A Review on Graphene’s Light Stabilizing Effects for Reduced Photodegradation of Polymers

Abstract

1. Introduction

2. Physical and Chemical Aspects of Polymer Photodegradation

2.1. Introduction

2.2. How Does Light Affect Polymers?

2.2.1. Photodegradation

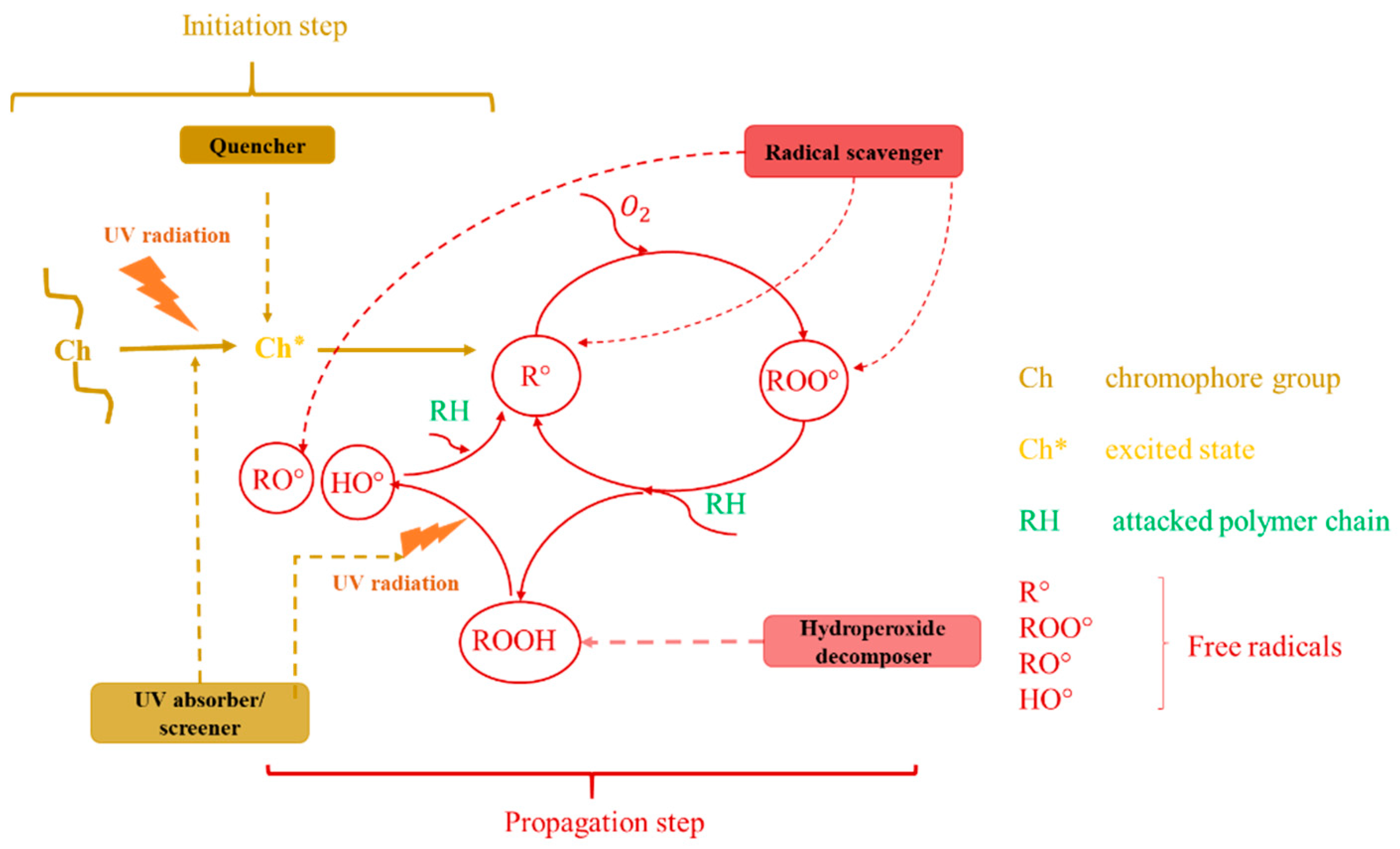

2.2.2. Photo-Oxidative Degradation

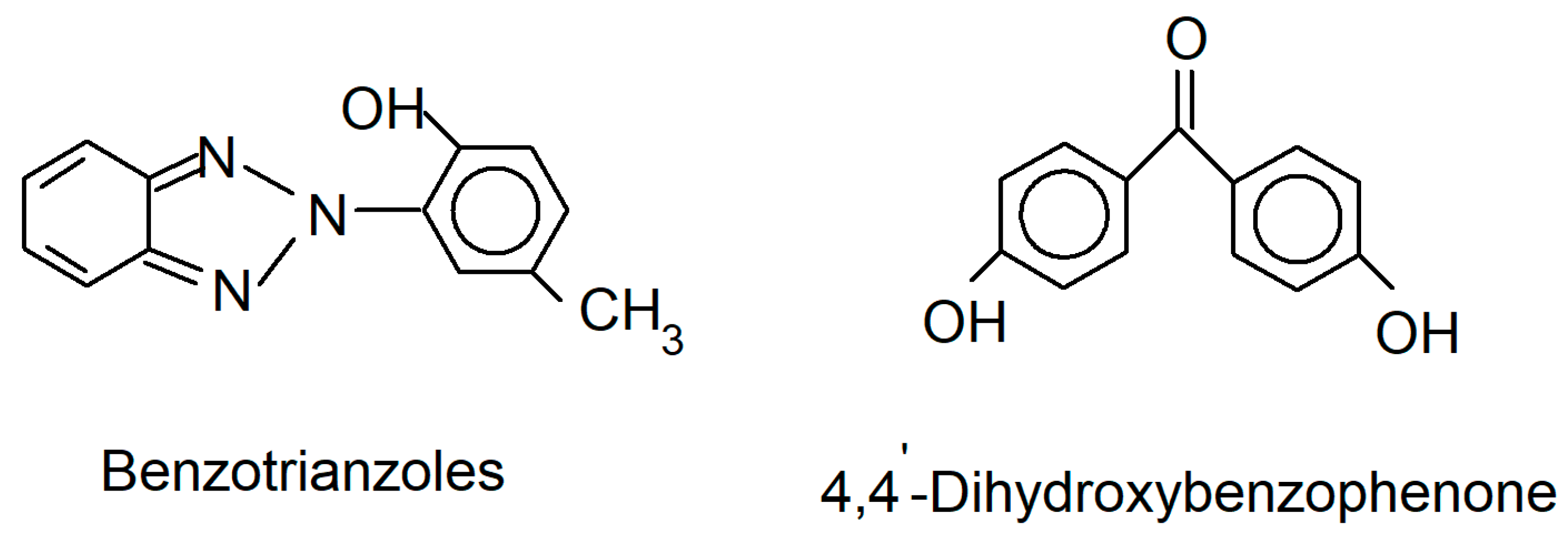

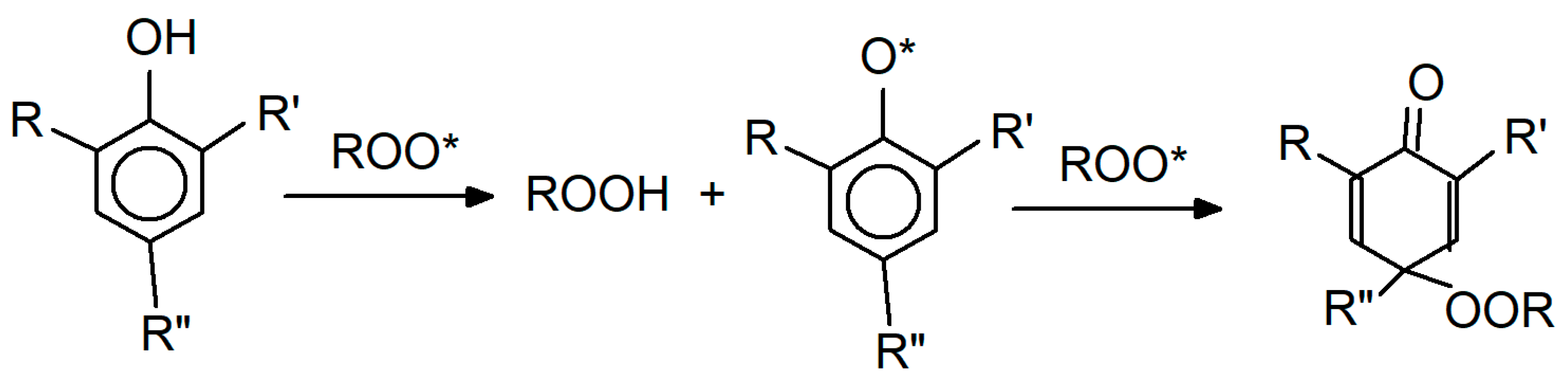

2.2.3. Mechanisms of Actions of Photostabilizers

3. Graphene

3.1. Types of Graphene

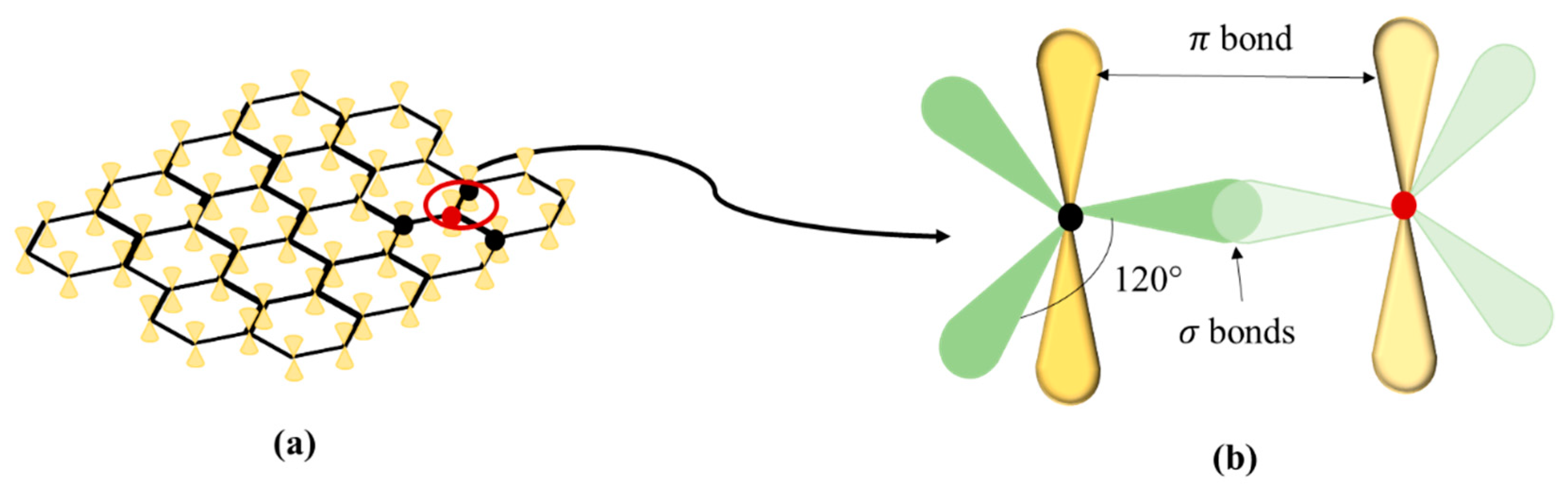

3.2. Structure of Graphene

3.3. Graphene Derivatives

4. How Graphene Slows down Photodegradation in Polymers

5. Discussion

6. Conclusions

Funding

Conflicts of Interest

References

- Claudé, B.; Gonon, L.; Verney, V.; Gardette, J. Consequences of photoageing on the durability of plastic glasses for automotive applications. Polym. Test. 2001, 20, 771–778. [Google Scholar] [CrossRef]

- Fondriest Environmental. Solar Radiation and Photosynethically Active Radiation. 2014. Available online: https://www.fondriest.com/environmental-measurements/parameters/weather/photosynthetically-active-radiation/ (accessed on 10 November 2020).

