Recent Progress in Flexible Graphene-Based Composite Fiber Electrodes for Supercapacitors

Abstract

:1. Introduction

2. Classification of Graphene-Based Composite Fiber Electrodes

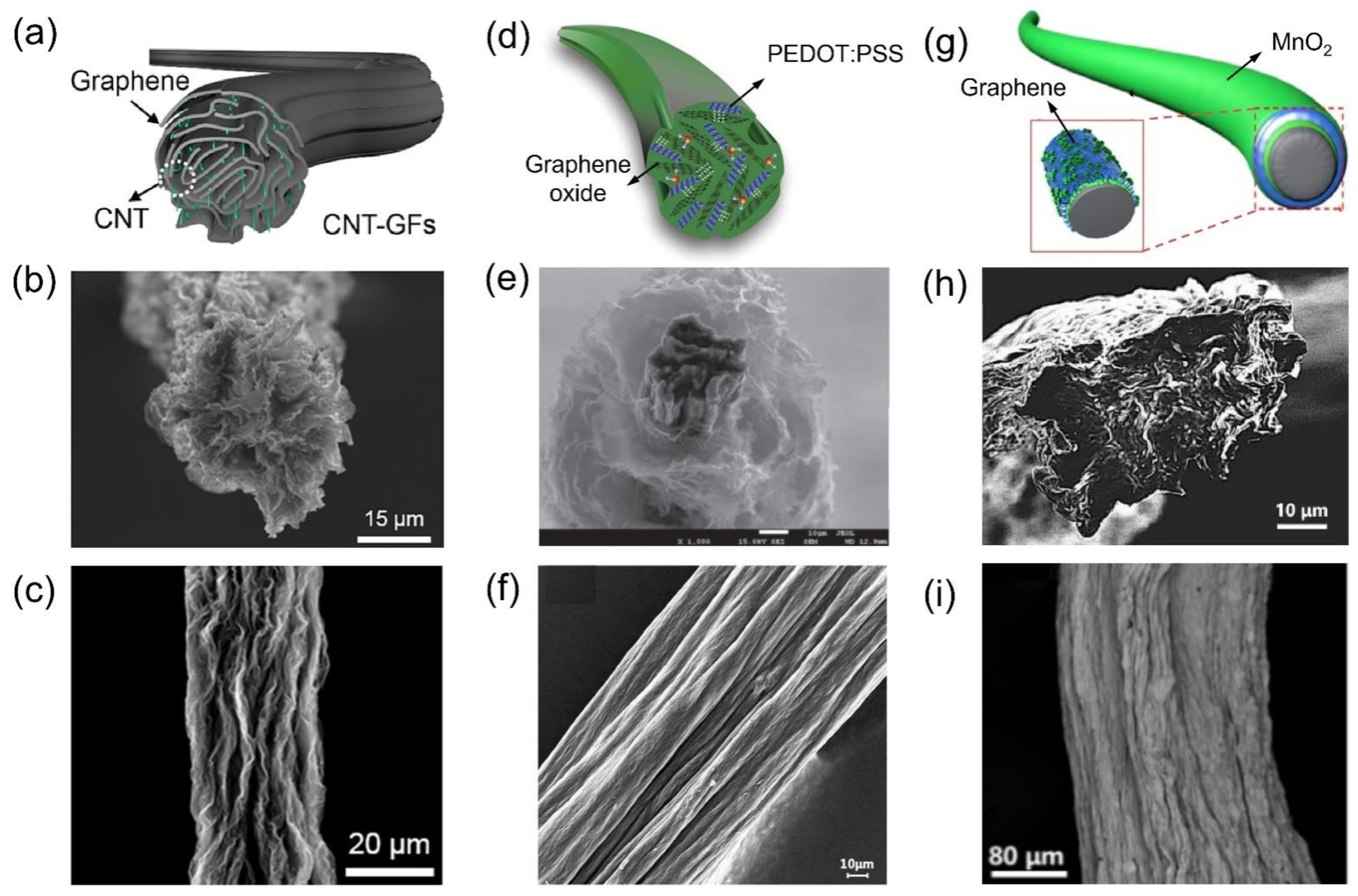

2.1. Carbon Allotropy

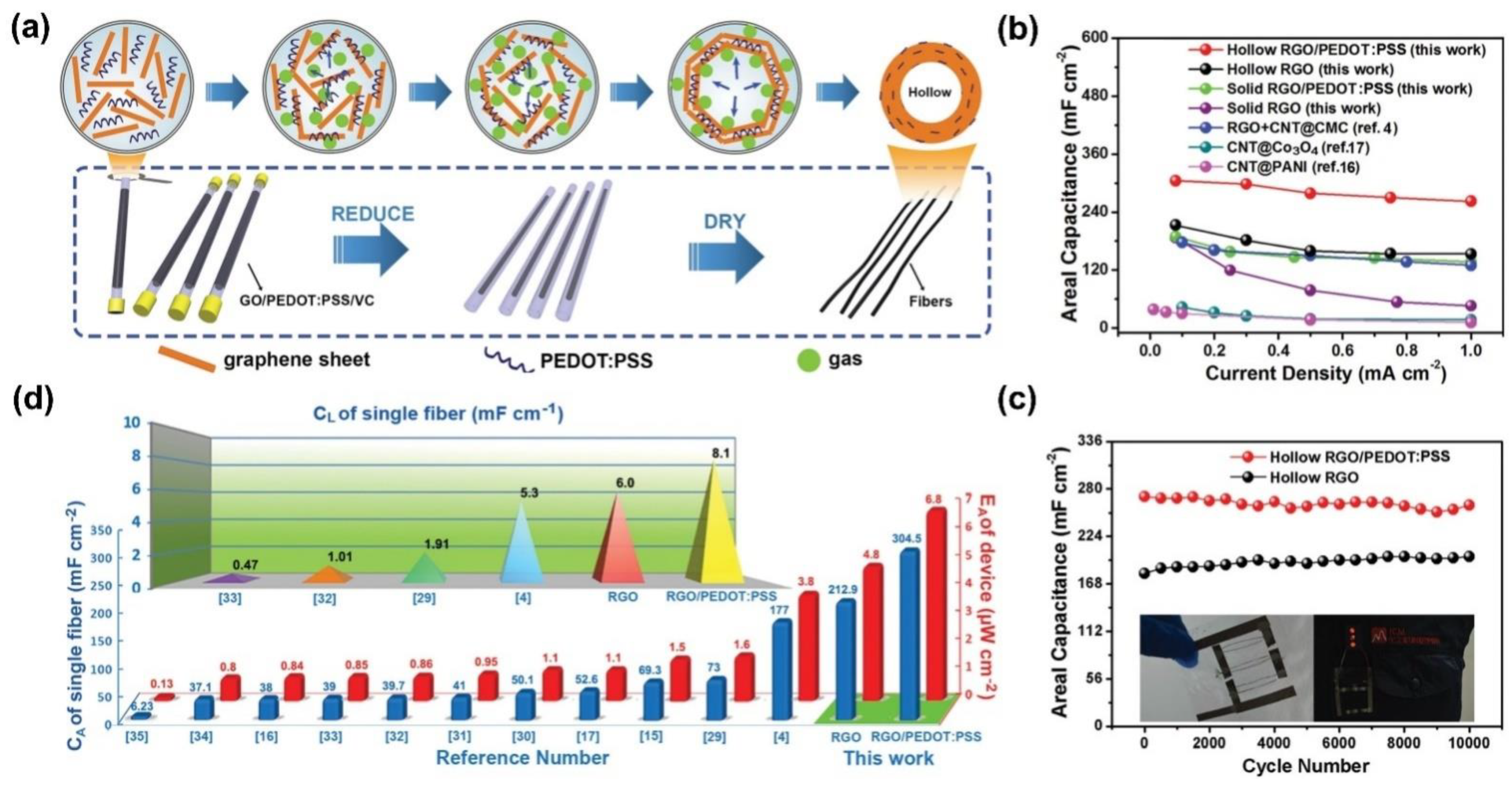

2.2. Conductive Polymer

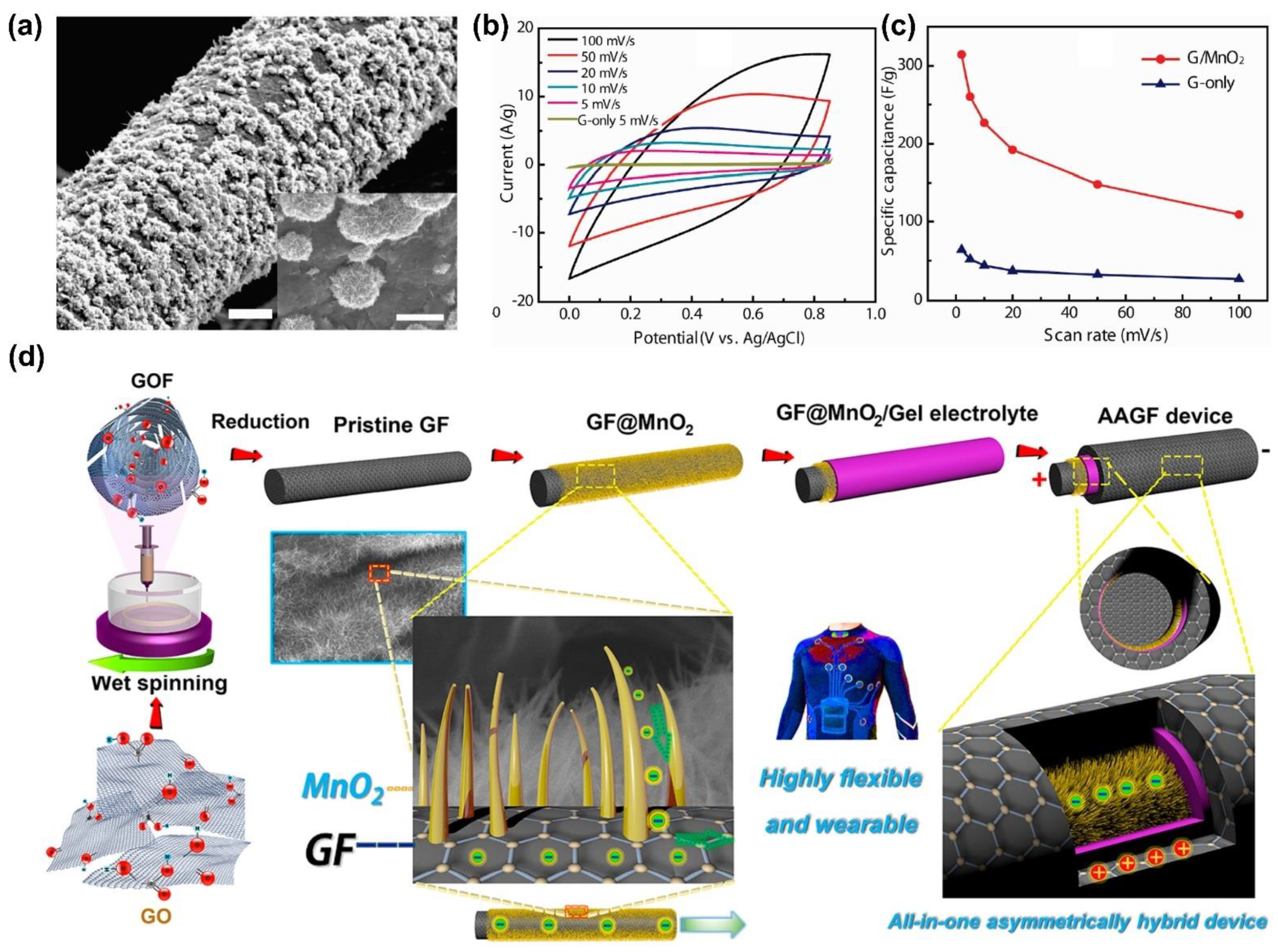

2.3. Metal Oxide

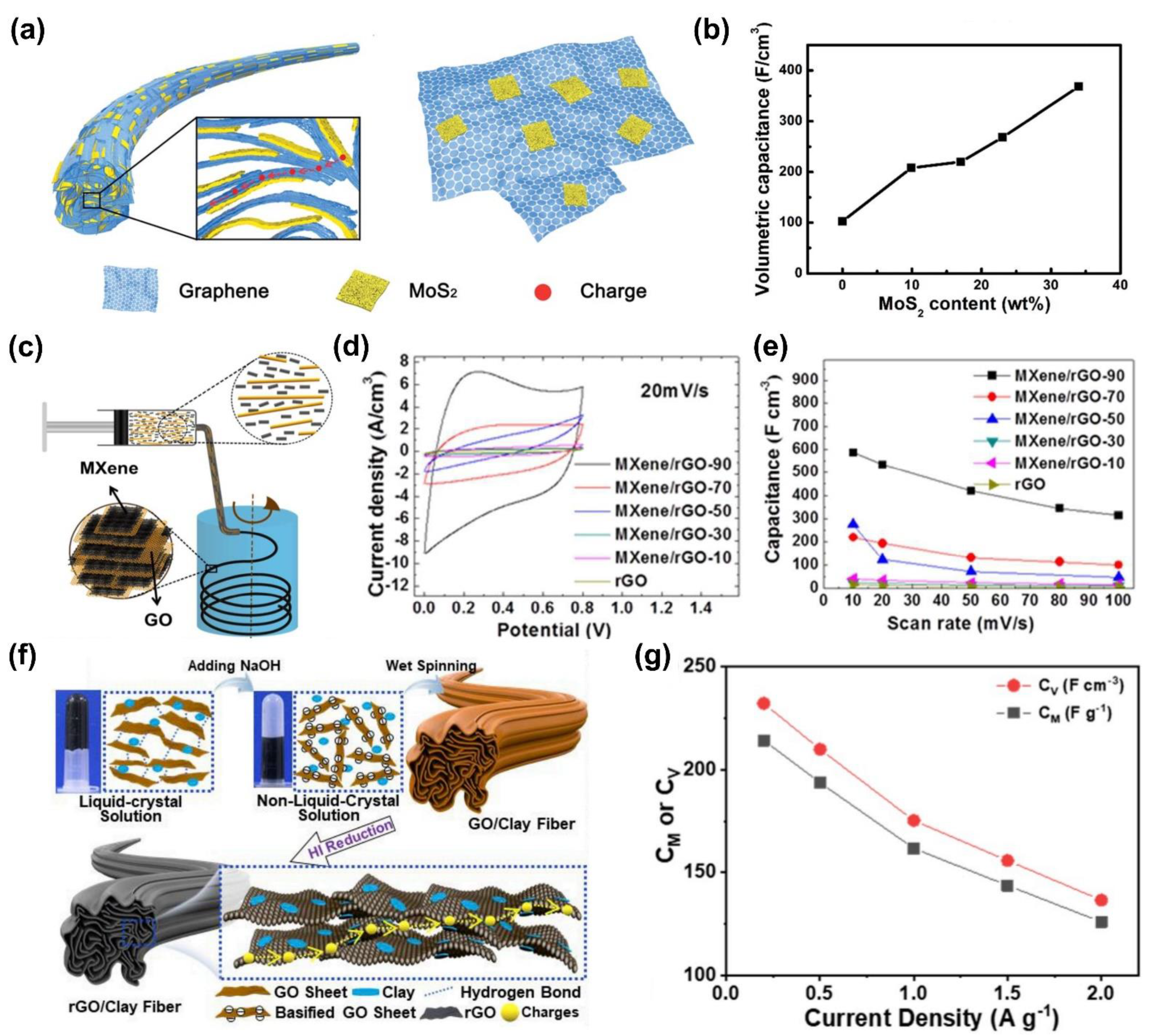

2.4. Other Layered Materials

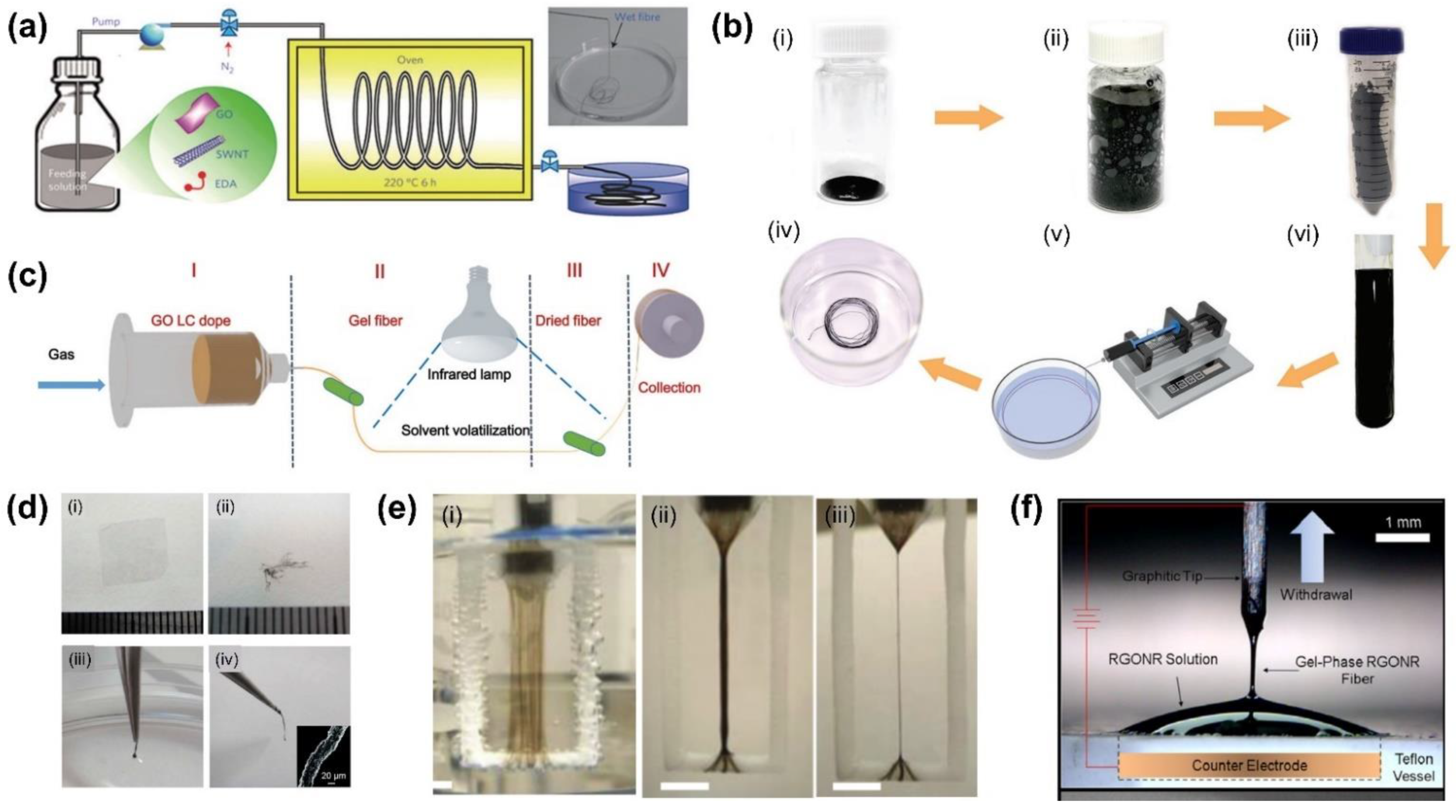

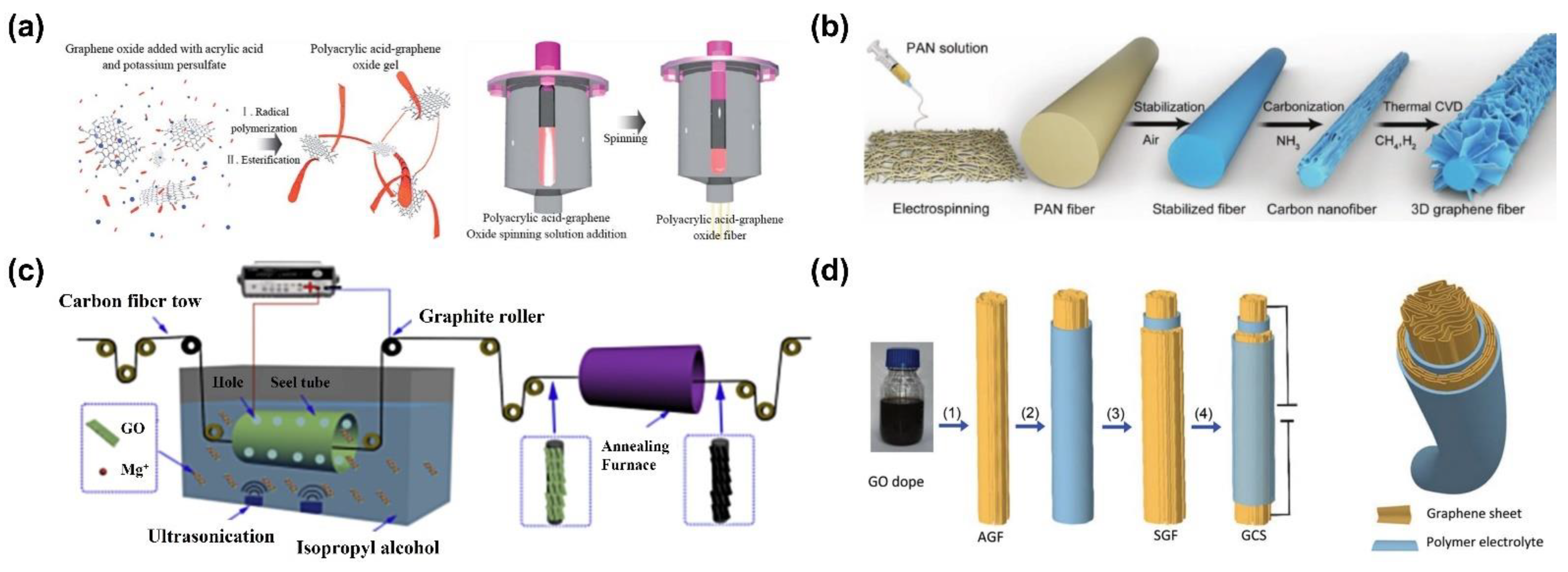

3. Preparation Methods of Graphene-Based Composite Fibers

3.1. Solution Mixing

3.2. In Situ Polymerization

3.3. CVD Growth

3.4. Electrophoretic Deposition

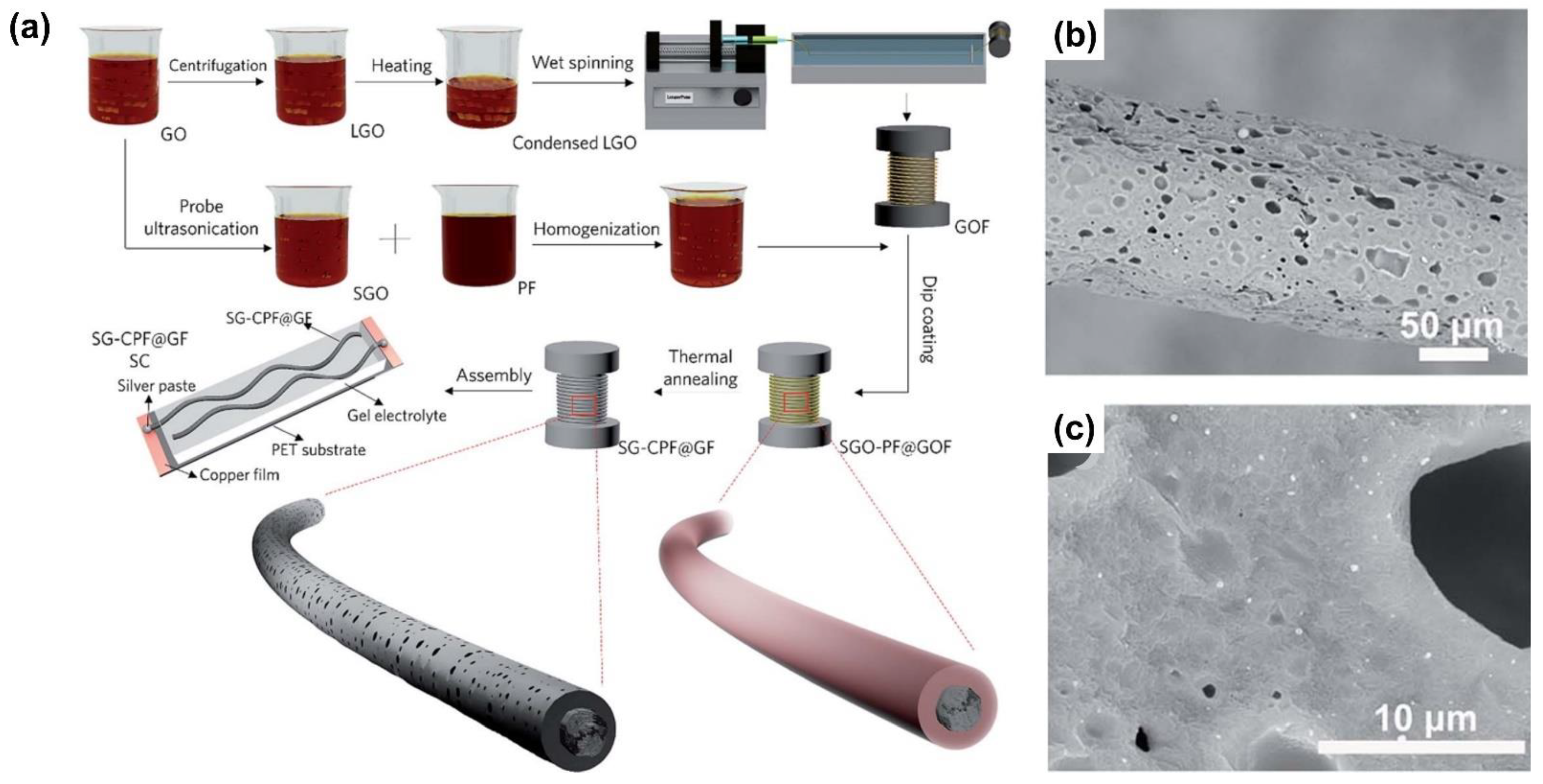

3.5. Direct Coating

4. Performance Optimization of Graphene-Based Composite Fiber Electrodes

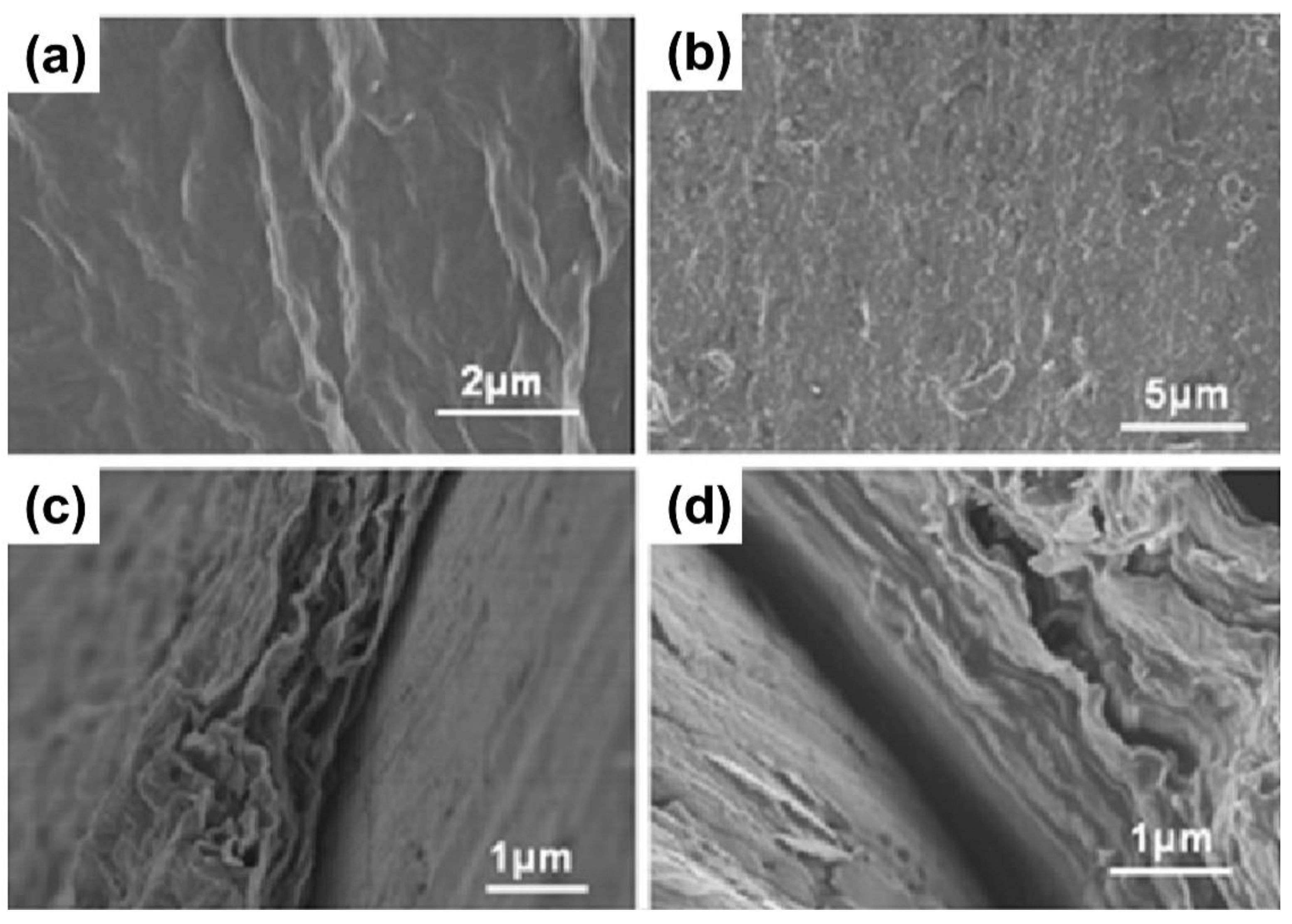

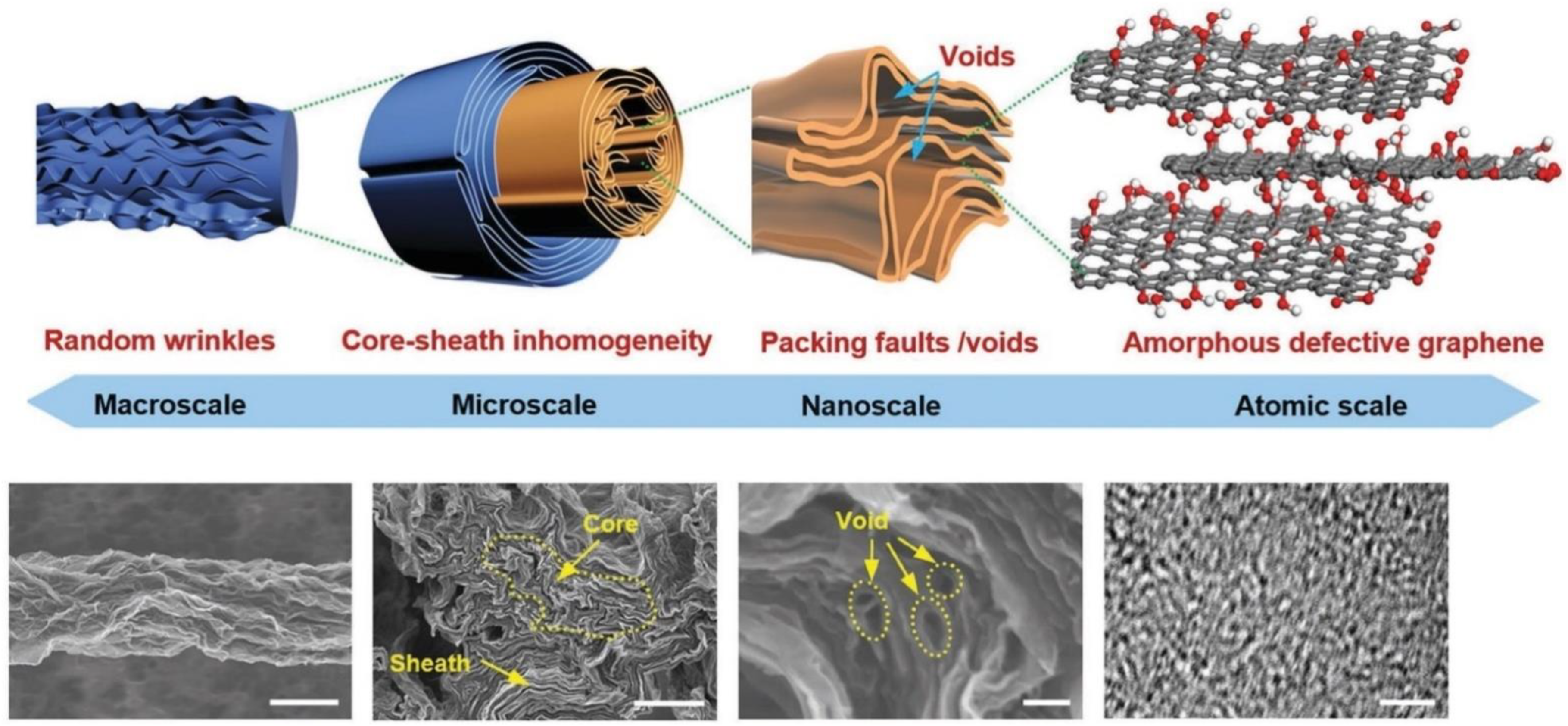

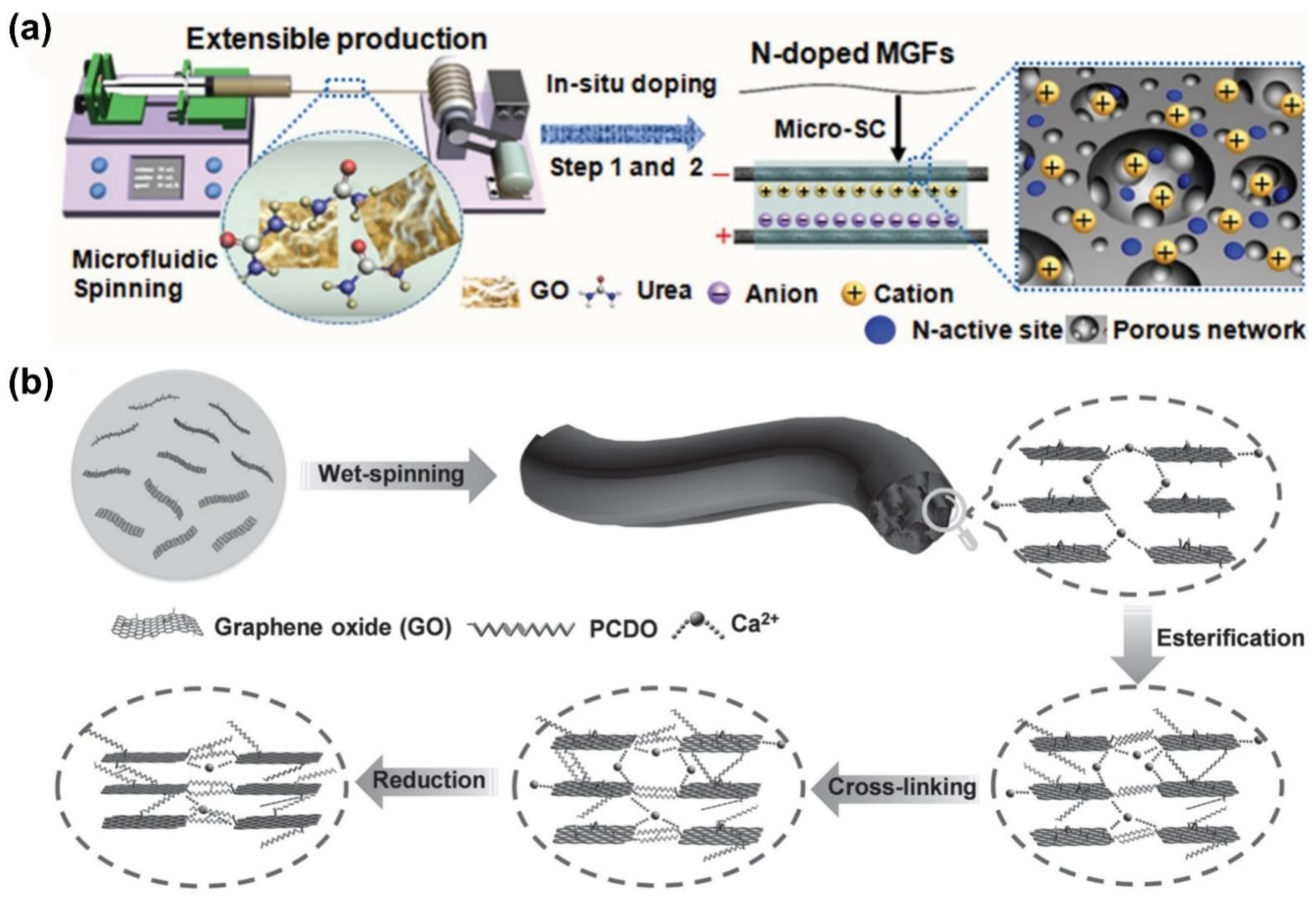

4.1. Microstructure Design

4.2. Surface Modification

