Effect of Rare Earth Elements on Stability and Sintering Resistance of Tetragonal Zirconia for Advanced Thermal Barrier Coatings

Abstract

1. Introduction

2. Research Methods

2.1. Experimental

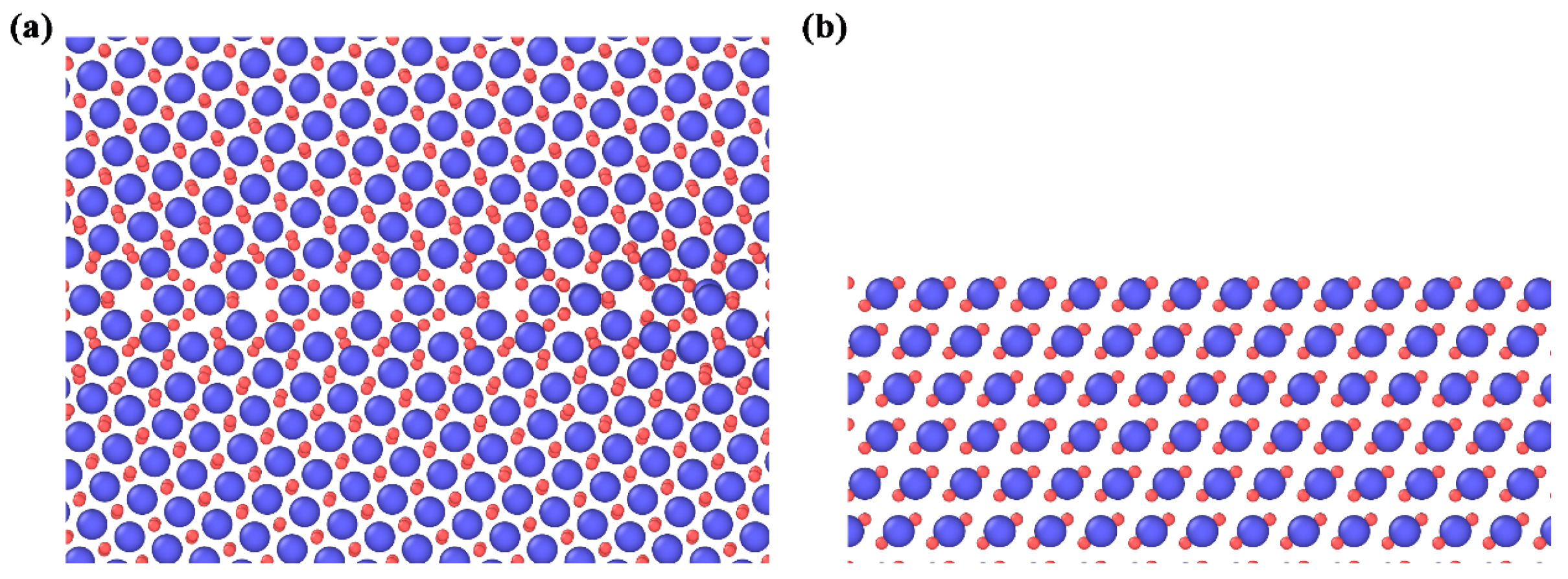

2.2. Numerical Approach

3. Results and Discussion