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene. SpringerPlus 2013, 2, 398. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, R.R. Photostabilization of Polymers. J. Polym. Polym. Compos. A Ref. Ser. 2015, 1–10. [Google Scholar]

- Kumar, A.P.; Depan, D.; Tomer, N.S.; Singh, R.P. Nanoscale particles for polymer degradation and stabilization—trends and future perspectives. Prog. Polym. Sci. 2009, 34, 479–515. [Google Scholar] [CrossRef]

- Tipton, D.A.; Lewis, J.W. Effects of a hindered amine light stabilizer and a UV light absorber used in maxillofacial elastomers on human gingival epithelial cells and fibroblasts. J. Prosthet. Dent. 2008, 100, 220–231. [Google Scholar] [CrossRef]

- Chaudhuri, I.; Fruijtier-Pölloth, C.; Ngiewih, Y.; Levy, L. Evaluating the evidence on genotoxicity and reproductive toxicity of carbon black: A critical review. Crit. Rev. Toxicol. 2018, 48, 143–169. [Google Scholar] [CrossRef]

- chemBlink. Material Safety Data Sheet (MSDS) of Chimassorb 944. 2017. Available online: https://www.chemblink.com/MSDS/MSDSFiles/71878-19-8_Matrix.pdf (accessed on 10 November 2020).

