Impact of Phase Structure on Piezoelectric Properties of Textured Lead-Free Ceramics

Abstract

1. Introduction

2. Materials and Methods

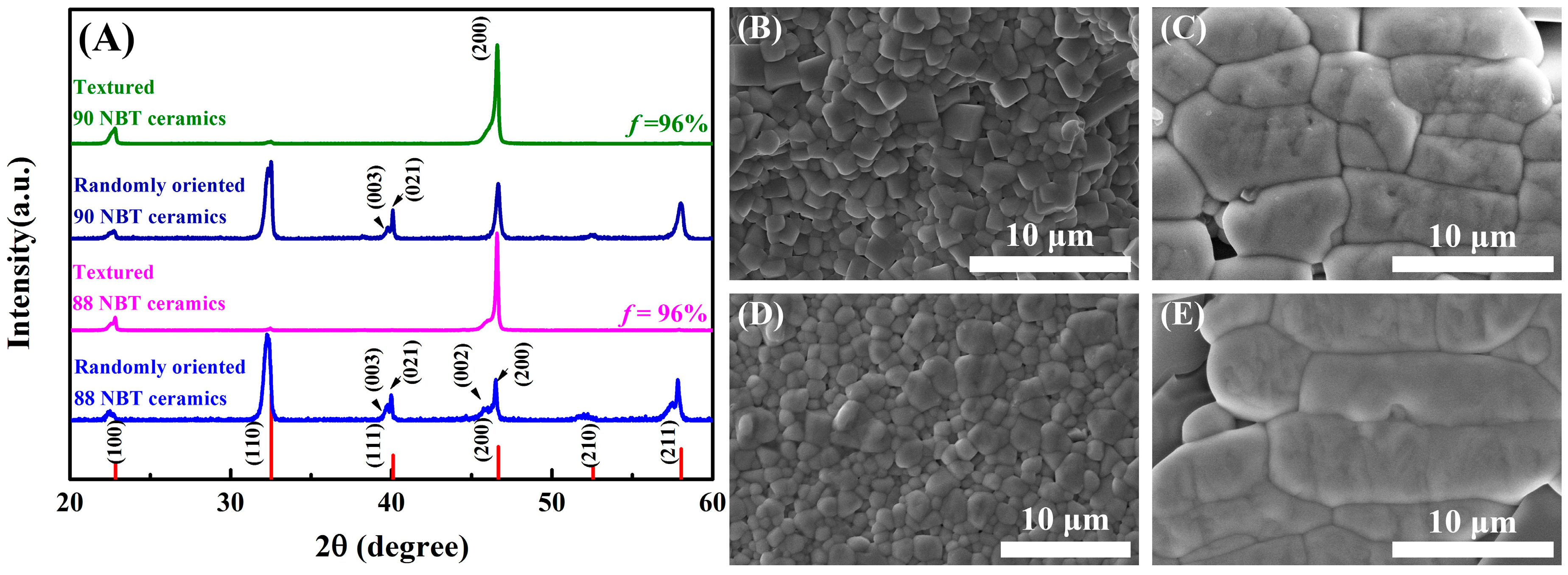

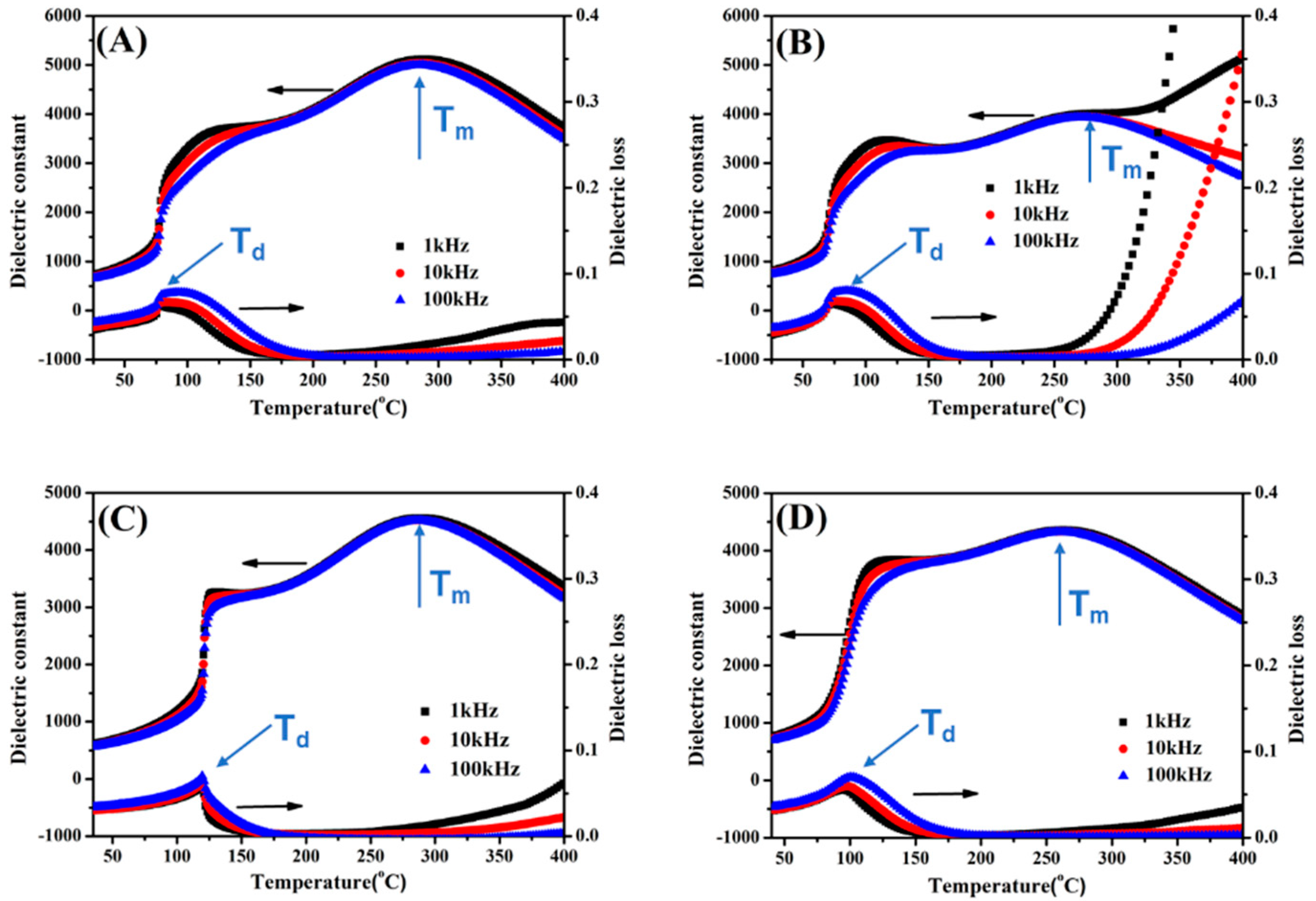

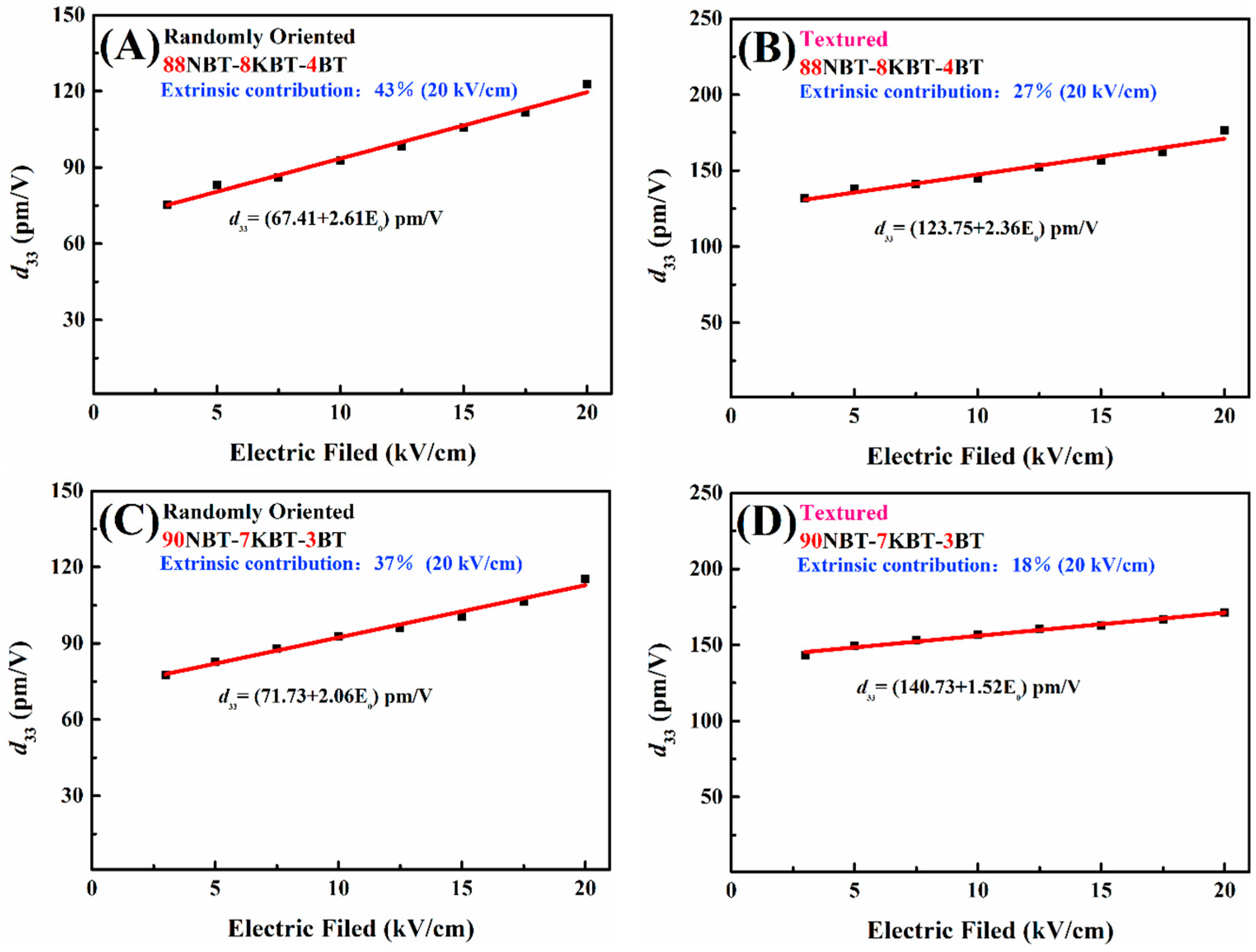

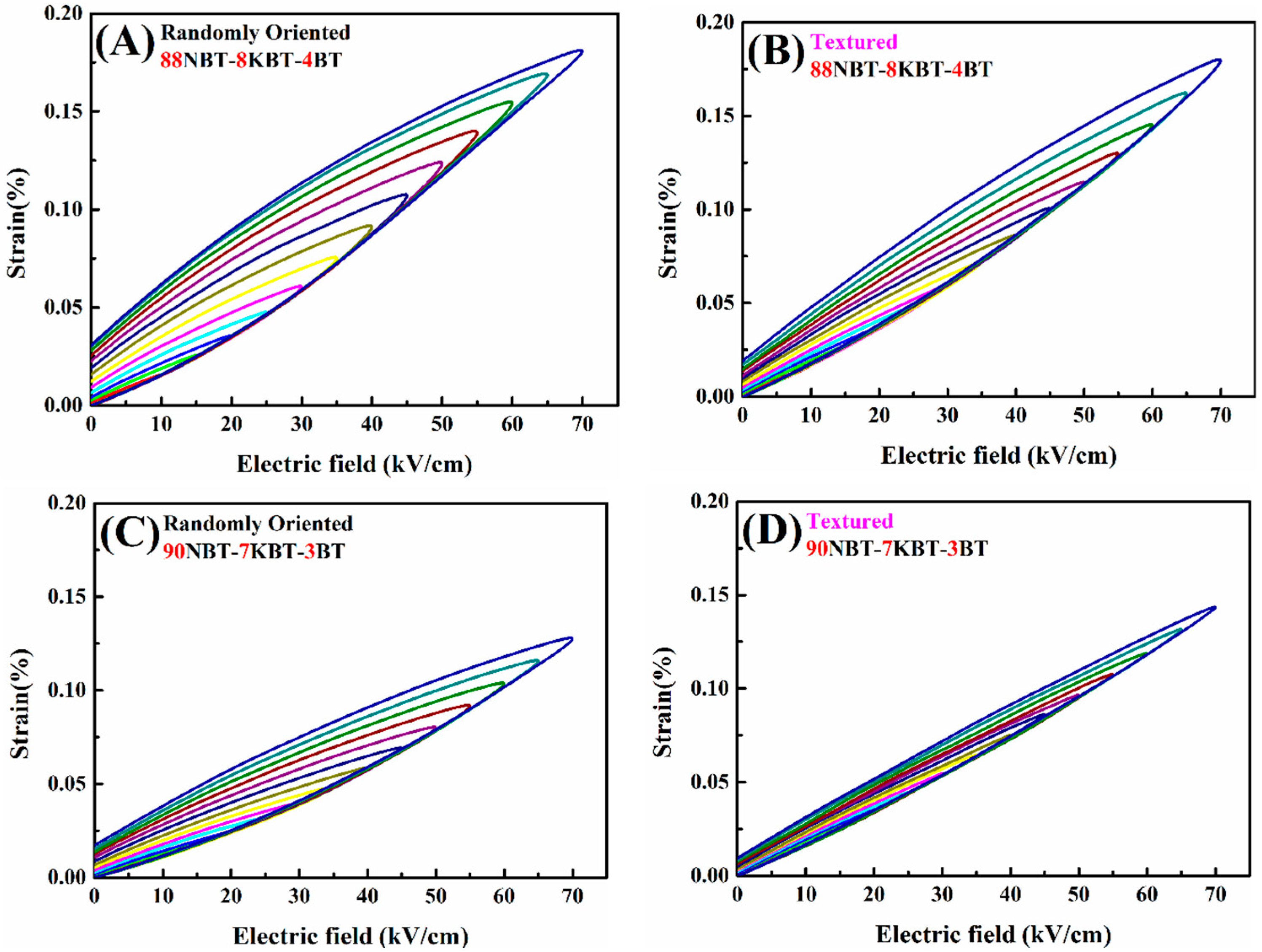

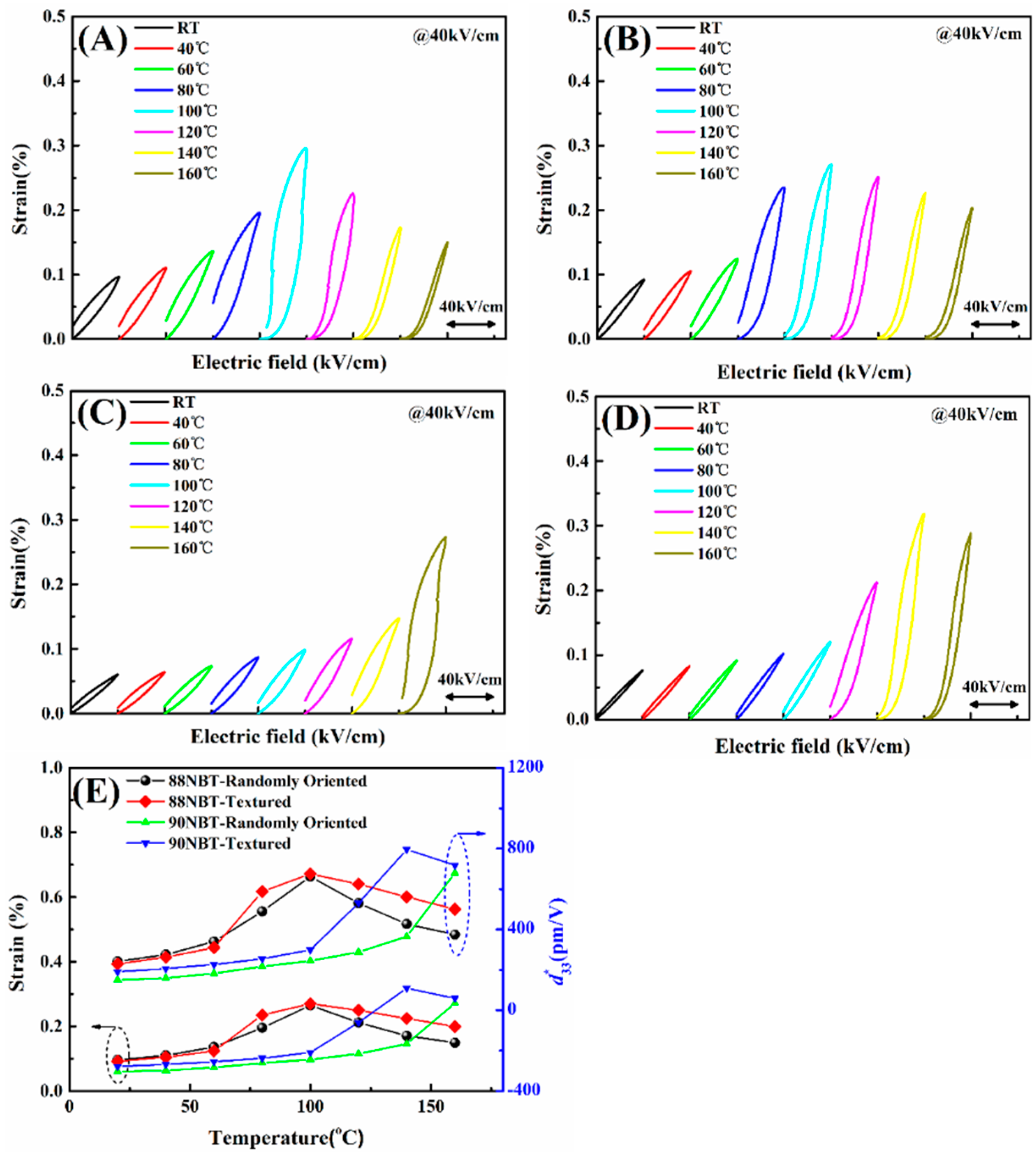

