Influence of Temperature and Plastic Strain on Deformation Mechanisms and Kink Band Formation in Homogenized HfNbTaTiZr

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

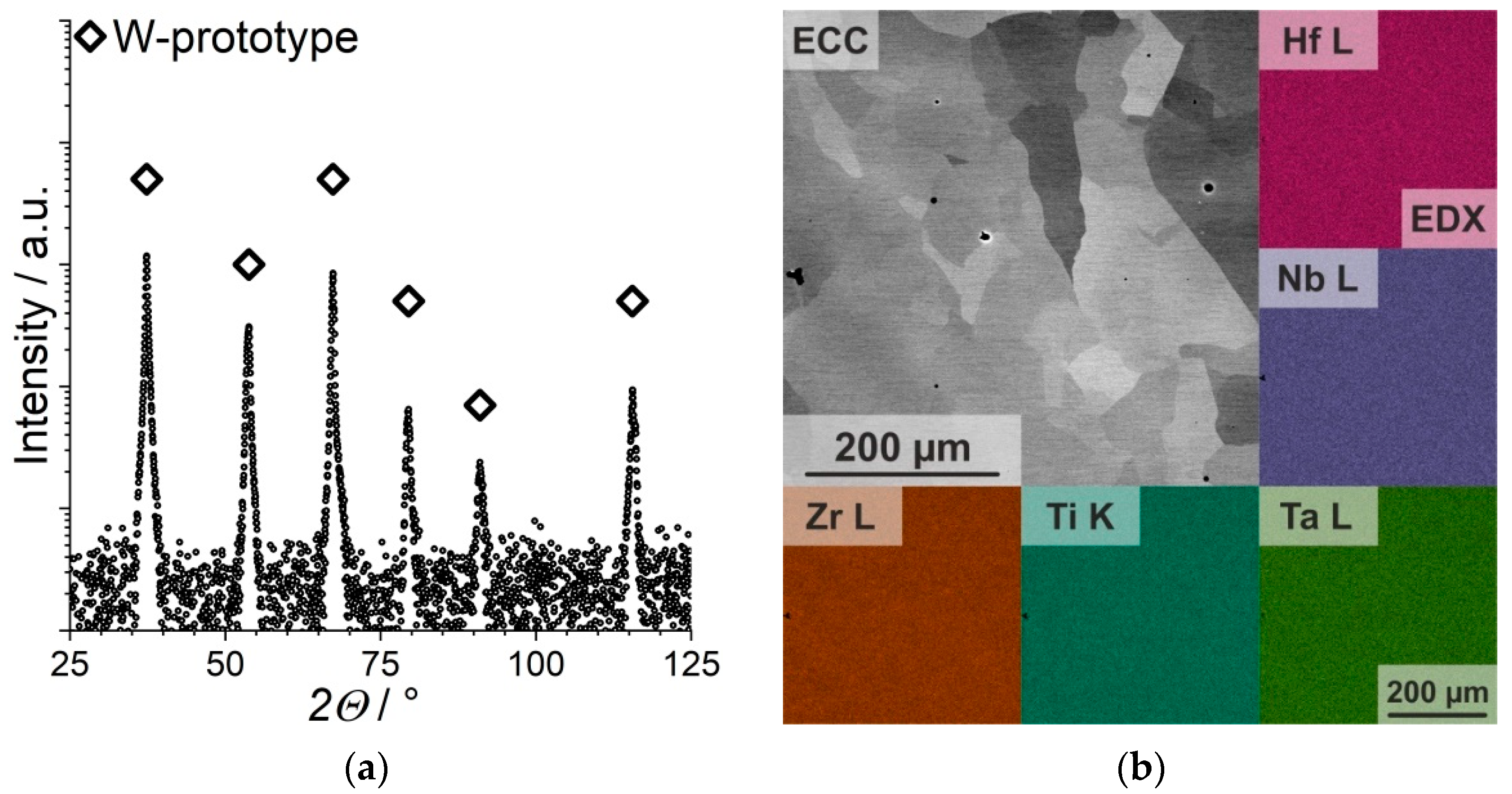

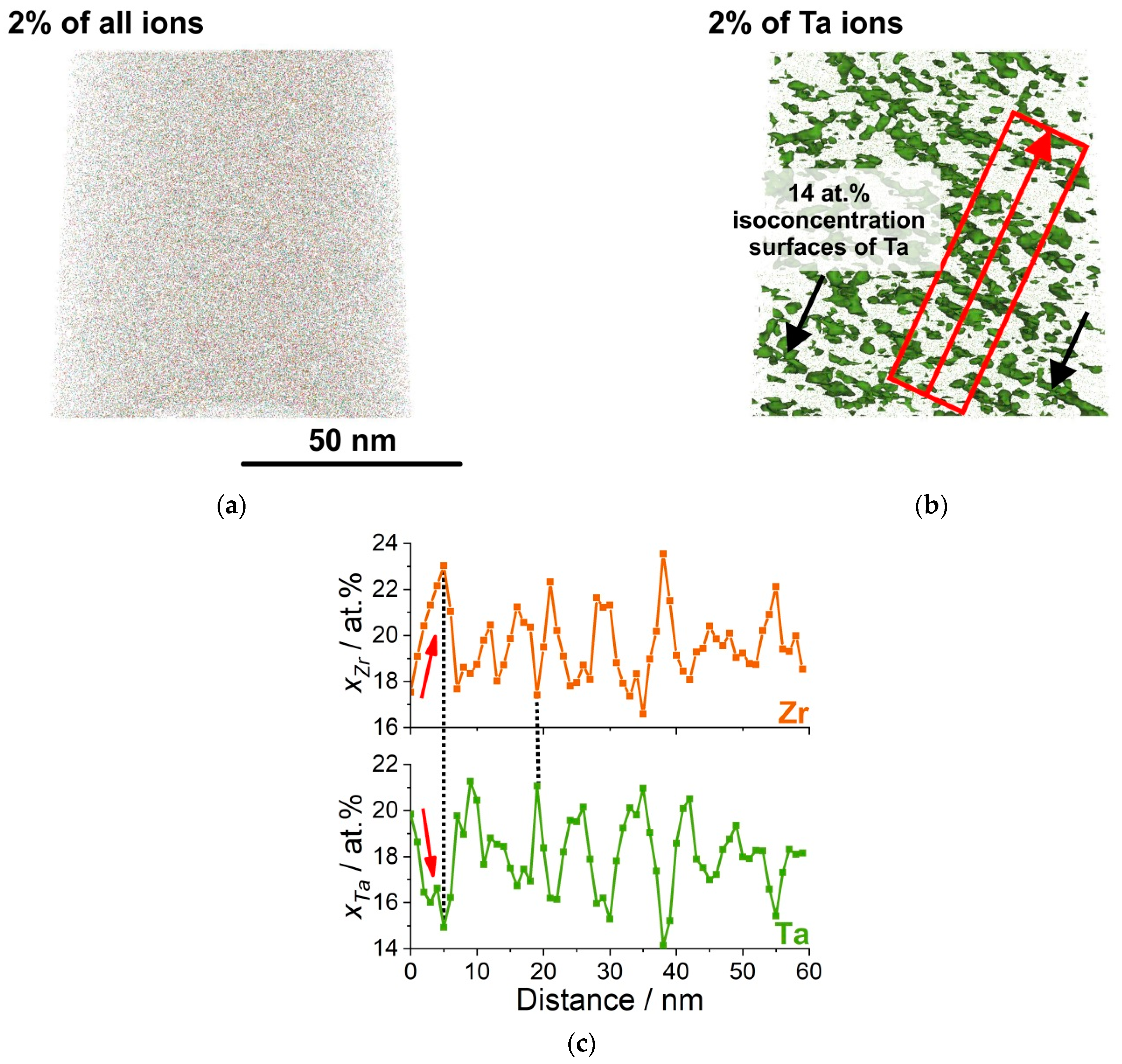

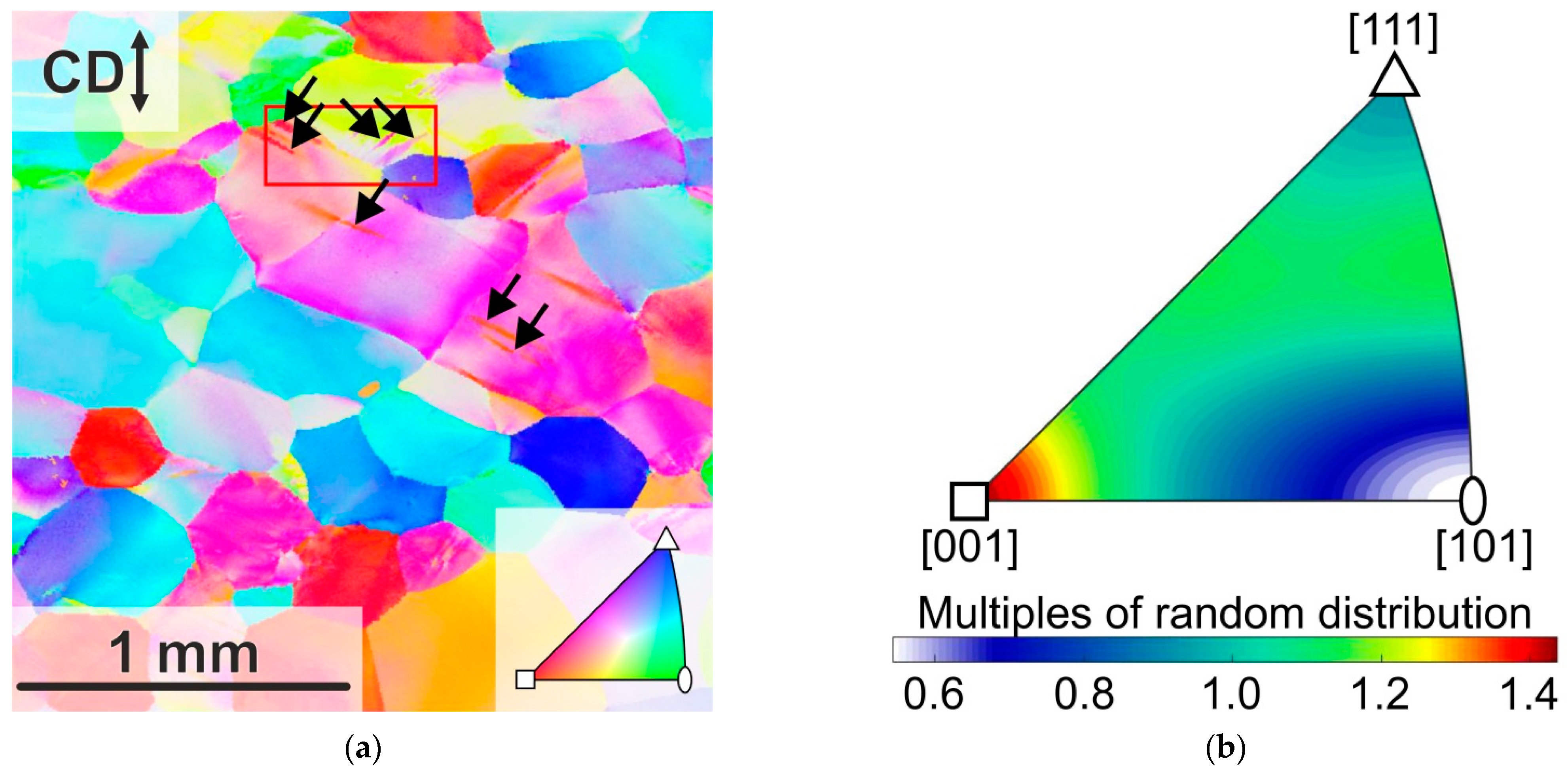

3.1. Microstructural and Chemical Analysis

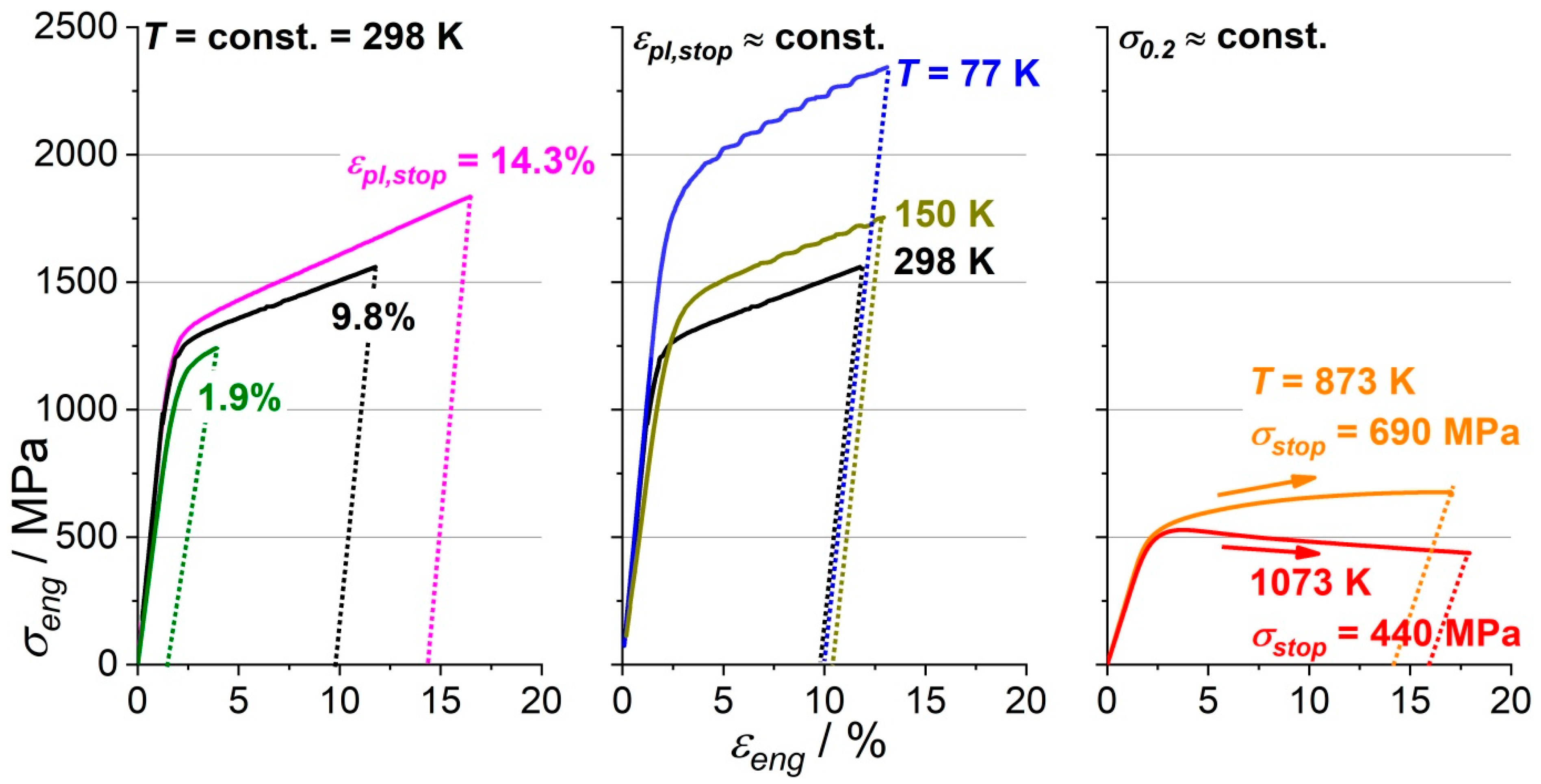

