Single-Crystal Growth of Sr2RuO4 by the Floating-Zone Method Using an Infrared Image Furnace with Improved Halogen Lamps

Abstract

1. Introduction

2. Experimental Section

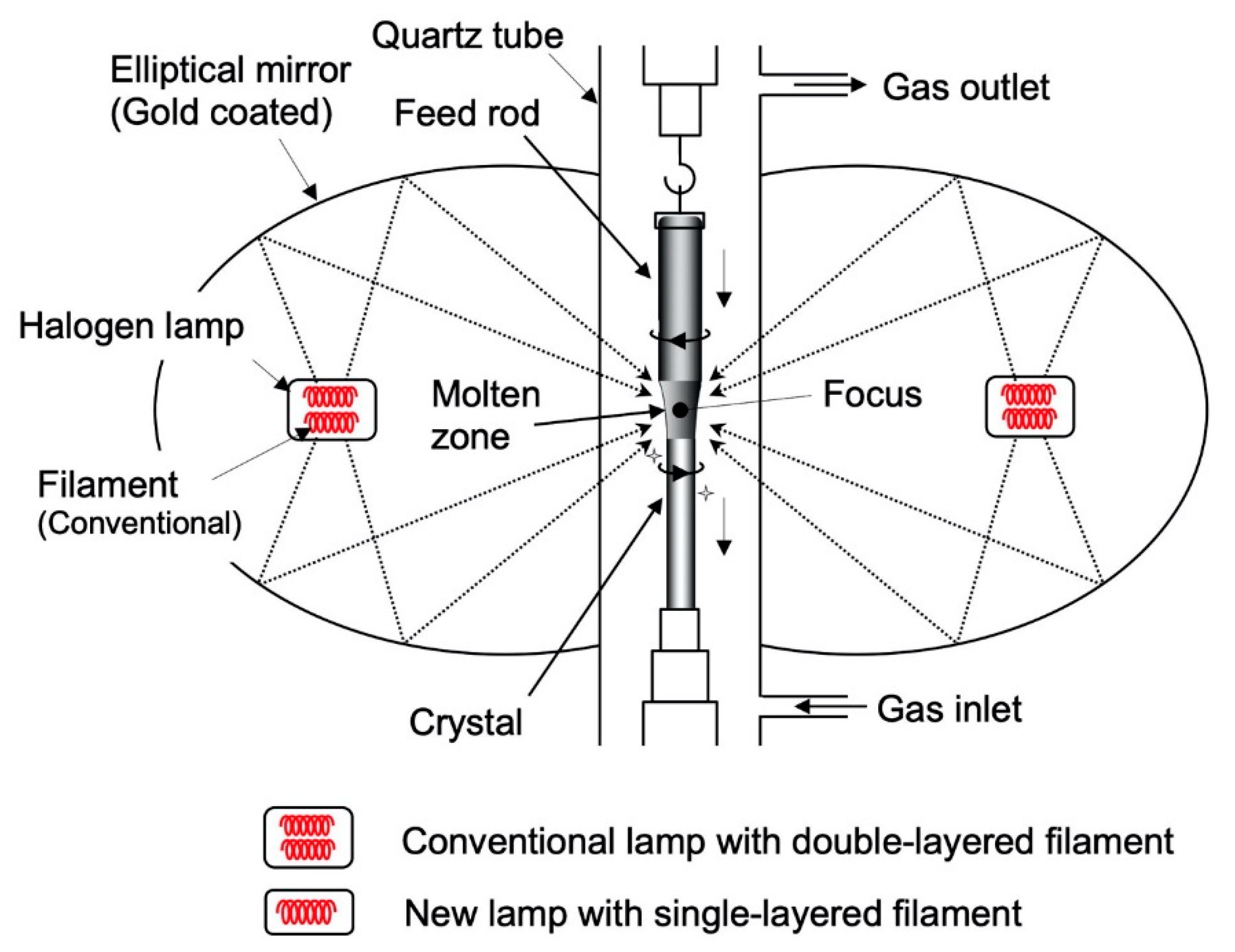

2.1. Floating-Zone Technique