5. Electrochemical Performance of Graphene-Based Composite Fiber Electrodes in Supercapacitors

5.1. Carbon Allotropy/Graphene

5.2. Conductive Polymer/Graphene

5.3. Metal Oxide/Graphene

5.4. Other 2D Materials: Graphene and Clay/Graphene

5.5. Multiple Functional Materials/Graphene

6. Conclusions and Perspectives

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, Y.; Wang, M.; Wan, C.; Cai, P.; Loh, X.J.; Chen, X. Devising materials manufacturing toward lab-to-fab translation of flexible electronics. Adv. Mater. 2020, 32, e2001903. [Google Scholar] [CrossRef] [PubMed]

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Fu, X.; He, J.; Shi, X.; Chen, T.; Chen, P.; Wang, B.; Peng, H. Application challenges in fiber and textile electronics. Adv. Mater. 2020, 32, e1901971. [Google Scholar] [CrossRef] [PubMed]

- Weng, W.; Chen, P.; He, S.; Sun, X.; Peng, H. Smart electronic textiles. Angew. Chem. Int. Ed. Engl. 2016, 55, 6140–6169. [Google Scholar] [CrossRef] [PubMed]

- Cherenack, K.; van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 091301. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Zhang, L.; Zhang, J. A review of electrode materials for electrochemical supercapacitors. Chem. Soc. Rev. 2012, 41, 797–828. [Google Scholar] [CrossRef] [Green Version]

- Chmiola, J.; Largeot, C.; Taberna, P.-L.; Simon, P.; Gogotsi, Y. Monolithic carbide-derived carbon films for micro-supercapacitors. Science 2010, 328, 480–483. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Yu, Z.; Neff, D.; Zhamu, A.; Jang, B.Z. Graphene-based supercapacitor with an ultrahigh energy density. Nano Lett. 2010, 10, 4863–4868. [Google Scholar] [CrossRef]

- Zhang, L.L.; Zhao, X. Carbon-based materials as supercapacitor electrodes. Chem. Soc. Rev. 2009, 38, 2520–2531. [Google Scholar] [CrossRef]

- Peng, Z.; Ye, R.; Mann, J.A.; Zakhidov, D.; Li, Y.; Smalley, P.R.; Lin, J.; Tour, J.M. Flexible Boron-doped laser-induced graphene microsupercapacitors. ACS Nano 2015, 9, 5675–5868. [Google Scholar] [CrossRef]

- Frackowiak, E. Carbon materials for supercapacitor application. Phys. Chem. Chem. Phys. 2007, 9, 1774–1785. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Song, Y.; Xia, Y. Electrochemical capacitors: Mechanism, materials, systems, characterization and applications. Chem. Soc. Rev. 2016, 45, 5925–5950. [Google Scholar] [CrossRef]

- Yu, Z.; Tetard, L.; Zhai, L.; Thomas, J. Supercapacitor electrode materials: Nanostructures from 0 to 3 dimensions. Energ. Environ. Sci. 2015, 8, 702–730. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Deng, J.; Chen, X.; Ren, J.; Peng, H. A highly stretchable, fiber-shaped supercapacitor. Angew. Chem. Int. Ed. Engl. 2013, 52, 13453–13457. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Xu, C.; Li, Y.; Huang, Z.-H.; Kang, F.; Yang, Q.-H.; Zhao, X. Flexible electrodes and supercapacitors for wearable energy storage: A review by category. J. Mater. Chem. A 2016, 4, 4659–4685. [Google Scholar] [CrossRef]

