Use of the Correlation between Grain Size and Crystallographic Orientation in Crystal Plasticity Simulations: Application to AISI 420 Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

3. Modelling

3.1. CPFFT by DAMASK

3.2. VPSC90

3.3. Hardening Law

3.4. Fitting of Parameters

3.5. Virtual Microstructures

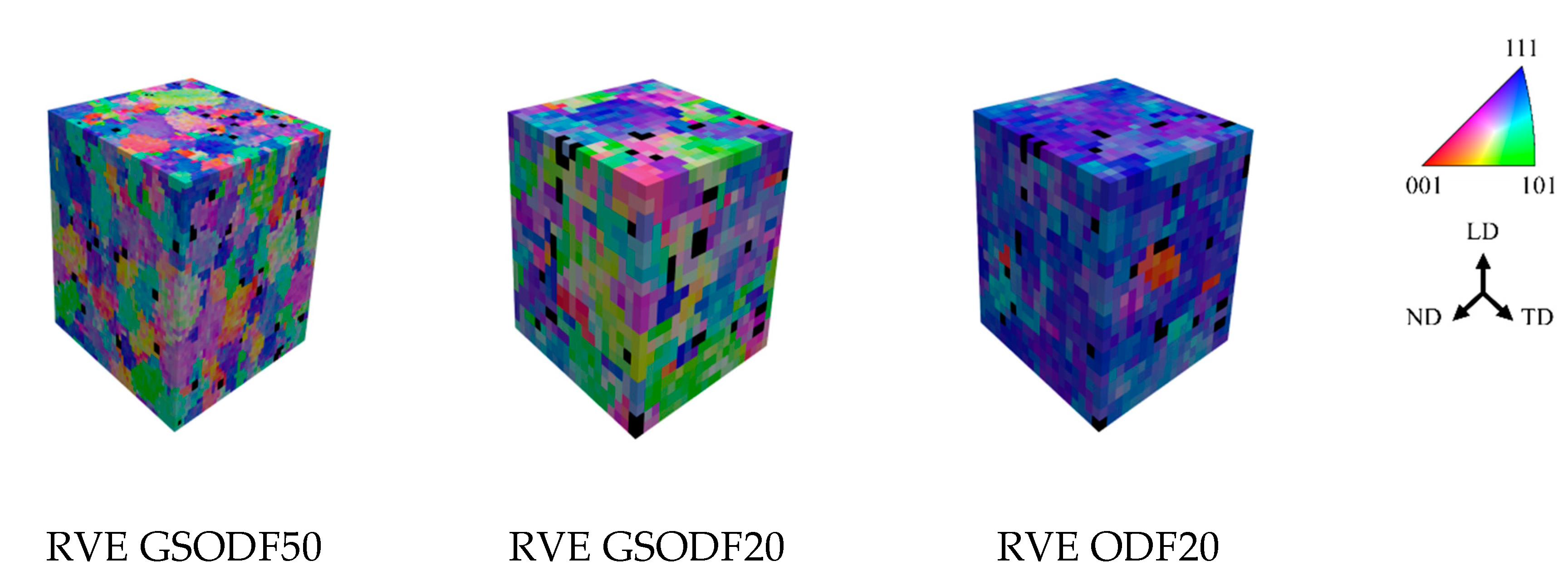

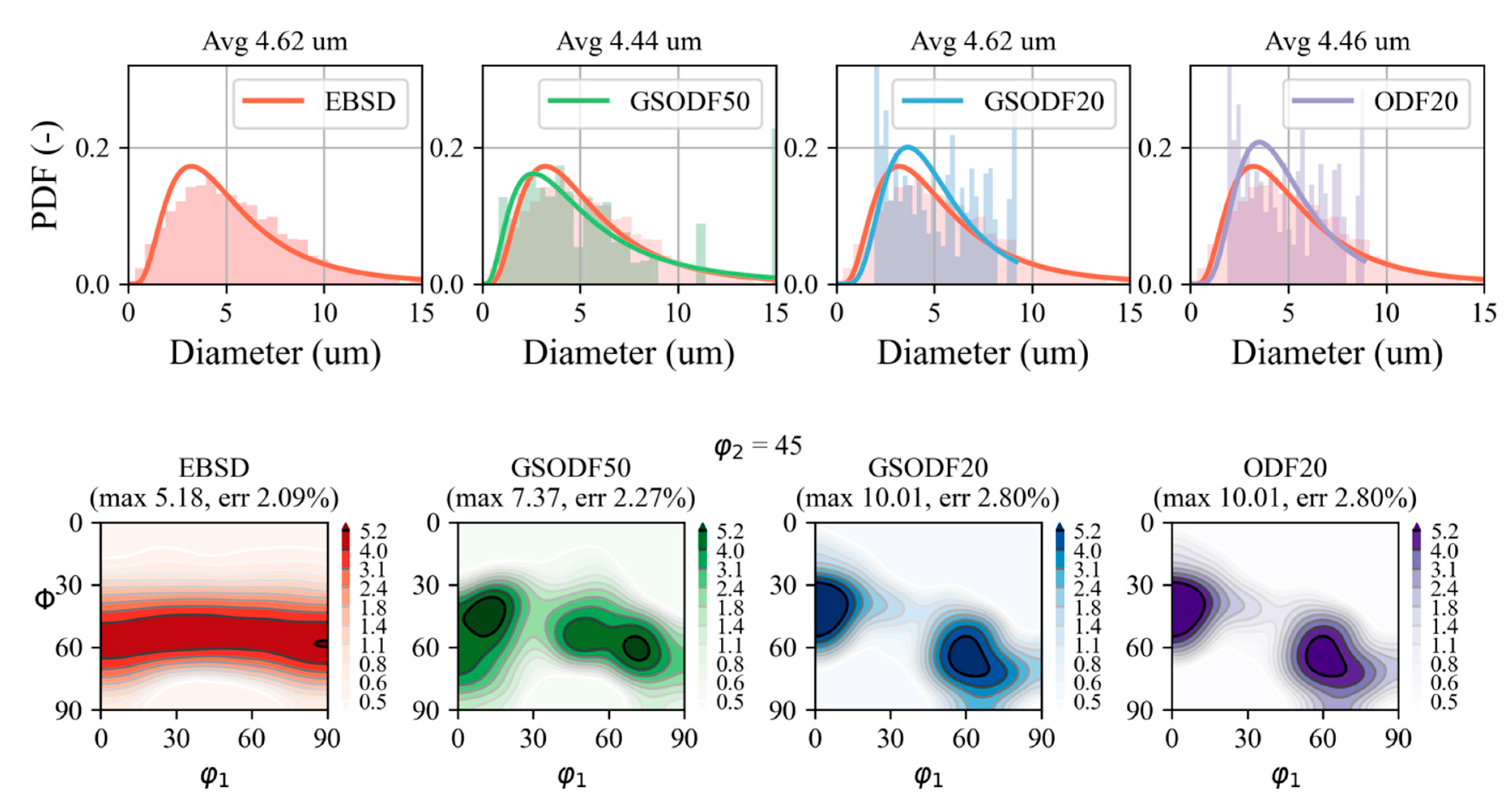

- A grain list is generated with the average orientation and area of each ferrite grain in the EBSD experiment (grains are defined with an orientation tolerance of maximum 5°).