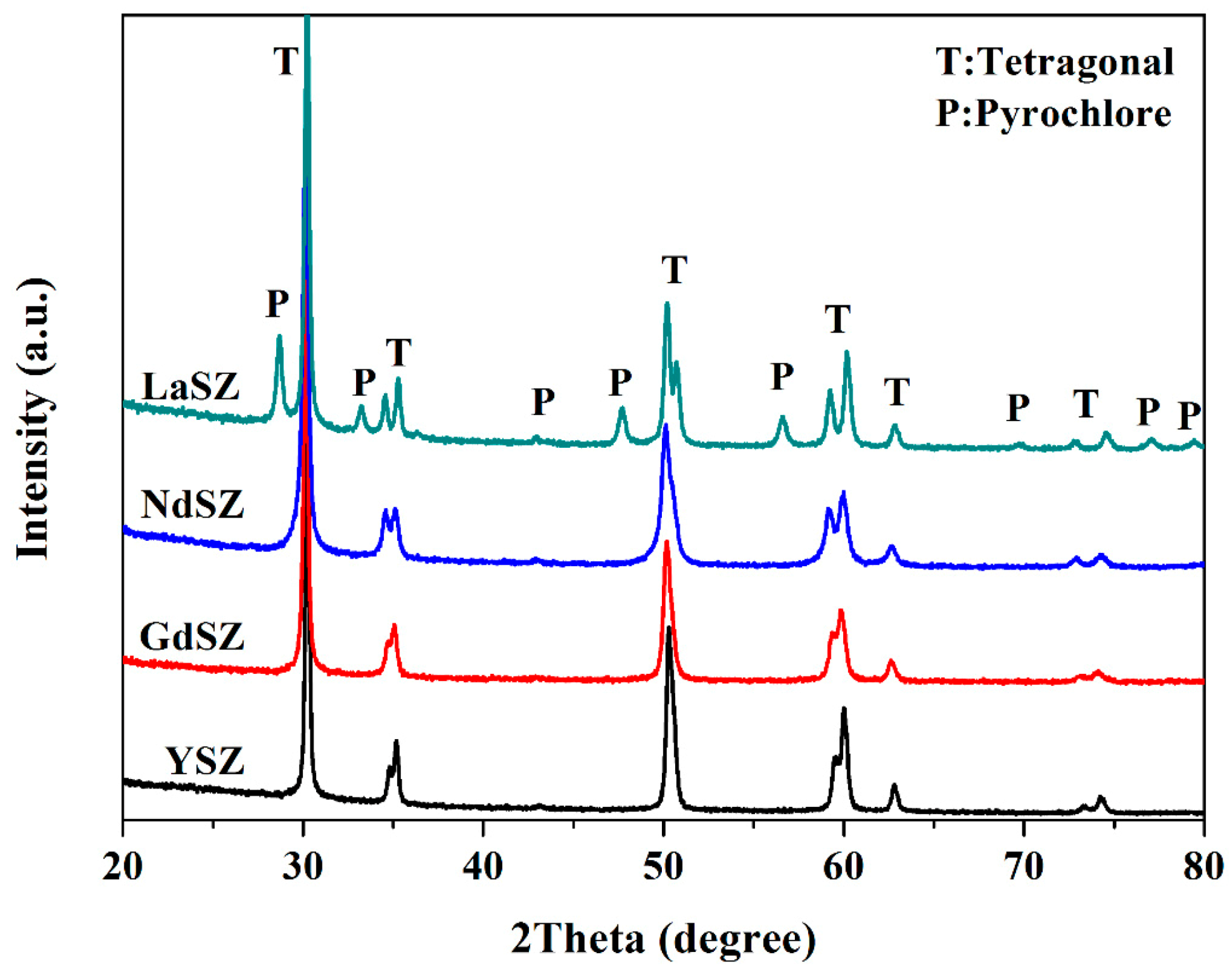

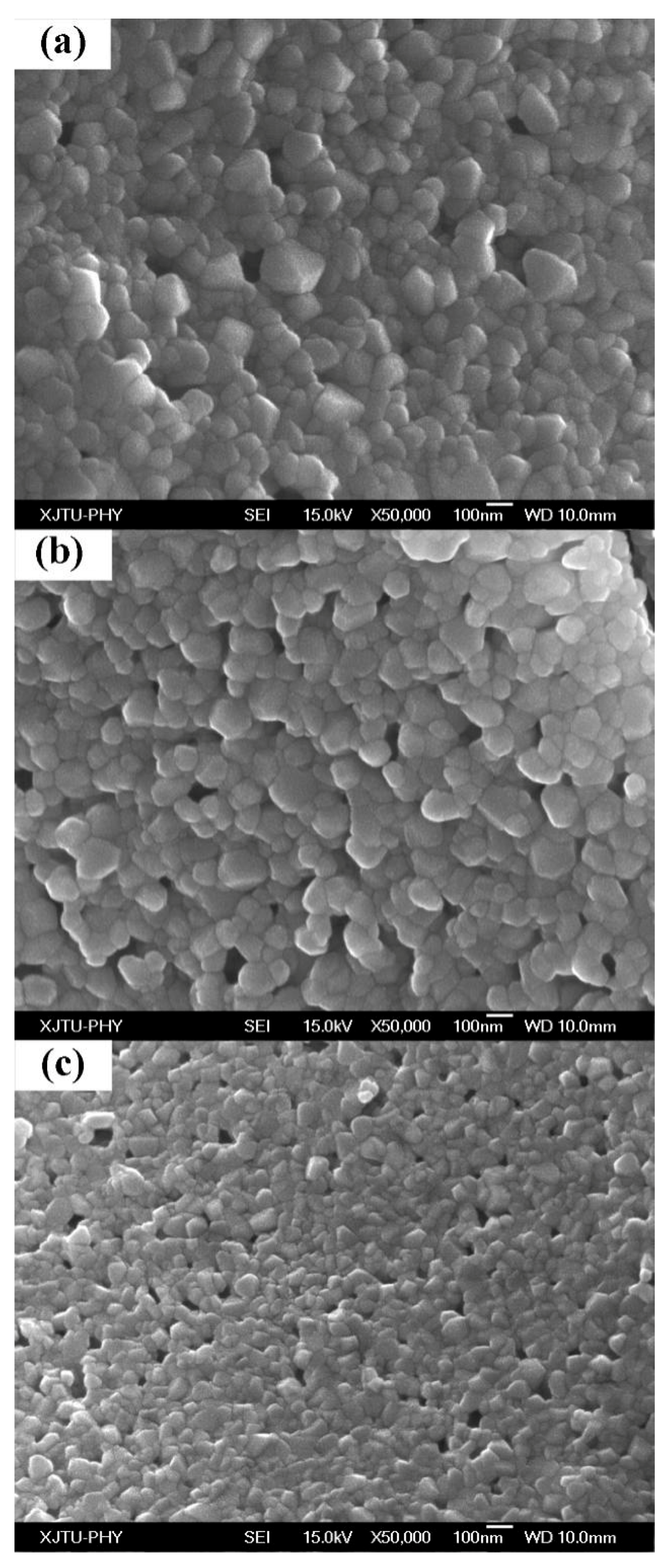

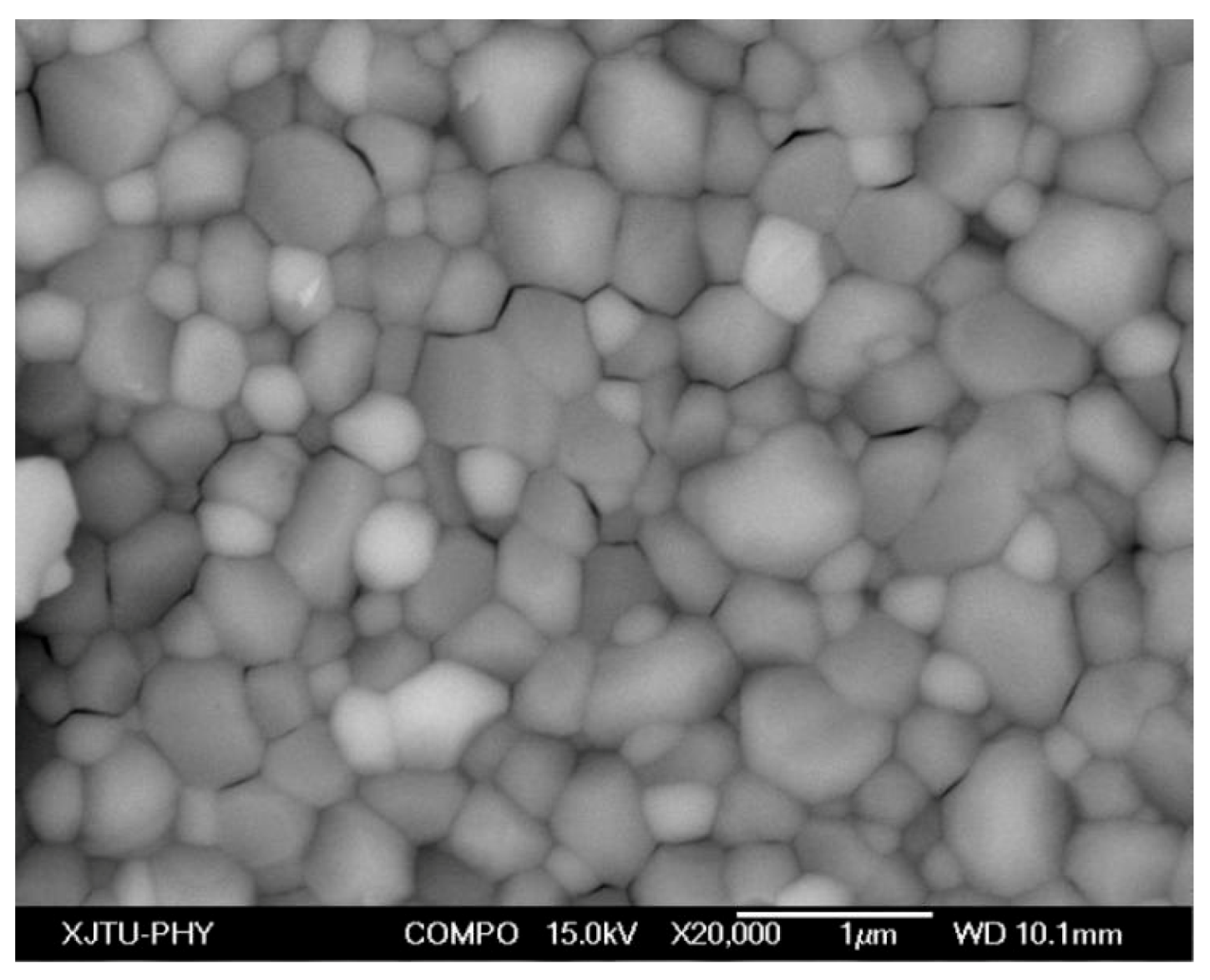

3.1. The Anti-Sintering Ability of LnSZ

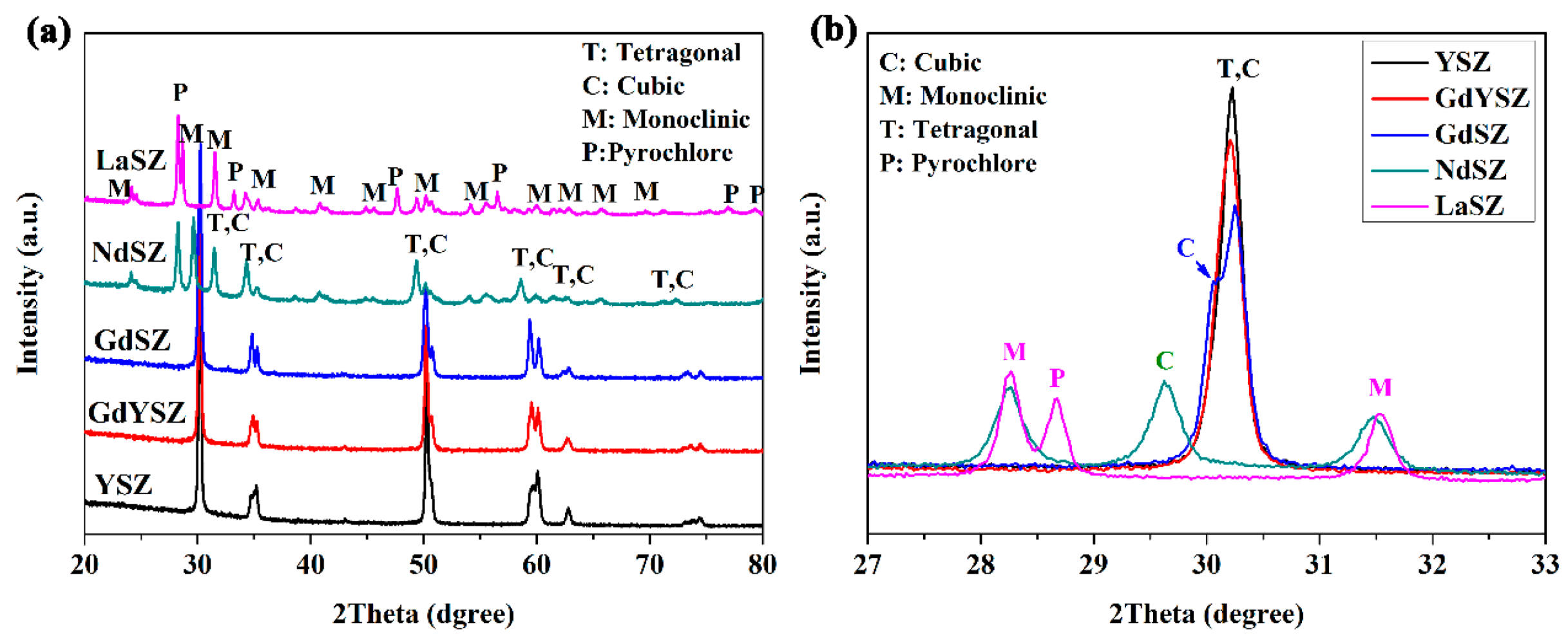

3.2. High-Temperature Phase Stability of LnSZ

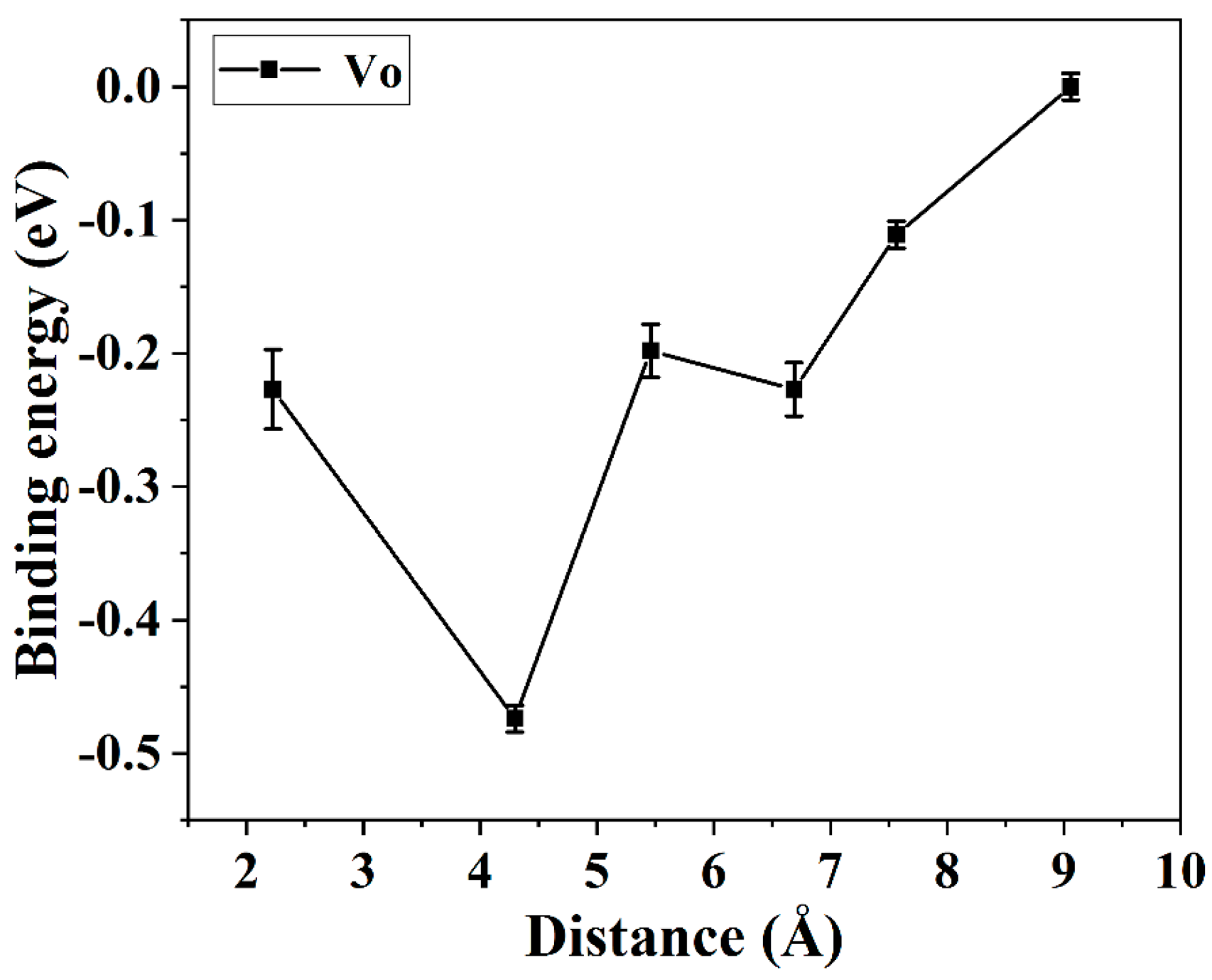