- Choi, C.; Kim, S.H.; Sim, H.J.; Lee, J.A.; Choi, A.Y.; Kim, Y.T.; Lepró, X.; Spinks, G.M.; Baughman, R.H.; Kim, S.J. Stretchable, weavable coiled carbon nanotube/MnO2/polymer fiber solid-state supercapacitors. Sci. Rep. 2015, 5, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Cai, Z.; Li, L.; Ren, J.; Qiu, L.; Lin, H.; Peng, H. Flexible, weavable and efficient microsupercapacitor wires based on polyaniline composite fibers incorporated with aligned carbon nanotubes. J. Mater. Chem. A 2013, 1, 258–261. [Google Scholar] [CrossRef]

- Li, Z.; Shao, M.; Zhou, L.; Zhang, R.; Zhang, C.; Han, J.; Wei, M.; Evans, D.G.; Duan, X. A flexible all-solid-state micro-supercapacitor based on hierarchical CuO@ layered double hydroxide core–shell nanoarrays. Nano Energy 2016, 20, 294–304. [Google Scholar]

- Jiang, H.; Lee, P.S.; Li, C. 3D carbon based nanostructures for advanced supercapacitors. Energ. Environ. Sci. 2013, 6, 41–53. [Google Scholar] [CrossRef]

- Chen, X.; Qiu, L.; Ren, J.; Guan, G.; Lin, H.; Zhang, Z.; Chen, P.; Wang, Y.; Peng, H. Novel electric double-layer capacitor with a coaxial fiber structure. Adv. Mater. 2013, 25, 6436–6441. [Google Scholar] [CrossRef]

- Kou, L.; Huang, T.; Zheng, B.; Han, Y.; Zhao, X.; Gopalsamy, K.; Sun, H.; Gao, C. Coaxial wet-spun yarn supercapacitors for high-energy density and safe wearable electronics. Nat. Commun. 2014, 5, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Luo, J.; Jang, H.D.; Huang, J. Effect of sheet morphology on the scalability of graphene-based ultracapacitors. ACS Nano 2013, 7, 1464–1471. [Google Scholar] [CrossRef]

- Stoller, M.D.; Park, S.; Zhu, Y.; An, J.; Ruoff, R.S. Graphene-based ultracapacitors. Nano Lett. 2008, 8, 3498–3502. [Google Scholar] [CrossRef]

- Zhang, L.L.; Zhou, R.; Zhao, X. Graphene-based materials as supercapacitor electrodes. J. Mater. Chem. 2010, 20, 5983–5992. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, J.; Chen, Y. An overview of the applications of graphene-based materials in supercapacitors. Small 2012, 8, 1805–1834. [Google Scholar] [CrossRef]

- Shao, Y.; El-Kady, M.F.; Wang, L.J.; Zhang, Q.; Li, Y.; Wang, H.; Mousavi, M.F.; Kaner, R.B. Graphene-based materials for flexible supercapacitors. Chem. Soc. Rev. 2015, 44, 3639–3665. [Google Scholar] [CrossRef]

- Zheng, X.; Hu, Q.; Zhou, X.; Nie, W.; Li, C.; Yuan, N. Graphene-based fibers for the energy devices application: A comprehensive review. Mater Des. 2021, 201, 109476. [Google Scholar] [CrossRef]

- Wu, S.; Qureshi, T.; Wang, G. Application of graphene in fiber-reinforced cementitious composites: A review. Energies 2021, 14, 4614. [Google Scholar] [CrossRef]

- Sun, P.Z.; Yang, Q.; Kuang, W.J.; Stebunov, Y.V.; Xiong, W.Q.; Yu, J.; Nair, R.R.; Katsnelson, M.I.; Yuan, S.J.; Grigorieva, I.V.; et al. Limits on gas impermeability of graphene. Nature 2020, 579, 229–232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Berry, V. Impermeability of graphene and its applications. Carbon 2013, 62, 1–10. [Google Scholar] [CrossRef]

- Bolotin, K.I.; Sikes, K.J.; Jiang, Z.; Klima, M.; Fudenberg, G.; Hone, J.; Kim, P.; Stormer, H.L. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 2008, 146, 351–355. [Google Scholar] [CrossRef] [Green Version]

- Balandin, A.A.; Ghosh, S.; Bao, W.Z.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

- Owais, M.; Zhao, J.; Imani, A.; Wang, G.; Zhang, H.; Zhang, Z. Synergetic effect of hybrid fillers of boron nitride, graphene nanoplatelets, and short carbon fibers for enhanced thermal conductivity and electrical resistivity of epoxy nanocomposites. Compos. Part A Appl. Sci. Manuf. 2019, 117, 11–22. [Google Scholar] [CrossRef]

- Wang, K.; Qu, C.; Wang, J.; Quan, B.; Zheng, Q. Characterization of a microscale superlubric graphite interface. Phys. Rev. Lett. 2020, 125, 026101. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Dai, Z.; Wang, Y.; Tan, P.; Liu, L.; Xu, Z.; Wei, Y.; Huang, R.; Zhang, Z. Measuring interlayer shear stress in bilayer graphene. Phys. Rev. Lett. 2017, 119, 036101. [Google Scholar] [CrossRef]

- Arif, T.; Wang, G.; Sodhi, R.N.S.; Colas, G.; Filleter, T. Role of chemical vs. physical interfacial interaction and adsorbed water on the tribology of ultrathin 2D-material/steel interfaces. Tribol. Int. 2021, 163, 107194. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Dai, Z.; Xiao, J.; Feng, S.; Weng, C.; Liu, L.; Xu, Z.; Huang, R.; Zhang, Z. Bending of multilayer van der Waals materials. Phys. Rev. Lett. 2019, 123, 116101. [Google Scholar] [CrossRef]

- Xia, J.; Chen, F.; Li, J.; Tao, N. Measurement of the quantum capacitance of graphene. Nat. Nanotechnol. 2009, 4, 505–509. [Google Scholar] [CrossRef]

- Wan, S.; Chen, Y.; Wang, Y.; Li, G.; Wang, G.; Liu, L.; Zhang, J.; Liu, Y.; Xu, Z.; Tomsia, A.P.; et al. Ultrastrong graphene films via long-chain π-bridging. Matter 2019, 1, 389–401. [Google Scholar] [CrossRef] [Green Version]

- Cong, H.-P.; Chen, J.-F.; Yu, S.-H. Graphene-based macroscopic assemblies and architectures: An emerging material system. Chem. Soc. Rev. 2014, 43, 7295–7325. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, L.; Sun, B.; Wang, G.; Zhang, Z. Preparation of lipophilic graphene oxide derivates via a concise route and its mechanical reinforcement in thermoplastic polyurethane. Compos. Sci. Technol. 2016, 134, 36–42. [Google Scholar] [CrossRef]

- Duan, F.; Li, W.; Wang, G.; Weng, C.; Jin, H.; Zhang, H.; Zhang, Z. Can insulating graphene oxide contribute the enhanced conductivity and durability of silver nanowire coating? Nano Res. 2019, 12, 1571–1577. [Google Scholar] [CrossRef]

- Marcano, D.C.; Kosynkin, D.V.; Berlin, J.M.; Sinitskii, A.; Sun, Z.; Slesarev, A.; Alemany, L.B.; Lu, W.; Tour, J.M. Improved synthesis of graphene oxide. ACS Nano 2010, 4, 4806–4814. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, Y.; Zhao, X.; Peng, L.; Sun, H.; Xu, Y.; Ren, X.; Jin, C.; Xu, P.; Wang, M. Ultrastiff and strong graphene fibers via full-scale synergetic defect engineering. Adv. Mater. 2016, 28, 6449–6456. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, Z.; Zhan, J.; Li, P.; Gao, C. Superb electrically conductive graphene fibers via doping strategy. Adv. Mater. 2016, 28, 7941–7947. [Google Scholar] [CrossRef]

- Xin, G.; Zhu, W.; Deng, Y.; Cheng, J.; Zhang, L.T.; Chung, A.J.; De, S.; Lian, J. Microfluidics-enabled orientation and microstructure control of macroscopic graphene fibres. Nat. Nanotechnol. 2019, 14, 168–175. [Google Scholar] [CrossRef]

- Lim, L.; Liu, Y.; Liu, W.; Tjandra, R.; Rasenthiram, L.; Chen, Z.; Yu, A. All-in-one graphene based composite fiber: Toward wearable supercapacitor. ACS Appl. Mater. Interfaces 2017, 9, 39576–39583. [Google Scholar] [CrossRef]

- Zheng, X.; Yao, L.; Qiu, Y.; Wang, S.; Zhang, K. Core–sheath porous polyaniline nanorods/graphene fiber-shaped supercapacitors with high specific capacitance and rate capability. ACS Appl. Energy Mater. 2019, 2, 4335–4344. [Google Scholar] [CrossRef]

- Yu, G.-H.; Han, Q.; Qu, L.-T. Graphene Fibers: Advancing Applications in Sensor, Energy Storage and Conversion. Chin. J. Polym. Sci. 2019, 37, 535–547. [Google Scholar] [CrossRef]

- Li, J.; Huang, X.; Cui, L.; Chen, N.; Qu, L. Preparation and supercapacitor performance of assembled graphene fiber and foam. Prog. Nat. Sci. Mater. Int. 2016, 26, 212–220. [Google Scholar] [CrossRef] [Green Version]

- Fang, B.; Chang, D.; Xu, Z.; Gao, C. A review on graphene fibers: Expectations, advances, and prospects. Adv. Mater. 2020, 32, e1902664. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.; Qian, Q.; Wei, L.; Jiang, W.; Goh, K.; Wei, J.; Zhang, J.; Chen, Y. Emergence of fiber supercapacitors. Chem. Soc. Rev. 2015, 44, 647–662. [Google Scholar] [CrossRef]

- Galhena, D.T.L.; Bayer, B.C.; Meyer, J.C.; Hofmann, S.; Amaratunga, G.A.J. Reduced graphene oxide as a monolithic multifunctional conductive binder for activated carbon supercapacitors. ACS Omega 2018, 3, 9246–9255. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, H.; Ambade, R.B.; Noh, S.H.; Eom, W.; Koh, K.H.; Ambade, S.B.; Lee, W.J.; Kim, S.H.; Han, T.H. Porous graphene-carbon nanotube scaffolds for fiber supercapacitors. ACS Appl. Mater. Interfaces 2019, 11, 9011–9022. [Google Scholar] [CrossRef] [PubMed]

- Beidaghi, M.; Wang, C. Micro-supercapacitors based on interdigital electrodes of reduced graphene oxide and carbon nanotube composites with ultrahigh power handling performance. Adv. Funct. Mater. 2012, 22, 4501–4510. [Google Scholar] [CrossRef]