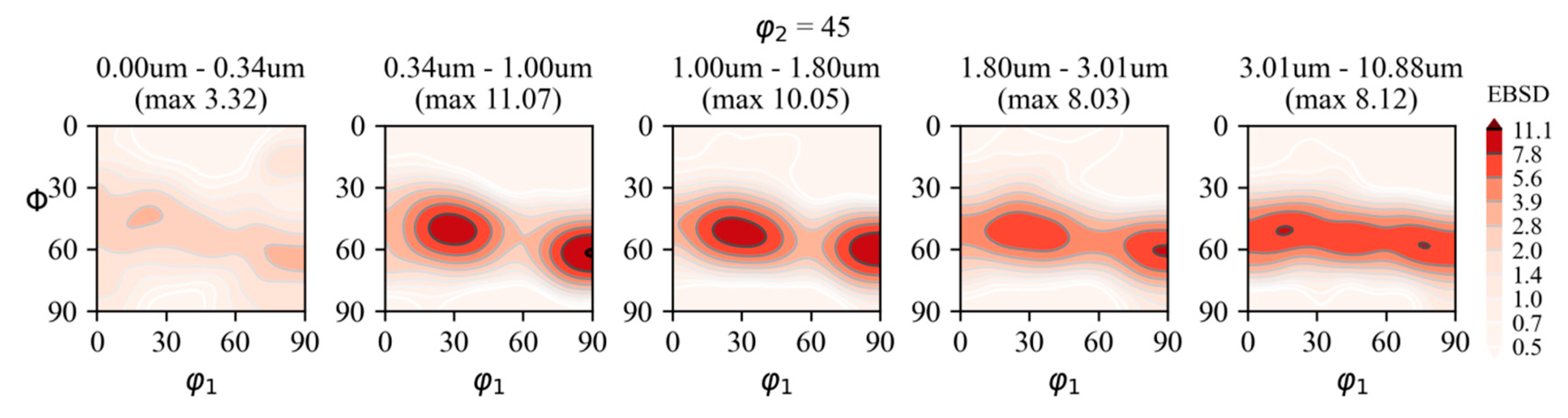

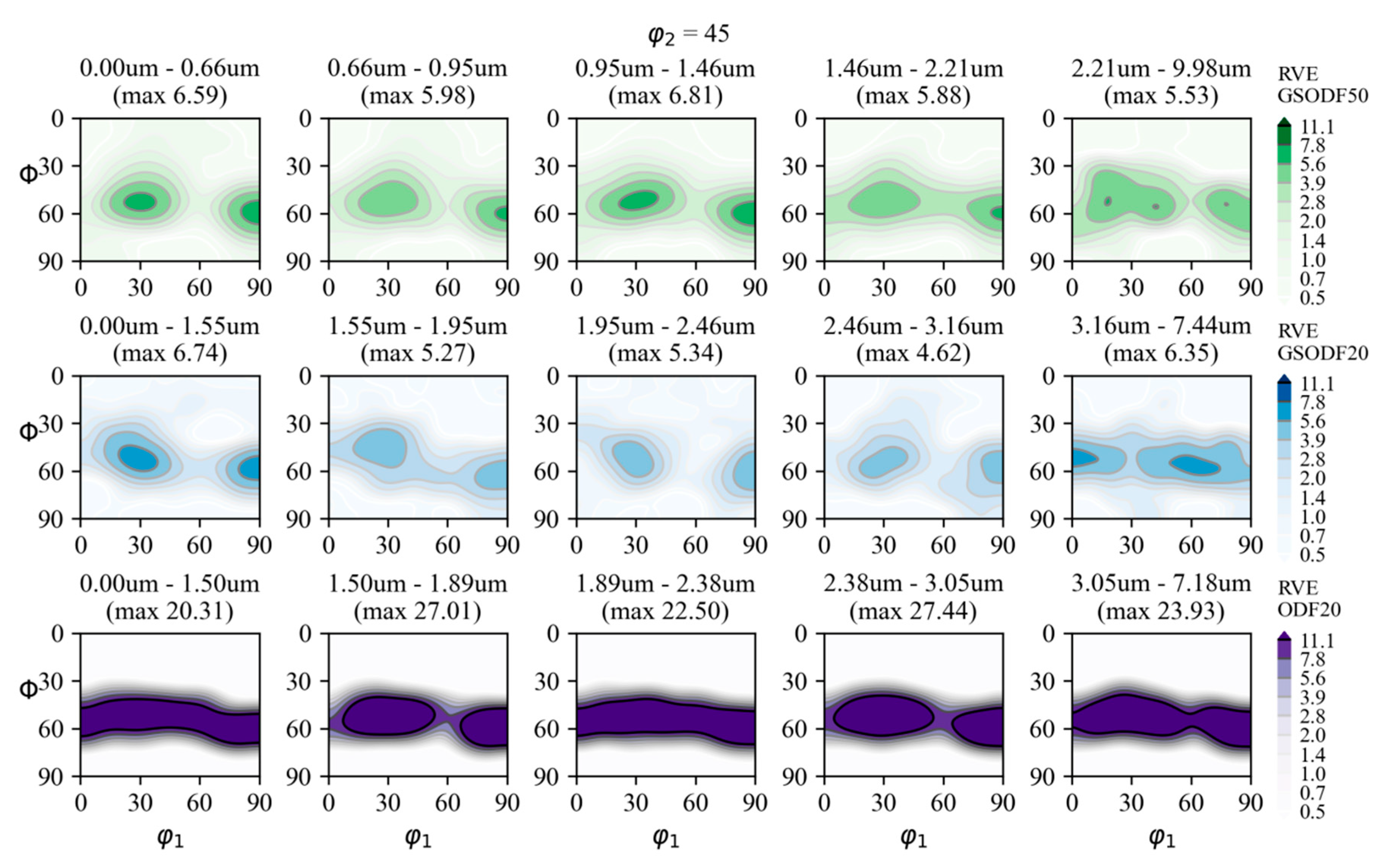

- The list is divided in five bins corresponding to different size ranges, such that each bin contains the same number of grains (approximately 500 grains in the available experimental data). The number of bins was decided such that the number of grains in each bin is enough to reproduce the experimental texture with a low error.