- Additives for Polymers. Material Safety Data Sheet (MSDS) of Light Stabilizer Tinuvin 292. Available online: https://www.additivesforpolymer.com/portfolio/hals-292/ (accessed on 10 November 2020).

- Afirm-Group. UV Absorbers/Stabilizer. 2019. Available online: https://www.afirm-group.com/wp-content/uploads/2019/09/afirm_uv_absorbers_stabilizers_v1.pdf (accessed on 10 November 2020).

- European Chemicals Agency. Candidate List of Substances of Very High Concern for Authorisation. 2020. Available online: https://echa.europa.eu/candidate-list-table (accessed on 10 November 2020).

- IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. Carbon Black, Titanium Dioxide, and Talc. IARC Monogr. Eval. Carcinog. Risks Hum. 2010, 93, 1–413. [Google Scholar]

- Kolanthai, E.; Bose, S.; Bhagyashree, K.; Bhat, S.; Asokan, K.; Kanjilal, D.; Chatterjee, K. Graphene scavenges free radicals to synergistically enhance structural properties in a gamma-irradiated polyethylene composite through enhanced interfacial interactions. Phys. Chem. Chem. Phys. 2015, 17, 22900–22910. [Google Scholar] [CrossRef]

- Hasani, M.; Mahdavian, M.; Yari, H.; Ramezanzadeh, B. Versatile protection of exterior coatings by the aid of graphene oxide nano-sheets; comparison with conventional UV absorbers. Prog. Org. Coat. 2018, 116, 90–101. [Google Scholar] [CrossRef]

- Soldano, C.; Mahmood, A.; Dujardin, E. Production, properties and potential of graphene. Carbon 2010, 48, 2127–2150. [Google Scholar] [CrossRef]

- Helal, E.; Kurusu, R.S.; Moghimian, N.; Gutierrez, G.; David, E.; Demarquette, N.R. Correlation between morphology, rheological behavior, and electrical behavior of conductive cocontinuous LLDPE/EVA blends containing commercial graphene nanoplatelets. J. Rheol. 2019, 63, 961–976. [Google Scholar] [CrossRef]

- Batista, N.L.; Helal, E.; Kurusu, R.S.; Moghimian, N.; David, E.; Demarquette, N.R.; Hubert, P. Mass-produced graphene—HDPE nanocomposites: Thermal, rheological, electrical, and mechanical properties. Polym. Eng. Sci. 2019, 59, 675–682. [Google Scholar] [CrossRef]

- Serenari, F.; Madinehei, M.; Moghimian, N.; Fabiani, D.; David, E. Development of Reinforced Polyester/Graphene Nanocomposite Showing Tailored Electrical Conductivity. Polymers 2020, 12, 2358. [Google Scholar] [CrossRef]

- Contributors, W. 2020. Available online: https://en.wikipedia.org/w/index.php?title=History_of_graphene&oldid=956897282 (accessed on 10 November 2020).

- Bae, S.; Kim, S.J.; Shin, D.; Ahn, J.-H.; Hong, B.H. Towards industrial applications of graphene electrodes. Phys. Scr. 2012, 2012, 014024. [Google Scholar] [CrossRef]

- Fu, Y.; Wei, Q.; Zhang, G.; Zhong, Y.; Moghimian, N.; Tong, X.; Sun, S. LiFePO4-graphene composites as high-performance cathodes for lithium-ion batteries: The impact of size and morphology of graphene. Materials 2019, 12, 842. [Google Scholar] [CrossRef] [PubMed]

- Reiss, T.; Hjelt, K.; Ferrari, A. Graphene is on track to deliver on its promises. Nat. Nanotechnol. 2019, 14, 907–910. [Google Scholar] [CrossRef] [PubMed]

- Moghimian, N.; Nazarpour, S. The Future of Carbon: An Update on Graphene’s Dermal, Inhalation, and Gene Toxicity. Crystals 2020, 10, 718. [Google Scholar] [CrossRef]

- Sanchez, V.C.; Jachak, A.; Hurt, R.H.; Kane, A.B. Biological interactions of graphene-family nanomaterials: An interdisciplinary review. Chem. Res. Toxicol. 2012, 25, 15–34. [Google Scholar] [CrossRef]

- Fadeel, B.; Bussy, C.; Merino, S.; Vázquez, E.; Flahaut, E.; Mouchet, F.; Evariste, L.; Gauthier, L.; Koivisto, A.J.; Vogel, U. Safety assessment of graphene-based materials: Focus on human health and the environment. ACS Nano 2018, 12, 10582–10620. [Google Scholar] [CrossRef]

- Tsai, P.-J.; Shieh, H.-Y.; Hsieh, L.-T.; Lee, W.-J. The fate of PAHs in the carbon black manufacturing process. Atmos. Environ. 2001, 35, 3495–3501. [Google Scholar] [CrossRef]

- Nanoxplore. Sustainability. Available online: https://www.nanoxplore.ca/sustainability/ (accessed on 10 November 2020).

- Rabek, J.F. Polymer Photodegradation: Mechanisms and Experimental Methods; Chapman & Hall: London, UK, 1995. [Google Scholar]

- Bateman, L.; Gee, G. A kinetic investigation of the photochemical oxidation of certain non-conjugated olefins. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1948, 195, 376–391. [Google Scholar]

- Yousif, E.; Hasan, A. Photostabilization of poly (vinyl chloride)–Still on the run. J. Taibah Univ. Sci. 2015, 9, 421–448. [Google Scholar] [CrossRef]

- Rånby, B. Photodegradation and photo-oxidation of synthetic polymers. J. Anal. Appl. Pyrolysis 1989, 15, 237–247. [Google Scholar] [CrossRef]

- Kamweru, P.K.; Ndiritu, F.G.; Kinyanjui, T.; Muthui, Z.W.; Ngumbu, R.G.; Odhiambo, P.M. UV absorption and dynamic mechanical analysis of polyethylene films. Int. J. Phys. Sci. 2014, 9, 545–555. [Google Scholar]

- Photochemistry1. Photodegradation and Stabilization of Polymers. Available online: https://www.epfl.ch/labs/gdp/wp-content/uploads/2019/09/PC1_Lesson_11.pdf (accessed on 10 November 2020).