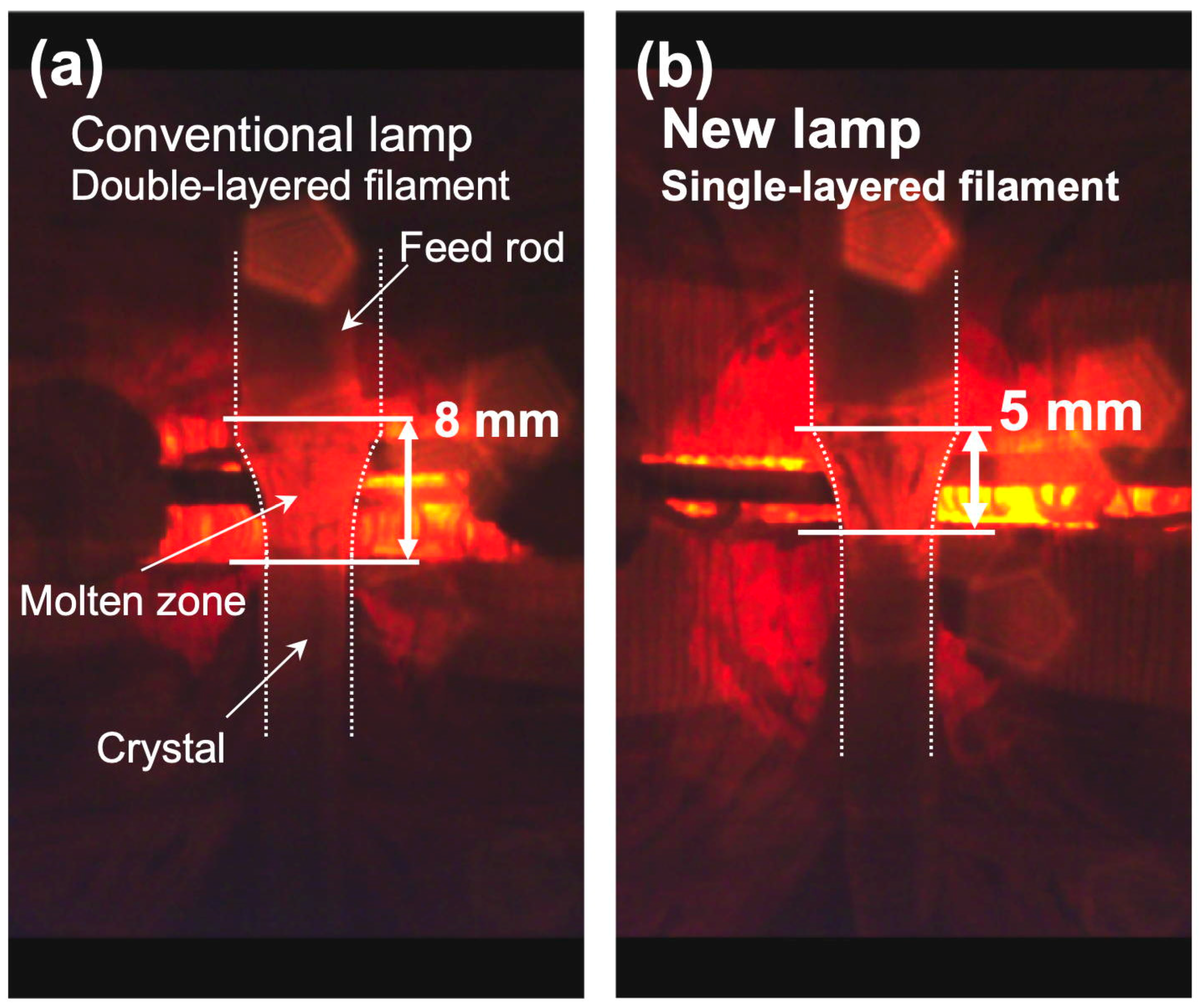

2.2. Controlling the Molten Zone

3. Results and Discussion

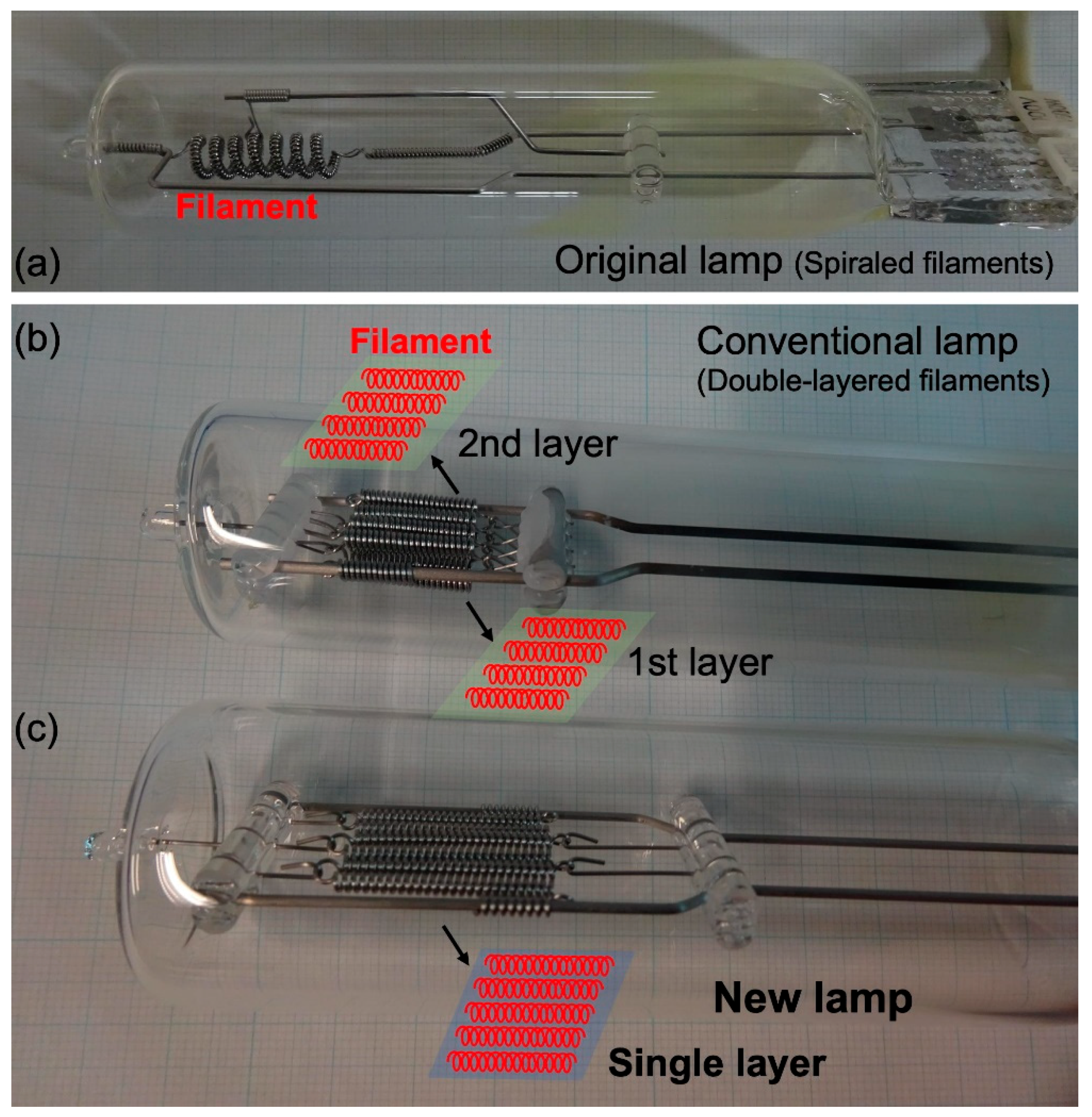

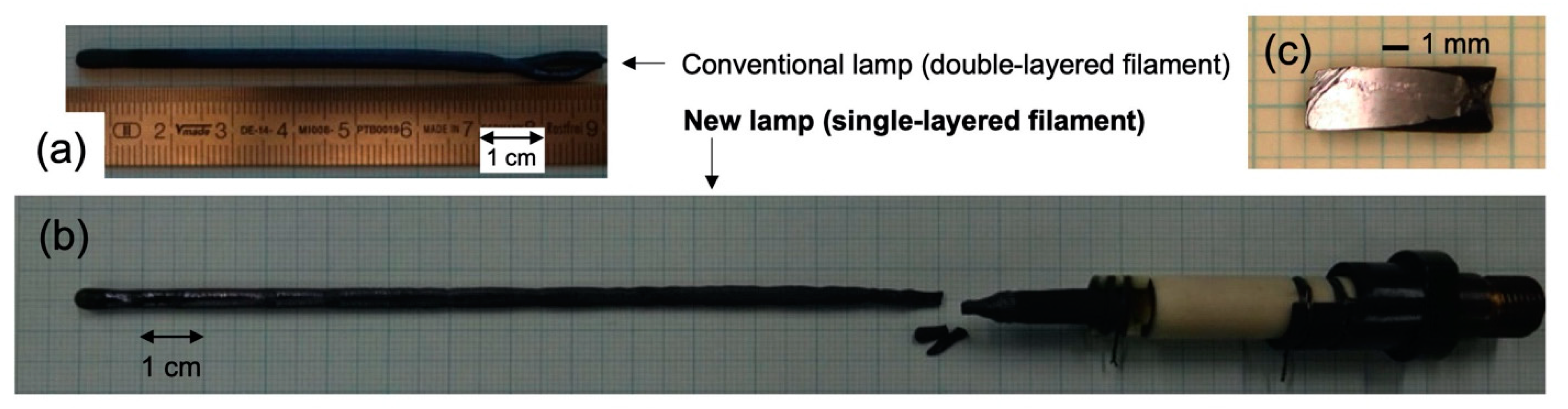

3.1. Crystal Growth with the Newly Developed Filament

