Effect of Sintering Temperature on Microstructure and Mechanical Properties of Hot-Pressed Fe/FeAl2O4 Composite

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Preparation Principle of Fe/FeAl2O4 Composite

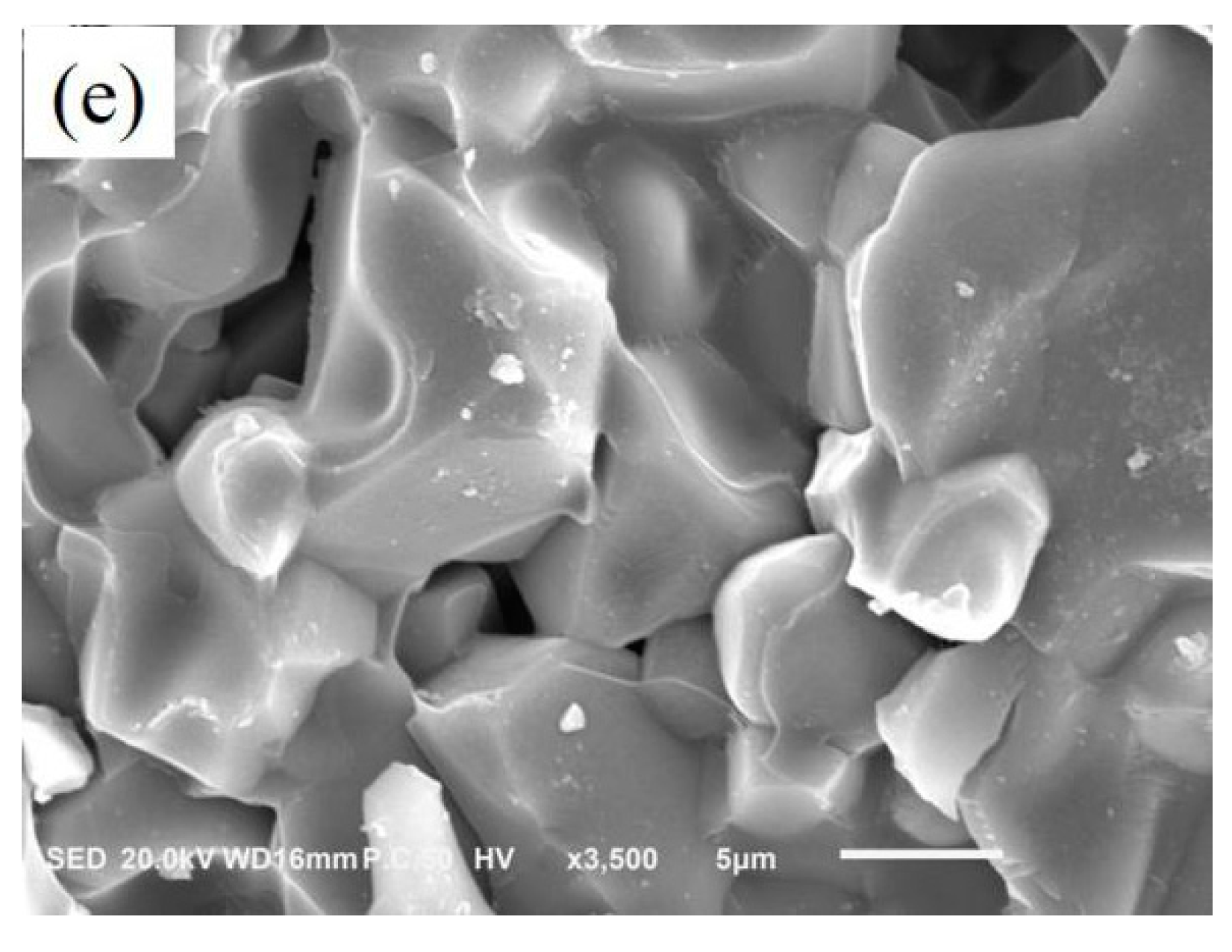

3.2. Effect on Microstructure

3.3. Effect on Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, G.Q.; Ding, P.D.; Tang, J.X. The study of the microstructure and properties of iron-based metal and ceramic composite material. J. Chongqing Univ. (Nat. Sci. Ed.) 1995, 18, 55–60. [Google Scholar]