- For each of these bins, an orientation distribution function (ODF) is calculated using the generalized harmonics series expansion method [38], assuming orthorhombic symmetry.

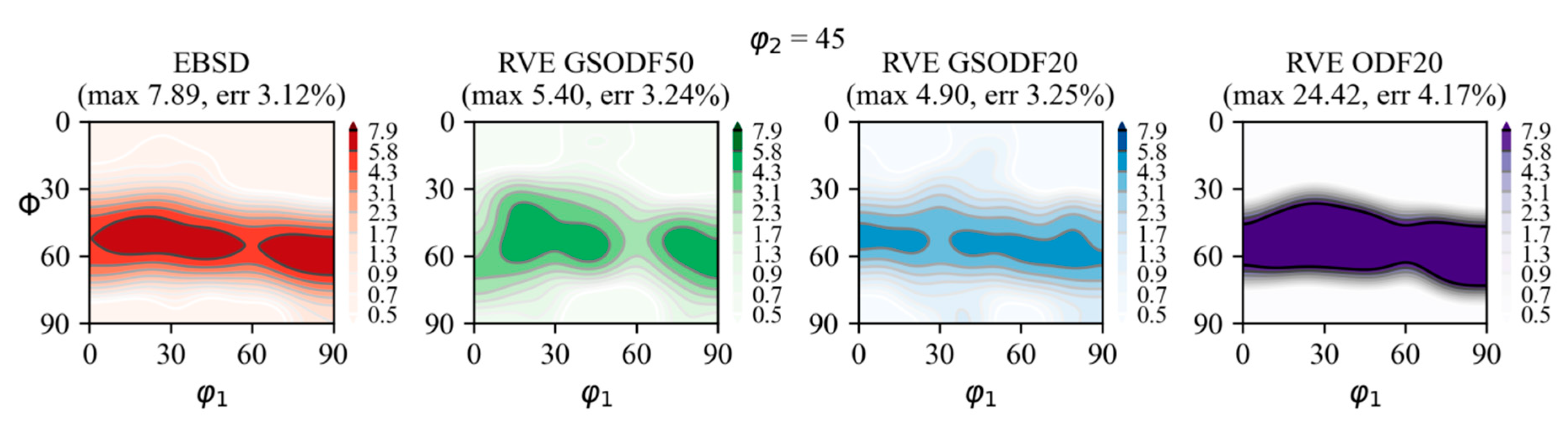

- Orientations are randomly assigned to the grains in the RVE according to the ODF calculated for the corresponding grain size range. The orientations are sampled from the discrete texture obtained evaluating the ODF in a regular grid in Euler space, with a spacing of 5°.