3.2. Plastic Deformation Behavior

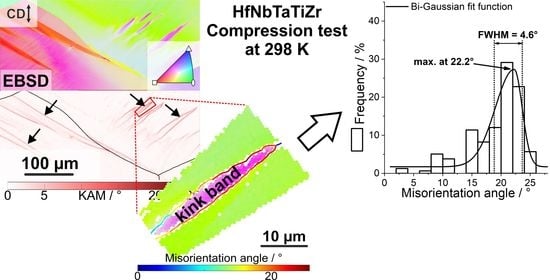

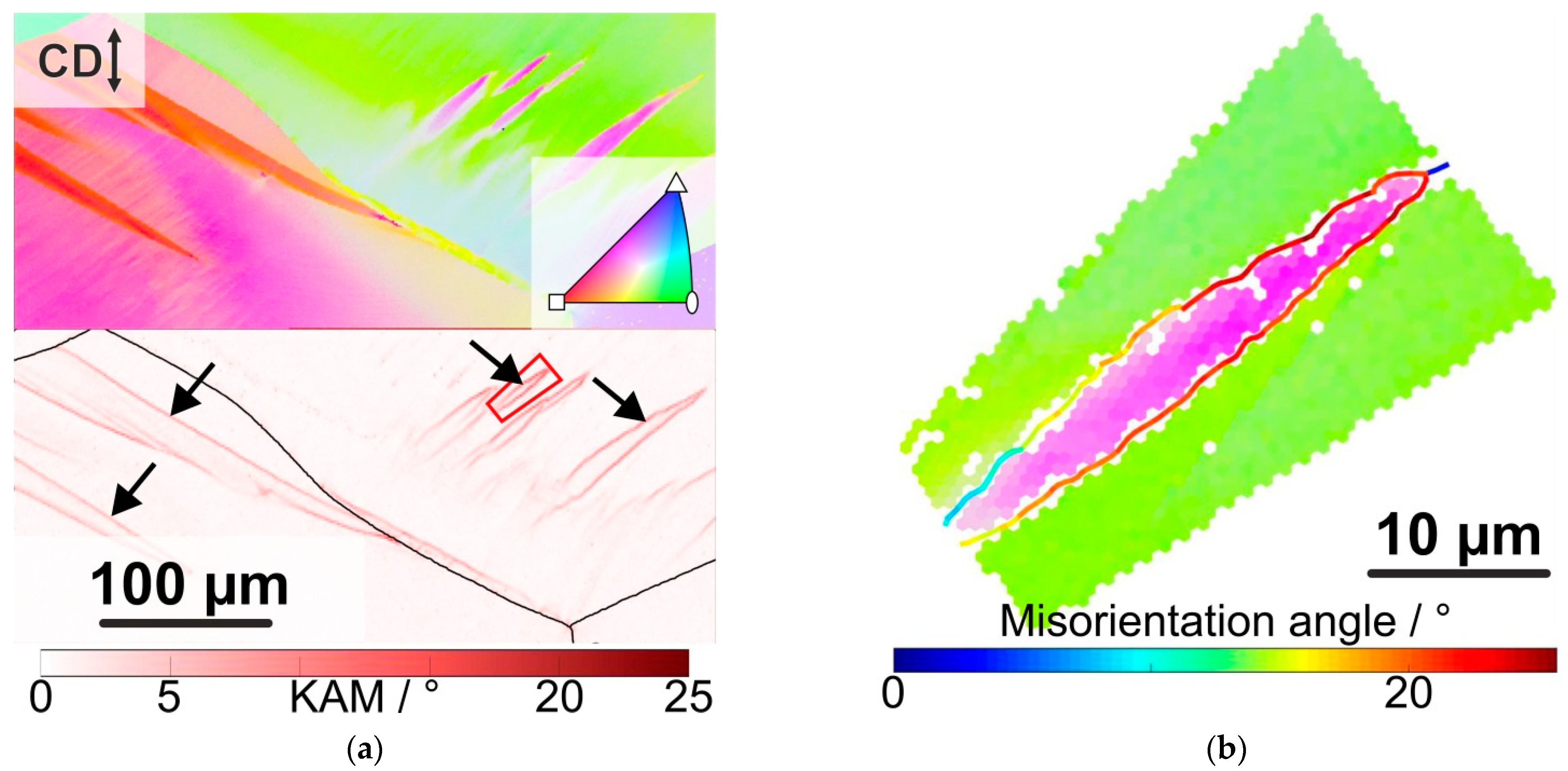

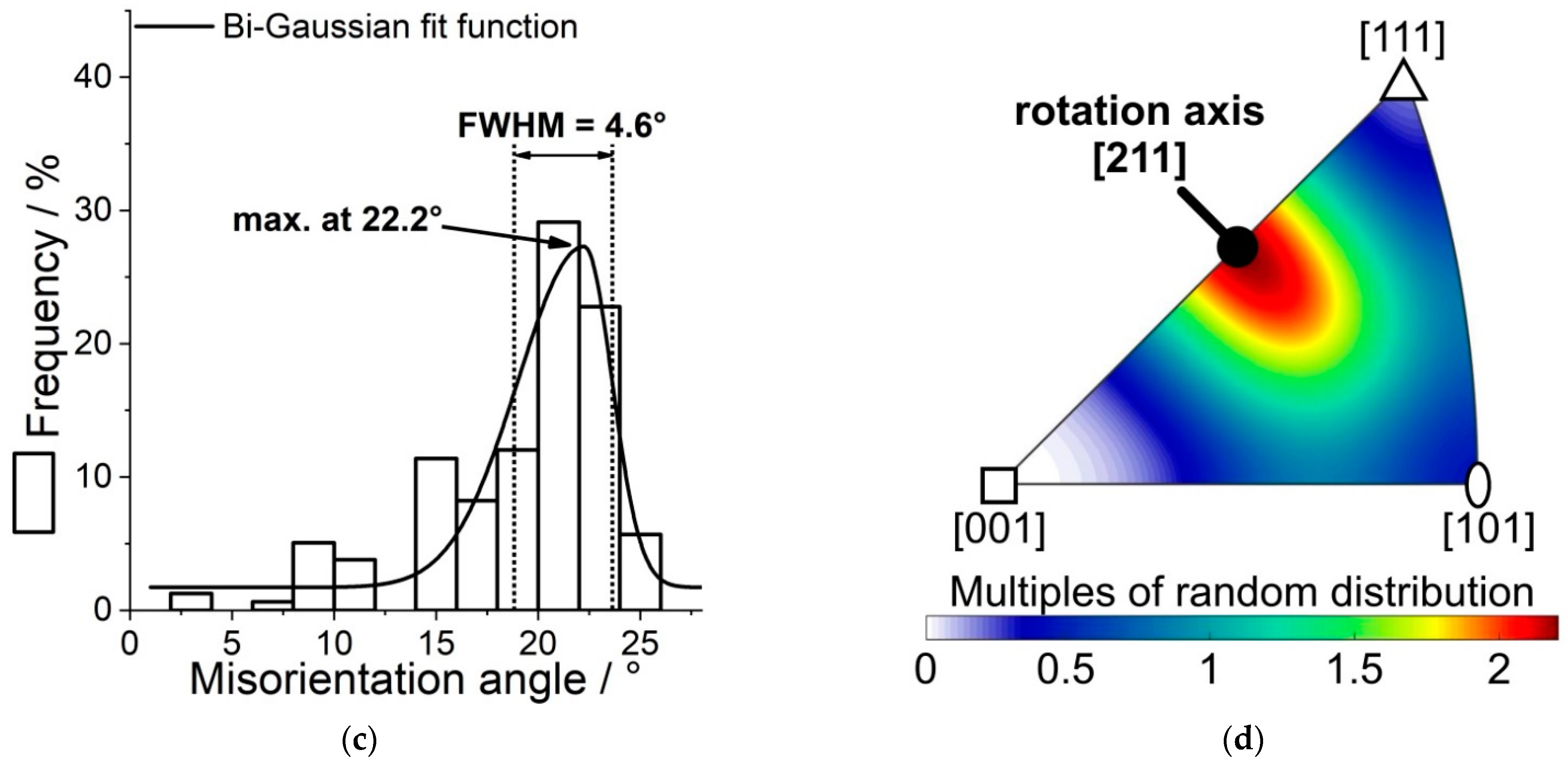

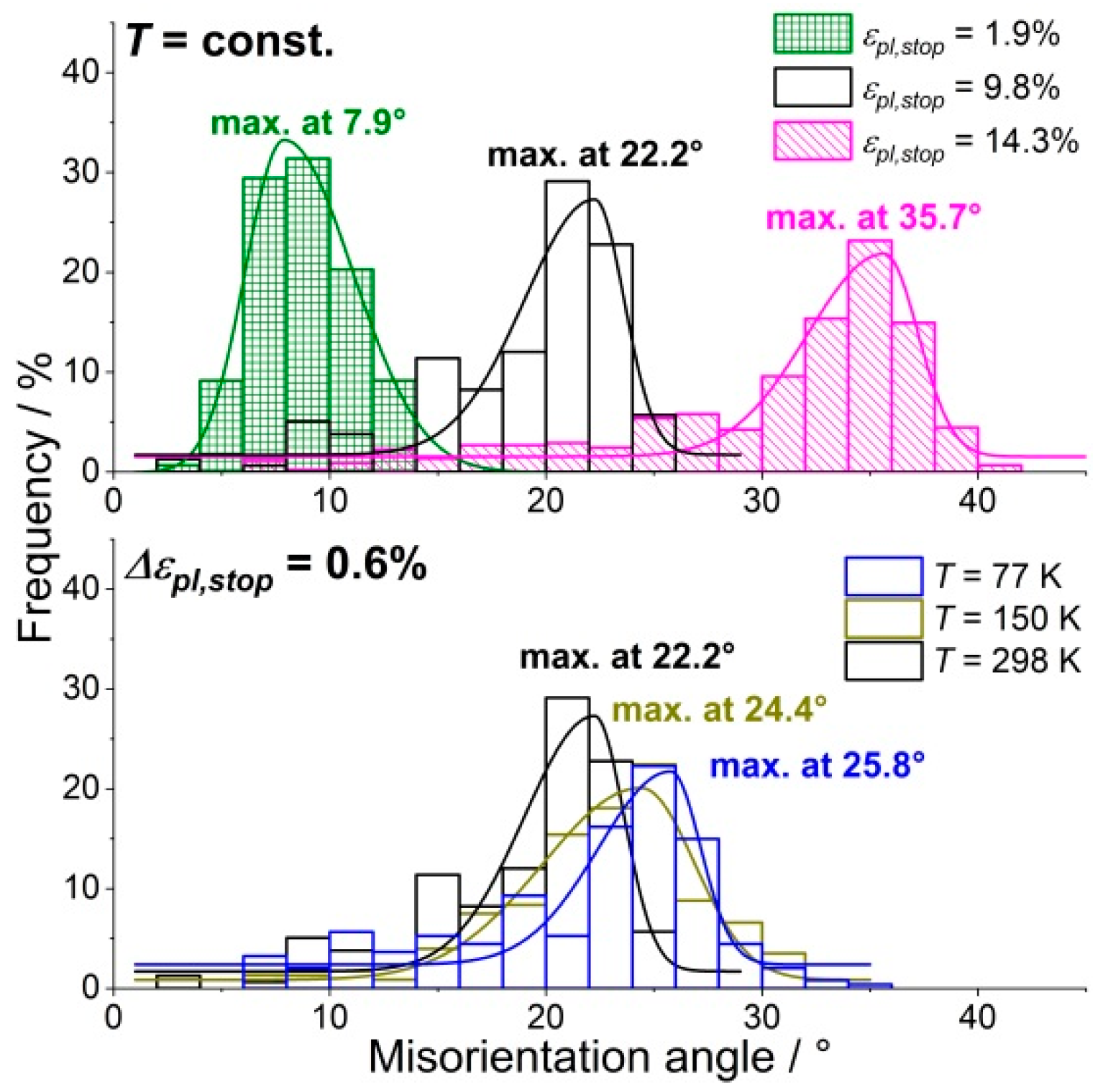

