Optimization of AlSi10MgMn Alloy Heat Treatment Process Based on Orthogonal Test and Grey Relational Analysis

Abstract

1. Introduction

2. Test Materials and Methods

3. Experiment Results and Analysis

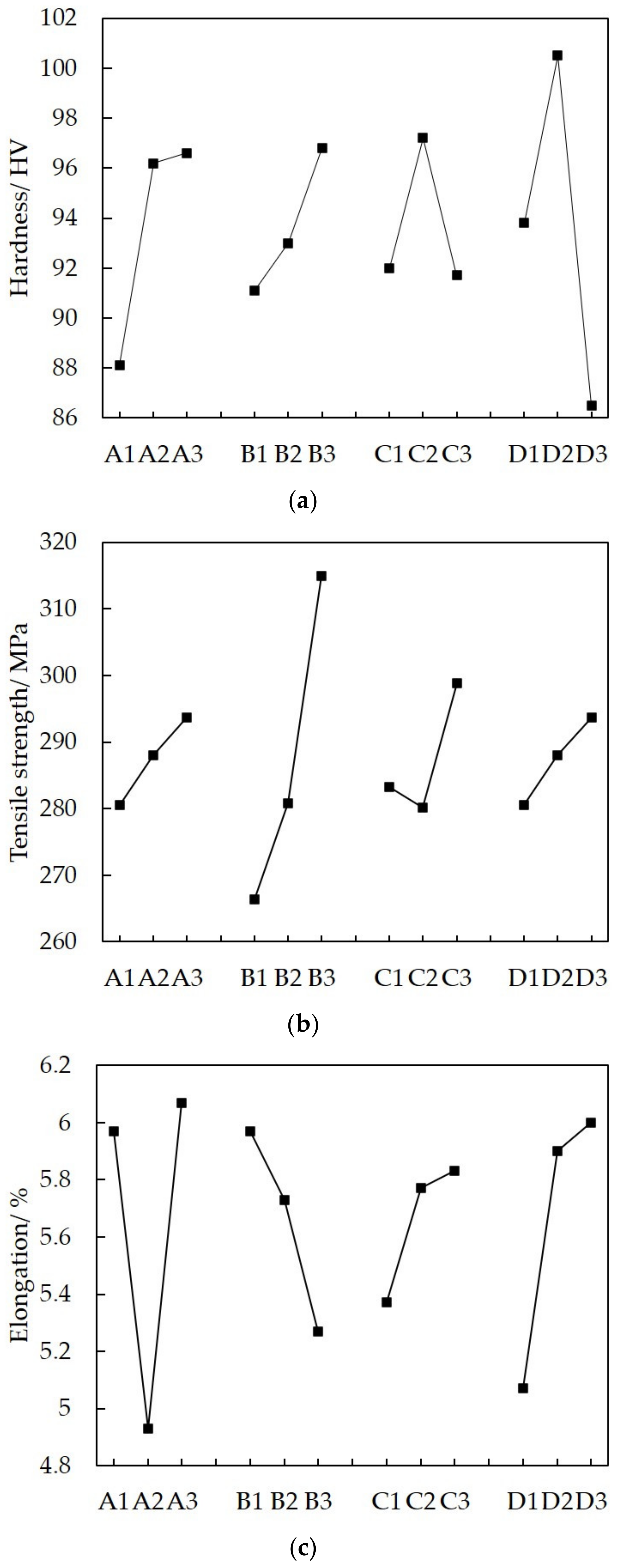

3.1. Range Analysis of Orthogonal Test Results

3.2. Grey Relational Analysis of Orthogonal Test Results

3.3. Alloy Toughness Prediction Model

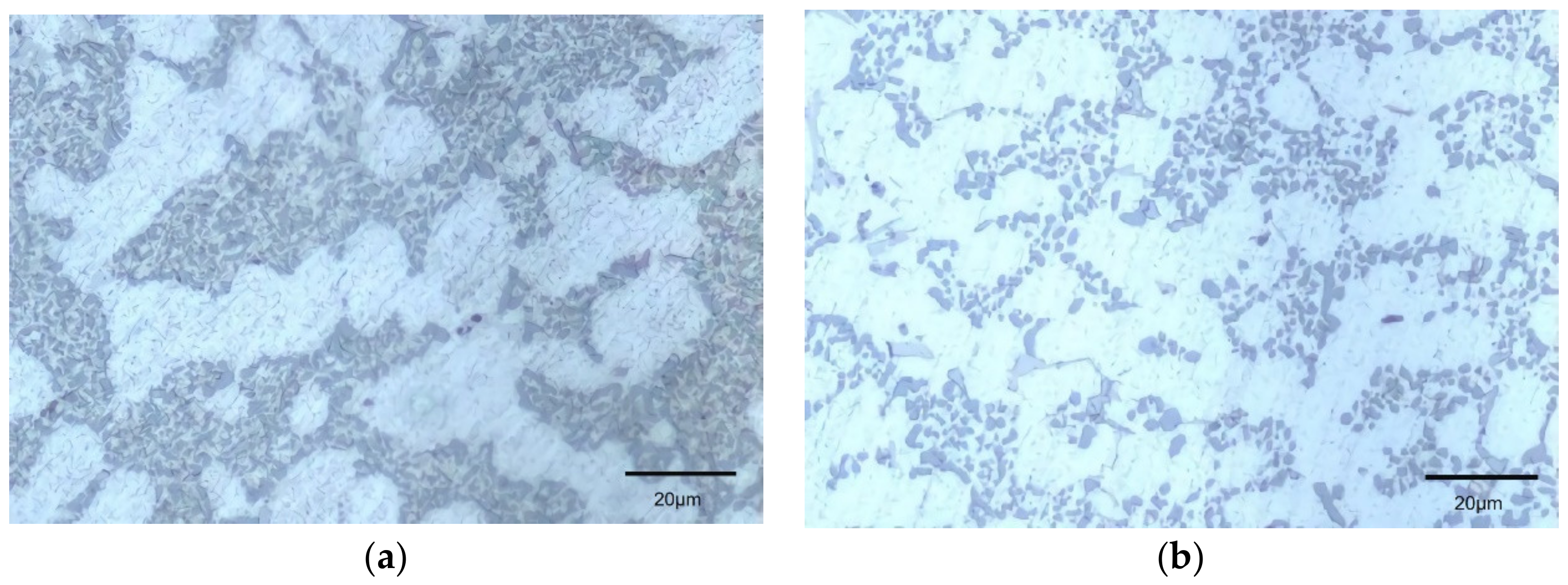

4. Metallographic Structure Analysis

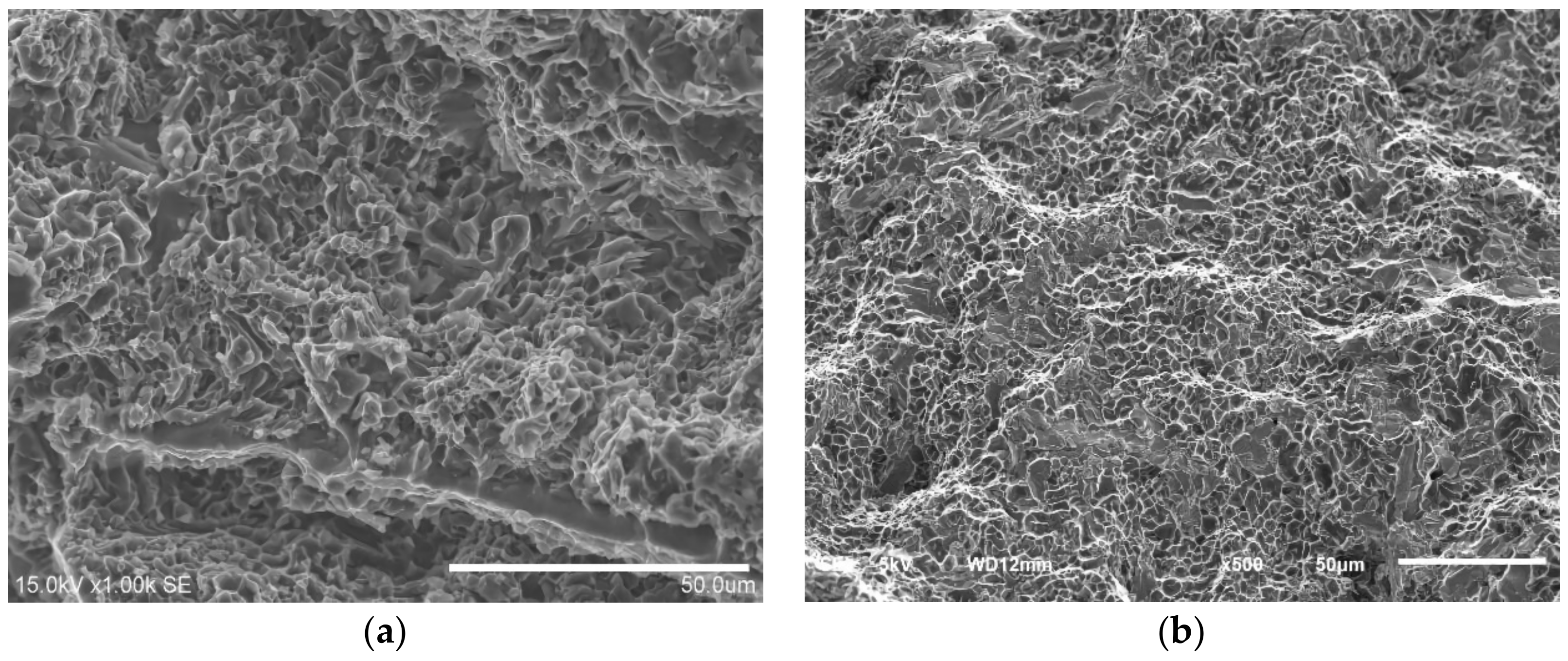

5. Tensile Fracture SEM Scanning Analysis

6. Conclusions

- (1)

- According to the range analysis of the orthogonal test, it can be seen intuitively that the aging time and the solution temperature are the first and second main factors affecting the alloy’s hardness. The solution time and the solution temperature are the first and second main factors affecting the alloy tensile strength. The solution temperature and the aging time are the first and second main factors affecting the alloy elongation.

- (2)