- Li, T.; Zhou, C.; Jiang, M. UV absorption spectra of polystyrene. Polym. Bull. 1991, 25, 211–216. [Google Scholar] [CrossRef]

- Hasan, M.; Kumar, R.; Barakat, M.; Lee, M. Synthesis of PVC/CNT nanocomposite fibers using a simple deposition technique for the application of Alizarin Red S (ARS) removal. RSC Adv. 2015, 5, 14393–14399. [Google Scholar] [CrossRef]

- Das, S.; Ghosh, T.; Satpati, B.; Sanyal, A.; Bala, T. Keggin-lysine hybrid nanostructures in the shape modulation of gold. Mater. Res. Express 2014, 1, 015007. [Google Scholar] [CrossRef]

- Durmus, H.; Safak, H.; Akbas, H.Z.; Ahmetli, G. Optical properties of modified epoxy resin with various oxime derivatives in the UV-VIS spectral region. J. Appl. Polym. Sci. 2011, 120, 1490–1495. [Google Scholar] [CrossRef]

- Ouchi, I.; Miyamura, R.; Sakaguchi, M.; Hosaka, S.; Kitagawa, M. Excitation and emission spectra of polyethylene terephthalate and polyethylene 2,6-naphthalate films. Polym. Adv. Technol. 1999, 10, 195–198. [Google Scholar] [CrossRef]

- Allen, N.S.; Parkinson, A. Ultraviolet derivative absorption spectra of nylon 6, 6: Effect of photolysis versus photo-induced oxidation. Polym. Degrad. Stab. 1982, 4, 239–244. [Google Scholar] [CrossRef]

- Shamey, R.; Sinha, K. A review of degradation of nylon 6. 6 as a result of exposure to environmental conditions. Rev. Prog. Coloration Relat. Top. 2003, 33, 93–107. [Google Scholar]

- Wiles, D.; Carlsson, D. Photostabilisation mechanisms in polymers: A review. Polym. Degrad. Stab. 1980, 3, 61–72. [Google Scholar] [CrossRef]

- Allen, N.S.; Edge, M.; Ortega, A.; Sandoval, G.; Liauw, C.M.; Verran, J.; Stratton, J.; McIntyre, R.B. Degradation and stabilisation of polymers and coatings: Nano versus pigmentary titania particles. Polym. Degrad. Stab. 2004, 85, 927–946. [Google Scholar] [CrossRef]

- Nikafshar, S.; Zabihi, O.; Ahmadi, M.; Mirmohseni, A.; Taseidifar, M.; Naebe, M. The effects of UV light on the chemical and mechanical properties of a transparent epoxy-diamine system in the presence of an organic UV absorber. Materials 2017, 10, 180. [Google Scholar] [CrossRef] [PubMed]

- Pascal Xanthopoulos. Light Stabilizers/UV Absorbers for Polymers. 2019. Available online: https://polymer-additives.specialchem.com/selection-guide/light-uv-stabilizers-selection-for-polymers (accessed on 10 November 2020).

- Ashton, H. Radiation and other weather factors. In Canadian Building Digests 101–150; National Research Council of Canada: Ottawa, ON, Canada, 1970; p. 4. [Google Scholar]

- Alotaibi, M.; McKinley, A.; Patterson, B.; Reeder, A. Benzotriazoles in the aquatic environment: A review of their occurrence, toxicity, degradation and analysis. Water Air Soil Pollut. 2015, 226, 226. [Google Scholar] [CrossRef]

- Asimakopoulos, A.G.; Ajibola, A.; Kannan, K.; Thomaidis, N.S. Occurrence and removal efficiencies of benzotriazoles and benzothiazoles in a wastewater treatment plant in Greece. Sci. Total Environ. 2013, 452, 163–171. [Google Scholar] [CrossRef]

- Kusk, K.O.; Avdolli, M.; Wollenberger, L. Effect of 2,4-dihydroxybenzophenone (BP1) on early life-stage development of the marine copepod Acartia tonsa at different temperatures and salinities. Environ. Toxicol. Chem. 2011, 30, 959–966. [Google Scholar] [CrossRef]

- Han, D.; Meng, Z.; Wu, D.; Zhang, C.; Zhu, H. Thermal properties of carbon black aqueous nanofluids for solar absorption. Nanoscale Res. Lett. 2011, 6, 1–7. [Google Scholar] [CrossRef]

- Padrón, A.J.C. Mechanistic aspects of polymer photostabilization. J. Photochem. Photobiol. A Chem. 1989, 49, 1–39. [Google Scholar] [CrossRef]

- Kockler, J.; Oelgemöller, M.; Robertson, S.; Glass, B.D. Influence of titanium dioxide particle size on the photostability of the chemical UV-filters butyl methoxy dibenzoylmethane and octocrylene in a microemulsion. Cosmetics 2014, 1, 128–139. [Google Scholar] [CrossRef]

- Smijs, T.G.; Pavel, S. Titanium dioxide and zinc oxide nanoparticles in sunscreens: Focus on their safety and effectiveness. Nanotechnol. Sci. Appl. 2011, 4, 95. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Bary, E.M. Handbook of Plastic Films; iSmithers Rapra Publishing: Shrewsbury, UK, 2003. [Google Scholar]

- Hande Gürse. What Is the Difference Between Graphene Oxide and Reduced Graphene Oxide. 2020. Available online: https://nanografi.com/blog/what-is-the-difference-between-graphene-oxide-and-reduced-graphene-oxide/ (accessed on 10 November 2020).

- Zweifel, H. Stabilization of polymeric materials. Ann. de Chim. Sci. des Mater. 1999, 4, 401. [Google Scholar] [CrossRef]

- Horrocks, A.R.; Liu, M. UV stabilising synergies between carbon black and hindered light stabilisers in linear low density polyethylene films. Macromol. Symp. 2003, 202, 199–220. [Google Scholar] [CrossRef]

- Horrocks, A.; Mwila, J.; Miraftab, M.; Liu, M.; Chohan, S. The influence of carbon black on properties of orientated polypropylene 2. Thermal and photodegradation. Polym. Degrad. Stab. 1999, 65, 25–36. [Google Scholar] [CrossRef]

- Javadi, Y.; Hosseini, M.S.; Aghjeh, M.K.R. The effect of carbon black and HALS hybrid systems on the UV stability of high-density polyethylene (HDPE). Iran. Polym. J. 2014, 23, 793–799. [Google Scholar] [CrossRef]

- Liu, M.; Horrocks, A. Effect of carbon black on UV stability of LLDPE films under artificial weathering conditions. Polym. Degrad. Stab. 2002, 75, 485–499. [Google Scholar] [CrossRef]

- Bigger, S.W.; Delatycki, O. The effects of pigments on the photostability of polyethylene. J. Mater. Sci. 1989, 24, 1946–1952. [Google Scholar] [CrossRef]

- Peña, J.; Allen, N.; Edge, M.; Liauw, C.; Roberts, I.; Valange, B. Triplet quenching and antioxidant effect of several carbon black grades in the photodegradation of LDPE doped with benzophenone as a photosensitiser. Polym. Degrad. Stab. 2000, 70, 437–454. [Google Scholar] [CrossRef]