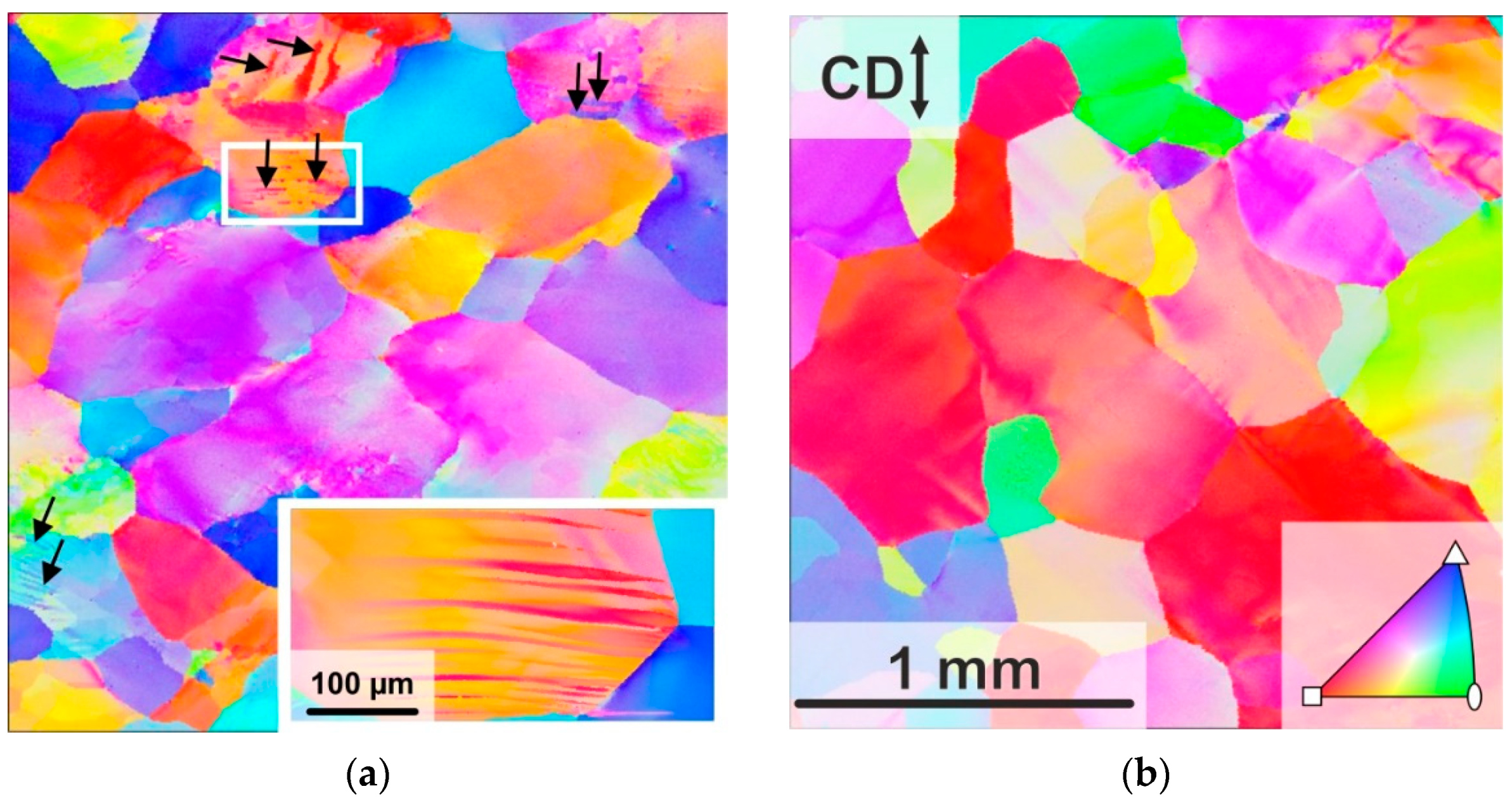

3.3. Appearance and Properties of Kink Bands

4. Conclusions

- In the homogenized state, segregation on the nanometer scale could be revealed by an isoconcentration surface analysis of the APT tip reconstruction only. In general, it is hence recommended to apply isoconcentration surface analysis for evaluating the homogeneity of HfNbTaTiZr and concentrated solid solutions. The autocorrelation factor can be used as an indicator for segregation.

- Kernel average misorientation analysis is suited to detect kink bands from EBSD data.

