Effect of Transition Metals Oxides on the Physical and Mechanical Properties of Sintered Tungsten Heavy Alloys

Abstract

1. Introduction

2. Planning of Experiments

2.1. Selection of Orthogonal Array

2.2. Executing Experimental Work

3. Results and Discussion

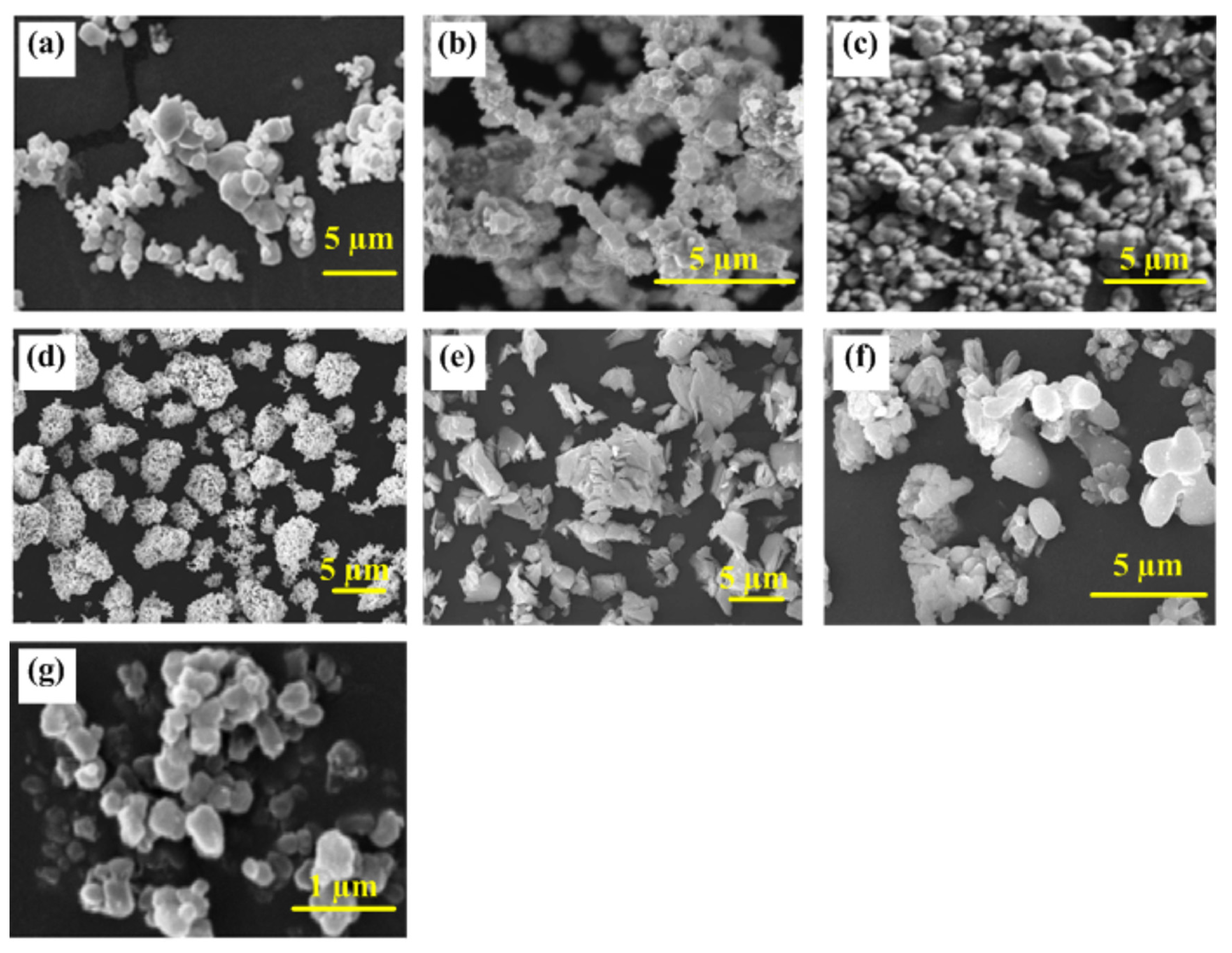

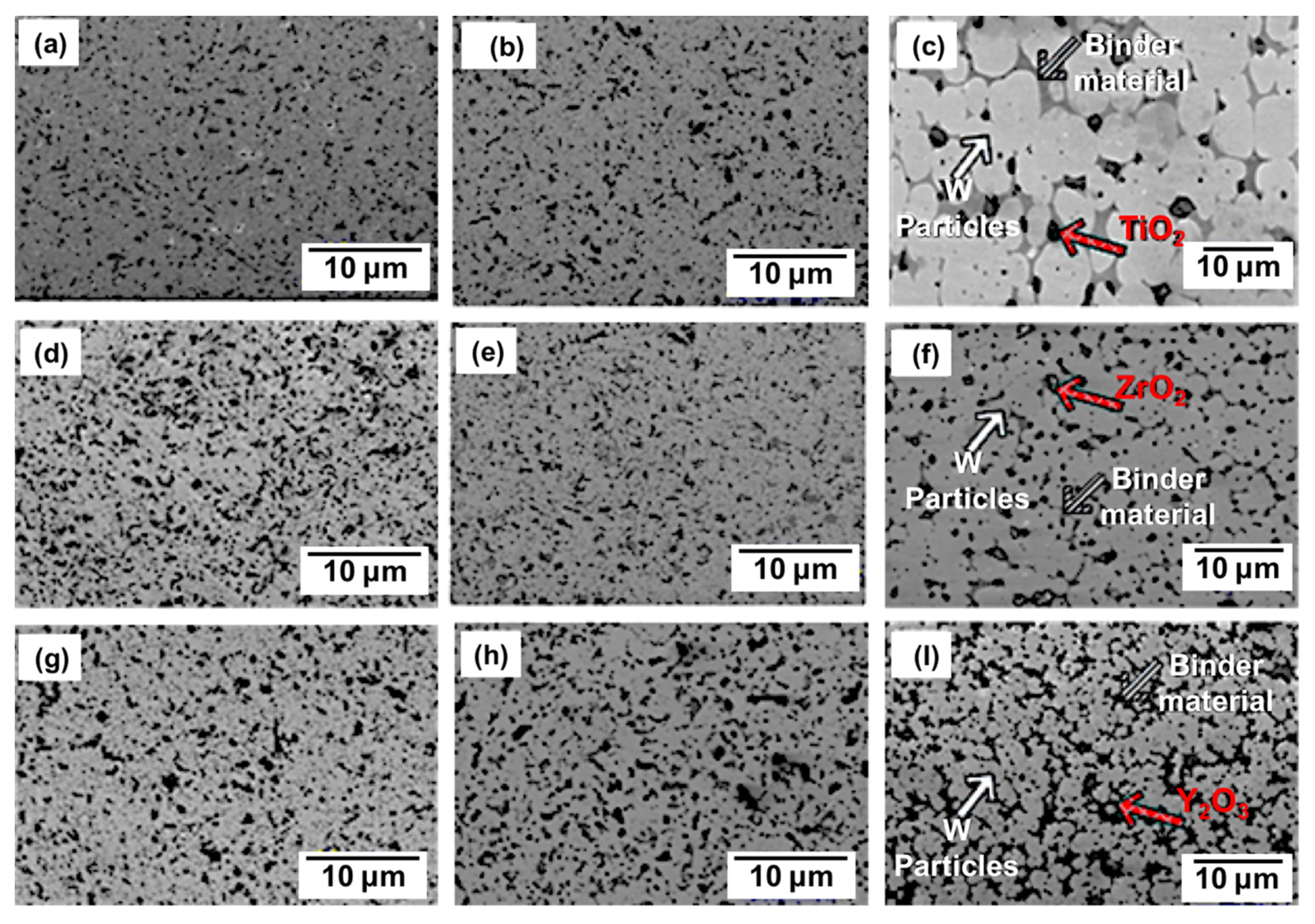

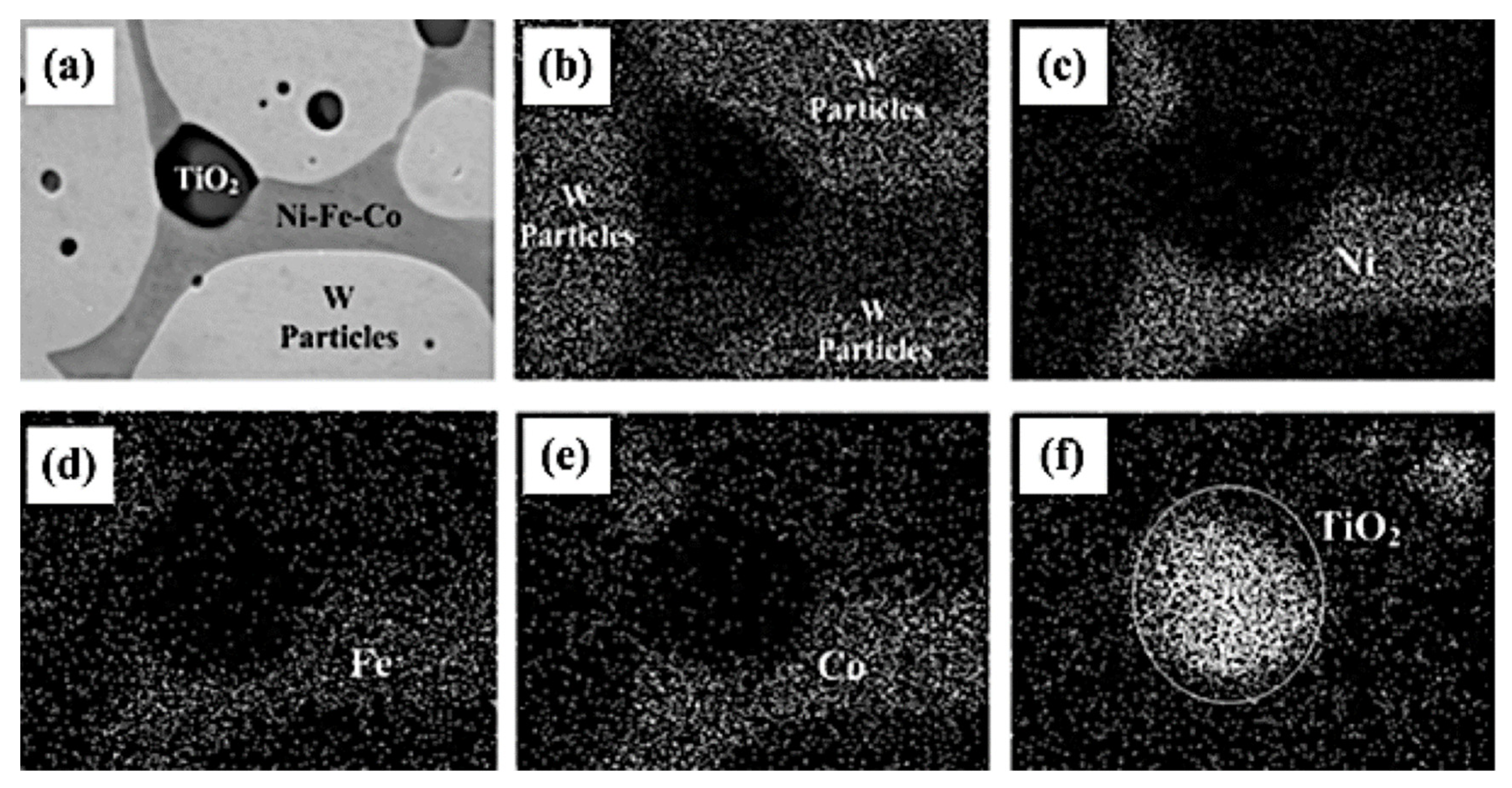

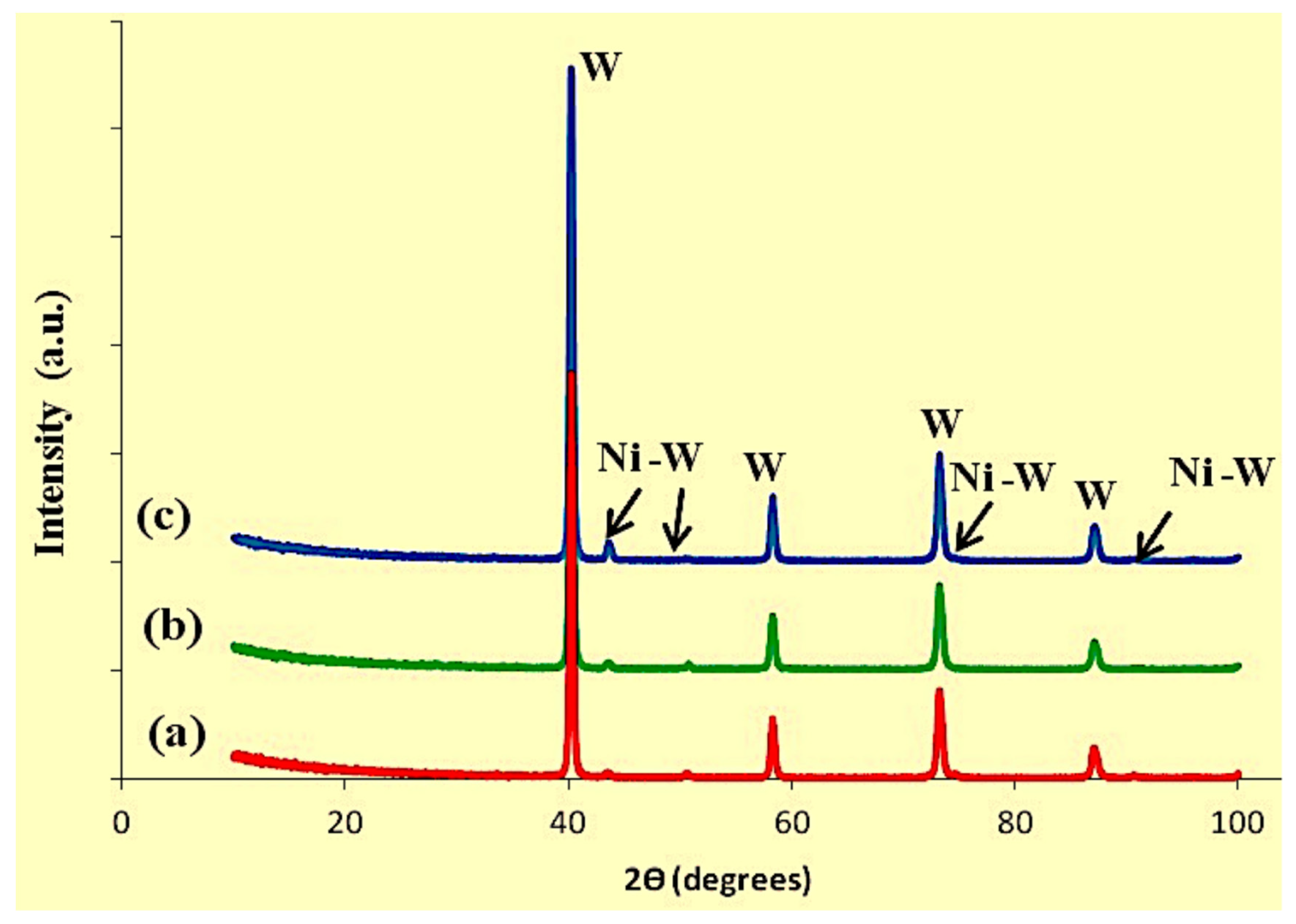