- Lu, Z.; Foroughi, J.; Wang, C.; Long, H.; Wallace, G.G. Superelastic hybrid CNT/graphene fibers for wearable energy storage. Adv. Energy Mater. 2018, 8, 1702047. [Google Scholar] [CrossRef]

- Li, B.; Cheng, J.; Wang, Z.; Li, Y.; Ni, W.; Wang, B. Highly-wrinkled reduced graphene oxide-conductive polymer fibers for flexible fiber-shaped and interdigital-designed supercapacitors. J. Power Sources 2018, 376, 117–124. [Google Scholar] [CrossRef]

- Meng, Y.; Zhao, Y.; Hu, C.; Cheng, H.; Hu, Y.; Zhang, Z.; Shi, G.; Qu, L. All-graphene core-sheath microfibers for all-solid-state, stretchable fibriform supercapacitors and wearable electronic textiles. Adv. Mater. 2013, 25, 2326–2331. [Google Scholar] [CrossRef]

- Sha, Z.; Zhou, Y.; Huang, F.; Yang, W.; Yu, Y.; Zhang, J.; Wu, S.; Brown, S.A.; Peng, S.; Han, Z.; et al. Carbon fibre electrodes for ultra long cycle life pseudocapacitors by engineering the nano-structure of vertical graphene and manganese dioxides. Carbon 2021, 177, 260–270. [Google Scholar] [CrossRef]

- Wu, G.; Yang, X.; Hou, C.; Li, Y.; Zhang, Q.; Wang, H. High volumetric energy density asymmetric fibrous supercapacitors with coaxial structure based on graphene/MnO2 hybrid fibers. ChemElectroChem 2020, 7, 4641–4648. [Google Scholar] [CrossRef]

- Li, P.; Jin, Z.; Peng, L.; Zhao, F.; Xiao, D.; Jin, Y.; Yu, G. Stretchable all-gel-state fiber-shaped supercapacitors enabled by macromolecularly interconnected 3D graphene/nanostructured conductive polymer hydrogels. Adv. Mater. 2018, 30, e1800124. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, Y.; Yao, Z.; Liu, A.; Shi, G. Supercapacitors based on flexible graphene/polyaniline nanofiber composite films. ACS Nano 2010, 4, 1963–1970. [Google Scholar] [CrossRef]

- Huang, Y.; Tao, J.; Meng, W.; Zhu, M.; Huang, Y.; Fu, Y.; Gao, Y.; Zhi, C. Super-high rate stretchable polypyrrole-based supercapacitors with excellent cycling stability. Nano Energy 2015, 11, 518–525. [Google Scholar] [CrossRef]

- Roberts, M.E.; Wheeler, D.R.; McKenzie, B.B.; Bunker, B.C. High specific capacitance conducting polymer supercapacitor electrodes based on poly (tris (thiophenylphenyl) amine). J. Mater. Chem. 2009, 19, 6977–6979. [Google Scholar] [CrossRef]

- Song, Y.; Liu, T.Y.; Xu, X.X.; Feng, D.Y.; Li, Y.; Liu, X.X. Pushing the cycling stability limit of polypyrrole for supercapacitors. Adv. Funct. Mater. 2015, 25, 4626–4632. [Google Scholar] [CrossRef]

- Xu, T.; Ding, X.; Liang, Y.; Zhao, Y.; Chen, N.; Qu, L. Direct spinning of fiber supercapacitor. Nanoscale 2016, 8, 12113–12117. [Google Scholar] [CrossRef]

- Hu, X.; Rajendran, S.; Yao, Y.; Liu, Z.; Gopalsamy, K.; Peng, L.; Gao, C. A novel wet-spinning method of manufacturing continuous bio-inspired composites based on graphene oxide and sodium alginate. Nano Res. 2016, 9, 735–744. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, J.; Li, M.; Saiz, E.; Wolf, S.E.; Cheng, Q. Bioinspired supertough graphene fiber through sequential interfacial interactions. ACS Nano 2018, 12, 8901–8908. [Google Scholar] [CrossRef]

- Najafi, F.; Wang, G.; Mukherjee, S.; Cui, T.; Filleter, T.; Singh, C.V. Toughening of graphene-based polymer nanocomposites via tuning chemical functionalization. Compos. Sci. Technol. 2020, 194, 108140. [Google Scholar] [CrossRef]

- Wang, G.; Dai, Z.; Liu, L.; Hu, H.; Dai, Q.; Zhang, Z. Tuning the interfacial mechanical behaviors of monolayer graphene/PMMA nanocomposites. ACS Appl. Mater. Interfaces 2016, 8, 22554–22562. [Google Scholar] [CrossRef]

- Wu, Z.-S.; Ren, W.; Wang, D.-W.; Li, F.; Liu, B.; Cheng, H.-M. High-energy MnO2 nanowire/graphene and graphene asymmetric electrochemical capacitors. ACS Nano 2010, 4, 5835–5842. [Google Scholar] [CrossRef]

- Wu, Z.-S.; Zhou, G.; Yin, L.-C.; Ren, W.; Li, F.; Cheng, H.-M. Graphene/metal oxide composite electrode materials for energy storage. Nano Energy 2012, 1, 107–131. [Google Scholar] [CrossRef]

- Chen, G.; Ai, Y.; Mugaanire, I.T.; Ma, W.; Hsiao, B.S.; Hou, K.; Zhu, M. A simple inorganic hybrids strategy for graphene fibers fabrication with excellent electrochemical performance. J. Power Sources 2020, 450, 227637. [Google Scholar] [CrossRef]

- Ge, W.; Ma, Q.; Ai, Z.; Wang, W.; Jia, F.; Song, S. Three-dimensional reduced graphene oxide/montmorillonite nanosheet aerogels as electrode material for supercapacitor application. Appl. Clay Sci. 2021, 206, 106022. [Google Scholar] [CrossRef]

- Xu, T.; Zhang, Z.; Qu, L. Graphene-based fibers: Recent advances in preparation and application. Adv. Mater. 2020, 32, e1901979. [Google Scholar] [CrossRef]

- Zhang, G.; Han, Y.; Shao, C.; Chen, N.; Sun, G.; Jin, X.; Gao, J.; Ji, B.; Yang, H.; Qu, L. Processing and manufacturing of graphene-based microsupercapacitors. Mater. Chem. Front. 2018, 2, 1750–1764. [Google Scholar] [CrossRef]

- Yu, D.; Goh, K.; Wang, H.; Wei, L.; Jiang, W.; Zhang, Q.; Dai, L.; Chen, Y. Scalable synthesis of hierarchically structured carbon nanotube–graphene fibres for capacitive energy storage. Nat. Nanotechnol. 2014, 9, 555–562. [Google Scholar] [CrossRef] [PubMed]

- Tian, Q.; Xu, Z.; Liu, Y.; Fang, B.; Peng, L.; Xi, J.; Li, Z.; Gao, C. Dry spinning approach to continuous graphene fibers with high toughness. Nanoscale 2017, 9, 12335–12342. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.; Zhao, T.; Wang, K.; Yang, Y.; Wei, J.; Kang, F.; Wu, D.; Zhu, H. Directly drawing self-assembled, porous, and monolithic graphene fiber from chemical vapor deposition grown graphene film and its electrochemical properties. Langmuir 2011, 27, 12164–12171. [Google Scholar] [CrossRef]

- Carretero–González, J.; Castillo–Martínez, E.; Dias–Lima, M.; Acik, M.; Rogers, D.M.; Sovich, J.; Haines, C.S.; Lepró, X.; Kozlov, M.; Zhakidov, A. Oriented graphene nanoribbon yarn and sheet from aligned multi-walled carbon nanotube sheets. Adv. Mater. 2012, 24, 5695–5701. [Google Scholar] [CrossRef]

- Jang, E.Y.; Carretero-González, J.; Choi, A.; Kim, W.J.; Kozlov, M.E.; Kim, T.; Kang, T.J.; Baek, S.J.; Kim, D.W.; Park, Y.W. Fibers of reduced graphene oxide nanoribbons. Nanotechnology 2012, 23, 235601. [Google Scholar] [CrossRef]

- Al Faruque, M.A.; Syduzzaman, M.; Sarkar, J.; Bilisik, K.; Naebe, M. A review on the production methods and applications of graphene-based materials. Nanomaterials 2021, 11, 2414. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Li, Q.; Chen, M.; Li, J.; Li, J.; Huang, Y.; Besenbacher, F.; Dong, M. Mechanical reinforcement fibers produced by gel-spinning of poly-acrylic acid (PAA) and graphene oxide (GO) composites. Nanoscale 2013, 5, 6265–6269. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Wang, X.; Yang, T.; Zhang, P.; Wei, X.; Zhang, L.; Li, H. Polyaniline/graphene hybrid fibers as electrodes for flexible supercapacitors. Synth. Met. 2020, 268, 116484. [Google Scholar] [CrossRef]

- Ren, H.; Zheng, L.; Wang, G.; Gao, X.; Tan, Z.; Shan, J.; Cui, L.; Li, K.; Jian, M.; Zhu, L.; et al. Transfer-medium-free nanofiber-reinforced graphene film and applications in wearable transparent pressure sensors. ACS Nano 2019, 13, 5541–5548. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Deng, B.; Sun, J.; Peng, H.; Liu, Z. Bridging the gap between reality and ideal in chemical vapor deposition growth of graphene. Chem. Rev. 2018, 118, 9281–9343. [Google Scholar] [CrossRef]

- Xiong, G.; Meng, C.; Reifenberger, R.G.; Irazoqui, P.P.; Fisher, T.S. Graphitic petal electrodes for all-solid-state flexible supercapacitors. Adv. Energy Mater. 2014, 4, 1300515. [Google Scholar] [CrossRef]

- Zeng, J.; Ji, X.; Ma, Y.; Zhang, Z.; Wang, S.; Ren, Z.; Zhi, C.; Yu, J. 3D graphene fibers grown by thermal chemical vapor deposition. Adv. Mater. 2018, 30, e1705380. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Sun, S.; Li, X.; Zhao, F.; Jiang, B.; Huang, Y. Electrophoretic deposition of graphene oxide on continuous carbon fibers for reinforcement of both tensile and interfacial strength. Compos. Sci. Technol. 2016, 135, 46–53. [Google Scholar] [CrossRef]