- The misorientation angle distribution along an individual kink band was fitted by a Bi-Gaussian peak function. The angle of maximum frequency and the FWHM can be used to characterize the kink band properties.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hull, D.; Bacon, D.J. Introduction to Dislocations, 5th ed.; Elsevier/Butterworth-Heinemann: Amsterdam, The Netherlands, 2011; ISBN 978-0-08-096672-4. [Google Scholar]

- Piehler, H.R.; Backofen, W.A. A Theoretical Examination of the Plastic Properties of Bcc Crystals Deforming by 〈111〉 Pencil Glide. Metall. Trans. 1971, 2, 249–255. [Google Scholar] [CrossRef]

- Orowan, E. A Type of Plastic Deformation New in Metals. Nature 1942, 149, 643–644. [Google Scholar] [CrossRef]

- Flewitt, P.E.J.; Crocker, A.G. The Formation of Deformation Kinks in Body Centred Cubic Crystals. Philos. Mag. 1976, 34, 877–891. [Google Scholar] [CrossRef]

- Wang, S.; Wu, M.; Sun, B. Kinking in a Refractory TiZrHfNb0.7 Medium-Entropy Alloy. Mater. Lett. 2020, 264, 4. [Google Scholar] [CrossRef]

- Besse, M.; Castany, P.; Gloriant, T. Mechanisms of Deformation in Gum Metal TNTZ-O and TNTZ Titanium Alloys: A Comparative Study on the Oxygen Influence. Acta Mater. 2011, 59, 5982–5988. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, S.Q.; Li, G.P.; Li, Y.L.; Lu, Y.F.; Yang, K.; Ge, P. Evolution of Deformation Mechanisms of Ti–22.4Nb–0.73Ta–2Zr–1.34O Alloy during Straining. Acta Mater. 2010, 58, 2778–2787. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Yurchenko, N.; Shaysultanov, D.; Tikhonovsky, M.; Salishchev, G.; Stepanov, N. Microstructure and Mechanical Properties Evolution in HfNbTaTiZr Refractory High-Entropy Alloy During Cold Rolling. Adv. Eng. Mater. 2020, 2000105. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Miracle, D.B.; Woodward, C.F. Microstructure and Room Temperature Properties of a High-Entropy TaNbHfZrTi Alloy. J. Alloys Compd. 2011, 509, 6043–6048. [Google Scholar] [CrossRef]

- Eleti, R.R.; Stepanov, N.; Zherebtsov, S. Mechanical Behavior and Thermal Activation Analysis of HfNbTaTiZr Body-Centered Cubic High-Entropy Alloy during Tensile Deformation at 77 K. Scr. Mater. 2020, 188, 118–123. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Meisenkothen, F.; Miracle, D.B.; Woodward, C.F. Microstructure and Elevated Temperature Properties of a Refractory TaNbHfZrTi Alloy. J. Mater. Sci. 2012, 47, 4062–4074. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Chen, S.Y.; Tong, Y.; Tseng, K.-K.; Yeh, J.-W.; Poplawsky, J.D.; Wen, J.G.; Gao, M.C.; Kim, G.; Chen, W.; Ren, Y.; et al. Phase Transformations of HfNbTaTiZr High-Entropy Alloy at Intermediate Temperatures. Scr. Mater. 2019, 158, 50–56. [Google Scholar] [CrossRef]

- Sestak, B.; Seeger, A. Gleitung Und Verfestigung in Kubisch-Raumzentrierten Metallen Und Legierungen (III). Z. Met. 1978, 69, 425–432. [Google Scholar]

- Caillard, D. Geometry and Kinetics of Glide of Screw Dislocations in Tungsten between 95K and 573K. Acta Mater. 2018, 161, 21–34. [Google Scholar] [CrossRef]

- Šesták, B.; Seeger, A. The Relationship between the Work-Hardening of B.C.C. and F.C.C. Metals. Phys. Stat. Solidi 1971, 43, 433–444. [Google Scholar] [CrossRef]

- Sestak, B.; Seeger, A. Gleitung und Verfestigung in kubisch-raumzentrierten Metallen und Legierungen (I). Z. Met. 1978, 69, 195–202. [Google Scholar]

- Conrad, H. Thermally Activated Deformation of Metals. JOM 1964, 16, 582–588. [Google Scholar] [CrossRef]

- Chen, H.; Kauffmann, A.; Laube, S.; Choi, I.-C.; Schwaiger, R.; Huang, Y.; Lichtenberg, K.; Müller, F.; Gorr, B.; Christ, H.-J.; et al. Contribution of Lattice Distortion to Solid Solution Strengthening in a Series of Refractory High Entropy Alloys. Metall. Mater. Trans. A 2018, 49, 772–781. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. In Solid State Phenomena; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2010; Volume 160, pp. 63–68. [Google Scholar] [CrossRef]

- Moody, M.P.; Stephenson, L.T.; Ceguerra, A.V.; Ringer, S.P. Quantitative Binomial Distribution Analyses of Nanoscale Like-solute Atom Clustering and Segregation in Atom Probe Tomography Data. Microsc. Res. Tech. 2008, 71, 542–550. [Google Scholar] [CrossRef]

- Yao, M.J.; Pradeep, K.G.; Tasan, C.C.; Raabe, D. A Novel, Single Phase, Non-Equiatomic FeMnNiCoCr High-Entropy Alloy with Exceptional Phase Stability and Tensile Ductility. Scr. Mater. 2014, 72–73, 5–8. [Google Scholar] [CrossRef]

- Lee, C.; Song, G.; Gao, M.C.; Feng, R.; Chen, P.; Brechtl, J.; Chen, Y.; An, K.; Guo, W.; Poplawsky, J.D.; et al. Lattice Distortion in a Strong and Ductile Refractory High-Entropy Alloy. Acta Mater. 2018, 160, 158–172. [Google Scholar] [CrossRef]

- Thiel, F.; Geissler, D.; Nielsch, K.; Kauffmann, A.; Seils, S.; Heilmaier, M.; Utt, D.; Albe, K.; Motylenko, M.; Rafaja, D.; et al. Origins of Strength and Plasticity in the Precious Metal Based High-Entropy Alloy AuCuNiPdPt. Acta Mater. 2020, 185, 400–411. [Google Scholar] [CrossRef]