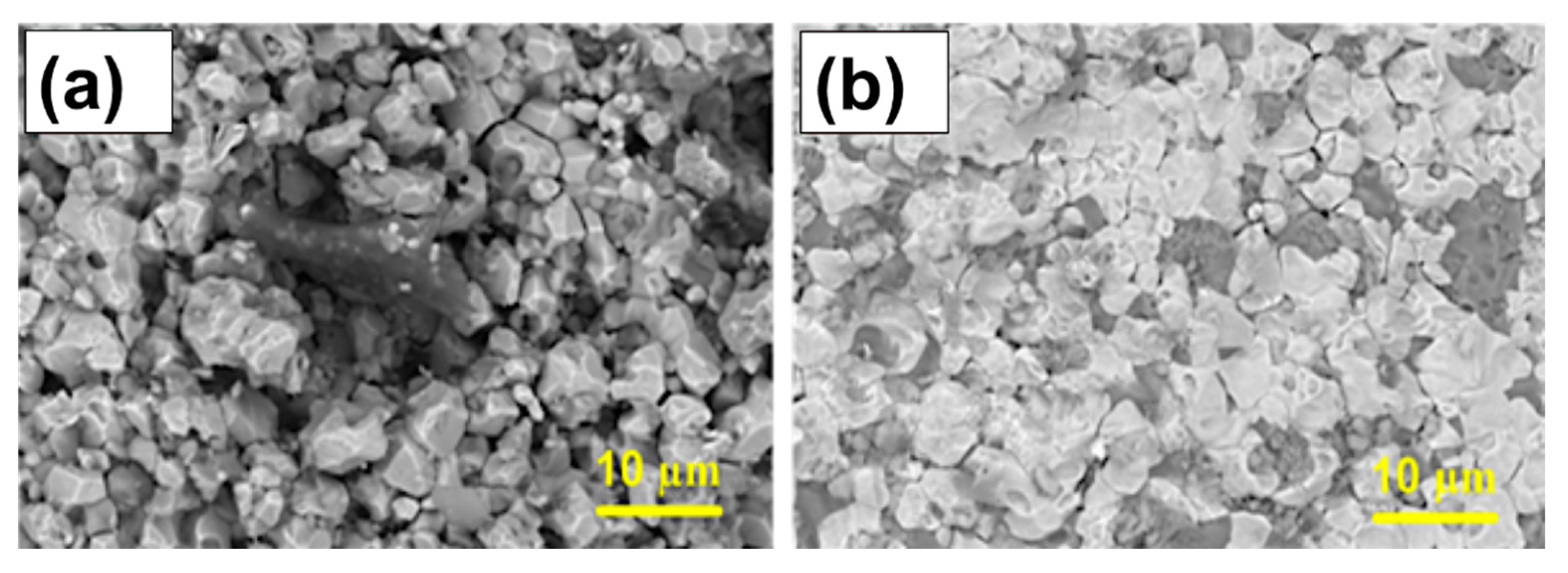

3.1. Microstructure Investigation

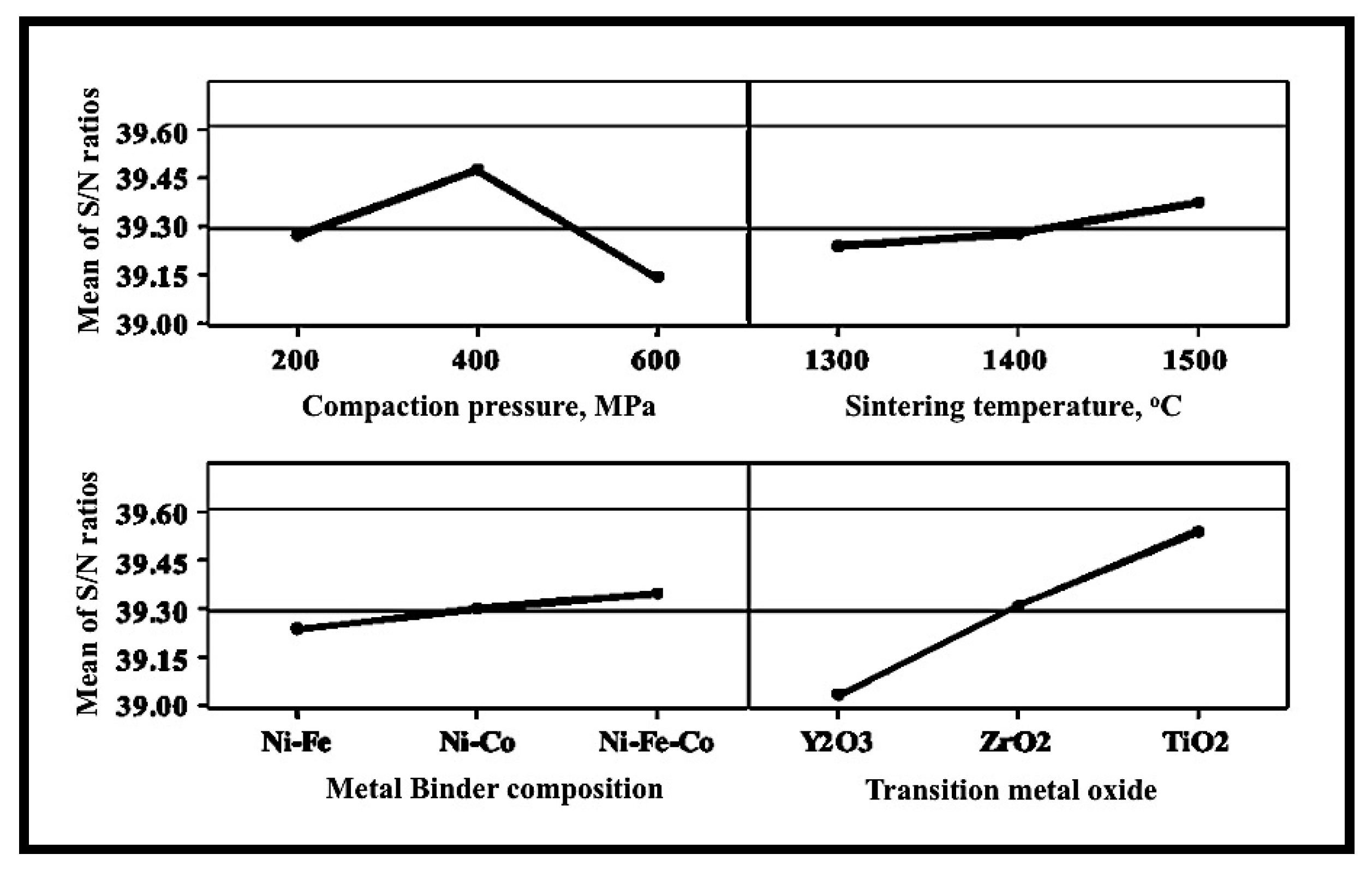

3.2. Physical Properties Analysis Using Taguchi Method

