The Influence of Supercooling and Hydrodynamics on the Mosaic and Radial Inhomogeneity of K2NiXCo(1–X)(SO4)2·6H2O Mixed Crystal

Abstract

:1. Introduction

2. Experimental Section

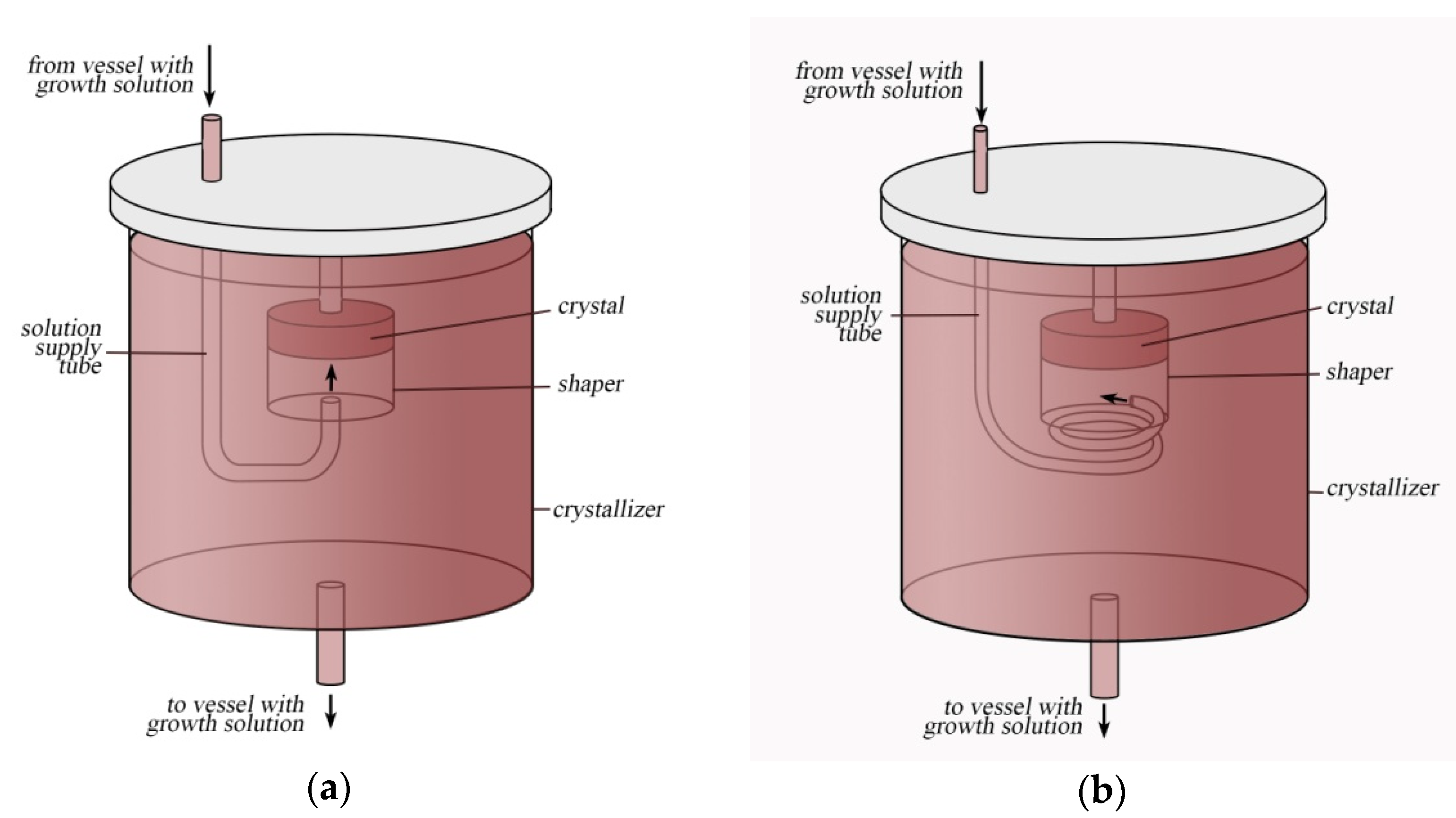

2.1. Growing of Shaped Mixed KCNSH Crystals

2.2. Study of the Composition of Mixed KCNSH Crystals by Energy-Dispersive Analysis

3. Results and Discussion

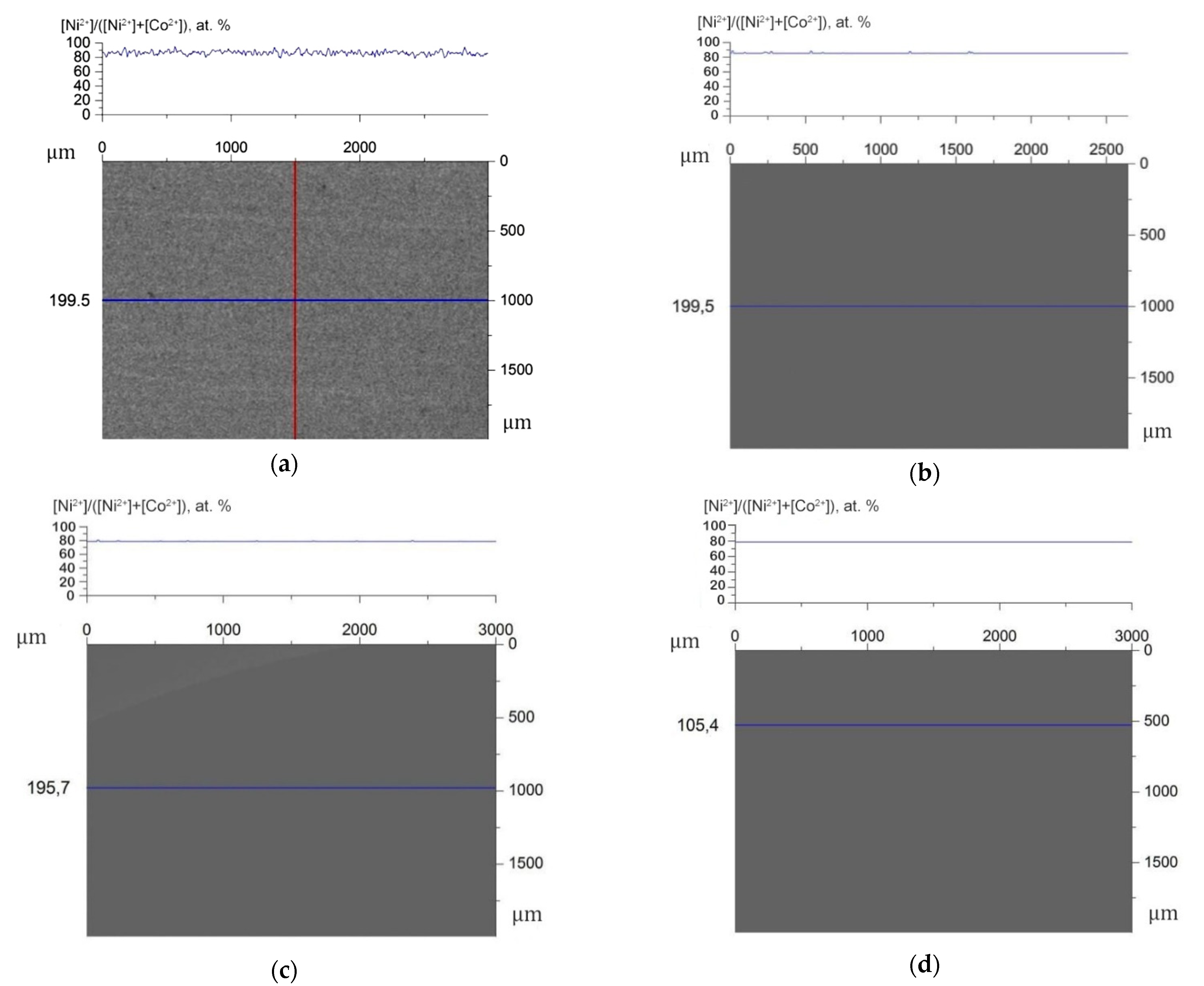

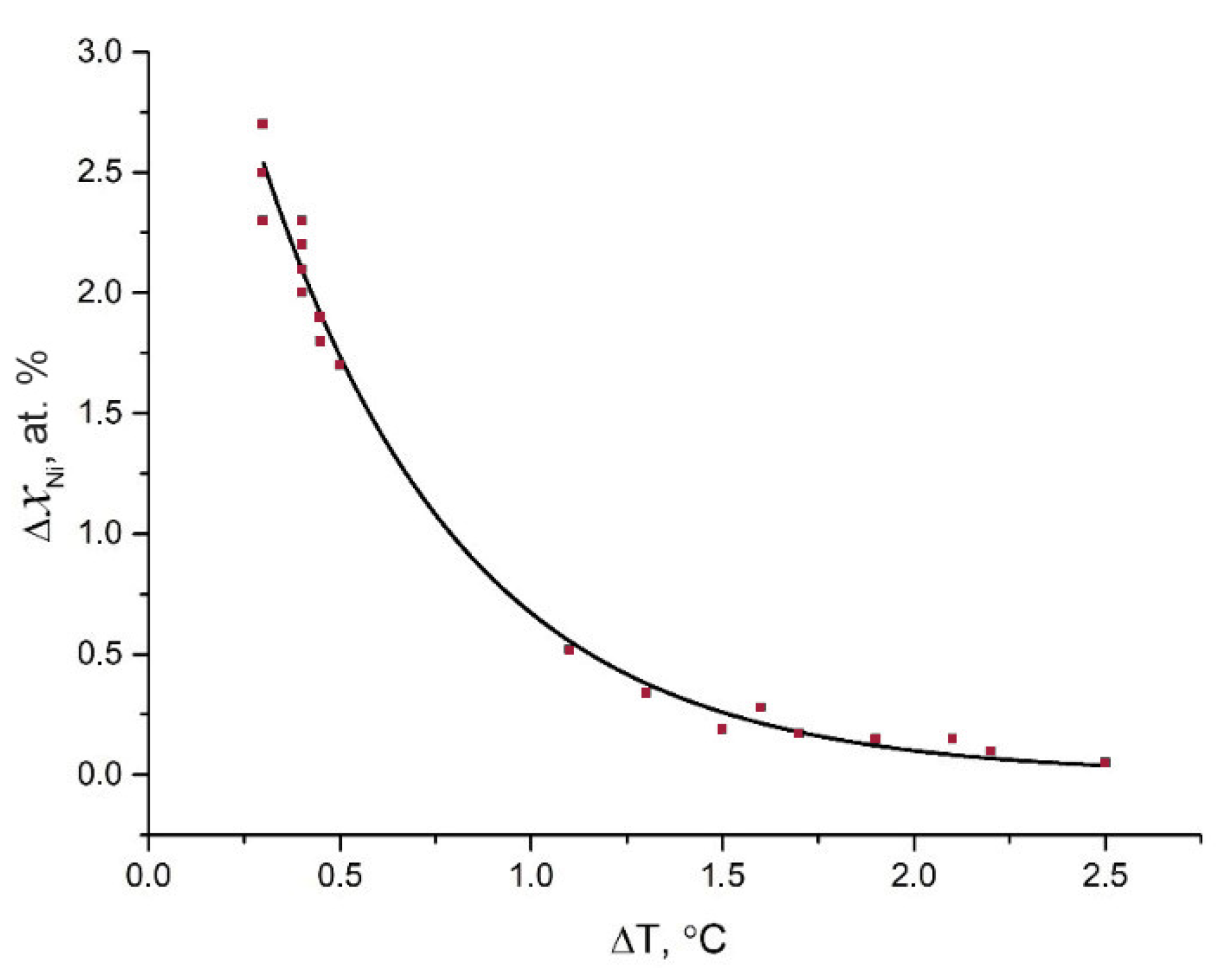

3.1. Study of Mosaic Inhomogeneity of Mixed KCNSH Crystals

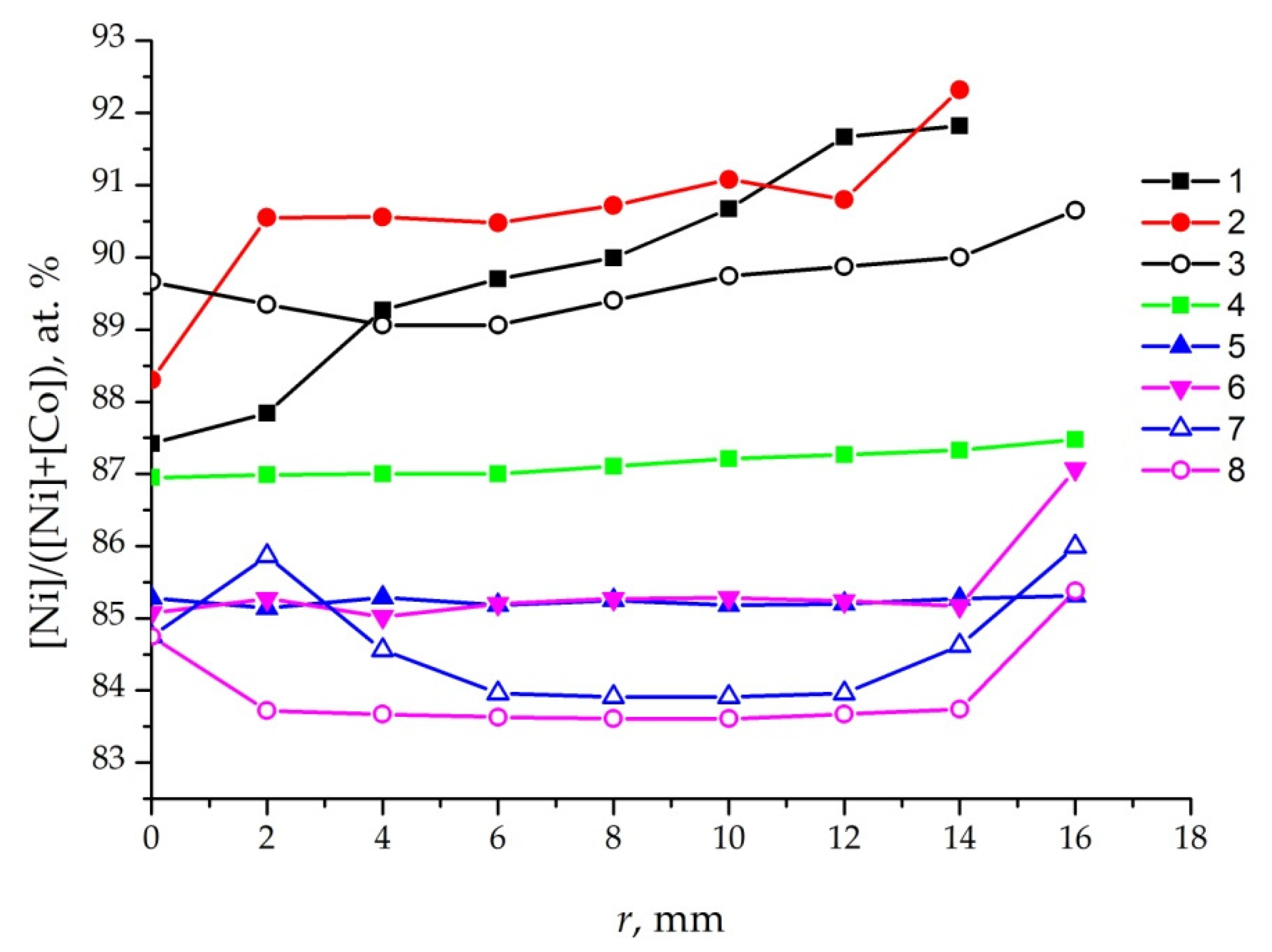

3.2. Study of the Radial Inhomogeneity of KCNSH Crystals