- Rosso, M. Ceramic and metal matrix composites: Routes and properties. J. Mater. Process. Technol. 2006, 175, 364–375. [Google Scholar] [CrossRef]

- Reshetenko, T.V.; Avdeeva, L.B.; Khassin, A.A.; Kustova, G.N.; Ushakov, V.A.; Moroz, E.M.; Shmakov, A.N.; Kriventsov, V.V.; Kochubey, D.I.; Pavlyukhin, Y.T. Coprecipitated iron-containing catalysts (Fe-Al2O3, Fe-Co-Al2O3, Fe-Ni-Al2O3) for methane decomposition at moderate temperatures I. Genesis of calcined and reduced catalysts. Appl. Catal. A 2004, 268, 127–138. [Google Scholar] [CrossRef]

- Shi, Z.L.; Du, X.K.; Yu, H.R.; Li, C.A. Study on the microstructure and properties of iron-base metal-ceramic braking materials. J. Lanzhou Univ. (Nat. Sci.) 2001, 37, 36–41. [Google Scholar]

- Shi, Z.L.; Zhang, G.Q.; Du, X.K.; Li, C.A. Study of the tribological behaviors of iron based metal ceramic composites. J. Lanzhou Univ. (Nat. Sci.) 2002, 38, 39–43. [Google Scholar]

- Shi, Z.L.; Du, X.K.; Li, C.A. Fabrication and properties of the iron-based metal-ceramic braking materials for high-speed train. J. Lanzhou Univ. (Nat. Sci.) 2000, 19, 82–84. [Google Scholar]

- Shi, Z.L.; Du, X.K.; Li, C.A. Study on the iron base ceramic metal braking materials for high-speed train. J. China Railw. Soc. 2001, 23, 29–32. [Google Scholar]

- Wang, X.F.; Li, D.S. Iron-composite friction materials for aircraft application. Mater. Eng. 1999, 3, 27–29. [Google Scholar]

- Gatti, A. Iron-alumina materials. Trans. AIME 1959, 215, 753–755. [Google Scholar]

- Chen, W.P.; Yang, S.F.; Han, M.Y. Research development of ceramic/Fe-based alloy composites. Chin. J. Nonferrous Met. 2010, 20, 257–265. [Google Scholar]

- Bansal, C. Metal-to-ceramic bonding in (Al2O3+Fe) composite studied by Miissbauer spectroscopy. Bull. Mater. Sci. 1984, 6, 13–16. [Google Scholar] [CrossRef]

- Konopka, K.; Ozieblo, A. Microstructure and the fracture toughness of the Al2O3-Fe composites. Mater. Charact. 2001, 46, 125–129. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, J.F.; Ding, Y.S. Fabrication and Properties of Fe/Al2O3 Composites. Chin. J. Mater. Res. 2012, 26, 206–210. [Google Scholar]

- Konopka, K. Shape, size and distribution of metal particles embedded in a ceramic matrix. Solid State Phenom. 2015, 231, 57–63. [Google Scholar] [CrossRef]

- Atlas, L.M.; Sumida, W.K. Solidus, Subsolidus, and Subdissociation Phase Equilibria in the System Fe-Al-O. Am. Ceram. Soc. Atlas Sumida. 1958, 41, 150–160. [Google Scholar] [CrossRef]

- Gupta, P.; Kumar, D.; Quraishi, M.A.; Parkash, O. Corrosion behavior of Al2O3 reinforced Fe metal matrix nanocomposites produced by powder metallurgy technique. Adv. Sci. Eng. Med. 2013, 5, 366–370. [Google Scholar] [CrossRef]