3.2.1. Sintered Densities of Investigated Samples

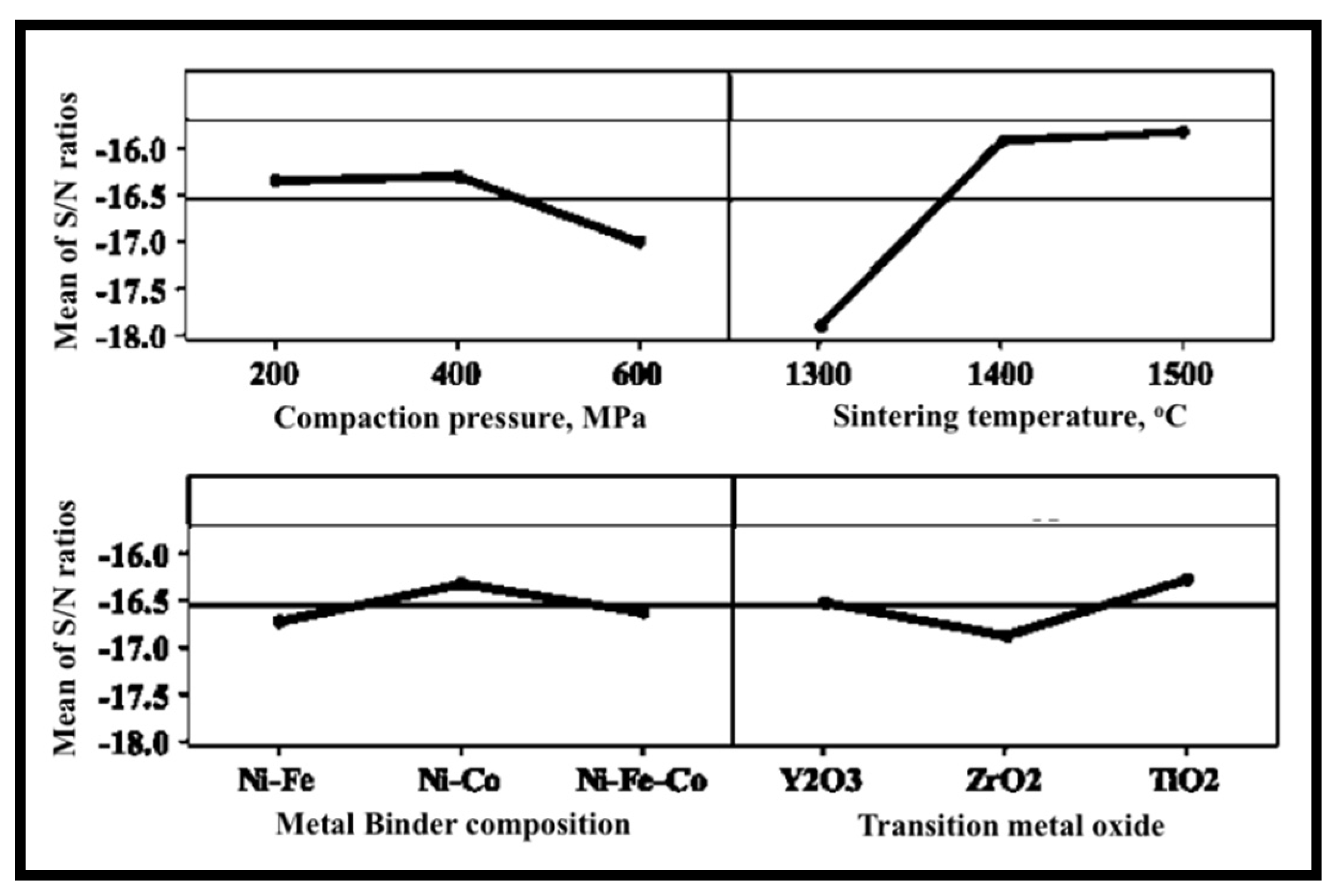

3.2.2. Electrical Conductivities of ODS Tungsten Heavy Alloys

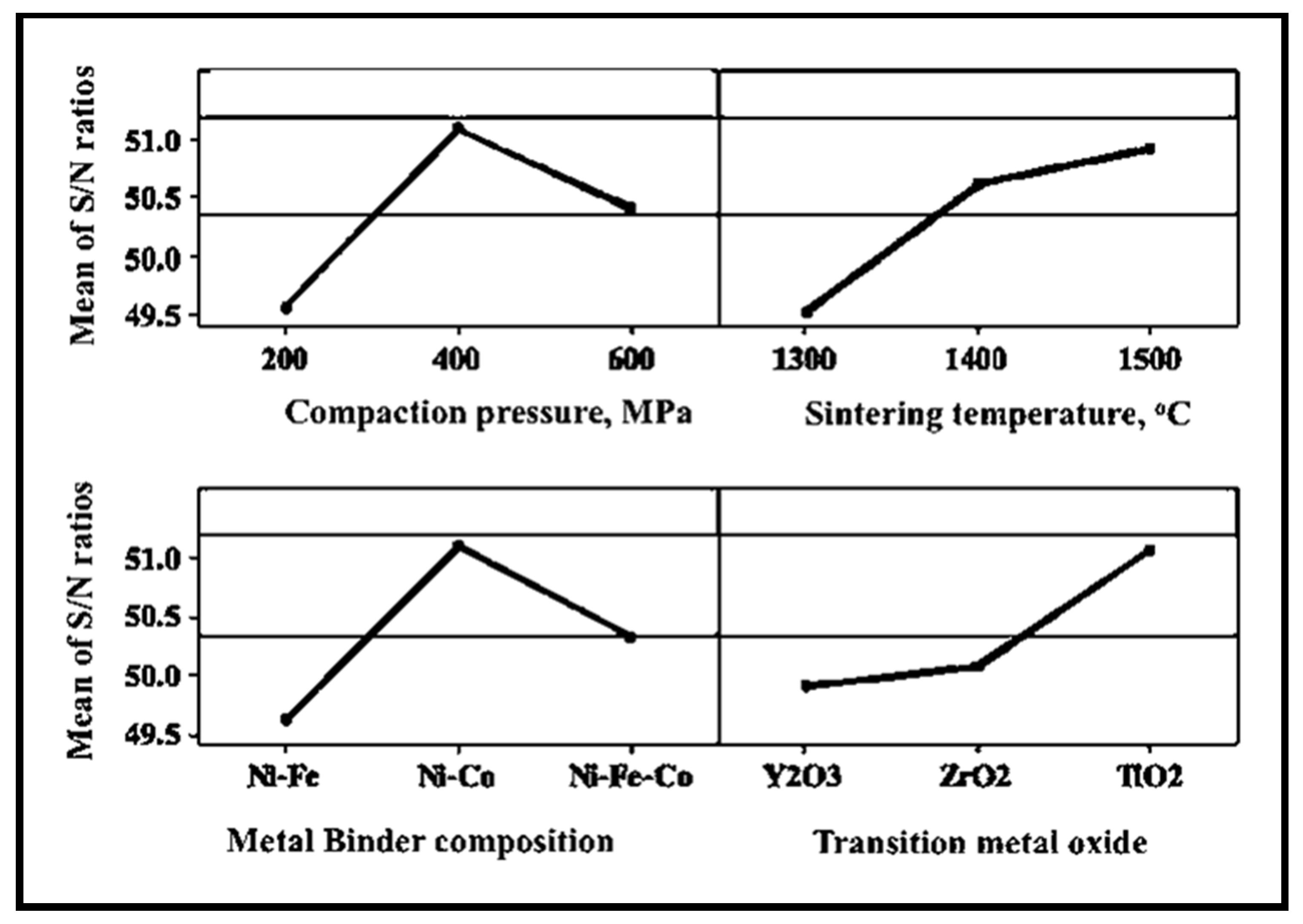

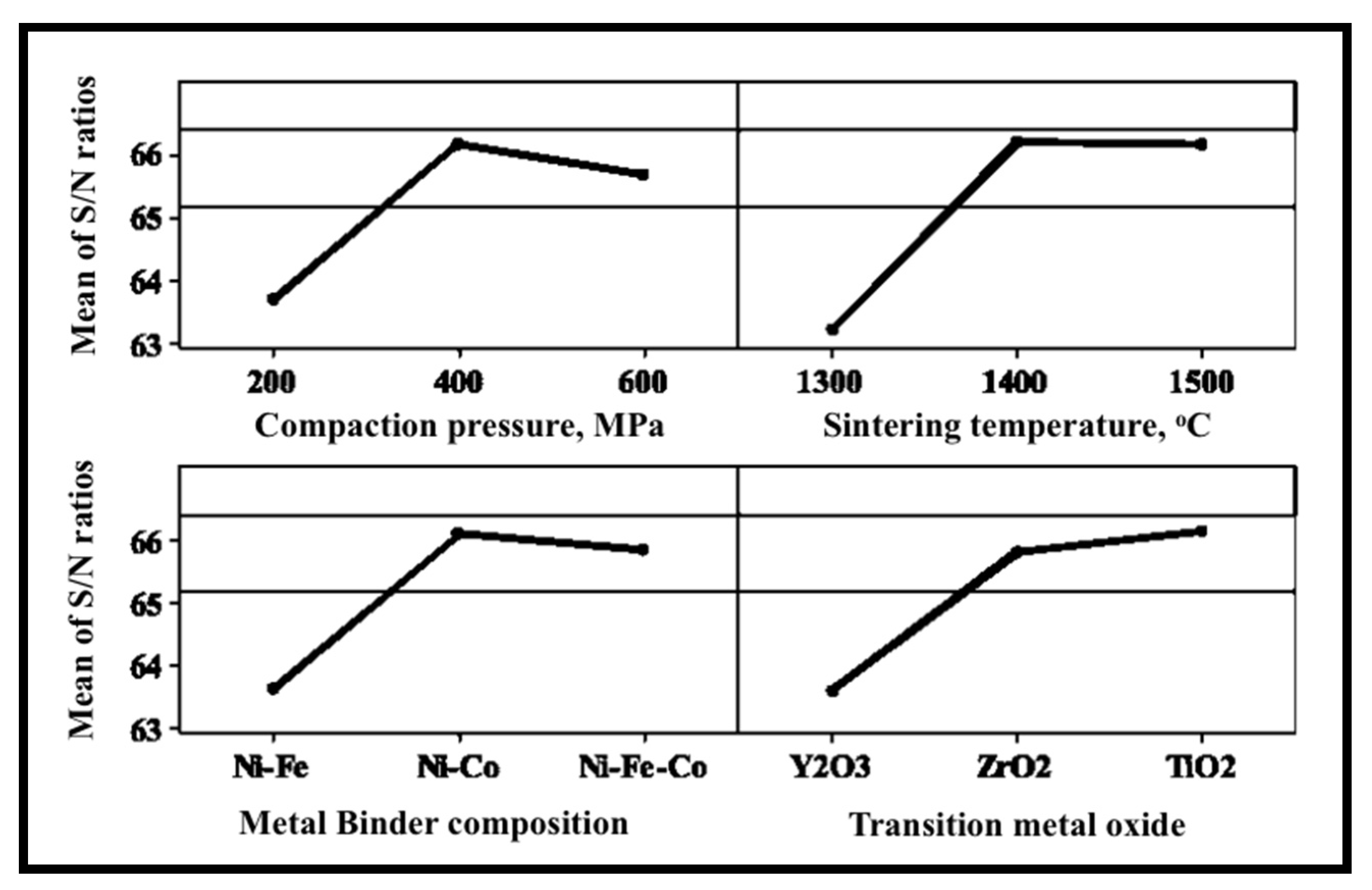

3.3. Mechanical Properties Analysis Using Taguchi Method

3.3.1. Hardness of ODS Tungsten Heavy Alloys

3.3.2. Compressive Strength of ODS Tungsten Heavy Alloys

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hafızo ğlu, H.; Durlu, N. Effect of sintering temperature on the high strain rate-deformation of tungsten heavy alloys. Int. J. Impact Eng. 2018, 121, 44–54. [Google Scholar] [CrossRef]