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vasilyeva, N.A.; Grigoryeva, M.S.; Grebenev, V.V.; Voloshin, A.E. Growth and properties of mixed K2NixCo1−x(SO4)2∙6H2O crystals. Crystallogr. Rep. 2013, 58, 646. [Google Scholar] [CrossRef]

- Voloshin, A.E.; Manomenova, V.L.; Rudneva, E.B.; Vasilyeva, N.A.; Masalov, V.M.; Zhokhov, A.A.; Emelchenko, G.A. Growth of high-perfect mixed K2NixCo1−x(SO4)2∙6H2O crystals for fabrication of high-efficiency UV optical filters. J. Cryst. Growth 2018, 500, 98. [Google Scholar] [CrossRef]

- Glikin, A.E.; Kovalev, S.I.; Rudneva, E.B.; Kryuchkova, L.Y.; Voloshin, A.E. Phenomena and mechanisms of mixed crystal formation in solutions I. General concept on the example of the system KHC8H4O4–RbHC8H4O4–H2O. J. Cryst. Growth 2003, 255, 150. [Google Scholar] [CrossRef]

- Voloshin, A.E.; Kovalev, S.I.; Rudneva, E.B.; Glikin, A.E. Phenomena and mechanisms of mixed crystal formation in solutions II. Mechanism of interface processes. J. Cryst. Growth 2004, 261, 105. [Google Scholar] [CrossRef]

- Voloshin, A.; Rudneva, E.; Manomenova, V.; Vasilyeva, N.; Kovalev, S.; Emelchenko, G.; Masalov, V.; Zhokhov, A. The problem of formation of mixed crystals and high-efficiency K2(Co,Ni)(SO4)2∙6H2O optical filters. Crystals 2019, 9, 390. [Google Scholar] [CrossRef] [Green Version]