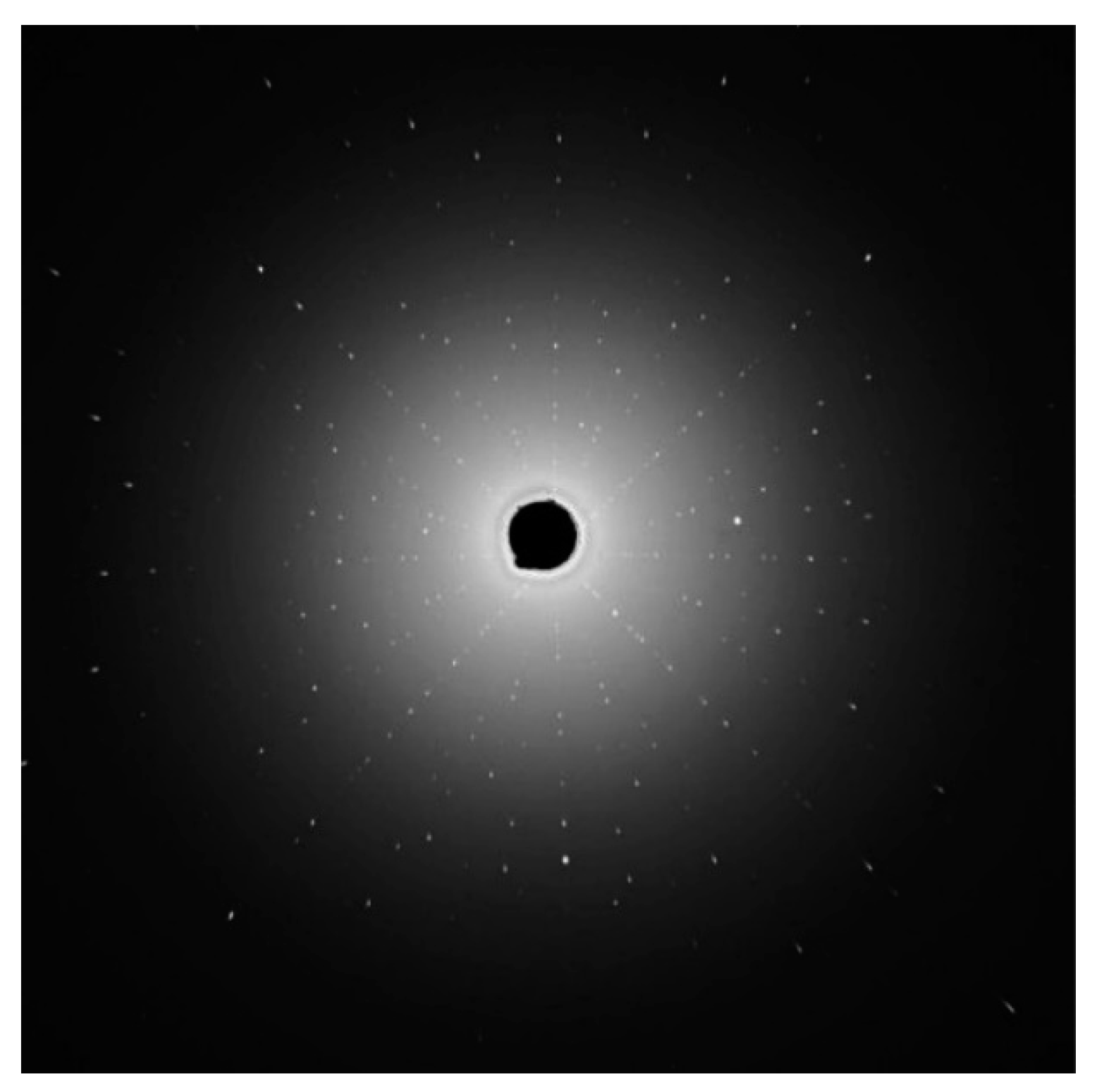

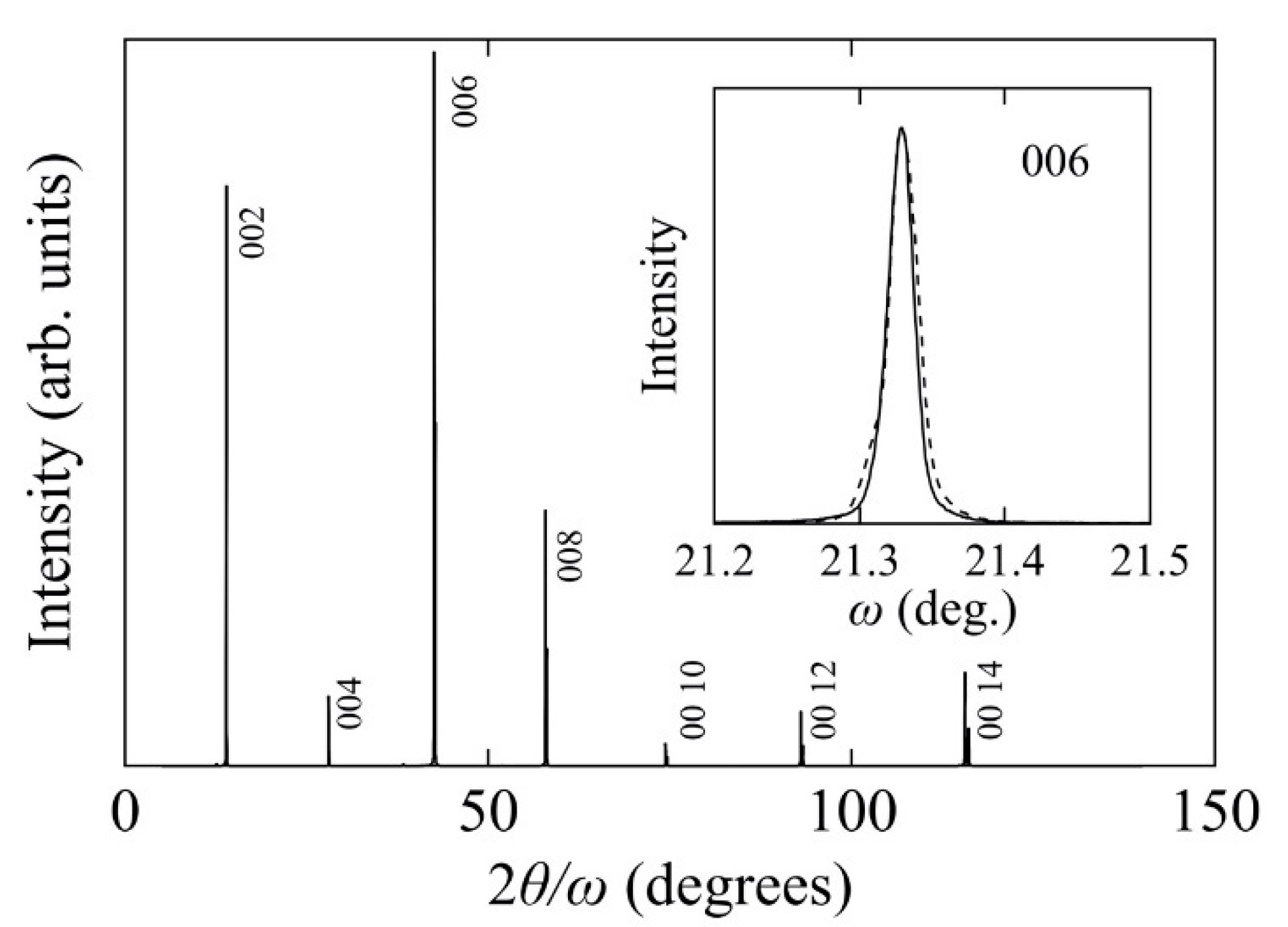

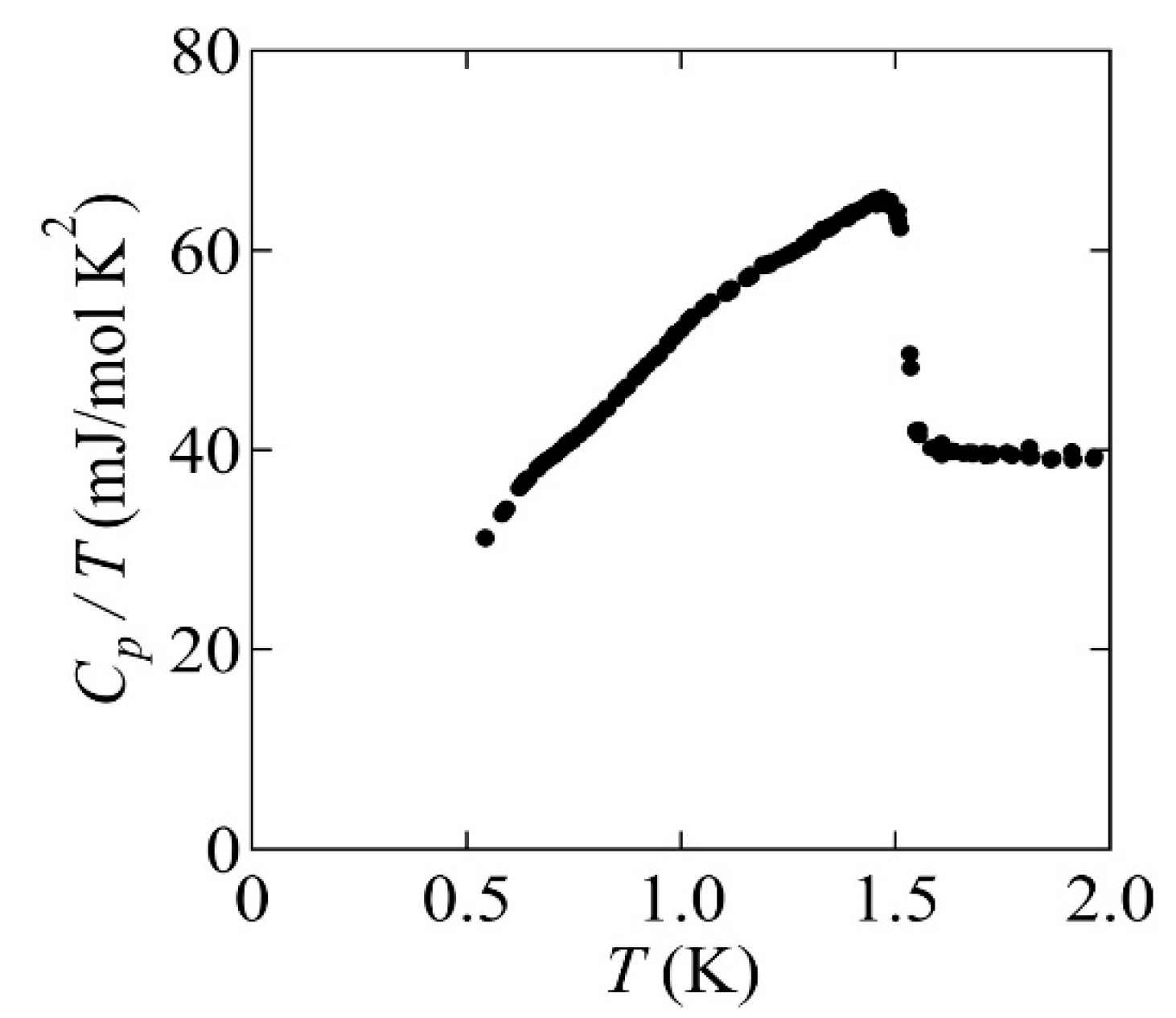

3.2. Characterization of the As-Grown Crystal

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maeno, Y.; Hashimoto, H.; Yoshida, K.; Nishizaki, S.; Fujita, T.; Bednorz, J.G.; Lichtenberg, F. Superconductivity in a layered perovskite without copper. Nature 1994, 372, 532. [Google Scholar] [CrossRef]

- Mackenzie, A.P.; Maeno, Y. The superconductivity of Sr2RuO4 and the physics of spin-triplet pairing. Rev. Mod. Phys. 2003, 75, 657. [Google Scholar] [CrossRef]

- Maeno, Y.; Kittaka, S.; Nomura, T.; Yonezawa, S.; Ishida, K. Evaluation of Spin-Triplet Superconductivity in Sr2RuO4. J. Phys. Soc. Jpn. 2012, 81, 011009. [Google Scholar] [CrossRef]

