Abstract

A large drilled single domain SmBa2Cu3O7−δ (SmBCO) bulk superconductor with a diameter of 32 mm and different hole sizes was successfully fabricated using the modified top-seeded infiltration and growth (TSIG) process. The morphology, superconducting properties, and grain boundary orientation growth of the drilled SmBCO samples were investigated. It was found that not only are the properties of the drilled sample equivalent to those of normal SmBCO bulk superconductors, but also the NdBCO seed crystal can be well controlled because of the increase in the specific surface area in the solid phase pellet. In addition, the growth orientation along the tangent direction of the holes was first noticed in the drilled single domain SmBCO bulk superconductor. This conclusion is highly important for the accurate control of the growth temperature of high temperature bulk superconductors.

1. Introduction

Due to their zero-resistance property and diamagnetism, superconducting materials have attracted significant attention since their discovery [,,]. Single domain (RE)Ba2Cu3O7−δ (REBCO) (RE a is rare-earth element, such as Nd, Sm, Gd, and Y) bulk superconductors have been widely investigated during the past three decades because of their remarkable potential in various applications areas [,,,,]. Compared to the growth of YBCO and GdBCO bulk superconductors, single domain SmBCO bulk superconductors attract greater attention because their peak effect allows a high critical current density (Jc) to be maintained in a larger applied magnetic field [,].

Various reasons restrict the further growth of SmBCO bulk superconductors, such as the rapid growth rate, high peritectic reaction temperature, high melting temperature, and the requirement for processing the material under lower oxygen partial pressure to inhibit the substitution of Sm/Ba in the superconducting SmBa2Cu3O7−δ (Sm-123) phase []. Therefore, it is difficult to grow a large single domain SmBCO bulk superconductor with good superconducting properties without any dopant under atmospheric conditions. It has been reported that the development of MgO-NdBCO generic seed was used for fabricating REBCO bulk superconductors in the air using top-seeded melted texture growth (TSMTG) and top-seeded infiltration and growth (TSIG) processes [,]. It appears that the MgO-NdBCO generic seed has a higher melting temperature and similar crystal structure to all bulk superconductors in REBCO, although the difference in melting temperature between SmBCO precursor powders and the seed crystal is relatively small. However, no explanation was provided in the above references for the melting of NdBCO seed crystal without MgO doping during the processing of SmBCO bulk superconductors.

During the process of fabricating SmBCO bulk superconductors, the difference in the thermal field in the furnace, and the composition differences between the solid phase and NdBCO seed crystal, cause the heat release of the molten solid phase to be uneven and slow, and result in gradual accumulation of energy inside the solid phase. The energy accumulation between the solid phase and the seed crystal leads to abrupt changes in the interface. The interfacial energy is sufficiently high that the undersurface of the NdBCO seed crystal melts, and it appears that induction from the seed is ineffective. Therefore, to avoid melting the NdBCO seed crystals during the growth of SmBCO bulk superconductors, two aspects should be considered. The first is to increase the melting temperature (Tm) of the NdBCO seed crystal to maintaining its thermal stability, which has been studied by several research groups [,,]. The second is to enhance the heat dissipation of the solid phase rapidly and effectively to reduce the energy accumulation. Chaud et al. reported that a successful YBCO bulk superconductor from drilled preforms with a porous network structure of holes presented a high performance in terms of increasing the specific surface area []. As indicated, such a porous structure can increase the surface area ratio, which allows the interfacial energy to be released efficiently.

Hence, in the current study, crack-free SmBCO bulk superconductors with a porous structure derived from the thin-wall material concept of reference [] were successfully fabricated on the basis of the conventional NdBCO seed crystal with the modified TSIG process. When the porous structure was introduced, the surface temperature field distribution of the sample was changed during the growth process. The heat capacity of the upper surface of the sample increased when there were holes in the sample, so the surface temperature was lower than that of the normal sample due to the release of interfacial energy during the heating process. It was clear that the NdBCO seed was well controlled due to the release of interfacial energy from the solid phase pellet. In addition, the growth characteristics, and superconducting properties and growth orientation of the drilled samples, were investigated in detail.