- Kryuchkova, L.Y.; Glikin, A.E. Variations of the mechanism of single crystal isomorphic replacement. In Proceedings of the Fedorov Session, St. Petersburg, Russia, 11–14 October 2010; p. 111. [Google Scholar]

- Glikin, A.E. Phase relations of mixed crystals with solutions. In Proceedings of the 18th International Workshop on Industrial Crystallization, Delft, The Netherlands, 7–9 September 2011; p. 233. [Google Scholar]

- Kryuchkova, L.Y.; Sinai, M.Y.; Glikin, A.E. Compositional distribution of isomorphic crystals during spontaneous crystallization. Acta Cryst. 2011, 67, 469. [Google Scholar] [CrossRef] [Green Version]

- Glikin, A.E.; Kryuchkova, L.Y.; Plotkina, Y.V.; Taratin, N.V. Micromosaic distribution of components and features of genesis of mixed crystals in solution. Rep. Russ. Acad. Sci. 2010, 433, 85. [Google Scholar]

- Grigoryeva, M.S.; Vasilyeva, N.A.; Artemov, V.V.; Voloshin, A.E. Mosaic microinhomogeneity in crystals of (Co,Ni)K2(SO4)2·6H2O solid solutions. Crystallogr. Rep. 2014, 59, 276. [Google Scholar] [CrossRef]

- Vasilyeva, N.A.; Rudneva, E.B.; Manomenova, V.L.; Grigoriev, Y.V.; Masalov, V.M.; Zhokhov, A.A.; Emelchenko, G.A.; Voloshin, A.E. Study of the radial heterogeneity and mosaic microheterogeneity in KCNSH mixed crystals. Crystallogr. Rep. 2019, 64, 828–833. [Google Scholar] [CrossRef]