- Mackenzie, A.P.; Scaffidi, T.; Hicks, C.W.; Maeno, Y. Even odder after twenty-three years: The superconducting order parameter puzzle of Sr2RuO4. NPJ Quantum Mater. 2017, 2, 40. [Google Scholar] [CrossRef]

- Mackenzie, A.P.; Julian, S.R.; Diver, A.J.; McMullan, G.J.; Ray, M.P.; Lonzarich, G.G.; Maeno, Y.; Nishizaki, S.; Fujita, T. Quantum oscillations in the layered perovskite superconductor Sr2RuO4. Phys. Rev. Lett. 1996, 76, 3786. [Google Scholar] [CrossRef]

- Bergemann, C.; Mackenzie, A.P.; Julian, S.R.; Forsythe, D.; Ohmichi, E. Quasi-two-dimensional Fermi liquid properties of the unconventional superconductor Sr2RuO4. Adv. Phys. 2003, 52, 639–725. [Google Scholar] [CrossRef]

- Damascelli, A.; Lu, D.H.; Shen, K.M.; Armitage, N.P.; Ronning, F.; Feng, D.L.; Kim, C.; Shen, Z.-X.; Kimura, T.; Tokura, Y.; et al. Fermi surface, surface states, and surface reconstruction in Sr2RuO4. Phys. Rev. Lett. 2000, 85, 5194. [Google Scholar] [CrossRef] [PubMed]

- Tamai, A.; Zingl, M.; Rozbicki, E.; Cappelli, E.; Riccò, S.; de la Torre, A.; McKeown Walker, S.; Bruno, F.Y.; King, P.D.C.; Meevasana, W.; et al. High-Resolution Photoemission on Sr2RuO4 Reveals Correlation-Enhanced Effective Spin-Orbit Coupling and Dominantly Local Self-Energies. Phys. Rev. X 2019, 9, 021048. [Google Scholar] [CrossRef]

- Suderow, H.; Crespo, V.; Guillamon, I.; Vieira, S.; Servant, F.; Lejay, P.; Brison, J.P.; Flouquet, J. A nodeless superconducting gap in Sr2RuO4 from tunneling spectroscopy. New J. Phys. 2009, 11, 093004. [Google Scholar] [CrossRef]

- Hassinger, E.; Bourgeois-Hope, P.; Taniguchi, H.; de Cotret, S.R.; Grissonnanche, G.; Anwar, M.S.; Maeno, Y.; Doiron-Leyraud, N.; Taillefer, L. Vertical line nodes in the superconducting gap structure of Sr2RuO4. Phys. Rev. X 2017, 7, 011032. [Google Scholar] [CrossRef]

- Kittaka, S.; Nakamura, S.; Sakakibara, T.; Kikugawa, N.; Terashima, T.; Uji, S.; Sokolov, D.A.; Mackenzie, A.P.; Irie, K.; Tsutsumi, Y.; et al. Searching for gap zeros in Sr2RuO4 via field-angle-dependent specific-heat measurement. J. Phys. Soc. Jpn. 2018, 87, 093703. [Google Scholar] [CrossRef]

- Sharma, R.; Edkins, S.D.; Wang, Z.; Kostin, A.; Sow, C.; Maeno, Y.; Mackenzie, A.P.; Davis, J.C.S.; Madhavan, V. Momentum-resolved superconducting energy gaps of Sr2RuO4 from quasiparticle interference imaging. Proc. Natl. Acad. Sci. USA 2020, 117, 5222–5227. [Google Scholar] [CrossRef]

- Mackenzie, A.P.; Haselwimmer, R.K.W.; Tyler, A.W.; Lonzarich, G.G.; Mori, Y.; Nishizaki, S.; Maeno, Y. Extremely strong dependence of superconductivity on disorder in Sr2RuO4. Phys. Rev. Lett. 1998, 80, 161. [Google Scholar] [CrossRef]

- Mao, Z.Q.; Mori, Y.; Maeno, Y. Suppression of superconductivity in Sr2RuO4 caused by defects. Phys. Rev. B 1999, 60, 610. [Google Scholar] [CrossRef]

- Kikugawa, N.; Maeno, Y. Non-Fermi-liquid behavior in Sr2RuO4 with nonmagnetic impurities. Phys. Rev. Lett. 2002, 89, 117001. [Google Scholar] [CrossRef]

- Kikugawa, N.; Mackenzie, A.P.; Maeno, Y. Effects of In-Plane Impurity Substitution in Sr2RuO4. J. Phys. Soc. Jpn. 2003, 72, 237–240. [Google Scholar] [CrossRef]

- Mao, Z.Q.; Maeno, Y.; Fukazawa, H. Crystal growth of Sr2RuO4. Mater. Res. Bull. 2000, 35, 1813. [Google Scholar] [CrossRef]

- Bobowski, J.S.; Kikugawa, N.; Miyoshi, T.; Suwa, H.; Xu, H.-S.; Yonezawa, S.; Sokolov, D.A.; Mackenzie, A.P.; Maeno, Y. Improved Single-Crystal Growth of Sr2RuO4. Condens. Matter 2019, 4, 6. [Google Scholar] [CrossRef]