- Through grey relational analysis, the optimal process parameters can be effectively selected from the existing test data. Furthermore, the optimal T6 heat treatment process of the AlSi10MgMn alloy was obtained as follows: the solution temperature is 530 °C, the solution time is 1 h, the aging temperature is 190 °C, and the aging time is 6 h.

- (3)

- Through the planning and solving of the prediction model, the T6 heat treatment process parameter selection was carried out in the whole range. The final optimal T6 heat treatment process of the AlSi10MgMn alloy was as follows: solution temperature is 530 °C, solution time is 3 h, aging temperature is 190 °C, and aging time is 8 h. At this point, the alloy hardness is 96.9 HV, the tensile strength is 344.6 MPa, and the elongation is 6.1%. By contrast, the toughness of the alloy is better than the toughness of the alloy obtained based on the grey relational analysis.

- (4)

- After T6 heat treatment, the microstructure of AlSi10MgMn alloy is refined. Needle-shaped and blocky silicon phases become dark-etching phase evenly distributed in the alloy. The tearing edge and cleavage platform in the alloy’s fracture are reduced, while the small and deep dimples are significantly increased. The mechanical properties of the alloy are improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, Y.C.; Luo, S.C.; Huang, J.; Yin, L.K.; Jiang, X.Y. Effects of solution treatment on microstructures and micro-hardness of a Sr-modified Al-Si-Mg alloy. Mater. Sci. Eng. A 2018, 725, 530–540. [Google Scholar] [CrossRef]

- Beroual, S.; Boumerzoug, Z.; Paillard, P.; Borjon-Pironb, Y. Effects of heat treatment and addition of small amounts of Cu and Mg on the microstructure and mechanical properties of Al-Si-Cu and Al-Si-Mg cast alloys. J. Alloys Compd. 2019, 784, 1026–1035. [Google Scholar] [CrossRef]

- Lin, Y.C.; Luo, S.C.; Yin, L.X.; Huang, J. Microstructural evolution and high temperature flow behaviors of a homogenized Sr-modified Al-Si-Mg alloy. J. Alloys Compd. 2018, 739, 590–599. [Google Scholar] [CrossRef]

- Ibrahim, A.I.; Elgallad, E.M.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Effects of Addition of Transition Metals on Intermetallic Precipitation in Al–2%Cu–1%Si-Based Alloys. Inter. Metalcast. 2018, 12, 574–588. [Google Scholar] [CrossRef]

- Žihalová, M.; Marek, M. Change in the Microstructure of AlSi10MgMn Alloy with Higher Iron Content Due to an Increase in the Amount of Nickel. Tehnički Vjesnik 2021, 28, 34–37. [Google Scholar]