- Grebenev, V.V.; Lyasnikova, M.S.; Kovalyov, S.I.; Vasilyeva, N.A.; Rudneva, E.B.; Manomenova, V.L.; Voloshin, A.E. Interferometric study of the stability of K2CoxNi(1−x)(SO4)2·6H2O (KCNSH) mixed crystal faces depending on the composition and flow velocity of the solution. Crystals 2020, 10, 1112. [Google Scholar] [CrossRef]

- Prostomolotov, A.I.; Verezub, N.A.; Vasilyeva, N.A.; Voloshin, A.E. Hydrodynamics and mass transfer during the solution growth of the K2(Co,Ni)(SO4)2·6H2O mixed crystals in the shapers. Crystals 2020, 10, 982. [Google Scholar] [CrossRef]

- Koldaeva, M.V.; Rudneva, E.B.; Manomenova, V.L.; Voloshin, A.E.; Masalov, V.M.; Zhokhov, A.A.; Emelchenko, G.A. Study of the fracture toughness of K2NixCo(1−x)(SO4)2·6h2o crystals in dependence of the growth direction and rate. Crystallogr. Rep. 2019, 64, 926. [Google Scholar] [CrossRef]

| KCNSH Crystal | Supercooling ∆T, °C | Growth Rate, mm/day | Solution Velocity, cm/s | Solution Supply Mode | Radial Inhomogeneity, |

|---|---|---|---|---|---|

| 1 | 2.1 | 0.70 | 175 | centre | 4.4 |

| 2 | 1.6 | 0.33 | 85 | centre | 4.0 |

| 3 | 1.3 | 0.18 | 170 | periphery | 1.6 |

| 4 | 1.9 | 0.50 | 135 | periphery | 0.5 |

| 5 | 1.7 | 0.37 | 55 | periphery | 0.17 |

| 6 | 1.5 | 0.25 | 55 | periphery | 2.0 |

| 7 | 2.2 | 0.82 | 10 | periphery | 2.1 |

| 8 | 2.5 | 1.00 | 10 | periphery | 1.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasilyeva, N.A.; Rudneva, E.B.; Manomenova, V.L.; Grigoriev, Y.V.; Voloshin, A.E. The Influence of Supercooling and Hydrodynamics on the Mosaic and Radial Inhomogeneity of K2NiXCo(1–X)(SO4)2·6H2O Mixed Crystal. Crystals 2021, 11, 1368. https://doi.org/10.3390/cryst11111368

Vasilyeva NA, Rudneva EB, Manomenova VL, Grigoriev YV, Voloshin AE. The Influence of Supercooling and Hydrodynamics on the Mosaic and Radial Inhomogeneity of K2NiXCo(1–X)(SO4)2·6H2O Mixed Crystal. Crystals. 2021; 11(11):1368. https://doi.org/10.3390/cryst11111368

Chicago/Turabian StyleVasilyeva, Natalia A., Elena B. Rudneva, Vera L. Manomenova, Yuriy V. Grigoriev, and Alexey E. Voloshin. 2021. "The Influence of Supercooling and Hydrodynamics on the Mosaic and Radial Inhomogeneity of K2NiXCo(1–X)(SO4)2·6H2O Mixed Crystal" Crystals 11, no. 11: 1368. https://doi.org/10.3390/cryst11111368

APA StyleVasilyeva, N. A., Rudneva, E. B., Manomenova, V. L., Grigoriev, Y. V., & Voloshin, A. E. (2021). The Influence of Supercooling and Hydrodynamics on the Mosaic and Radial Inhomogeneity of K2NiXCo(1–X)(SO4)2·6H2O Mixed Crystal. Crystals, 11(11), 1368. https://doi.org/10.3390/cryst11111368