- Hicks, C.W.; Brodsky, D.O.; Yelland, E.A.; Gibbs, A.S.; Bruin, J.A.N.; Barber, M.E.; Edkins, S.D.; Nishimura, K.; Yonezawa, S.; Maeno, Y.; et al. Strong Increase of Tc of Sr2RuO4 Under Both Tensile and Compressive Strain. Science 2014, 344, 283–285. [Google Scholar] [CrossRef]

- Hicks, C.W.; Barber, M.E.; Edkins, S.D.; Brodsky, D.O.; Mackenzie, A.P. Piezoelectric-based apparatus for strain tuning. Rev. Sci. Instrum. 2014, 85, 065003. [Google Scholar] [CrossRef]

- Barber, M.E.; Lechermann, F.; Streltsov, S.V.; Skornyakov, S.L.; Ghosh, S.; Ramshaw, B.J.; Kikugawa, N.; Sokolov, D.A.; Mackenzie, A.P.; Hicks, C.W.; et al. Role of correlations in determining the Van Hove strain in Sr2RuO4. Phys. Rev. B 2019, 100, 245139. [Google Scholar] [CrossRef]

- Steppke, A.; Zhao, L.; Barber, M.E.; Scaffidi, T.; Jerzembeck, F.; Rosner, H.; Gibbs, A.S.; Maeno, Y.; Simon, S.H.; Mackenzie, A.P.; et al. Strong peak in Tc of Sr2RuO4 under uniaxial pressure. Science 2017, 355, eaaf9398. [Google Scholar] [CrossRef]

- Barber, M.E.; Gibbs, A.S.; Maeno, Y.; Mackenzie, A.P.; Hicks, C.W. Resistivity in the vicinity of a van Hove singularity: Sr2RuO4 under uniaxial pressure. Phys. Rev. Lett. 2018, 120, 076602. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.-S.; Kikugawa, N.; Sokolov, D.A.; Jerzembeck, F.; Gibbs, A.S.; Maeno, Y.; Hicks, C.W.; Nicklas, M.; Mackenzie, A.P. High sensitivity heat capacity measurements on Sr2RuO4 under uniaxial pressure. Proc. Nat. Acad. Sci. USA 2021, 118, e2020492118. [Google Scholar] [CrossRef] [PubMed]

- Sunko, V.; Abarca Morales, E.; Marković, I.; Barber, M.E.; Milosavljević, D.; Mazzola, F.; Sokolov, D.A.; Kikugawa, N.; Cacho, C.; Dudin, P.; et al. Direct observation of a uniaxial stress-driven Lifshitz transition in Sr2RuO4. NPJ Quantum Mater. 2019, 4, 46. [Google Scholar] [CrossRef]

- Pustogow, A.; Luo, Y.; Chronister, A.; Su, Y.-S.; Sokolov, D.A.; Jerzembeck, F.; Mackenzie, A.P.; Hicks, C.W.; Kikugawa, N.; Raghu, S.; et al. Constraints on the superconducting order parameter in Sr2RuO4 from oxygen-17 nuclear magnetic resonance. Nature 2019, 574, 72–75. [Google Scholar] [CrossRef]

- Ishida, K.; Manago, M.; Kinjo, K.; Maeno, Y. Reduction of the 17O Knight Shift in the Superconducting State and the Heat-up Effect by NMR Pulses on Sr2RuO4. J. Phys. Soc. Jpn. 2020, 89, 034712. [Google Scholar] [CrossRef]

- Ishida, K.; Mukuda, H.; Kitaoka, Y.; Asayama, K.; Mao, Z.Q.; Mori, Y.; Maeno, Y. Spin-triplet superconductivity in Sr2RuO4 identified by 17O Knight shift. Nature 1998, 396, 658–660. [Google Scholar] [CrossRef]

- Grinenko, V.; Ghosh, S.; Sarkar, R.; Orain, J.-C.; Nikitin, A.; Elender, M.; Das, D.; Guguchia, Z.; Brückner, F.; Barber, M.E.; et al. Split superconducting and time-reversal symmetry-breaking transitions, and magnetic order in Sr2RuO4 under uniaxial stress. Nat. Phys. 2021. [Google Scholar] [CrossRef]

- Liu, Y.-C.; Zhang, F.-C.; Rice, T.M.; Wang, Q.-H. Theory of the evolution of superconductivity in Sr2RuO4 under anisotropic strain. NPJ Quantum Mater. 2017, 2, 1. [Google Scholar] [CrossRef]

- Suh, H.G.; Menke, H.; Brydon, P.M.R.; Timm, C.; Ramires, A.; Agterberg, D.F. Stabilizing even-parity chiral superconductivity in Sr2RuO4. Phys. Rev. Res. 2020, 2, 032023. [Google Scholar] [CrossRef]

- Yonezawa, S.; Kajikawa, T.; Maeno, Y. First-order superconducting transition of Sr2RuO4. Phys. Rev. Lett. 2013, 110, 077003. [Google Scholar] [CrossRef] [PubMed]

- Kittaka, S.; Kasahara, A.; Sakakibara, T.; Shibata, D.; Yonezawa, S.; Maeno, Y.; Tenya, K.; Machida, K. Sharp magnetization jump at the first-order superconducting transition in Sr2RuO4. Phys. Rev. B 2014, 90, 220502. [Google Scholar] [CrossRef]