- Shuaishuai, L.; Jiaqiao, Z.; Hongjun, N.; Xingxing, W.; Yu, Z.; Tao, G. Study on Preparation of Aluminum Ash Coating Based on Plasma Spray. Appl. Sci. 2019, 9, 4980. [Google Scholar]

- Žihalová, M.; Bolibruchová, D. Influence of iron in AlSi10MgMn alloy. Arch. Foundry Eng. 2014, 14, 109–112. [Google Scholar] [CrossRef]

- Kumar, P.; Upadrasta, R. Microstructural optimization through heat treatment for enhancing the fracture toughness and fatigue crack growth resistance of selective laser melted Ti6Al4V alloy. Acta Mater. 2019, 169, 45–59. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Davies, C.H.J.; Huang, A.; Wu, X. Effect of heat treatment on the microstructure and anisotropy in mechanical properties of A357 alloy produced by selective laser melting. Mater. Des. 2018, 154, 275–290. [Google Scholar] [CrossRef]

- Zhu, M.; Jian, Z.; Yang, G.; Zhou, Y. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater. Des. 2012, 36, 243–249. [Google Scholar] [CrossRef]

- Sharma, S.; Nanda, T.; Pandey, O.P. Investigation of T4 and T6 heat treatment on the wear properties of sillimanite reinforced LM30 aluminium alloy composites. Wear 2019, 426, 27–36. [Google Scholar] [CrossRef]

- Mahathaninwong, N.; Plookphol, T.; Wannasin, J.; Wisutmethangoon, S. T6 heat treatment of rheocasting 7075 Al alloy. Mater. Sci. Eng. A 2012, 532, 91–99. [Google Scholar] [CrossRef]

- Mohamed, A.M.A.; Samuel, F.H. A review on the heat treatment of Al-Si-Cu/Mg casting alloys. In Heat Treatment-Conventional and Novel Applications; InTec: Rijeka, Croatia, 2012; pp. 55–72. [Google Scholar]

- China National Standardization Management Committee. GB/T4340.1-2009. Metal Hardness Testing; China National Standardization Management Committee: Beijing, China, 2010. (In Chinese) [Google Scholar]

- China National Standardization Management Committee. GB/T 228-2002. Metallic Materials Tensile Testing at Ambient Temperature; China National Standardization Management Committee: Beijing, China, 2006. (In Chinese) [Google Scholar]

- Gopalan, R.; Prabhu, N.K. Oxide bifilms in aluminium alloy castings—A review. Mater. Sci. Technol. 2011, 27, 1757–1769. [Google Scholar] [CrossRef]

- Kertész, L.; Kojnok, J.; Szász, A. The determination of Mg surface enrichment in heat treated AlMgSi alloys using the sxes method. Acta Phys. Acad. Sci. Hung. 1980, 49, 169–174. [Google Scholar] [CrossRef][Green Version]

- Rinderer, B.; Couper, M.; Xiong, X.Y.; Gao, S.X.; Nie, J.F. Precipitation Sequence in an Al-Si-Mg Foundry Alloy. Mater. Sci. Forum 2010, 654, 590–595. [Google Scholar] [CrossRef]

- Sha, G.; Möller, H.; Stumpf, W.E.; Xia, J.H.; Govender, G.; Ringer, S.P. Solute nanostructures and their strengthening effects in Al–7Si–0.6 Mg alloy F357. Acta Mater. 2012, 60, 692–701. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, T.; Yu, T.; Zhao, J. Assessment and optimization of grinding process on AISI 1045 steel in terms of green manufacturing using orthogonal experimental design and grey relational analysis. J. Clean. Prod. 2020, 253, 119896. [Google Scholar] [CrossRef]

- Lian, G.; Zhang, H.; Zhang, Y.; Tanaka, M.L.; Chen, C.; Jiang, J. Optimizing Processing Parameters for Multi-Track Laser Cladding Utilizing Multi-Response Grey Relational Analysis. Coatings 2019, 9, 356. [Google Scholar] [CrossRef]

- Agboola, O.O.; Ikubanni, P.P.; Adeleke, A.A.; Adediran, A.A.; Adesina, O.S.; Aliyu, S.J.; Olabamiji, T.S. Optimization of heat treatment parameters of medium carbon steel quenched in different media using Taguchi method and grey relational analysis. Heliyon 2020, 6, e04444. [Google Scholar] [CrossRef]

- Ilmaya, R.M.; Pranowo, S.; Rachman, F. Optimasi Kekerasan Baja S45C pada Proses Hardening Helical Gear Menggunakan Metode Taguchi. In Proceedings of the Conference on Design Manufacture Engineering and Its Application; 2018; Volume 2, pp. 159–164. Available online: https://core.ac.uk/download/pdf/236670678.pdf (accessed on 1 December 2018).