- Zhao, X.; Zheng, B.; Huang, T.; Gao, C. Graphene-based single fiber supercapacitor with a coaxial structure. Nanoscale 2015, 7, 9399–9404. [Google Scholar] [CrossRef]

- Park, S.; Kim, S. Effect of carbon blacks filler addition on electrochemical behaviors of Co3O4/graphene nanosheets as a supercapacitor electrodes. Electrochim. Acta 2013, 89, 516–522. [Google Scholar] [CrossRef]

- Sun, H.; You, X.; Deng, J.; Chen, X.; Yang, Z.; Ren, J.; Peng, H. Novel graphene/carbon nanotube composite fibers for efficient wire-shaped miniature energy devices. Adv. Mater. 2014, 26, 2868–2873. [Google Scholar] [CrossRef]

- Jiang, N.; Huang, F.; Xia, W.; Wei, J.; Zhou, L.; Huo, Z.; Pang, Q. Facile fabrication of rGO/CNT hybrid fibers for high-performance flexible supercapacitors. J. Mater. Sci. Mater. Electron. 2017, 28, 12147–12157. [Google Scholar] [CrossRef]

- Wang, B.; Fang, X.; Sun, H.; He, S.; Ren, J.; Zhang, Y.; Peng, H. Fabricating continuous supercapacitor fibers with high performances by integrating all building materials and steps into one process. Adv. Mater. 2015, 27, 7854–7860. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Chen, S.; Yang, S.; Chen, W.; Weng, W.; Zhu, M. Bottom-up fabrication of activated carbon fiber for all-solid-state supercapacitor with excellent electrochemical performance. ACS Appl. Mater. Interfaces 2016, 8, 14622–14627. [Google Scholar] [CrossRef] [PubMed]

- Ho, B.T.; Lim, T.; Jeong, M.H.; Suk, J.W. Graphene fibers containing activated graphene for high-performance solid-state flexible supercapacitors. ACS Appl. Energy Mater. 2021, 4, 8883–8890. [Google Scholar] [CrossRef]

- Qu, G.; Cheng, J.; Li, X.; Yuan, D.; Chen, P.; Chen, X.; Wang, B.; Peng, H. A fiber supercapacitor with high energy density based on hollow graphene/conducting polymer fiber electrode. Adv. Mater. 2016, 28, 3646–3652. [Google Scholar] [CrossRef] [PubMed]

- PadmajanSasikala, S.; Lee, K.E.; Lim, J.; Lee, H.J.; Koo, S.H.; Kim, I.H.; Jung, H.J.; Kim, S.O. Interface-confined high crystalline growth of semiconducting polymers at graphene fibers for high-performance wearable supercapacitors. ACS Nano 2017, 11, 9424–9434. [Google Scholar] [CrossRef]

- Ding, X.; Zhao, Y.; Hu, C.; Hu, Y.; Dong, Z.; Chen, N.; Zhang, Z.; Qu, L. Spinning fabrication of graphene/polypyrrole composite fibers for all-solid-state, flexible fibriform supercapacitors. J. Mater. Chem. A 2014, 2, 12355–12360. [Google Scholar] [CrossRef]

- Ma, W.; Chen, S.; Yang, S.; Chen, W.; Cheng, Y.; Guo, Y.; Peng, S.; Ramakrishna, S.; Zhu, M. Hierarchical MnO2 nanowire/graphene hybrid fibers with excellent electrochemical performance for flexible solid-state supercapacitors. J. Power Sources 2016, 306, 481–488. [Google Scholar] [CrossRef]

- Li, X.; Zhao, T.; Chen, Q.; Li, P.; Wang, K.; Zhong, M.; Wei, J.; Wu, D.; Wei, B.; Zhu, H. Flexible all solid-state supercapacitors based on chemical vapor deposition derived graphene fibers. Phys. Chem. Chem. Phys. 2013, 15, 17752–17757. [Google Scholar] [CrossRef]

- Chen, Q.; Meng, Y.; Hu, C.; Zhao, Y.; Shao, H.; Chen, N.; Qu, L. MnO2-modified hierarchical graphene fiber electrochemical supercapacitor. J. Power Sources 2014, 247, 32–39. [Google Scholar] [CrossRef]

- Tang, M.; Wu, Y.; Yang, J.; Xue, Y. Hierarchical core-shell fibers of graphene fiber/radially-aligned molybdenum disulfide nanosheet arrays for highly efficient energy storage. J. Alloys Compd. 2020, 828, 153622. [Google Scholar] [CrossRef]

- Wang, B.; Wu, Q.; Sun, H.; Zhang, J.; Ren, J.; Luo, Y.; Wang, M.; Peng, H. An intercalated graphene/(molybdenum disulfide) hybrid fiber for capacitive energy storage. J. Mater. Chem. A 2017, 5, 925–930. [Google Scholar] [CrossRef]

- Yang, Q.; Xu, Z.; Fang, B.; Huang, T.; Cai, S.; Chen, H.; Liu, Y.; Gopalsamy, K.; Gao, W.; Gao, C. MXene/graphene hybrid fibers for high performance flexible supercapacitors. J. Mater. Chem. A 2017, 5, 22113–22119. [Google Scholar] [CrossRef]

- He, N.; Liao, J.; Zhao, F.; Gao, W. Dual-core supercapacitor yarns: An enhanced performance consistency and linear power density. ACS Appl. Mater. Interfaces 2020, 12, 15211–15219. [Google Scholar] [CrossRef]

- He, N.; Patil, S.; Qu, J.; Liao, J.; Zhao, F.; Gao, W. Effects of electrolyte mediation and MXene size in fiber-shaped supercapacitors. ACS Appl. Energy Mater. 2020, 3, 2949–2958. [Google Scholar] [CrossRef]

- Zhi, M.; Xiang, C.; Li, J.; Li, M.; Wu, N. Nanostructured carbon–metal oxide composite electrodes for supercapacitors: A review. Nanoscale 2013, 5, 72–88. [Google Scholar] [CrossRef]

- Salanne, M.; Rotenberg, B.; Naoi, K.; Kaneko, K.; Taberna, P.-L.; Grey, C.P.; Dunn, B.; Simon, P. Efficient storage mechanisms for building better supercapacitors. Nat Energy 2016, 1, 1–10. [Google Scholar] [CrossRef]

- Chmiola, J.; Yushin, G.; Gogotsi, Y.; Portet, C.; Simon, P.; Taberna, P.-L. Anomalous increase in carbon capacitance at pore sizes less than 1 nanometer. Science 2006, 313, 1760–1763. [Google Scholar] [CrossRef] [Green Version]

- Largeot, C.; Portet, C.; Chmiola, J.; Taberna, P.-L.; Gogotsi, Y.; Simon, P. Relation between the ion size and pore size for an electric double-layer capacitor. J. Am. Chem. Soc. 2008, 130, 2730–2731. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, K.; Yao, L.; Qiu, Y.; Wang, S. Hierarchically porous sheath–core graphene-based fiber-shaped supercapacitors with high energy density. J. Mater. Chem. A 2018, 6, 896–907. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Q. Fibrous and flexible electrodes comprising hierarchical nanostructure graphene for supercapacitors. Micro Nano Lett. 2020, 15, 992–996. [Google Scholar] [CrossRef]

- Wang, G.; Liu, L.; Zhang, Z. Interface mechanics in carbon nanomaterials-based nanocomposites. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106212. [Google Scholar] [CrossRef]

- Wu, G.; Tan, P.; Wu, X.; Peng, L.; Cheng, H.; Wang, C.F.; Chen, W.; Yu, Z.; Chen, S. High-performance wearable micro-supercapacitors based on microfluidic-directed nitrogen-doped graphene fiber electrodes. Adv. Funct. Mater. 2017, 27, 1702493. [Google Scholar] [CrossRef]

- Chen, P.; Yang, J.-J.; Li, S.-S.; Wang, Z.; Xiao, T.-Y.; Qian, Y.-H.; Yu, S.-H. Hydrothermal synthesis of macroscopic nitrogen-doped graphene hydrogels for ultrafast supercapacitor. Nano Energy 2013, 2, 249–256. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Ming, P.; Zhang, Q.; Liu, T.; Jiang, L.; Cheng, Q. Ultrastrong bioinspired graphene-based fibers via synergistic toughening. Adv. Mater. 2016, 28, 2834–2839. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Li, P.; Sedloff, J.W.; Zhang, X.; Zhang, H.; Liu, J. Conductive graphene fibers for wire-shaped supercapacitors strengthened by unfunctionalized few-walled carbon nanotubes. ACS Nano 2015, 9, 1352–1359. [Google Scholar] [CrossRef]

- Qu, Q.; Zhang, P.; Wang, B.; Chen, Y.; Tian, S.; Wu, Y.; Holze, R. Electrochemical performance of MnO2 nanorods in neutral aqueous electrolytes as a cathode for asymmetric supercapacitors. J. Phys. Chem. C 2009, 113, 14020–14027. [Google Scholar] [CrossRef]

- Xu, C.; Li, B.; Du, H.; Kang, F.; Zeng, Y. Supercapacitive studies on amorphous MnO2 in mild solutions. J. Power Sources 2008, 184, 691–694. [Google Scholar] [CrossRef]

- Yu, G.; Hu, L.; Vosgueritchian, M.; Wang, H.; Xie, X.; McDonough, J.R.; Cui, X.; Cui, Y.; Bao, Z. Solution-processed graphene/MnO2 nanostructured textiles for high-performance electrochemical capacitors. Nano Lett. 2011, 11, 2905–2911. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Liu, N.; Su, J.; Li, L.; Long, F.; Zou, Z.; Jiang, X.; Gao, Y. Highly Stretchable and Self-Healable Supercapacitor with Reduced Graphene Oxide Based Fiber Springs. ACS Nano 2017, 11, 2066–2074. [Google Scholar] [CrossRef]