2. Facile Preparation of Drilled SmBCO Bulk Superconductor

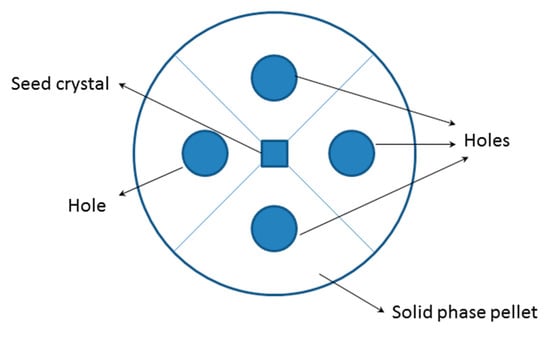

First, powders of BaCuO2 were fabricated in-house using the raw materials BaCO3 (purity 99.9%) and CuO (purity 99.9%). Only one type of powder (BaCuO2) was required to fabricate single domain SmBCO bulk superconductors during the preparation process. Next, Sm2O3 (purity 99.9%) and BaCuO2 powders were weighed according to molar ratio Sm2O3:CaCuO2 = 1:1.2, then mixed and pressed in batches of 30 g, as a solid phase pellet with a diameter of 32 mm and a height of 13 mm. Then, four symmetrical holes with an inner diameter of 3.5 mm were drilled parallel to the c-axis on the surface of the solid phase pellet; a diagram of the drilled solid phase precursor block is shown in Figure 1. The liquid phase pellet, using a Y-based liquid source, was prepared following references [,]. The Yb2O3 powder (purity 99.9%) was then pressed into a thin cylindrical block, with a diameter of 40 mm, as a ground substrate to support the liquid phase during the heating process to prevent the loss of the liquid phase []. Finally, the precursor sample was assembled via the typical configuration before the TSIG process, with a NdBCO seed crystal placed at the center of the top surface of the drilled SmBCO pellet and the a-b plane parallel to the surface [].

Figure 1.

Diagrammatic drawing of the drilled solid phase precursor pellet.

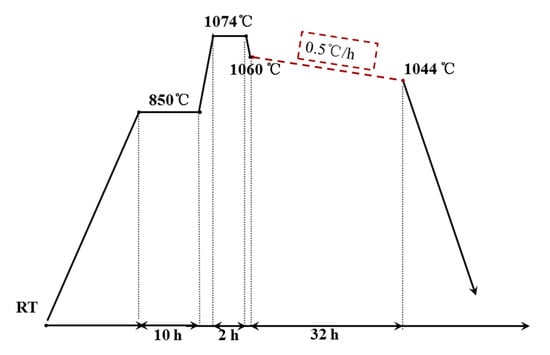

The assembled sample was placed in a self-designed high temperature tube furnace with an appropriate temperature gradient, which prevented the random nucleation of SmBCO crystals at the edges of samples [,]. The next sample was heated to dwelling temperature (Td, 850 °C) at a rate of 150 °C/h. This was followed by 10 h dwelling for nodulizing to achieve the Sm2BaCuO5 (Sm211) phase and venting the gas from precursor sample, and then heating to 1074 °C in 1.5 h and holding for 2 h. During the heating process, Ba and Cu particles in the liquid phase were infiltrated into the solid phase pellet through capillary operation by the NdBCO seed, and the Sm123 phase was subsequently generated. In the heat preservation process, the Sm123 phase was decomposed into the Sm211 phase and Ba-Cu rich phase. At that moment, the liquid phase was completely infiltrated into the solid phase pellet and the solid phase pellet remained in a semi-molten state for some time. Then, the sample was rapidly cooled to 1060 °C; the sample was then cooled slowly to 1044 °C at a lower rate of 0.5 °C/h. In this slow cooling process, the Sm211 phase and Ba-Cu rich phase reacted to grow the Sm123 phase, and the texture was induced by the NdBCO seed crystal to grow a tetragonal phase structure. Finally, the furnace was cooled to room temperature; the temperature profile is shown in Figure 2. The as-grown SmBCO sample bulk was heated to 290 °C and then cooled to 270 °C slowly for 200 h at the oxygen flow rate of 200 mL/min, so that the as-grown drilled single domain SmBCO could further accomplish the phase transition from the tetragonal phase to the orthorhombic phase, and possess superconducting properties. Furthermore, the magnetic levitation force of the SmBCO sample was measured in a self-designed 3D levitation force measuring device [].