- Satolo, E.G.; Leite, C.; Calado, R.D.; Goes, D.A.; Salgado, D.D. Ranking lean tools for world class reach through grey relational analysis. Grey Syst. Theory Appl. 2018, 8, 399–423. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, L.; Shi, C.; Wang, Y.; Zhu, F. Research on optimal decision-making of cloud manufacturing service provider based on grey correlation analysis and TOPSIS. Int. J. Prod. Res. 2020, 58, 748–757. [Google Scholar] [CrossRef]

- Wang, X.; Yang, C.; Yong, G.; Feng, D. The influence of shrinkage-reducing agent solution properties on shrinkage of cementitious composite using grey correlation analysis. Constr. Build. Mater. 2020, 264, 120194. [Google Scholar]

- Das, M.K.; Kumar, K.; Barman, T.K.; Sahoo, P. Optimization of process parameters in plasma arc cutting of EN 31 steel based on MRR and multiple roughness characteristics using grey relational analysis. Procedia Mater. Sci. 2014, 5, 1550–1559. [Google Scholar] [CrossRef]

- Borko, K.; Eva, T.; Mária, C. The Impact of Sr content on Fe-intermetallic phases morphology changes in alloy AlSi10MgMn. Manuf. Technol. 2016, 16, 20–26. [Google Scholar]

- Ni, H.; Zhang, J.; Lv, S.; Wang, X.; Zhu, Y.; Gu, T. Preparation and Performance Optimization of Original Aluminum Ash Coating Based on Plasma Spraying. Coatings 2019, 9, 770. [Google Scholar] [CrossRef]

- Tillová, E.; Chalupová, M.; Borko, K.; Kuchariková, L. Changes of fracture surface in recycled A356 cast alloy. Mater. Today 2016, 3, 1183–1188. [Google Scholar] [CrossRef]

| Level | Solution Temperature (°C) | Solution Time (h) | Aging Temperature (°C) | Aging Time (h) |

|---|---|---|---|---|

| A | B | C | D | |

| 1 | 510 | 1 | 160 | 4 |

| 2 | 520 | 2 | 175 | 6 |

| 3 | 530 | 3 | 190 | 8 |

| Number | Solution Temperature (°C) | Solution Time (h) | Aging Temperature (°C) | Aging Time (h) |

|---|---|---|---|---|

| A | B | C | D | |

| 1 | 510 | 1 | 160 | 4 |

| 2 | 510 | 2 | 175 | 6 |

| 3 | 510 | 3 | 190 | 8 |

| 4 | 520 | 1 | 175 | 8 |

| 5 | 520 | 2 | 190 | 4 |

| 6 | 520 | 3 | 160 | 6 |

| 7 | 530 | 1 | 190 | 6 |

| 8 | 530 | 2 | 160 | 8 |

| 9 | 530 | 3 | 175 | 4 |

| Number | Hardness (HV) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 1 | 84.2 | 238 | 5.4 |

| 2 | 97.9 | 257 | 6.4 |

| 3 | 82.3 | 315.5 | 6.1 |

| 4 | 90.1 | 263 | 5.7 |

| 5 | 93.8 | 283 | 4.6 |

| 6 | 104.6 | 309 | 4.5 |

| 7 | 99.1 | 298 | 6.3 |

| 8 | 87.2 | 302.5 | 6.2 |

| 9 | 103.5 | 320.5 | 5.2 |

| Testing index | Range | Solution Temperature (°C) | Solution Time (h) | Aging Temperature (°C) | Aging Time (h) |

|---|---|---|---|---|---|

| A | B | C | D | ||

| Hardness (HV) | k1 | 88.1 | 91.1 | 92 | 93.8 |

| k2 | 96.2 | 93.0 | 97.2 | 100.5 | |

| k3 | 96.6 | 96.8 | 91.7 | 86.5 | |

| Range R | 8.5 | 5.7 | 5.2 | 14 | |

| Impact Factor | Aging time > Solution temperature > Solution time > Aging temperature | ||||