- Ghasemi-Kahrizsangi, A.; Neshati, J.; Shariatpanahi, H.; Akbarinezhad, E. Improving the UV degradation resistance of epoxy coatings using modified carbon black nanoparticles. Prog. Org. Coat. 2015, 85, 199–207. [Google Scholar] [CrossRef]

- Najafi, E.; Shin, K. Radiation resistant polymer–carbon nanotube nanocomposite thin films. Colloids Surf. A Physicochem. Eng. Asp. 2005, 257, 333–337. [Google Scholar] [CrossRef]

- Morlat-Therias, S.; Fanton, E.; Gardette, J.-L.; Peeterbroeck, S.; Alexandre, M.; Dubois, P. Polymer/carbon nanotube nanocomposites: Influence of carbon nanotubes on EVA photodegradation. Polym. Degrad. Stab. 2007, 92, 1873–1882. [Google Scholar] [CrossRef]

- Martínez, A.; Galano, A. Free radical scavenging activity of ultrashort single-walled carbon nanotubes with different structures through electron transfer reactions. J. Phys. Chem. C 2010, 114, 8184–8191. [Google Scholar] [CrossRef]

- Mistretta, M.; Botta, L.; Vinci, A.; Ceraulo, M.; La Mantia, F. Photo-oxidation of polypropylene/graphene nanoplatelets composites. Polym. Degrad. Stab. 2019, 160, 35–43. [Google Scholar] [CrossRef]

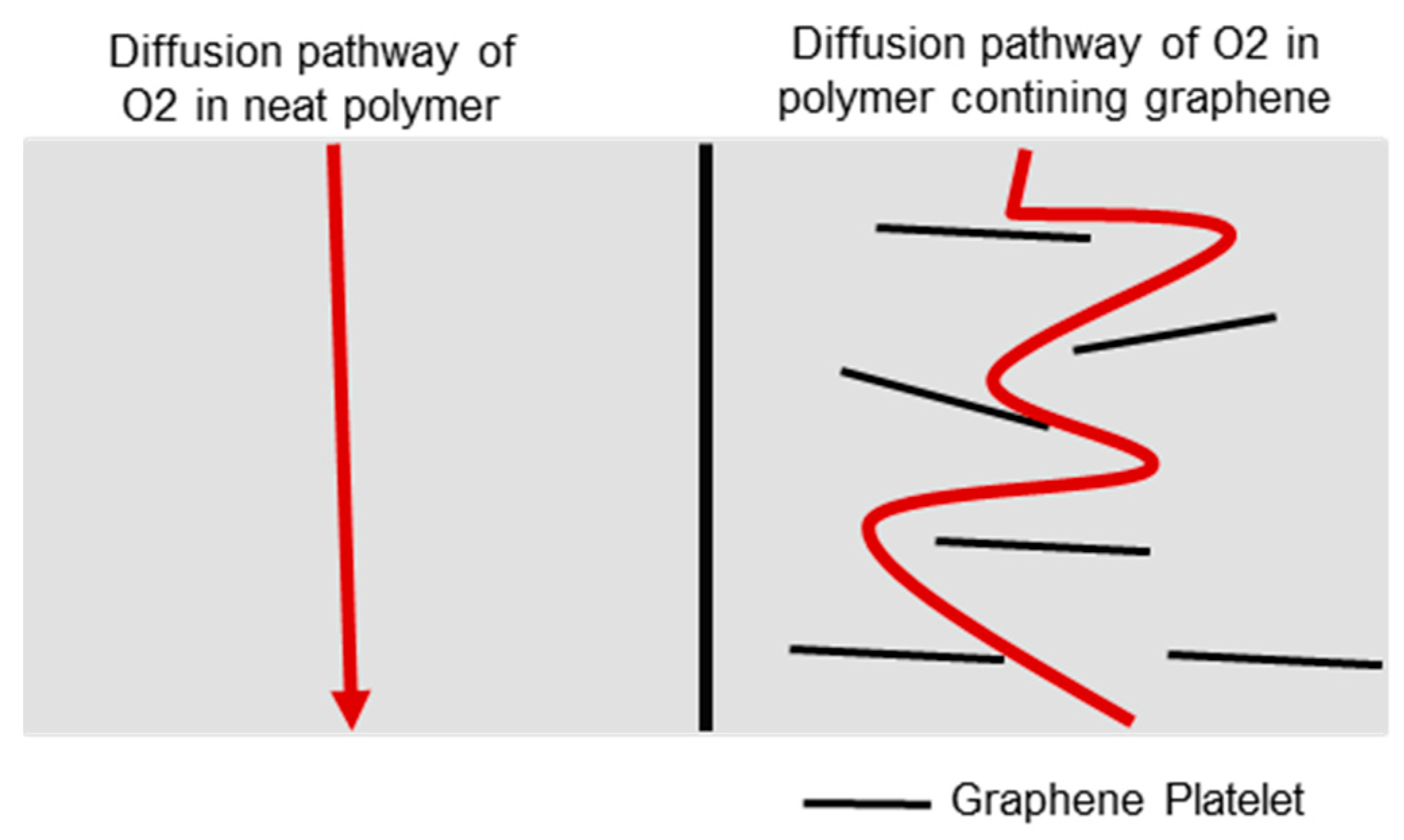

- Yoo, B.M.; Shin, H.J.; Yoon, H.W.; Park, H.B. Graphene and graphene oxide and their uses in barrier polymers. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Allen, M.J.; Tung, V.C.; Kaner, R.B. Honeycomb carbon: A review of graphene. Chem. Rev. 2010, 110, 132–145. [Google Scholar] [CrossRef] [PubMed]

- Terrones, M.; Martín, O.; González, M.; Pozuelo, J.; Serrano, B.; Cabanelas, J.C.; Vega-Díaz, S.M.; Baselga, J. Interphases in graphene polymer-based nanocomposites: Achievements and challenges. Adv. Mater. 2011, 23, 5302–5310. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Fan, X.; Wang, L. Graphene with outstanding anti-irradiation capacity as multialkylated cyclopentanes additive toward space application. Sci. Rep. 2015, 5, 12734. [Google Scholar] [CrossRef]

- Chowdhury, I.; Hou, W.-C.; Goodwin, D.; Henderson, M.; Zepp, R.G.; Bouchard, D. Sunlight affects aggregation and deposition of graphene oxide in the aquatic environment. Water Res. 2015, 78, 37–46. [Google Scholar] [CrossRef]

- Moghimian, N.; Saeidlou, S.; Lentzakis, H.; Rosi, G.F.; Song, N.; David, É. Electrical conductivity of commercial graphene polyethylene nanocomposites. In Proceedings of the 2017 IEEE 17th International Conference on Nanotechnology (IEEE-NANO), Pittsburgh, PA, USA, 25–27 July 2017; pp. 757–761. [Google Scholar]