Figure 2.

Heat treatment profile used for the drilled single domain SmBCO bulk superconductor.

3. Results and Discussion

3.1. The Surface Morphology of the Drilled Single Domain SmBCO Bulk Superconductor

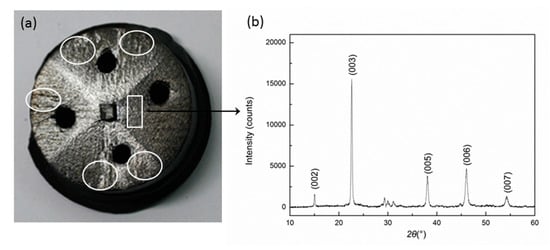

Figure 3a shows the top surface macroscopic feature of the drilled SmBCO bulk superconductor fabricated by the modified TSIG process []. It can be seen that the drilled SmBCO bulk superconductor displayed a clear “X-type” a/b growth sector boundary (a/b-GSB), which indicated that the drilled SmBCO sample was grown as a single domain bulk. Meanwhile, the sample exhibited clear, fourfold growth sector boundaries on the top surface, and no spontaneous satellite grains were observed in the SmBCO sample. Here, it is noted that spacing between holes and growth morphology is not symmetric. This is because the symmetry between the holes and growth morphology depends on the position and direction of the seed crystal placement. In this work, firstly the solid phase pellet with a porous structure was prepared and the NdBCO seed crystal was then placed manually in the center of the upper surface sample. During the placement of the crystal, it is very difficult to recognize the a/b face orientation. Hence, it is not easy to obtain a perfectly symmetrical structure. It can be seen that the porous structure cannot affect the growth morphology of the single domain SmBCO bulk superconductors; this is the essential characteristic of the single domain bulk superconductor. It is also noted that the perforation can avoid the melting of the NdBCO seed crystal and result in normal growth due to the release of interfacial energy from the solid phase pellet. Interestingly, some of the sub-domain boundaries from the surface near the holes were observed, and are marked by white circles in Figure 3a (the reason will be explained in detail later in this paper). The X-ray diffraction (XRD) of the drilled SmBCO bulk superconductor was also undertaken for a small specimen cleaved from the surface sample. Figure 3b shows that only (00L) diffraction peaks were observed, indicating that the sample was highly oriented with the c-axis perpendicular to the surface. This result indicates that the drilled SmBCO sample had the classic characteristic of a single domain with better texture orientation.

Figure 3.

(a) The top surface macroscopic features of the as-grown drilled SmBCO single domain sample with a diameter of 32 mm; (b) the X-ray diffraction pattern of the drilled sample.