- Kikugawa, N.; Terashima, T.; Uji, S.; Sugii, K.; Maeno, Y.; Graf, D.; Baumbach, R.; Brooks, J. Superconducting subphase in the layered perovskite ruthenate Sr2RuO4 in a parallel magnetic field. Phys. Rev. B 2016, 93, 184513. [Google Scholar] [CrossRef]

- Ghosh, S.; Brückner, F.; Nikitin, A.; Grinenko, V.; Elender, M.; Mackenzie, A.P.; Luetkens, H.; Klauss, H.-H.; Hicks, C.W. Piezoelectric-driven uniaxial pressure cell for muon spin relaxation and neutron scattering experiments. Rev. Sci. Instrum. 2020, 91, 103902. [Google Scholar] [CrossRef]

- Ikeda, S.I.; Azuma, U.; Shirakawa, N.; Nishihara, Y.; Maeno, Y. Bulk single-crystal growth of strontium ruthenates by a floating-zone method. J. Cryst. Growth 2002, 237–239, 787–791. [Google Scholar] [CrossRef]

- Perry, R.S.; Maeno, Y. Systematic approach to the growth of high-quality single crystals of Sr3Ru2O7. J. Cryst. Growth 2004, 271, 134–141. [Google Scholar] [CrossRef]

- Kikugawa, N.; Balicas, L.; Mackenzie, A.P. Physical Properties of Single-Crystalline CaRuO3 Grown by a Floating-Zone Method. J. Phys. Soc. Jpn. 2009, 78, 014701. [Google Scholar] [CrossRef]

- Kikugawa, N.; Baumbach, R.; Brooks, J.S.; Terashima, T.; Uji, S.; Maeno, Y. Single-Crystal Growth of a Perovskite Ruthenate SrRuO3 by the Floating-Zone Method. Cryst. Growth Des. 2015, 15, 5573. [Google Scholar] [CrossRef]

- Liang, R.; Bonn, D.A.; Hardy, W.N. Growth of high quality YBCO single crystals using BaZrO3 crucibles. Phys. C Supercond. 1998, 304, 105–111. [Google Scholar] [CrossRef]

- NishiZaki, S.; Maeno, Y.; Mao, Z. Effect of impurities on the specific heat of the spin-triplet superconductor Sr2RuO4. J. Low Temp. Phys. 1999, 117, 1581–1585. [Google Scholar] [CrossRef]

- Benhabib, S.; Lupien, C.; Paul, I.; Berges, L.; Dion, M.; Nardone, M.; Zitouni, A.; Mao, Z.Q.; Maeno, Y.; Georges, A.; et al. Ultrasound evidence for a two-component superconducting order parameter in Sr2RuO4. Nat. Phys. 2021, 17, 194–198. [Google Scholar] [CrossRef]

- Ghosh, S.; Shekhter, A.; Jerzembeck, F.; Kikugawa, N.; Sokolov, D.A.; Brando, M.; Mackenzie, A.P.; Hicks, C.W.; Ramshaw, B.J. Thermodynamic evidence for a two-component superconducting order parameter in Sr2RuO4. Nat. Phys. 2021, 17, 199–204. [Google Scholar] [CrossRef]

- Ito, T.; Ushiyama, T.; Yanagisawa, Y.; Tomioka, Y.; Shindo, I.; Yanase, A. Laser-diode-heated floating zone (LDFZ) method appropriate to crystal growth of incongruently melting materials. J. Cryst. Growth 2013, 363, 264–269. [Google Scholar] [CrossRef]

- Kaneko, Y.; Tokura, Y. Floating zone furnace equipped with a high power laser of 1 kW composed of five smart beams. J. Cryst. Growth 2020, 533, 125435. [Google Scholar] [CrossRef]

- Rey-García, F.; Ibáñez, R.; Angurel, L.A.; Costa, F.M.; de la Fuente, G.F. Laser Floating Zone Growth: Overview, Singular Materials, Broad Applications, and Future Perspectives. Crystals 2021, 11, 38. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kikugawa, N.; Sokolov, D.A.; Nagasawa, T.; Mackenzie, A.P. Single-Crystal Growth of Sr2RuO4 by the Floating-Zone Method Using an Infrared Image Furnace with Improved Halogen Lamps. Crystals 2021, 11, 392. https://doi.org/10.3390/cryst11040392

Kikugawa N, Sokolov DA, Nagasawa T, Mackenzie AP. Single-Crystal Growth of Sr2RuO4 by the Floating-Zone Method Using an Infrared Image Furnace with Improved Halogen Lamps. Crystals. 2021; 11(4):392. https://doi.org/10.3390/cryst11040392

Chicago/Turabian StyleKikugawa, Naoki, Dmitry A. Sokolov, Tohru Nagasawa, and Andrew P. Mackenzie. 2021. "Single-Crystal Growth of Sr2RuO4 by the Floating-Zone Method Using an Infrared Image Furnace with Improved Halogen Lamps" Crystals 11, no. 4: 392. https://doi.org/10.3390/cryst11040392

APA StyleKikugawa, N., Sokolov, D. A., Nagasawa, T., & Mackenzie, A. P. (2021). Single-Crystal Growth of Sr2RuO4 by the Floating-Zone Method Using an Infrared Image Furnace with Improved Halogen Lamps. Crystals, 11(4), 392. https://doi.org/10.3390/cryst11040392