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Smolensky, G. New ferroelectrics of complex composition IV. Sov. Phys. Solid State. 1961, 2, 2651–2654. [Google Scholar]

- Li, Y.; Chen, W.; Zhou, J.; Xu, Q.; Sun, H.; Liao, M. Dielectric and ferroelectric properties of lead-free Na0.5Bi0.5TiO3-K0.5Bi0.5TiO3 ferroelectric ceramics. Ceram. Int. 2005, 31, 139–142. [Google Scholar] [CrossRef]

- Chen, M.; Xu, Q.; Kim, B.H.; Ahn, B.K.; Ko, J.H.; Kang, W.J.; Nam, O.J. Structure and electrical properties of (Na0.5Bi0.5)1-xBaxTiO3 piezoelectric ceramics. J. Eur. Ceram. Soc. 2008, 28, 843–849. [Google Scholar] [CrossRef]

- Swain, S.; Kumar, P. Dielectric, ferroelectric and bipolar electric field induced strain properties of MPB composition of NBT-xKNN system. J. Electroceram. 2013, 32, 102–107. [Google Scholar] [CrossRef]

- Zhang, S.; Shrout, T.R.; Nagata, H.; Hiruma, Y.; Takenaka, T. Piezoelectric properties in (K0.5Bi0.5)TiO3-(Na0.5Bi0.5)TiO3-BaTiO3 lead-free ceramics. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2007, 54, 910–917. [Google Scholar] [CrossRef]

- Zhang, L.; Pu, X.; Chen, M.; Bai, S.; Pu, Y. Influence of BaSnO3 additive on the energy storage properties of Na0.5Bi0.5TiO3-based relaxor ferroelectrics. J. Eur. Ceram. Soc. 2018, 38, 2304–2311. [Google Scholar] [CrossRef]