3.2. The Superconducting Properties of the Drilled Single Domain SmBCO Bulk Superconductor

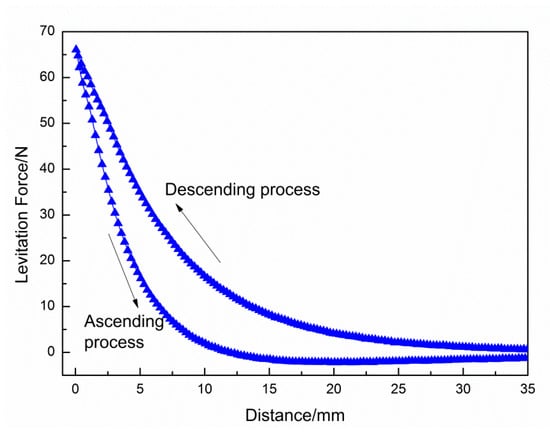

Figure 4 shows the levitation force–distance z (F-z; z is the distance between the NdFeB permanent magnet and the surface of the drilled SmBCO bulk) curves between the cylindrical NdFeB magnet (Φ = 32 mm, B = 0.5 T) and the drilled SmBCO sample, which was measured at 77 K under a zero-field cooling (ZFC) state, using the 3D magnetic force and field measuring device designed by ourselves. The NdFeB permanent magnet then moved following a path set by the program instruction perpendicular to the surface sample. The descending and ascending speeds of the NdFeB permanent magnet to the surface of the drilled SmBCO sample were at the same velocity of 0.4 mm/s. In this experiment, the peak value of magnetic levitation force measured was obtained at the smallest gap (0.1 mm) between the two nearest surfaces of the magnet and the drilled SmBCO sample. The levitation force recorded during the motion is shown in Figure 4. As can be seen, the highest levitation force of the drilled SmBCO sample reached 66.3 N, and the density of the levitation force was close to 8.24 N/cm2. This result indicates that the drilled single domain SmBCO bulk superconductor had a slightly lower performance compared with the normal REBCO (RE = Y, Gd, and Sm) bulk superconductor fabricated at SNNU [,,]. This may be because the sub-domain boundaries from the surface near the holes exist as the specific surface area increases.

Figure 4.

Levitation force–distance z curves of the drilled SmBCO bulk sample under zero-field cooled state at 77 K.

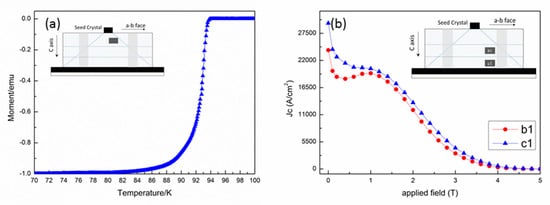

The critical temperature (Tc) and critical current density (Jc) of the drilled SmBCO bulk sample were measured using a vibrating sample magnetometer (VSM). Initially, the sample was cleaved from the center position for measurement as shown in the inset of Figure 5. Then, the magnet moment was tested with temperature descending from 100 to 70 K under an external magnetic field of 0.01 T applied parallel to the ab-axis. The size of the specimen was 2 × 3 × 2 mm2. As seen in Figure 5a, this resulted in a steep superconducting transition curve with an onset temperature of 93.85 K, with a transition width less than 2 K (the difference in temperature between 10% and 80% of the maximum diamagnetic momentum). This result is similar to the Tc values of a normal SmBCO bulk superconductor prepared with ZrO2 doping [].

Figure 5.

The superconducting properties of specimens cut from different positions in a drilled single domain SmBCO bulk superconductor: (a) critical temperature; (b) critical current density.

The measured value of Jc is shown in Figure 5b, values of which were calculated from magnetic loop measurements using the extended Bean mode [,]. The Jc–H curve (77K, H//c-axis) is shown for the drilled single domain SmBCO bulk sample with two different specimens at positions b1 and c1 (the specimens are marked in the inset of Figure 5b). As shown in the figure, all of the data exhibits a decrease, with H at a low field, and then an evident strong peak effect at an intermediate field between 1 and 1.5 T, which is the fishtail peak (also called the peak effect). We can see that the specimen c1 exhibits a zero-field Jc value of 2.95 × 104 A/cm2, and a secondary peak of 2.04 × 104 A/cm2 is presented at a field of 1 T. The specimen b1 exhibits a zero-field Jc value of 2.41 × 104 A/cm2, and a secondary peak of 1.94 × 104 A/cm2, which is lower than that value of the b1 specimen. There are two possible reasons. The first is due to the weak link effect. There are four existing zones (100/010) which can easily lead to a weak link with growth in the c-direction, and the lower values of specimen b1 can be traced to the weak link from the a-b boundary line. The other reason relates to the pushing-trapping theory; during the partially molten state, the critical growth rate (R) of the SmBCO samples gradually increases with the decrease in the growth temperature. It can be deduced that the critical radius of Sm211 particles that were trapped by the liquid phase source becomes smaller. As a result, the smaller size particles that are pushed to the edge of the growth front remain in the growth area, so a number of Sm211 particles exist in the depth of the sample. Hence, the critical current density of c1 is higher than that of b1.