4. Results

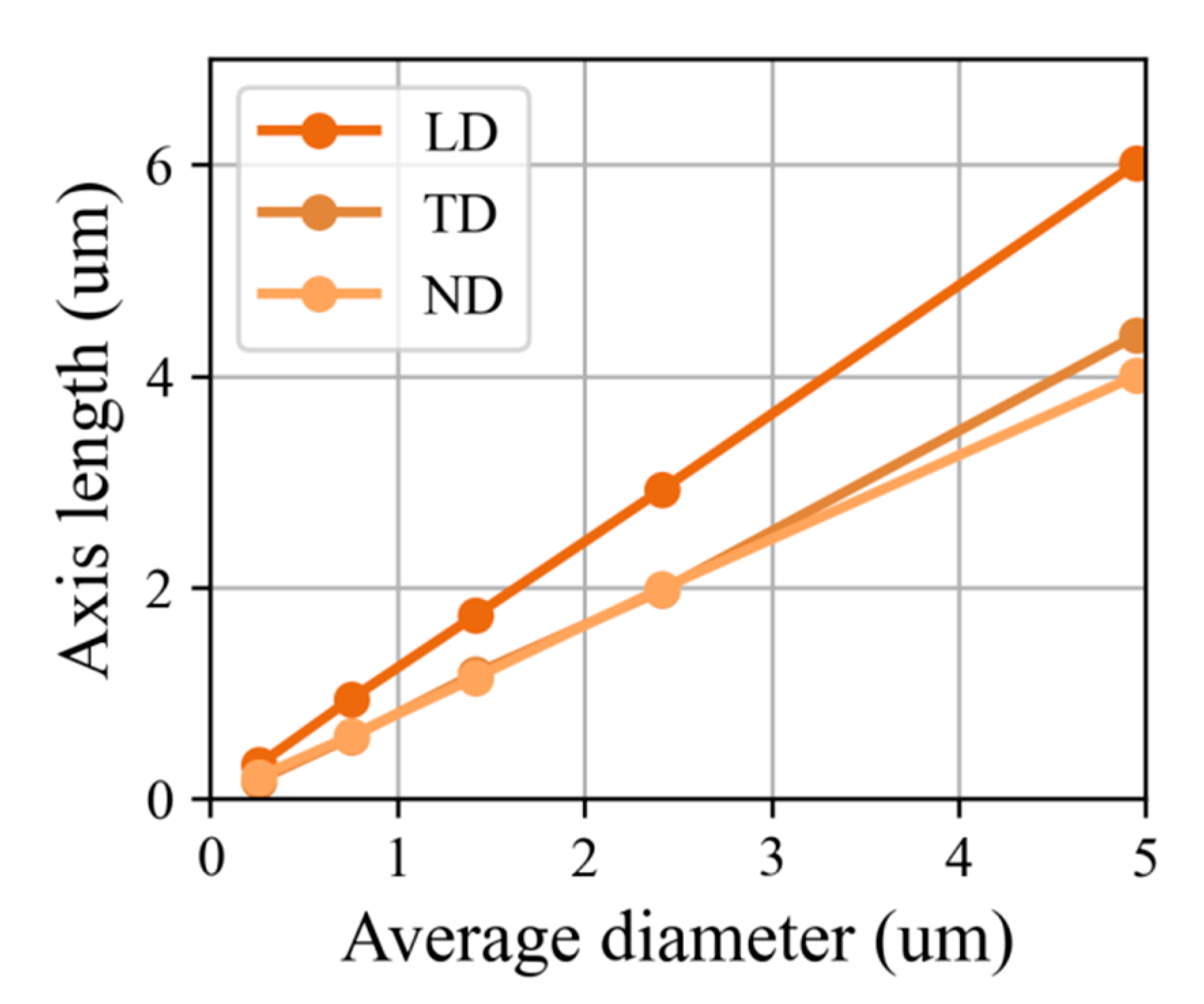

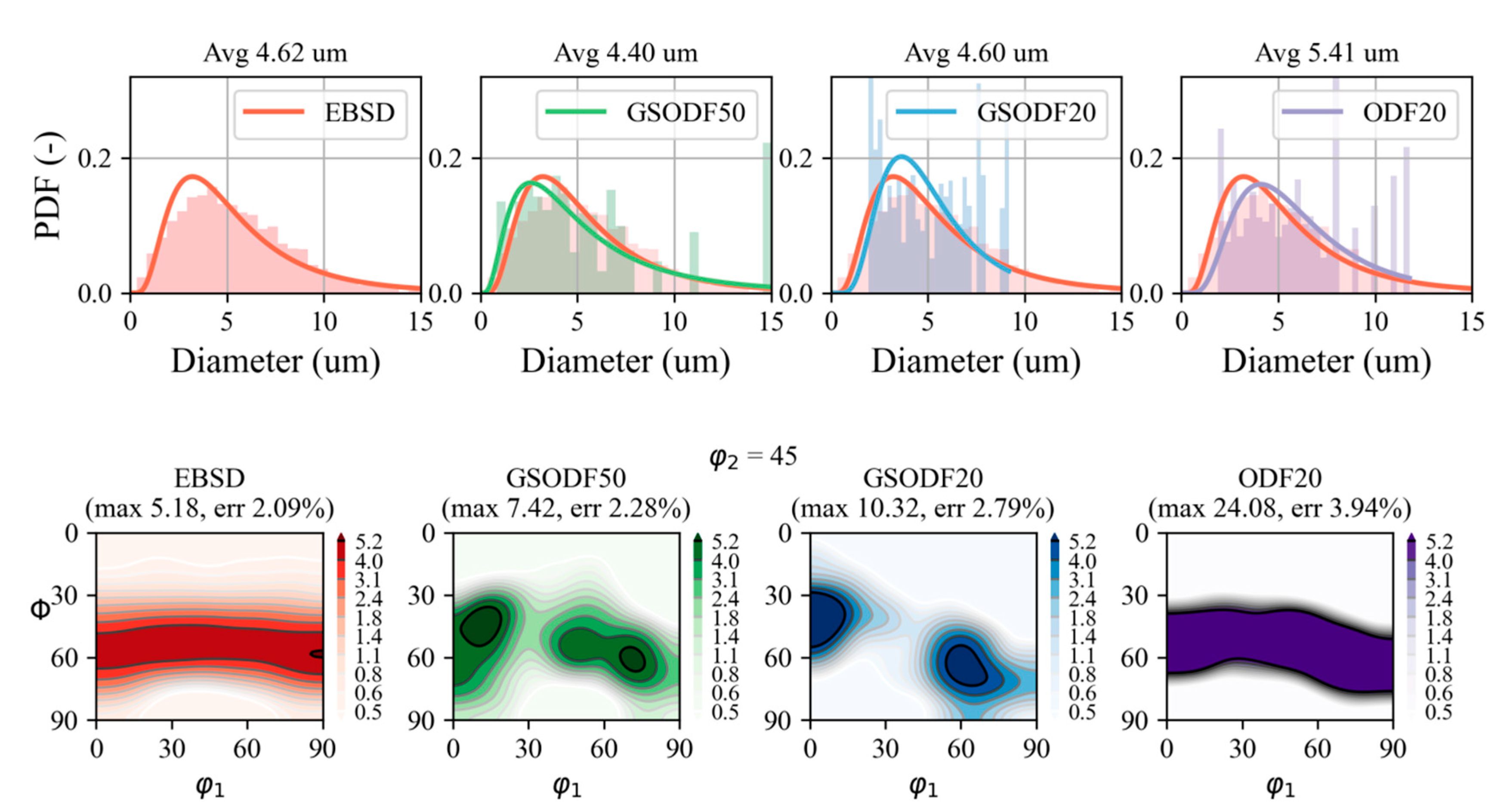

4.1. Experimental and Virtual Microstructures

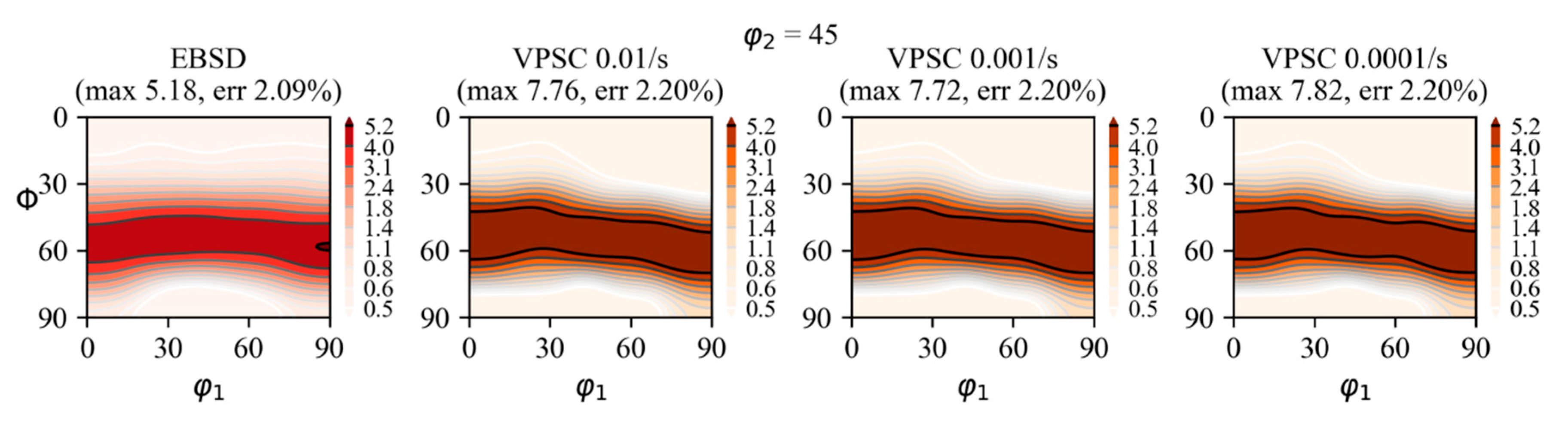

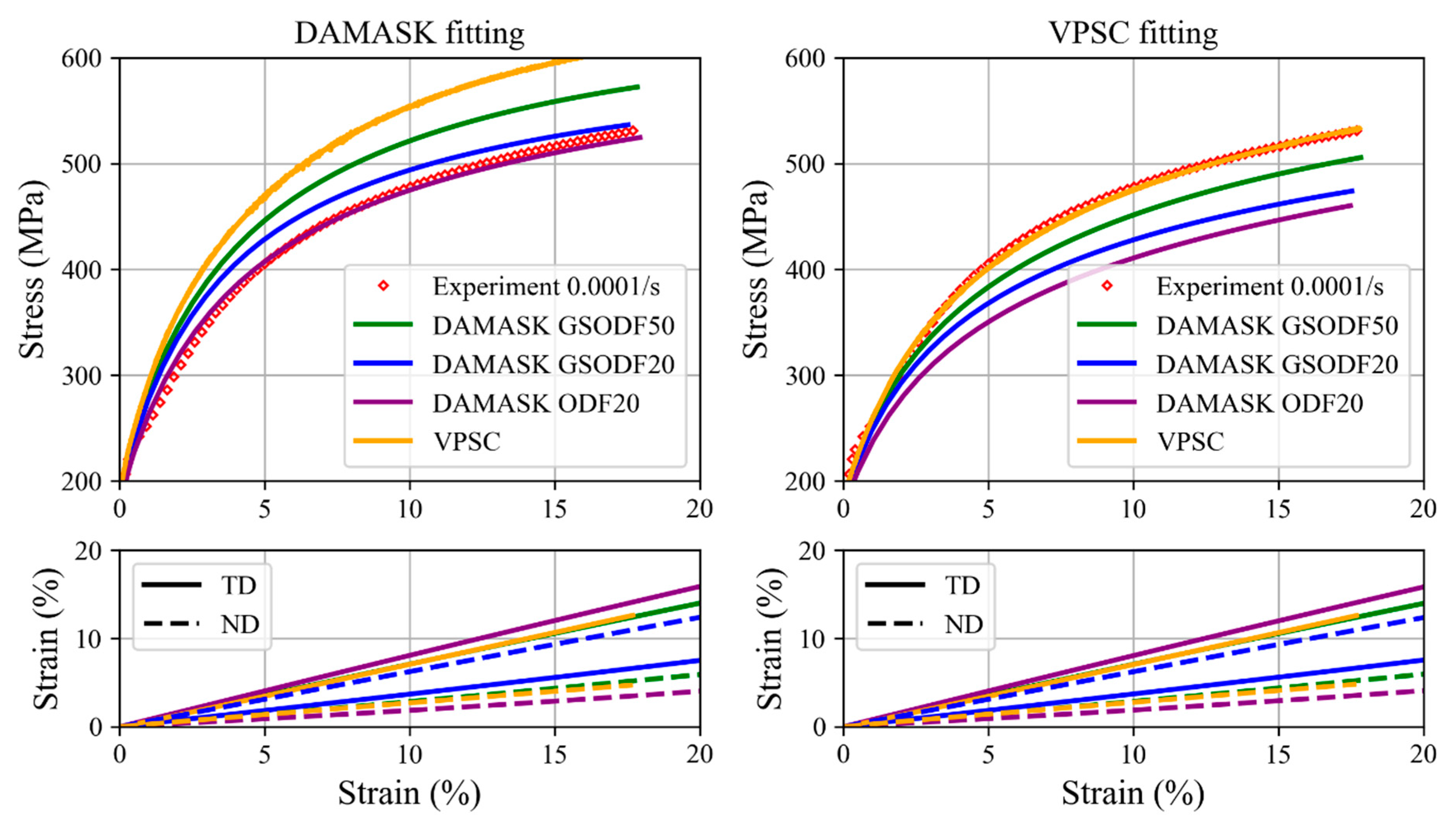

4.2. Fitting of Hardening Parameters

4.3. Deformed Microstructure

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Masuyama, F. History of power plants and progress in heat resistant steels. ISIJ Int. 2001, 41, 612–625. [Google Scholar] [CrossRef]

- Rojas, D.; Garcia, J.; Prat, O.; Sauthoff, G.; Kaysser-Pyzalla, A.R. 9%Cr heat resistant steels: Alloy design, microstructure evolution and creep response at 650 °C. Mater. Sci. Eng. A 2011, 528, 5164–5176. [Google Scholar] [CrossRef]