- Mak, K.F.; Ju, L.; Wang, F.; Heinz, T.F. Optical spectroscopy of graphene: From the far infrared to the ultraviolet. Solid State Commun. 2012, 152, 1341–1349. [Google Scholar] [CrossRef]

- Dash, G.; Pattanaik, S.R.; Behera, S. Graphene for electron devices: The panorama of a decade. IEEE J. Electron Devices Soc. 2014, 2, 77–104. [Google Scholar] [CrossRef]

- Shams, M.; Guiney, L.M.; Huang, L.; Ramesh, M.; Yang, X.; Hersam, M.C.; Chowdhury, I. Influence of functional groups on the degradation of graphene oxide nanomaterials. Environ. Sci. Nano 2019, 6, 2203–2214. [Google Scholar] [CrossRef]

- Du, T.; Adeleye, A.S.; Zhang, T.; Jiang, C.; Zhang, M.; Wang, H.; Li, Y.; Keller, A.A.; Chen, W. Influence of light wavelength on the photoactivity, physicochemical transformation, and fate of graphene oxide in aqueous media. Environ. Sci. Nano 2018, 5, 2590–2603. [Google Scholar] [CrossRef]

- Tarcan, R.; Todor-Boer, O.; Petrovai, I.; Leordean, C.; Astilean, S.; Botiz, I. Reduced graphene oxide today. J. Mater. Chem. C 2020, 8, 1198–1224. [Google Scholar] [CrossRef]

- de Moraes, A.C.M.; Andrade, P.F.; de Faria, A.F.; Simões, M.B.; Salomão, F.C.C.S.; Barros, E.B.; do Carmo Gonçalves, M.; Alves, O.L. Fabrication of transparent and ultraviolet shielding composite films based on graphene oxide and cellulose acetate. Carbohydr. Polym. 2015, 123, 217–227. [Google Scholar] [CrossRef]

- Johra, F.T.; Lee, J.-W.; Jung, W.-G. Facile and safe graphene preparation on solution based platform. J. Ind. Eng. Chem. 2014, 20, 2883–2887. [Google Scholar] [CrossRef]

- Demchenko, A.P. Excitons in Carbonic Nanostructures. C J. Carbon Res. 2019, 5, 71. [Google Scholar] [CrossRef]

- de Oliveira, Y.D.; Amurin, L.G.; Valim, F.C.; Fechine, G.J.; Andrade, R.J. The role of physical structure and morphology on the photodegradation behaviour of polypropylene-graphene oxide nanocomposites. Polymer 2019, 176, 146–158. [Google Scholar] [CrossRef]

- Qu, L.; Tian, M.; Hu, X.; Wang, Y.; Zhu, S.; Guo, X.; Han, G.; Zhang, X.; Sun, K.; Tang, X. Functionalization of cotton fabric at low graphene nanoplate content for ultrastrong ultraviolet blocking. Carbon 2014, 80, 565–574. [Google Scholar] [CrossRef]

- Prosheva, M.; Aboudzadeh, M.A.; Leal, G.P.; Gilev, J.B.; Tomovska, R. High-Performance UV Protective Waterborne Polymer Coatings Based on Hybrid Graphene/Carbon Nanotube Radicals Scavenging Filler. Part. Part. Syst. Charact. 2019, 36, 1800555. [Google Scholar] [CrossRef]

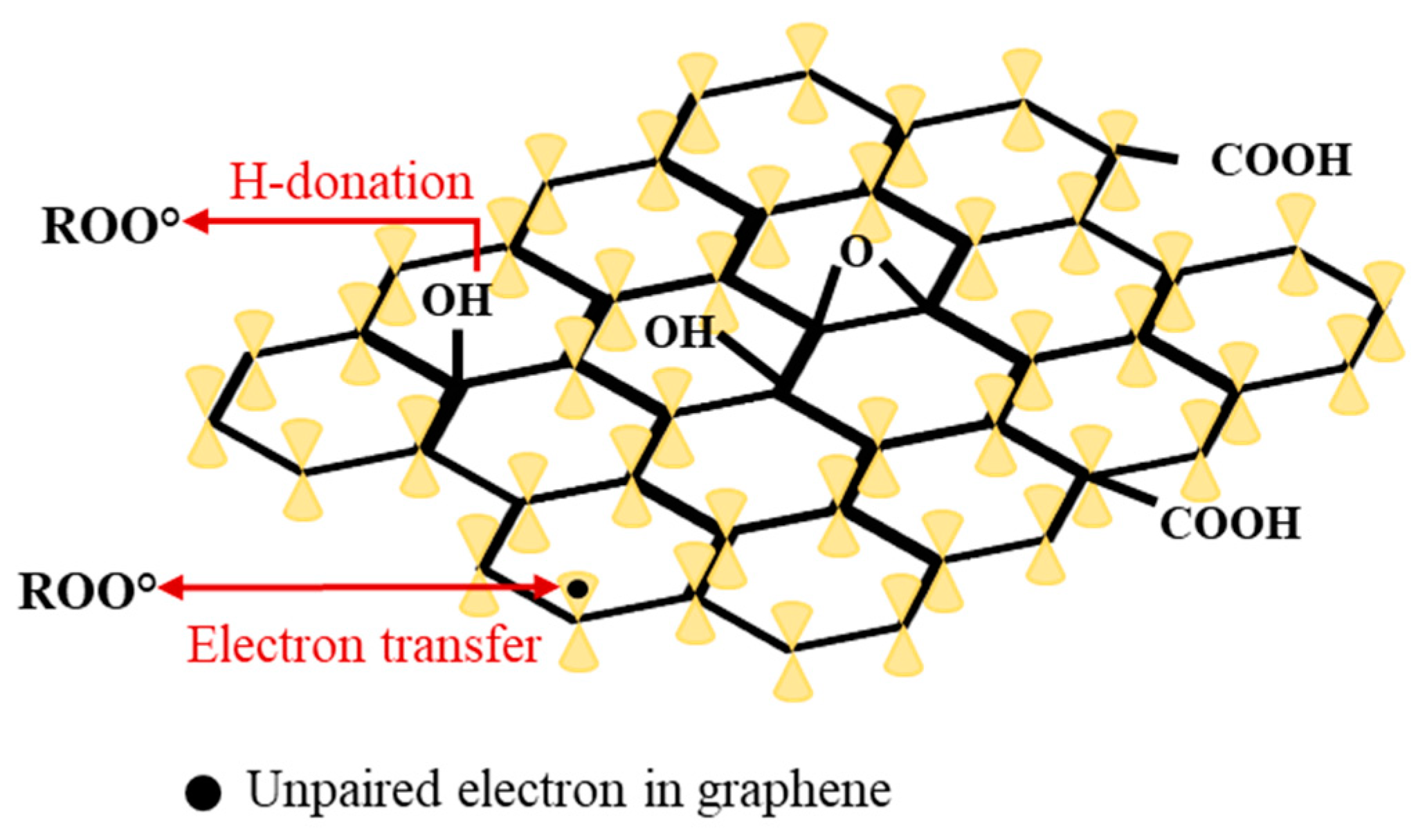

- Qiu, Y.; Wang, Z.; Owens, A.C.; Kulaots, I.; Chen, Y.; Kane, A.B.; Hurt, R.H. Antioxidant chemistry of graphene-based materials and its role in oxidation protection technology. Nanoscale 2014, 6, 11744–11755. [Google Scholar] [CrossRef] [PubMed]