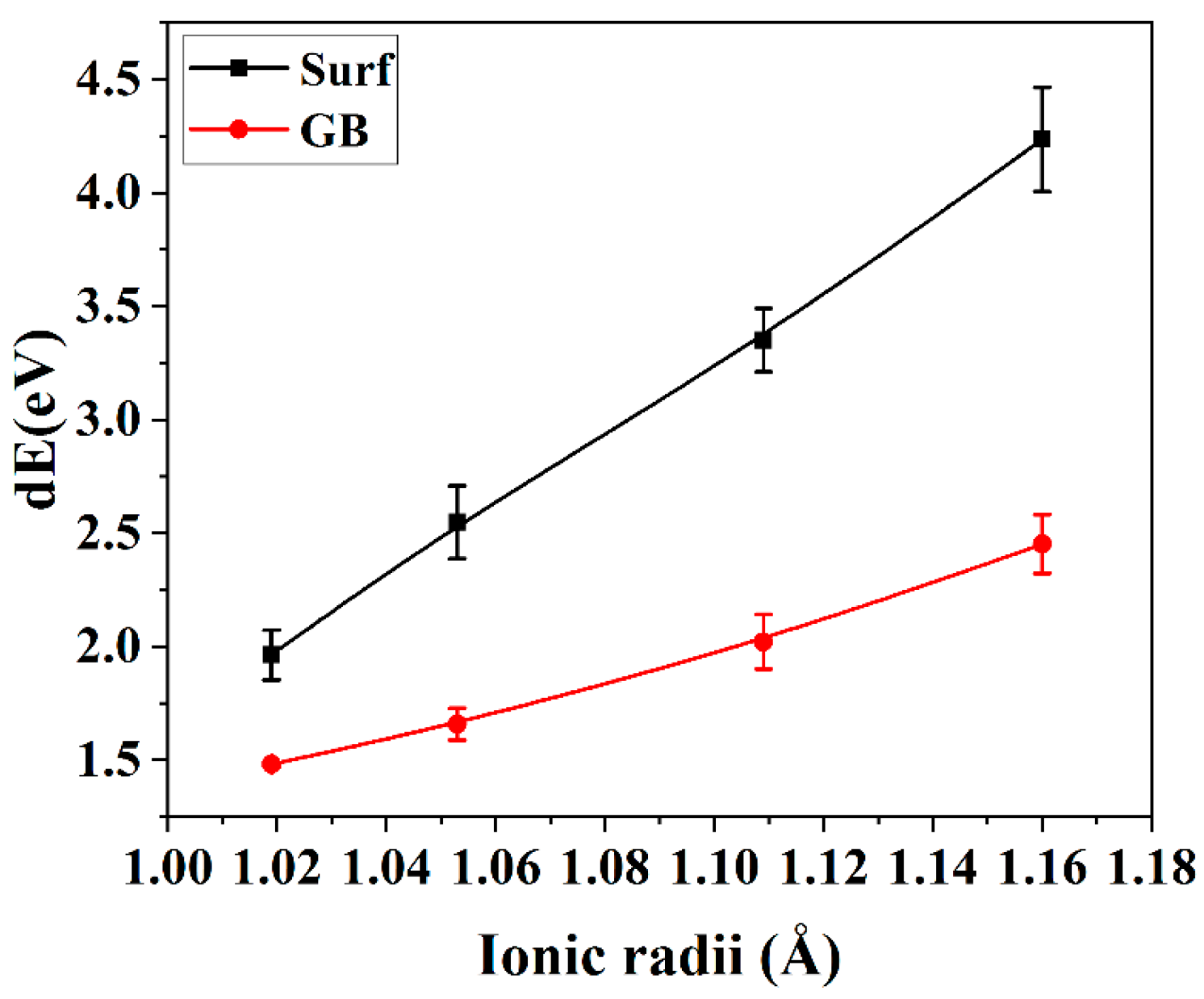

4. Simulation and Discussion

5. Conclusions

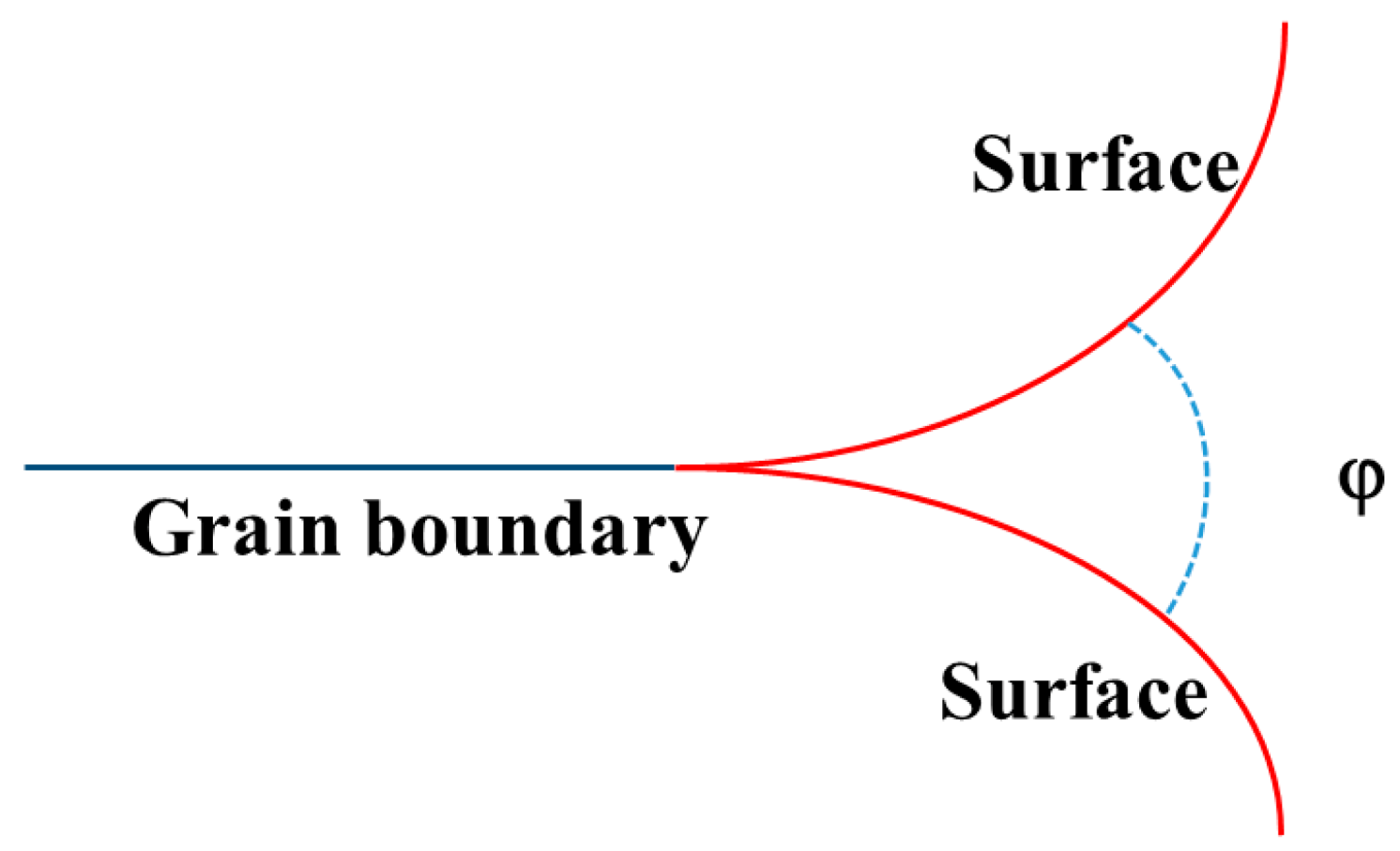

- A certain amount (8 mol% LnO1.5) of large-sized rare earth ions (La3+, Nd3+, and Gd3+) used as dopants in ZrO2 could effectively improve the sintering