- Majumdar, S.; Kishor, J.; Paul, B.; Kain, V. Densification behaviour, microstructural characteristics and mechanic al properties of liquid phase sintered W-2Ni-1Fe alloy. J. Alloys Compd. 2020, 818, 1–8. [Google Scholar] [CrossRef]

- Abdel Hamid, Z.; Moustafa, S.F.; Daoush, W.M.; Abdel Mouez, F.; Hassan, M. Fabrication and Characterization of Tungsten Heavy Alloys Using Chemical Reduction and Mechanical Alloying Methods. Open J. Appl. Sci. 2013, 3, 15–27. [Google Scholar] [CrossRef]

- Jingang, Z.; Weimin, W.; Wei, J.; Kai, Y. Ultrafie Grain Tungsten Heavy Alloys with Excellent Performance Prepared by Spark Plasma Sintering. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2020, 735, 393–398. Available online: www.jwutms.net (accessed on 16 September 2020).

- Chen, C.L.; Huang, C.L. Milling Media and Alloying Effects on Synthesis and Characteristics of Mechanically Alloyed ODS Heavy Tungsten Alloys. Int. J. Refract. Met. Hard Mater. 2014, 44, 19–26. [Google Scholar] [CrossRef]

- Prabhu, G.; Arockia Kumar, R.; Nandy, T.K. Effct of Yttrium Oxide Dispersion on the Microstructure and Properties of Tungsten Heavy Alloys. Def. Sci. J. 2018, 68, 406–411. [Google Scholar]

- Senthilnathan, N.; Raja Annamalai, A.; Venkatachalam, G. Microstructure and mechanical properties of spark plasma sintered tungsten heavy alloys. Mater. Sci. Eng. A 2018, 710, 66–73. [Google Scholar] [CrossRef]

- Chen, C.; Huang, C.; Zeng, Y. Synthesis of ODS heavy tungsten alloys through post-annealing and secondary ball milling. Int. J. Refract. Met. Hard Mater. 2015, 48, 359–364. [Google Scholar] [CrossRef]

- Daoush, W.M.; El Sayed, A.H.; El Kady, O.A.; Sayed, M.A. Enhancement of Physical and Mechanical Properties of Oxide Dispersion Strengthened Tungsten Heavy Alloys. Metall. Mater. Trans. A 2016, 47, 2387–2395. [Google Scholar] [CrossRef]

- Chen, C.H.; Sutrisna. The Effect of Mo and Dispersoids on Microstructure, Sintering Behavior, and Mechanical Properties of W-Mo-Ni-Fe-Co Heavy Tungsten Alloys. Metals 2019, 9, 111. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, S.; Zhang, B.; Ahmad, T.; Wang, C.; Zhou, L.; Liang, T.; Yang, B. Effect of Y2O3 Addition on the Microstructure, Wear Resistance, and Corrosion Behavior of W-4.9Ni-2.1Fe Heavy Alloy. J. Mater. Eng. Perform. 2019, 28, 4801–4810. [Google Scholar] [CrossRef]

- Sayed, M.A.; Dawood, O.M.; EL Sayed, A.H.; Daoush, W.M. Application of Taguchi Method in Optimization of Process Parameters of ODS WHAs. Adv. Mater. Res. 2017, 6, 79–91. [Google Scholar] [CrossRef]

- Veleva, L. Contribution to the Production and Characterization of W-Y, W-Y2O3 and W-TiC Materials for Fusion Reactors. Dr. Philos. 2011, 1–164. [Google Scholar] [CrossRef]

- Akhtar, F. An Investigation on the Solid State Sintering of Mechanically Alloyed Nano-Structured 90W–Ni–Fe Tungsten Heavy Alloy. Int. J. Refract. Met. Hard Mater. 2008, 26, 145–151. [Google Scholar] [CrossRef]

- Wu, Y.; German, R.M.; Marx, B.; Bollina, R.; Bell, M. Characteristics of Densification and Distortion of Ni/Cu liquid-phase sintered tungsten heavy alloy. Mater. Sci. Eng. 2003, 344, 158–167. [Google Scholar] [CrossRef]

- Eliasson, A. Liquid Phase Sintering of W-Ni-Fe Composites—Initial Melt Penetration, Agglomerate Separation and Particle Interaction; Trita-MG AVH; KTH: Stockholm, Sweden, 2006; pp. 1–15. [Google Scholar]

- Zhu, Y.B.; Wang, Y.; Zhang, X.Y.; Qin, G.W. W/NiFe Phase Interfacial Characteristics of Liquid-Phase Sintered W-Ni-Fe Alloy. Int. J. Refract. Met. Hard Mater. 2007, 25, 275–279. [Google Scholar] [CrossRef]

- Bollina, R.; German, R.M. Heating Rate Effects on Microstructural Properties of Liquid Phase Sintered Tungsten Heavy Alloys. Int. J. Refract. Met. Hard Mater. 2004, 22, 117–127. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Klečková, Z. Effects of Sintering Conditions on Structures and Properties of Sintered Tungsten Heavy Alloy. Mater. 2020, 13, 2338. [Google Scholar] [CrossRef]

- Otto, K.N.; Antonsson, E.K. Extensions to the Taguchi Method of Product Design. ASME J. Mech. Des. 1993, 115, 5–13. [Google Scholar] [CrossRef]