- Lou, G.; Yin, Q.; Duan, A.; Cao, D.; Yin, X. Structure, dielectric properties and impedance analysis of lead-free (1-x)Na0.5Bi0.5TiO3-xSrTiO3 ceramics. J. Mater. Sci. Mater. Electron. 2018, 29, 6283–6288. [Google Scholar] [CrossRef]

- Liu, X.; Li, F.; Zhai, J.; Shen, B.; Li, P.; Liu, B. Composition-induced structural transitions and enhanced strain response in nonstoichiometric NBT-based ceramics. J. Am. Ceram. Soc. 2017, 100, 3636–3645. [Google Scholar] [CrossRef]

- Moriana, A.D.; Zhang, S. Lead-free textured piezoceramics using tape casting: A review. J. Materiomics. 2018, 4, 277–303. [Google Scholar] [CrossRef]

- Messing, G.L.; Trolier-McKinstry, S.; Sabolsky, E.; Duran, C.; Kwon, S.; Brahmaroutu, B.; Park, P.; Yilmaz, H.; Rehrig, P.; Eitel, K. Templated grain growth of textured piezoelectric ceramics. Crit. Rev. Solid State Mater. Sci. 2004, 29, 45–96. [Google Scholar] [CrossRef]

- Seabaugh, M.M.; Cheney, G.L.; Hasinska, K.; Azad, A.-M.; Sabolsky, E.M.; Swartz, S.L.; Dawson, W.J. Development of a templated grain growth system for texturing piezoelectric ceramics. J. Intell. Mater. Syst. Struct. 2004, 15, 209–214. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F. High performance ferroelectric relaxor-PbTiO3 single crystals: Status and perspective. J. Appl. Phys. 2012, 111, 031301. [Google Scholar] [CrossRef]

- Zhang, S.; Sherlock, N.P.; Meyer, R.J., Jr.; Shrout, T.R. Crystallographic dependence of loss in domain engineered relaxor-PT single crystals. Appl. Phys. Lett. 2009, 94, 162906. [Google Scholar] [CrossRef] [PubMed]

- Davis, M.; Damjanovic, D.; Hayem, D.; Setter, N. Domain engineering of the transverse piezoelectric coefficient in perovskite ferroelectrics. J. Appl. Phys. 2005, 98, 014102. [Google Scholar] [CrossRef]

- Bell, A.J. Phenomenologically derived electric field-temperature phase diagrams and piezoelectric coefficients for single crystal barium titanate under fields along different axes. J. Appl. Phys. 2001, 89, 3907–3914. [Google Scholar] [CrossRef]

- Li, P.; Zhai, J.; Shen, B.; Zhang, S.; Li, X.; Zhu, F.; Zhang, X. Ultrahigh piezoelectric properties in textured (K, Na)NbO3-based lead-free ceramics. Adv. Mater. 2018, 30, 1705171. [Google Scholar] [CrossRef]

- Li, P.; Liu, B.; Shen, B.; Zhai, J.; Zhang, Y.; Li, F.; Liu, X. Mechanism of significantly enhanced piezoelectric performance and stability in textured potassium-sodium niobate piezoelectric ceramics. J. Eur. Ceram. Soc. 2018, 38, 75–83. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, J.; Yao, W.; Lu, C.; Zhang, S. Domain configuration and thermal stability of (K0.48Na0.52)(Nb0.96Sb0.04)O3-Bi0.50(Na0.82K0.18)0.50ZrO3 Piezoceramics with High d33 coefficient. ACS Appl. Mater. Interfaces 2016, 8, 7257–7265. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, P.; Patterson, E.; Zang, J.; Jiang, S.; Rödel, J. Preparation and enhanced electrical properties of grain-oriented (Bi1/2Na1/2)TiO3-based lead-free incipient piezoceramics. J. Eur. Ceram. Soc. 2015, 35, 2501–2512. [Google Scholar] [CrossRef]

- Liu, Y.; Chang, Y.; Li, F.; Yang, B.; Sun, Y.; Wu, J.; Zhang, S.; Wang, R.; Cao, W. Exceptionally high piezoelectric coefficient and low strain hysteresis in grain-oriented (Ba, Ca)(Ti, Zr)O3 through integrating crystallographic texture and domain engineering. ACS Appl. Mater. Interfaces 2017, 9, 29863–29871. [Google Scholar] [CrossRef]