- Vivas, J.; Capdevila, C.; Altstadt, E.; Houska, M.; San-Martín, D. Importance of austenitization temperature and ausforming on creep strength in 9Cr ferritic/martensitic steel. Scr. Mater. 2018, 153, 14–18. [Google Scholar] [CrossRef]

- Vivas, J.; Capdevila, C.; Altstadt, E.; Houska, M.; Sabirov, I.; San-Martín, D. Microstructural Degradation and Creep Fracture Behavior of Conventionally and Thermomechanically Treated 9% Chromium Heat Resistant Steel. Met. Mater. Int. 2019, 25, 343–352. [Google Scholar] [CrossRef]

- Taylor, G.I. Plastic strain in metals. Plast. Strain Met. 1938, 62, 307–324. [Google Scholar]

- Sachs, G. Plasticity problems in metals. Trans. Faraday Soc. 1928, 24, 84–92. [Google Scholar] [CrossRef]

- Houtte, P.V.; Li, S.; Seefeldt, M.; Delannay, L. Deformation texture prediction: From the Taylor model to the advanced Lamel model. Int. J. Plast. 2005, 21, 589–624. [Google Scholar]

- Lebensohn, R.A.; Tomé, C.N. A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: Application to zirconium alloys. Acta Metall. Mater. 1993, 41, 2611–2624. [Google Scholar] [CrossRef]

- Galán, J.; Verleysen, P.; Lebensohn, R.A. An improved algorithm for the polycrystal viscoplastic self-consistent model and its integration with implicit finite element schemes. Model. Simul. Mater. Sci. Eng. 2014, 22, 55023. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Hantcherli, L.; Tjahjanto, D.D.; Bieler, T.R.; Raabe, D. Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 2010, 58, 1152–1211. [Google Scholar] [CrossRef]