- Trumblei, K.P. Thermodynamic Analysis of Aluminate Formation at Fe/Al2O3 and Cu/Al2O3 Interfaces. Acta Met. mater. 1992, 40, S105–S110. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Chai, J.L.; Li, Y. Formations of ferrous oxide and hercynite. Naihuo Cailiao. 2005, 39, 207–210. [Google Scholar]

- Zhang, J.B.; Zhang, G.; Xiao, G.Q. Preparation of hercynite. Bull. Chin. Ceram. Soc. 2007, 26, 1003–1006. [Google Scholar]

- Liu, H.L.; Li, Y.; Cao, H.F.; Ren, X.Y.; Shen, W.P. Sintering synthesis of hercynite clinker. Naihuo Cailiao. 2003, 37, 333–335. [Google Scholar]

- Aksay, I.A.; Hoge, C.E.; Pask, J.A. Wetting under chemical-equilibrium and nonequilibrium conditions. J. Phys. Chem. 1976, 78, 1178–1183. [Google Scholar] [CrossRef]

- Qu, W.; Fang, T.X. Advances in the wettability research of metal /ceramic systems: Experimental characterization and theoretical Estimation. Mater. Rep. 2019, 33, 3606–3612. [Google Scholar]

- Liu, X.Y. Research on the wettability and interfacial interaction between Ti-Al molten alloys and ceramics. Chongqing Univ. 2016, 3, 11. [Google Scholar] [CrossRef]

- Zhang, M.; Zhou, Z.H.; Yuan, T.C.; Li, R.D.; Zhang, W.S.; Zhang, Y.J.; Wang, M.B.; Xie, S.Y. Analysis of abnormal grain growth behavior during hot-press sintering of boron carbide. Ceram. Int. 2020, 46, 16345–16353. [Google Scholar] [CrossRef]

- Zhang, X.; Han, X.Y.; Zhang, Y.D.; Liang, J.L.; Wang, C.; Liang, J.S. Effect of holding time and pressure on the densification, microstructure and mechanical properties of hot pressed Al2O3-CA6-ZrO2/Ni multi-phase composites. J. Alloys Compd. 2021, 850, 1–10. [Google Scholar] [CrossRef]

| Sample | T/°C | t/min | Pressure/MPa | Mass Ratio |

|---|---|---|---|---|

| S1 | 1300 | 120 | 30 | 6:1:2 |

| S2 | 1350 | 120 | 30 | 6:1:2 |

| S3 | 1400 | 120 | 30 | 6:1:2 |

| S4 | 1450 | 120 | 30 | 6:1:2 |

| S5 | 1500 | 120 | 30 | 6:1:2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Li, Y.; Yan, H.; Wang, C.; Li, H.; Liang, J.; Dang, J. Effect of Sintering Temperature on Microstructure and Mechanical Properties of Hot-Pressed Fe/FeAl2O4 Composite. Crystals 2021, 11, 422. https://doi.org/10.3390/cryst11040422

Zhang K, Li Y, Yan H, Wang C, Li H, Liang J, Dang J. Effect of Sintering Temperature on Microstructure and Mechanical Properties of Hot-Pressed Fe/FeAl2O4 Composite. Crystals. 2021; 11(4):422. https://doi.org/10.3390/cryst11040422

Chicago/Turabian StyleZhang, Kuai, Yungang Li, Hongyan Yan, Chuang Wang, Hui Li, Jinglong Liang, and Jie Dang. 2021. "Effect of Sintering Temperature on Microstructure and Mechanical Properties of Hot-Pressed Fe/FeAl2O4 Composite" Crystals 11, no. 4: 422. https://doi.org/10.3390/cryst11040422

APA StyleZhang, K., Li, Y., Yan, H., Wang, C., Li, H., Liang, J., & Dang, J. (2021). Effect of Sintering Temperature on Microstructure and Mechanical Properties of Hot-Pressed Fe/FeAl2O4 Composite. Crystals, 11(4), 422. https://doi.org/10.3390/cryst11040422