- Ekbom, L.; Antonsson, T. Tungsten Heavy Alloy: Deformation Texture and Recrystallization of Tungsten Particles. Int. J. Refract. Met. Hard Mater. 2002, 20, 375–379. [Google Scholar] [CrossRef]

- Ibrahim, A.; Abdallah, M.; Mostafa, S.F.; Hegazy, A.A. An Experimental Investigation on the W-Cu Composites. Mater. Des. 2009, 30, 1398–1403. [Google Scholar] [CrossRef]

- Kamaruddin, S.; Khan, Z.A.; Foong, S.H. Application of Taguchi Method in the Optimization of Injection Moulding Parameters for Manufacturing Products from Plastic Blend. Int. J. Eng. Technol. 2010, 2, 574–580. [Google Scholar] [CrossRef]

- Upadhyaya, G.S. Powder Metallurgy Technology; Cambridge International Science Publishing: Cambridge, UK, 2002. [Google Scholar]

- Callister, W.D. Fundamentals of Materials Science and Engineering, 5th ed.; John Wiley and Sons Inc.: New York, NY, USA, 2001. [Google Scholar]

- Das, J.; Ravi Kiran, U.; Chakraborty, A.; Eswara Prasad, N. Hardness and Tensile Properties of Tungsten Based Heavy Alloys Prepared by Liquid Phase Sintering Technique. Int. J. Refract. Met. Hard Mater. 2009, 27, 577–583. [Google Scholar] [CrossRef]

- Islam, S.H.; Akhtar, F.; Askari, S.J.; Jokhio, M.T.; Qu, X. Tensile Behavior Change Depending on the Varying Tungsten Content of W–Ni–Fe Alloys. Int. J. Refract. Met. Hard Mater. 2007, 25, 380–385. [Google Scholar]

- Hong, S.H.; Ryu, H.J.; Baek, W.H. Matrix Pools in a Partially Mechanically Alloyed Tungsten Heavy Alloy for Localized Shear Deformation. Mater. Sci. Eng. A 2002, 333, 187–192. [Google Scholar] [CrossRef]

- Gero, R.; Borukhin, L.; Pikus, I. Some Structural Effects of Plastic Deformation on Tungsten Heavy Metal Alloys. Mater. Sci. Eng. A 2001, 302, 162–167. [Google Scholar] [CrossRef]

| Exp. No. | Samples Composition, (wt.%) | Sintering Temperature, (°C) | Compaction Pressure, (MPa) |

|---|---|---|---|

| 1 | 91 W- 4.9 Ni- 2.1 Fe- 2 Y2O3 | 1300 | 200 |

| 2 | 91 W- 4.9 Ni- 2.1 Co- 2 ZrO2 | 1400 | 200 |

| 3 | 91 W- 4.9 Ni- 1.05 Fe-1.05 Co -2 TiO2 | 1500 | 200 |

| 4 | 91 W- 4.9 Ni- 2.1 Co- 2 TiO2 | 1300 | 400 |

| 5 | 91 W- 4.9 Ni- 1.05 Fe- 1.05 Co-2 Y2O3 | 1400 | 400 |

| 6 | 91 W- 4.9 Ni- 2.1 Fe- 2ZrO2 | 1500 | 400 |

| 7 | 91 W- 4.9 Ni-1.05 Fe- 1.05 Co- 2 ZrO2 | 1300 | 600 |

| 8 | 91 W- 4.9 Ni- 2.1 Fe- 2 TiO2 | 1400 | 600 |

| 9 | 91 W- 4.9 Ni- 2.1 Co- 2 Y2O3 | 1500 | 600 |

| Experiment | Relative | Electrical | Vickers | Compressive |

|---|---|---|---|---|

| no. | Density% | Resistivity, µΩ.cm | Hardness, Hv | Strength, MPa |

| 1 | 88 | 0.128 | 242.3 | 845.3 |

| 2 | 92 | 0.162 | 327.8 | 2048.9 |

| 3 | 96.1 | 0.17 | 348.5 | 2057.8 |

| 4 | 96.3 | 0.139 | 385.7 | 2005.3 |

| 5 | 91.6 | 0.164 | 350.3 | 2057.5 |

| 6 | 94.5 | 0.157 | 341.4 | 2052.5 |

| 7 | 90.6 | 0.115 | 291.1 | 1772.4 |

| 8 | 92.4 | 0.153 | 341.2 | 2029.7 |

| 9 | 88.6 | 0.158 | 366.7 | 1995.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsayed, A.H.; Sayed, M.A.; Dawood, O.M.; Daoush, W.M. Effect of Transition Metals Oxides on the Physical and Mechanical Properties of Sintered Tungsten Heavy Alloys. Crystals 2020, 10, 825. https://doi.org/10.3390/cryst10090825

Elsayed AH, Sayed MA, Dawood OM, Daoush WM. Effect of Transition Metals Oxides on the Physical and Mechanical Properties of Sintered Tungsten Heavy Alloys. Crystals. 2020; 10(9):825. https://doi.org/10.3390/cryst10090825

Chicago/Turabian StyleElsayed, Ayman H., Mohamed A. Sayed, Osama M. Dawood, and Walid M. Daoush. 2020. "Effect of Transition Metals Oxides on the Physical and Mechanical Properties of Sintered Tungsten Heavy Alloys" Crystals 10, no. 9: 825. https://doi.org/10.3390/cryst10090825

APA StyleElsayed, A. H., Sayed, M. A., Dawood, O. M., & Daoush, W. M. (2020). Effect of Transition Metals Oxides on the Physical and Mechanical Properties of Sintered Tungsten Heavy Alloys. Crystals, 10(9), 825. https://doi.org/10.3390/cryst10090825