3.3. The Crystal Growth Orientation Analysis of the Drilled Single Domain SmBCO Bulk Superconductor

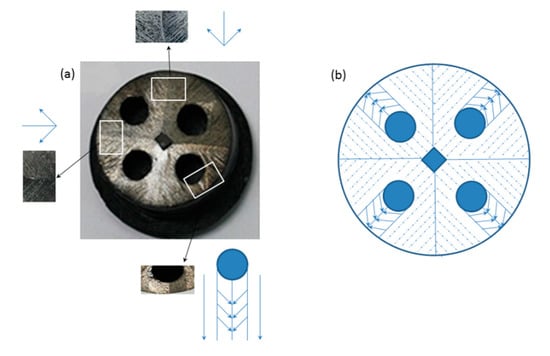

As previously mentioned, the drilled single domain SmBCO bulk sample displays a slightly reduced performance, which appears to be weakly affected by the holes. To determine the effect of the holes on the growth of the drilled SmBCO bulk sample, another drilled single domain SmBCO bulk sample was fabricated with four larger holes with an inner diameter of 6.5 mm; the top surface macrostructure is shown in Figure 6a. The growth orientation of the drilled SmBCO sample induced by the NdBCO seed crystal can be clearly observed. In each domain sector of the drilled sample, the crystal growth orientation extends from the seed crystal along the diameter to the edge and converges at the sector boundaries to form a vertical angle, as shown in the upper and left marks of Figure 6a. In addition, it appears that beyond the two parallel tangents of the hole, the crystal orientation is along the diameter with normal growth. However, within two parallel tangents of the hole, the crystals are oriented at an angle and converge at the center, as shown in Figure 6a. For further clarification of the growth orientation of the drilled SmBCO sample, the top surface schematic illustration of the drilled sample is shown in Figure 6b. As can be seen, the NdBCO seed crystal induced the orientation of crystal growth within the four sectors, and the orientation of crystal growth from the seed crystal is from the diameter to the edge, and the junction between the vertical angles. In addition, the epitaxial growth of the fan-shaped region from the central seed crystal continues to grow along the tangent line at the edge of the hole position, and then presents the phenomenon of aggregating to the center. This result provides further understanding for investigating the growth of the drilled single domain SmBCO bulk superconductor.

Figure 6.

(a) The top surface morphology of the as-grown drilled SmBCO single domain sample with a 32 mm diameter and 6.5 mm inner diameter; (b) The top surface schematic illustration of the drilled sample.

