction to Ceramics; John Wiley & Sons: Oxford, UK, 1976. [Google Scholar]

- Brugnara, M.; Degasperi, E.; Della, C.V.; Maniglio, D.; Penati, A.; Siboni, S. Wettability of porous materials. II. Can we obtain the contact angle from the Washburn equation? Contact Angle Wettability Adhes. 2006, 4, 143–164. [Google Scholar]

| Raw Materials | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | TiO2 | Loss |

|---|---|---|---|---|---|---|---|---|---|---|

| Steel slag | 16.46 | 6.20 | 20.11 | 43.46 | 6.83 | 0.34 | 0.04 | 0.33 | - | - |

| Cement clinker | 22.04 | 5.73 | 2.86 | 62.05 | 1.33 | 2.91 | - | - | - | 1.50 |

| Lime | 0.15 | 1.03 | 0.49 | 97.25 | 0.25 | - | - | - | - | 1.22 |

| Bauxite | - | 90 | 1.5 | 0.2 | 0.2 | 4.64 | - | - | 3 | 0.46 |

| Sample | BOF Slag | Lime | Bauxite |

|---|---|---|---|

| RS | 75 | 21 | 4 |

| Sample | SSA (m2/kg) |

|---|---|

| OS | 303.1 |

| RS | 354.5 |

| Sample | wt % | |||

|---|---|---|---|---|

| BOF Slag | Lime | Bauxite | SiC | |

| PRS1 | 75 | 21 | 4 | 0.4 |

| PRS2 | 0.8 | |||

| PRS3 | 1.2 | |||

| PRS4 | 1.6 | |||

| PRS5 | 2 | |||

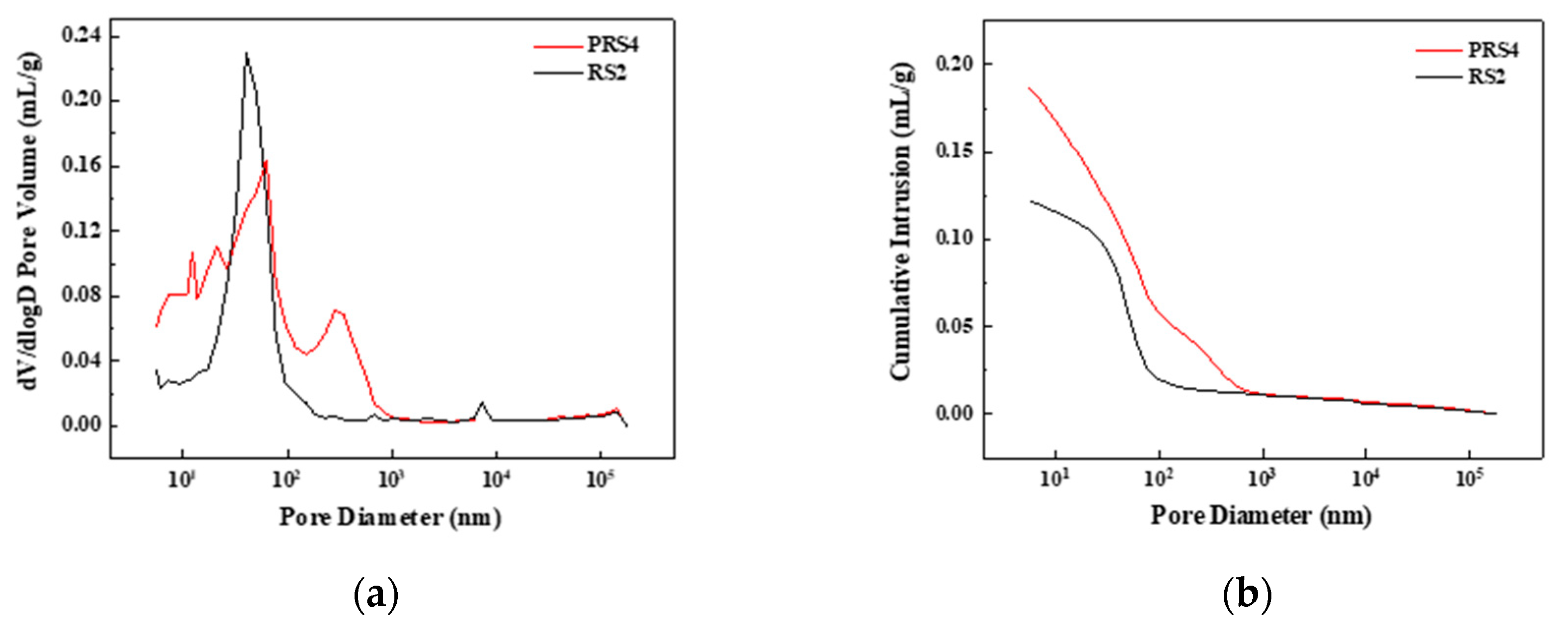

| Sample | Porosity (%) | Average Pore Size (nm) | Medium Pore Size (nm) | Total Pore Volume (mL/g) | Total Pore Area (m2/g) |

|---|---|---|---|---|---|

| RS2 | 21.48 | 33.7 | 48.4 | 0.1228 | 14.554 |

| PRS4 | 31.79 | 28 | 52.4 | 0.1872 | 26.724 |

| Sample | SSA (m2/kg) |

|---|---|

| PRS1 | 356.2 |

| PRS2 | 367.7 |

| PRS3 | 389.1 |

| PRS4 | 424.4 |

| PRS5 | 395.6 |

| RS | 354.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, R.; Chen, P.; Liu, R.; Hu, C.; Wan, D.; Fan, J.; Wei, J. Phases Reconstruction and Foaming Modification of Basic Oxygen Furnace Slag on Its Grindability. Crystals 2021, 11, 1051. https://doi.org/10.3390/cryst11091051

Xiang R, Chen P, Liu R, Hu C, Wan D, Fan J, Wei J. Phases Reconstruction and Foaming Modification of Basic Oxygen Furnace Slag on Its Grindability. Crystals. 2021; 11(9):1051. https://doi.org/10.3390/cryst11091051

Chicago/Turabian StyleXiang, Ruiheng, Ping Chen, Rongjin Liu, Cheng Hu, Dandan Wan, Jintao Fan, and Jiazhan Wei. 2021. "Phases Reconstruction and Foaming Modification of Basic Oxygen Furnace Slag on Its Grindability" Crystals 11, no. 9: 1051. https://doi.org/10.3390/cryst11091051

APA StyleXiang, R., Chen, P., Liu, R., Hu, C., Wan, D., Fan, J., & Wei, J. (2021). Phases Reconstruction and Foaming Modification of Basic Oxygen Furnace Slag on Its Grindability. Crystals, 11(9), 1051. https://doi.org/10.3390/cryst11091051