- Roters, F.; Eisenlohr, P.; Bieler, T.; Raabe, D. Crystal Plasticity Finite Element Methods: In Materials Science and Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Roters, F.; Diehl, M.; Shanthraj, P.; Eisenlohr, P.; Reuber, C.; Wong, S.L.; Maiti, T.; Ebrahimi, A.; Hochrainer, T.; Fabritius, H.O.; et al. DAMASK—The Düsseldorf Advanced Material Simulation Kit for modeling multi-physics crystal plasticity, thermal, and damage phenomena from the single crystal up to the component scale. Comput. Mater. Sci. 2019, 158, 420–478. [Google Scholar] [CrossRef]

- Eisenlohr, P.; Diehl, M.; Lebensohn, R.A.; Roters, F. A spectral method solution to crystal elasto-viscoplasticity at finite strains. Int. J. Plast. 2013, 46, 37–53. [Google Scholar] [CrossRef]

- Chatterjee, K.; Echlin, M.P.; Kasemer, M.; Callahan, P.G.; Pollock, T.M.; Dawson, P. Prediction of tensile stiffness and strength of Ti-6Al-4V using instantiated volume elements and crystal plasticity. Acta Mater. 2018, 157, 21–32. [Google Scholar] [CrossRef]

- Zaefferer, S.; Wright, S.I.; Raabe, D. Three-Dimensional Orientation Microscopy in a Focused Ion Beam–Scanning Electron Microscope: A New Dimension of Microstructure Characterization. Metall. Mater. Trans. A 2008, 39, 374–389. [Google Scholar] [CrossRef]

- Balzani, D.; Scheunemann, L.; Brands, D.; Schröder, J. Construction of two- and three-dimensional statistically similar RVEs for coupled micro-macro simulations. Comput. Mech. 2014, 54, 1269–1284. [Google Scholar] [CrossRef]

- Pirgazi, H. On the alignment of 3D EBSD data collected by serial sectioning technique. Mater. Charact. 2019, 152, 223–229. [Google Scholar] [CrossRef]

- Swaminathan, S.; Ghosh, S.; Pagano, N.J. Statistically equivalent representative volume elements for unidirectional composite microstructures: Part I—Without damage. J. Compos. Mater. 2006, 40, 583–604. [Google Scholar] [CrossRef]

- Brands, D.; Balzani, D.; Scheunemann, L.; Schröder, J.; Richter, H.; Raabe, D. Computational modeling of dual-phase steels based on representative three-dimensional microstructures obtained from EBSD data. Arch. Appl. Mech. 2016, 86, 575–598. [Google Scholar] [CrossRef]

- Zhang, P.; Balint, D.; Lin, J. Controlled Poisson Voronoi tessellation for virtual grain structure generation: A statistical evaluation. Philos. Mag. 2011, 91, 4555–4573. [Google Scholar] [CrossRef]

- Bargmann, S.; Klusemann, B.; Markmann, J.; Schnabel, J.E.; Schneider, K.; Soyarslan, C.; Wilmers, J. Generation of 3D representative volume elements for heterogeneous materials: A review. Prog. Mater. Sci. 2018, 96, 322–384. [Google Scholar] [CrossRef]

- Quey, R.; Dawson, P.R.; Barbe, F. Large-scale 3D random polycrystals for the finite element method: Generation, meshing and remeshing. Comput. Methods Appl. Mech. Eng. 2011, 200, 1729–1745. [Google Scholar] [CrossRef]

- Kasemer, M.; Quey, R.; Dawson, P. The influence of mechanical constraints introduced by β annealed microstructures on the yield strength and ductility of Ti-6Al-4V. J. Mech. Phys. Solids 2017, 103, 179–198. [Google Scholar] [CrossRef]

- Vittorietti, M.; Kok, P.J.J.; Sietsma, J.; Jongbloed, G. Accurate representation of the distributions of the 3D Poisson-Voronoi typical cell geometrical features. Comput. Mater. Sci. 2019, 166, 111–118. [Google Scholar] [CrossRef]

- Vittorietti, M.; Kok, P.J.J.; Sietsma, J.; Li, W.; Jongbloed, G. General framework for testing Poisson-Voronoi assumption for real microstructures. Appl. Stoch. Models Bus. Ind. 2020. [Google Scholar] [CrossRef]

- Groeber, M.; Ghosh, S.; Uchic, M.D.; Dimiduk, D.M. A framework for automated analysis and simulation of 3D polycrystalline microstructures. Part 2: Synthetic structure generation. Acta Mater. 2008, 56, 1274–1287. [Google Scholar] [CrossRef]

- ASTM-E8-E8M-13a. Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2013; Volume E8 E8M-13a, p. 28. [Google Scholar]

- Asaro, R.J.; Needleman, A. Overview no. 42 Texture development and strain hardening in rate dependent polycrystals. Acta Metall. 1985, 33, 923–953. [Google Scholar] [CrossRef]

- Chakraborty, A.; Eisenlohr, P. Evaluation of an inverse methodology for estimating constitutive parameters in face-centered cubic materials from single crystal indentations. Eur. J. Mech. A/Solids 2017, 66, 114–124. [Google Scholar] [CrossRef]

- Nelder, J.A.; Mead, R. A Simplex Method for Function Minimization. Comput. J. 1965, 7, 308–313. [Google Scholar] [CrossRef]