- Hu, G.; Xu, B.; Yan, X.; Li, J.; Gao, F.; Liu, Z.; Zhang, Y.; Sun, H. Fabrication and electrical properties of textured Ba(Zr0.2Ti0.8)O3-(Ba0.7Ca0.3)TiO3 ceramics using plate-like BaTiO3 particles as templates. J. Mater. Sci. Mater. Electron. 2014, 25, 1817–1827. [Google Scholar] [CrossRef]

- Maurya, D.; Zhou, Y.; Yan, Y.; Priya, S. Synthesis mechanism of grain-oriented lead-free piezoelectric Na0.5Bi0.5TiO3-BaTiO3 ceramics with giant piezoelectric response. J. Mater. Chem. C 2013, 1, 2102–2111. [Google Scholar] [CrossRef]

- Bai, W.; Chen, D.; Zheng, P.; Xi, J.; Zhou, Y.; Shen, B.; Zhai, J.; Ji, Z. NaNbO3 templates-induced phase evolution and enhancement of electromechanical properties in <00l> grain oriented lead-free BNT-based piezoelectric materials. J. Eur. Ceram. Soc. 2017, 37, 2591–2604. [Google Scholar] [CrossRef]

- Hao, J.; Ye, C.; Shen, B.; Zhai, J. Enhanced electrostricitive properties and thermal endurance of textured (Bi0.5Na0.5)TiO3-BaTiO3-(K0.5Na0.5)NbO3 ceramics. J. Appl. Phys. 2013, 114, 054101. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Bai, W.; Shen, B.; Zhai, J.; Chen, H. Synthesis of high aspect ratio (K, Na)NbO3 plate-like particles and study on the synthesis mechanism. Dalton Trans. 2015, 44, 11621–11625. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Zhou, X.; Zhou, K.; Chen, C.; Luo, H.; Yuan, X.; Zhang, D. Grain oriented Na0.5Bi0.5TiO3-BaTiO3 ceramics with giant strain response derived from single-crystalline Na0.5Bi0.5TiO3-BaTiO3 templates. J. Eur. Ceram. Soc. 2016, 36, 1377–1383. [Google Scholar] [CrossRef]

- Lotgering, F.K. Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures-I. J. Inorg. Nucl. Chem. 1959, 9, 113–123. [Google Scholar] [CrossRef]

- Liu, G.; Jiang, W.; Zhang, L.; Cai, J.; Wang, Z.; Liu, K.; Liu, X.; Chen, Y.; Liu, H.; Yan, Y. Effects of sintering temperature and KBT content on microstructure and electrical properties of (Bi0.5Na0.5)TiO3-BaTiO3-(Bi0.5K0.5)TiO3 Pb-free ceramics. Ceram. Int. 2018, 44, 9303–9311. [Google Scholar] [CrossRef]

- Damjanovic, D.; Demartin, M. Contribution of the irreversible displacement of domain walls to the piezoelectric effect in barium titanate and lead zirconate titanate ceramics. J. Phys. Condens Matter. 1997, 9, 4943–4953. [Google Scholar] [CrossRef]

- Davis, M.; Damjanovic, D.; Setter, N. Temperature dependence of the direct piezoelectric effect in relaxor-ferroelectric single crystals: Intrinsic and extrinsic contributions. J. Appl Phys. 2006, 100, 084103. [Google Scholar] [CrossRef]

- Wang, Y.U. Three intrinsic relationships of lattice parameters between intermediate monoclinic MC and tetragonal phases in ferroelectric Pb[(Mg1/3Nb2/3)1−xTix]O3 and Pb[(Zn1/3Nb2/3)1−xTix]O3 near morphotropic phase boundaries. Phys Rev. B Condens. Matter Mater. Phys. 2006, 73, 014113. [Google Scholar] [CrossRef]