resistance and high-temperature stability of pores of ZrO2 materials by significantly reducing the surface energy and the grain boundary energy.

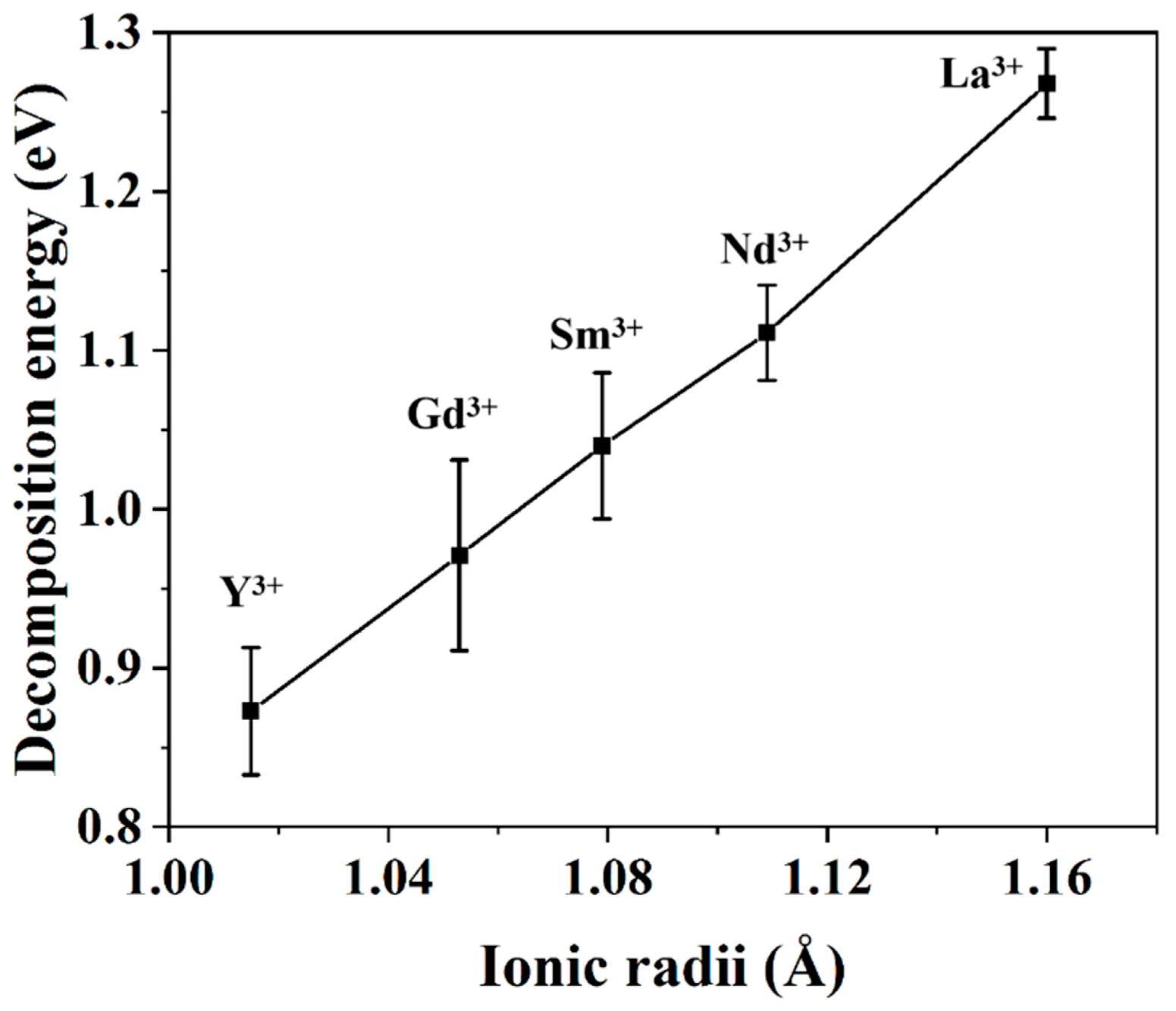

- The phase stability of the doped ZrO2 was found to decrease with the increasing ionic radius of the relevant rare earth element. The decomposition of tetragonal-RSZ can be theoretically ascribed to the formation of the RE3+-VO-RE3+ defect cluster, which can be quantitatively computed by using atomistic simulation. The larger mismatch between ionic radii induced by doping resulted in the faster diffusion and the higher decomposition energy, compared with some second-phase particles with a pyrochlore structure or a cubic structure, which were shown to not only reduce the sintering resistance of the TBC materials, but also deteriorate the stability of the ZrO2 tetragonal phase.