- Ran, C.; Wang, M.; Gao, W.; Ding, J.; Shi, Y.; Song, X.; Chen, H.; Ren, Z. Study on photoluminescence quenching and photostability enhancement of MEH-PPV by reduced graphene oxide. J. Phys. Chem. C 2012, 116, 23053–23060. [Google Scholar] [CrossRef]

- Cui, Y.; Kundalwal, S.; Kumar, S. Gas barrier performance of graphene/polymer nanocomposites. Carbon 2016, 98, 313–333. [Google Scholar] [CrossRef]

- Chang, K.-C.; Hsu, C.; Lu, H.; Ji, W.; Chang, C.; Li, W.; Chuang, T.; Yeh, J.; Liu, W.; Tsai, M. Advanced anticorrosive coatings prepared from electroactive polyimide/graphene nanocomposites with synergistic effects of redox catalytic capability and gas barrier properties. Express Polym. Lett. 2014, 8, 243–255. [Google Scholar] [CrossRef]

- Kalaitzidou, K.; Fukushima, H.; Drzal, L.T. Multifunctional polypropylene composites produced by incorporation of exfoliated graphite nanoplatelets. Carbon 2007, 45, 1446–1452. [Google Scholar] [CrossRef]

- Xue, Q.; Lv, C.; Shan, M.; Zhang, H.; Ling, C.; Zhou, X.; Jiao, Z. Glass transition temperature of functionalized graphene–polymer composites. Comput. Mater. Sci. 2013, 71, 66–71. [Google Scholar] [CrossRef]

- Mahendia, S.; Kandhol, G.; Deshpande, U.P.; Kumar, S. Determination of glass transition temperature of reduced graphene oxide-poly (vinyl alcohol) composites using temperature dependent Fourier transform infrared spectroscopy. J. Mol. Struct. 2016, 1111, 46–54. [Google Scholar] [CrossRef]

- Klonos, P.; Kripotou, S.; Kyritsis, A.; Papageorgiou, G.Z.; Bikiaris, D.; Gournis, D.; Pissis, P. Glass transition and segmental dynamics in poly (l-lactic acid)/graphene oxide nanocomposites. Thermochim. Acta 2015, 617, 44–53. [Google Scholar] [CrossRef]

- Lee, S.; Hong, J.Y.; Jang, J. The effect of graphene nanofiller on the crystallization behavior and mechanical properties of poly (vinyl alcohol). Polym. Int. 2013, 62, 901–908. [Google Scholar] [CrossRef]

- Zhao, S.; Chen, F.; Huang, Y.; Dong, J.-Y.; Han, C.C. Crystallization behaviors in the isotactic polypropylene/graphene composites. Polymer 2014, 55, 4125–4135. [Google Scholar] [CrossRef]

- Karimi, S.; Ghasemi, I.; Abbassi-Sourki, F. A study on the crystallization kinetics of PLLA in the presence of Graphene Oxide and PEG-grafted-Graphene Oxide: Effects on the nucleation and chain mobility. Compos. Part B Eng. 2019, 158, 302–310. [Google Scholar] [CrossRef]

- Zepp, R.; Ruggiero, E.; Acrey, B.; Davis, M.J.; Han, C.; Hsieh, H.-S.; Vilsmeier, K.; Wohlleben, W.; Sahle-Demessie, E. Fragmentation of polymer nanocomposites: Modulation by dry and wet weathering, fractionation, and nanomaterial filler. Environ. Sci. Nano 2020, 7, 1742–1752. [Google Scholar] [CrossRef]

- Goodwin, D.G., Jr.; Shen, S.-J.; Lyu, Y.; Lankone, R.; Barrios, A.C.; Kabir, S.; Perreault, F.; Wohlleben, W.; Nguyen, T.; Sung, L. Graphene/polymer nanocomposite degradation by ultraviolet light: The effects of graphene nanofillers and their potential for release. Polym. Degrad. Stab. 2020, 182, 109365. [Google Scholar] [CrossRef]

- Goodwin, D.G., Jr.; Lai, T.; Lyu, Y.; Lu, C.Y.; Campos, A.; Reipa, V.; Nguyen, T.; Sung, L. The impacts of moisture and ultraviolet light on the degradation of graphene oxide/polymer nanocomposites. NanoImpact 2020, 19, 100249. [Google Scholar] [CrossRef]

- Moon, Y.-E.; Yun, J.-M.; Kim, H.-I.; Lee, Y.-S. Effect of graphite oxide on photodegradation behavior of poly (vinyl alcohol)/graphite oxide composite hydrogels. Carbon Lett. 2011, 12, 138–142. [Google Scholar] [CrossRef]

- Bussière, P.-O.; Peyroux, J.; Chadeyron, G.; Therias, S. Influence of functional nanoparticles on the photostability of polymer materials: Recent progress and further applications. Polym. Degrad. Stab. 2013, 98, 2411–2418. [Google Scholar] [CrossRef]

- Frasca, D.; Schulze, D.; Wachtendorf, V.; Krafft, B.; Rybak, T.; Schartel, B. Multilayer graphene/carbon black/chlorine isobutyl isoprene rubber nanocomposites. Polymers 2016, 8, 95. [Google Scholar] [CrossRef]

- Nuraje, N.; Khan, S.I.; Misak, H.; Asmatulu, R. The addition of graphene to polymer coatings for improved weathering. ISRN Polym. Sci. 2013, 2013, 1–8. [Google Scholar] [CrossRef]