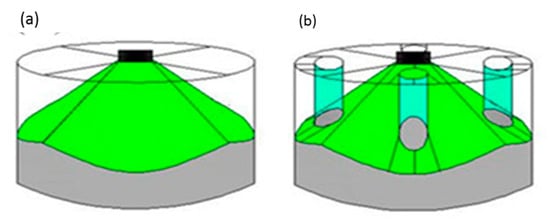

Figure 7 shows a three-dimensional (3D) growth simulation illustration of the single domain SmBCO bulk superconductor with different crystallization structure. Figure 7a shows a typical 3D macroscopic crystallization structure of a large faceted interface for a normal REBCO sample [,,]. It is noted that the grown REBCO crystal consists of five regions: four regions of a-axis growth and one region of c-axis growth [], which are perpendicular to the other two faces. Regarding the geometrical model, the crystal face towards the growth direction of the RE123 crystals in directional solidification was found to be close to the (110) face (a-b boundary), which was selected as a result of preferential growth. The growth rate of a-axis faces has been evaluated to be 1.5 times faster than that of c-axis faces from the steady state condition []. Therefore, for the drilled sample, as mentioned above, the epitaxial growth of the domain region occurs along the tangent line at the edge of the hole position when the orientation of crystal growth from the seed crystal is from the diameter to the edge. Encouragingly, the surface macroscopic images of the drilled single domain SmBCO sample (Figure 3 and Figure 6) also reflect this point.

Figure 7.

Three-dimensional simulation illustration showing changes of the single domain SmBCO crystallization structure: (a) normal sample; (b) drilled sample.

4. Conclusions

Drilled single domain SmBCO bulk superconductors with different hole sizes were fabricated using the modified TSIG process in this work. By drilling the holes in four different growth sectors, it was found that random melting of the NdBCO seed can rarely be well controlled by this process due to the increase in the specific surface area of the solid phase pellet. Most importantly, for the first time, the growth pattern in the tangent direction was successfully noted in the drilled single domain SmBCO bulk, providing further understanding of the growth mechanism in high temperature superconductors.

Author Contributions

The author contributions of the paper are as follows: M.W. and W.-m.Y. proposed the conceptualization and methodology; Y.L. and H.X. conducted the tests; X.W. analyzed the data; M.W. wrote the paper; W.-m.Y. reviewed and edited the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Nature Science Foundation of China (No. 51802247), the Young Talent fund of University Association for Science and Technology in Shaanxi (No. 20190422), and the 3rd Batch of Young Outstanding Talents Support Program for Colleges and Universities in Shaanxi Province.

Institutional Review Board Statement

The study is not involving humans or animals.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

All data generated or analyzed during this study are included included in this article.

Acknowledgments

The author would like to thank Shi Zhong Liu for his kind discussion in this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Onnes, H.K. Further experiments with liquid helium. On the change of electrical resistance of pure metals at very low temperatures etc. IV. The resistance of pure mercury at helium temperatures. Through measurement to knowledge. Boston Stud. Philos. Sci. 1911, 124, 113–115. [Google Scholar]

- Wu, M.K.; Ashburn, J.R.; Torng, C.J. Suerconductivity at 93 K in a new mixed-phase Y-Ba-Cu-O compound xyxtem at ambient pressure. Phys. Rev. Lett. 1987, 58, 908–910. [Google Scholar] [CrossRef] [PubMed]

- Hanna, A.R.N.; Hafiez, M.A. Single-crystal growth and small anisotropy of the lower critical field in oxypnictides: NdFeAsO1-xFx. Crystals 2020, 10, 362. [Google Scholar] [CrossRef]

- Moon, F.; Chang, P. High-speed rotation of magnets on high Tc superconducting bearings. Appl. Phys. Lett. 1990, 56, 397–400. [Google Scholar] [CrossRef]

- Campbell, A.; Cardwell, D.A. Bulk high temperature superconductors for magnet application. Cryogenics 1997, 37, 567–575. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, L.; Liu, J.; Wang, Q. Synthesis of ErBa2Cu3O7−δ superconductor solder for the fabrication of superconducting joint between Gdba2cu3o7−δ coated conductor. Crystals 2019, 9, 492. [Google Scholar] [CrossRef]

- Deng, Z.G.; He, D.; Zheng, J. Levitation performance of rectangular bulk superconductor arrays above applied permanent magnet guide ways. IEEE Trans. Appl. Supercond. 2015, 25, 3600106. [Google Scholar]