- The most optimal strategy for stabilization of the ZrO2 structure for TBC applications was determined by employing small-sized rare earth ions (e.g., Y3+, Er3+, or Yb3+) as dopants with concentrations in the range of 0.5–1.5 mol%. This allows for the reduction in the surface energy and the grain boundary energy in order to achieve a further decrease of the driving force for the sintering reaction, thus improving the sintering resistance of the relevant materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Vassen, R.; Stoever, D. Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 2004, 24, 1–10. [Google Scholar] [CrossRef]

- Vaßen, R.; Jarligo, M.O.; Steinke, T.; Mack, D.E.; Stöver, D. Overview on advanced thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 938–942. [Google Scholar] [CrossRef]

- Clarke, D.R.; Oechsner, M.; Padture, N.P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012, 37, 891–898. [Google Scholar] [CrossRef]

- Li, G.; Xie, H.; Yang, G.; Liu, G.; Li, C.; Li, C. A comprehensive sintering mechanism for TBCs-Part I: An overall evolution with two-stage kinetics. J. Am. Ceram. Soc. 2017, 100, 2176–2189. [Google Scholar] [CrossRef]

- Cheng, B.; Zhang, Y.-M.; Yang, N.; Zhang, M.; Chen, L.; Yang, G.-J.; Li, C.-X.; Li, C.-J. Sintering-induced delamination of thermal barrier coatings by gradient thermal cyclic test. J. Am. Ceram. Soc. 2017, 100, 1820–1830. [Google Scholar] [CrossRef]

- Yi, H.; Che, J.; Xu, Z.; Liang, G.; Liu, X. Sintering resistance of La2Ce2O7, La2Zr2O7, and yttria stabilized zirconia ceramics. Ceram. Int. 2021, 47, 4197–4205. [Google Scholar] [CrossRef]

- Li, G.; Xie, H.; Yang, G.; Liu, G.; Li, C.; Li, C. A comprehensive sintering mechanism for TBCs-Part II: Multiscale multipoint interconnection-enhanced initial kinetics. J. Am. Ceram. Soc. 2017, 100, 4240–4251. [Google Scholar] [CrossRef]

- Liu, X.; Xu, Z.; Liang, G. Comparative study of the sintering behaviors between YSZ and LZ/YSZ composite. Mater. Lett. 2017, 191, 108–111. [Google Scholar] [CrossRef]

- Che, J.; Wang, X.; Liu, X.; Liang, G.; Zhang, S. Outstanding sintering resistance in pyrochlore-type La2(Zr0.7Ce0.3)2O7 for thermal barrier coatings material. Ceram. Int. 2021, 47, 6996–7004. [Google Scholar] [CrossRef]

- Ziyuan, W.; Meng, Z.; Jun, Y.; Zongyuan, L.; Min, W.; Wei, P. Effect of SiO2 Content on Sintering Characteristics of YSZ in High Temperature Aging. Rare Metal Mater. Eng. 2020, 49, 688–694. [Google Scholar]

- Jiang, K.; Liu, S.; Li, Y.; Li, Y. Effects of RE3+ Ionic Radius on Monoclinic Phase Content of 8 mol% REO 1.5 Partially Stabilized ZrO2 (RE = Yb, Y, Gd, and Nd) Powder Compacts after Annealing at High Temperature. J. Am. Ceram. Soc. 2014, 97, 990–995. [Google Scholar] [CrossRef]

- Li, G.-R.; Wang, L.-S.; Yang, G.-J. A novel composite-layered coating enabling self-enhancing thermal barrier performance. Scr. Mater. 2019, 163, 142–147. [Google Scholar] [CrossRef]

- Matsumoto, M.; Yamaguchi, N.; Matsubara, H. Low thermal conductivity and high temperature stability of ZrO2–Y2O3–La2O3 coatings produced by electron beam PVD. Scr. Mater. 2004, 50, 867–871. [Google Scholar] [CrossRef]

- Fan, W.; Wang, Z.; Bai, Y.; Che, J.; Wang, R.; Ma, F.; Tao, W.; Liang, G. Improved properties of scandia and yttria co-doped zirconia as a potential thermal barrier material for high temperature applications. J. Eur. Ceram. Soc. 2018, 38, 4502–4511. [Google Scholar] [CrossRef]

- Fan, W.; Bai, Y.; Wang, Y.; He, T.; Gao, Y.; Zhang, Y.; Zhong, X.; Li, B.; Chang, Z.; Ma, Y. Microstructural design and thermal cycling performance of a novel layer-gradient nanostructured Sc2O3–Y2O3 co-stabilized ZrO2 thermal barrier coating. J. Alloy. Compd. 2020, 829, 154525. [Google Scholar] [CrossRef]