- Yalcinkaya, T.; Brekelmans, W.A.M.; Geers, M.G.D. BCC single crystal plasticity modeling and its experimental identification. Model. Simul. Mater. Sci. Eng. 2008, 16, 85007. [Google Scholar] [CrossRef]

- Tasan, C.C.; Hoefnagels, J.P.M.; Diehl, M.; Yan, D.; Roters, F.; Raabe, D. Strain localization and damage in dual phase steels investigated by coupled in-situ deformation experiments and crystal plasticity simulations. Int. J. Plast. 2014, 63, 198–210. [Google Scholar] [CrossRef]

- Maresca, F.; Kouznetsova, V.G.; Geers, M.G.D. On the role of interlath retained austenite in the deformation of lath martensite. Model. Simul. Mater. Sci. Eng. 2014, 22, 45011. [Google Scholar] [CrossRef]

- Maresca, F.; Kouznetsova, V.G.; Geers, M.G.D. Reduced crystal plasticity for materials with constrained slip activity. Mech. Mater. 2016, 92, 198–210. [Google Scholar] [CrossRef]

- Liu, Y.; Jiang, Y.; Xing, J.; Zhou, R.; Feng, J. Mechanical properties and electronic structures of M23C6 (M = Fe, Cr, Mn)-type multicomponent carbides. J. Alloy. Compd. 2015, 648, 874–880. [Google Scholar] [CrossRef]

- Press, W.H.; Flannery, B.P.; Teukolsky, S.A.; Vetterling, W.T. Numerical Recipes in C: The Art of Scientific Computing; Cambridge University Press: Cambridge, UK, 1988. [Google Scholar]

- Groeber, M.A.; Jackson, M.A. DREAM.3D: A Digital Representation Environment for the Analysis of Microstructure in 3D. Integr. Mater. Manuf. Innov. 2014, 3, 56–72. [Google Scholar] [CrossRef]

- Van Houtte, P. A method for the generation of various ghost correction algorithms—The example of the positivity method and the exponential method. Texture Stress Microstruct. 1991, 13, 199–212. [Google Scholar] [CrossRef]

- Inoue, A.; Arakawa, S.; Masumoto, T. Effect of Alloying Elements on Defect Structure and Hardness of M23C6 Type Carbides. Trans. Jpn. Inst. Met. 1979, 20, 585–592. [Google Scholar] [CrossRef]

- Hidalgo, J.; Vittorietti, M.; Farahani, H.; Vercruysse, F.; Petrov, R.; Sietsma, J. Influence of M23C6 Carbides on the Heterogeneous Strain Development in Annealed 420 Stainless Steel. Available online: https://ssrn.com/abstract=3558254 (accessed on 15 September 2020).

- Zecevic, M.; Lebensohn, R.A.; McCabe, R.J.; Knezevic, M. Modeling of intragranular misorientation and grain fragmentation in polycrystalline materials using the viscoplastic self-consistent formulation. Int. J. Plast. 2018, 109, 193–211. [Google Scholar] [CrossRef]

- Galán-López, J.; Verleysen, P. Simulation of the plastic response of Ti–6Al–4V thin sheet under different loading conditions using the viscoplastic self-consistent model. Mater. Sci. Eng. A 2018, 712, 1–11. [Google Scholar] [CrossRef]

- Przybyla, C.; Adams, B.; Miles, M. Methodology for Determining the Variance of the Taylor Factor: Application in Fe-3%Si. J. Eng. Mater. Technol. 2007, 129. [Google Scholar] [CrossRef][Green Version]

| Ferrite | M23C6 | |||

|---|---|---|---|---|

| Parameter | Unit | VPSC GSODF | DAMASK RVEODF20 | Adopted |

| C11, C12, C44 | GPa | 233, 135, 128 [32,33] | 472, 216, 135 [35] | |

| s−1 | 1 × 10−6 [32,33] | 1 × 10−6 | ||

| nslip | - | 62.4 | 65 | 200 |

| MPa | 72.5 | 77 | 1200 | |

| MPa | 241.0 | 226 | 2000 | |

| h0 | MPa | 2659.9 | 2534 | 20 |

| a | - | 2.83 | 1.75 | 1.1 |

| MPa m1/2 | 0.738 | - | - | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galán-López, J.; Hidalgo, J. Use of the Correlation between Grain Size and Crystallographic Orientation in Crystal Plasticity Simulations: Application to AISI 420 Stainless Steel. Crystals 2020, 10, 819. https://doi.org/10.3390/cryst10090819

Galán-López J, Hidalgo J. Use of the Correlation between Grain Size and Crystallographic Orientation in Crystal Plasticity Simulations: Application to AISI 420 Stainless Steel. Crystals. 2020; 10(9):819. https://doi.org/10.3390/cryst10090819

Chicago/Turabian StyleGalán-López, Jesús, and Javier Hidalgo. 2020. "Use of the Correlation between Grain Size and Crystallographic Orientation in Crystal Plasticity Simulations: Application to AISI 420 Stainless Steel" Crystals 10, no. 9: 819. https://doi.org/10.3390/cryst10090819

APA StyleGalán-López, J., & Hidalgo, J. (2020). Use of the Correlation between Grain Size and Crystallographic Orientation in Crystal Plasticity Simulations: Application to AISI 420 Stainless Steel. Crystals, 10(9), 819. https://doi.org/10.3390/cryst10090819