- Jin, Y.; Wang, Y.U.; Khachaturyan, A.G.; Li, J.; Viehland, D. Conformal miniaturization of domains with low domain-wall energy: Monoclinic ferroelectric states near the morphotropic phase boundaries. Phys. Rev. Lett. 2003, 91, 197601. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Zhang, S.; Xu, Z.; Chen, L.Q. The contributions of polar nanoregions to the dielectric and piezoelectric responses in domain-engineered relaxor-PbTiO3 crystals. Adv. Funct. Mater. 2017, 27, 1700310. [Google Scholar] [CrossRef]

- Sun, E.; Cao, W. Relaxor-based ferroelectric single crystals: Growth, domain engineering, characterization and applications. Prog. Mater. Sci. 2014, 65, 124–210. [Google Scholar] [CrossRef]

- Cao, W.; Randall, C. Grain size and domain size relations in bulk ceramic ferroelectric materials. J. Phys. Chem. Solids 1996, 57, 1499–1505. [Google Scholar] [CrossRef]

- Hoshina, T.; Kigoshi, Y.; Hatta, S.; Teranishi, T.; Takeda, H.; Tsurumi, T. Size effect and domain-wall contribution of Barium titanate ceramics. Ferroelectrics 2010, 402, 29–36. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Xu, Z.; Wei, X.; Luo, J.; Shrout, T.R. Composition and phase dependence of the intrinsic and extrinsic piezoelectric activity of domain engineered (1-x)Pb(Mg1/3Nb2/3)O3-xPbTiO3 crystals. J. Appl. Phys. 2010, 108, 034106. [Google Scholar] [CrossRef]

- Zhang, S.-T.; Yang, B.; Cao, W. The temperature-dependent electrical properties of Bi0.5Na0.5TiO3-BaTiO3-Bi0.5K0.5TiO3 near the morphotropic phase boundary. Acta Mater. 2012, 60, 469–475. [Google Scholar] [CrossRef]

- Wang, F.; Xu, M.; Tang, Y.; Wang, T.; Shi, W.; Leung, C.M. Large strain response in the ternary Bi0.5Na0.5TiO3-BaTiO3-SrTiO3 solid solutions. J. Am. Ceram. Soc. 2012, 95, 1955–1959. [Google Scholar] [CrossRef]

| Material | Phase Structure | ε (1 kHz) | tanδ (at 1 kHz) | Sm (at 70 kV/cm) | d33 (pC/N) | d33 Enhancement | d33* (pm/V) | d33* Enhancement | H |

|---|---|---|---|---|---|---|---|---|---|

| Randomly oriented 90NBT ceramic | R | 590 | 0.029% | 0.13% | 110 | 60% | 180 | 13% | 26% |

| Textured 90NBT ceramic | R | 760 | 0.027% | 0.14% | 175 | 205 | 12% | ||

| Randomly oriented 88NBT ceramic | MPB | 730 | 0.035% | 0.18% | 150 | 20% | 260 | none | 28% |

| Textured 88NBT ceramic | MPB | 810 | 0.029% | 0.18% | 185 | 255 | 21% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Dong, N.; Xia, F.; Guo, Q.; Hao, H.; Liu, H.; Zhang, S. Impact of Phase Structure on Piezoelectric Properties of Textured Lead-Free Ceramics. Crystals 2020, 10, 367. https://doi.org/10.3390/cryst10050367

Gao X, Dong N, Xia F, Guo Q, Hao H, Liu H, Zhang S. Impact of Phase Structure on Piezoelectric Properties of Textured Lead-Free Ceramics. Crystals. 2020; 10(5):367. https://doi.org/10.3390/cryst10050367

Chicago/Turabian StyleGao, Xiaoyi, Nannan Dong, Fangquan Xia, Qinghu Guo, Hua Hao, Hanxing Liu, and Shujun Zhang. 2020. "Impact of Phase Structure on Piezoelectric Properties of Textured Lead-Free Ceramics" Crystals 10, no. 5: 367. https://doi.org/10.3390/cryst10050367

APA StyleGao, X., Dong, N., Xia, F., Guo, Q., Hao, H., Liu, H., & Zhang, S. (2020). Impact of Phase Structure on Piezoelectric Properties of Textured Lead-Free Ceramics. Crystals, 10(5), 367. https://doi.org/10.3390/cryst10050367