- Liu, J.; Wang, L.; Qin, L.; Wang, Q.; Dai, Y. Design, fabrication, and test of a 12 T REBCO insert for a 27 T all-superconducting magnet. IEEE Trans. Appl. Supercond. 2020, 30, 5203006. [Google Scholar] [CrossRef]

- Yamada, T.; Ikuta, H.; Yoshikawa, M.; Yanagi, Y.; Itoh, Y.; Oka, T.; Mizutani, U. Oxygen diffusivity in melt-processed SmBCO and YBCO bulk-superconductors. Phys. C 2002, 378–381, 713–717. [Google Scholar] [CrossRef]

- Shi, Y.H.; Desmedt, M.; Durrell, J.; Dennis, A.R.; Cardwell, D.A. Improving the superconducting properties of single grain Sm–Ba–Cu–O bulk superconductors fabricated in air by increased control of Sm/Ba substitution effects. Supercond. Sci. Technol. 2013, 26, 095012. [Google Scholar]

- Shi, Y.H.; Babu, N.H.; Iida, K.; Cardwell, D.A. Mg-doped Nd-Ba-Cu-O generic seed crystals for the top-seeded melt growth of large-grain (rare earth)-Ba-Cu-O bulk superconductors. J. Mater. Res. 2006, 21, 1355–1362. [Google Scholar] [CrossRef]

- Li, G.Z.; Li, D.J.; Deng, X.Y.; Deng, J.H.; Yang, W.M. Infiltration growth of Mg-doped Nd–Ba–Cu–O seed crystals for the fabrication of large grain RE–Ba–Cu–O bulk superconductors. Supercond. Sci. Technol. 2013, 26, 055019. [Google Scholar] [CrossRef]

- Cheng, L.; Li, T.; Yan, S.; Sun, L.; Yao, X.; Puzniak, R. Large size and high performance of a Gd-Ba-Cu-O bulk superconductor grown using new approaches. J. Am. Ceram. Soc. 2011, 94, 3139–3143. [Google Scholar] [CrossRef]

- Li, G.Z.; Deng, X.Y.; Dong, L. Facile preparation of large Mg-NdBCO crystal for seeding growth of high-performance YBCO single-grain superconductor. J. Alloy. Compd. 2016, 656, 551–554. [Google Scholar] [CrossRef]

- Kenfaui, D.; Sibeud, P.F.; Louradour, E.; Noudem, J.G.; Chaud, X. High trapped field performances in thin-wall YBa2Cu3O7−δ bulk cryomagnets. Appl. Phys. Lett. 2013, 102, 202602. [Google Scholar] [CrossRef]

- Prikhna, T.A.; Vlasenko, A.V.; Dub, S.N.; Mel’nikov, V.S.; Savchuk, Y.M.; Moshchil’, V.E.; Joulain, A. Improvement of superconductive and mechanical properties of bulk and thin-wall MT-YBCO ceramics in oxygenation. J. Super. Mater. 2008, 30, 215–232. [Google Scholar] [CrossRef]

- Li, G.Z.; Yang, W.M.; Liang, W.; Li, J.W. Fabrication of large single-domain Gd–Ba–Cu–O bulks using Y-based liquid source. Mater. Lett. 2011, 65, 304–306. [Google Scholar] [CrossRef]

- Wang, M.; Yang, W.M.; Li, J.W.; Feng, Z.L.; Chen, S.L. Fabrication method of large size single domain GdBCO bulk superconductor using a new solid source. Phys. C 2013, 492, 129–132. [Google Scholar] [CrossRef]

- Wang, M.; Yang, P.T.; Yang, W.M.; Li, J.W.; Hassan, Q.U. The fabrication process of a high performance and purec-axis grown GdBCO bulk superconductor with the TSMT-IG technique. Supercond. Sci. Technol. 2015, 28, 105011. [Google Scholar]

- Yang, W.M.; Chen, L.P.; Wang, X.J. A new RE + 011 TSIG method for the fabrication of high quality and large size single domain YBCO bulk superconductors. Supercond. Sci. Technol. 2016, 29, 024004. [Google Scholar] [CrossRef]