| Optimal Composition | 530 °C/3 h + 175 °C/6 h | ||||

| Tensile Strength (MPa) | k1 | 270.2 | 266.3 | 283.2 | 280.5 |

| k2 | 285 | 280.8 | 280.2 | 288 | |

| k3 | 307 | 315 | 298.8 | 293.7 | |

| Range R | 37.2 | 48.7 | 15.6 | 13.2 | |

| Impact Factor | Solution time > Solution temperature > Aging temperature > Aging time | ||||

| Optimal Composition | 530 °C/3 h + 190 °C/8 h | ||||

| Elongation (%) | k1 | 5.97 | 5.97 | 5.37 | 5.07 |

| k2 | 4.93 | 5.73 | 5.77 | 5.9 | |

| k3 | 6.07 | 5.27 | 5.83 | 6 | |

| Range R | 1.14 | 0.75 | 0.46 | 0.93 | |

| Impact Factor | Solution temperature > Aging time > Solution time > Aging temperature | ||||

| Optimal Composition | 530 °C/1 h + 190 °C/8 h | ||||

| Testing Index | Tensile Strength (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|

| 312 | 6.5 | 84.5 |

| Number | Signal-to-Noise Ratio | Dimension Value xij | Correlation Coefficient | Correlation Degree γi | Order | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| HV | Rm | δ | HV | Rm | δ | HV | Rm | δ | |||

| 1 | 38.51 | 47.53 | 14.65 | 0.10 | 0 | 0.44 | 0.49 | 0.47 | 0.61 | 0.52 | 9 |

| 2 | 39.82 | 48.20 | 16.12 | 0.72 | 0.26 | 0.85 | 0.76 | 0.54 | 0.86 | 0.72 | 5 |

| 3 | 38.32 | 49.98 | 15.71 | 0 | 0.95 | 0.74 | 0.47 | 0.94 | 0.77 | 0.73 | 4 |

| 4 | 39.09 | 48.40 | 15.12 | 0.38 | 0.34 | 0.57 | 0.59 | 0.57 | 0.67 | 0.61 | 7 |

| 5 | 39.44 | 49.04 | 13.26 | 0.55 | 0.58 | 0.05 | 0.66 | 0.68 | 0.48 | 0.61 | 7 |

| 6 | 40.39 | 49.80 | 13.06 | 1 | 0.88 | 0 | 1 | 0.88 | 0.47 | 0.78 | 3 |

| 7 | 39.92 | 49.48 | 16.65 | 0.77 | 0.76 | 1 | 0.80 | 0.78 | 1 | 0.86 | 1 |

| 8 | 38.81 | 49.61 | 15.85 | 0.24 | 0.81 | 0.78 | 0.54 | 0.82 | 0.80 | 0.72 | 5 |

| 9 | 40.30 | 50.12 | 14.32 | 0.96 | 1 | 0.35 | 0.95 | 1 | 0.58 | 0.84 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Zhang, J.; Ni, H.; Zhu, Y.; Wang, X.; Wan, X.; Chen, K. Optimization of AlSi10MgMn Alloy Heat Treatment Process Based on Orthogonal Test and Grey Relational Analysis. Crystals 2021, 11, 385. https://doi.org/10.3390/cryst11040385

Zhang F, Zhang J, Ni H, Zhu Y, Wang X, Wan X, Chen K. Optimization of AlSi10MgMn Alloy Heat Treatment Process Based on Orthogonal Test and Grey Relational Analysis. Crystals. 2021; 11(4):385. https://doi.org/10.3390/cryst11040385

Chicago/Turabian StyleZhang, Fubao, Jiaqiao Zhang, Hongjun Ni, Yu Zhu, Xingxing Wang, Xiaofeng Wan, and Ke Chen. 2021. "Optimization of AlSi10MgMn Alloy Heat Treatment Process Based on Orthogonal Test and Grey Relational Analysis" Crystals 11, no. 4: 385. https://doi.org/10.3390/cryst11040385

APA StyleZhang, F., Zhang, J., Ni, H., Zhu, Y., Wang, X., Wan, X., & Chen, K. (2021). Optimization of AlSi10MgMn Alloy Heat Treatment Process Based on Orthogonal Test and Grey Relational Analysis. Crystals, 11(4), 385. https://doi.org/10.3390/cryst11040385