- Tian, M.; Wang, Z.; Qu, L.; Wang, K.; Zhu, S.; Zhang, X.; Liu, R. Enhanced UV photo-stabilization of Nylon 6 filament with reduced graphene oxide/polyurethane nanocomposite Inks. Int. J. Cloth. Sci. Technol. 2018, 30, 817–827. [Google Scholar] [CrossRef]

| Polymer | Groups Triggered by UV | Absorption Peak (nm) | Absorptivity to Solar Spectrum | Overall Photostability | Cause of Degradation |

|---|---|---|---|---|---|

| Poly(ethylene) | - | 300–310, 340 [32] | Low | High [28,33] | 1 |

| Poly(propylene) | - | 290–300, 330, 370 | Low | High [28,33] | 1 |

| Poly(styrene) |  | 290 [34] | Moderate | Moderate [33] | 2 |

| Poly(vinyl chloride) | - | 210 [35] | Low | Low [28,33] | 1 |

| Poly(methyl acrylates) | - | 700, 1030 [36] | Low | High [33] | 1 |

| Epoxy resins |  | 240–300 [37] | High | Moderate [33] | 2 |

| Poly(ethylene terephthalate) |  | 240,300 [38] | High | Low [33] | 2 |

| Nylon 6,6 |  | 290 [39,40] | High | Moderate [33] | 2 |

| Type | Example | Role |

|---|---|---|

| Pigments | TiO2 ZnO Fe2O3 Cr2O3 | UV screener UV absorber |

| Phenolic and nonphenolic UV absorbers | Hydroxyphenyl benzoate Hydroxyphenyl benzotriazoles | UV absorber |

| Hindered amine light stabilizer | Derivatives of Tetramethylpiperidine | Radical scavenger Quencher |

| Phenolic antioxidants | Calixarene | Radical scavenger |

| Metal chelates | Nickel chelates | Quencher |

| Carbon-based materials | Carbon black CNT | UV absorber UV screener Radical scavenger |

| Matrix | Graphene Derivatives | Concentration (Wt%) | Process/Characterizations | UV Test Conditions | Assessment of Photostabilization | Ref. |

|---|---|---|---|---|---|---|

| PP | Graphene nanoplatelets | 0.5 1 2 | Twin-screw extruder Rheology Mechanical ATR-FTIR | Device: Q-UV chamber Wavelength: UV-B region Exposure period: 144 h Cycle: 8 h of light at T = 50 °C followed by 4 h condensation at T = 40 °C and RH 40% ± 3. |

| [66] |

| PP | GO | 0.1 0.5 1 2 | Mini-lab extruder FTIR | Device: QUV chamber Intensity: 0.89 W/m2 Wavelength: UV-B region Exposure period: 4 weeks. Cycle: (a) 8 h exposure at T = 50 °C (b) 4 h cooling with DI water |

| [82] |

| Polyuretane (PU) | GO vs. organic UV absorber | 0.1 | Solution mixing Surface roughness Surface hardness Contact angle FTIR | Device: Weathering chamber Intensity: 0.71 W/m2 Wavelength: UV-A region Exposure period: 700 h Cycle: 8 h of UV radiation followed by 4 h humidity at T = 50 °C |

| [14] |

| PU | Graphene | 2 4 6 | Lay-up technique ATR-FTIR AFM Contact angle | Q-UV chamber Wavelength: UV-A Exposure period: 20 days Cycle: 12 h exposure to UV 12 h salt spray at T = 32 °C |

| [102] |

| Poly(vinyl alcohol)(PVA) | GO | 1 3 5 10 | Solution Calculating the amount of soluble gel | Device: mercury vapor lamp intensity:500, 1000, 1500, 2000 KJ/m2 Wavelength: 254 nm Temperature: room temperature Exposure period: not specified |

| [99] |

| Poly[2-methoxy-5-(2-ethylhexyloxy)-1,4-phenylenevinylene] (MEH-PPV) | rGO | 0.05, 0.1, 0.15, 0.2, 0.25, 0.3, 0.4, 0.5 | Solution UV absorption peak before and after exposure | Device: 365 nm UV lamp Intensity: 0.978 mW/cm2, Exposure period: 4, 8, 12, 16 h Temperature: room temperature |

| [86] |

| Cellulose Acetate (CA) | GO | 0.1 0.25 0.5 | Solution | Ultraviolet-visible (UV–vis) spectroscopy (200–800 nm) On an Agilent/VarianCary 50 UV–vis spectrophotometer. |

| [79] |

| PU | Graphene/CNT | 1 (different ratios) | Solution ATR-FTIR | Device: UV lamp Intensity:550 mW/cm2 Wavelength:366 nm Exposure period: 400 h T = 55 °C |

| [84] |

| Polyamide 6 filaments coated with PU | rGO | 1 2 4 | Solution Tensile strength | Device: UV lamp Power: 125 w Wavelength: 365 nm Exposure time: 4, 10, 20, 40, 60, 100 h |

| [103] |

| PU | GO | 0.4 1.2 | Solution ATR-FTIR | Device: weathering chamber Intensity: 140 W/m2 Wavelength: 295–400 nm Exposure period: ranging from 15 d–140 d Temperature: 55 °C Humidity: 0 and 75% |

| [98] |

| TPU | Graphene | 3 | Twin-screw extruder FTIR | Device: weathering chamber Intensity: 140 W/m2 Wavelength: 295–400 nm Exposure period: ranging from 0–60 d Temperature: 55 °C Humidity: 0 and 75% |

| [97] |

| Epoxy | Graphene | 1 | FTIR Contact angle | Device: weathering chamber Intensity: 60 W/m2 Wavelength: 300–400 nm Exposure period: 500, 1000, 2500 h Temperature: 65 °C Wet condition: 120 min cycles of simulated rainfall (102 min without water spraying and 18 min with water spraying) | ● Presence of graphene improve the stability of epoxy against UV | [96] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karimi, S.; Helal, E.; Gutierrez, G.; Moghimian, N.; Madinehei, M.; David, E.; Samara, M.; Demarquette, N. A Review on Graphene’s Light Stabilizing Effects for Reduced Photodegradation of Polymers. Crystals 2021, 11, 3. https://doi.org/10.3390/cryst11010003

Karimi S, Helal E, Gutierrez G, Moghimian N, Madinehei M, David E, Samara M, Demarquette N. A Review on Graphene’s Light Stabilizing Effects for Reduced Photodegradation of Polymers. Crystals. 2021; 11(1):3. https://doi.org/10.3390/cryst11010003

Chicago/Turabian StyleKarimi, Samira, Emna Helal, Giovanna Gutierrez, Nima Moghimian, Milad Madinehei, Eric David, Mazen Samara, and Nicole Demarquette. 2021. "A Review on Graphene’s Light Stabilizing Effects for Reduced Photodegradation of Polymers" Crystals 11, no. 1: 3. https://doi.org/10.3390/cryst11010003

APA StyleKarimi, S., Helal, E., Gutierrez, G., Moghimian, N., Madinehei, M., David, E., Samara, M., & Demarquette, N. (2021). A Review on Graphene’s Light Stabilizing Effects for Reduced Photodegradation of Polymers. Crystals, 11(1), 3. https://doi.org/10.3390/cryst11010003