- Couzinié, J.P.; Dirras, G.; Perrière, L.; Chauveau, T.; Leroy, E.; Champion, Y.; Guillot, I. Microstructure of a Near-Equimolar Refractory High-Entropy Alloy. Mater. Lett. 2014, 126, 285–287. [Google Scholar] [CrossRef]

- Argon, A.S. The lattice resistance. In Strengthening Mechanisms in Crystal Plasticity; Oxford Series on Materials Modelling; Oxford University Press: Oxford, UK, 2008; pp. 78–135. [Google Scholar]

- Senkov, O.N.; Gorsse, S.; Miracle, D.B. High Temperature Strength of Refractory Complex Concentrated Alloys. Acta Mater. 2019, 175, 394–405. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Rivera-Díaz-del-Castillo, P.E.J. Modelling Plastic Deformation in BCC Metals: Dynamic Recovery and Cell Formation Effects. Mater. Sci. Eng. A 2012, 558, 641–648. [Google Scholar] [CrossRef]

- Cai, Y.; Zhong, Z.Y.; Tang, M.X.; Zhu, X.R.; Wang, L.; Luo, S.N. Texture of Nanocrystalline Solids: Atomic Scale Characterization and Applications. J. Appl. Cryst. 2018, 51, 124–132. [Google Scholar] [CrossRef]

- Chen, H.; Kauffmann, A.; Gorr, B.; Schliephake, D.; Seemüller, C.; Wagner, J.N.; Christ, H.-J.; Heilmaier, M. Microstructure and Mechanical Properties at Elevated Temperatures of a New Al-Containing Refractory High-Entropy Alloy Nb-Mo-Cr-Ti-Al. J. Alloys Compd. 2016, 661, 206–215. [Google Scholar] [CrossRef]

- Wang, S.; Wu, M.; Shu, D.; Zhu, G.; Wang, D.; Sun, B. Mechanical Instability and Tensile Properties of TiZrHfNbTa High Entropy Alloy at Cryogenic Temperatures. Acta Mater. 2020, 201, 517–527. [Google Scholar] [CrossRef]

- Couzinié, J.-P.; Lilensten, L.; Champion, Y.; Dirras, G.; Perrière, L.; Guillot, I. On the Room Temperature Deformation Mechanisms of a TiZrHfNbTa Refractory High-Entropy Alloy. Mater. Sci. Eng. A 2015, 645, 255–263. [Google Scholar] [CrossRef]

| Hf | Nb | Ta | Ti | Zr | |

|---|---|---|---|---|---|

| /at.% | 19.3 | 20.3 | 20.6 | 20.1 | 19.7 |

| Hf | Nb | Ta | Ti | Zr | |

|---|---|---|---|---|---|

| / | 5.1 | 10.2 | 24.7 | 14.1 | 14.0 |

| /K | /MPa | /% | /MPa |

|---|---|---|---|

| 77 | 1670 | 10.4 | 2340 |

| 150 | 1210 | 10.0 | 1750 |

| 298 (RT) | 1040 | 1.9 | 1240 |

| 1110 | 9.8 | 1560 | |

| 1190 | 14.3 | 1830 | |

| 873 | 480 | 13.9 | 690 |

| 1073 | 460 | 16.2 | 440 |

| /K | /% | Misorientation Angle at Frequency Maximum/° | FWHM/° | |

|---|---|---|---|---|

| 298 | 1.9 | 7.9 | 5.0 | 0.99 |

| 298 | 9.8 | 22.2 | 4.6 | 0.83 |

| 298 | 14.3 | 35.7 | 5.1 | 0.92 |

| 77 | 10.4 | 25.8 | 4.7 | 0.83 |

| 150 | 10.0 | 24.4 | 7.0 | 0.93 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Hanemann, T.; Seils, S.; Schliephake, D.; Tirunilai, A.S.; Heilmaier, M.; Weiss, K.-P.; Kauffmann, A. Influence of Temperature and Plastic Strain on Deformation Mechanisms and Kink Band Formation in Homogenized HfNbTaTiZr. Crystals 2021, 11, 81. https://doi.org/10.3390/cryst11020081

Chen H, Hanemann T, Seils S, Schliephake D, Tirunilai AS, Heilmaier M, Weiss K-P, Kauffmann A. Influence of Temperature and Plastic Strain on Deformation Mechanisms and Kink Band Formation in Homogenized HfNbTaTiZr. Crystals. 2021; 11(2):81. https://doi.org/10.3390/cryst11020081

Chicago/Turabian StyleChen, Hans, Theresa Hanemann, Sascha Seils, Daniel Schliephake, Aditya Srinivasan Tirunilai, Martin Heilmaier, Klaus-Peter Weiss, and Alexander Kauffmann. 2021. "Influence of Temperature and Plastic Strain on Deformation Mechanisms and Kink Band Formation in Homogenized HfNbTaTiZr" Crystals 11, no. 2: 81. https://doi.org/10.3390/cryst11020081

APA StyleChen, H., Hanemann, T., Seils, S., Schliephake, D., Tirunilai, A. S., Heilmaier, M., Weiss, K.-P., & Kauffmann, A. (2021). Influence of Temperature and Plastic Strain on Deformation Mechanisms and Kink Band Formation in Homogenized HfNbTaTiZr. Crystals, 11(2), 81. https://doi.org/10.3390/cryst11020081