- Huang, M.; Liu, X.; Feng, Y.; Wan, C.; Pan, W.; Yang, J.; Zhao, X. Structure and Properties of Nonstoichiometric Y1−xNbxO1.5+x for Thermal Barrier Coatings. J. Eur. Ceram. Soc. 2021, 41, 526–534. [Google Scholar] [CrossRef]

- Liu, X.; Che, J.; Yi, H.; Liang, G. Chemical compatibility between Ln2Zr2O7 (Ln = Nd, Sm, Gd) and tetragonal yttria stabi-lized zirconia after annealing at high temperatures. Mater. Lett. 2019, 234, 159–162. [Google Scholar] [CrossRef]

- Liu, X.; Yi, H.; Che, J.; Liang, G. Phase, compositional, structural, and chemical stability of La2Ce2O7 after high temperature heat treatment. Ceram. Int. 2019, 45, 5030–5035. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Gale, J.D.; Rohl, A.L. The general utility lattice program (GULP). Mol. Simul. 2003, 29, 291–341. [Google Scholar] [CrossRef]

- Liu, X.; Che, J.; Yi, H.; Zhang, J.; Liang, G. Diffusion mechanism of oxygen ions in La2Zr2O7/YSZ composite ceramics. J. Alloy. Compd. 2019, 778, 522–531. [Google Scholar] [CrossRef]

- Minervini, L.; Grimes, R.W.; Sickafus, K.E. Disorder in Pyrochlore Oxides. J. Am. Ceram. Soc. 2004, 83, 1873–1878. [Google Scholar] [CrossRef]

- Lughi, V.; Clarke, D.R. Transformation of Electron-Beam Physical Vapor-Deposited 8 wt% Yttria-Stabilized Zirconia Thermal Barrier Coatings. J. Am. Ceram. Soc. 2005, 88, 2552–2558. [Google Scholar] [CrossRef]

- Suresh, A.; Mayo, M.J.; Porter, W.D.; Rawn, C.J. Crystallite and Grain-Size-Dependent Phase Transformations in Yttria-Doped Zirconia. J. Am. Ceram. Soc. 2003, 86, 360–362. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Javed, A.; Zhu, C.; Liang, G. Phase transition behavior of yttria-stabilized zirconia from tetragonal to monoclinic in the lanthanum zirconate/yttria-stabilized zirconia coupled-system using molecular dynamics simulation. J. Mol. Liq. 2015, 207, 309–314. [Google Scholar] [CrossRef]

- Song, N.; Wang, Z.; Xing, Y.; Zhang, M.; Wu, P.; Qian, F.; Feng, J.; Qi, L.; Wan, C.; Pan, W. Evaluation of Phase Transformation and Mechanical Properties of Metastable Yttria-Stabilized Zirconia by Nanoindentation. Materials 2019, 12, 1677. [Google Scholar] [CrossRef]

- Witz, G.; Shklover, V.; Steurer, W.; Bachegowda, S.; Bossmann, H.-P. Phase Evolution in Yttria-Stabilized Zirconia Thermal Barrier Coatings Studied by Rietveld Refinement of X-Ray Powder Diffraction Patterns. J. Am. Ceram. Soc. 2007, 90, 2935–2940. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Javed, A.; Zhu, C.; Liang, G. The effect of sintering temperature on the microstructure and phase trans-formation in tetragonal YSZ and LZ/YSZ composites. Ceram. Int. 2016, 42, 2456–2465. [Google Scholar] [CrossRef]

- Castro, R.; van Benthem, K. Sintering: Mechanisms of Convention Nanodensification and Field Assisted Processes; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Zhang, S.; Sha, H.; Castro, R.H.; Faller, R. Atomistic modeling of La3+ doping segregation effect on nanocrystalline yt-tria-stabilized zirconia. Phys. Chem. Chem. Phys. 2018, 20, 13215–13223. [Google Scholar] [CrossRef]

| Species Pair | Aij (eV) | ρij (Ǻ) | Cij (eV Ǻ6) |

|---|---|---|---|

| O2−-O2− | 9547.96 | 0.2192 | 32 |

| Zr4+-O2− | 1502.11 | 0.3477 | 5.1 |

| Y3+-O2− | 1766.40 | 0.33849 | 19.43 |

| Gd3+-O2− | 1885.75 | 0.3399 | 20.34 |

| Nd3+-O2− | 1995.20 | 0.3430 | 22.59 |

| La3+-O2− | 2088.79 | 0.3460 | 23.25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, H.; Che, J.; Liang, G.; Liu, X. Effect of Rare Earth Elements on Stability and Sintering Resistance of Tetragonal Zirconia for Advanced Thermal Barrier Coatings. Crystals 2021, 11, 287. https://doi.org/10.3390/cryst11030287

Yi H, Che J, Liang G, Liu X. Effect of Rare Earth Elements on Stability and Sintering Resistance of Tetragonal Zirconia for Advanced Thermal Barrier Coatings. Crystals. 2021; 11(3):287. https://doi.org/10.3390/cryst11030287

Chicago/Turabian StyleYi, Hao, Junwei Che, Gongying Liang, and Xiangyang Liu. 2021. "Effect of Rare Earth Elements on Stability and Sintering Resistance of Tetragonal Zirconia for Advanced Thermal Barrier Coatings" Crystals 11, no. 3: 287. https://doi.org/10.3390/cryst11030287

APA StyleYi, H., Che, J., Liang, G., & Liu, X. (2021). Effect of Rare Earth Elements on Stability and Sintering Resistance of Tetragonal Zirconia for Advanced Thermal Barrier Coatings. Crystals, 11(3), 287. https://doi.org/10.3390/cryst11030287