- Yang, W.M.; Zhou, L.; Feng, Y.; Zhang, P.X.; Zhang, C.P. The effect of temperature gradient on the morphology of YBCO bulk superconductors by melt texture growth processing. J. Alloy. Compd. 2006, 415, 276–279. [Google Scholar] [CrossRef]

- Guo, Y.X.; Yang, W.M.; Li, J.W.; Guo, L.P.; Chen, L.P.; Li, Q. Effects of vertical temperature gradient on the growth morphology and properties of single domain YBCO bulks fabricated by a new modified TSIG technique. Cryst. Growth Des. 2015, 15, 1771–1775. [Google Scholar] [CrossRef]

- Chen, S.L.; Yang, W.M.; Li, J.W.; Yuan, X.C.; Ma, J.; Wang, M. A new 3D levitation force measuring device for REBCO bulk superconductors. Phys. C 2014, 496, 39–43. [Google Scholar] [CrossRef]

- Li, J.W.; Yang, W.M.; Wang, M.; Guo, Y.X.; Feng, Z.L. High-efficient method for introducing nanometer Y2Ba4CuNbOx flux pinning centers in single-domain YBa2Cu3O7-δ bulk superconductors by TSIG process. J. Supercond. Nov. Magn. 2015, 28, 1725–1728. [Google Scholar] [CrossRef]

- Yang, W.M.; Zhi, X.; Chen, S.L.; Wang, M.; Li, J.W.; Ma, J.; Chao, X.X. Fabrication of single domain GdBCO bulk superconductors by a new modified TSIG technique. Phys. C 2014, 496, 1–4. [Google Scholar] [CrossRef]

- Wang, Y.N.; Yang, W.M.; Yang, P.T.; Zhang, C.Y.; Chen, J.L.; Zhang, L.J.; Chen, L. Influence of trapped field on the levitation force of SmBCO bulk superconductor. Phys. C 2017, 542, 28–33. [Google Scholar] [CrossRef]

- Zhao, W.; Shi, Y.H.; Dennis, A.R.; Cardwell, D.A. Use of Sm 123 + Sm 211 mixed-powder buffers to assist the growth of SmBCO and ZrO2-doped SmBCO single grain, bulk superconductors. IEEE Trans. Appl. Supercond. 2015, 25, 6801305. [Google Scholar] [CrossRef]

- Bean, C.P. Magnetization of hard superconductors. Phys. Rev Lett. 1962, 8, 250. [Google Scholar] [CrossRef]

- Vojtkova, L.; Diko, P.; Rajnak, M. Influence of Sm2O3 and La2O3 additions on the microstructure and properties of YBCO bulk superconductors prepared by TSIG process. IEEE Trans. Appl. Supercond. 2018, 28, 7200704. [Google Scholar] [CrossRef]

- Nakamura, Y.; Furuya, K.; Izumi, T.; Shiohara, Y. Crystal orientation and growth anisotropy of YBa2Cu3O6+x fabricated by directional solidification method. J. Mater. Res. 1994, 9, 1350–1356. [Google Scholar] [CrossRef]

- Shiohara, Y.; Endo, A. Crystal growth of bulk high-Tc superconducting oxide materials. Mater. Sci. Eng. R 1997, 19, 1–86. [Google Scholar] [CrossRef]

- Li, G.Z.; Li, D.J.; Deng, X.Y.; Deng, J.H.; Yang, W.M. Infiltration growth and crystallization characterization of single-grain Y-Ba-Cu-O superconductors. Cryst. Growth Des. 2013, 13, 1246–1251. [Google Scholar] [CrossRef]

- Endo, A.; Chauhan, H.S.; Shiohara, Y. Entrapment of Y2BaCuO5 particles in melt-textured YBa2Cu3O7−δ crystals and its effect on. Phys. C 1996, 273, 107–119. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).