- Liu, D.; Du, P.; Wei, W.; Wang, H.; Wang, Q.; Liu, P. Skeleton/skin structured (RGO/CNTs)@PANI composite fiber electrodes with excellent mechanical and electrochemical performance for all-solid-state symmetric supercapacitors. J. Colloid Interface Sci. 2018, 513, 295–303. [Google Scholar] [CrossRef] [PubMed]

| Electrodes | Prepration Methods | Electrolyte | Agents | Time/Temperature | Ref. |

|---|---|---|---|---|---|

| Graphene + Carbon Allotropy | |||||

| rGO/CNT | Wetspinning + hydrothermal activation | PVA/KOH | H2O2 + NH4OH | Chemical reduction with HI at 80 °C for 6 h; Dried at 60 °C for 30 min | [55] |

| SWNT/nitrogen-doped rGO | Hydrothermal process in fused-silica capillary column | PVA/H3PO4 | ethylenediamine | Hydrothermal reaction at 220 °C for 6 h; Dried at room temp. for 4 h | [78] |

| GO/CNT | Biscrolling method | PVA/H3PO4 | NA | Chemical reduction with HI at 80 °C for 8 h; Dried in vacuum for 12 h | [93] |

| rGO/CNT | Low-temperature chemical reduction assembly method | NA | Vitamin C | Dried in air at 40 °C | [94] |

| rGO/CNT | Dryspinning of CNT fiber + dip coating of GO | PVA/H3PO4 | NA | NA | [95] |

| Graphene/active carbon | Wetspinning | PVA/H3PO4 | NA | Chemical reduction with HI at 95 °C for 12 h; Dried at 60 °C for 12 h | [96] |

| rGO/active carbon | Wetspinning | PVA/LiCl | KOH | Chemical reduction with HI at 95 °C for 12 h; Dried at room temp. overnight | [97] |

| Graphene + Conductive Polymer | |||||

| rGO/PEDOT:PSS | Hydrothermally process in a sealed mold pipe | PVA/H3PO4 | Vitamin C | Chemical reduction at 90 °C | [98] |

| rGO/PEDOT:PSS rGO//PANI rGO/PPy | Wet spinning + in situ polymerization | PVA/H2SO4 | NA | Chemical reduction with HI at 65 °C for 6 h; | [99] |

| Graphene/PANI | Wet spinning + thermal annealing + dip coating | PVA/H2SO4 | NA | Thermal annealing at 800 °C for 3 h; Dip coating at 0 °C for 24 h under slight stirring | [49] |

| Graphene/PPy | Wet spinning | PVA/H2SO4 | NA | Chemical reduction with HI at 80 °C for 8 h | [100] |

| rGO/PANI | Macromolecular self-assembly | PVA/H2SO4 | NA | Reduction at 180 °C for 12 h | [62] |

| Graphene + Metal Oxide | |||||

| rGO/MnO2 | Wet spinning + electrodeposition | PVA/H3PO4 | NA | Chemical reduction with HI at 80 °C | [48] |

| rGO/MnO2 | Wet spinning | PVA/H3PO4 | NA | Dried at 60 °C in vacuum; Reduction at 85°C for 24h | [101] |

| Graphene/MnO2 | Self-assembly of CVD graphene + MnO2 deposition | PVA/H3PO4 | NA | CVD growth at 1000 °C within 5 min with Ar/H2/CH4; MnO2 depositionat 80 °C for 6 min | [102] |

| GO/MnO2 | Electrochemically electrolyzing GO on graphene fiber + MnO2 deposition | PVA/H3PO4 | NA | Baked in an oven at 230 °C for 2 h | [103] |

| Graphene + Layered Materials | |||||

| rGO/MoS2 | Wetspinning + hydrothermal process | PVA/H2SO4 | NA | Chemical reduction with HI/acetic acid at 90 °C for 8 h; Hydrothermal reaction at 200 °C for 24 h | [104] |

| rGO/MoS2 | Hydrothermal process | PVA/H2SO4 | NA | Hydrothermal reaction at 220 °C for 6 h; Dried in air for 2 h | [105] |

| rGO/Mxene | Wet spinning | PVA/H3PO4 | NA | Chemical reduction with HI/acetic acid at 90 °C for 12 h | [106] |

| rGO/Mxene | Wet spinning + twisting | PVA/H2SO4 | NA | NA | [107] |

| rGO/Mxene | Wet spinning | PVA/H2SO4 | NA | Chemical reduction with HI/acetic acid at 85 °C for 12 h | [108] |

| rGO/clay | Non-liquid-crystal spinning | PVA/H2SO4 | NA | Chemical reduction with HI/acetic acid at 85 °C for 9 h; Dried at 60 °C in vacuum | [74] |

| Electrodes | Electrolyte | WorkWindow (V) | Strength (MPa) | Electrical Conductivity (S/cm) | Specific Capacitance | Energy Density | Power Density | Cycling Stability | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Graphene + Carbon Allotropy | |||||||||

| rGO/CNT | PVA/KOH | 0.8 | 78.4 | 133.3 | 60.75 F/cm3 | 4.83 mWh/cm3 | 18.1 mW/cm3 | 94% (10,000 cycles) | [55] |

| SWNT/nitrogen-doped rGO | PVA/H3PO4 | 1.0 | 84 | 102 | 300 F/cm3 | 6.3 mWh/cm3 | 1085 mW/cm3 | 93% (10,000 cycles) | [78] |

| GO/CNT | PVA/H3PO4 | 1.0 | 630 | 450 | 31.50 F/g | NA | NA | ~100% (5000 cycles) | [93] |

| rGO/CNT | NA | 1.2 | 46 | 153.6 | 559.9 F/cm3 | 11.6 Wh/kg | NA | 97.1% (5000 cycles) | [94] |

| rGO/CNT | PVA/H3PO4 | 1.0 | 392.5 | NA | 68.4 F/cm3 | 2.4 mWh/cm3 | 18 mW/cm3 | ~100% (10,000 cycles) | [95] |

| Graphene/active carbon | PVA/H3PO4 | 0.8 | 22.7 | 185 | 27.6 F/cm3 | 2.5 mWh/cm3 | 5 mW/cm3 | 90.4% (10,000 cycles) | [96] |

| rGO/active carbon | PVA/LiCl | 1.0 | 4.2 | 47.3 | 145.1 mF/cm2 | 5.04 μWh/cm2 | 0.5 mW/cm2 | 91.5% (10,000 cycles) | [97] |

| Graphene + Conductive Polymer | |||||||||

| rGO/PEDOT:PSS | PVA/H3PO4 | 0.8 | 631 | ~42–47 | 143.3 F/cm3 | 12.7 mWh/cm3 | 66.5 μWh/cm2 | 96% (10,000 cycles) | [98] |

| rGO/PEDOT:PSS | PVA/H2SO4 | 1.0 | NA | 387.1 | 263.1 F/cm3 | ~7.0 mWh/cm3 | NA | 97.2% (20,000 cycles) | [99] |

| rGO/PANI | PVA/H2SO4 | 1.0 | NA | 282.7 | 155.2 F/cm3 | ~3.8 mWh/cm3 | NA | 94.1% (20,000 cycles) | [99] |

| Graphene/PANI | PVA/H2SO4 | 0.8 | 484 | 14 | 357.1 mF/cm2 | 7.93 μWh/cm2 | 0.23 mW/cm2 | 96.2% (5000 cycles) | [49] |

| rGO/PPy | PVA/H2SO4 | 1.0 | NA | 259.4 | 184.1 F/cm3 | ~4.1 mWh/cm3 | NA | 94.8% (20,000 cycles) | [99] |

| Graphene/PPy | PVA/H2SO4 | 0.8 | 80 | 137-144 | 107.2 F/cm3 | 6.6 μWh/cm2 | NA | 98% (1000 cycles) | [100] |

| rGO/PANI | PVA/H2SO4 | 0.8 | 140 | NA | 148 F/cm3 | 8.8 mWh/cm3 | 30.77 mW/cm3 | NA | [62] |

| Graphene + Metal Oxide | |||||||||

| Graphene/MnO2 | PVA/H3PO4 | 1.8 | NA | NA | 26.9 F/cm3 | NA | NA | 93% (1000 cycles) | [48] |

| rGO/MnO2 | PVA/H3PO4 | 0.8 | 117 | 25.2 | 66.1 F/cm3 | 5.8 mWh/cm3 | 0.51 mW/cm3 | 96% (10,000 cycles) | [101] |

| Graphene/MnO2 | PVA/H3PO4 | 1.0 | NA | 172 | 42 F/cm3 | 1.46 μWh/cm2 | 2.9 mW/cm2 | 92% (1000 cycles) | [102] |

| GO/MnO2 | PVA/H3PO4 | 0.8 | NA | 10 | 34-36 F/g | NA | NA | ~100% (1000 cycles) | [103] |

| Graphene + Layered Materials | |||||||||

| rGO/MoS2 | PVA/H2SO4 | 0.8 | NA | NA | 189.73 mF/cm2 | 6.5 mWh/cm3 | 268.66 mW/cm3 | 89.7% (5000 cycles) | [104] |

| rGO/MoS2 | PVA/H2SO4 | 0.8 | 181 | NA | 368 F/cm3 | NA | NA | 80% (8000 cycles) | [105] |

| rGO/Mxene | PVA/H3PO4 | 0.8 | 12.9 | 290 | 586.4 F/cm3 | 13 mWh/cm3 | 0.59 mW/cm3 | 94% (3000 cycles) | [106] |

| rGO/Mxene | PVA/H2SO4 | 0.8 | NA | NA | 253 mF/cm2 | 27.1 μWh/cm2 | 2.5 mW/cm2 | 82% (1000 cycles) | [107] |

| rGO/Mxene | PVA/H2SO4 | 0.8 | 110.7 | 743.1 | 342.6 mF/cm2 | 9.85 mWh/cm3 | 7.1 mW/cm3 | 85% (10,000 cycles) | [108] |

| rGO/clay | PVA/H2SO4 | 1.0 | 102.7 | 10.4 | 230.9 F/cm3 | 6.14 mWh/cm3 | 28 mW/cm3 | ~100% (5000 cycles) | [74] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S. Recent Progress in Flexible Graphene-Based Composite Fiber Electrodes for Supercapacitors. Crystals 2021, 11, 1484. https://doi.org/10.3390/cryst11121484

Wu S. Recent Progress in Flexible Graphene-Based Composite Fiber Electrodes for Supercapacitors. Crystals. 2021; 11(12):1484. https://doi.org/10.3390/cryst11121484

Chicago/Turabian StyleWu, Songmei. 2021. "Recent Progress in Flexible Graphene-Based Composite Fiber Electrodes for Supercapacitors" Crystals 11, no. 12: 1484. https://doi.org/10.3390/cryst11121484

APA StyleWu, S. (2021). Recent Progress in Flexible Graphene-Based Composite Fiber Electrodes for Supercapacitors. Crystals, 11(12), 1484. https://doi.org/10.3390/cryst11121484